Page 1

SAVE THESE INSTRUCTIONS

QM Series

Positive Displacement Fuel Meter

Owner’s Manual

TABLE OF CONTENTS

General Information ���������������������������2

Installation �����������������������������������������3

Operation �������������������������������������������4

Calibration �����������������������������������������5

Maintenance ��������������������������������������5

Troubleshooting ���������������������������������6

Specications ������������������������������������7

Informative Table - Diesel ����������������� 8

Informative Table - Unleaded ����������� 9

Illustrated Parts List �������������������������10

Parts and Service ����������������������������15

To the owner…

Congratulations on receiving your

FLOMEC® QM150/QM240 Meter� We

are pleased to provide you with a meter

designed to give you maximum reliability

and efciency�

Our business is the design, manufacture

and marketing of liquid handling,

agricultural and recreational products� We

succeed because we provide customers

with innovative, reliable, safe, timely and

competitively-priced products� We pride

ourselves in conducting our business with

integrity and professionalism�

Great Plains Industries, Inc� is a member

of the Petroleum Equipment Institute.

04/2019

We are proud to provide you with a quality

product and the support you need to

obtain years of safe, dependable service�

Victor Lukic, President

Great Plains Industries, Inc�

921528-01 Rev. D

Page 2

GENERAL INFORMATION

The purpose of this manual is to

assist you in installing, operating and

maintaining your mechanical fuel meter�

Please take a few moments to read

these instructions before installing and

operating your fuel meter�

SAFETY INSTRUCTIONS

The following safety alert symbols are

used in this manual�

DANGER

DANGER indicates a hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a hazardous

situation which, if not avoided, may

result in minor or moderate injury.

It is your responsibility to:

• Know and follow applicable national, state and local safety codes

pertaining to installing and operating equipment for use with ammable liquids�

• Know and follow all safety precautions when handling petroleum

fuels

• Ensure that all equipment operators

have access to adequate instructions concerning safe operation and

maintenance�

1. Appropriate Use of QM Meter:

a� The UL Approved version of

this meter is for use only with

thin viscosity petroleum fuels

such as gasoline, gasolineethanol blends (E15 maximum),

diesel and kerosene�

b� The non-UL Approved version

of this meter is for use only with

diesel fuel and kerosene�

2�

DANGER

Observe precautions against re or explosion when

dispensing fuel� Do not operate the

meter in the presence of any source

of ignition including running or hot

engines, lighted cigarettes, or gas

or electric heaters�

WARNING

3�

Any components

such as hose, nozzle, or pump

added to your meter must be statically grounded and approved for

use with petroleum fuels�

WARNING

4�

Avoid prolonged

skin contact with petroleum fuels�

Use protective goggles, gloves,

and aprons in case of accidental

splashing or spillage� Change

saturated clothing and wash skin

contact areas promptly with soap

and water�

This meter is designed for the field

measurement of thin viscosity

petroleum fuels only and intended for

use with pump systems up to 40 GPM

(150 LPM) ow range (not intended for

gravity ow systems)� Using mechanical

gears, these meters translate ow data

from positive displacement oval gears

into calibrated units which are indicated

on the face of the meter� This meter is

factory calibrated for diesel fuel� Field

calibration feature is available for other

uids, see Calibration section�

2

Page 3

INSTALLATION

Liquid can ow in a horizontal direction,

or a vertical direction, but in each case

Before installing your meter, review

the safety instructions given above�

Examine your meter to make sure

there are no visible signs of shipment

damage� Plan your meter installation

by reviewing the following procedures�

Your system must be mounted on a

vented tank� If the tank is unvented,

your local dealer or distributor can

supply a pressure cap�

If the meter is located in a rigid piping

system where the fluid is trapped

(for example, by gravity, valves or

nozzles) thermal expansion of the uid

can create pressure spikes that can

damage a meter� Install a thermal relief

valve or otherwise allow for thermal

expansion of the uid�

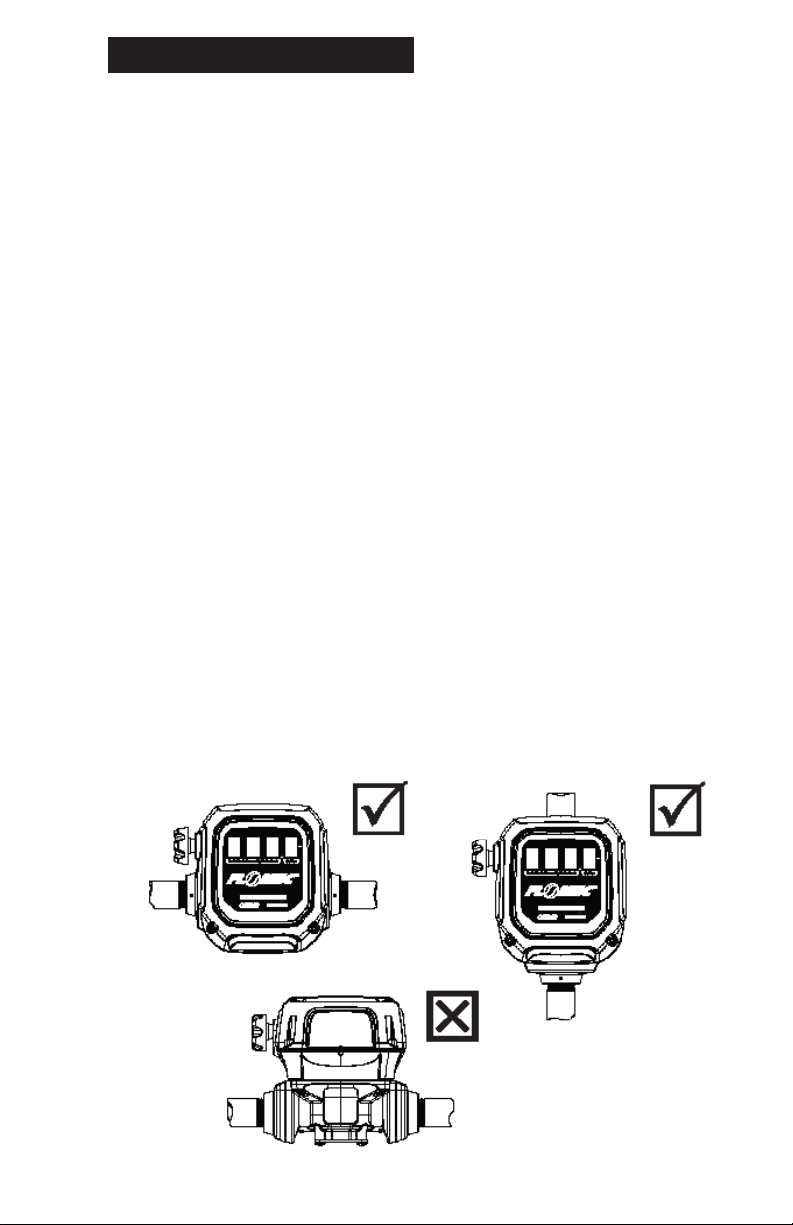

The owmeter MUST be mounted so

that the rotor shafts are in a horizontal

plane� Mounting the meter with the

mechanical display facing horizontally

will orient the rotor shafts correctly�

The mechanical display should never

face upwards or toward the ground�

the rotor shafts must be in a horizontal

plane�

It is preferred to install the ow-meter

upstream of a ow control or shut-off

valve, as the back pressure provided

by the valve will be benecial to system

accuracy� The flow meter should

remain full of liquid at all times when

connected�

Do not operate the ow-meter directly

discharging to the atmosphere�

Prior to installation, determine whether

horizontal or vertical ow is required�

For vertical ow installations the liquid

should travel from bottom to top, i�e�

it should rise vertically through the

ow-meter� This will ensure that the

ow-meter remains full of liquid, and

will prevent air entrapment in the meter�

The back of the meter housing is

embossed with “INLET” and “OUTLET”

adjacent to its respective port to assist

in correct piping connections�

The weight of the rotors must be

supported by the horizontal rotor shafts�

If installed incorrectly, performance,

life or accuracy could be affected�

(see Figure 1)

gure 1

Horizontal Flow

Correct

Correct

Vertical Flow

InCorrect

3

Page 4

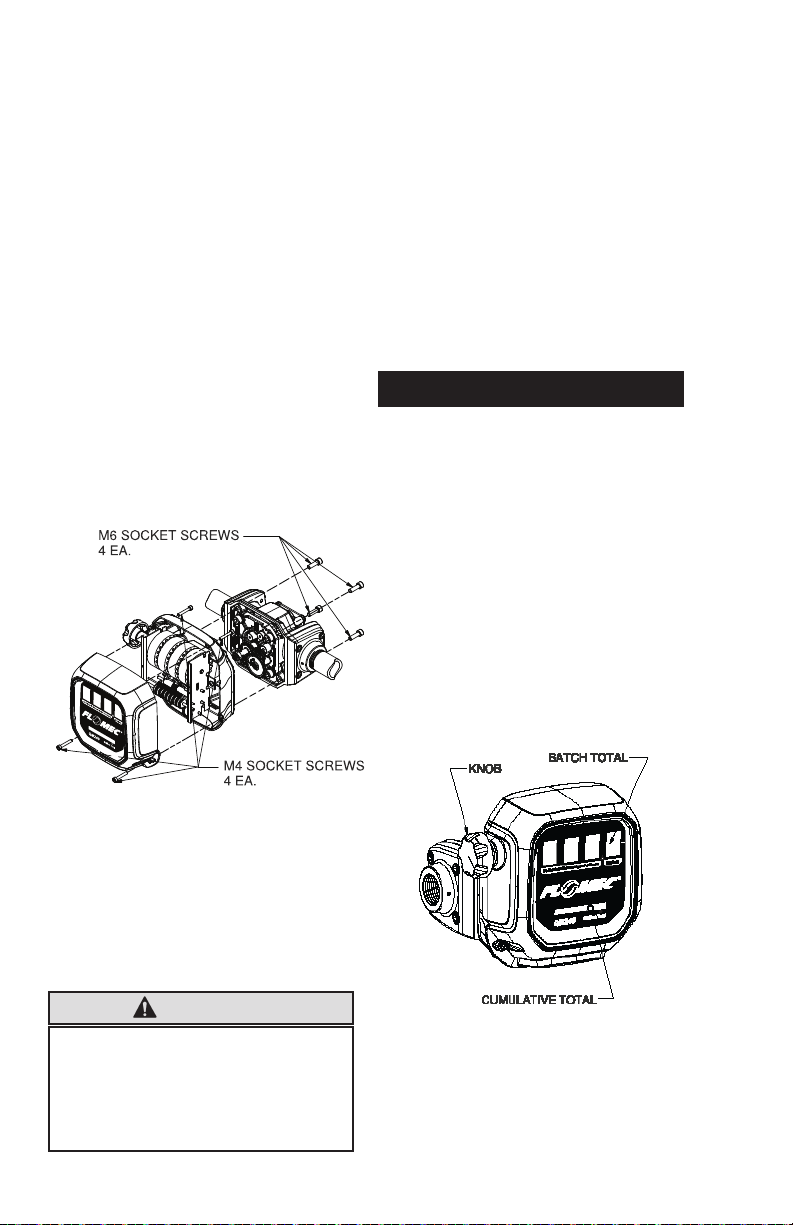

Changing Display Orientation

1� The mechanical display case can

be removed, rotated and reinstalled

for easy reading with either horizontal or vertical ow� (see Figure 2)

2� Using the 5mm hex L-wrench pro-

vided with the meter, remove the (4)

M6 socket screws that attach the

register case to the housing�

3� Without separating the mechanical

display from the housing, rotate to

desired orientation�

4� Reinstall the (4) M6 socket

screws and tighten to 42-46 lb-in

[4�7-5�2 N•m] torque�

Note: By first removing the (4) M4

socket screws and top cover, better

interior viewing can be achieved� This

is not a mandatory step though�

2� Wrap threaded male connections

with thread tape or use a pipe

sealant compound compatible with

petroleum fuels�

3� Install the meter on the pump us-

ing an appropriately sized nipple�

The bottom of the meter housing

is embossed with “INLET” and

“OUTLET” adjacent to its respective port to assist in correct piping

connections�

4� Install other system components

onto the meter and tighten�

OPERATION

ALWAYS FOLLOW SAFETY PRECAUTIONS

WHEN OPERATING THIS EQUIPMENT. REVIEW

THE SAFETY INSTRUCTIONS. Before each

use, visually check the meter to ensure

it is securely connected to other system

components and there is no leakage�

Promptly wipe spilled fuel from the

meter’s exterior and other system

components�

The large meter display represents

the Batch Total for each fuel delivery�

Before dispensing, reset the Batch

Total to zero by turning the knob� (see

Figure 3)

gure 2

Meter Installation

1� Remove the protective plugs from

the meter inlet and outlet ports� The

inlet port has a 100 mesh stainless

steel conical strainer installed�

CAUTION

The mesh strainer must always be

installed when operating the meter;

otherwise, particles may enter the

meter chamber and disrupt the

smooth operation of the oval gears�

4

gure 3

The small display represents the

Cumulative Total of all fuel deliveries

and cannot be reset�

Page 5

CALIBRATION

The meter is accurately calibrated at the

factory for use with diesel fuel� Due to

differences in viscosity and ow rates,

the meter may require recalibration

to measure other fuels or to adjust

for inaccuracies� A gear replacement

kit is available (PN 139500-15, see

Illustrated Parts List section) to

convert the meter to unleaded fuels�

1� To adjust the calibration of the me-

ter, gain access to the calibration

screw by performing the following:

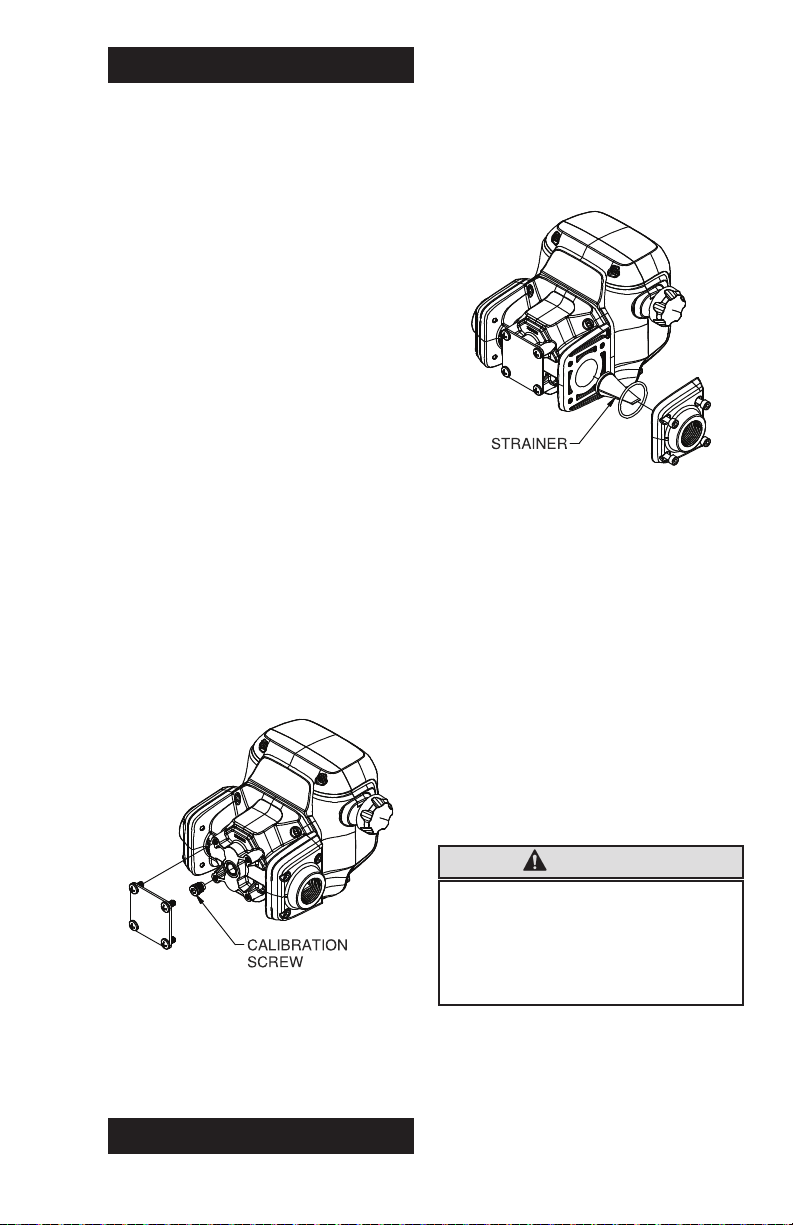

(see Figure 4)

2� Remove the back plate and the

(4) screws retaining it� The O-ring

seal under the plate must not be

damaged�

3� Using the 5MM hex L-wrench

provided with the meter, adjust the

calibration screw as required�

4� Note: The calibration screw set-

ting may have been adjusted at

the factory� The gasoline setting

is approximately fully closed (turn

clockwise)� Do not overtighten the

screw against the seat�

at regular intervals, especially if reduced

ow is encountered�

Clean or Replace Strainer

1� Remove the socket screws at the

inlet tting� Remove the tting, Oring and strainer� (see Figure 5)

gure 5

2� The strainer rim is pressed into the

housing inlet but can be removed

by carefully grasping the end with

pliers and pulling with a wiggling

motion until free�

3� Using a ne brush, clean the strainer�

Replace the strainer as necessary�

4� Wipe the housing inlet clean and

reinstall strainer, pressing it into

the strainer bore� It is designed to

be eld pressed back into place

using the end of a clean 1” pipe

nipple or similar tube tool using light

hammer taps�

gure 4

5� Reinstall the plate, (4) screws

and the O-ring seal if removed�

Tighten (4) screws to 42-46 lb-in

[4�7-5�2 N•m] torque�

MAINTENANCE

The meter’s strainer should be cleaned

CAUTION

The mesh strainer must always be

installed when operating the meter;

otherwise, particles may enter the

meter chamber and disrupt the

smooth operation of the oval gears�

5� Wipe clean the tting and O-ring

groove� Coat the O-ring with oil or

light grease and seat into the tting

groove�

6� Reinstall the inlet tting and screws�

Tighten screws to 42-46 lb-in

[4�7-5�2 N•m] torque�

5

Page 6

TROUBLESHOOTING

Symptom Probable Cause Corrective Action

A� Meter counter does

not operate� (Normal

fuel ow)

B� Meter counter does

not operate�

(Little or no fuel ow)

C� Fuel leakage� Leakage between

Broken counter

Replace counter�

assembly�

Counter alignment Look for loose or

missing fasteners, bent

or misaligned parts�

Foreign material in

counter assembly�

Missing or worn bevel

Remove and clean

counter assembly�

Replace bevel gear�

gear�

Clogged strainer in

meter inlet�

Jammed rotors from

foreign material in rotor

Clean or replace

strainer

Remove and clean rotor

assembly�

assembly�

Other system

components

malfunctioning�

Check all system

components tank to

nozzle for clogs and/or

malfunctions� Repair as

necessary�

Remove coverplate and

coverplate and housing�

inspect for damaged,

missing or incorrectly

seated seal� Replace

as required�

Leakage at ttings Remove ttings and

inspect for damaged,

missing or incorrectly

seated seals� Replace

as required�

Leakage at threads� Remove meter and

reseal all threaded

connections with thread

tape or pipe thread

sealing compound

approved for use with

ammable liquids�

6

Page 7

SPECIFICATIONS

Gallon Models Litre Models

Model

Designation

Unit of Measure U�S� Gallon Litre

Flow Range 2 to 40 GPM 8 to 150 LPM

Typical Accuracy

(Factory Set)

Typical Accuracy

(Field/Customer

1

Set)

1

Diesel: ±0�25% at a given flow (15-30 GPM/57-113 LPM)

Unleaded: ±0�5% at a given flow (2-23 GPM/8-87 LPM)

Resolutional

Error (Display)

Operating

Temperature

Maximum Working Pressure

Wetted Materials:

Housing / Cover

/ Fittings

Rotors PPS (Polyphenylene Sulde)

Shafts / Strainer Stainless Steel

Seals NBR (Nitrile Butadiene Rubber)

Mag-Drive Acetal, Stainless Steel and Neodymium (Nickel Plated)

Inlet/Outlet Ports 1" NPT (female) 1" NPT (female)

Pressure Drop

(at Max� Flow)

Maximum

Batch Total

Maximum

Cumulative Total

Technology Positive Displacement

QM240N QM150N

Diesel: ±0�5% (15-30 GPM/57-113 LPM)

±1�0% all other flowrates

Unleaded: +0�5% to -1�5% (15-30 GPM/57-113 LPM)

±2�0% all other flowrates

±0�5% all other given flows

±0�5% at a given flow (23-40 GPM/87-150 LPM)2

(0�01/Dispensed

Amount)*100

(0�1/Dispensed

Amount)*100

-20°F to 125°F -29°C to 52°C

50 PSIG / 3�4 Bar

Aluminum

Diesel: 7�0 PSI / 0�5 Bar

Unleaded: 4�5 PSI / 0�3 Bar

999�9 9999

9,999,999�9 99,999,999

1

Results may vary due to application variations�

2

Unleaded Fuel Kit required (Part No� 139500-15)

Note: Field Calibration is available on all models.

7

Page 8

PRESSURE DROP PSI

0

1

2

3

4

5

6

7

8

FLOWRATE GPM

FACTORY SETTING NOMINAL UPPER RANGE FACTORY SETTING NOMINAL LOWER RANGE

QM240 ACCURACY & PRESSURE DROP vs FLOWRATE - DIESEL

0 5 10 15 20 25 30 35 40

1.5

1.0

0.5

0.0

-0.5

ERROR %

-1.0

-1.5

CALIBRATION SCREW IN CALIBRATION SCREW OUT 2 TURNS PRESSURE DROP

8

Page 9

PRESSURE DROP PSI

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

FLOWRATE GPM

QM240 ACCURACY & PRESSURE DROP vs FLOWRATE - UNLEADED

SCREW IN ORIGINAL EQUIPMENT SCREW IN WITH GEAR KIT SC REW OUT 2 TURNS WITH GEAR KIT PRESSURE DROP

0 5 10 15 20 25 30 35 40

2.0

1.5

1.0

0.5

0.0

ERROR %

-0.5

-1.0

-1.5

*A gear replacement kit is available (P/N 139500-15) to convert the meter to unleaded fuels. Replacement gear kit will adjust entire ow curve up 1.5%.

9

Page 10

E

K

L

A

B

C

B

C

F

G

H

I

J

N

ILLUSTRATED PARTS LIST

10

Page 11

Includes (1) calibration screw, (1) O-

ring

Includes (1) back plate, (1) O-ring, at-

taching hardware

Includes (1) strainer

Not shown

I 139500-09 KIT, CALIBRATION SCREW:

J 139500-10 KIT, BACK PLATE:

- 139500-15 KIT, UNLEADED FUEL, QM240:

N 139500-14 KIT, STRAINER:

ITEM PART NO. DESCRIPTION

Includes (1) housing O-ring, (2) tting

O-rings, (1) back plate O-ring

Includes (2) ttings, (2) tting O-rings,

(1) strainer, attaching hardware

Includes (2) ttings, (2) tting O-rings,

(1) strainer, attaching hardware

Includes (1) rotor set

Includes (1) assembled coverplate

(gears, mag drives), housing seal, at-

taching hardware

Includes (1) assembled coverplate

(gears, mag drives), housing seal, at-

taching hardware

A 139500-01 KIT, SEAL:

ITEM PART NO. DESCRIPTION

Kits and Accessories

B 139500-02 KIT, FITTING, 1” NPT:

C 139500-03 KIT, FITTING, 1” BSPP:

F 139500-06 KIT, ROTOR:

G 139500-07 KIT, COVERPLATE ASSEMBLY, GAL:

H 139500-08 KIT, COVERPLATE ASSEMBLY, LITRE:

11

Page 12

D

E

K

L

M

H

ILLUSTRATED PARTS LIST

12

Page 13

Includes (1) knob assembly

Includes (1) counter assembly, attach-

ing hardware

Includes (1) top cover w/gallon decal,

attaching hardware

Includes (1) top cover w/litre decal,

attaching hardware

Includes (1) middle cover, attaching

hardware

Not shown

E 139500-05 KIT, COUNTER ASSEMBLY:

D 139500-04 KIT, KNOB ASSEMBLY:

ITEM PART NO. DESCRIPTION

Kits and Accessories

K 139500-11 KIT, TOP COVER, GALLON:

L 139500-12 KIT, TOP COVER, LITRE:

M 139500-13 KIT, MIDDLE COVER:

- 139500-15 KIT, UNLEADED FUEL, QM240:

13

Page 14

14

Page 15

PARTS AND SERVICE

For warranty consideration, parts,

or other service information, contact

your local distributor� If you need

further assistance, please contact

GPI Customer Service Department

in Wichita, Kansas during normal

business hours at:

1-800-835-0113�

To obtain prompt, efficient service,

always be prepared with 1�) the model

number of your meter, 2�) the manufacturing date located on the back of the

meter, and 3�) specic information, as

necessary, obtained from the Illustrated

Parts List� For warranty work always be

prepared with proof of purchase date�

Please contact GPI before returning any

parts� It may be possible to diagnose

the trouble and identify needed parts

without returning parts� GPI can also

inform you of any special handling

requirements you will need to follow

covering the transportation and handling of fuel transfer equipment� Before

packing for shipment, make sure the

meter is thoroughly drained and free

of fuel and vapors�

CAUTION

Do not return meters or parts

without specic authority from the

GPI Customer Service Department�

Due to strict regulations governing

shipment of ammable liquids,

meters may be refused and

returned to the sender if sent

without authorization�

15

Page 16

Limited Warranty Policy

Great Plains Industries, Inc. 5252 E. 36th Street North, Wichita, KS USA 67220-3205, hereby provides a limited

warranty against defects in material and workmanship on all products manufactured by Great Plains Industries,

Inc. This product includes a 4 year warranty from date of purchase as evidenced by the original sales receipt.

A 54 month warranty from product date of manufacture will apply in cases where the original sales receipt is

not available. Reference product labeling for the warranty expiration date based on 54 months from date of

manufacture. Manufacturer’s sole obligation under the foregoing warranties will be limited to either, at Manufacturer’s option, replacing or repairing defective Goods (subject to limitations hereinafter provided) or refunding

the purchase price for such Goods theretofore paid by the Buyer, and Buyer’s exclusive remedy for breach of

any such warranties will be enforcement of such obligations of Manufacturer. The warranty shall extend to the

purchaser of this product and to any person to whom such product is transferred during the warranty period.

This warranty shall not apply if:

A. theproducthasbeenalteredormodiedoutsidethewarrantor’sdulyappointedrepresentative;

B. the product has been subjected to neglect, misuse, abuse or damage or has been installed or

operated other than in accordance with the manufacturer’s operating instructions.

To make a claim against this warranty, contact the GPI Customer Service Department at 316-686-7361 or

800-835-0113. Or by mail at:

Great Plains Industries, Inc.

5252 E. 36th St. North

Wichita, KS, USA 67220-3205

GPI will step you through a product troubleshooting process to determine appropriate corrective actions.

GREAT PLAINS INDUSTRIES, INC., EXCLUDES LIABILITY UNDER THIS WARRANTY FOR DIRECT, INDIRECT, INCIDENTAL AND CONSEQUENTIAL DAMAGES INCURRED IN THE USE OR LOSS OF USE OF

THE PRODUCT WARRANTED HEREUNDER.

Thecompanyherewithexpresslydisclaimsanywarrantyofmerchantabilityortnessforanyparticularpurpose

other than for which it was designed.

ThiswarrantygivesyouspecicrightsandyoumayalsohaveotherrightswhichvaryfromU.S.statetoU.S.state.

Note: In compliance with MAGNUSON MOSS CONSUMER WARRANTY ACT – Part 702 (governs the resale

availability of the warranty terms).

Some models are not UL Listed.

Check your model for UL label if in doubt.

© 2019 GREAT PLAINS INDUSTRIES, INC. All Rights Reserved.

and FLOMEC are registered trademarks of Great Plains Industries, Inc.

04/2019 921528-01 Rev. D

Loading...

Loading...