Page 1

Industrial Oval Gear Flowmeters

with pulse output or electronic display

Operation Manual

Page 2

Your flow-meter and any associated electronics are precision instruments,

CAUTION

•

General Information

This manual provides the necessary information for installation of your Oval Gear

flowmeter; for information on any integral electronics or accessories fitted to your

flowmeter please consult the relevant electronics or accessory manual. Your Oval Gear

flowmeter should only be installed by persons familiar with local regulations, particularly

those for workplace Health and Safety, or Hazardous Area regulations where relevant.

For best results, please make yourself familiar with the contents of all relevant product

manuals prior to installation and commissioning. If further assistance is required please

consult the distributor from whom you purchased your flowmeter.

to avoid unnecessary damage please treat them with care.

DISPOSAL WITHIN THE EUROPEAN UNION - WEEE

The WEEE Directive requires that this product be recycled

when disposed of within the European Union

• The crossed out wheelie bin symbol shown in this manual

signifies that this product should not be disposed of in general

waste or landfill.

• Please contact the local dealer or national distributor from

whom this product was purchased for information on recycling

electronic equipment within your region.

2

Page 3

Table of Contents

1. Introduction ............................................................................................................... 5

1.1 Operating Principle .......................................................................................................5

1.2 Specifications ................................................................................................................6

2. Installation ................................................................................................................. 8

2.1 Mechanical Installation.................................................................................................8

2.1.1 Installation Orientation .................................................................................................8

2.1.2 Piping Construction .......................................................................................................9

2.1.3 Mechanical Support ......................................................................................................9

2.1.4 Filtration / Straining ....................................................................................................10

2.1.5 Pipe Connections .........................................................................................................10

2.2 Electrical Installation ..................................................................................................11

2.2.1 Wiring .........................................................................................................................11

2.2.2 Hall Effect Outputs ......................................................................................................11

2.2.3 Reed Switch Outputs ...................................................................................................12

2.2.4 Quadrature Pulse Outputs ..........................................................................................13

2.3 Making Electrical Connections ....................................................................................13

2.4 Wiring Diagrams .........................................................................................................14

2.4.1 Standard Pulse Output Board .....................................................................................14

2.4.2 Reed Only Pulse Output Board ....................................................................................16

2.4.3 Reed Only Outputs as Simple Apparatus.....................................................................17

2.4.4 Hall Only Output .........................................................................................................18

2.4.5 Quadrature Pulse Output ............................................................................................19

2.5 Meter Calibration Factor (K-Factor, Scale Factor)

2.6 Integral Instruments ...................................................................................................19

2.7 Installations in Hazardous Areas .................................................................................20

2.7.1 ATEX/IECEx Flameproof Flowmeters (Ex db) ...............................................................20

2.7.2 Conforming Standards ................................................................................................21

2.7.3 Temperature Limits for Flameproof Flowmeters ........................................................22

2.7.4 Special Conditions of Use ............................................................................................22

2.7.5 Earthing of Flameproof Flowmeters ...........................................................................23

2.7.6 Intrinsically Safe Flowmeters (EX i) .............................................................................24

2.8 Commissioning ............................................................................................................25

2.9 Fault Finding ...............................................................................................................26

2.10 Troubleshooting Guide ................................................................................................27

3. Maintenance and Repairs......................................................................................... 28

3.1 Parts Identification......................................................................................................29

3.2 Flowmeter Disassembly ..............................................................................................31

3.3 Flowmeter Inspection..................................................................................................31

3.4 Re-assembly of Flowmeter ..........................................................................................32

4. EC Declaration of Conformity ................................................................................... 33

.......................................................19

3

Page 4

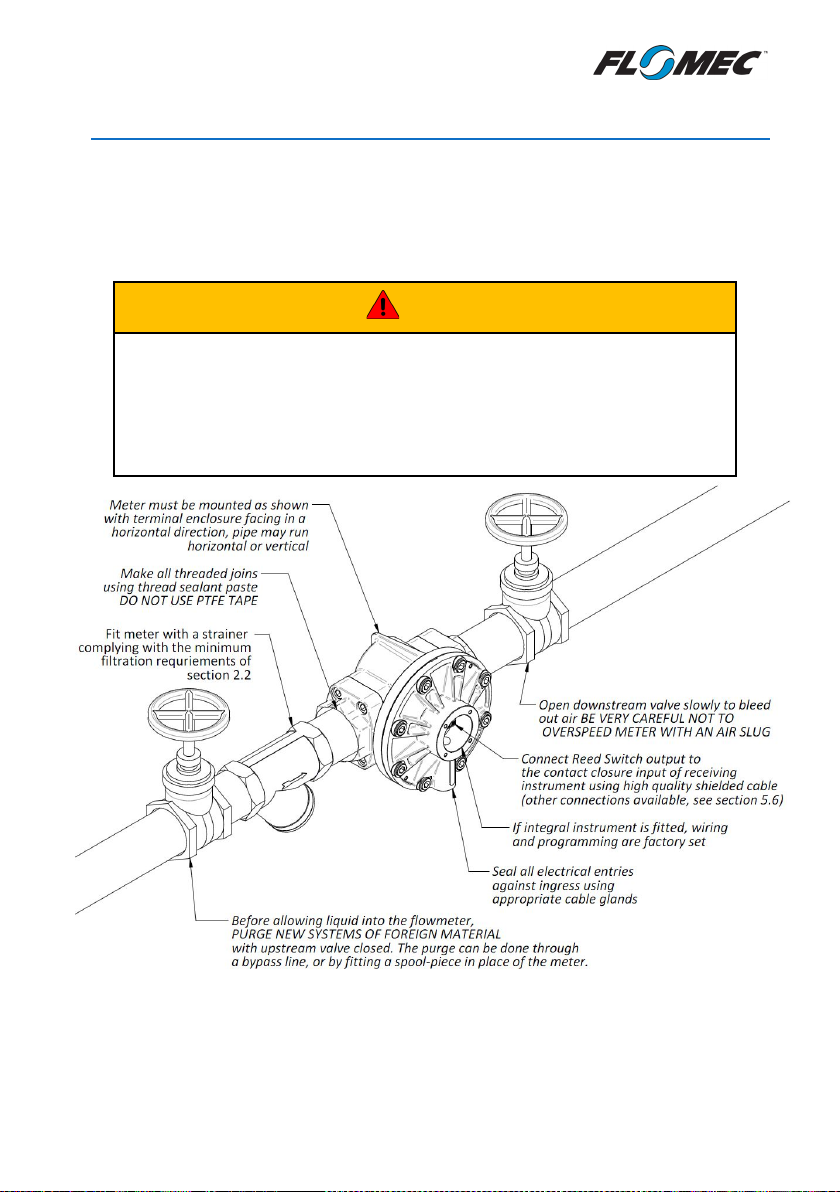

Quick Start Guide

Users installing product in Hazardous Areas must read this entire manual

CAUTION

The ‘quick start’ instructions shown below are intended for users who are experienced in

the use of flowmeters and who want to quickly set up their new meter with limited

functionality, and start using their product right away. The ‘quick start’ instructions will

allow the user to set up their meter without the risk of damage, allowing the use of the

product while the complete instructions are read in detail at a later date.

before installing their product.

Damage caused to meters by users who have only read the ‘Quick Start Guide’

will not be accepted as a justification for a warranty claim; if you are unsure,

read the whole manual before installing your meter.

4

Page 5

1. Introduction

The Oval gear meter is a precise positive displacement flowmeter incorporating a pair of

oval geared rotors. These meters are capable of measuring the flow of a broad range of

clean liquids.

Stainless Steel flowmeters are suited to most liquid products and chemicals; including

many water based liquids, acids, bases and salt solutions, and Aluminium meters are

suitable for fuels, oils & most non-aggressive lubricating liquids.

Oval Gear flowmeters are available as blind meters with a pulse signal output capable of

interfacing to most monitoring and control instrumentation, or the meter can be fitted with

instruments such as totalisers, rate totalisers or batch controllers. These instruments also

have monitoring and control output options including 4-20mA, scaled pulse, flow-rate

alarms and batch control logic (preset metering).

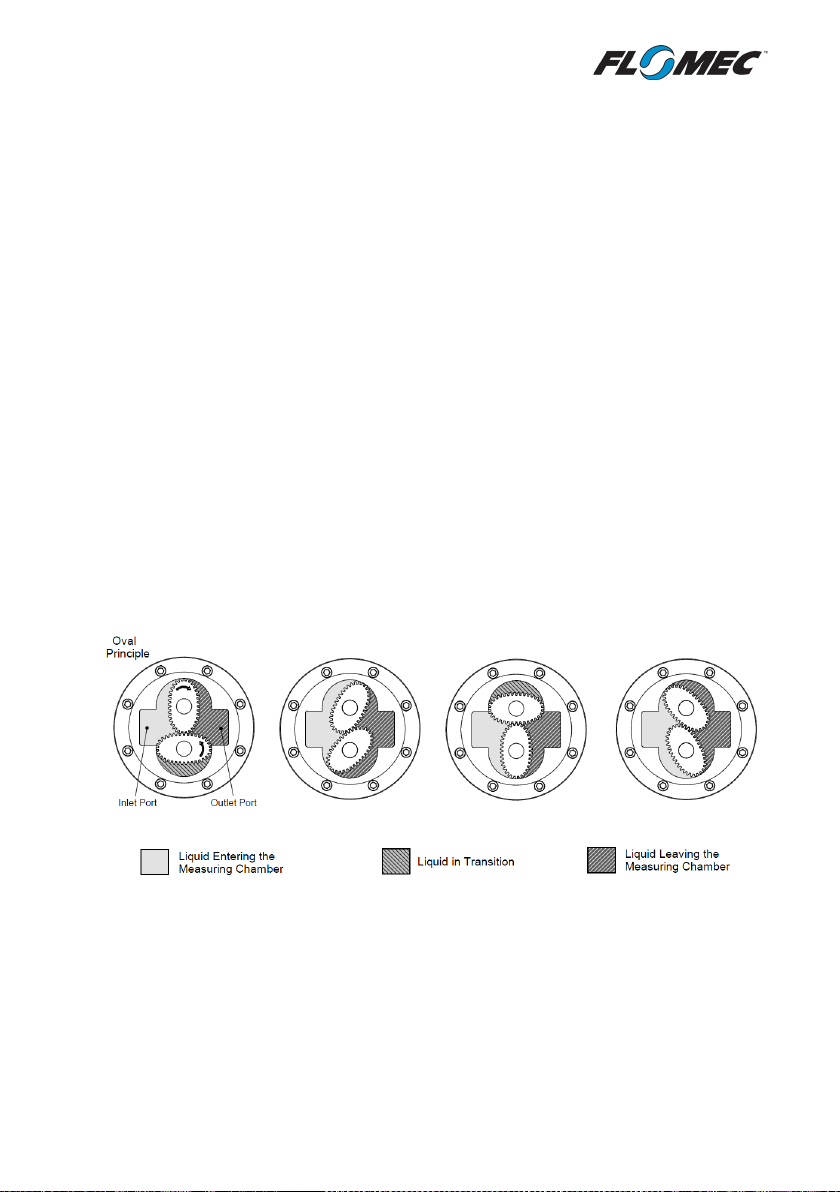

1.1 Operating Principle

Oval Gear flowmeters are positive displacement devices where the passage of liquid

causes two oval geared rotors to rotate within a precision measuring chamber. Each

rotation of the Oval rotors will transmit 4 identical volumes of liquid from the meter inlet to

outlet (as shown in the diagram below); providing electronic pulses via magnetic sensors to

a digital instrument.

5

Page 6

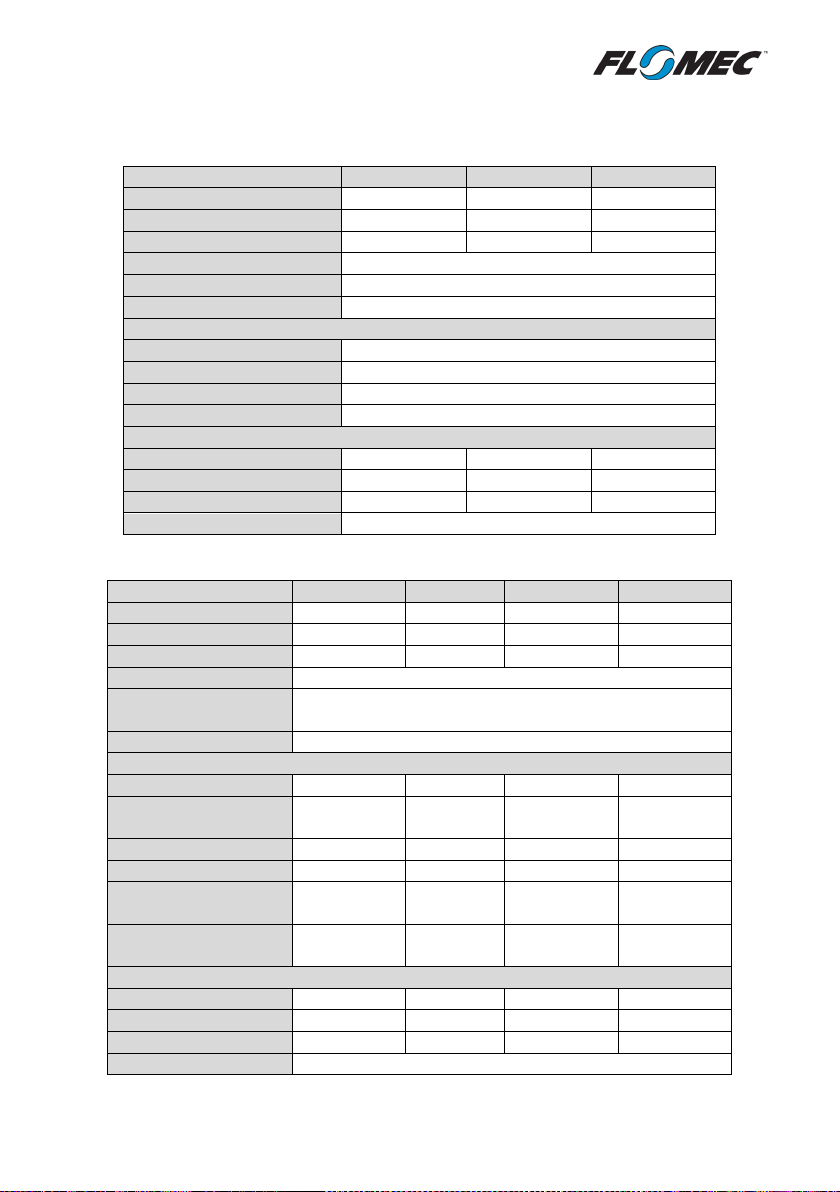

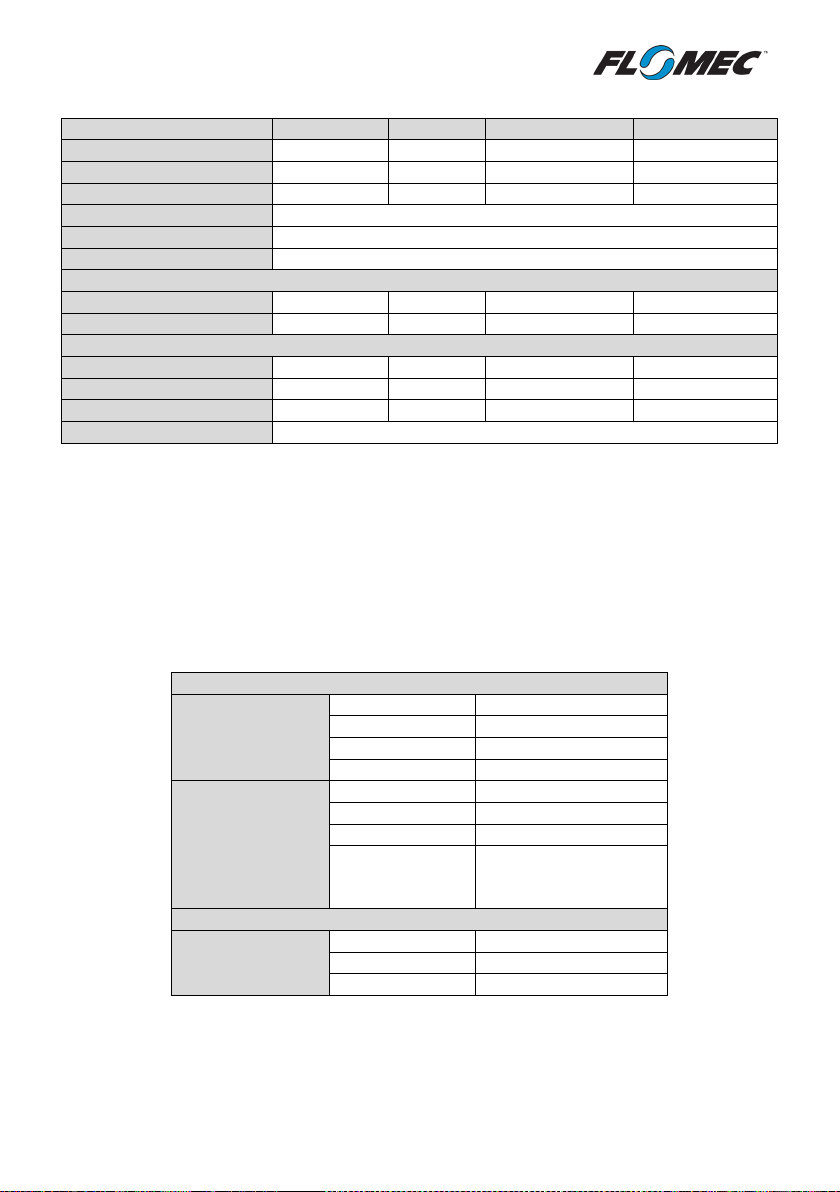

1.2 Specifications

Model Prefix

004

006

008

Nominal Size

1/8” (4mm)

1/4” (6mm)

3/8” (8mm) 1

Flow range2 (USG/hr)

0.26 ~ 9.5

0.5 ~ 27

4 ~ 145

Flow range2 (L/hr)

1.0 ~ 36

2 ~ 100

15 ~ 550

Accuracy ( liquids ≥ 3cP)

± 1% of reading (± 0.2% with optional RT14)3

Repeatability (liquids ≥ 3cP)

Typically ± 0.03%

Temperature Range

-4oF ~ +250oF (-20oC ~ +120oC)4

Pressure Ratings – PSI (Bar) – threaded meters only

5

Aluminium

220 (15)

Stainless Steel

495 (34)

Intermediate Pressure SS

1450 (100)

High Pressure Models

5800 (400)

Nominal Output Pulse Resolution – Pulses/USG (Pulses/Litre)

Hall Effect

21200 (2800)

7950 (2100)

2690 (710)

Reed Switch

10600 (2800)

7950 (2100)

1345 (355)

High-Resolution Hall Option

42400 (11200)

15900 (4200) - Minimum Filtration

200 mesh (75 micron)

6

Model Prefix

015

025

040

050

Nominal Size

1/2" (15mm)

1” (25mm)

1.5” (40mm)

2” (50mm)

Flow range2 (USG/min)

0.26 ~ 10.6

2.6 ~ 40

4 ~ 66

8 ~ 120

Flow range2 (L/min)

1 ~ 40

10 ~ 150

15 ~ 250

30 ~ 450

Accuracy (liquids≥3cP)

± 0.5% of reading (± 0.2% with optional RT14)

3

Repeatability

(liquids≥3cP)

Temperature Range

-4oF ~ +250oF (-20oC ~ +120oC)

4

Pressure Ratings – PSI (Bar) – threaded meters only

5

Aluminium

990 (68)

990 (68)

435 (30)

285 (20)

Intermediate Pressure

Aluminium

Stainless Steel

990 (68)

990 (68)

435 (30)

550 (38)

PPS (Ryton®)

-

73 (5) - -

Intermediate Pressure

Stainless Steel

High Pressure Stainless

Steel

Nominal Output Pulse Resolution – Pulses/USG (Pulses/Litre)

Hall Effect

636 (168)

405 (107)

212 (56)

99 (26)

Reed Switch

318 (84)

102 (27)

53 (14)

25 (6.5)

Quadrature Hall Option

636 (168)

204 (54)

106 (28)

49 (13)

Minimum Filtration

100 mesh (150 micron)

6

1.2.1 Small Capacity Models

1.2.2 Medium Capacity Models

Typically ± 0.03%

- 2000 (138) - -

1450 (100) 1450 (100) 725 (50) 725 (50)

5800 (400) 5800 (400) 5800 (400) 4350 (300)

6

Page 7

1.2.3 Large Capacity Models

Model Prefix

080

080E

100

100E

Nominal Size

3” (80mm)

3” (80mm)

4” (100m)

4” (100mm)

Flow range2 (USG/min)

10 ~ 200

13 ~ 260

20 ~ 400

40 ~ 660

Flow range2 (L/min)

35 ~ 750

50 ~ 1000

75 ~ 1500

150 ~ 2500

Accuracy (liquids ≥ 3cP)

± 0.5% of reading (± 0.2% with optional RT14)3

Repeatability (liquids ≥ 3cP)

Typically ± 0.03%

Temperature Range

-4oF ~ +250oF (-20oC ~ +120oC)4

Pressure Ratings – PSI (Bar) – threaded meters only 5

Aluminium

175 (12)

175 (12)

145 (10)

145 (10)

Stainless Steel

175 (12) - -

-

Nominal Output Pulse Resolution – Pulses/USG (Pulses/Litre)

Hall Effect

40 (10.65)

22.7 (6.0)

16.6 (4.4)

8.5 (2.24)

Reed Switch

10 (2.65)

5.7 (1.5)

4.15 (1.1)

2.1 (0.56)

Quadrature Hall Option

20 (5.33)

11.4 (3.0)

8.3 (2.2)

4.24 (1.12)

Minimum Filtration

40 mesh (350 micron)6

Standard Pulse Output Board

Output Type

NPN Open Collector

Voltage Range

5 ~ 24V (dc)

Current Draw

20mA Maximum

Switching Current

10mA Maximum

Output Type

Contact Closure

Voltage

24V (dc) Maximum

Current

50mA Maximum

Recommended

Long Switch Life

Reed Only Option (Intrinsically Safe Simple Apparatus)

Voltage

24V (dc) Maximum

1

Current

16mA Maximum

2

Power

0.4W Maximum3

1. OM008H meter have a nominal port size of ¼” (6mm)

2. Maximum flow rate must be reduced with increased viscosity, maintain maximum pressure drop across the

meter at below 14.5psi (1 Bar)

3. 0.2% accuracy achievable using RT14 with non-linearity correction and multi-point calibration.

4. Temperature range stated for standard pulse output meters; higher and lower temperature rating options are

available. Meters fitted with integral instruments will have a reduced maximum temperature. OM008 meters

fitted with PPS rotors are limited to +176

5. Flanged meter pressure rating is in accordance with applicable flange standard, or with threaded meter

rating, whichever is lower.

6. Filtration requirements are for soft particles only; hard particles of any size are not acceptable.

o

F (+80oC).

1.2.4 Electrical Specifications

Hall Effect Output

Reed Switch Output

Reed Switch Output

(per switch)

1. 30V (dc) maximum peak voltage allowed for non-hazardous (safe area) installations

2. Up to 200mA possible with internal current limit bypassed (not recommended, safe area only)

3. Up to 6W possible with internal current limit bypassed (not recommended, safe area only)

Maximums for

7

5V (dc) @ 10mA

Page 8

2. Installation

Please note that all flow-meters are calibrated with either Castrol ISO4113

available from the manufacturer or via an internet search.

All flowmeters are inspected and calibrated prior to shipment, and are sent out in perfect

condition. Should damage be present on receipt of the product please inspect the delivery

packaging for visible mishandling and contact the parcel service / freight forwarder.

Maintain any protective plugs/caps until installation.

or Exxsol D130 immediately prior to shipment, residual oil may be present;

please take the appropriate precautions for health and safety. An MSDS is

2.1 Mechanical Installation

Before installing your flowmeter, it is recommended that you confirm the meter is

suitable for your application conditions such as; fluid compatibility with meter materials,

flow rate, pressure, and temperature. Fluid entering the meter must remain a liquid at all

times; avoid solidification or gelling of the metered medium. If hydraulic shock or pressure

surges of any kind are possible, the system upstream of the meter must be fitted with a

surge suppressor or pressure relief valve to protect the meter from damage.

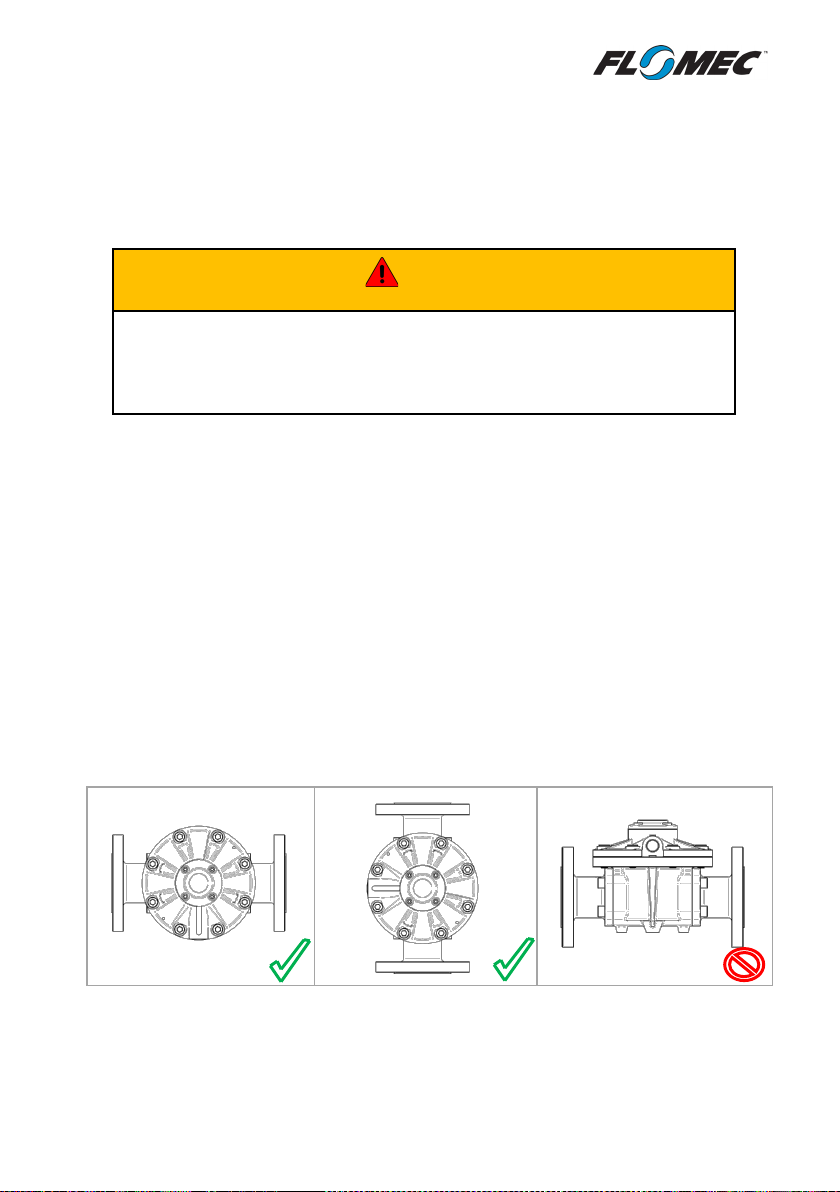

2.1.1 Installation Orientation

The flowmeter MUST be mounted with the rotor shafts in a horizontal plane. Failure to

mount your Oval Gear flowmeter in the correct orientation (as shown in the diagrams

below) will cause the weight of the rotors to bear down on the thrust bearings. The short

term effects of incorrect mounting orientation will be a loss in accuracy, with long term

effects ranging from reduced lifespan to fairly rapid catastrophic damage.

Liquid can flow in a horizontal direction, or a vertical direction, but in each case the rotor

shafts must be in a horizontal plane. This is achieved by mounting the meter so that the

terminal cover, or integral instrument display, is facing in a horizontal direction. For pulse

output flowmeters the direction of flow is not important, as the output is non-directional.

CAUTION

8

Page 9

2.1.2 Piping Construction

Strainer

Flowmeter

Isolation valve

Isolation valve

By-pass valve

It is preferred to install the flowmeter upstream of a flow control or shut-off valve, as the

back pressure provided by the valve will be beneficial to system accuracy; do not operate a

flowmeter directly discharging to atmosphere. Piping should be designed so that the

flowmeter is full of liquid at all times; this is achieved by designing the inlet and outlet

piping for the flowmeter to be lower than all surrounding piping.

For vertical installations the liquid should travel from bottom to top, i.e. it should rise

vertically through the flowmeter. This will ensure that the flowmeter remains full of liquid

and will stop air entrapment in the meter.

All piping surrounding your flowmeter should be well supported on secure footings,

preferably at the point where the piping joins to the flowmeter; unsupported piping will

cause severe pipe stress on the flowmeter.

The best piping designs provide a bypass line, as shown in the following diagram, which

allows isolation of the flowmeter and strainer from the main process line. The benefits of

installing a bypass line are that your system can be purged before start-up, and any

maintenance on the flowmeter or strainer can be carried out quickly and economically

without interrupting critical processes.

2.1.3 Mechanical Support

All flowmeters of nominal size 3” and 4” must have adequate mechanical support. Failure to

adequately support the flowmeter and the connected piping may result in structural damage

to the flowmeter housing. It is recommended that a solid structural support be provided at the

first flange connection, on both sides of the flowmeter. If possible, the housing of the

flowmeter can be directly supported, however piping should still be supported as close as

possible to the flowmeter. It is never acceptable to support the flowmeter and use the housing

of the flowmeter to support the weight of your piping.

9

Page 10

2.1.4 Filtration / Straining

Flange bolts in Aluminium flanges should never be tightened to torque

CAUTION

It is recommended to fit the inlet side of your flowmeter directly to a strainer of

appropriate pipe size and mesh size. The minimum mesh size as shown in the specifications

section of this manual should be adhered to where ever possible. When metering medium

or high viscosity fluids it may be necessary to use a strainer one pipe size larger than the

flowmeter nominal size, in order to limit the pressure drop across the strainer basket and

maintain strainer efficiency (i.e. a 1.5” strainer on a 1” meter).

In systems where there is potential for hard particles of any size, the filtration levels of the

system should be improved so as to eliminate the flow of hard particles through the meter.

While soft particles may pass through the rotating meter components without damage (if

they are small enough) hard particles are abrasive and will always cause rotor and bearing

damage regardless of size.

2.1.5 Pipe Connections

When installing a flowmeter, it is important that no upstream pipe join between the

flowmeter and the strainer are sealed using PTFE sealing tape. Lose pieces of PTFE tape

are common causes of failure in new meter installations due to the tendency to wrap

around the rotating components inside the meter. It is recommended that the sealing of

pipe joins should be done with a sealing paste or liquid (such as Loctite® 565 thread

sealant paste).

Flanged connections should be made using gaskets and bolting suitable for the metered

liquid and the system pressure; flowmeters fitted with stainless steel flanges may be

installed using metallic gaskets and high strength bolting if required. For meters fitted

with Aluminium flanges it is only suitable to make pipe connections in accordance with

the relevant flange standard requirements for cast iron flanges; gaskets according to

ASME B16.5 Annex C gasket group 1a are recommended, and only low strength or

intermediate strength bolting may be used.

For all flanged pipe connections to flowmeters it is essential that flange faces are well

aligned and closely fitting.

values greater than 110ft.lb (150Nm)

10

Page 11

2.2 Electrical Installation

Two types of output are available from an Oval Gear flowmeter; NPN Hall Effect and Reed

Switch (contact closure). Some meter configurations will have one of these outputs, some

will have both; a flowmeter may be installed using any of the available outputs.

2.2.1 Wiring

All wiring of electrical outputs should use high quality instrument cable; twisted pair low

capacitance shielded instrument cable (20AWG [0.5mm

only high temperature cable where process temperatures exceed 185

drain or screen should be terminated on a DC common or a specifically assigned shield

terminal at the readout instrument end only; in order to protect the signal from mutual

inductive interference. The cable shield at the meter end of the cable must be isolated

with tape or similar, do not connect the cable shield to ground at the meter.

The cable should not be run in a common conduit, or parallel with, power cables or high

inductive load carrying cables; as interference will affect the transmitted pulse signal. Run

all instrument cables in their own separate conduit. Where instrument cables must cross

high power cables be sure that the cables intersect at 90 degrees in order to limit induced

interference.

Do not combine any inductive loads on the same voltage supply as your flowmeter wiring,

as these components are commonly sources of high frequency interference that may affect

the quality of the output signals. Inductive loads on a common voltage source also have the

potential for voltage spikes well in excess of the 24V (dc) limit of the flowmeter electronics.

The maximum wire cross section that can be connected to the terminals of an Oval Gear

pulse meter is 16AWG (1.5mm

2

).

2

] minimum) is recommended. Use

o

F (85oC). The cable

2.2.2 Hall Effect Outputs

The Hall Effect is a solid state 3 wire device which provides an open collector, NPN signal.

The output of the Hall Effect must be fitted with a pull-up resistor between the signal

output ( ) and the voltage supply. The Hall Effect output provides a square wave pulse

signal, which alternates between ground potential and the DC voltage available at the pullup resistor.

The NPN Hall Effect output is a reliable output type, producing a consistent output

irrespective of supply voltage variations, temperature variations, or mechanical shock. The

service life of the Hall Effect output is theoretically infinite, so long as it is protected from

high energy voltage spikes. Hall Effect outputs are protected against reverse polarity, and

against low energy voltage spikes; however, they are not protected against constant overvoltage above the maximum limit of 24V (dc) (±5%).

11

Page 12

Many secondary flow instruments are fitted with an integral pull-up resistor, but if

connecting the Hall Effect output to an electronic device that does not contain an integral

pull-up resistor, one MUST be fitted by the installer. The pull-up resistor is connected

between the signal terminal and the +VDC terminal; the recommended pull-up resistor

value is 10kΩ, 2.4kΩ is the minimum value in a 24V (dc) system.

In low voltage systems using low pull-up resistor values, cases may occur where the

voltage level at the terminal will not be low enough to trigger the low-level logic on

receiving instruments. The equation below approximates the minimum pull-up resistor

value required based on the pull-up voltage level, and the low logic voltage threshold of the

instrument.

112

=

0.05

102

= Minimum value of pull-up resistor

= Voltage that signal is being pulled up to

= Low logic voltage threshold

Note: The hall effect sensor circuitry incorporates 2 x 51 ohm resistors in series with the

signal output.

2.2.3 Reed Switch Outputs

The reed switch output is a two wire normally-open SPST voltage free contact ideal for

installations without power, or for use as a simple apparatus in hazardous area locations.

When using the reed switch output the liquid temperature must not change at a rate

greater than 18°F (10°C) per minute, or the switch will be damaged. Reed switch reliability

and lifetime are very dependent on the voltage and current used; reducing system voltage

and switching current to a minimal value is recommended. Under ordinary conditions the

service life of the reed switch will exceed 2 billion actuations when switching less than 5V

(dc) and 10mA (as is the case when used with any of the available Integral Instruments)

12

Page 13

2.2.4 Quadrature Pulse Outputs

The Quadrature Pulse (QP) output is an optional type of output that provides two

independent Hall Effect outputs that are electrically 90 degrees out of phase. When

installing a meter with Quadrature Pulse output it is important to remember that each

output terminal is independent, and as such each will require its own pull-up resistor as

described in Section 2.2.2 above.

2.3 Making Electrical Connections

To gain access to the electrical connections on a meter without an instrument, you must

first remove the terminal cover by removing the four cover screws with a 4mm Hex Key

(Allen Key). When removing the terminal cover, take care not to damage or lose the O-Ring.

Standard Pulse Output Boards utilise a pluggable terminal block which can be removed for

fitment of wires. Reed Only Pulse Output Boards use Cage Clamp terminal blocks which

require insertion of a screw driver into the wedging slot as show below. All wiring requires

a 0.1” (2.5mm) wide Flat Blade Screw Driver (or smaller).

For meters fitted with an integral instrument refer to the instruments instruction manual

that accompanied the meter.

When refitting a terminal cover for a Flameproof (EXd) flowmeter the terminal cover

screws must be tightened to a torque of 2.95ft-lb (4Nm). See section 2.7.3 for more

details.

Connecting wiring to Reed Only Pulse Output Boards

13

Page 14

2.4 Wiring Diagrams

2.4.1 Standard Pulse Output Board

Applicable Models: 006, 008, 015, 025, 040, 050

Applicable Models: 004, 080, 080E, 100, 100E

14

Page 15

Notes for Connection of standard Hall/Reed Pulse Output Boards

1. Pull up resistor required for operation of Hall Effect output; 10 kΩ is recommended. See

section 2.2.2 for further information.

2. For installations subject to electrical noise; signal filtering can be enabled on the Reed

Switch output by wiring the negative terminal of the reed switch (terminal 5) to the

GND terminal (terminal 2). When not using filtering on the Reed Switch output the

polarity of the wiring is not important.

3. Installing a current limiting resistor is recommended to extend the life of the Reed

Switch device; 800Ω is recommended as a minimum resistance value for a 24V system.

Resistor not required when connecting to battery powered flow instruments.

15

Page 16

2.4.2 Reed Only Pulse Output Board

Applicable Models: 015,025,040, 050, 080, 080E, 100, 100E

Applicable Models: 004,006,008

16

Page 17

Notes for Connection of Reed Only Pulse Output Boards

1. Reed Only pulse output boards are fitted with an on-board current limiting resistor

which will limit the total power into the circuit to less than 1W at 24V (dc) (when using

both outputs). This limitation provides perfect conditions for maximum Reed Switch

service life, and is required for use as a Simple Apparatus within a Hazardous Area.

When used in a Safe Area (non-hazardous) the current limiting resistor can be bypassed

by joining the solder link on the top surface of the PCB, however this will reduce Reed

Switch life. Please note that it is the responsibility of the user to ensure that total

power remains below 1W when used in a Hazardous Area.

2. The output resolution from each Reed Switch is as per the calibration sheet delivered

with the flowmeter; wiring the Reed Switch outputs in parallel will double the output

resolution (015 ~ 100 models only).

2.4.3 Reed Only Outputs as Simple Apparatus

When purchased with a ‘Reed Only” output the meter can be wired as an Intrinsically Safe

Simple Apparatus, see section 2.7.4 for further explanation of simple apparatus. The

wiring diagram below shows wiring of the Reed Switch signal from a meter located in the

hazardous area, to an MTL 5532 pulse isolator located in the safe area. The MTL pulse

isolator is shown as it is a common choice; however other brands and models of isolator

may be used in the same way provided they are designed for pulse or frequency signals.

Any barriers/isolators should only be installed after reading the manufacturer’s

instruction manual.

17

Page 18

2.4.4 Hall Only Output

Applicable Models: 004 ~ 015 Hall Only, 004 & 006 High Resolution Option

Applicable Models: 025, 040, 050, 080, 080E, 100, 100E

Notes for Connection of Hall Only Pulse Output Boards

1. Pull up resistor required for operation of Hall Effect output; 10 kΩ is recommended. See

section 2.2.2 for further information.

18

Page 19

2.4.5 Quadrature Pulse Output

90° phase shift

Quadrature

Common +V (dc)

Common -0V

2

1

REED

QUAD

NPN HALL EFFECT

Quadrature Pulse Outputs may be wired directly to any flow instruments that accept

quadrature signals for signal integrity verification (custody transfer applications) or for bidirectional flow.

Pulse

Output

between

2.5 Meter Calibration Factor (K-Factor, Scale Factor)

Each flowmeter is individually calibrated and supplied with a calibration certificate

showing the number of pulses per unit volume (e.g. pulses/Litre) which is characteristic to

individual outputs on your meter. Meters fitted with integral instruments will have the

relevant K-factor entered into the program of the instrument at the factory.

2.6 Integral Instruments

If your flowmeter was purchased with an integral Rate Totaliser then the instrument will

be factory wired for reed switch input into the instrument. If your flowmeter is fitted with

an integral Batch Controller, the NPN (open collector) output from the Hall Sensor is factory

wired and programmed. If you are unsure of the factory wiring of your instrument, remove

the instrument bezel to check the wiring.

Unless programming details were provided at time of order, the instrument program will

contain factory default parameters. Integral instruments will be programmed with the

relevant K-factor for the meter, however all output(s) are turned OFF, and if required need

to be turned ON and then configured to suit the application requirements.

19

Page 20

2.7 Installations in Hazardous Areas

Installations in Hazardous Areas are applications where the utmost care is necessary in

correctly selecting your flowmeter. If your flowmeter is to be used in a hazardous area it is

important that it has been correctly selected for the specific explosive atmosphere in which

it is to be used, and that installation be carried out by a competent person.

An Oval Gear flowmeter may be suitable for use in a hazardous area if it has been

purchased as Flameproof (EXd), Reed Only (Simple Apparatus), or with an integral certified

Intrinsically Safe instrument (EXi). Before installation ensure your meter is suitable for the

specific explosive gas or vapour present and the zone rating, gas group, and temperature

classification of your installation

For any installations measuring non-conductive liquids there may be a risk of electrostatic

build-up in the liquid. It is recommended that the guidance in IEC TS 60079-32-1 is followed.

2.7.1 ATEX/IECEx Flameproof Flowmeters (Ex db)

ATEX/IECEx flameproof (Ex db) Oval Gear flowmeters are designed and certified for use in

either Zone 1 or Zone 2 hazardous areas.

Flameproof flowmeters must be installed in accordance with hazardous area standards,

which require the use of certified cable glands, sealed conduit connections, and armoured

cable according to the international standards IEC/EN 60079:1 and IEC/EN 60079:14. The

extent of special wiring installation is dependent on the zone and gas group.

ATEX/IECEx flameproof flowmeters are available with either of the following equipment

ratings:

Group IIB – Aluminium or Stainless Steel meters suitable for hazardous gas atmospheres

in group IIB.

II 2 G

EX d IIB T6…T3 Gb

Group I/IIB – Stainless Steel meters suitable for mines subject to firedamp and gas

atmospheres in group IIB.

I M2 Ex d I Mb

II 2 G EX d IIB T6…T3 Gb

20

Page 21

2.7.2 Conforming Standards

ATEX Directive

IECEx Scheme

Flameproof flowmeters carrying ATEX/IECEx labels are certified in accordance with the

following standars. Prior to installation or use, review the approval markings on the product

and in this manual, as well as the conforming standards below, to confirm it is appropriate

for your country/region and site classification.

ATEX directive 2014/34/EU

EN 60079-0:2012 + A11 : 2013

EN 60079-1:2014

IEC 60079-0:2011 Edition 6.0

IEC 60079-1:2014-06 Edition 7.0

21

Page 22

2.7.3 Temperature Limits for Flameproof Flowmeters

Process (Liquid) and Ambient Temperature Limits

Marking

Allowable Temperature Range

EX d Mb

+14oF ≤ T ≤ +302oF (-10oC ≤ T ≤ +150oC)

EX d IIB T6 Gb

-40oF ≤ T ≤ +158oF (-40oC ≤ T ≤ +70oC)

EX d IIB T5 Gb

-40oF ≤ T ≤ +185oF (-40oC ≤ T ≤ +85oC)

EX d IIB T4 Gb

-40oF ≤ T ≤ +248oF (-40oC ≤ T ≤ +120oC)

EX d IIB T3 Gb

+14oF ≤ T ≤ +302oF (-10oC ≤ T ≤ +150oC)

When operating a Flameproof meter, the process (liquid) temperature must be kept below

the maximum limit which is allowed for the temperature class of the installation. This is a

critical requirement for explosion safety. For ATEX/IECEx rated equipment refer to the table

below to determine the temperature limits for a specific temperature class (e.g. T6

installations must be kept below 158oF [70oC])

2.7.4 Special Conditions of Use

The following conditions must be adhered to for use, service or maintenance of a Flameproof

(EXd) flowmeter.

o Flamepaths are not intended to be repaired, contact manufacturer.

o The maximum allowable diametric clearance of the cylindrical joint between the

terminal cover and the meter cap must not exceed 0.0059 inches (0.15mm).

o The property class of the hexagon socket head cap screws retaining the terminal

cover must be A2-70 or higher; e.g. A4-80.

o Terminal covers screws must be torqued to a value of 2.95ft-lb (4Nm).

22

Page 23

2.7.5 Earthing of Flameproof Flowmeters

A facility for the connection of an earthing conductor is provided inside the terminal

cover of all flameproof (EXd) flowmeters, as per below diagrams. The earthing connection

is fitted with a 5mm Philips head screw with a locking washer and allows for the fitment of

a 5mm ring terminal.

Applicable Models: 004, 006, 008, all High Pressure models

Applicable Models: 015,025,040, 050, 080, 080E, 100, 100E

The use of the internal earth connection as the only earthing connection may be

acceptable with wiring systems using steel wire armoured cable or metallic conduit. For all

other installations an external earthing connection must be used which may be connected

to the external threaded mounting holes on the flowmeter body or using metallic cable

glands with earthing tags.

23

Page 24

2.7.6 Intrinsically Safe Flowmeters (EX i)

Please consult with a hazardous area expert within your country/region

CAUTION

Intrinsically safe flowmeters and instruments are designed and certified for use in zone 1,

and zone 2; they function by limiting the power and energy available in the electrical

equipment to a level that is low enough that it cannot ignite the hazardous atmosphere.

Intrinsic safety installations are carried out in accordance with IEC/EN60079:14 and

IEC/EN60079:25.

Intrinsically safe products may be installed with standard wiring carried in regular

conduit; however any wiring that crosses from a hazardous area to a safe area must pass

through an appropriately certified Intrinsically Safe barrier/ isolator.

If your meter is fitted with an integral intrinsically safe Instrument; installation must not

be carried out before reading the Instrument product manual, and any supplementary

manual (if applicable).

In regions that operated under ATEX or IECEx schemes, meters purchased with the ‘Reed

Only’ option can be used as an Intrinsically Safe ‘simple apparatus’ if the reed switch output

is used in conjunction with suitably certified associated equipment. The use of ‘simple

apparatus’ is defined in the international standard EN60079:11 and in many

countries/regions is allowed to be used in all hazardous areas with a temperature class of

T4 provided it is wired to a certified Intrinsically safe receiving instrument within the same

zone, or to a certified Intrinsically Safe barrier in the safe area.

Pulse output flowmeters may be used with the following grouping:

Ex ib IIB T4 Gb (Tamb<80

Zones 1 & 2

Flowmeters fitted with an integral certified Intrinsically Safe instrument, use equipment

grouping from the certified instrument.

o

C)

before installing a simple apparatus flowmeter in a hazardous area

installation to be sure this is allowed in the relevant national standards.

NEVER INSTALL AN OM025P PLASTIC FLOWMETER IN A HAZARDOUS AREA

DUE TO THE RISK OF STATIC DISCHARGE.

24

Page 25

2.8 Commissioning

Once the meter has been mechanically and electrically installed in accordance with this

instruction manual, the meter is ready for commissioning.

The newly installed meter must NOT be run until the piping is completely flushed of

foreign materials. The most common foreign matter that is present in new or modified

piping is; welding slag, grinding dust, sealing tape/compound, and surface rust. If your

piping has been designed with a bypass line it will be easy to isolate your meter from the

remainder of the system to flush out the majority of the piping. If you have not installed a

bypass line around the meter, the best solution is to replace the meter with a spool-piece

for the duration of the flushing procedure.

The other critical concern when commissioning a meter is the presence of air slugs; this is

also a concern for any systems that have been shut down for long periods of time. Do not

start up your system for the first time by opening all valves and turning on the pump.

To safely start a meter for the first time, the best procedure is to eliminate the majority of

the air volume in your piping system using the bypass line described earlier. After bleeding

the majority of the air through the bypass line, the remainder of the air can be slowly

passed through the meter by gently opening the flow control valve downstream of the

meter. If a bypass line has not been incorporated into your system, and no alternative exists

for bleeding air upstream of the meter, then the entire air volume of your piping will need

to be bled very slowly through the valve downstream of the flowmeter.

Following the start-up procedure, and during the period of initial operation, it is

recommended that the inlet strainer on your meter be inspected regularly, and cleaned if

necessary, as it is possible that not all foreign material will be completely removed from

your system during the initial flushing.

25

Page 26

2.9 Fault Finding

Pulse meters have two distinct sections: the mechanical wetted section housing the rotors

and the electrical section housing the pulse output board. Meters fitted with integral

instruments have these two sections plus the instrument. The aim of fault finding is to trace

the source of the fault to one of these sections. If a fault is traced to an instrument section,

refer to the relevant instruction manual. Below are basic fault finding steps.

Step 1 - Check application, installation and set up; refer to installation sections for

installation and application factors that may affect the meter operation including incorrect

wiring. Check meter specifications for incorrect flow rate, temperature, pressure, or

materials compatibility.

Step 2 - Check for blockages; The most common cause of fault/unsatisfactory meter

operation, particularly for new or altered installations, is due to blockage within the system

or meter caused by foreign particles such as weld slag, sealing tape or compound, rust, etc.

Step 3 - Ensure flow is present; No flow or lower than normal minimum flow may be

attributed to a blocked strainer, jammed or damaged rotors within the flowmeter, a

malfunctioning pump, closed valves or low liquid level in feeder tank.

Step 4 - Ensure oval gears within meter are rotating; Rotation of the oval gears can be

heard by holding a screw driver blade to the meter body and pressing the handle hard

against the ear lobe. If necessary test the meter with the flow turned off and turned on to

familiarize yourself with the audible rotation signature.

Step 5 - Ensure pulses are being generated during flowing condition; a multi-meter is often

not fast enough to distinguish the pulse train from the reed switch or Hall Effect sensor. An

oscilloscope will allow you to view the output pulse train. When viewing the Hall effect

sensor signal ensure a pull up resistor is installed between the pulse output and the supply

voltage (refer electrical installation).

Step 6 - Confirm Instrument Operation; if an associated instrument is connected to the

flowmeter confirm its operation by simulating a pulse input onto the flow input terminals.

In most instances, a contact closure on the flow input terminals is an adequate simulation.

26

Page 27

2.10 Troubleshooting Guide

Possible

Cause

- confirm shielded cable has been used

power carrying cables such as valves and pumps/motors.

Entrained air

or gas

- Remove source of air or gas entrapment

- Install an upstream air-eliminator

Pulsating Flow

style pump

- Increase back pressure on pump

- Change pump style to a smooth delivery pump

Damaged or

worn rotors

Damage or

chamber

Output signal

interference

- Confirm correct wiring with shielded cable

- Check all electrical connections for firmness and continuity

- If meter has been recently field serviced, check that rotors

- Clean, repair, or replace rotors

Meter

reassembled

- Check terminal connections

- Check voltage/current are within maximum ratings

Not Reading

Instrument

Faulty

instrument

- Check hardware and software settings; DIP switches,

- Repair or replace receiving instrument

Symptom

Meter

Readings are

High

Meter

Readings are

Low

Output Signal

Interference

from

reciprocating

worn

measuring

Rotors

jammed

Solution

- ground cable shield at instrument end only

- isolate cable shield at flowmeter end

- re-route cabling from high electrical energy sources, or

- Install a fast response one-way (check) valve, or a surge

arrestor between pump and meter

Inspect, repair, clean, or replace rotors

Inspect measuring chamber for damage and consult

manufacturer for advice.

are not installed upside-down or incorrectly meshed

- Check for obstruction due to foreign particles

No Output

from

Flowmeter

on Receiving

incorrectly

No signal from

Pulse Output

Board

receiving

Consult manufacturer for advice.

- Ensure DC voltage is available at the terminals of the PCB,

and pull-up resistor is fitted if Hall Effect output is used.

- Ensure receiving instrument is configured correctly.

terminal connections, and programming settings

27

Page 28

3. Maintenance and Repairs

Adhering to the installation instructions is the most important requirement to ensure that

your Oval Gear meter provides the maximum level of operational performance. Oval Gear

meters are a mechanical device, and so will be subject to some wear and tear over their

operational life except under ideal circumstances. The amount of normal wear that the meter

will experience will be dependent on the operational conditions such as; flow rate,

temperature, cleanliness of the liquid, lubricity of the liquid, and the amount of continuous

duty required of the meter.

To maximise the operational availability of your meter, and reduce system downtime, a

periodic maintenance and inspection regime should be used. Frequency of maintenance

depends on the operational conditions of the meter and the criticality of the system; it is the

user’s responsibility to determine inspection frequency however the manufacturer can provide

guidance.

For any installations that require in-situ cleaning (CIP); it is important that the cleaning or

flushing procedures do not produce operating conditions that are outside of the acceptable

flow rate, pressure, or temperature ratings of the meter. High temperature cleaning

procedures that increase system temperature at a rate greater than 18°F (10°C) per minute

may damage the reed switch output. Chemical compatibility of cleaning solutions should be

checked against the materials of construction of the meter.

Before undertaking meter maintenance ensure the following:

Associated alarm(s) or control output(s) are isolated so not to affect the process

Voltage supply is isolated from the meter

Liquid supply to the meter is closed off

The meter is depressurised and liquid drained from the meter / pipeline

28

Page 29

3.1 Parts Identification

For identification of the parts within your Oval Gear meter refer to the following images

and tables.

Applicable Models: 004, 006, 008, 015

Applicable Models: 025, 040, 050, 050E

29

Page 30

Applicable Models: 080, 080E, 100, 100E

Applicable Models: 025P

30

Page 31

Parts Identification Table

1

Meter Body Assembly

2

Rotor Assembly

3

Meter Body O-Ring

4

Meter Cap

5

Meter Body Screw

6

Pulse Output Board

7

Pulse Output Board Screw

8

Terminal Cover O-Ring

9

Terminal Cover

10

Terminal Cover Screw

11

Flange Portion O-Ring

12

Flange Portion Screw

13

Flange Portion

Item No. Description

3.2 Flowmeter Disassembly

If required to gain access to the meter terminals and pulse output board, undo the 4 cap

screws (10), remove the terminal cover (9) carefully to avoid putting strain on the terminal

connections. The pulse output board (6) can now be accessed and removed if necessary by

removing the pulse output board screws (7).

To access the oval gear rotors, undo the meter body screws (5), and carefully pry the

meter body apart avoiding misplacing or damaging the O-ring (3). The rotors (2) can now be

removed and inspected.

If the meter is fitted with an integral instrument the instrument display assembly must be

removed in order to gain access to the instrument terminal connections, instrument battery

or pulse output board. This is achieved by undoing the 4 bezel screws and separating the

display assembly from its base. Do not stress or damage the wires that connect the display

assembly to the pulse output board. Take care not to misplace or damage O-ring(s). If

required, the pulse output board can now be accessed; to remove the pulse output board

first undo the screws that fix the instrument base to the flowmeter.

3.3 Flowmeter Inspection

Inspect O-rings for damage, chemical attack, deformity or any form of deterioration.

Remove, inspect and clean the rotors, and check the measuring chamber for damage or

scoring, the rotor shafts should NOT be loose or able to be rotated. Rotors should turn

freely, and should spin without scraping or catching on any part of the meter body.

31

Page 32

3.4 Re-assembly of Flowmeter

When re-installing the rotors the magnets MUST be correctly positioned so that they are

facing the sensors located in the meter cap, for meters ranging from 004 to 015 sizes the

magnets are inserted from the underside of the rotor so will not be visible when the rotors

are installed. Meters from 025 size and larger will have the magnets visible from the top; if

you are unsure of magnet location it is easiest to test using a small steel object such as a

steel ruler or small screw driver.

Both rotors will only engage correctly if fitted precisely at an orientation of 90 degrees to

each other. Rotate the rotors slowly by hand to ensure they are correctly fitted, at the same

time check the rotor shafts & rotor bearings for wear. If you are able to rotate the engaged

rotors through a complete 360, then you have installed them at the correct 90 degree

angle.

Fit the O-ring into the groove and assemble the meter cap onto the meter body; small

meters are visibly aligned using a small dimple on the top face of the meter cap and the

underside of the meter cap. Larger meters are aligned using a location pin or a pair of

dowel pins.

Fit the body cap screws (5) and tighten in a star sequence, then carryout a final tighten in

the same sequence to a firm torque. This sequence and procedure ensures the meter

bodies are assembled correctly and evenly. Fit the pulse output board, terminal cover or

instrument as appropriate.

32

Page 33

4. EU Declaration of Conformity

We, Trimec Industries Pty Ltd, of Sydney Australia, trading as Great Plains Industries

Australia declare under our sole responsibility that the OM-Series flow-meter products are

in conformance with the following European directives and European harmonized

standards.

2011/65/EU RoHS Directive and amending directive (EU)2015/863

EN50581:2012

Technical documentation for the assessment of electrical and electronic products with

respect to the restriction of hazardous substances

2014/30/EU EMC Directive

EN61326-1:2013

Electrical equipment for measurement, control and laboratory use - EMC requirements

– Part 1: General requirements

2014/68/EU Pressure Equipment Directive

Compliance is declared according to Article 4, paragraph 3 – SEP

Annex II, table 3

Models OM050H, OM100A, and OM100E are PED compliant under SEP only for Group II

liquids according to Annex II, table 4.

When purchased as EXd these products are additionally in conformance with:

2014/34/EU ATEX Directive

EN 60079-0: 2004

Electrical apparatus for explosive gas atmosphere - Part 0: General requirements

EN 60079-1: 2004

Electrical apparatus for explosive gas atmosphere - Part 1: Flameproof Enclosures

Type examination has been carried out by Sira Certification Service, Notified Body number

0518 and the following certificates issued:

Sira05ATEX1296X - ATEX Equipment Certificate

IECEx SIR07.0014X - IECEx Equipment Certificate

Signed for and on behalf of Trimec Industries Pty. Ltd. 1/16 Atkinson Road, Taren Point, NSW,

Australia.

Matthew Wyres Sydney, Australia

Engineering Manager January 2018

33

Page 34

Notes:

34

Page 35

Notes:

35

Page 36

Service & Warranty

For Technical Assistance, warranty

replacement or repair in North or

South America contact your Flomec

Distributor or contact

Great Plains Industries, Inc.

5252 East 36

Industrial Oval Gear Meter Instruction Manual

1314009 Rev.1819

th

St. North Wichita,

KS, USA 67220-3205

888-996-3837

www.flomec.net

For Technical Assistance, warranty

replacement or repair outside North

or South America contact your

Flomec Distributor or contact

GPI Australia

1/16 Atkinson Road

Taren Point NSW 2229

Sydney, Australia

+61 02 9540 4433

36

Loading...

Loading...