Flomec G Series Owner's Manual

921977-01C06/15

G SERIES TURBINES

(Industrial and Chemical Models)

Owner’s Manual

SAVE THESE INSTRUCTIONS

2 921977-01C

TABLE OF CONTENTS

General Information .............................2

Installation ...........................................3

Maintenance ........................................4

Troubleshooting .................................10

Specications ....................................13

Service...............................................15

To the owner…

Congratulations on receiving your

FLOMEC® G Series Turbine. We are

pleased to provide you with a product

designed to give you maximum reli-

ability and efciency.

Our business is the design, manufacture, and marketing of liquid handling,

agricultural, and recreational products. We succeed because we provide

customers with innovative, reliable,

safe, timely, and competitively-priced

products. We pride ourselves in conducting our business with integrity and

professionalism.

We are proud to provide you with a

quality product and the support you

need to obtain years of safe, dependable service.

President

Great Plains Industries, Inc.

GENERAL INFORMATION

This manual will assist you in installing and maintaining your FLOMEC G

Series Turbine. For best results, take

the time to fully acquaint yourself with

all information about all components of

your G Series Turbine. If you need assistance, contact the distributor from

whom you purchased your turbine.

Product Description

FLOMEC G Series Turbine owmeters are volumetric ow measurement

devices. The moving uid is used to

turn a rotor, which is suspended in

the ow stream. The rotating speed

of the rotor is proportional to the uid

velocity or owrate. As the blades from

a spinning rotor pass by a magnetic

sensor, an AC voltage pulse is generated and transmitted to the readout

instrument. Each pulse is equal to a

given volume of liquid, therefore “x”

number of pulses are equal to a gallon, litre, pound, barrel, etc.

Turbine Sizing

FLOMEC G Series Turbines are

identied by the internal diameter of

the inlet and outlet.

Model 050 ½ in. (0.6-6.0 gpm)

Model 051 ½ in. (0.8-6.0 gpm)

Model 075 ¾ in. (1.6-16 gpm)

Model 075E ¾ in. (2.3-23 gpm)

Model 100 1 in. (6.7-67 gpm)

Model 150 1½ in. (17.7-177 gpm)

Model 200 2 in. (33-330 gpm)

Model 300 3 in. (60-600 gpm)

Turbine owmeters should be sized

in accordance to the actual owrate

and not the process pipe size. For

example: a process having a owrate

of 10-20 GPM in a 1-½" process line

requires either a Model 075E or Model

100 turbine owmeter.

Another important factor to take into

consideration when sizing a turbine

owmeter is instantaneous owrate.

3

921977-01C

This is extremely important when

sizing a turbine owmeter where

the volume is measured per hour or

per day. For example, an application

where the total output is 500 barrels

per day, occurring in a 5 hour period;

the recommended turbine owmeter

should be sized according to the

instantaneous owrate:

(500 – 5) x 24 or 2,400 barrels per day

Thus, requiring an 1-½ inch turbine

owmeter.

INSTALLATION

Turbine owmeters are affected by

both upstream and downstream

process configurations. Turbine

owmeters should always be installed

with a minimum of 10 pipe diameters

upstream and 5 pipe diameters

downstream. The only exception is

the placement of the pumps, valves,

etc., on the upstream end. When this

occurs, 20 diameters of straight pipe

should be used. The direction of ow is

indicated by the arrow on the turbine.

All turbine owmeters are designed

to measure ow in only one direction.

Check the items below once the

turbine owmeter is installed in the

process line. This will ensure a successful start-up.

1. Before installing the magnetic sensor, make sure that it is functioning

properly. This can be accomplished

by checking the ohm resistance.

Refer to Checking Magnetic Pickup

in the Troubleshooting section.

2. If a magnetic pickup enclosure is

used on a sanitary turbine, discard

the seal cap that is included with the

unit. If no enclosure is used, install

the magnetic pickup and slip the

seal cap over the magnetic pickup

and threads on the adapter.

NOTE: This is not applicable for units

that use a low prole adapter.

3. Check the interconnection cable

between the turbine owmeter and

readout device. Refer to Checking

the Cable Assembly section.

4. Make sure that the new or correct

K-factor is entered into the readout

device.

Initial Start-Up

Turbine owmeters can be installed

in the horizontal or vertical position.

When installing a turbine owmeter

in the vertical position, it is important

that the direction of ow be up through

the turbine owmeter.

A spool should be installed in place

of the turbine owmeter during initial

start-up of a new process line. The

process line should be purged, thus

eliminating any solids contained in

the line. Once this is completed, the

spool can be removed and the turbine

owmeter installed.

Whenever possible, use 20 straight

pipe diameters upstream and down-

stream of the turbine owmeter. The

length of straight pipe upstream and

downstream of the turbine owmeter

can be reduced with the use of ow

straighteners or straightening vanes.

A minimum of 10 straight pipe diameters upstream and 5 downstream

are required.

NOTE: Control valves should always

be installed downstream of the

turbine owmeter.

The turbine owmeter should be

installed in a location where the process line will remain full of liquid at all

times. Otherwise, when the process

line becomes empty and a valve is

opened, the high velocity uid hitting

the turbine owmeter rotor can cause

severe damage.

When there is entrained air in the

process line, an air eliminator should

be used. This entrained air causes

air pockets and these air pockets

4 921977-01C

will cause the rotor to spin at a faster

rate than liquid, thus resulting in incorrect readings, which results in an

overstatement of actual owrate and

volume. This condition can damage

the owmeter.

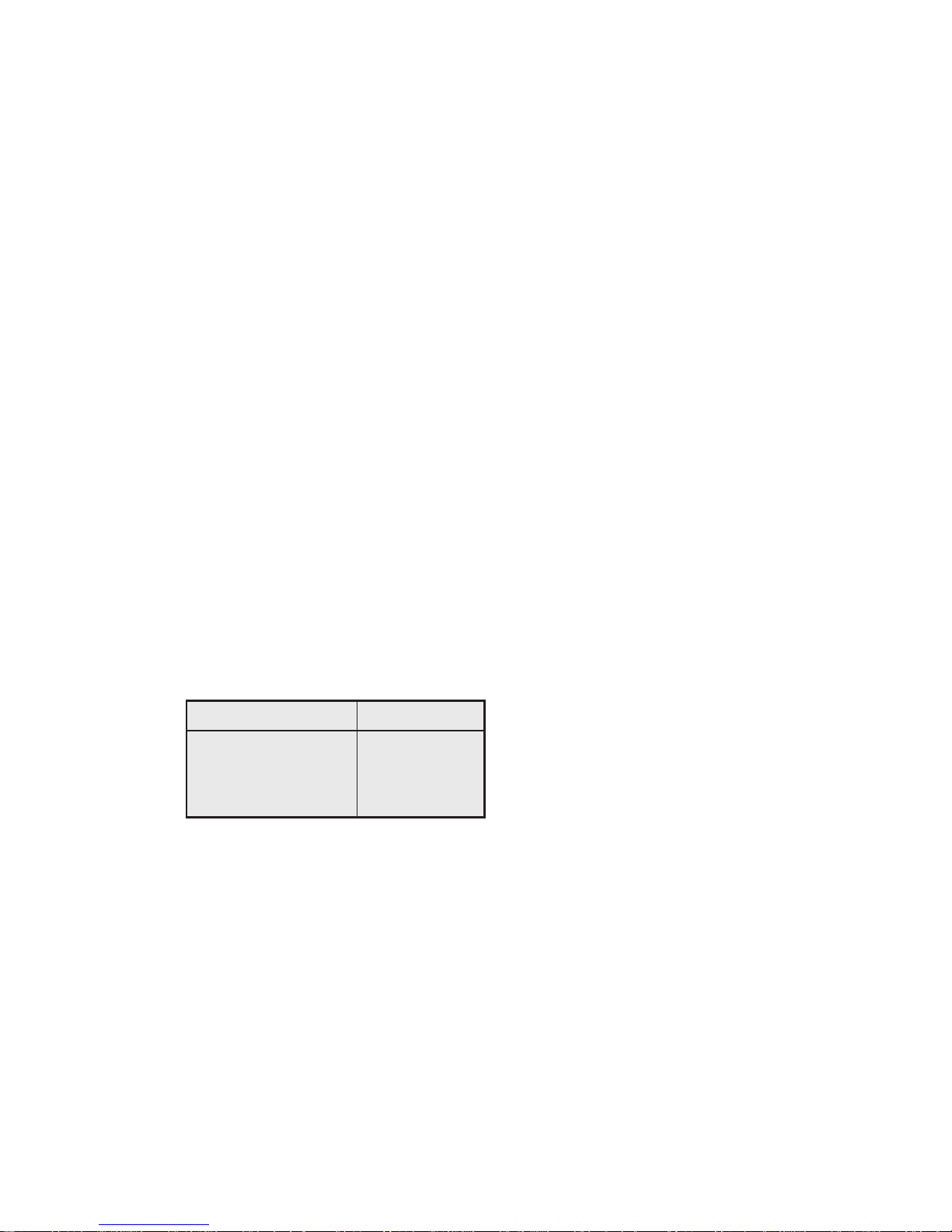

In process lines where particulates

are present, a lter/strainer should

be used. Refer to the table below for

the recommended mesh size.

Turbine

Flowmeter Size

Mesh Size

½ inch 40

¾ inch 40

1 inch 40

1-½ inch 18

2 inch 14

3 inch 14

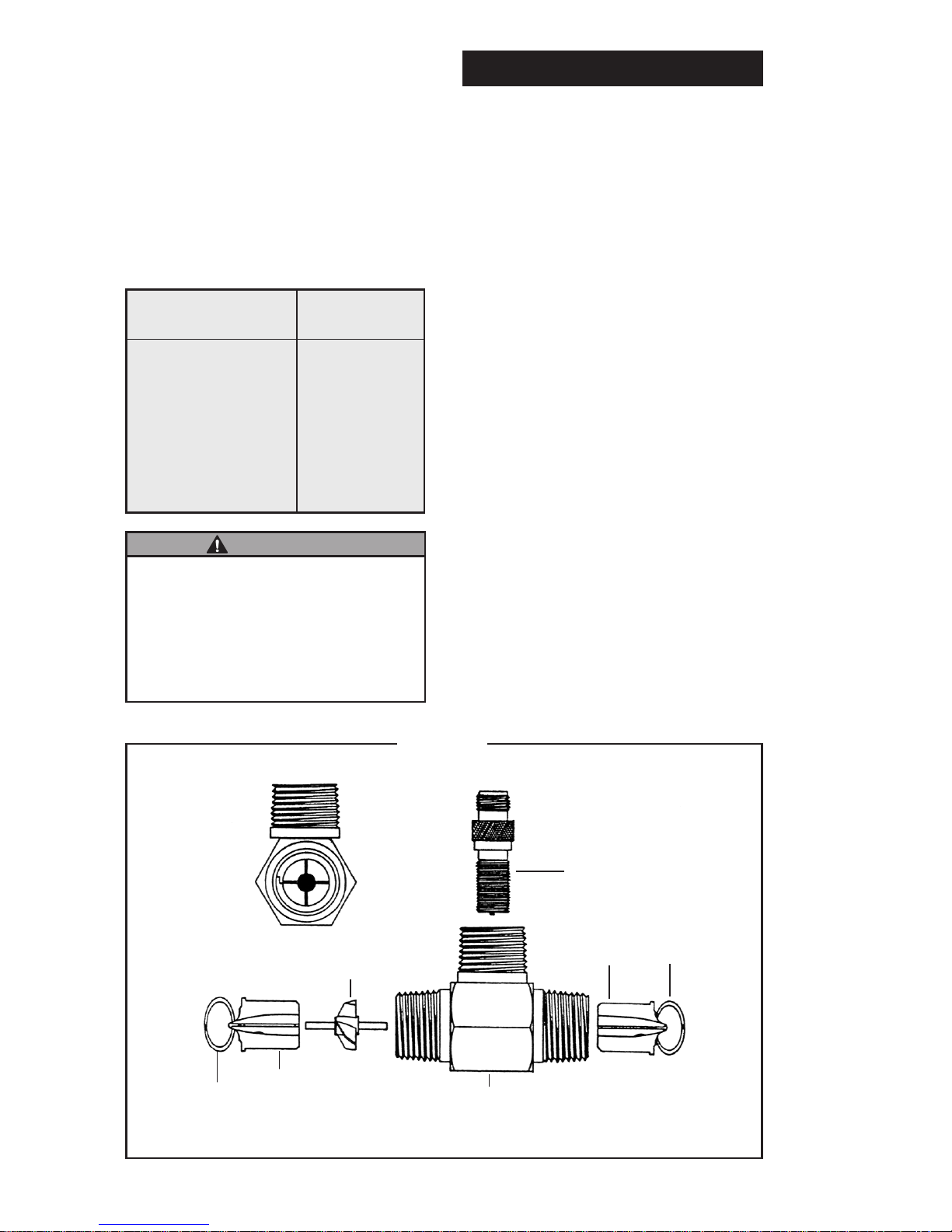

Figure 1

Contact the factory for sanitary versions of this meter.

MAGNETIC PICKUP

(HAND TIGHTEN ONLY)

END VIEW

RETAINING

RING

ROTOR

SUPPORT

ROTOR

BODY

ROTOR

SUPPORT

RETAINING

RING

F L O W

➞

MAINTENANCE

Disassembling the Turbine

1. Disconnect the turbine owmeter

cable from the magnetic pickup.

Refer to Figure 1.

2. Remove the magnetic pickup.

3. Ensure that the process line is

depressurized and empty prior to

removal of the turbine owmeter.

Remove the turbine owmeter from

the process line.

4. Using a small screwdriver or similar

tool, insert it into the radius notch

of the retaining ring, pull away from

the groove and up, removing the

retaining ring from one end of the

turbine owmeter. This will allow

the support to slide out of the

turbine owmeter body. Remove

the rotor before proceeding to the

other support.

NOTE: To remove the other support,

simply repeat this operation.

If liquid being measured by

sleeved bearing turbine owmeters contains large solids, install a

lter or strainer. Without the use

of a lter or strainer, damage can

occur to the internal components.

WARNING

5

921977-01C

5. Once the turbine owmeter is taken

apart, inspect the turbine owmeter

body for signs of wear or defects.

The body bore should be smooth

and show no evidence of wear.

NOTE: Do not install a new replace-

ment kit into a turbine owmeter

body that shows signicant signs

of wear.

6. Examine the rotor for broken and/

or bent blades.

7. Examine the supports for signs of

deterioration, such as wear marks

and/or burrs along the outer edge

of the support vanes.

8. When the rotor or the supports

show any sign of deterioration,

a new replacement kit should

be installed. Do not install a new

replacement kit into a defective

turbine owmeter body.

Replacement Kits

A replacement kit is comprised of all

the internal component parts within

the turbine owmeter. A replacement

kit consists of the following:

Parts Description Quantity

Rotor Assembly 1

Support Assembly* 2

Retaining Ring 2

* The support assemblies come complete with bush-

ings and thrust balls, which are factory installed.

Proper selection of bearing material is critical when

ordering a new replacement kit.

FLOMEC® supports are identical in

design, thus eliminating assembly error. Each support incorporates a thrust

bearing, which allows for bidirectional

ow and prevents damage to the rotor

and/or supports in the event the tur-

bine owmeter is installed backwards

with respect to the direction of ow.

Notice that the direction of ow is

displayed on the body of the turbine

owmeter. This is important when

installing the rotor and also denotes

the direction in which the turbine

owmeter was calibrated.

NOTE: FLOMEC rotors are tapered on

one end (except ½" and ¾"). The

tapered end should be installed

on the inlet side. See Figure 1.

The ½" and ¾" rotors are marked

with a point on the hub and should

be installed with the marked side

of the rotor hub on the inlet side.

1. Install a support on the inlet side

(where the ow starts), placing a

vane between the notches in the

turbine owmeter body. Install a

retaining ring – this will keep the

support in place.

2. Place the rotor with the shaft in

the support that has not been in-

stalled. Hold the turbine owmeter

body with the open end down and

slide the rotor and support into the

turbine owmeter body. Make sure

the vane is placed between the

notches.

3. Once the support is in place, install

the retaining ring.

4. Blow into the turbine owmeter to

ensure the rotor spins freely.

Installation of the replacement kit is

complete and the turbine owmeter

can be reinstalled into the process line.

5. Install the magnetic pickup. HAND

TIGHTEN ONLY.

NOTE: Be sure to use the proper

magnetic pickup, cable and connector for the application.

6. Enter the new K-factor supplied

with the replacement kit into the

electronic readout device. (Refer

to the calibration report.)

NOTE: All internal replacement kits

are factory calibrated and are sup-

plied with a ve point calibration

certicate.

Loading...

Loading...