Page 1

G2 SERIES

(

PRECISION TURBINE METERS

A full line of FLOMEC® G2 Series Precision Turbine Meters

are available in a variety of housing materials. Rugged and

dependable, the G2 Series offers:

• Stainless Steel for most water, chemical, and fuel products

• Aluminum for petroleum based products

• PVDF for aggressive chemicals

)

FEATURES / BENEFITS

• Meter is designed for thin uids < 100 cp

• Modular design allows for use with Output Modules, Sensors

and Remote Transmitters

• 2 Totals (Batch = Resettable, Cumulative = Non-resettable);

Rate of Flow, Factory calibrated in gallons or litres. Field

calibratable. Includes non-volatile totals.

• High accuracy meter

• Internal parts are simple to replace for easy maintenance

• AAA Alkaline battery life: 2 years

PRODUCT CONFIGURATION

1

PRODUCT IDENTIFIER:

G2 = Industrial Grade Flowmeters

2

TURBINE MATERIAL:

S = Stainless Steel

A = Aluminum

P = PVDF (1/2 in. & 1 in. only)

H = High Pressure Stainless Steel

3

TURBINE SIZE:

05 = ½ in.

07 = ¾ in.

10 = 1 in.

4

FITTING TYPE:

I = ISO (Female) BSPT (ISO 7 Designation is RC)

N = NPT (Female)

F = 150# ANSI Flange (Available on S10, S15 & S20 only)

T = Tri-Clover® tting (Available on S05-S20 only)

X = Electronics only (For metal meters)

Z = Electronics only (For plastic meters)

APPLICATIONS

• Batching

• Blending

• Water

• Industrial uids

• Plating solutions

• Ammonium

15 = 1-½ in.

20 = 2 in.

• Food and beverage

processing

• Fuel products

• Monitoring clean

uids

• Plant process water

• Chemical feed lines

• Harsh chemicals

(sulfuric acid and

bleach)

ELECTRONIC CHOICE:

5

Local Computer w/Display, Meter Mounted

Q9 = Q9 2-Button Computer

Q1 = Q9 2-Button Computer, Vertical Mount (90° Adapter)

Local Computer w/Display & Module, Meter Mounted*

P9 = Q9 2-Button Computer w/Pulse Out Module, includes Ex-

ternal Power and 10 ft. of Cable

42 = Q9 2-Button Computer w/4-20mA Module and 10 ft. of Cable

Module, Meter Mounted (No Display)*

PO = Pulse Out (Unscaled) Conditioned Signal Module w/Cable

QSI Options, Meter Mounted (No Display)*

81 = QSI Version 1 (Scales Pulse, RS485 [Modbus or BACnet],

BTU Calculator, Bluetooth®)

82 = QSI Version 2 (Scales Pulse, BTU Calculator, Bluetooth®)

83 = QSI Version 3 (Scales Pulse, 4-20 mA, Bluetooth®)

Retrot Computer Kit (Display Only)

R9 = Q9 2-Button Computer Retrot Kit (Replaces 09 Display)

No Electronics - Turbine Only

XX = No Electronics - Turbine Only

6

CALIBRATION OF COMPUTER / DISPLAY:

GM = Gallons Per Minute (Gallons Default)

LM = Liters Per Minute (Litres Default)

XX = No Calibration

7

PACKAGING:

A = 05 Thru 10 Turbines, Turbine Only or w/Q9 Electronics

05 Thru 20 Electronics Only (Q9 Replacement Kit or R9

Retrot Kit)

B = 15 & 20 Turbines, Turbine Only or w/Q9 Electronics

05 Thru 10 Turbines w/Q1 Electronics

C = 15 Thru 20 Turbine w/Q1 Electronics

05 Thru 20 Turbines w/P9, 42, PO, 81, 82, 83 Electronics

D = 10 Turbines with ANSI Flange Turbine Only or w/Q9, Q1, P9,

42, PO Electronics

E = 15 & 20 Turbines with ANSI Flange Turbine Only or w/Q9, Q1,

P9, 42, PO Electronics

10 Turbines with ANSI Flange w/81, 82, & 83 Electronics

F = 05 Thru 20 Turbines w/81, 82, & 83 Electronics

G = 15 & 20 Turbines with ANSI Flange w/81, 82, & 83 Electronics

1 2 3 4 5 6 7

--->>>> G2 S 15 N Q9 GM B

*All Electronics Approvals Void

Page 2

© 2020 Great Plains Industries, Inc. All Rights Reserved.

SPECIFICATIONS

1/2", 3/4", 1"

STYLE

C

Fitting Type: NPT or ISO (Female) BSPT* (*ISO 7 designation is RC)

150# ANSI (Stainless Steel only)

Tri-Clover® (Stainless Steel only) - Clamp size is one size

bigger than meter size

Housing Material: 316 Stainless Steel, Aluminum, PVDF

Meter Sizes Available: 1/2” 3/4” 1” 1-1/2” 2”

Flow Range: 1/2" (05) 1 - 10 GPM (3.8 - 38 L/min)

1/2” (05)

PVDF only

3/4" (07) 2 - 20 GPM (7.6 - 76 L/min)

1" (10) 5 - 50 GPM (19 - 190 L/min)

1-1/2" (15)

2" (20) 20 - 200 GPM (76 - 760 L/min)

Accuracy (% of Reading): Turbine Only Turbine w/Computer

1/2” (05) ± 2.0% ± 1.5%

3/4” (07) ± 1.5% ± 1.0%

1” (10) ± 1.5% ± 1.0%

1-1/2” (15)

2” (20) ± 1.0% ± 0.75%

Repeatability: ± 0.1% (PVDF is ± 0.3%)

Pressure Rating:

316 Stainless Steel (SS) 1,500 psi (102 bar)

Aluminum 300 psi (21 bar)

High Pressure 316 SS 3000 psi (207 bar) (CE Approval ONLY)

ANSI Flange 316 SS Flange Rule

Sanitary Flange 316 SS Limited by tting & clamp size & temperature

PVDF 100 psi (6.9 bar)

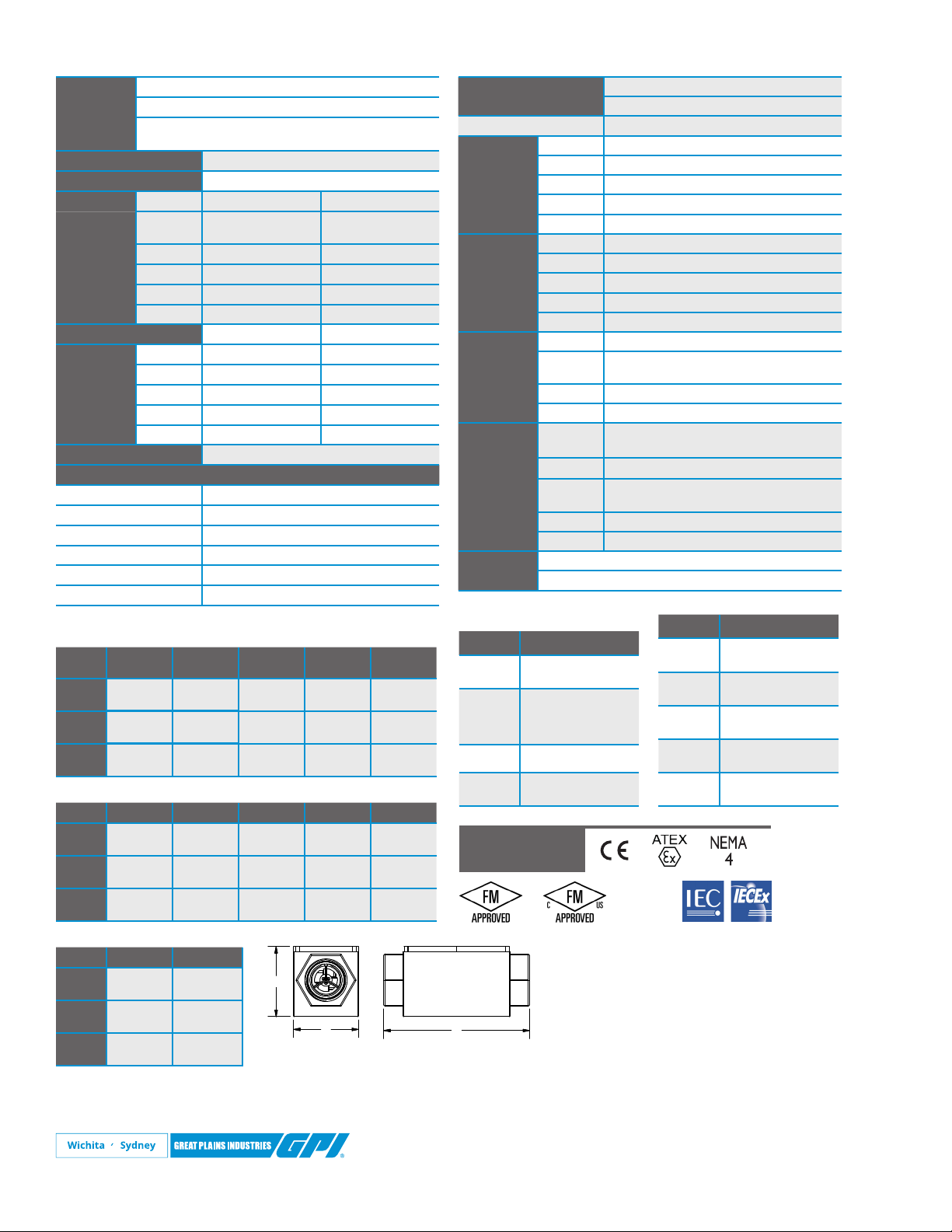

DIMENSIONS

S05 & H05

½ in.

A =

Height

B =

Width

C =

Length

A =

Height

B =

Width

C =

Length

A =

Height

B =

Width

C =

Length

ANSI Flange and Sanitary Flange dimensions not shown. For those dimensions, please refer

to product manuals or our website FLOMECmeters.com.

1.4 in.

(35.6 mm)

2.0 in.

(50.8 mm)

4.2 in.

(106.7 mm)

Aluminum Models

A05, ½ in. A07, ¾ in. A10, 1 in. A15, 1½ in. A20, 2 in.

1.8 in.

(45.7 mm)

2.0 in.

(50.8 mm)

4.2 in.

(106.7 mm)

PVDF Models

P05, ½ in. P10, 1 in.

3.2 in.

(81.3 mm)

2.1 in.

(53.3 mm)

7.3 in.

(185.4 mm)

1.2 - 12 GPM (4.5 - 45 L/min)

10 - 100 GPM (38 - 380 L/min)

± 1.0% ± 0.75%

NOTE: Q9 Display adds 0.72 in. (18 mm) to height

Stainless Steel (SS) and SS High Pressure Models

S07 & H07

¾ in.

1.6 in.

(40.6 mm)

2.0 in.

(50.8 mm)

4.3 in.

(109.2 mm)

2.0 in.

(50.8 mm)

2.0 in.

(50.8 mm)

4.3 in.

(109.2 mm)

3.3 in.

(83.8 mm)

2.8 in.

(71.1 mm)

8.1 in.

(205.7 mm)

S10 & H10

1 in.

1.9 in.

(48.3 mm)

2.0 in.

(50.8 mm)

4.5 in.

(114.3 mm)

2.2 in.

(55.9 mm)

2.0 in.

(50.8 mm)

4.5 in.

(114.3 mm)

NOTE: For representation purpose only. Actual

product models vary in shape, design, etc.

A

S15 & H15

1½ in.

2.6 in.

(66.0 mm)

2.7 in.

(68.6 mm)

5.3 in.

(134.6 mm)

2.8 in.

(71.1 mm)

2.7 in.

(68.6 mm)

5.3 in.

(134.6 mm)

B

S20 & H20

2 in.

3.1 in.

(78.7 mm)

3.4 in.

(86.4 mm)

6.3 in.

(160.0 mm)

3.2 in.

(81.3 mm)

3.3 in.

(83.8 mm)

6.3 in.

(160.0 mm)

Operating Temperature

Range:

with Display: 14° F to 140° F (-10° C to 60° C)

Typical

K-Factor:

Wetted

Materials:

Wetted

Materials

PVDF:

Frequency

Range:

Calibration

Report:

ACCESSORIES

Part No. Description

113435-10

125060-10

125100-10

120077-01

APPROVALS

C

-40° F to 250° F (-40° C to 121° C)

(PVDF) -20° F to 180° F (-28° C to 82° C)

1/2" (05) 2,500 PPG (660 Pulses/L)

3/4" (07) 1,100 PPG (291 Pulses/L)

1" (10) 565 PPG (149 Pulses/L)

1-1/2" (15) 215 PPG (57 Pulses/L)

2" (20) 100 PPG (26 Pulses/L)

Housing: 316 Stainless Steel or Aluminum

Bearings: 96% Alumina Oxide Ceramic

Shaft: Tungsten Carbide

Rotor: PVDF

Rings: 316 Stainless Steel

Housing: PVDF (15% Carbon Fiber Filled)

Bearings

& Shaft:

Rotor: PVDF

Rings: Fluorocarbon (Optional PTFE)

1/2" (05) 42-420 Hz @ 1-10 GPM (3.8-38 L/min) / 48-

3/4" (07) 37-370 Hz @ 2-20 GPM (7.6-76 L/min)

1" (10) 47-470 Hz @ 5-50 GPM (19-190 L/min) / 45-

1-1/2" (15) 36-360 Hz @ 10-100 GPM (38-380 L/min)

2" (20) 33-330 Hz @ 20-200 GPM (76-760 L/min)

Comes standard with G2 Series meters.

N.I.S.T. – Certication available.

96% Alumina Ceramic

480 Hz @ 1.2-12 GPM (4.5-45 L/min) (PVDF)

450 Hz @ 5-50 GPM (19-190 L/min) (PVDF)

Part No. Description

ATEX Approved

Sensor

90° Display

Adaptor Kit

FM Approved

Remote Kit

½ in. Teon

O-Rings (2)

1 in. Teon

O-Rings (2)

Conditioned Signal

Module

Pulse Out, Extended

Power, Scaled Pulse

Module

4-20 mA Module

FM Approved

Sensor

120077-02

125260-02

1132 75-10

125260-2

125260-1

IP65

Service & Warranty: For technical assistance, warranty replacement or repair contact your

FLOMEC® or GPI® distributor: In North or South America: 888-996-3837 / FLOMECmeters.com

Outside North or South America: +61 2 9540 4433 / FLOMECmeters.com

IND-1043-G2 09/2020

Loading...

Loading...