Page 1

Page 1

FL_F116P_v1702_01_EN

Signal input flowmeter: pulse, Namur and coil

Output: (0)4-20mA / 0-10V ref. flow rate, pulse ref. total and negative

flow

Options: Intrinsically safe, Modbus communication and backlight

F-Series - Field mounted indicators for safe and hazardous areas.

Page 2

Page 2

FL_F116P_v1702_01_EN

Page 3

Page 3

FL_F116P_v1702_01_EN

SAFETY INSTRUCTIONS

Any responsibility is lapsed if the instructions and procedures as described in this manual

are not followed.

LIFE SUPPORT APPLICATIONS: The F116-P is not designed for use in life support

appliances, devices, or systems where malfunction of the product can reasonably be

expected to result in a personal injury. Customers using or selling these products for use

in such applications do so at their own risk and agree to fully indemnify the manufacturer

and supplier for any damages resulting from such improper use or sale.

Electro static discharge does inflict irreparable damage to electronics! Before installing or

opening the F116-P, the installer has to discharge himself by touching a well-grounded

object.

The F116-P must be installed in accordance with the EMC guidelines (Electro Magnetic

Compatibility).

Do connect a proper grounding to the metal enclosure as indicated if the F116-P has an

incoming power line which carries a 115-230V AC. The Protective Earth (PE) wire may

never be disconnected or removed.

Intrinsically safe applications: follow the instructions as mentioned in Chapter 0 and

consult “Fluidwell F1..-..-XI - Documentation for Intrinsic safety”

DISPOSAL OF ELECTRONIC WASTE

The WEEE Directive requires the recycling of disposed electrical and electronic

equipment in the European Union. When the WEEE Directive does not apply to your

region, we support its policy and ask you to be aware on how to dispose of this product.

The crossed out wheelie bin symbol as illustrated and found on our products tells that this

product shall not be disposed of into the general waste system or into a landfill.

At the end of its life, equipment shall be disposed of according to the local regulations

regarding waste of the electrical and the electronic equipment.

Please contact your local dealer, national distributor or the manufacturer’s Technical

helpdesk for information on the product disposal.

SAFETY RULES AND PRECAUTIONARY MEASURES

The manufacturer accepts no responsibility whatsoever if the following safety rules and

precautions instructions and the procedures as described in this manual are not followed.

Modifications of the F116-P implemented without preceding written consent from the

manufacturer, will result in the immediate termination of product liability and warranty

period.

Mounting, electrical installation, start-up and maintenance of this device may only be

carried out by trained persons authorized by the operator of the facility. Persons must

read and understand this manual before carrying out its instructions.

This device may only be operated by persons who are authorized and trained by the

operator of the facility. All instructions in this manual are to be observed.

Check the mains voltage and information on the manufacturer's plate before installing the

unit.

Check all connections, settings and technical specifications of the various peripheral

devices with the F116-P supplied.

Open the enclosure only if all leads are free of potential.

Never touch the electronic components (ESD sensitivity).

Never expose the system to heavier conditions than allowed according the classification

of the enclosure (see manufacture's plate and chapter 4).

If the operator detects errors or dangers, or disagrees with the safety precautions taken,

then inform the owner or principal responsible.

The local labor and safety laws and regulations must be adhered to.

Page 4

Page 4

FL_F116P_v1702_01_EN

ABOUT THE MANUAL

This manual is divided into two main sections:

The daily use of the F116-P is described in chapter 2 “Operational”. These instructions are

meant for users.

The following chapters and appendices are exclusively meant for electricians/technicians. These

provide a detailed description of all software settings and hardware installation guidance.

This manual describes the standard unit as well as the available options. For additional information,

please contact your supplier.

A hazardous situation may occur if the F116-P is not used for the purpose it was designed for

or is used incorrectly. Please carefully note the information in this manual indicated by the

pictograms:

A "warning !" indicates actions or procedures which, if not performed correctly, may lead to

personal injury, a safety hazard or damage of the F116-P or connected instruments.

A "caution !" indicates actions or procedures which, if not performed correctly, may lead to

personal injury or incorrect functioning of the F116-P or connected instruments.

A "note !" indicates actions or procedures which, if not performed correctly, may indirectly

affect operation or may lead to an instrument response which is not planned.

Hardware version : 03.01.xx

Software version : 03.01.xx

Manual : FL_F116-P_v1702_01_EN

© Copyright 2017 : Fluidwell B.V. - The Netherlands.

Information in this manual is subject to change without prior notice. The

manufacturer is not responsible for mistakes in this material or for incidental

damage caused as a direct or indirect result of the delivery, performance or use of

this material.

© All rights reserved. No parts of this publication may be reproduced or used in

any form or by any means without written permission of your supplier.

Page 5

Page 5

FL_F116P_v1702_01_EN

CONTENTS MANUAL

SAFETY INSTRUCTIONS .................................................................................................................... 3

DISPOSAL OF ELECTRONIC WASTE ............................................................................................... 3

SAFETY RULES AND PRECAUTIONARY MEASURES .................................................................... 3

ABOUT THE MANUAL ......................................................................................................................... 4

CONTENTS MANUAL .......................................................................................................................... 5

1 INTRODUCTION ...................................................................................................................... 6

1.1 System description ...................................................................................................................6

2 OPERATIONAL ....................................................................................................................... 7

2.1 Control panel ............................................................................................................................7

2.2 Operator information and functions ..........................................................................................8

3 CONFIGURATION ................................................................................................................... 9

3.1 How to program the F116-P .....................................................................................................9

3.1.1 Setup menu – Settings .......................................................................................................... 11

3.1.2 Explanation of SETUP-menu 1 - Total-A............................................................................... 12

3.1.3 Explanation of SETUP-menu 2 - Flow rate-A ........................................................................ 13

3.1.4 Explanation of SETUP-menu 3 - Total-B............................................................................... 14

3.1.5 Explanation of SETUP-menu 4 - Flow rate-B ........................................................................ 14

3.1.6 Explanation of SETUP-menu 5 - Display .............................................................................. 14

3.1.7 Explanation of SETUP-menu 6 - Power management .......................................................... 15

3.1.8 Explanation of SETUP-menu 7 - Flowmeter ......................................................................... 16

3.1.9 Explanation of SETUP-menu 8 - Analog output .................................................................... 16

3.1.10 Explanation of SETUP-menu 9 - Pulse ................................................................................. 18

3.1.11 Explanation of SETUP-menu A - Communication (option) ................................................... 18

3.1.12 Explanation of SETUP-menu B - Others ............................................................................... 18

4 INSTALLATION ..................................................................................................................... 19

4.1 General directions ................................................................................................................. 19

4.2 Installation / surrounding conditions ...................................................................................... 19

4.3 Dimensions- Enclosure.......................................................................................................... 20

4.4 Installing the hardware .......................................................................................................... 22

4.4.1. General installation guidelines .............................................................................................. 22

4.4.2. Aluminum enclosure - Field mounted .................................................................................... 23

4.4.3. Aluminum enclosure - Panel mounted .................................................................................. 23

4.4.4. Plastic (GRP) enclosure ........................................................................................................ 24

4.4.5. Terminal connectors .............................................................................................................. 25

5 INTRINSICALLY SAFE APPLICATIONS.............................................................................. 32

5.1 General information and safety instructions .......................................................................... 32

5.2 Terminal connectors Intrinsically safe applications ............................................................... 34

5.3 Configuration examples Intrinsically safe applications .......................................................... 36

6 MAINTENANCE ..................................................................................................................... 38

6.1 General directions ................................................................................................................. 38

6.2 Instructions for repair ............................................................................................................. 38

6.3 Battery replacement .............................................................................................................. 39

6.3.1 Safety instructions ................................................................................................................. 39

6.3.2 Replace the battery (hazardous area) ................................................................................... 39

6.3.3 Disposal of batteries .............................................................................................................. 39

TECHNICAL SPECIFICATION ................................................................................. 40

PROBLEM SOLVING ............................................................................................... 43

COMMUNICATION ................................................................................................... 44

DECLARATION OF CONFORMITY ......................................................................... 48

INDEX OF THIS MANUAL.................................................................................................................. 49

LIST OF FIGURES IN THIS MANUAL ............................................................................................... 49

Page 6

Page 6

FL_F116P_v1702_01_EN

1 INTRODUCTION

1.1 SYSTEM DESCRIPTION

Functions and features

The flow rate / totalizer model F116-P is a microprocessor driven instrument designed to show the

flow rate, the total and the accumulated total as well as for the calculation of differential flow

measurement and to sum two separate flows. This product has been designed with a focus on:

two multi-purpose pulse inputs;

ultra-low power consumption to allow long-life battery powered applications (type PB/PC),

Intrinsic safety for use in hazardous applications (type XI);

several mounting possibilities with aluminum or GRP enclosures for harsh industrial

surroundings;

ability to process all types of flowmeter signals;

transmitting possibilities with analog / pulse and communication outputs.

Flowmeter and temperature input

This manual describes the unit with a pulse input from the flowmeter. Other versions are available to

process (0)4-20mA signals. Two flowmeters with a passive or active pulse, Namur or sine wave

(coil) signal output can be connected to the F116-P. To power the sensor, several options are

available.

Standard output

Pulse output to transmit a pulse that represents a totalized quantity as programmed.

Linear (0)4-20mA or 0-10V analog output to represent the actual calculated differential flow rate

as programmed. The (0)4-20mA or 0-10V signal limits can be tuned.

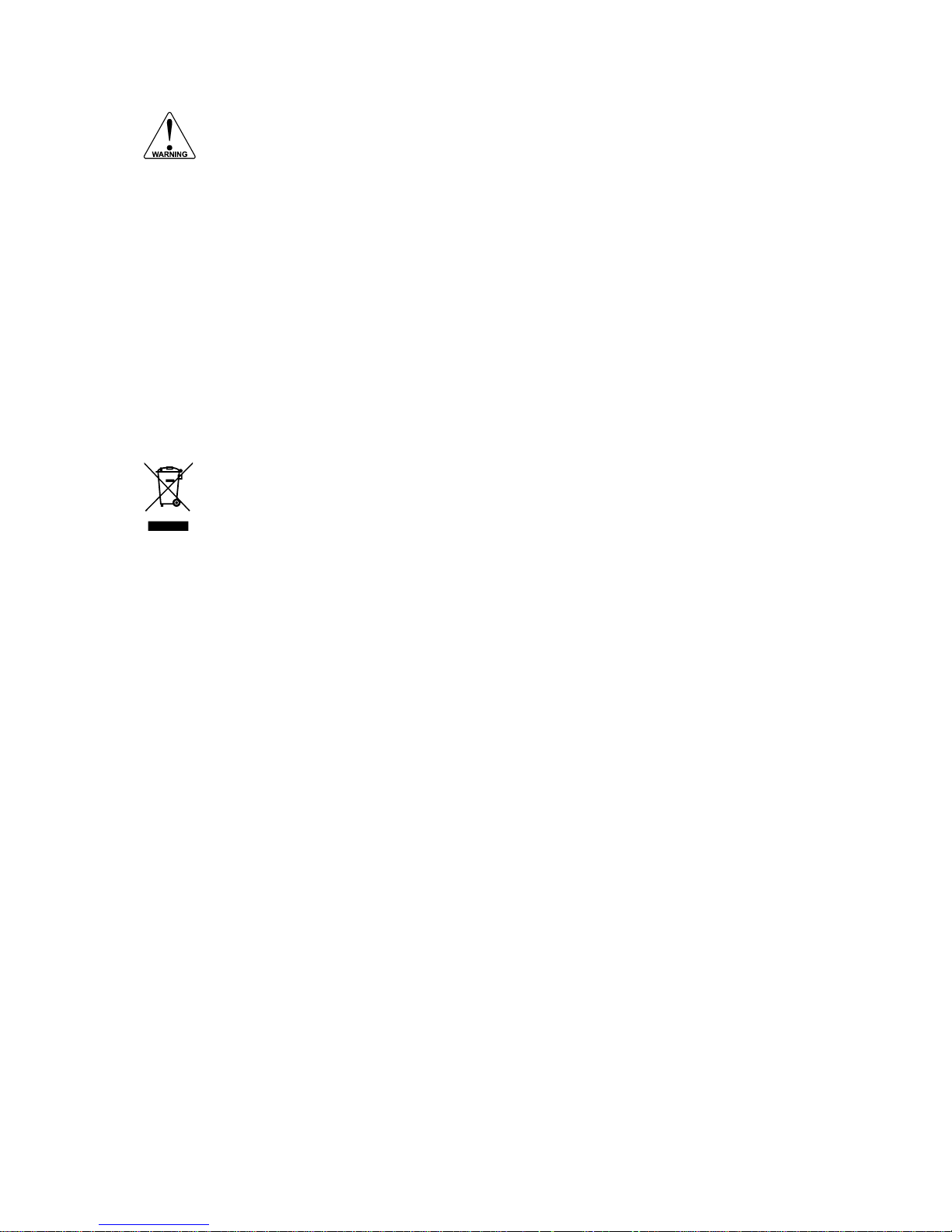

Fig. 1: Typical application

Page 7

Page 7

FL_F116P_v1702_01_EN

Configuration

The F116-P is designed for use in many types of applications. For that reason, a setup menu is

available to program the F116-P according to your specific requirements.

The setup includes several important features, such as K-Factors, engineering units, signal

selection, power management (to extend battery life-time), etc. All settings are stored in a nonvolatile memory and therefore kept in the event of a power failure or an exhausted battery.

Display information

The unit has a LCD with (optional) backlight to show the process information, status and alarm

messages. The display refresh rate is programmed in the setup menu.

At a key press, the display refresh rate will switch to FAST for 30 seconds. When 'OFF' is selected,

the display goes off after 30 seconds after the last key press. The display temporarily comes on after

a key press.

A backup of the total and accumulated total in EEPROM memory is made every minute.

Backlight

A backlight is available as an option. The brightness can be tuned as desired (requires power supply

type PD/PF/PM). For battery and loop powered applications the backlight will not function.

Options

The following options are available: isolated or active (0)4-20mA / 0-10V analog output, full Modbus

communication RS232/485/TTL (also battery powered), Intrinsic safety, mechanical relay or active

output, power- and sensor-supply options, panel-mount, wall-mount and weather-proof enclosures,

flame proof enclosure and LED backlight.

2 OPERATIONAL

This device may only be operated by persons who are authorized and trained by the

operator of the facility. All instructions in this manual are to be observed.

Take careful notice of the "Safety rules, instructions and precautionary measures" in the

front of this manual.

This chapter describes the daily use of the F116-P. This instruction is meant for users / operators.

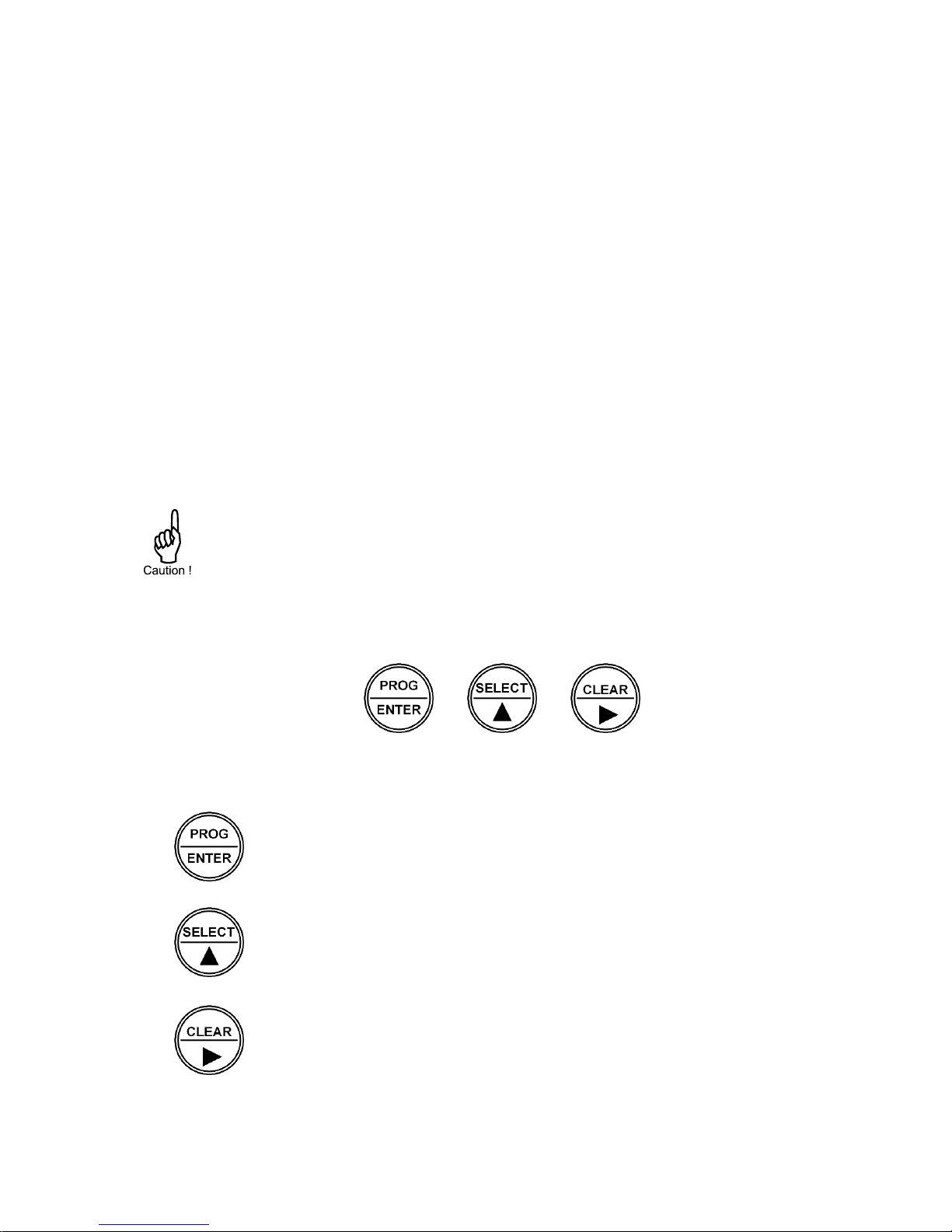

2.1 CONTROL PANEL

The control panel has three keys. The available keys are:

Fig. 2: Control panel

Functions of the keys

This key is used to program and save new values or settings.

The PROG/ENTER key is also used to gain access to the setup menu (read

chapter 3).

This key is used to select the differential or sum accumulated total, flow rate A and B

and accumulated total A and B

The SELECT/ key is also used to increase a value after the PROG/ENTER key has

been pressed (read chapter 3)..

This key is used to reset the total.

The CLEAR/ key is also used to select a digit or an option after the PROG/ENTER

key has been pressed (read chapter 3).

Page 8

Page 8

FL_F116P_v1702_01_EN

2.2 OPERATOR INFORMATION AND FUNCTIONS

In general, the F116-P operates in the operator

mode. The shown information depends on the

settings which are made in the setup menu.

The signal from the connected sensor is processed

by the F116-P in the background, independent from

the selected display refresh rate.

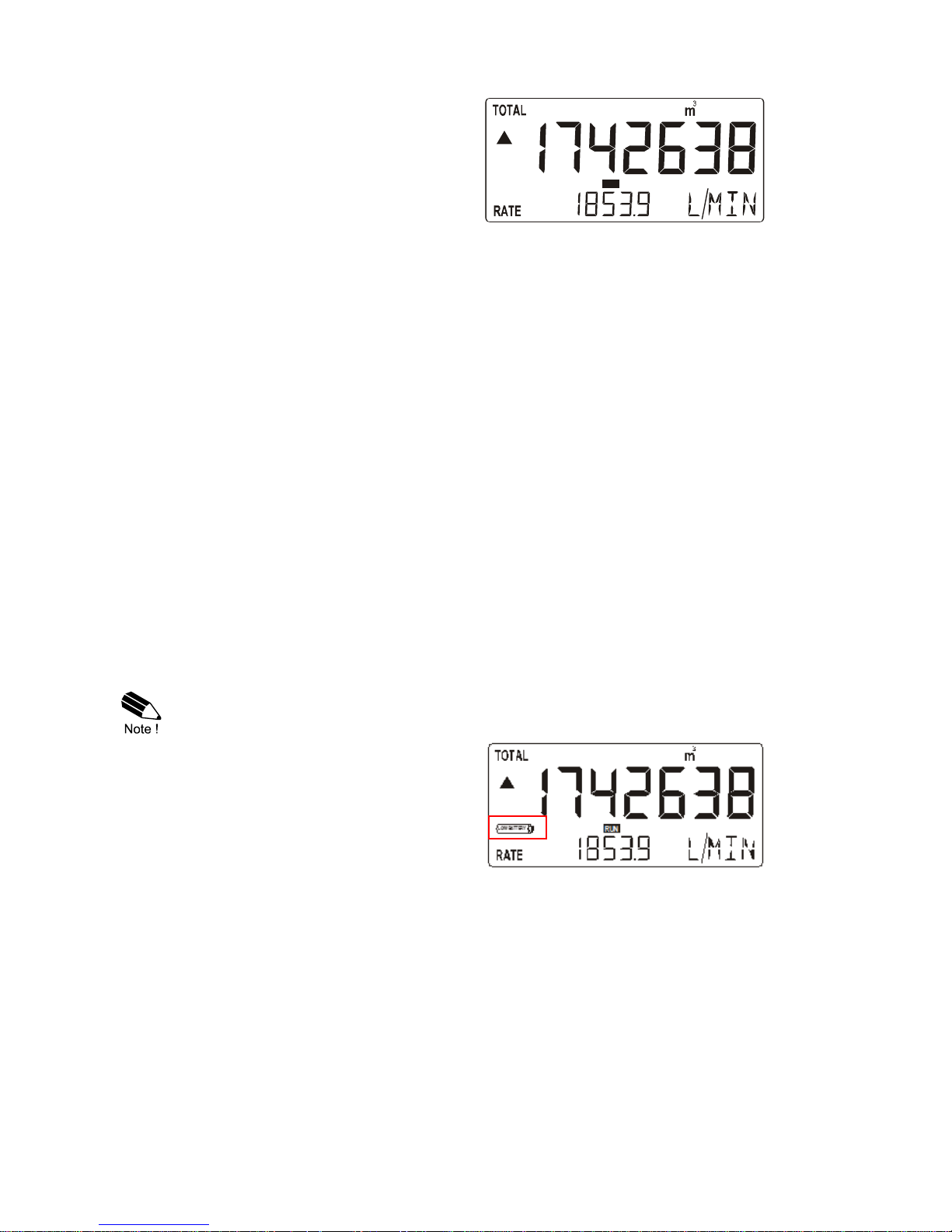

Fig. 3: Process information (typical)

For the Operator, the following functions are available:

Display (differential or summed) total/rate

Total/rate is the main display of the F116-P. After the selection of any other information, it will

always return to this main display automatically. Total is shown on the upper line of the display

and flow rate on the bottom line. When selected in the setup menu, the display shows the flow

rate only or all. When the SELECT/ key is pressed, the other information shows momentarily.

When "-------" is shown, then the flow rate value is too high to be shown. The arrows indicate

the increase/decrease of the flow rate trend. If the consumption is very low, it might be that a

stable low flow rate and total is shown; this is due to the settings of the F116-P.

Clear total

The value for total can be reset. To do so, press the CLEAR/ key twice. When the key is

pressed once, the text "PUSH CLEAR" is shown. To avoid a reset at this stage, press another

key other than the CLEAR/ key or wait for 20 seconds. A reset of the total does not influence

the accumulated total.

Display accumulated total

When the SELECT/ key is pressed, total and accumulated total are shown. The accumulated

total cannot be reset. The value will count up to 99,999,999,999. The unit and number of

decimals are shown according to the settings for the total.

Display Flow rate-A, Flow rate-B, (accumulated) total-A, (accumulated) total-B

The setting All shows the (differential or summed) flow rate. When the SELECT/ key is pressed

again, the total/accumulated total, the flow rate A, the accumulated total A, the flow rate B and

the accumulated total B are shown temporarily.

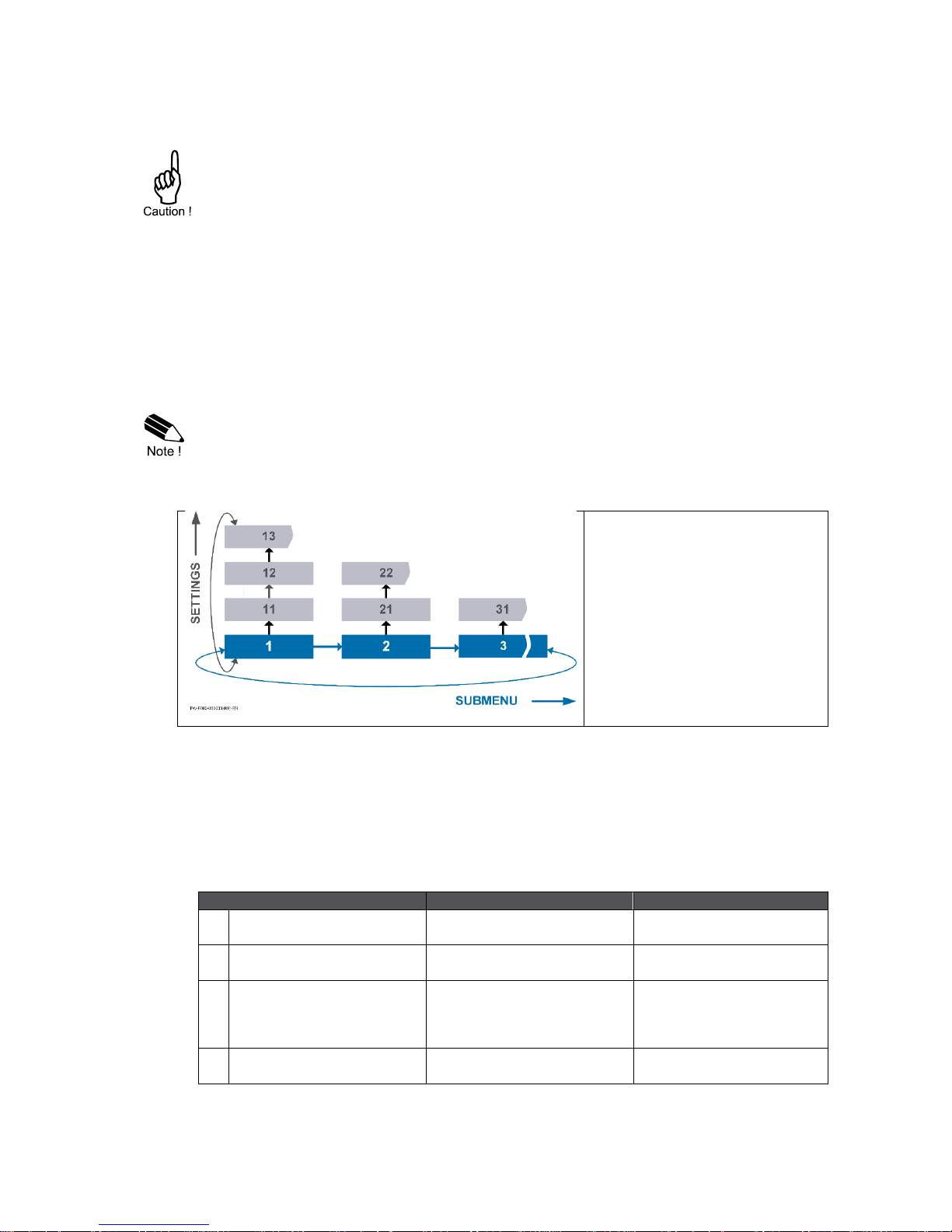

Low-battery alarm

Only use original batteries. Original batteries can be ordered at the manufacturer.

The use of unapproved batteries will void the warranty.

At the end of the battery’s life-time, the

voltage starts to drop. When the voltage

becomes too low, the battery indicator comes

on. When the battery indicator is on, install a

new and fresh battery as soon as possible.

Fig. 4: Low-battery alarm (typical)

Alarm

When the alarm indicator is shown, refer to Appendix B: Problem Solving.

RUN

Page 9

Page 9

FL_F116P_v1702_01_EN

3 CONFIGURATION

This and the following chapters are exclusively meant for electricians and non-operators. In these,

an extensive description of all software settings and hardware connections are provided.

Mounting, electrical installation, start-up and maintenance of this device may only be

carried out by trained persons authorized by the operator of the facility. Persons must

read and understand this manual before carrying out its instructions.

This device may only be operated by persons who are authorized and trained by the

operator of the facility. All instructions in this manual are to be observed.

Make sure, the measuring system is correctly wired up according to the wiring diagrams.

Protection against accidental contact is no longer assured when the housing cover is

removed or the panel cabinet has been opened (danger from electrical shock). The

housing may only be opened by trained persons authorized by the operator of the facility.

Take careful notice of the "Safety rules, instructions and precautionary measures" in the

front of this manual.

The SETUP menu is used to program the F116-P

The SETUP menu is accessible at all times while the F116-P remains fully operational. Be aware

that in this case any change to the settings may have an influence on the operation.

It is possible to prevent access to the SETUP menu with a password. A password may be

required to enter the SETUP menu. Without this password, access to SETUP is denied.

3.1 HOW TO PROGRAM THE F116-P

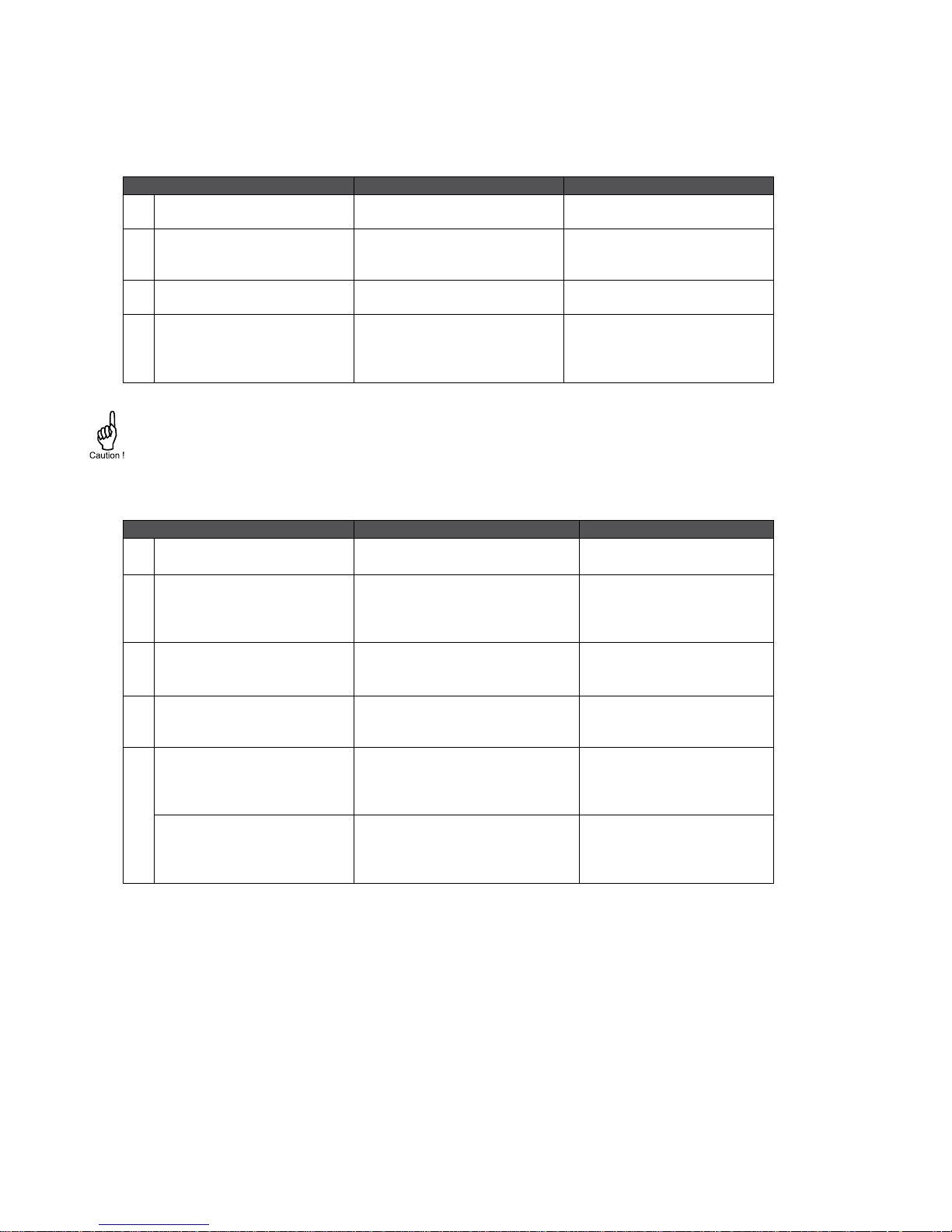

The setup menu has different

submenus. Each submenu has an

unique number which is shown in

front of the menu name.

Each setting has an unique twodigit number which is shown in

front of the setting. The first digit

refers to the submenu and the

second digit refers to the setting.

Note that sometimes the name of

the setting is shown on the upper

line of the display.

How to enter the setup menu

When the setup menu is protected by a password, the F116-P asks for a password to access the

setup menu. When in the operator mode, press and hold the PROG/ENTER key for 7 seconds to

access the setup menu.

How to navigate in the setup menu

The setup menu has different submenus to program the F116-P. For navigation, the submenus

and the settings are identified with numbers (for the submenu: e.g. 1; for the setting: e.g. 12.).

The CLEAR/► key and the PROG/ENTER key are used for navigation. The explanation

assumes that you are in the submenu TOTAL.

Action

Result

Remark

1

Press the CLEAR/► key to

select the next submenu.

The submenu FLOW

RATE shows

-

2

Press again to go to the

next submenu.

The submenu DISPLAY

shows.

-

3

Momentarily, press the

PROG/ENTER key to

select the previous

submenu.

The submenu FLOW

RATE shows

The PROG/ENTER key is

used as a ◄ key.

4

Press again to go to the

previous submenu.

The submenu TOTAL

shows

The PROG/ENTER key is

used as a ◄ key.

Page 10

Page 10

FL_F116P_v1702_01_EN

The SELECT/▲ key and the CLEAR/► key are used for navigation.

The explanation assumes that you are in the submenu TOTAL. When you are:

in the first setting and you navigate to the previous setting, the F116-P goes back to the related

main menu.

in the last setting and you navigate to the next setting, the F116-P goes to the related main

menu.

Action

Result

Remark

1

Press the SELECT/▲ key

to select the first setting.

The setting UNIT shows.

-

2

Press the SELECT/▲ key

again to go to the next

setting.

The setting DECIMALS

shows.

3

Press the CLEAR/► key to

select the previous setting.

The setting UNIT shows.

-

4

Press the CLEAR/►key

again to go to the previous

setting.

The submenu TOTAL

shows

This is normal behavior

because the setting UNIT is

the first setting of the

submenu TOTAL.

How to make a setting

Changes are only saved when you press the PROG/ENTER key.

The explanation assumes that you are in the submenu TOTAL and the setting UNIT. When you do

not want to save the change, wait for approximately 20 seconds or press and hold the

PROG/ENTER key for approximately 3 seconds.

Action

Result

Remark

1

Momentarily, press the

PROG/ENTER key.

The PROG indicator blinks.

The engineering unit L shows.

To access the setting.

2

Press the SELECT/▲ key to

select the next engineering

unit.

The PROG indicator blinks.

The engineering unit m3 shows.

If you wait too long, the

program mode goes off and

changes are not saved, this

is normal behavior.

3

Press the SELECT/▲ key to

select the next engineering

unit.

The PROG indicator blinks.

The engineering unit US GAL

shows.

-

4

Press the CLEAR/► key to

select the previous

engineering unit

The PROG indicator blinks.

The engineering unit m3 shows.

-

5

To confirm the changes:

Momentarily, press the

PROG/ENTER key.

The PROG indicator goes off.

The change is saved.

The engineering unit m3 shows.

If you do not press the

PROG/ENTER key to

confirm, your selection is not

saved.

To discard the changes:

Press and hold the

PROG/ENTER key for

approximately 3 seconds.

The PROG indicator goes off.

The change is discarded.

The engineering unit L shows.

-

Page 11

Page 11

FL_F116P_v1702_01_EN

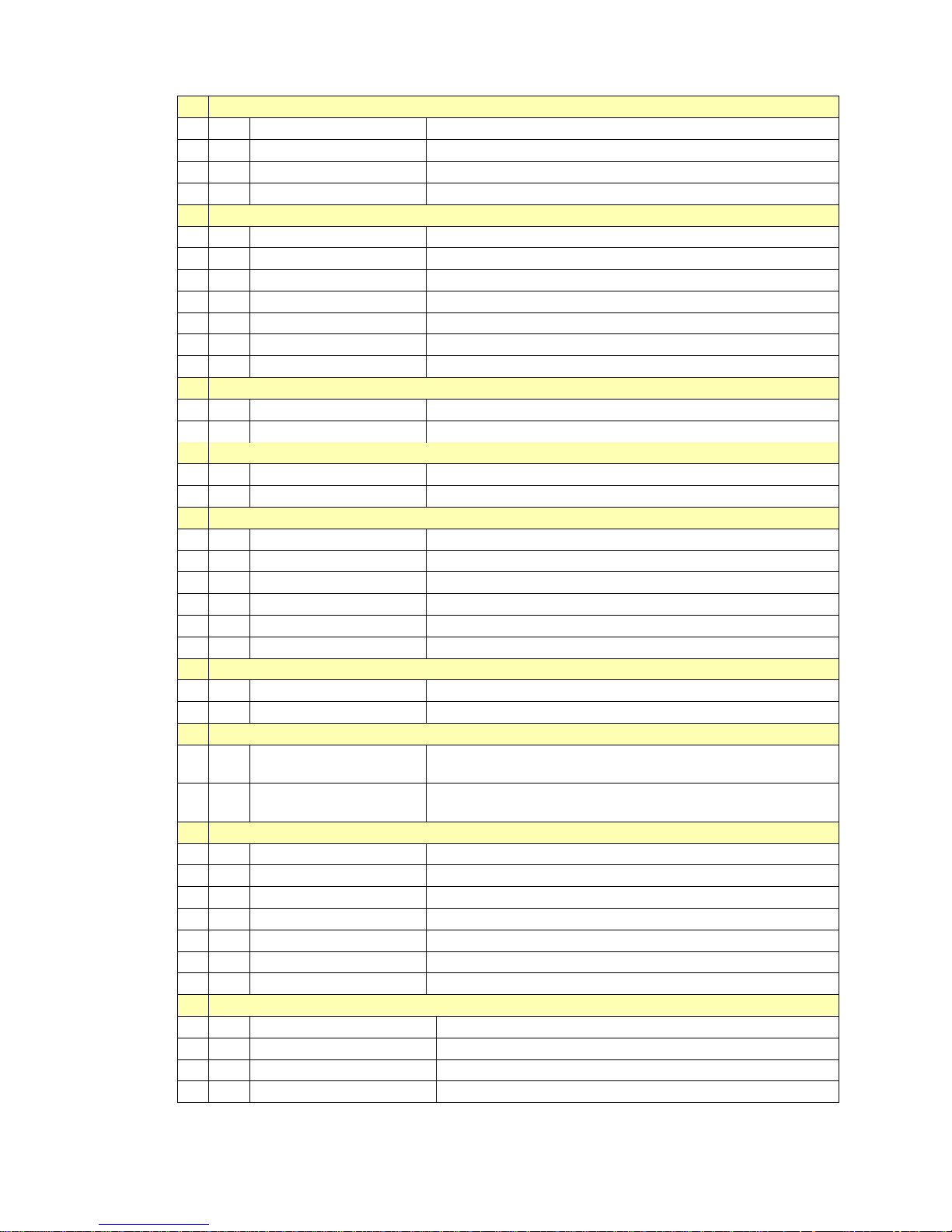

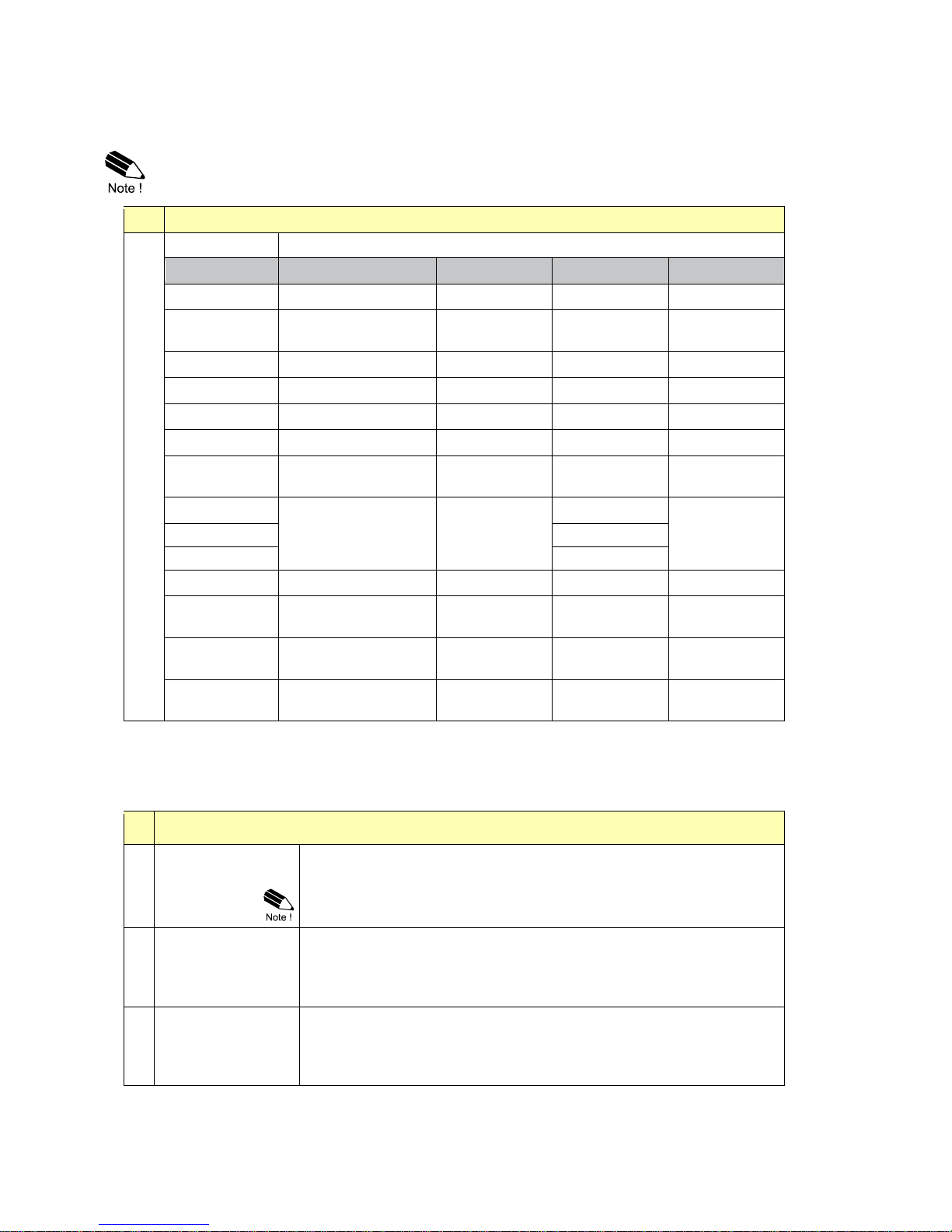

3.1.1 SETUP MENU – SETTINGS

1

TOTAL-A

11

unit

L; m3; kg; lb; GAL; USGAL; bbl; no unit

12

decimals

0000000; 111111.1; 22222.22; 3333.333

13

K-factor

0.000010 - 9999999

14

decimals K-factor

0 - 6

2

FLOW RATE-A

21

unit

mL; L; m3; mg; g; kg; ton; gal; bbl; lb; cf; rev; - - - - (no unit); scf; nm3; nL; p

22

time

/sec; /min; /hour; /day

23

decimals

0000000; 111111.1; 22222.22; 3333.333

24

K-factor

0.000010 - 9999999

25

decimals K-factor

0 - 6 26

filter

0 - 99

27

period

0.1 - 99.9 seconds

3

TOTAL-B

31

K-factor:

0.000010 - 9999999

32

decimals K-factor

0 - 6

4

FLOW RATE-B

41

K-factor

0.000010 - 9999999

42

decimals K-factor

0 - 6

5

DISPLAY

51

function

total; rate; all

52

light

0% (off); 20%; 40%; 60%;- 80%; 100% (full brightness)

53

calculate

add; differ

54

measurement

bi-direct; not negative; threshold; stationary

55

stationary flow rate

0000.000 - 9999999

56

stationary total

0000.000 - 9999.999

6

POWER MANAGEMENT

61

LCD new

fast; 1 sec; 3 sec; 15 sec; 30 sec; off

62

battery mode

operational; shelf

7

FLOWMETER

71

signal A

npn; npn-lp; reed; reed-lp; pnp; pnp-lp; namur; coil-hi; coil-lo; 8-1 DC;

12 DC; 24 DC

72

signal B

npn; npn-lp; reed; reed-lp; pnp; pnp-lp; namur; coil-hi; coil-lo; 8-1 DC;

12 DC; 24 DC

8

ANALOG

81

output

disable; enable

82

rate-min

000.000 - 999999

83

rate-max

000.000 - 999999

84

cut-off

0.0 - 9.9%

85

tune-min

0 - 9999

86

tune-max

0 - 9999

87

filter

01 - 99

9

PULSE

91

mode

signed; not negative; separated

92

width

0.001 – 9

93

decimals

0000000; 111111.1; 22222.22; 3333.333

94

amount

0.001 – 9999999

Page 12

Page 12

FL_F116P_v1702_01_EN

A

COMMUNICATION

C1

speed

1200; 2400; 4800; 9600

C2

address

1 - 247

C3

mode

bus-rtu; bus-asc; off

D

OTHERS

D1

model

F116-P

D2

software version

nn:nn:nn

D3

serial no.

nnnnnnn

D4

password

0000 - 9999

D5

tag-nr

0000000 - 9999999

3.1.2 EXPLANATION OF SETUP-MENU 1 - TOTAL-A

1

TOTAL-A

11

unit

This setting is used to select the engineering unit for the indication of the total (A

and B), the accumulated total (A and B), and the pulse output.

When you change the engineering unit, you must recalculate and

reprogram the K-factor for the (accumulated) total. When you

recalculate and reprogram the K-Factor, the history for

(accumulated) total is not correct anymore, because the

(accumulated) total is not recalculated. For future reference, best

practice is to make a note of the accumulated total before you

program the recalculated K-Factor.

12

decimals

This setting is used to set the amount of digits behind the decimal point for the

(accumulated) total indication (A and B).

13

K-factor

This setting is used to set the K-Factor for the total (A). With the K-Factor, the

flowmeter pulse signals are converted to a quantity. The K-Factor is based on the

number of pulses generated by the flowmeter per selected engineering unit, for

example per m3. A more accurate K-Factor (more decimals, as set in decimals

K-Factor) allows for a more accurate operation of the system.

Example 1: Calculating the K-Factor.

The flowmeter generates 2.4813 pulses per liter and the selected unit is m3. A

cubic meter consists of 1000 liter which gives 2.4813 pulses*1000 liter=2481.3

pulses per m3. So, the K-Factor is 2481.3. Enter for the Flowmeter K-Factor:

24813 and for the flowmeter K-Factor decimals: 1.

Example 2: Calculating the K-Factor.

The flowmeter generates 6.5231 pulses per gallon and the selected engineering

unit is gallons. So, the K-Factor is 6.5231. Enter for the Flowmeter K-Factor:

65231 and for the Flowmeter K-Factor decimals: 4.

When you recalculate and reprogram a new K-Factor, the history for

(accumulated) total is not correct anymore, because the

(accumulated) total is not recalculated. For future reference, best

practice is to make a note of the accumulated total before you

program the recalculated K-Factor.

14

decimals K-factor

This setting is used to set the amount of digits behind the decimal point for the

K-Factor (A).

Page 13

Page 13

FL_F116P_v1702_01_EN

3.1.3 EXPLANATION OF SETUP-MENU 2 - FLOW RATE-A

The settings for total and flow rate are entirely separate. In this way, different engineering units can

be used for each e.g. cubic meters for total and liters for flow rate.

2

FLOW RATE-A

21

unit

This setting is used to select the engineering unit for the indication of the flow

rate (A and B).

Alteration of the engineering unit will have consequences for

operator and setup values, they will not be automatically

recalculated to the value of the new selected unit. The K-Factor has

to be adapted as well; the calculation is not done automatically.

22

time

This setting is used to set the time unit for the flow rate calculation (A and B).

Note that the flow rate is given in engineering unit/time unit, e.g. liters/minute

(l/min).

When you change this setting, also recalculate and change the settings

for the analog rate-min and analog rate-max.

23

decimals

This setting is used to set the amount of digits behind the decimal point for the

flow rate indication (A and B).

24

K-factor

This setting is used to set the K-Factor for the flow rate (A). With the K-Factor,

the flowmeter pulse signals are converted to a quantity. The K-Factor is based on

the number of pulses generated by the flowmeter per selected engineering unit,

for example per m3. A more accurate K-Factor (more decimals, as set in

decimals K-Factor) allows for a more accurate operation of the system.

25

decimals K-factor

This setting is used to set the amount of digits behind the decimal point for the

K-Factor (A).

26

filter

This setting is used to stabilize the output signal. With the help of this digital filter

a more stable but less actual representation of the flow rate can be obtained.

The filter principal is based on three input values: the filter level (01-99), the last

calculated flow rate and the last average value. The higher the filter level, the

longer the response time on a value change will be.

27

period

This setting is used to calculate the flow rate by counting the number of pulses

within a certain time, for example 1 second. The longer the time the more

accurate the flow rate will be.

This setting does influence the update time for the analog output directly. If the

output response is too slow, decrease the number of pulses.

The shorter the update time, the higher the power consumption of the unit will

be (important for battery powered applications).

Page 14

Page 14

FL_F116P_v1702_01_EN

3.1.4 EXPLANATION OF SETUP-MENU 3 - TOTAL-B

The engineering units are the same as used in SETUP-menu 1 - Total-A.

3

TOTAL-B

31

K-factor

This setting is used to set the K-Factor for the total (B). With the K-Factor, the

flowmeter pulse signals are converted to a quantity. The K-Factor is based on the

number of pulses generated by the flowmeter per selected engineering unit, for

example per m3. A more accurate K-Factor (more decimals, as set in decimals

K-Factor) allows for a more accurate operation of the system.

32

decimals K-factor

This setting is used to set the amount of digits behind the decimal point for the

(accumulated) total indication (B).

3.1.5 EXPLANATION OF SETUP-MENU 4 - FLOW RATE-B

The engineering units are the same as used in SETUP-menu 2 - Flow rate-A.

4

FLOW RATE-B

41

K-factor

This setting is used to set the K-Factor for the flow rate (B). With the K-Factor, the

flowmeter pulse signals are converted to a quantity. The K-Factor is based on the

number of pulses generated by the flowmeter per selected engineering unit, for

example per m3. A more accurate K-Factor (more decimals, as set in decimals

K-Factor) allows for a more accurate operation of the system.

42

decimals K-factor

This setting is used to set the amount of digits behind the decimal point for the

K-Factor (B).

3.1.6 EXPLANATION OF SETUP-MENU 5 - DISPLAY

5

DISPLAY

51

function

This setting can be set to display total or rate.

When 'total' is selected, simultaneously, (differential or summed) total and

(differential or summed) flow rate is shown. When SELECT is pressed, the

(differential or summed) accumulated total is shown temporarily.

When 'rate' is selected, only (differential or summed) flow rate is shown

together with its engineering unit. When SELECT is pressed, the (differential or

summed) total and the (differential or summed) accumulated total are shown

temporarily.

When ‘All’ is selected, only (differential or summed) flow rate is shown together

with its engineering unit. When SELECT is pressed again, the (differential or

summed) total/accumulated total, the flow rate A, the accumulated total A, the

flow rate B and the accumulated total B are shown temporarily.

52

light

The backlight brightness can be adjusted from 0% (off) to 100% (full brightness)

in steps of 20%.

When the F116-P is only loop powered, the backlight is disabled. An external

power supply is required to supply the backlight.

53

measurement

To solve undesired display readings during low or even negative consumption

situations, four different measurement methods have been implemented. Note

that the selection does influence the analog output value (ref. flow rate) as well.

bi-directional

Shown flow rate: positive and negative.

Shown total: increases or decreases.

not negative

Shown flow rate: only positive or zero.

Shown total: increases or decreases.

Page 15

Page 15

FL_F116P_v1702_01_EN

threshold

Shown flow rate: as soon as the flow rate is lower than SETUP 54 or negative,

zero flow rate is shown.

Shown total: as soon as the flow rate is lower than SETUP 54 or negative,

totalization will stop.

stationary

Shown flow rate: as soon as the flow rate is lower than SETUP 54 or negative,

the stationary flow rate (SETUP 54) is shown.

Shown total: as soon as the flow rate is lower as SETUP 54 or negative,

stationary totalization (SETUP 55) will be activated. However, if the value of

setting 54 is zero, totalization increases or decreases.

54

stationary flow rate

Enter here the flow rate according SETUP 53: threshold or stationary. The time

and measuring units are according to flow rate SETUP 21 and 22.

threshold

Flow rate zero is shown as soon as the flow rate will be lower as this setting.

stationary

As soon as the flow rate is lower as this setting, this flow rate is shown.

If the flowmeters do not generate pulses, the flow rate shows zero.

55

stationary total

Enter here a flow rate per hour according to SETUP 53 – ‘stationary’.

The measuring unit is according to TOTAL (A and B) - SETUP 11.

This flow rate is converted to a total which will be used as long as the flow rate is

lower as SETUP 54.

If the flowmeters do not generate pulses, the totalization will stop.

This function is disabled if value zero has been entered.

3.1.7 EXPLANATION OF SETUP-MENU 6 - POWER MANAGEMENT

When used with the internal battery option (type PB/PC), the user can expect reliable measurement over a long

period of time. The F116-P has several smart power management functions to extend the battery life time

significantly. Two of these functions can be set.

6

POWER MANAGEMENT

61

lcd new

The calculation of the display-information influences the power consumption

significantly. When the application does not require a fast display refresh rate, it is

strongly advised to select a slow refresh rate. Please understand that NO

information will be lost; every pulse will be counted and the output signals will be

generated in the normal way.

At a key press, the display refresh rate will switch to FAST for 30 seconds. When

'OFF' is selected, the display goes off after 30 seconds after the last key press.

The display temporarily comes on after a key press.

Example battery life-time with a coil pick-up:

1kHz pulse and FAST update: about 2 years;

1kHz pulse and 1 sec update: about 5 years.

62

battery mode

The F116-P has two modes: operational or shelf.

After "shelf" has been selected, the F116-P can be stored for several years; it will

not process the sensor signal; the display is switched off but all settings and totals

are stored. In this mode, power consumption is extremely low.

To wake up the F116-P again, press the SELECT/ key two times.

Page 16

Page 16

FL_F116P_v1702_01_EN

3.1.8 EXPLANATION OF SETUP-MENU 7 - FLOWMETER

The F116-P is able to handle several types of input signal. The pickup / signal is selected with:

SETUP 71 (Input A), Read also chapter 4

SETUP 72 (Input B), Read also chapter 4.

The selections "active pulse" offer a detection level of 50% of the supply voltage.

7

FLOWMETER

71/72

SIGNAL

TYPE OF SIGNAL

EXPLANATION

RESISTANCE

FREQ. / mV

REMARK

NPN

NPN input

100 kΩ pull-up

max. 6 kHz.

(open collector)

NPN-LP

NPN with low pass filter

100 kΩ pull-up

max. 1.2 kHz.

(open collector)

less sensitive

REED

Reed-switch input

1 MΩ pull-up

max. 600 Hz.

REED-LP

Reed-with low pass filter

1 MΩ pull-up

max. 120 Hz.

Less sensitive

PNP

PNP input

100 kΩ pull-down

max. 6 kHz.

PNP-LP

PNP with low pass filter

100 kΩ pull-down

max. 1.2 kHz.

Less sensitive

NAMUR

NAMUR input

820 Ω pull-down

max. 4 kHz.

External power

required

COIL-HI

High sensitive coil input

-

min. 20 mVpp

Sensitive for

interference!

COIL-HI (option ZF)

min. 10 mVpp

COIL-HI (option ZG)

min. 5 mVpp

COIL-LO

Low sensitive coil input

-

min. 80 mVpp

Normal sensitivity

8-1 DC

Active pulse input

detection level 8.2V DC

3.9 kΩ

max. 10 kHz.

External power

required

12 DC

Active pulse input

detection level 12V DC

4 kΩ

max. 10 kHz.

External power

required

24 DC

Active pulse input

detection level 24V DC

3 kΩ

max. 10 kHz.

External power

required

3.1.9 EXPLANATION OF SETUP-MENU 8 - ANALOG OUTPUT

A linear 4-20mA signal (option AB: 0-20mA or option AU: 0-10V) output signal is generated that

represents the flow rate. The settings for the flow rate influence the analog output directly. The

relationship between the flow rate and the analog output is set with the following settings.

8

ANALOG OUTPUT

81

output

If the analog output is not used, select disable to minimize the power

consumption (e.g. save battery life-time).

Option AP: When a power supply is available but the output is disabled, a 3.5mA

signal will be generated.

82

rate-min

Enter here the flow rate at which the output should generate the minimum signal

(0)4mA or 0V - in most applications at zero flow. The number of decimals shown

depend upon setup 23. The engineering units/time (e.g. L/min) are dependent

upon setup 21 and 22.

83

rate-max

Enter here the flow rate at which the output should generate the maximum signal

(20mA or 10V) - in most applications at maximum flow. The number of decimals

shown depend upon setup 23. The engineering units/time (e.g. L/min) are

dependent upon setup 21 and 22.

Page 17

Page 17

FL_F116P_v1702_01_EN

84

cut-off

To ignore leakage of the flow for example, a low flow cut-off can be set as a

percentage of the full range of 16mA, 20mA or 10V.

When the flow is less than the required rate, the current will be the minimum

signal (0)4mA or 0V.

Example: Calculate the cut-off.

Rate-min: 0L/min [4mA], Rate-max: 100 L/min [16mA], Cut-off: 2%

Required rate [L/min]: (rate-max - rate-min)*cut-off: (100-0)*2%=2.0L/min

Output [mA]: rate-min + (rate-max*cut-off): 4+(16*2%)=4.32mA

85

tune-min

The (0)4mA or 0V value can be tuned precisely with this setting. The initial

minimum analog output value is (0)4mA or 0V. However, this value might differ

slightly due to ambient influences such as temperature for example.

Before tuning the signal, make sure that the analog signal is idle (not used)

for any application!

After pressing PROG, the current will be about 4mA (0mA or 0V). The current

can be increased / decreased with the arrow keys and is directly active. Press

ENTER to store the new value.

If required, you can program the analog output 'up-side-down'. The (0)4mA or 0V

represents the maximum flow rate and the 20mA or 10V represents the minimum

flow rate.

86

tune-max

The 20mA or 10V value can be tuned precisely with this setting. The initial

maximum analog output value is 20mA or 10V However, this value might differ

slightly due to ambient influences such as temperature for example.

Before tuning the signal, make sure that the analog signal is idle (not used)

for any application!

After pressing PROG, the current will be about 20mA or 10V. The current can be

increased / decreased with the arrow keys and is directly active. Press ENTER to

store the new value.

If required, you can program the analog output 'up-side-down'. The (0)4mA or 0V

represents the maximum flow rate and the 20mA or 10V represents the minimum

flow rate.

87

filter

This setting is used to stabilize the output signal. With the help of this digital filter

a more stable but less actual representation of the flow rate can be obtained.

The filter principal is based on three input values: the filter level (01-99), the last

calculated flow rate and the last average value. The higher the filter level, the

longer the response time on a value change will be.

filter value

RESPONSE TIME ON STEP CHANGE OF ANALOG VALUE. TIME IN SECONDS

influence

01

02

03

05

10

20

30

50

75

99

50%

filter disabled

0.1 sec

0.3 sec

0.5 sec

0.9 sec

1.8 sec

2.6 sec

4.4 sec

6.5 sec

8.6 sec

75%

filter disabled

0.3 sec

0.5 sec

0.9 sec

1.8 sec

3.5 sec

5.1 sec

8.6 sec

13 sec

17 sec

90%

filter disabled

0.5 sec

0.8 sec

1.4 sec

2.8 sec

5.6 sec

8.5 sec

14 sec

22 sec

28 sec

99%

filter disabled

0.9 sec

1.5 sec

2.6 sec

5.5 sec

11 sec

17 sec

29 sec

43 sec

57 sec

Page 18

Page 18

FL_F116P_v1702_01_EN

3.1.10 EXPLANATION OF SETUP-MENU 9 - PULSE

9

PULSE

91

mode

The unit has three scaled pulse output modes. This functionality drives two pulse

outputs which, depending on the mode, can be used as follows:

signed

On pulse output R1 a pulse will be send when the total has increased or

decreased with the set quantity (SETUP 94). Pulse output R2 will send a 0 for

increase or 1 for decrease.

not negative

On pulse output R1 a pulse will be sent when the total has increased with the set

quantity (SETUP 94). On pulse output R2 the sign of the flow rate will be send

(positive=0, negative=1).

separated

On pulse output R1 a pulse will be sent when the total has increased with the set

quantity (SETUP 94). On pulse output R2 a pulse will be sent when the total has

decreased with the set quantity (SETUP 94).

92

width

The pulse width determines the time that the output will be active; in other words

the pulse duration. Value “zero” will disable the pulse output.

The pulse signal always has a 50% duty cycle, hence the minimum time between

the pulses is equal to the pulse width setting. If the frequency should go out of

range – when the flow rate increases for example – an internal buffer will be used

to “store the missed pulses”: As soon as the flow rate slows down, the buffer will

be “emptied”.

It might be that pulses will be missed due to a buffer-overflow, so it is advised to

program this setting within its range!

93

decimals

This setting is used to set the amount of digits behind the decimal point for the

amount.

94

amount

A pulse will be generated every time a certain quantity is added to the total. Enter

this quantity here while taking the decimals for pulse into account.

3.1.11 EXPLANATION OF SETUP-MENU A - COMMUNICATION (OPTION)

This product is designed for the connection to a communication network. Products with a

communication option do not include cyber security functions. Fluidwell cannot take any

responsibility for the cyber security, omissions or errors in the communication safety. To maintain a

secure operation, automation and control, it is the sole responsibility of the owner to install and

manage the appropriate safety measures to protect the network, the product and the communication

against any kind of security breaches.

The functions described below deal with hardware that is not part of the standard delivery.

Programming of these functions does not have any effect if this hardware has not been installed.

Consult Appendix C and the Modbus communication protocol description for a detailed explanation.

A

COMMUNICATION

A1

speed

This setting is used to set the Baudrate.

A2

address

This setting is used to set the communication address for the F116-P.

A3

mode

This setting is used to set the Modbus transmission mode. Select OFF to disable

the communication.

3.1.12 EXPLANATION OF SETUP-MENU B - OTHERS

For support and maintenance it is important to have information about the characteristics of the F116-P. Your

supplier will ask for this information when support is required.

B

OTHERS

B1

model

This setting shows the model name.

B2

software version

This setting shows the version number of the firmware (software).

B3

serial no.

This setting shows the serial number.

B4

password

This setting is used to set a password (pin code) to limit the access for the setup

menu. Only persons who know the pin code can access the setup menu. The pin

code 0000 disables the pin code to allow for access by any person.

B5

tag-nr

This setting is used to set a tag number for the F116-P.

Page 19

Page 19

FL_F116P_v1702_01_EN

4 INSTALLATION

4.1 GENERAL DIRECTIONS

Mounting, electrical installation, start-up and maintenance of this device may only be

carried out by trained persons authorized by the operator of the facility. Persons must

read and understand this manual before carrying out its instructions.

This device may only be operated by persons who are authorized and trained by the

operator of the facility. All instructions in this manual are to be observed.

Make sure, the measuring system is correctly wired up according to the wiring diagrams.

Protection against accidental contact is no longer assured when the housing cover is

removed or the panel cabinet has been opened (danger from electrical shock). The

housing may only be opened by trained persons authorized by the operator of the facility.

Take careful notice of the "Safety rules, instructions and precautionary measures" at the

front of this manual.

4.2 INSTALLATION / SURROUNDING CONDITIONS

Take the relevant IP classification of the

enclosure into account (see identification plate).

Even an enclosure rated for IP67 / TYPE 4(X)

should NEVER be exposed to strongly varying

(weather) conditions.

When panel-mounted, the front panel of the

F116-P is rated for IP65 / TYPE 4(X)!

When used in very cold surroundings or varying

climatic conditions, inside the instrument case,

take the necessary precautions against moisture.

Mount the F116-P onto a solid structure to avoid

vibrations.

Page 20

Page 20

FL_F116P_v1702_01_EN

4.3 DIMENSIONS- ENCLOSURE

Fig. 5: Aluminum enclosures - Dimensions

75 mm (2.95")

130 mm (5.12")

112 mm (4.40")

1

2

0

m

m

(

4

.

7

2

”

)

M20 x 1,5

PG9

PG9

30mm 30mm

M20 x 1,5

M16 x 1,5 M16 x 1,5

30mm 30mm

M20 x 1,5

M20 x 1,5 M20 x 1,5

25mm 25mm

1/2"NPT

0

.

9

”

3x 1/2"NPT

0.12" 0.12"

HA

HM

HN

HO

HP

HT

HU

6 x M12

12mm

12mm

24mm 24mm

36mm

36mm

1

4

m

m

1

7

m

m

115 mm (4.53”)

HB

29.1 mm (1.15”)

31 mm

(1.22”)

HZ

4x M20 x 1,5

15 15

HV

23 23

1

6

mm

1/2"NPT 1/2"NPT

25mm 25mm

2

2

,

5

m

m

HL

2

2

,

5

m

m

2

2

,

5

m

m

2

2

,

5

m

m

2

2

,

5

m

m

0

.

9

”

1

5

6

0

m

m

(

2

.

3

6

”

)

9

8

m

m

(

3

.

8

6

”

)

Page 21

Page 21

FL_F116P_v1702_01_EN

Fig. 6: GRP enclosures - Dimensions

75 mm (2.95")

130 mm (5.12")

112 mm (4.40")

60 mm (2.36")

120 mm (4.72")

HD

HK

HK back box:

(flat bottom)

HE

HF

HG

HH

D=12mm

12mm

12mm

24mm24mm

36mm

36mm

14mm

17mm

22,5mm

30mm 30mm

D=16mm

D=20mm

0.9"

D=22mm (0.866")

22,5mm

25mm 25mm

D=20mm D=20mm

D=16mm

HC

75 mm (2.95")

118 mm (4.65”)

104 mm (4.09”)

HJ

0.9”

0.12” 0.12”

3x D=22mm (0.866”)

115 mm (4.53”)

98 mm (3.86”)

29.1 mm (1.15”)

31 mm

(1.22”)

Page 22

Page 22

FL_F116P_v1702_01_EN

4.4 INSTALLING THE HARDWARE

Electro static discharge does inflict irreparable damage to electronics! Before installing or

opening the F116-P , the installer has to discharge himself by touching a well-grounded

object.

Do ground the aluminum enclosure properly as indicated. It is the responsibility of the

installer to install, connect and test the Protective Earth connections in accordance with

the (inter)national Rules and Regulations.

This chapter shows general information regarding the electrical installation of the F116-P

. Chapter 5 gives additional specific information regarding Intrinsically safe installation

and overrules the information given in this chapter.

When installed in an aluminum enclosure and a potentially explosive atmosphere

requiring apparatus of equipment protection level Ga and Da, the unit must be installed

such that, even in the event of rare incidents, an ignition source due to impact or friction

sparks between the enclosure and iron/steel is excluded.

4.4.1. GENERAL INSTALLATION GUIDELINES

In the F116-P , different types of bonding and earthing are used. The common (ground) is mostly

used for termination of the wire shields and the Protective Earth (PE) is used for electrical safety.

The F116-P that came with a power module type PM; 110V-230V AC or type PD/PF with an

option OR (the relays can handle 110V-230V AC) shall be connected to the Protective Earth (PE)

stud which is installed in the metal back panel. The metal front panel is connected to the

Protective Earth by the mounting screws and serrated washers.

For V AC applications, the terminal 00 shall not be connected to avoid earth loops.

For V DC applications, the terminal 00 shall be connected to the common (do NOT use for PE).

The wire screens (shield) are meant to prevent electromagnetic interference and shall be,

galvanic isolated, connected to the common ground terminals that belong to the specific sensor

connection. The wire screens shall be terminated at one side to prevent wire loops. Inside of the

Fluidwell unit, the different common ground terminals are connected to each other. It is advised,

as illustrated, to terminate the wire screens in the vicinity of the sensor and to insulated the wire

screen with a shrink tube at the Fluidwell unit side.

Separate cable glands with effective IP67 / TYPE 4(X) seals for all wires.

Unused cable entries: ensure that you fit IP67 / TYPE 4(X) plugs to maintain rating.

A reliable ground connection for both the sensor, and if applicable, for the metal enclosure

(above).

An effective screened cable for the input signal, and grounding of its screen to the “┴ “ terminal or

at the sensor itself, whichever is appropriate to the application.

Field mounted

Panel mounted

Page 23

Page 23

FL_F116P_v1702_01_EN

4.4.2. ALUMINUM ENCLOSURE - FIELD MOUNTED

Risk of damage to equipment!

Do not use the terminal 00 to connect the protective earth wire, the 00 and the common

ground terminals are internally connected. Be careful, to prevent damage to equipment when

you connect different power supplies (sensor, PLC, etc.). Inside the Fluidwell display, the

common grounds are internally connected to each other.

The PE connection

The PE connection is made with the PE stud

inside the back panel and the 4 mounting

screws that attach the cover to the back panel.

Type PM (110-230V AC)

The PE connection in the

metal back panel is made

with a serrated washer, a

terminal, a washer and a

screw.

The PE connection to the

metal cover is made with the

serrated washers and the

mounting screws.

Type PD-OR / PF-OR (8-24V AC)

Type PD-OR / PF-OR (8-30V DC)

4.4.3. ALUMINUM ENCLOSURE - PANEL MOUNTED

The PE connection

The PE connection is made with one of the

mounting screws that attaches the front panel

to the panel.

Type PM (110-230V AC)

The PE connection to the

metal cover is made with the

serrated washers and the

mounting screws.

The PE connection to the

panel is made with the

washer, the nut, the

terminal, the washer and a

lock nut.

Type PD-OR / PF-OR (8-24V AC)

Type PD-OR / PF-OR (8-30V DC)

Page 24

Page 24

FL_F116P_v1702_01_EN

4.4.4. PLASTIC (GRP) ENCLOSURE

The PE connection

The F116-P in a GRP enclosure meets the

requirements of class 2 (double insulated).

Therefore the incoming PE wire is terminated

with an insulating end cap.

Type PM (110-230V AC)

Type PD-OR / PF-OR (8-24V AC)

Type PD-OR / PF-OR (8-30V DC)

Page 25

Page 25

FL_F116P_v1702_01_EN

4.4.5. TERMINAL CONNECTORS

For Intrinsically safe applications: read chapter 5.

Fig. 7: Overview of terminal connectors - Standard configuration and options

SENSOR SUPPLY

For type PB/PC; PX; AP: There is no real sensor supply out available. Only a limited power supply

is available. This power supply MAY NOT be used to supply the flowmeters electronics, converters

etc. as it will not provide adequate sustained power ! All energy used by the flowmeters pick-up will

directly influence the battery life-time. It is strongly advised to use a "zero power" pickup such as a

coil or reed-switch when operating without external power. It is possible to use some low power NPN

or PNP output signals, but the battery life time will be significantly reduced (consult your distributor).

For type PD; PF; PM: It is possible to supply the sensor with different voltages. You can set the

voltage with the switches. Internal power is only applicable for low power sensors (Coil, Reed). The

sensor supply is fixed: 1.2V DC or 3V DC (set by the firmware). External power is only available

when the main external power supply is connected. The sensor supply voltage is selectable: 8.2; 12

or 24V DC.

Page 26

Page 26

FL_F116P_v1702_01_EN

Set the sensor supply

1. Make the F116-P safe. If applicable, mind the battery power.

2. Open the F116-P and carefully remove the cable-connectors and the protective cover.

3. Find and set the switches and select the V

out

as required.

4. Close the protective cover and install the cable connectors.

5. Close the F116-P.

Risk of electrocution - High voltage!

Make sure, all the leads to the terminals are disconnected from the F116-P and NEVER

connect the mains power supply to the unit when the protection cover has been removed!

Option PD

Power supply in: 8-24V AC / 8-30V DC

Switch location (Typical)

Sensor

V

out

selection

Sensor supply out

A

B

1 2 3

4

NOTE: Use an AC

autotransformer (spartrafo) with

galvanic isolation.

int

int

off

off

Coil 1.2V DC; <1mA

Reed 3V DC; <1mA

ext

ext

on

on

off

on

off

off

8.2V DC; 50mA (max)

12V DC; 50mA (max)

24V DC; 50mA (max)

Option PF

Power supply in: 24V AC / 24V DC ±10%

Switch location (Typical)

Sensor

V

out

selection

Sensor supply out

A

B

1 2 3 4

int

int

off

off

Coil 1.2V DC; <1mA

Reed 3V DC; <1mA

ext

ext

on

on

off

on

off

off

8.2V DC; 400mA (max)

12V DC; 400mA (max)

24V DC; 400mA (max)

Option PM

Power supply in: 115V AC - 230V AC ±10%

Switch location (Typical)

Sensor

V

out

selection

Sensor supply out

A

B

1 2 3 4

int

int

off

off

Coil 1.2V DC; <1mA

Reed 3V DC; <1mA

ext

ext

on

on

off

on

off

off

8.2V DC; 400mA (max)

12V DC; 400mA (max)

24V DC; 400mA (max)

Fig. 8: Sensor supply voltage - Switch setting

Page 27

Page 27

FL_F116P_v1702_01_EN

Terminal 05-06 (R1) / 03-04 (R2, negative total); scaled pulse output

SETUP A (read chapter 3) determines the pulse output function. The maximum pulse frequency of

this output is 500Hz. If a relay output option has been supplied, be sure that the output frequency

does not exceed 5Hz or else the life-time of the relay will be reduced significantly.

Type OA

An active 24V DC pulse signal output is available with this option.

Max. driving capacity 50mA@24V per output. (Requires power supply type PD/PF/PM).

Fig. 9: Terminal connections - Active output (typical)

Type OR

A mechanical relay output is available with this option.

Max. switch power 240V 0,5A per output. (Requires power supply type PD/PF/PM). Be sure that the

output frequency does not exceed 5Hz, else the relay life time will be reduced significantly.

Fig. 10: Terminal connections - Mechanical relay output (typical)

Type OT

A passive transistor output is available with this option. Max. driving capacity 300mA@50V DC.

Fig. 11: Terminal connections - Pulse output (typical)

Terminal 07-08; basic POWER SUPPLY - type AP - output loop powered

Connect an external power supply of 8-30VDC to these terminals or a (0)4-20mA loop.

Do connect the "-" to terminal 7 and the "+" to terminal 8. When power is applied to these terminals,

the (optional) internal battery will be disabled / enabled automatically to extend the battery life time.

Terminal 07-08 analog output (SETUP 7) :

An analog output signal proportional to the (differential or summed) flow rate is available as

standard.

Page 28

Page 28

FL_F116P_v1702_01_EN

Type AA

An active 4-20mA signal proportional to the (differential or summed) flow rate is available with this

option. When the output is disabled, a 3.5mA signal will be generated on these terminals.

Max. driving capacity 1000 Ohm @ 24VDC. (Requires power supply type PD/PF/PM).

Fig. 12: Terminal connections - 4-20mA analog output (typical)

Type AB

An active 0-20mA signal proportional to the (differential or summed) flow rate is available with this

option. Max. driving capacity 1000 Ohm @ 24VDC. (Requires power supply type PD/PF/PM).

Fig. 13: Terminal connections - Active 0-20mA analog output (typical)

Type AF

For the Intrinsically safe floating 4-20mA signal: please read Chapter 5.

Type AI

An isolated 4-20mA signal proportional to the (differential or summed) flow rate is available with this

option. When the output is disabled, a 3.5mA signal will be generated on these terminals.

Max. driving capacity 1000 Ohm @ 30VDC.

This option can be used with a battery powered unit but the battery life time is about 2 -3 years.

Fig. 14: Terminal connections - Isolated 4-20mA analog output (typical)

Page 29

Page 29

FL_F116P_v1702_01_EN

Type AP

A passive 4-20mA signal proportional to the (differential or summed) flow rate is available with this

option. When a power supply is connected but the output is disabled, a 3.5mA signal will be

generated. Max. driving capacity 1000 Ohm. This output does loop power the unit as well.

Fig. 15: Terminal connections - Passive 4-20mA analog output (typical)

Type AU

A 0-10VDC signal proportional to the (differential or summed) flow rate is available with this option.

Max. load 10mA @ 10VDC. (Requires power supply type PD/PF/PM).

Fig. 16: Terminal connections - Active 0-10V analog output (typical)

Terminal 09-11; Terminal 12-14; Flowmeter input A and B:

Three basic types of flowmeter signals can be connected to the unit: pulse, active pulse or coil. The

connections for flowmeter A (Terminal 09-11) and B (Terminal 12-14) are the same. The screen of

the signal wire must be connected to the related common ground terminal (unless earthed at the

sensor itself) The maximum input frequency is approximately 10 kHz (depending on the type of

signal). The input signal type has to be selected in the flowmeter setup (read chapter 3).

Sine-wave signal (Coil):

The F116-P is suitable for use with flowmeters which have a coil output signal.

Two sensitivity levels can be selected:

COIL-LO: sensitivity from about 80mVpp;

COIL-HI: sensitivity from about 20mVpp;

type ZF, COIL-HI: sensitivity from about 10mVpp;

type ZG, COIL-HI: sensitivity from about 5mVpp.

Fig. 17: Terminal connections - Coil signal input (typical)

Page 30

Page 30

FL_F116P_v1702_01_EN

Pulse-signal NPN / NPN-LP:

The F116-P is suitable for use with flowmeters which have a NPN output signal. For reliable pulse

detection, the pulse amplitude has to go below 1.2V. Signal setting NPN-LP employs a low-pass

signal noise filter, which limits the maximum input frequency (read chapter 3).

Fig. 18: Terminal connections - NPN signal input (typical)

Pulse-signal PNP / PNP-LP:

The F116-P is suitable for use with flowmeters which have a PNP output signal. 3V is offered on

terminal 11 which has to be switched by the sensor to terminal 10 (SIGNAL). For a reliable pulse

detection, the pulse amplitude has to go above 1.2V. Signal setting PNP-LP employs a low-pass

signal noise filter, which limits the maximum input frequency (read chapter 3).

A sensor supply voltage of 8.2, 12 or 24V DC can be provided with power supply type PD, PF, PM.

For a signal detection level of 50% of the supply voltage: please refer to "active signals".

Fig. 19: Terminal connections - PNP signal input (typical)

Active signal 8.2V, 12V and 24V:

If a sensor gives an active signal (read chapter 3).The detection levels are 50% of the selected

supply voltage; approx. 4V (8-1 DC) or 6V (12 DC) or 12V (24 DC). Active signal selection may well

be desired in case of power supply type PD, PF, PM is available for sensor supply.

Fig. 20: Terminal connections - Active signal input (typical)

Reed-switch:

The F116-P is suitable for use with flowmeters which have a reed-switch. To avoid pulse bounce

from the reed-switch, it is advised to select REED LP - low-pass filter (read chapter 3).

Page 31

Page 31

FL_F116P_v1702_01_EN

Fig. 21: Terminal connections - Reed-switch signal input (typical)

NAMUR-signal:

The F116-P is suitable for flowmeters with an NAMUR signal. The standard F116-P is not able to

power the NAMUR sensor, as an external power supply for the sensor is required. However, a 8.2V

sensor supply voltage (terminal 11) can be provided with type PD, PF, PM.

Fig. 22: Terminal connections - NAMUR signal input (typical)

Terminal 26-31: type CB / CH / CI / CT - communication RS232 / RS485 / TTL (option)

For connections, refer to figure: Overview of terminal connectors - Standard configuration and options

Full serial communications and computer control in accordance with RS232 (length of cable max. 15

meters) or RS485 (length of cable max. 1200 meters) is possible.

When using the RS232 communication option, terminal 27 is used for supplying the interface.

Please connect the DTR (or the RTS) signal of the interface to this terminal and set it active (+12V).

If no active signal is available it is possible to connect a separate supply between terminals

26 and 27 with a voltage between 8V and 24V.

Terminal 00 - 01: type ZB backlight (option):

If the unit is supplied with a power supply:

type PD, PF or PM, the backlight supply is integrated.

type PX, use the terminals 00 and 01 to supply the backlight.

The backlight intensity is set in the setup menu: Display.

Page 32

Page 32

FL_F116P_v1702_01_EN

5 INTRINSICALLY SAFE APPLICATIONS

5.1 GENERAL INFORMATION AND SAFETY INSTRUCTIONS

For the combined connection of the different supply, input and output circuits, the

instructions in this manual must be observed. From the safety point of view the circuits

shall be considered to be connected to earth

Certificates, safety values, control drawing and declaration of compliance can be found in

the document named: “Fluidwell F1..-..-XI - Documentation for Intrinsic safety”

For installation under ATEX directive: this Intrinsically safe device must be installed in

accordance with the latest ATEX directive and product certificate KEMA 03ATEX1074 X.

For installation under IECEx scheme: this Intrinsically safe device must be installed in

accordance the product certificate IECEx DEK 11.0042X.

Exchange of Intrinsically safe battery FWLiBAT-0xx with certificate number

KEMA 03ATEX1071 U or IECEx KEM 08.0005U is allowed in Hazardous Area.

Read chapter 6 for battery replacement instructions.

When the enclosure of the F116-P is made of aluminum alloy, when used in a potentially

explosive atmosphere requiring apparatus of EPL Ga, the indicator shall be installed so,

that even in the event of rare incidents, an ignition source due to impact or friction sparks

between the enclosure and iron/steel is excluded.

When two or more active Intrinsically safe circuits are connected to the indicator, in order

to prevent voltage and/or current addition, applicable to the external circuits, precautions

must be taken to separate the Intrinsically safe circuits in accordance with EN 60079-11.

To maintain the degree of protection of at least IP65 in accordance with IEC 60529,

suitable cable entries and blanking elements must be used and correctly installed.

For enclosures and windows with a high surface resistance, potential charging hazard

exists. Do not rub these surfaces of the indicator. Clean window and enclosure only with

a lint-free cleaning cloth made damp with a mild soap solution.

Chapter 4 shows general information regarding the electrical installation of your indicator.

This chapter gives additional specific information regarding Intrinsically safe installation

and overrules the information given in chapter 4.

Mounting, electrical installation, start-up and maintenance of this device may only be

carried out by trained persons authorized by the operator of the facility. Persons must

read and understand this manual before carrying out its instructions.

This device may only be operated by persons who are authorized and trained by the

operator of the facility. All instructions in this manual are to be observed.

Make sure, the measuring system is correctly wired up according to the wiring diagrams.

Protection against accidental contact is no longer assured when the housing cover is

removed or the panel cabinet has been opened (danger from electrical shock). The

housing may only be opened by trained persons authorized by the operator of the facility.

Take careful notice of the "Safety rules, instructions and precautionary measures" in the

front of this manual.

Special conditions for safe use mentioned in both the certificate and the installation

instructions must be observed for the connection of power to both input and / or output

circuits.

When installing this device in hazardous areas, the wiring and installation must comply

with the appropriate installation standards for your industry.

Study the following pages with wiring diagrams per classification.

Page 33

Page 33

FL_F116P_v1702_01_EN

Serial number and year of production

This information can be looked-up in the setup menu: Others.

Fig. 23: Example serial number (typical)

Label information pulse input type – F1xx-..-..-XI (inside and outside the enclosure)

Fig. 24: Label information - Intrinsically safe application (typical)

Page 34

Page 34

FL_F116P_v1702_01_EN

5.2 TERMINAL CONNECTORS INTRINSICALLY SAFE APPLICATIONS

The unit is classified as group IIB/IIIC by default

Classification of the unit as group IIC is only possible under the following conditions:

The indicator is either supplied by

the internal supply (type PC);

the external supply connected to terminals 0 and 1 (type PD);

the circuit supply connected to terminals 7 and 8 (type AP);

The maximum values for any of those circuits are those as defined for group IIB/IIIC;

No other active external Intrinsically safe circuits may be connected to the indicator, with

exception of circuits connected to terminals 3 and 4 and/or terminals 5 and 6; the maximum

values for any of those circuits are those as defined for group IIB/IIIC.

Terminal connectors F116-P-XI:

Fig. 25: Overview terminal connectors - Intrinsically safe (typical)

Page 35

Page 35

FL_F116P_v1702_01_EN

Type AF - Intrinsically safe floating 4-20mA analog output - Terminal 7-8

A floating 4-20mA signal proportional to the flow rate is available with this option. When the output is

disabled, a 3.5mA signal will be generated. Max. driving capacity 1000 Ohm @ 30V DC.

It is required to link the minus from the analog output - terminal 7 - with a ground terminal of

the unit; terminal: 00, 03, 05, 09, 12 or 15.

Fig. 26: Terminal connections - Intrinsically safe floating 4-20mA analog output (typical)

For type PD-XI: It is possible to supply the sensor with different voltages. You can set the voltage

with the switches. Internal power is only applicable for low power sensors (Coil, Reed). The sensor

supply is set by the firmware: 1.2V DC or 3V DC. External power is only available when the main

external power supply is connected. The sensor supply voltage is fixed: 8.2V DC.

Set the sensor supply

1. Make the F116-P safe. If applicable, mind the battery power.

2. Open the F116-P and carefully remove the cable-connectors and the protective cover.

3. Find and set the switches and select the V

out

as required.

4. Close the protective cover and install the cable connectors.

5. Close the F116-P.

Risk of electrocution - High voltage!

Make sure, all the leads to the terminals are disconnected from the F116-P and NEVER

connect the mains power supply to the unit when the protection cover has been removed!

Type PD-XI

Power supply in: 8-30V DC

Switch location (typical)

Sensor

Sensor supply out

A

B

1 2

off

off

Coil 1.2V DC; <1mA

Reed 3V DC; <1mA

on

on

8.2V DC; 50mA (max)

Fig. 27: Switch position voltage selection type PD-XI

Page 36

Page 36

FL_F116P_v1702_01_EN

5.3 CONFIGURATION EXAMPLES INTRINSICALLY SAFE APPLICATIONS

Fig. 28: F116-P-(AP)-(CT)-(OT)-PC-XI - Battery powered - IIB/IIC – IIIC

Page 37

Page 37

FL_F116P_v1702_01_EN

Fig. 29: F116-P-AP-(CT)-OT-(PX)-XI - Output loop powered - IIB/IIC - IIIC

Page 38

Page 38

FL_F116P_v1702_01_EN

6 MAINTENANCE

6.1 GENERAL DIRECTIONS

Mounting, electrical installation, start-up and maintenance of this device may only be

carried out by trained persons authorized by the operator of the facility. Persons must