Page 1

Single Detector Check

Models SDC 3” – 8”

Max Pressure – 175 PSI (12 BAR)

Max Temperature - 140ºF (60ºC)

Basic Installation Instructions

CAUTION: Installation of Backflow Preventers must be performed by qualified, licensed personnel.

Faulty installation could result in an improperly functioning device.

NOTE: CHECK WITH GOVERNING AUTHORITIES FOR LOCAL INSTALLATION REQUIREMENTS.

The installer should be sure the proper device has been selected for the particular installation.

Danfoss Flomatic Model SDC Single Detector Check Valves are for use on potable water lines where a health hazard

would not exist in the event of a backflow situation.

Proper performance is dependent upon following these installation instructions and prevailing govern-mental and

industry standards and codes. Failure to do so, according to Danfoss Flomatic’s Limited Warranty "releases Danfoss

Flomatic of any liability that it might otherwise have with respect to that device". Such failure could also result in an

improperly functioning device.

Damage to the device could result wherever water hammer and/or water thermal expansion could create excessive line

pressure. Where this could occur, shock arrestors and/or pressure relief valves should be installed downstream of the

device.

If installation is in a pit or vault, the SDC valve must never be submerged in water, this could cause a cross-connection.

Make sure that the pit or vault always remains dry by providing ample drainage; consult local codes.

1. Before installing a Model SDC Single Detector Check Valve, flush the lines thoroughly to remove all debris, chips and

other foreign matter. If required a strainer should be placed upstream of the Single Detector Check Valve. CAUTION:

Do not use a strainer in seldom used emergency water lines such as fire lines.

2. Provide adequate space around the installed unit so that the valve will be accessible

for testing and servicing.

3. Install the SDC valve at least 12" above the surrounding floor level.

4. Always consult local codes for installation methods, approvals and guidelines.

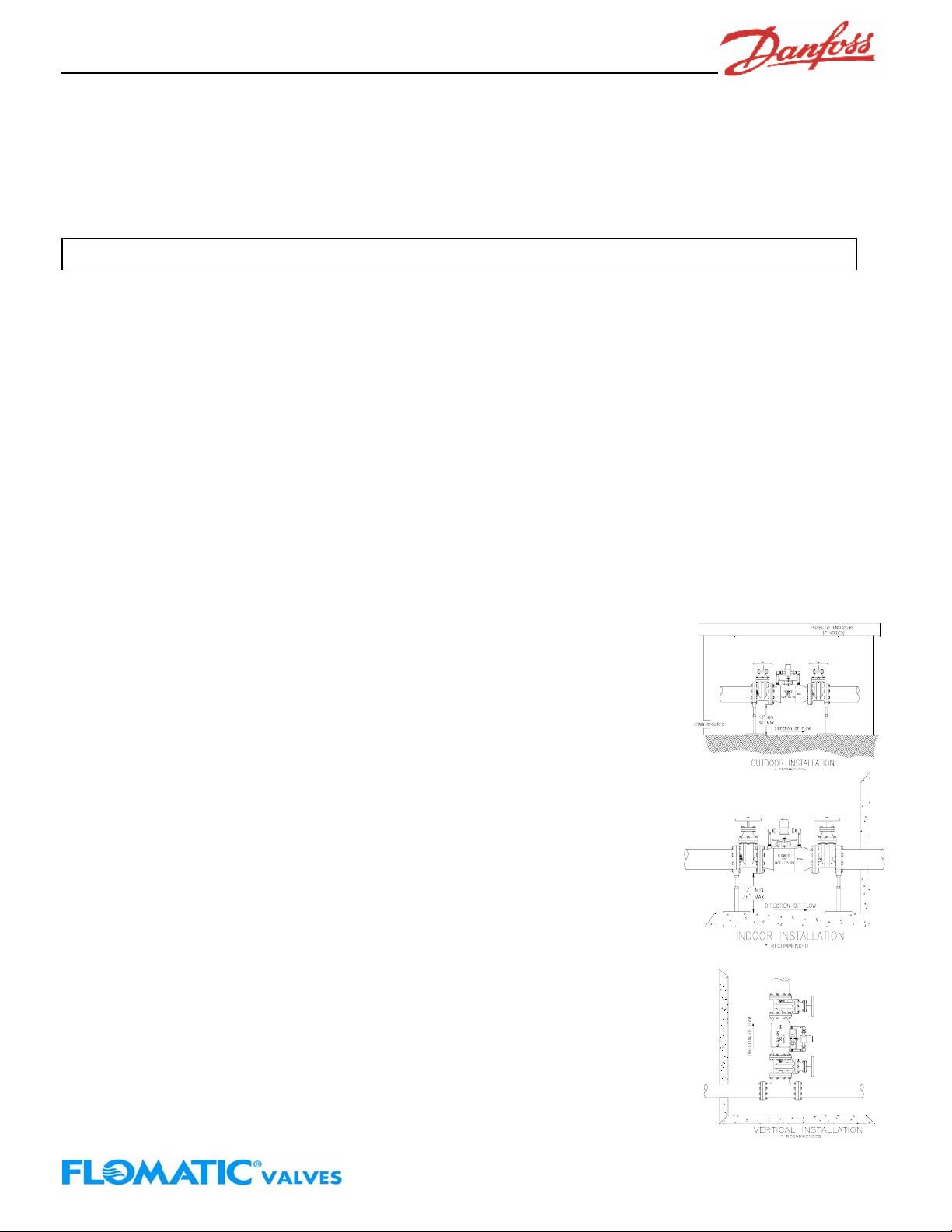

Outdoor Installation

Model SDC Single Detector Check Valve may be installed outdoors only if the device is

protected against any freezing conditions. Exposure to freezing conditions will result in

improper function or damage to the device. The installation location must be kept

above 32

Indoor Installations

Indoor installation is preferred in areas that are subject to freezing conditions. All the

basic installation instructions apply to such installations.

Vertical Installations

Vertical installation of Single Detector Valves is acceptable in applications where inlet

and outlet piping are flowing vertically UPWARDS. All the basic installation instructions

apply to such installations.

o

F (6ºC). All the basic installation instructions apply.

Installation Instructions

Danfoss Flomatic

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

SDC

Rev. 3 (7/08)

Page 2

Single Detector Check

Models SDC 3” – 8”

Placing the Device in Service

After the installation of a Model SDC unit has been completed, place the unit in service as follows:

1. Start with both shut-off valves closed. Slowly open the inlet shut-off valve until the SDC Single Detector Check Valve

is completely pressurized.

2. Slowly open the downstream shut-off valve. The Model SDC Single Detector Check Valve is now in service.

NOTE: Annual inspection, testing & cleaning of valves / system is required. This will help to insure maximum

life and proper function.

MAINTENANCE INSTRUCTIONS

The Danfoss Flomatic Model SDC Single Detector Check Valve must be inspected and maintained by licensed

personnel at least once a year or more frequently as specified by local codes. Replace any worn or damaged parts as

needed with only Danfoss Flomatic parts. Backflow prevention

valves should be thoroughly flushed after backflow conditions

occur to prevent any type of corrosive deterioration to its

components. Failure to do so could result in malfunction of the

device.

1. General

A. Clean all parts thoroughly with water after disassembly.

B. Carefully inspect silicone discs and o-rings for damage.

C. Ensure proper operation after reassembly.

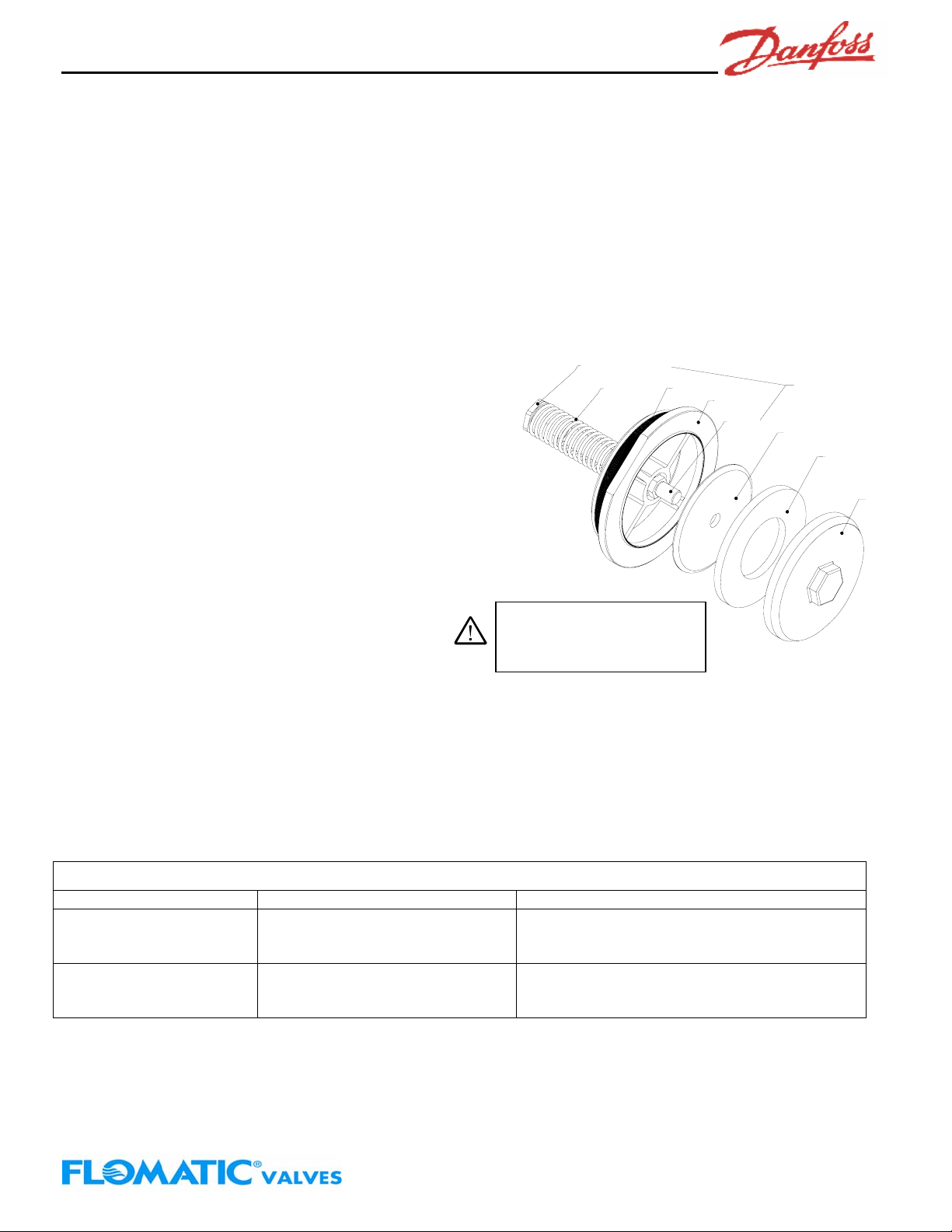

2. Servicing Check Valves

A. Close inlet & outlet shut-off valves

B. Remove the cover nuts/bolts & gasket from the grooved

coupling around the access cover.

C. Grasp on to the exposed ends of the check valve retainer,

which secures the check and squeeze ends together to

remove from groove.

D. Remove the check valve assembly. Separate the disc

holder from the assembly to expose the seat ring.

E. Inspect check valve seat ring, disc and o-ring for debris and damage. If the reverse side of the disc is unused, the

disc can be inverted and used TEMPORARILY until a new disc is obtained.

F. Inspect the valve cavity and seat areas. Flush with water to remove debris.

G. Lubricate the o-ring and reinstall the check in the body. Squeeze ends of retainer together and insert into groove.

H. Lubricate the gasket lips and gasket outside surface of the grooved coupling with FDA approved lubrican t. Make

sure the gasket is centered between the groove and does not become pinched while installing the coupling.

I. Place the valve back in service.

NOTE: Check valves can only be installed in one configuration, they are not reversible.

TROUBLESHOOTING:

Problem Possible Causes Corrective Action

1. Leaking Check Valves 1. Debris on seat or seat ring

2. Damaged seat area

3. Damaged seat o-ring

2. Low or No Flow 1. Device installed backwards

2. Gate valve not fully open

3. Low supply pressure

3 Year Limited Warranty: Danfoss Flomatic valves are guaranteed against defects of materials or workmanship when used for the

services recommended. If in any recommended service, a defect develops due to material or workmanship, and the device is

returned, freight prepaid, to Danfoss Flomatic within 36 months from the date of purchase, it will be repaired or replaced free of

charge. Danfoss Flomatics’ liability shall be limited to our agreement to repair or replace the valve only.

Installation Instructions

SPRING RETAINER

SPRING

DO NOT REMOVE THE SPRING

RETAINER FROM THE STEM

ASSEMBLY. Remove the disc

holder from the stem assembly.

1. Clean seat area

2. Replace check assembly

3. Replace seat o-ring

1. Verify flow direction arrow

2. Turn handles counterclockwise

3. Attach pressure gage to verify pressure

O-RING

Danfoss Flomatic

DO NOT DISASSEMBLE

SEAT RING

STEM

DISC RETAINER

DISC

DISC HOLDER

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

SDC

Rev. 3 (7/08)

Loading...

Loading...