Page 1

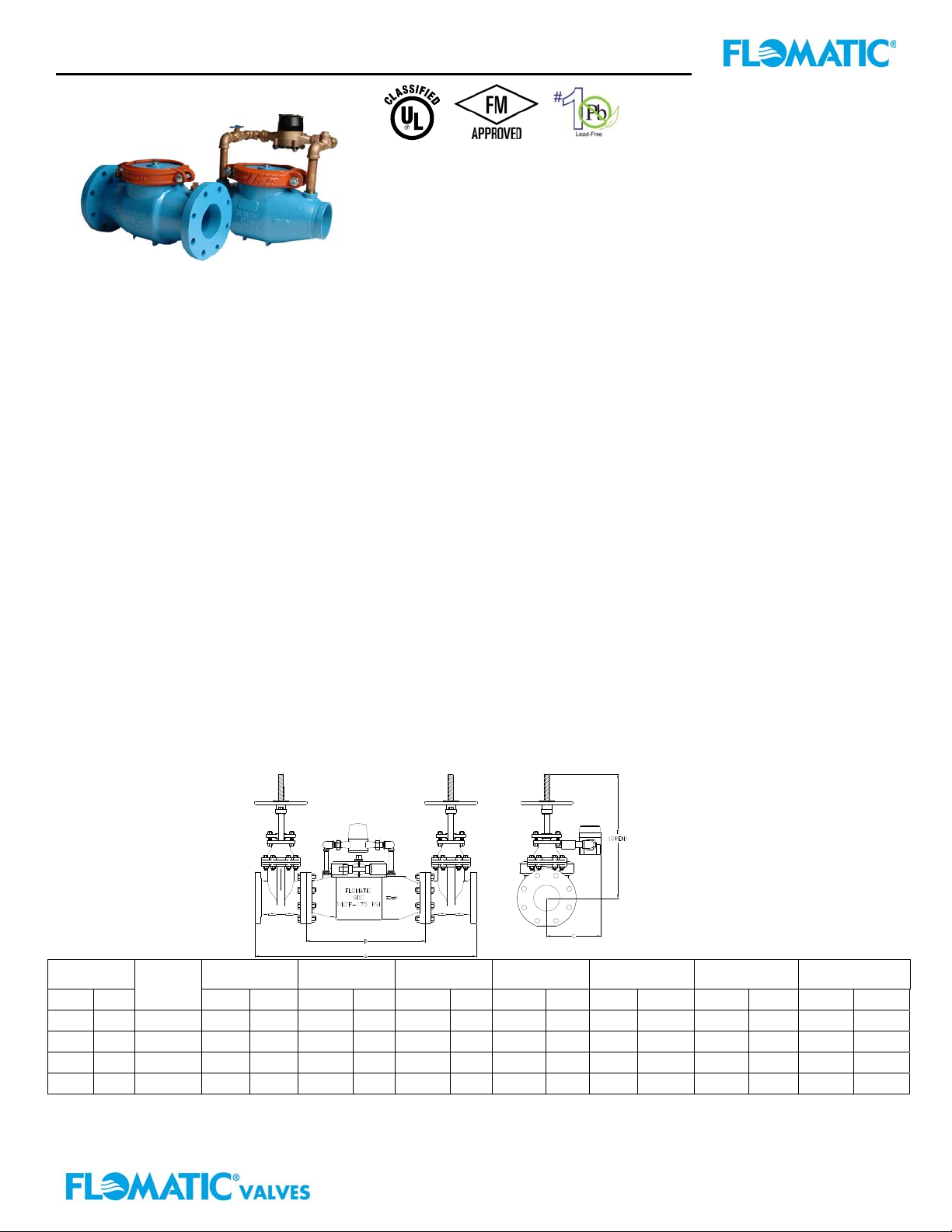

Single Detector Check Valve Specification Sheet

Model SDC (3”-8”)

FEATURES:

Sizes: □3” □4” □6” □8”

Max. working pressure: 175 PSI (1200 kPa)

Max. working temperature: 140

F (60C)

Hydrostatic Test Pressure: 350 PSI (2400 kPa)

Pipe connections:

Grooved (cut for steel pipe): AWWA C606

Flanged: ANSI B16.1 CL.125

MATERIALS:

Valve Body: Ductile Iron

Access Cover: Ductile Iron

Polymers: Noryl

TM,

NSF Listed

Elastomers: Silicone, Buna-N (FDA approved)

Springs: Stainless Steel

Coating: FDA approved fusion epoxy

OPTIONS:

G – Grooved pipe connection

D – with by-pass detector assembly

E – Australian flanged connection

1 – less NRS gate valves (ex: B9017-replace 3

rd

number with a 1)

OS&Y – with OS&Y valves

STANDARDS COMPLIANCE:

The Single Detector Check backflow preventer shall

meet the requirements of the following standards:

UL 312, FM-1045 4“ & 6” only

Complies with California Low Lead Plumbing Laws

IAPMO Certificate 6249

FLOMATIC SPECIFICATIONS:

Single Detector Check Valve Assembly backflow

preventer shall protect against backflow by either

backpressure or backsiphonage from a crossconnection between potable water systems and

substances that are non-health hazards in fire sprinkler

systems.

The device shall be constructed from ductile iron (6545-12). It shall consist of one (1) spring-loaded, center

stem, guided check valve. The device shall have a

cast ductile iron body, with a single access cover

utilizing a grooved pipe coupling. The assembly shall

have two (2) NPT/BSP tapped holes located upstream

and downstream of the check valve for installation of

the by-pass assembly (including a single check valve,

shutoff valve and water meter) for detecting low flow.

The seat of each check valve shall be constructed from

TM

Noryl

or bronze and shall be replaceable. The check

valve shall be held in place by a Noryl

Steel clip.

The backflow preventer shall be suitable for supply

pressure up to 175 psi and water temperatures

from 33

to 140 F.

Size A B C D Wgt (Flanged) Wgt (Grooved)

Inch mm

3 80 B9006 32.0 813 16.0 405 8 200 18.9 480 46 21 32 15 4 2

4 100 B9007 34.5 876 16.5 420 8.5 215 22.8 578 65 29 41 19 7 3

6 150 B9009 43.5 1105 22.5 570 10 250 30.1 765 120 54 90 41 9 4

8 200 B90010 49.5 1257 26.5 673 12 300 37.8 960 NA NA 185 84 11 5

Part #

Inch mm Inch mm Inch mm Inch mm lbs kg lbs kg lbs kg

Flomatic Corporation

TM

or Stainless

Wgt of

Bypass

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Nov. 27,2006 Rev. 2 (6/11)

Specification Sheet SDC-V

Page 2

Single Detector Check Valve Specification Sheet

Model SDC (3”-8”)

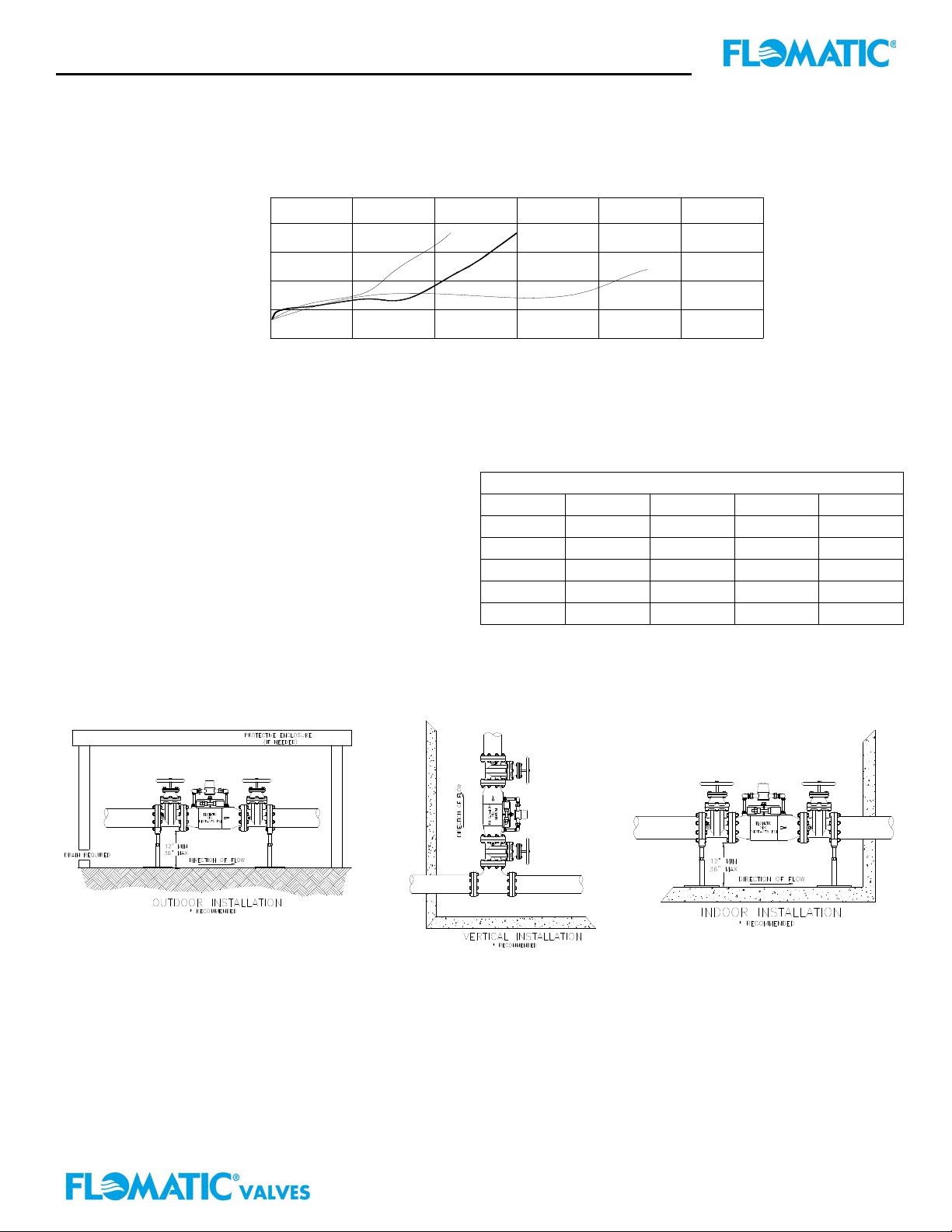

FLOW CHARACTERISTICS

P

R

M/WC

kPa

E

69 7 10

S

S

55 5.6

U

R

E

42 4.2 6

L

O

28 2.8

S

S

14 1.4 2

TYPICAL INSTALLATION

Model SDC Single Detector Check Valve Backflow

Preventers should be installed with adequate clearance

psi

8

FLOW CURVES

3" (80mm)

4" (100mm)

4

0

350

79.49

22.08

700

158.97

44.17

1050

238.45

66.26

FLOW RATE

1400

317.94

88.34

and easy accessibility for testing and maintenance and

must be protected from freezing. Local codes shall

govern installation requirements. Unless otherwise

specified, the assembly shall be mounted at a minimum

clearance of 12” (305mm) between port and floor or

grade. The assembly shall have a maximum of 30”

(762mm) above adequate drains with sufficient side

clearance for testing and maintenance. The installation

shall be made so that no part of the unit can be

submerged. Thermal water expansion can cause

excessive pressure. Excessive pressure situations

should be eliminated to avoid possible damage to the

Pipe size 5 ft/sec 7.5 ft/sec 10 ft/sec 15 ft/sec

2 ½”

3”

4”

6”

8”

Capacity thru Schedule 40 Pipe (GPM)

75 112 149 224

115 173 230 346

198 298 397 595

450 675 900 1351

780 1169 1559 2339

system and assembly.

WARRANTY: Flomatic valves are guaranteed against defects of materials or workmanship when used for the services

recommended. If in any recommended service, a defect develops due to material or workmanship, and the device is

returned, freight prepaid, to Flomatic within 12 months from the date of purchase, it will be repaired or replaced free of

charge. Flomatic Corporations’ liability shall be limited to our agreement to repair or replace the valve only.

Flomatic Corporation

6" (150mm)

1750

397.43

110.43

2100 gpm

476.91 M /H

132.51 lps

3

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Nov. 27,2006 Rev. 2 (6/11)

Specification Sheet SDC-V

Loading...

Loading...