Page 1

Reduced Pressure Zone Specification Submittal Sheet

Model RPZE II (½” & ¾”)

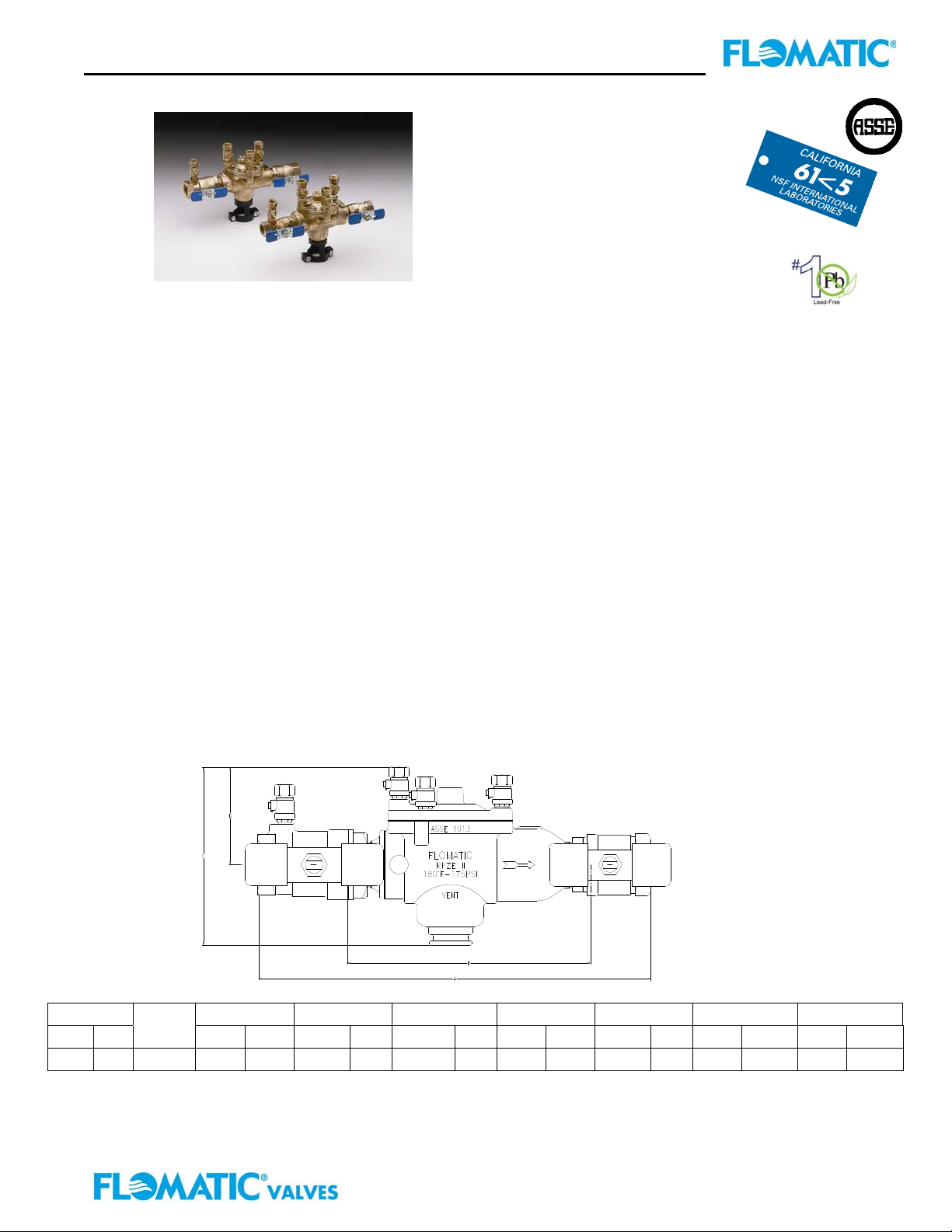

FEATURES:

Sizes: □½” □¾”

Max. working pressure: 175 PSI (1200 kPa)

Max. working temperature: 180F (82C)

Hydrostatic Test Pressure: 350 PSI (2400 kPa)

MATERIALS:

Valve Body: Unleaded Bronze

Access Cover: Unleaded Bronze

Polymers: Noryl

Elastomers: Silicone

Springs: Stainless Steel

OPTIONS:

1 – less ball valves (ex B9310E replace 3

UE– with union end ball valves

S – with bronze “Y” type strainer

TM,

NSF Listed

rd

number)

STANDARDS COMPLAINCE:

● ASSE® Listed 1013

● CSA® Listed

● AWWA Compliant C511

● City of Los Angeles Approved

● Approved by the Foundation for Cross-Connection

Control and Hydraulic Research at the University

of Southern California

● LEAD PLUMBING LAW COMPLIANCE

.25% Max Weighted Average Lead Content

Certified by IAPMO R&T Lab

FLOMATIC SPECIFICATIONS:

Reduced Pressure Principle backflow preventer shall

protect against backflow by either backpressure or

backsiphonage from a cross-connection between

potable water systems and substances that are nonhealth and health hazards.

The device shall be ANSI 3rd party certified to comply

with states lead plumbing law and shall be constructed

from unleaded bronze with less than 0.05% lead

content. It shall consist of two (2) mechanically

independent, spring loaded, center stem guided check

valves. It shall also have a hydraulically dependent

differential pressure relief valve with the sensing

passage set in an integral cast unleaded bronze body,

with a single access cover. The assembly shall have

four (4) vertical test cocks and two shut off valves

which are quarter-turn, full-port, resilient seated and

ball type which are constructed with low lead material,

less than 0.25% lead content (ASTM C90500) or

approved equal.

The relief valve shall have removable stainless steel

seat ring. The check valves shall be held into place by

stainless steel clips and the check valve assemblies

shall be non-interchangeable with silicone discs.

Size A B C D Width Wgt with BV Wgt less BV

Inch mm

½

¾ 20 B9300E 9-3/4 248 5-1/2 140 5-21/32 144 3-5/8 92 3-5/32 80 5 2.25 3.25 1.5

Part #

15 B9399E 9-1/4 235 5-1/2 140 5-21/32 144 3-5/8 92 3-5/32 80 4.5 2 3.25 1.5

Inch mm Inch mm Inch mm Inch mm Inch mm lbs kg lbs kg

Flomatic Corporation

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

November 17,2004 Rev. 6 (6/11)

Specification Sheet RPZEII

Page 2

Reduced Pressure Zone Specification Submittal Sheet

Model RPZE II (½” & ¾”)

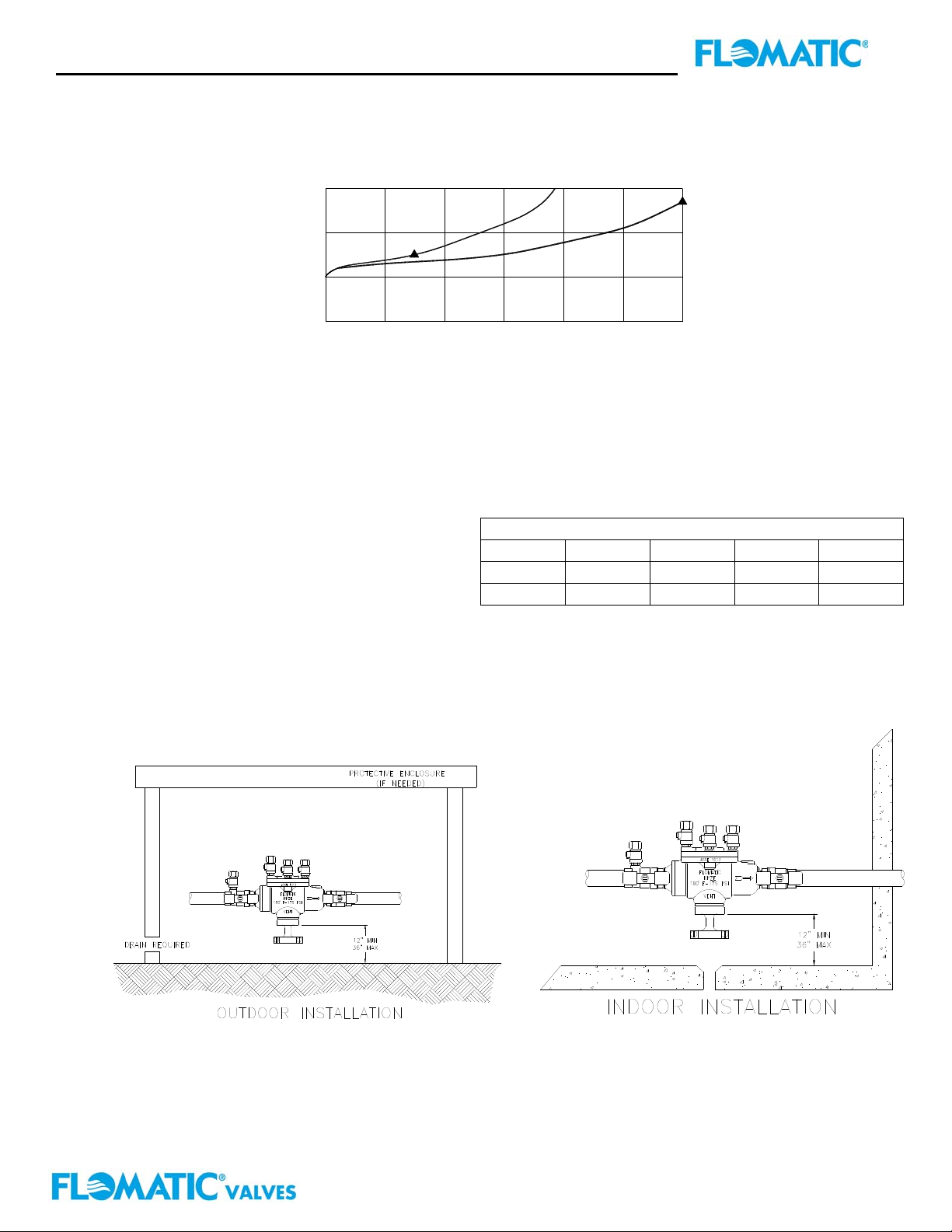

FLOW CHARACTERISTICS

i

a

s

P

p

k

138

20

S

S

O

103

15

L

E

R

U

S

69

10

S

E

R

P

35

5

0 10 20 30 gpm

FLOW CURVES w/ BALL VALVES

5

.32

(Established by Approval Agencies)

TYPICAL INSTALLATION

Model RPZE II Reduced Pressure Backflow

Preventers should be installed with adequate

clearance and easy accessibility for testing and

maintenance and must be

protected from freezing. Local codes shall govern

installation requirements. Unless otherwise specified,

the assembly shall be mounted at a minimum

clearance of 12” (305mm) between port and floor or

grade. The assembly shall have a maximum of 30”

(762mm) above adequate drains with sufficient side

clearance for testing and maintenance. The installation

shall be made so that no part of the unit can be

submerged. Thermal water expansion can cause

excessive pressure. Excessive pressure situations

should be eliminated to avoid possible damage to the

system and assembly.

WARRANTY: Flomatic valves are guaranteed against defects of materials or workmanship when used for the

services recommended. If in any recommended service, a defect develops due to material or workmanship, and the

device is returned, freight prepaid, to Flomatic Corporation within 12 months from the date of purchase, it will be

repaired or replaced free of charge. Flomatic Corporations’ liability shall be limited to our agreement to repair or

replace the valve only.

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

1/2" & 3/4"

1/2" (15mm)

15

.95

FLOW RATE

▲ RATED FLOW

1.58

25

Capacity thru Schedule 40 Pipe (GPM)

Pipe size 5 ft/sec 7.5 ft/sec 10 ft/sec 15 ft/sec

½”

¾”

5 7 9 14

8 12 17 25

Flomatic Corporation

3/4" (20mm)

1.89 lps1.26.63

November 17,2004 Rev. 6 (6/11)

Specification Sheet RPZEII

Page 3

Reduced Pressure Zone Specification Submittal Sheet

Model RPZE II (1-½”)

FEATURES:

Sizes: □1½”

Max. working pressure: 175 PSI (1200 kPa)

Max. working temperature: 180F (82C)

Hydrostatic Test Pressure: 350 PSI (2400 kPa)

MATERIALS:

Valve Body: Unleaded Bronze

Access Cover: Unleaded Bronze

Polymers: Noryl

Elastomers: Silicone

Springs: Stainless Steel

OPTIONS:

1 – less ball valves (ex B9313E replace 3

UE– with union end ball valves

S – with bronze “Y” type strainer

TM,

NSF Listed

rd

number)

STANDARDS COMPLAINCE:

● ASSE® Listed 1013

● AWWA Compliant C511

● City of Los Angeles Approved

● LEAD PLUMBING LAW COMPLIANCE

.25% Max Weighted Average Lead Content

Certified by IAPMO R&T Lab

FLOMATIC SPECIFICATIONS:

Reduced Pressure Principle backflow preventer shall

protect against backflow by either backpressure or

backsiphonage from a cross-connection between

potable water systems and substances that are nonhealth and health hazards.

The device shall be ANSI 3rd party certified to comply

with states lead plumbing law and shall be constructed

from unleaded bronze with less than 0.05% lead

content. It shall consist of two (2) mechanically

independent, spring loaded, center stem guided check

valves. It shall also have a hydraulically dependent

differential pressure relief valve with the sensing

passage set in an integral cast unleaded bronze body,

with a single access cover. The assembly shall have

four (4) vertical test cocks and two shut off valves

which are quarter-turn, full-port, resilient seated and

ball type which are constructed with low lead material,

less than 0.25% lead content (ASTM C90500) or

approved equal.

The relief valve shall have removable stainless steel

seat ring. The check valves shall be held into place by

stainless steel clips and the check valve assemblies

shall be non-interchangeable with silicone discs.

Size A B C D Width Wgt with BV Wgt less BV

Inch mm

1-½

Part #

40 B9303E 17 432 10-1/2 267 4-1/2 114 8 203 5-1/8 130 18.5 8.5 12 5.5

Inch mm Inch mm Inch mm Inch mm Inch mm lbs kg lbs kg

Flomatic Corporation

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

January 11,2010 Rev. 2 (6/11)

Specification Sheet RPZEII large

Page 4

Reduced Pressure Zone Specification Submittal Sheet

Model RPZE II (1-½”)

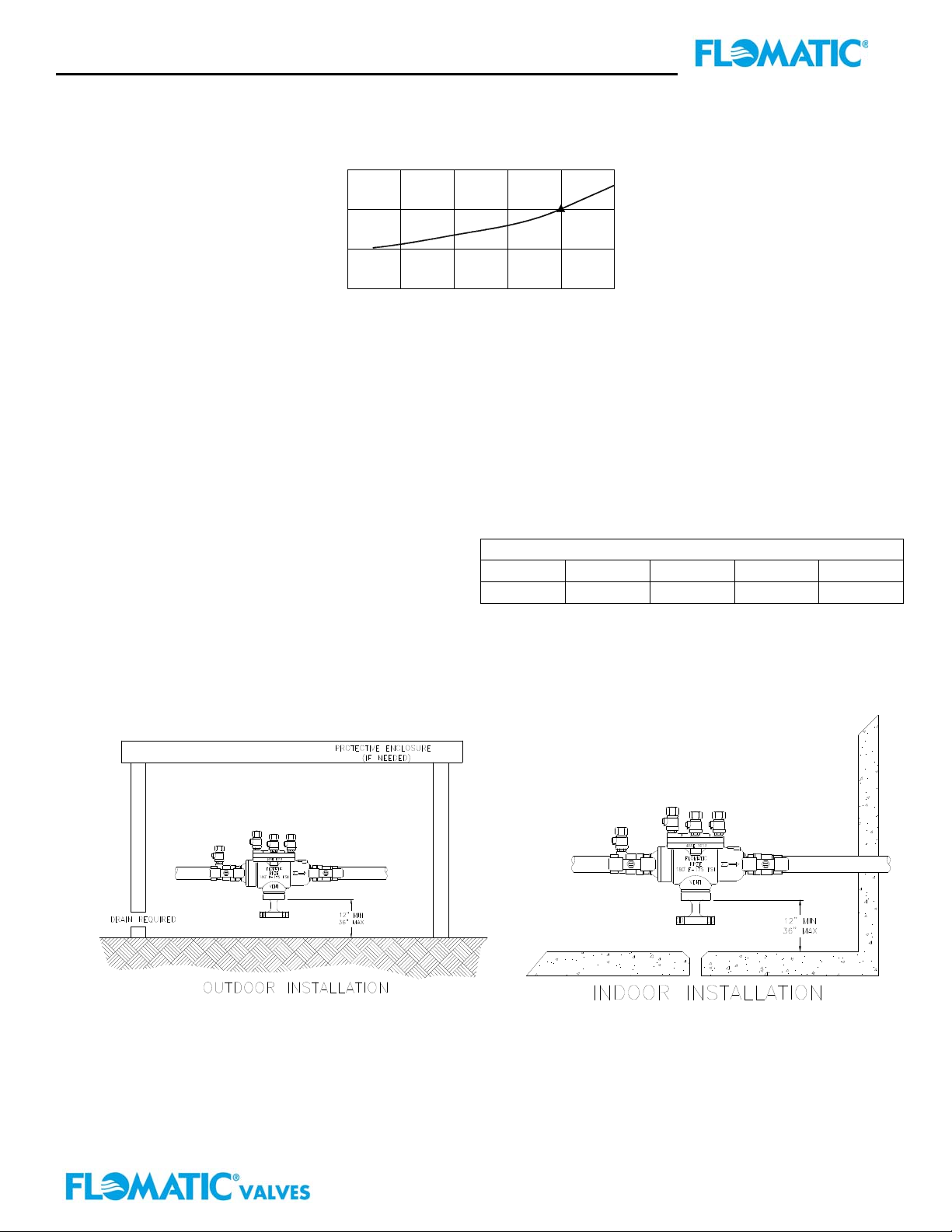

FLOW CHARACTERISTICS

P

k

138 20

S

S

O

103 15

L

E

R

U

S

S

E

R

P

35 5

i

a

s

p

1069

FLOW CURVES w/ BALL VALVES

0

1.58

25

(Established by Approval Agencies)

1-1/2"

1-1/2" (40mm)

3.15

7550

4.73

FLOW RATE

▲ RATED FLOW

6.31 7.89 lps

Flomatic Corporation

125 gpm100

TYPICAL INSTALLATION

Model RPZE II Reduced Pressure Backflow

Preventers should be installed with adequate

clearance and easy accessibility for testing and

maintenance and must be

protected from freezing. Local codes shall govern

installation requirements. Unless otherwise specified,

the assembly shall be mounted at a minimum

clearance of 12” (305mm) between port and floor or

grade. The assembly shall have a maximum of 30”

(762mm) above adequate drains with sufficient side

clearance for testing and maintenance. The installation

shall be made so that no part of the unit can be

submerged. Thermal water expansion can cause

excessive pressure. Excessive pressure situations

should be eliminated to avoid possible damage to the

system and assembly.

Pipe size 5 ft/sec 7.5 ft/sec 10 ft/sec 15 ft/sec

1 ½”

Capacity thru Schedule 40 Pipe (GPM)

32 48 63 95

WARRANTY: Flomatic valves are guaranteed against defects of materials or workmanship when used for the

services recommended. If in any recommended service, a defect develops due to material or workmanship, and the

device is returned, freight prepaid, to Flomatic Corporation within 12 months from the date of purchase, it will be

repaired or replaced free of charge. Flomatic Corporations’ liability shall be limited to our agreement to repair or

replace the valve only.

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

January 11,2010 Rev. 2 (6/11)

Specification Sheet RPZEII large

Loading...

Loading...