Page 1

Pressure Vacuum Breaker

Models PVB ¾“ &1”

Max Pressure – 175 PSI (12 BAR)

Max Temperature - 140ºF (60ºC)

Basic Installation Instructions

CAUTION: Installation of Backflow Preventers must be performed by qualified, licensed personnel.

Faulty installation could result in an improperly functioning device.

NOTE: CHECK WITH GOVERNING AUTHORITIES FOR LOCAL INSTALLATION REQUIREMENTS.

The installer should be sure the proper device has been selected for the particular installation.

The Danfoss Flomatic PVB contains an independently operating internally loaded check valve and an

independently operating loaded air inlet valve located on the discharge side of the check valve. When the

discharge pressure drops to 1 psi or below, the air vent opens and the spring loaded check valve closes the

valve inlet, preventing back-siphonage. During normal flow, the water opens the check valve assembly and

seat the vent disc holder against the bonnet as the body fills with water. The assembly is equipped with two

resilient-seat quarter turn shut-off valves and two test-cocks

The Danfoss Flomatic PVB is designer to prevent back-siphonage of contaminated water into the potable

water supply.

NOTE: Installations must have continuous pressure with no back pressure. For installations requiring

protection against backpressure install a Danfoss Flomatic RPZE or RPZE II.

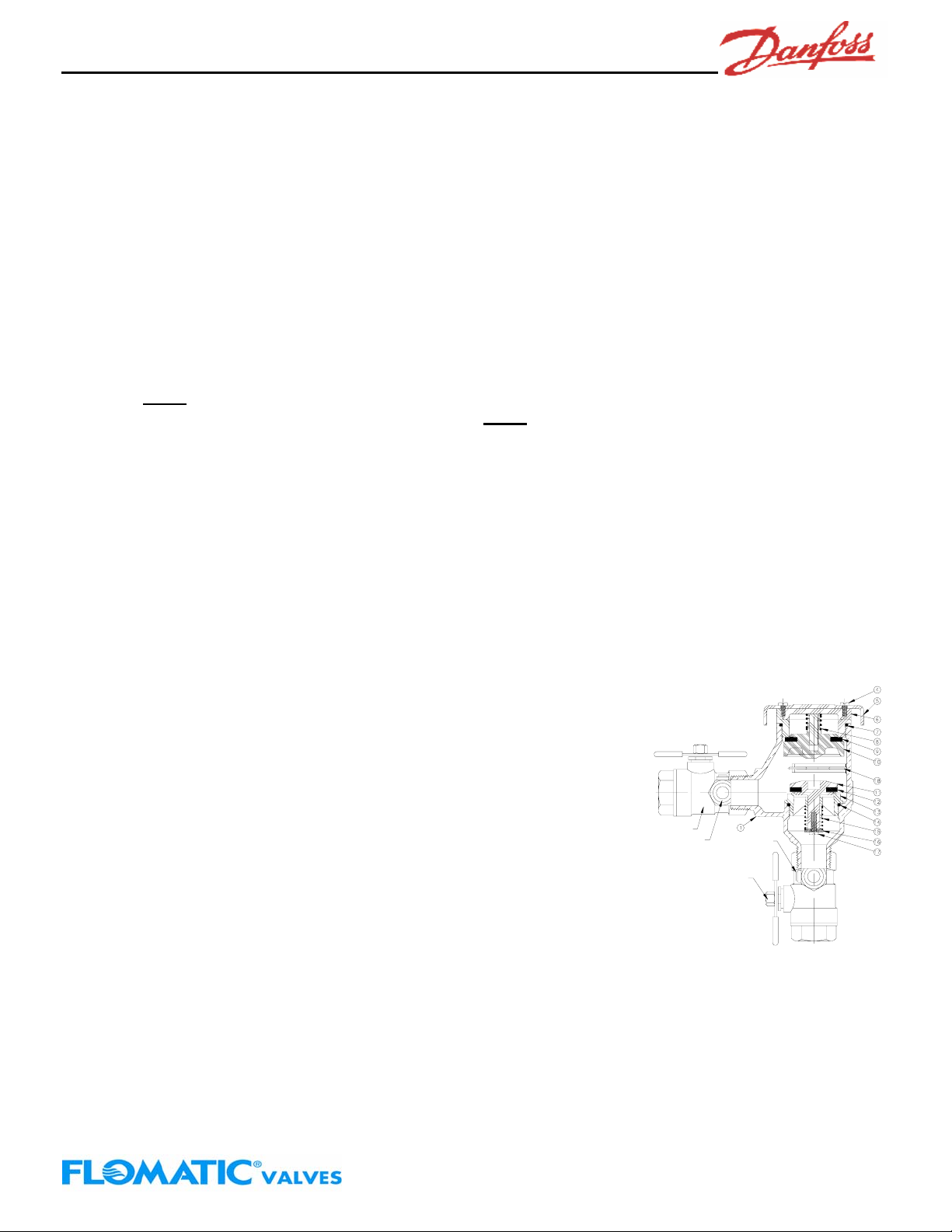

Installation

The Danfoss Flomatic Model PVB must be installed in a vertical position with the supply connected to the

bottom of the assembly, as shown above. The valve should be installed with adequate clearance on all sides

to allow for periodic inspection, testing, and maintenance. The Assembly must be installed at least 12" above

the highest downstream outlet. Do not install in a pit or vault. Protect the device from freezing. The

Assembly must not be installed where back pressure is present.

In case of possible warranty claim, contact your local supplier or Danfoss Flomatic representative. DO NOT

REMOVE ASSEMBLY FROM THE PIPELINE.

The assembly must be protected from freezing and excessive pressure increases. Pressure increases can

be caused by thermal expansion or water hammer. These excessive pressure situations must be eliminated

to protect the valve and the system from possible damage. For protection against water hammer shocks,

install a water hammer arrestor utilizing good plumbing practice.

Placing the Device in Service

After proper installation of a Danfoss Flomatic Model PVB, place the unit in service as follows:

1. Begin with both Shut Off Valves closed. Pressurize the system up to the Model PVB.

2. Open Shut Off Valve #1 completely. Some spillage may occur from the Canopy until the unit is

pressurized.

Note:

Do not install in an area where the spillage of water may cause damage or be objectionable.

Installation Instructions

Danfoss Flomatic

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Rev. 4 (7/09)

PVB

Page 2

Pressure Vacuum Breaker

Models PVB ¾“ &1”

3. Slowly open Shut Off Valve #2 to pressurize the downstream system. The Model PVB is now in service.

4. After the Model PVB has been properly installed and placed in service, the unit should be tested (See

Testing Procedures).

NOTE: Annual inspection, testing & cleaning of valves / system is required. This will help to insure

maximum life and proper function.

MAINTENANCE INSTRUCTIONS

1. Turn off the water supply to the Model PVB.

2. Release the pressure from the device.

3. Remove the Canopy Screws and Canopy.

4. Unscrew the bonnet from the body.

5. Remove spring clip (item 18) using needle nose pliers. Squeeze clip and disengage from side wall, then

remove. Note:

6. Unscrew the Check Valve Assembly from the body. Note:

hot water heater element wrench with the sides ground down will also work, consult factory for other tools.

A hot water heater element wrench with the sides ground down will also work. Consult factory for other

tools.

7. Clean and inspect all components thoroughly prior to reassembly.

8. Vent and Check Valve Silicone Disc are reversible.

9. Replace parts as needed and reassemble in reverse order.

Testing Procedures

Test No. 1 Air Inlet Opening Point

Purpose: To determine the pressure in the body when the air inlet valve opens.

Requirement: The air inlet valve shall open when the pressure in the body is no less than 1.0 psi above

atmospheric pressure, and the air inlet valve shall be fully open when the water drains from the body.

Steps:

a. Remove the Canopy.

b. Bleed water through both testcocks to eliminate foreign material.

c. Install appropriate fittings to testcocks.

d. Attach the high side hose of the differential pressure gage to

Testcock #2, slowly open Testcock #2, make sure the end of low hose

is level with Testcock #2.

e. Bleed air from the hose and gage by opening the high side bleed

needle valve. Close the high side bleed needle valve.

f. Close (outlet) Shut Off Valve #2, then close (inlet) Shut Off Valve #1.

g. Slowly open the high side bleed needle valve no more than one-

quarter (1/4) turn, being careful not to drop the differential pressure

reading of the gage too quickly. Record the differential pressure

reading of the gage when the air inlet valve opens, must be greater

then or equal to 1.0 psi.

h. Close Testcock #2.

i. Remove equipment.

j. Open Shut Off Valve #1.

Test No. 2 Check Valve Closing Point

Purpose: To determine the static pressure drop across the check valve.

Requirement: The static pressure drop across the check valve shall be at least 1.0 psi.

Starting July 1st 2005 on serial numbers P0001 and larger.

Installation Instructions

A 12 point 1-3/8" socket is recommended, a

Shut Off Valve #2

Testcock #2

Danfoss Flomatic

Testcock #1

Shut Off Valve #1

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Rev. 4 (7/09)

PVB

Page 3

Pressure Vacuum Breaker

Models PVB ¾“ &1”

Steps:

a. Attach high side hose of the differential pressure gage to Testcock #1, open Testcock #1.

b. Bleed all air from the hose and gage by opening high side bleed needle valve. Close high side bleed

needle valve.

c. Close Shut Off Valve #1 (Shut Off Valve #2 remains closed from Test #1).

d. Open Testcock #2. The water in the body will drain out through Testcock #2. When the flow of water

stops, the gage reading is the pressure drop across the check valve, must be greater then or equal to 1.0

psi.

e. Close both Testcocks.

f. Remove equipment.

g. Open Shut Off Valve #1, then Shut Off Valve #2.

h. Replace the Canopy.

TROUBLE SHOOTING GUIDE

Problem Possible Cause Solution

1. Check valve fails to

hold 1.0 psid minimum

2. Poppet fails to open

at 1.0 psig minimum

3. Minor leakage thru

air vent

4. Significant

discharge thru air vent

5. Chatter during flow

conditions

Winterization

1. Close main shut-off (1) to stop water supply to system.

2. Open the inlet (2) and outlet (6) drain valves, inlet (3) and outlet (5) shut-off valve on PVB and both

tescocks (4). All valves and testcocks must be left half open which is 45º to full open or close. This will

allow complete drainage.

A. Debris on sealing surfaces of valve

B. Damaged seat disc

C. Weak or broken spring

D. Poppet broken due to thermal expansion

A. Debris restricting free operation

B. Poppet seal adhering to bonnet

C. Weak spring load

A. Damaged poppet seal

B. Cracked or damaged poppet

C. Cracked bonnet or damaged sealing edge

D. Debris on sealing surface

A. Poppet not properly guided

B. Major poppet or seal failure

C. Low downstream pressure

D. Insufficient inlet volume to operate device

E. Poppet and/or bonnet broken

A. Worn, damaged or defective check valve

guide

Installation Instructions

Danfoss Flomatic

a. Disassemble and clean check

b. Disassemble & replace seal

c. Disassemble & replace spring

d. Replace broken poppet

a. Disassemble and clean check

b. Disassemble & clean or replace

damaged parts

c. Replace bonnet assembly

a. Disassemble & replace seal

b. Disassemble & replace poppet

seal

c. Disassemble & replace bonnet

seal

d. Disassemble & clean

a. Disassemble & clean or replace

damaged parts

b. Disassemble & clean or replace

damaged parts

c. Check pressure @ #2 testcock,

should be higher than 5 psig if low

system

d. Pressure needs to be increased

or partially closed outlet ball valve

to create higher pressure on

poppet

e. Replace broken bonnet/poppet

due to thermal expansion

a. Disassemble & repair or

replace guide

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Rev. 4 (7/09)

PVB

Page 4

Pressure Vacuum Breaker

Models PVB ¾“ &1”

3. Blowing out the system downstream will require the outlet drain valve (6) to be opened and the PVB outlet

shut-off valve (5) to be closed.

4. Attach air hose to the outlet drain valve (6), turn on air and make sure all water is removed from the

downstream part of system.

5. WARNING: Make sure to put the PVB outlet shut-off valve (5) and outlet drain valve (6) back to the 45º

open position after blowing open is completed.

6. If drain valves (2&6) are NOT part of your system and/or air is not used to blow out the system, make sure

to remove the PVB internal components for the winter.

7. WARNING: Make sure the resilient seated main shut-off valve (1) is completely shut and remains so to

prevent water from refilling the system causing damage.

Installation Instructions

Danfoss Flomatic

3 Year Limited Warranty

All products manufactured & sold by Danfoss Flomatic carry with them the following warranty: Danfoss Flomatic

warrants to the original purchaser (end user) all products manufactured by it will be free from defects in workmanship &

material for a period of three (3) years.

This warranty is applicable provided such products are used under normal conditions within the recognized pressure,

flow & temperature limits & are given normal service & care. DANFOSS FLOMATIC MAKES NO OTHER

REPRESENTATION OR WARRANTY OF ANY KIND EXPRESSED OR IMPLIED, IN FACT OR IN LAW, & EXPRESSLY

DISCLAIMS ALL OTHER WARRANTIES, INCLUDING WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. In the event of a defect in material or workmanship

of a product covered by this warranty, Danfoss Flomatic shall at its solo option, repair or replace such defective product.

Danfoss Flomatic shall not be liable for any labor required to repair or replace any product covered by this warranty. This

warranty is void with respect to any such product which is altered or tampered with by anyone without prior consent of

Danfoss Flomatic. Danfoss Flomatic shall not be liable under any circumstances for damages caused by accident,

misuse or abuse of the product or for failure to follow the installation, maintenance or operating instructions. IN NO

EVENT SHALL DANFOSS FLOMATIC BE LIABLE FOR INCIDENTAL, INDIRECT, PERSONAL INJURY, PROPERTY

OR PUNITIVE DAMAGES.

To make a claim under this warranty, the buyer must notify the factory in writing within ten (10) days of discovery of any

claimed defects or workmanship, & if authorized by the factory, shall return the product in the same condition as when

received by the buyer, transportation prepaid, to the factory or to such other location as directed by the factory. If said

returned product is found by the factory to be defective in workmanship or materials, it shall be repaired or replaced

without charge, pursuant to the terms of this warranty. This warranty excludes component parts or appurtenances not

manufactured by Danfoss Flomatic. Any claims with respect to such equipment must be made to the manufacturer in

accordance with the terms of the warranty, if any, given by such manufacturer, or pursuant to such warranties as may

exist by law. The physical or chemical properties of Danfoss Flomatic products represent typical, average values

obtained in accordance with test methods & are subject to normal manufacturing variations. This information is supplied

as a technical service and is subject to change without notice.

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

PVB

Rev. 4 (7/09)

Loading...

Loading...