Page 1

Flow Controller Installation Instructions

Model FC20 ¼” & ⅜”

Description:

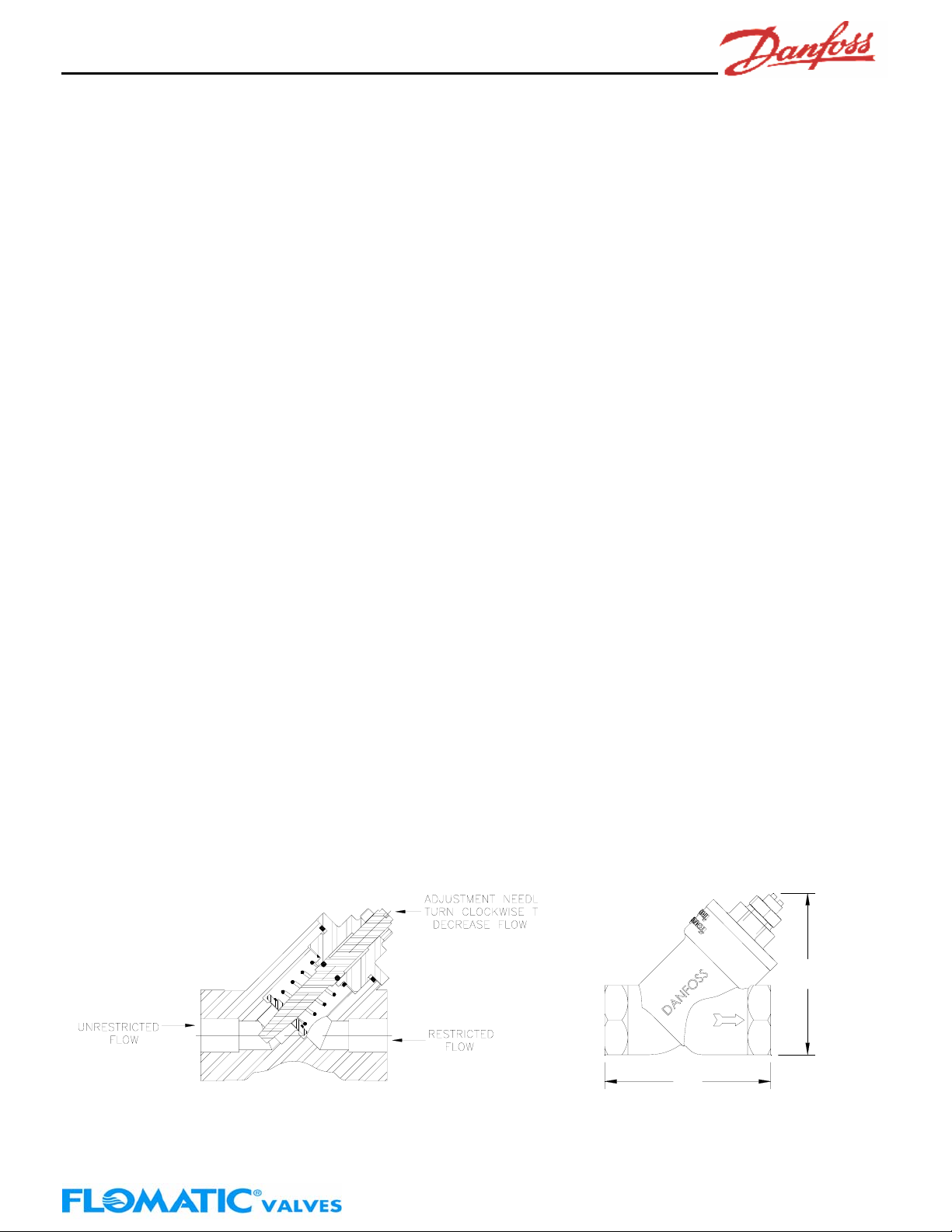

The FC20 Flow Control Valve is an all stainless steel spring-loaded needle type check valve. The flow rate is

unrestricted flow in one direction and restricted or metered flow in the other. The flow rate is only adjustable in the

restricted direction. It is to be used with automatic control valve pilot control systems.

Operation:

The FC20 Flow Control Valve permits full flow in the direction of the body marking arrow and restricted flow in the

reverse direction. Flow from inlet to outlet lifts the seat disc off of the seat thus allowing full flow. Flow in the opposite

direction causes the seat disc to seal, allowing fluid to pass thru the adjustable opening between the needle and seat

disc. Adjusting the needle counterclockwise increases the opening between the needle and the seat allowing more flow.

Adjusting the needle clockwise decreases the opening between the needle and the seat reducing flow.

Installation:

Installation must be performed by qualified, licensed personnel only.

The FC20 Flow Control Valve should be installed as shown in the piping schematic that came with your control valve.

Make sure all connections are tight to prevent leakage or damage to your valve.

Adjustment Procedure:

Loosen the adjustment needle jamb nut. Turning the needle out (counter-clockwise) increases the opening between the

needle and the seat disc, which increases the flow. Turning the needle in (clockwise) reduces the opening between the

needle and the seat disc, which reduces the flow. After adjustment is complete retighten the adjustment needle jamb

nut.

MAINTENANCE & REPAIR

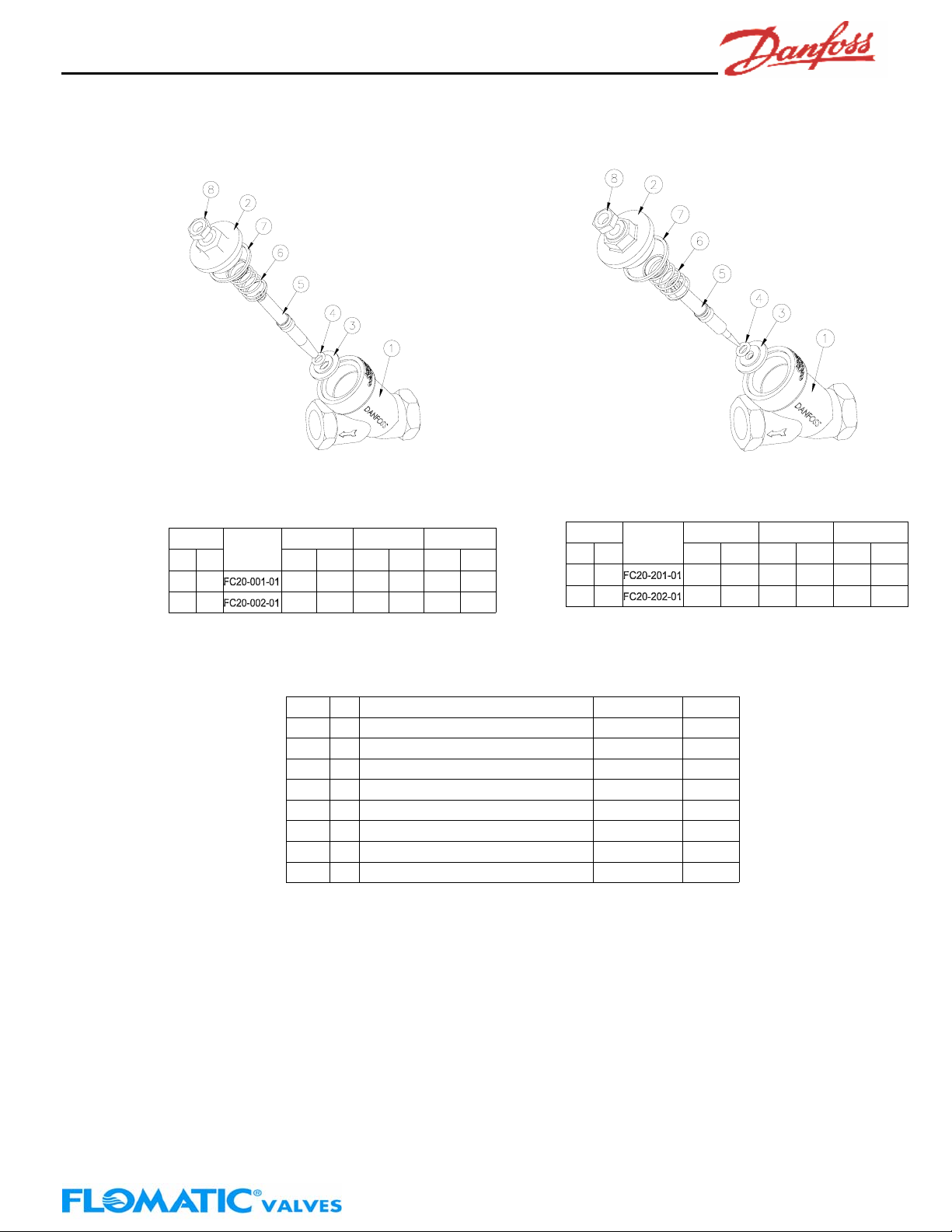

Annual inspection and maintenance is required of all plumbing system components. To ensure proper performance and

maximum life, the FC20 must be inspected, tested and cleaned on a regular basis. Disassemble the valve according to

the exploded diagram. Inspect all threads for signs of damage or cross-threading. Make sure the seat disc and seat of

valve body do not show wear, damage or foreign material which can stop the valve from opening or seating correctly.

The spring should be checked for cracks, damage or distortion. The adjustment needle should be free from nicks or burs

which can stop the valve from opening. Inspect all parts for damage, wear and corrosion. Replace all damaged

components and items that appear would keep the valve from functioning correctly. The o-ring and cover seal should be

replaced whenever the FV20 is serviced. Make sure to clean all parts before you reassemble the valve. Re-assemble

the valve according to the cross sectional view.

TEST PROCEDURE

The FC20 Speed Control Valve does not require testing before being re-installed.

Danfoss Flomatic

B

A

FREE FLOW IN DIRECTION OF ARROW

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

FC20

Rev. 4

Page 2

Flow Controller Installation Instructions

Model FC20 ¼” & ⅜”

inch

1/4

3/8

Size

mm

10

Part #

AB

inch

2.20 2.1556 1 .454

Weight

mminchmm

lbs kg

.45412.15562.20855

55

Item #

Qty

11

2

1

3

1

4

1

5

1

1

7

1

8

1

Body (W/ Tag & Plug)

Cap

Seat Disc

O-Ring

Needle

Spring6

Cover Seal

Adjusting Nut

Information needed to order repair parts:

Speed Controller Size

Limited One Year Warranty: Danfoss Flomatic valves are guaranteed against defects of material or workmanship

when used for the services recommended. If, in any recommended service a defect develops due to material or

workmanship, and the device is returned, freight prepaid, to Danfoss Flomatic within 12 months from date of purchase, it

will be repaired or replaced free of charge. Danfoss Flomatic’s liability shall be limited to our agreement to repair or

replacement of valve only.

Size

mm

inch

8

1/4

10

3/8

Stainless Steel

Buna-n

Teflon

Part #

MaterialDescription

Danfoss Flomatic

A

inch

mm

2.20

ASTM

316

316Stainless Steel

316Stainless Steel

----------

316Stainless Steel

316Stainless Steel

----------

316Stainless Steel

2.1556

562.20

B

Weight

lbs

.454

1

55

.454

1

552.15

kgmminch

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

FC20

Rev. 4

Loading...

Loading...