Flomatic 8080 Installation Manual

g

Backflow Preventer Installation Instructions

Model 8080 – ASSE 1024

FAILURE TO FOLLOW THESE INSTRUCTION WILL VOID ANY WARRANTY

The Danfoss Flomatic Model 8080 is designed to be installed down stream from the house wa ter meter where a

cross connection could result in pollution of potable water. This product is intended for use with copper or plastic

pipe only (do not use on steel pipe which is rated at a higher pressure rating). If a health hazard could result from a

cross connection, use a Flomatic RPZE Reduced Pressure Principle Backflow Preventer.

Installation Instructions:

1. Before installing the Model 8080, flush lines to

remove all sediment and foreign matter from the

line.

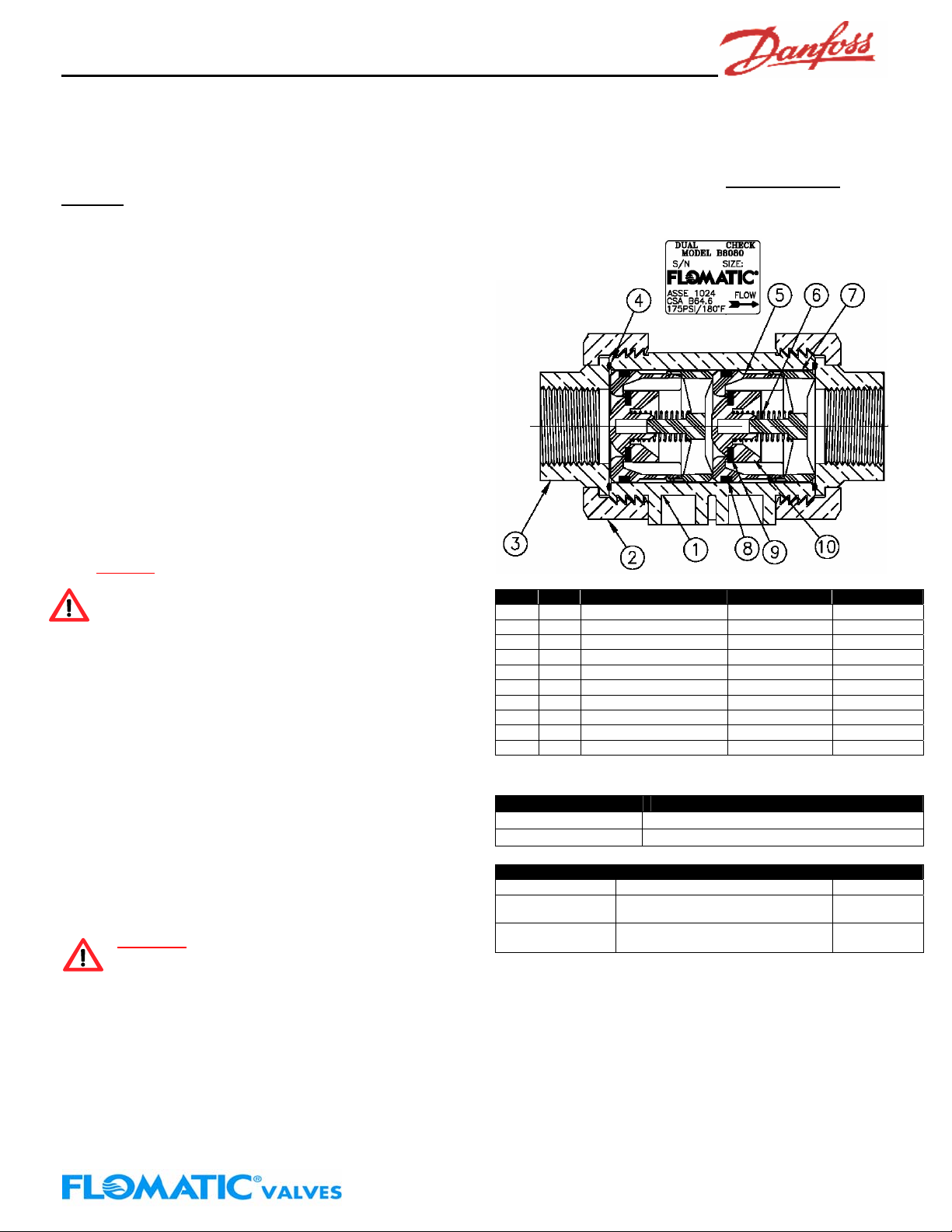

2. Plastic union nuts shall be hand tightened only.

Insure that “O”-rings (see #4 in figure) are properly

positioned before tightening union nuts.

DO NOT use tools as it will damage union nut.

3. Use only Teflon tape for sealing pipe threads.

DO NOT use Teflon tape or pipe sealant on union

nut threads.

4. DO NOT install in areas subject to freezing. Valve

will burst and cause severe damage to property

due to flooding.

5. A suitable strainer should be installed upstream of

the device when possible.

6. Caution:

As in any piping system, provisions

should be made to eliminate any water hammer

and thermal expansion as these conditions will

create damaging and dangerous high internal

pressures.

Maintenance:

Servicing the Model 8080 involves replacing the check

valve assemblies.

1) Turn off water supply and releif pressure in

system.

2) Open downstream fixture to relieve pressure to

valve.

3) After isolating backflow preventer, remove it

from line by loosening union nuts.

4) Remove check assemblies.

5) Clean inside of the valve body and replace

check assemblies in correct direction of fl ow.

Re-install the valve, hand tightening

union nuts.

Caution:

DO NOT USE TOOLS FOR

TIGHTENING UNION NUT. HAND

TIGTENING IS SUFFICIENT FOR SEAL.

1 Year Limited Warranty: Danfoss Flomatic valves are guaranteed against defects of materials or workmanship when

used for the services recommended. If in any recommended service, a defect develops due to material or workmanship,

and the device is returned, freight prepaid, to Danfoss Flomatic within 12 months from the date of purchase, it will be

repaired or replaced free of charge. Danfoss Flomatics’ liability shall be limited to our agreement to repair or replace the

valve only.

Item Qty Description Material ASTM

1 1 Valve Body NORYL® GFN2-780S

2 2 Tailpiece Union Nut Brass B16

3 2 Tailpiece Brass B16

4 2 Tailpiece O-Ring BUNA-N 5 2 Check Housing DELRIN® 6 2 Check Spring Stainless Steel 302

7 2 Check Spring Retainer DELRIN® 8 2 Check O-Ring BUNA-N 9 2 Check Disc SILICONE Grade 60

10 2 Check Poppet NORYL® GFN2-780S

NORYL® is a GE registered trademark & DELRN® is a DuPont registred

trademark.

Valve Size Part Number

¾” B8080

1” B8081

Repair Kit Description Part Nimber

Rubber Repair Kit 2 Valve seat discs-2 Union O-rings-

Major Repair Kit 2 Check Seats-2 Valve seat discs-

Repair Parts Kits

2 Seat O-rin

2Body O-Rings-2 Seat O-Rings

Danfoss Flomatic

B80RK00

s

89600PO

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

April 21,2004 Rev. F (7/08)

8080

Loading...

Loading...