Page 1

Backflow Preventer Specification Submittal Sheet

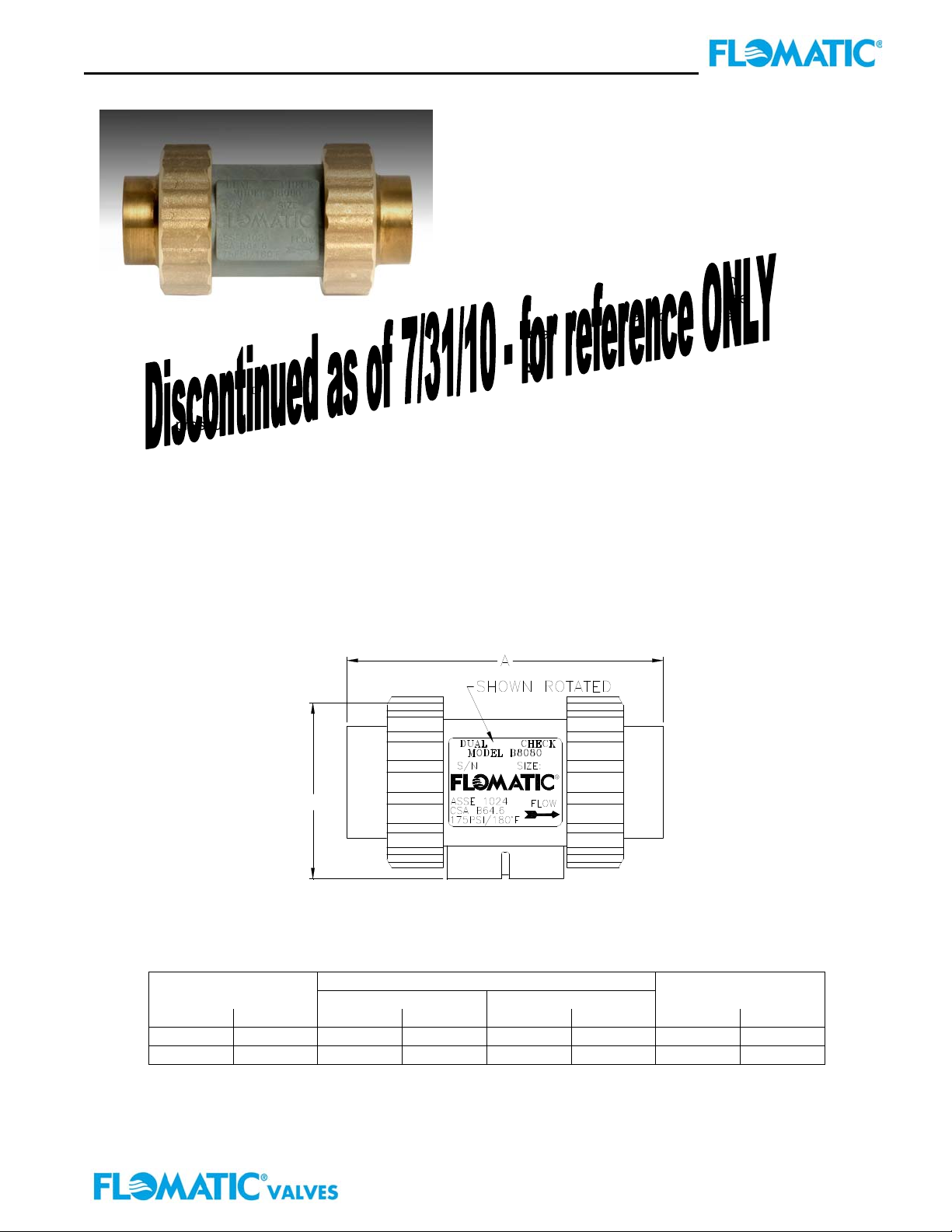

Models 8080

APPLICATION:

Designed for installation on potable water lines to

protect against both backsiphonage and backpressure

of polluted water into the potable water supply.

Assembly shall provide protection where a potential

health hazard does not exist. For use in indoor and

outdoor meter box as primary domestic water

protection. Lead free body and checks ensure safe

FEATURES:

Sizes: □¾” □1”

Max working pressure: 175psi

Max temperature: 180ºF

Connection: Threaded ANSI B 1.20.1

OPTIONS:

□ – Female NPT connection (standard)

□ FC – Female Copper Sweat

B

SIZE DIMENSIONS WEIGHT

A B

inch mm inch mm inch mm lbs kg

¾ 20 4-3/8 111 2-7/16 62 1 .5

1 25 4-3/8 111 2-7/16 62 1 .5

drinking water while providing maximum corrosion

resistance.

STANDARDS COMPLIANCE:

● ASSE

● CSA

MATERIALS:

Main valve body:

Elastomers:

Polymers: Delrin®, NSF Listed

Springs: Stainless Steel, 300 Series

Union End Nuts: Bass

®

Listed 1024

®

Listed B64.6

Flomatic Corporation

Noryl

Buna Nitrile (FDA approved)

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Novermber 29, 2004 Rev: 5 (6/11)

Specification Sheet 8080

Page 2

Backflow Preventer Specification Submittal Sheet

Models 8080E

i

a

s

P

p

k

10

69

S

S

O

L

E

R

U

S

S

E

R

P

41 6

855

428

214

5

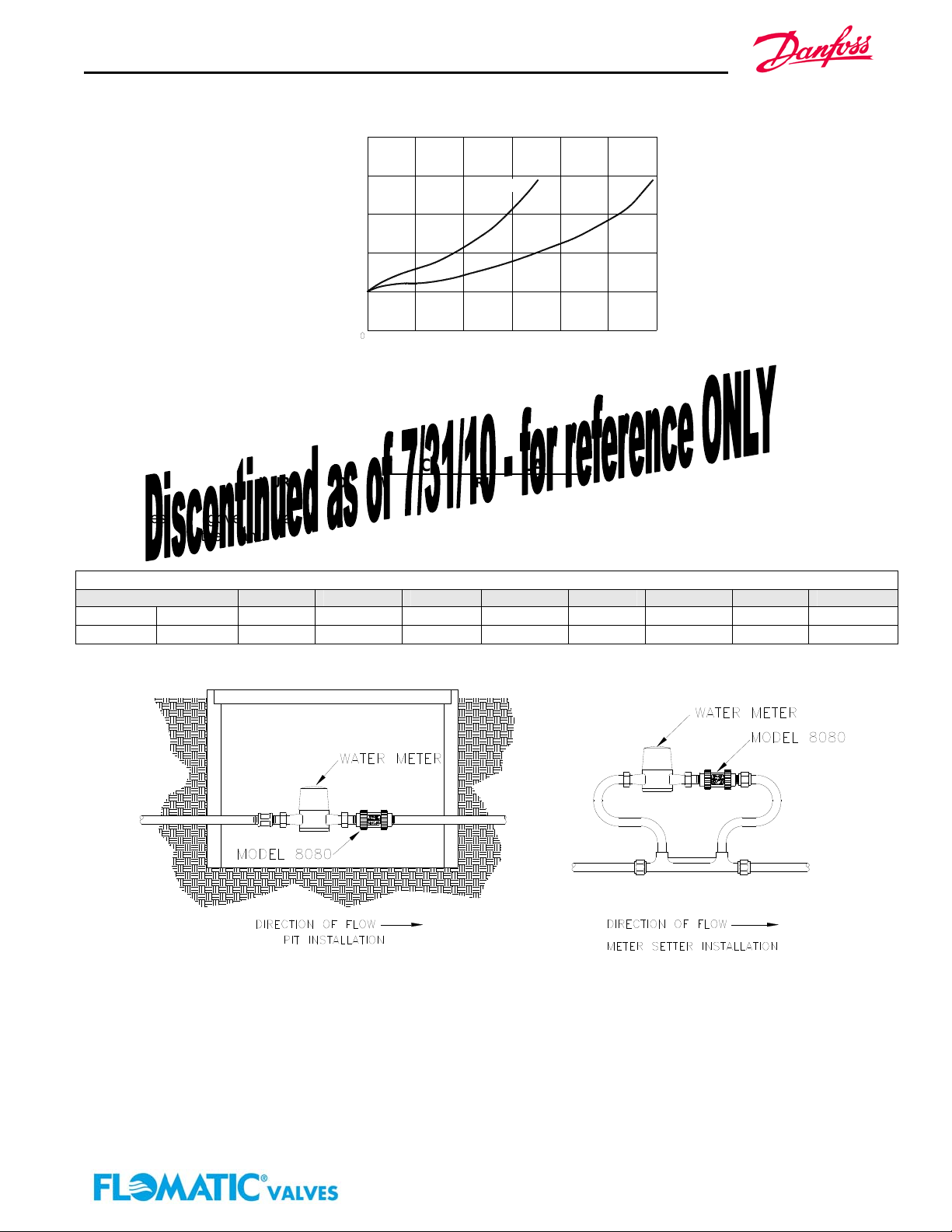

3/4" (20 mm)

1" (25 mm)

10 30 gpm20

.63 1.26 1.89 lps

15 25

.95

FLOW RATE

1.58.32

(Established by Approval Agencies)

▲ RATED FLOW

TYPICAL INSTALLATION:

FAILURE TO FOLLOW THESE INSTRUCTION WILL VOID ANY WARRANTY

Local codes shall govern installation requirements. Unless otherwise specified, the installation shall be in

accordance with the manufacturer’s instructions and the latest edition of the Uniform Plumbing Code. The

installation shall be made so that no part of the unit can be submerged.

Danfoss Flomatic

Capacity in GPM & liters per second (Schedule 40 Pipe)

Pipe Size

5 ft/sec

¾” 20 mm

1” 25 mm

8

13

1.5 M/sec

30

49

7.5 ft/sec

12

20

2.3 M/sec

45

75

10 ft/sec

17

27

3 M/sec

64

102

15 ft/sec

25

40

4.5 M/sec

94

151

SPECIFICATIONS:

The Dual Check Valve shall be ASSE® Listed 1024. The main body shall be Noryl, the check assemblies shall be

DELRIN®. The seal ring and o-rings shall be Buna Nitrile. The Dual Check Valve shall be a Flomatic Model 8080.

WARRANTY: Flomatic valves are guaranteed against defects of materials or workmanship when used for the services

recommended. If in any recommended service, a defect develops due to material or workmanship, and the device is returned,

freight prepaid, to Flomatic corporation within 12 months from the date of purchase, it will be repaired or replaced free of charge.

Flomatic Corporations’ liability shall be limited to our agreement to repair or replace the valve only.

Flomatic Corporation, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Novermber 29, 2004 Rev: 5 (6/11)

Specification Sheet 8080

Loading...

Loading...