Page 1

Swing Check Valves Installation Instructions

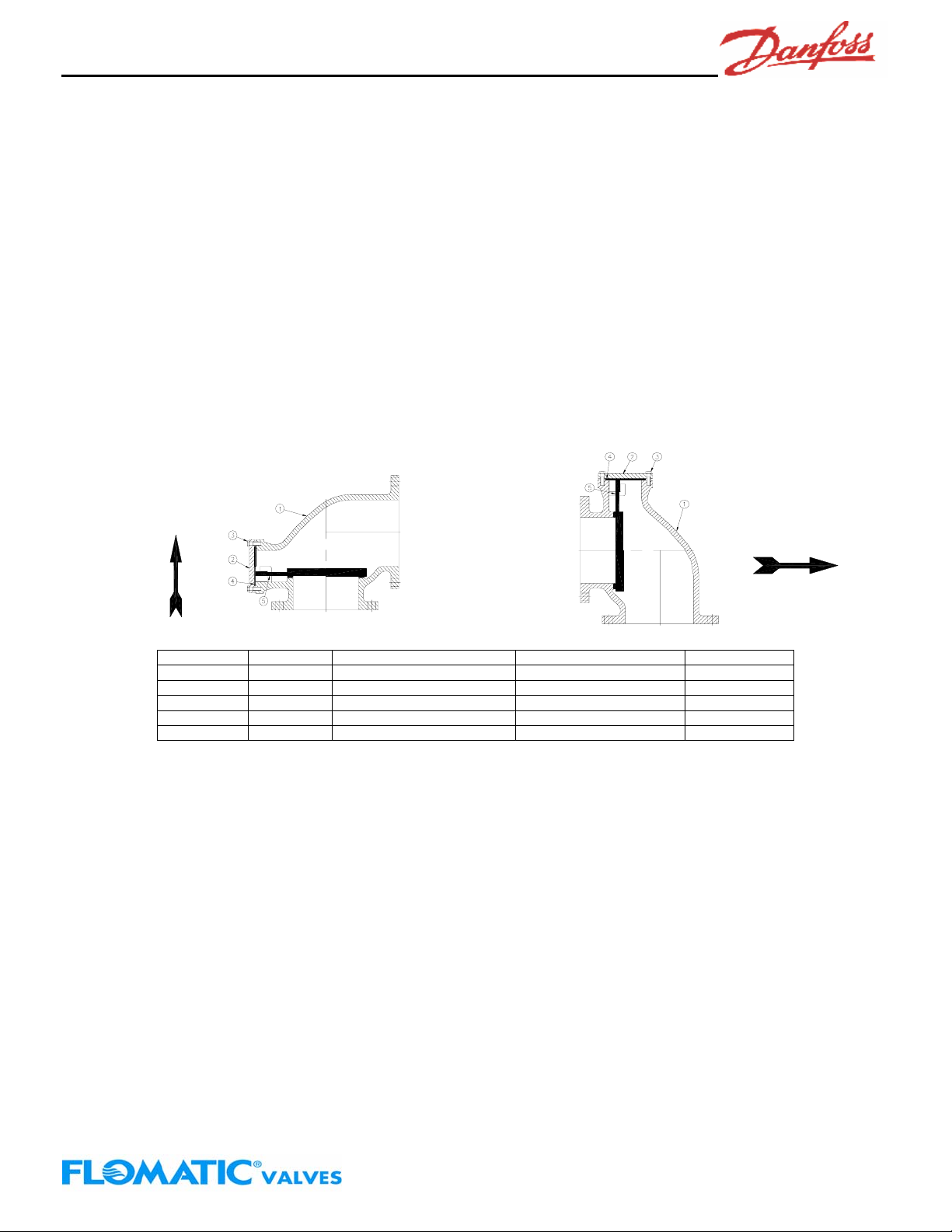

Models 78A

FAILURE TO FOLLOW THESE INSTRUCTION WILL VOID ANY WARRANTY

Description: Check valves shall be of swing check flapper type and meet materials requirements of AWWA C508.

Operation: Model 78A is a unique flapper style Swing Check with same dimensions as a standard ANSI 90° elbow that

permits flow in one direction only and is tight seated when the outlet pressure exceeds the inlet pressure.

Shipment: Model 78A is shipped as a complete pre-tested valve. Disassembling the unit will void the product warranty.

Installation:

1. Check inside the valve to be sure that any materials used in shipping are removed. Check for any foreign

material that should not be inside the valve and remove.

2. Check the operation of the flapper by pushing it away from the seating surface to be sure it moves freely.

3. Inspect the flange ends to be sure there are no raised burrs or edges that would cause them to not seal

properly.

4. Install the valve with the flow arrow in the direction of flow.

5. The 78A has the same flange to flange dimensions as a standard ANSI 90° elbow.

6. The valve can be installed in a vertical or horizontal position.

Maintenance: The Model 78A swing check does not require any regular maintenance.

Service / Repair: Disassembly of the valve may be required due to debris obstructing the valves ability to operate

correctly or for inspecting the valve for wear.

NOTE: BEFORE ATTEMPTING TO DISASSEMBLE THE VALVE BE SURE PUMP IS LOCKED OFF AND SYSTEM

PRESSURE IS RELIEVED AND ISOLATED FROM VALVE.

1. Loosen and remove cover bolts and remove the valve cover.

2. Remove the gasket and flapper from the valve.

3. Clean and inspect the flapper for damage and/or debris.

4. Examine the seat area for damage.

5. Reassemble valve with new or existing parts as needed.

6. Put valve back in operating service.

7. Inspect valve for any cover and end connection leaks.

1 Year Limited Warranty: Danfoss Flomatic valves are guaranteed against defects of materials or workmanship when used for the

services recommended. If in any recommended service, a defect develops due to material or workmanship, and the device is

returned, freight prepaid, to Danfoss Flomatic within 12 months from the date of purchase, it will be repaired or replaced free of

charge. Danfoss Flomatics’ liability shall be limited to our agreement to repair or replace the valve only.

FLOW

ITEM QTY DESCRIPTION MATERIAL ASTM

1 1 Body (Epoxy Coated) Cast Iron A126

2 1 Cover (Epoxy Coated) Cast Iron A126

3 A/R Cover Bolts Stainless Steel 18-8

4 1 Cover Gasket Buna-n -----5 1 Flapper Rubber ------

Danfoss Flomatic

FLOW

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

December 23, 2007 Rev. B

78A 3-14

Loading...

Loading...