Page 1

Swing Check Valves Installation Instructions

Models 745 Indicator Rod

FAILURE TO FOLLOW THESE INSTRUCTION WILL VOID ANY WARRANTY

CAUTION: Installation of Model 745 must be performed by qualified, licensed personnel. Faulty installation

could result in an improperly functioning device.

Proper performance depends upon following these installation instructions and prevailing governmental and

industry standards and codes. Failure to do so release’s Danfoss Flomatic of any liability that it might

otherwise have with respect to that device. NOTICE: Annual inspection and maintenance is required of all

plumbing system components. To ensure proper performance and maximum life, this product must be

subject to regular inspection, testing, adjustment and cleaning.

1. Remove line pressure and drain valve.

2. Remove pipe plug from cover.

3. Install Mounting Nut

IMPORTANT: The mounting nut must be oriented with wrench flats parallel to pipeline and

with angled threaded hole perpendicular to swing check valve flapper. This is required to

insure proper orientation of position indicator assembly to flapper for correct operation.

4. Install assembled position indicator with Teflon tape in mounting nut by inserting the shaft end with

ball through the threaded hole in mounting nut and tighten.

5. Adjust position indicator using the following sequence:

a) Remove Sight Housing

removing it from Indicator Nut

b) Remove Spring

c) Loosen Nut

d) Back off Spring Seat

e) The position of Sight Base

should be approximately a 3/8” gap between the Sight Base

f) Insure that the check valve flapper is in the fully closed position and manually push

Indicator Rod

g) Adjust Spring Seat (4) to a position approximately in the middle of threaded section of

Indicator Rod (13).

NOTE: spring seat should not contact the top of the sight base as this will limit travel in

the closed direction.

h) Tighten Nut

i) Reinstall Spring

j) Reinstall Sight Housing

turning it into Indicator Nut

6. Verify function of position indicator by manually opening the check valve flapper. The indicator rod

and contact should move up in the assembly and must return with the check valve flapper when

released. If the indicator rod and contact ball do not return and make contact with the check valve

flapper, the Spring Seat (4) should be adjusted up to increase spring compression.

NOTE: Packing compression adjustment affects operation of the indicator rod. It may be

necessary to readjust the spring tension after initial operation and adjustment of the

packing, as the assembly will move more freely once the packing glands are seated.

(10), with Teflon tape into cover.

(1) from Sight Base (6). Hold sight base with a wrench to avoid

(7).

(2).

(3) and back off.

(4).

(6) controls compression of the Packing (9). Initially there

(6) and Indicator Nut (7).

(13) down until Contact Ball (14) firmly contacts check valve flapper.

(3) against Spring Seat (4) to lock in position.

(2).

(1) onto Sight Base (6). Hold sight base with a wrench to avoid

(7) and changing the packing compression.

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

Danfoss Flomatic

May 12,2004 Rev. A

745_indicator

Page 2

Swing Check Valves Installation Instructions

Models 745 Indicator Rod

Danfoss Flomatic

1 Year Limited Warranty: Danfoss Flomatic valves are guaranteed against defects of materials or workmanship when used for the

services recommended. If in any recommended service, a defect develops due to material or workmanship, and the device is

returned, freight prepaid, to Danfoss Flomatic within 12 months from the date of purchase, it will be repaired or replaced free of

charge. Danfoss Flomatics’ liability shall be limited to our agreement to repair or replace the valve only.

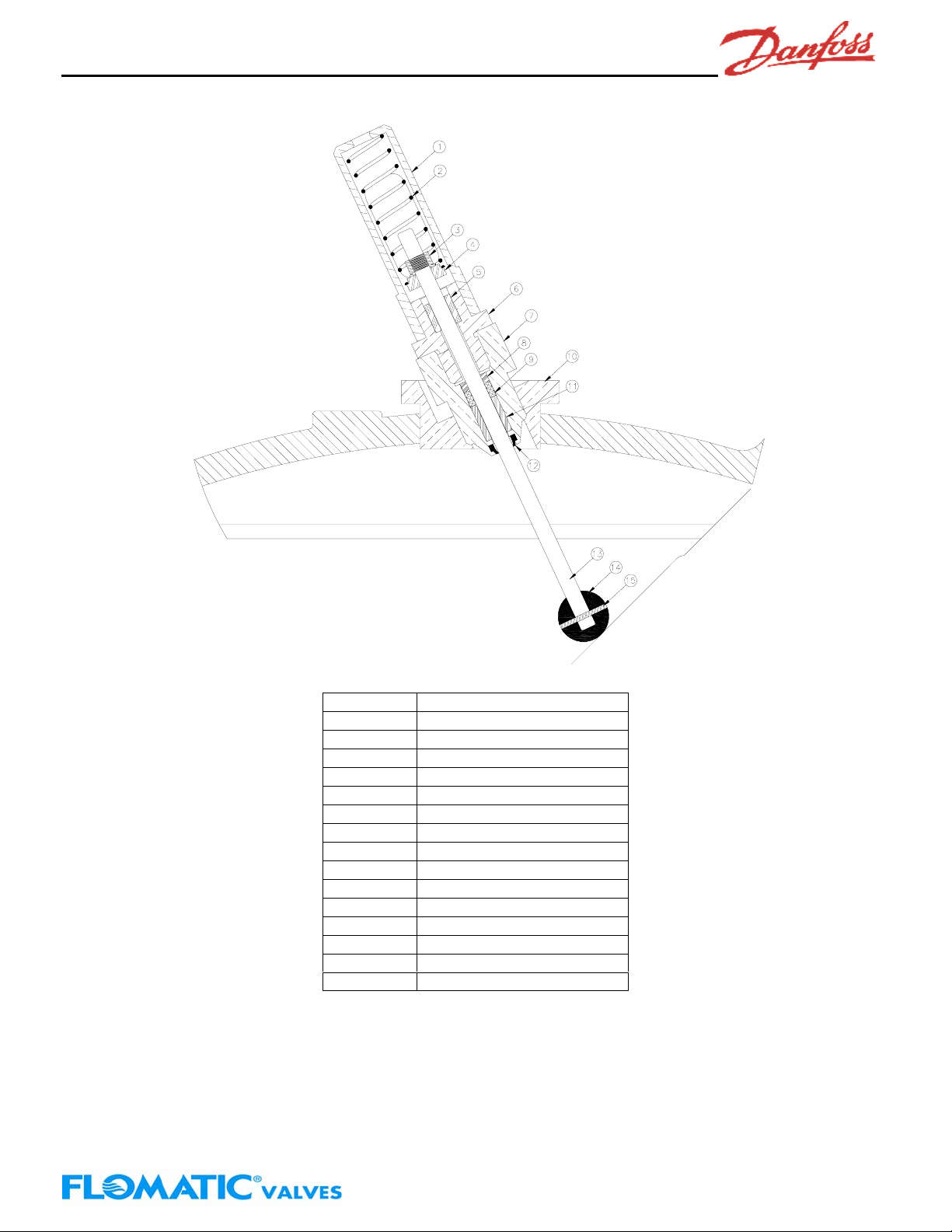

Item Description

1 Sight Housing

2 Spring

3 Nut/Washer

4 Spring Seat

5 Top Busing

6 Sight Base

7 Indicator Nut

8 Gland Bushing

9 Packing

10 Mounting Nut

11 Bottom Bushing

12 Rod Wiper

13 Rod

14 Contact Ball

15 Pin

Danfoss Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

May 12,2004 Rev. A

745_indicator

Loading...

Loading...