Page 1

Subject: Using the Flomatic Valve with Gauges

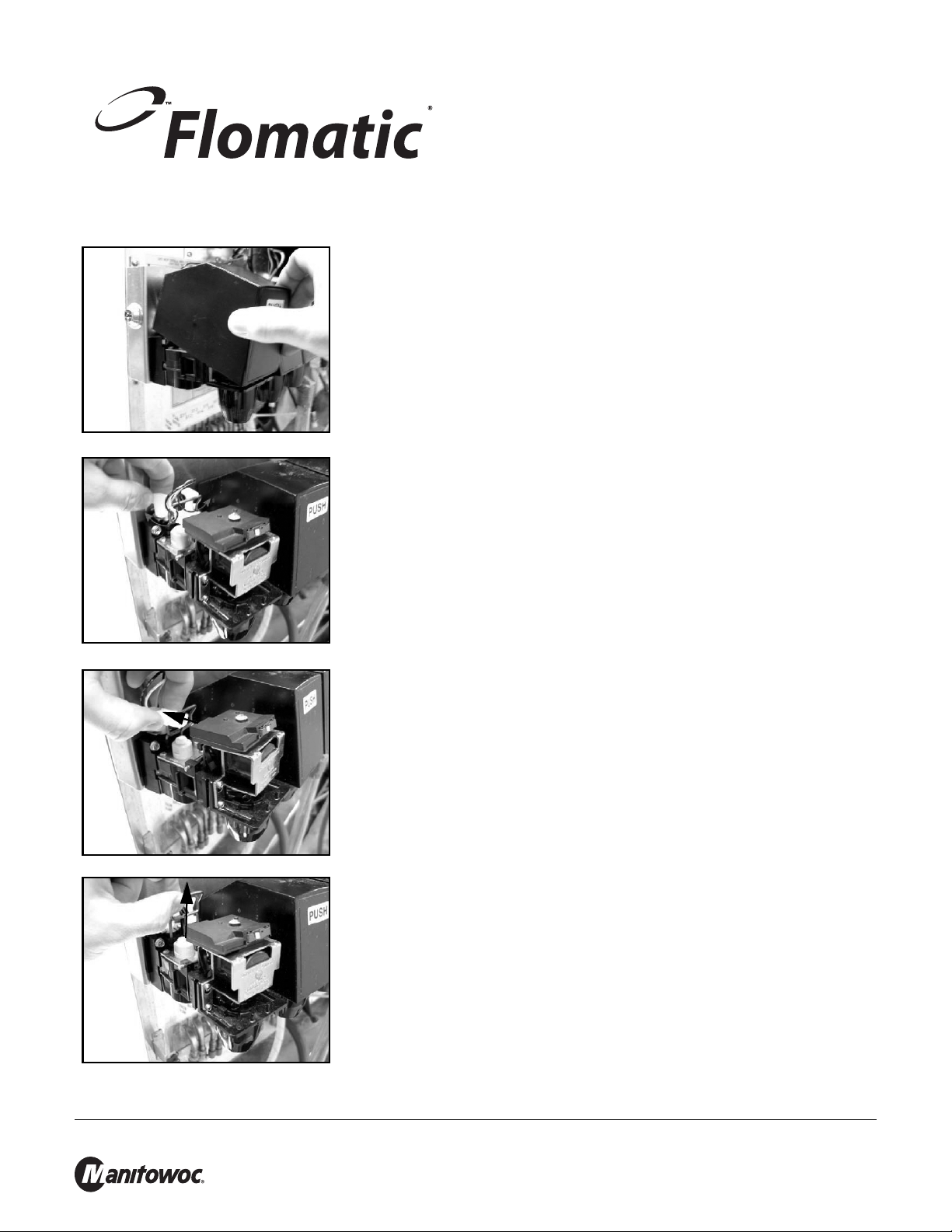

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

The Flomatic V alve with Gauges is designed to provide a trouble-shootin g device to

determine whether or not you have adequate water and syru p pressures entering a

beverage dispensing valve. Please follow the steps below for installing, and using

the Flomatic Valve with Gauges. If you have any questions about the functionality of

the valve, or how to install the valve please contact the Service Dep artment at

Manitowoc Beverage Systems, 1-800-367-4233.

Steps for using the Flomatic Valve with Gauges:

1. Remove the cover from the valve at location where incoming water & syrup

pressures need to be tested. (Figure 1)

2. Turn both shutoffs on valve back block to the of f position. (Figure 2)

5029717

1/11

Instructions

3. Press dispense switch on valve to release pressure in valve and to assure both

water and syrup are shut off at back block.

4. Disconnect the 24v low voltage connector from the valve solenoid. (Figure 3)

5. Pull latch pin up to release valve from back block. (Figure 4)

Manitowoc Foodservice Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

Page 2

Using the Flomatic Valve with Gauges 5029717 1/11

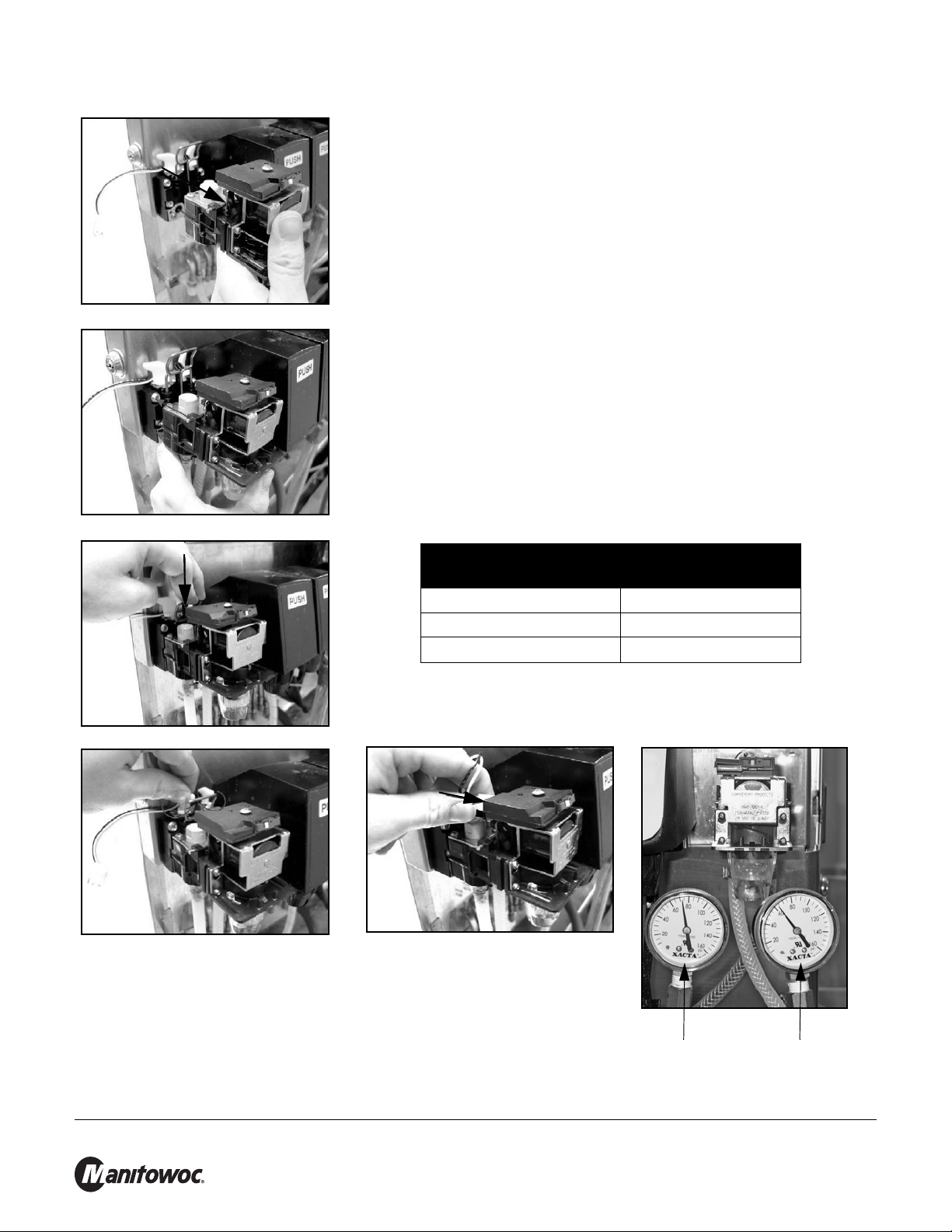

FIGURE 5

FIGURE 6

FIGURE 7

FIGURE 8

6. Remove the valve from unit by pulling the valve away from dispenser . (Figure 5)

7. Install the Flomatic V alve with Gauges on dispenser by lining the valve stems

up with back block and pushing into place. (Figure 6)

8. Push the latch pin down to secure valve into place. (Figure 7)

9. Turn both back block shutof f valves to the on position. (Figure 8)

10. Plug the 24v low voltage connector into the solenoid of the Flo matic V alve with

Gauges. (Figure 9)

1 1. Now the gauge s on the valve should be reading the S t atic pressure on the

valve. (Figure 10) Note: The gauge on the left side of the valve is r eading water

pressure, and the gauge on the right side of the valve is reading syrup

pressure.

12. Next read the Dynamic Pressure by monitoring the gauges while activating the

valve. The pressure each gauge reads when dispensing a beverage is the

Dynamic Pressure of the fluid being applied to the valve. Dynamic pressure

tells you how much pressure you have to a valve under a specific load. See the

chart below for minimum and maximum dynamic pressures for Flomatic

valves.

13. When finished using Flomatic valve with gauges for testing water and syrup

pressures, replace the original beverage valve by following steps 1-10 in

reverse order.

MINIMUM DYNAMIC PRESSURES

FOR FLOMATIC VALVES

Flomatic Valve Type Minimum Pressure

424 20 psi

464 20 psi

FIGURE 9

WATER

Manitowoc Foodservice Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

PRESSURE

GAUGE

FIGURE 10

SYRUP

PRESSURE

GAUGE

Loading...

Loading...