Page 1

Ward Strainer Installation Instructions

Model 16 & 16FL

EXCESSIVE HEAT WILL HARM SEAT

CAUTION:

It is the installers and/or system designers responsibility to insure that theses valves are installed in

accordance with applicable and current ANSI standards.

INSTALLATION:

FAILURE TO FOLLOW THESE INSTRUCTION WILL VOID ANY WARRANTY

1. Ward strainer are designed to be installed at any angle.

2. Remove cap, screen and gasket.

3. Before attempting to install (weld) the valve, put on proper clothing, gloves and eye protection.

4. After valve has cooled, install screen and new gasket (supplied) per installation instructions listed above.

5. Tighten cap to torque specified in table above.

6. Pressure and temperature rating of strainer shall not be exceeded.

MAINTENANCE:

1. Ward strainers are designed to be virtually maintenance free.

2. If a problem should arise, do not disassemble the strainer while the line is under pressure.

3. Repair kits are available should the screen need replacing.

FREEZING:

1. Provide means to protect the strainer from freezing and bursting when used with liquids.

FLUID COMPATIBILITY:

1. Consider the corrosive, erosive and adhesive effects of fluids on the strainer and piping components. It is

your responsibility to insure that the strainer is compatible with the material(s) used in the system.

Repair Kit Installation Instructions

Valve Size (in) Kit Part Number Cap Torque (ft/lbs)

¼, ⅜ & ½ CV24-000-06 30

¾ CV24-000-07 38

1 CV24-000-08 45

1-¼ CV24-000-09 50

1-½ CV24-000-09 55

2 CV24-000-11 60

Replace 000 (in Kit Part Number) with screen mesh size 020, 040, 060, 080 or 100

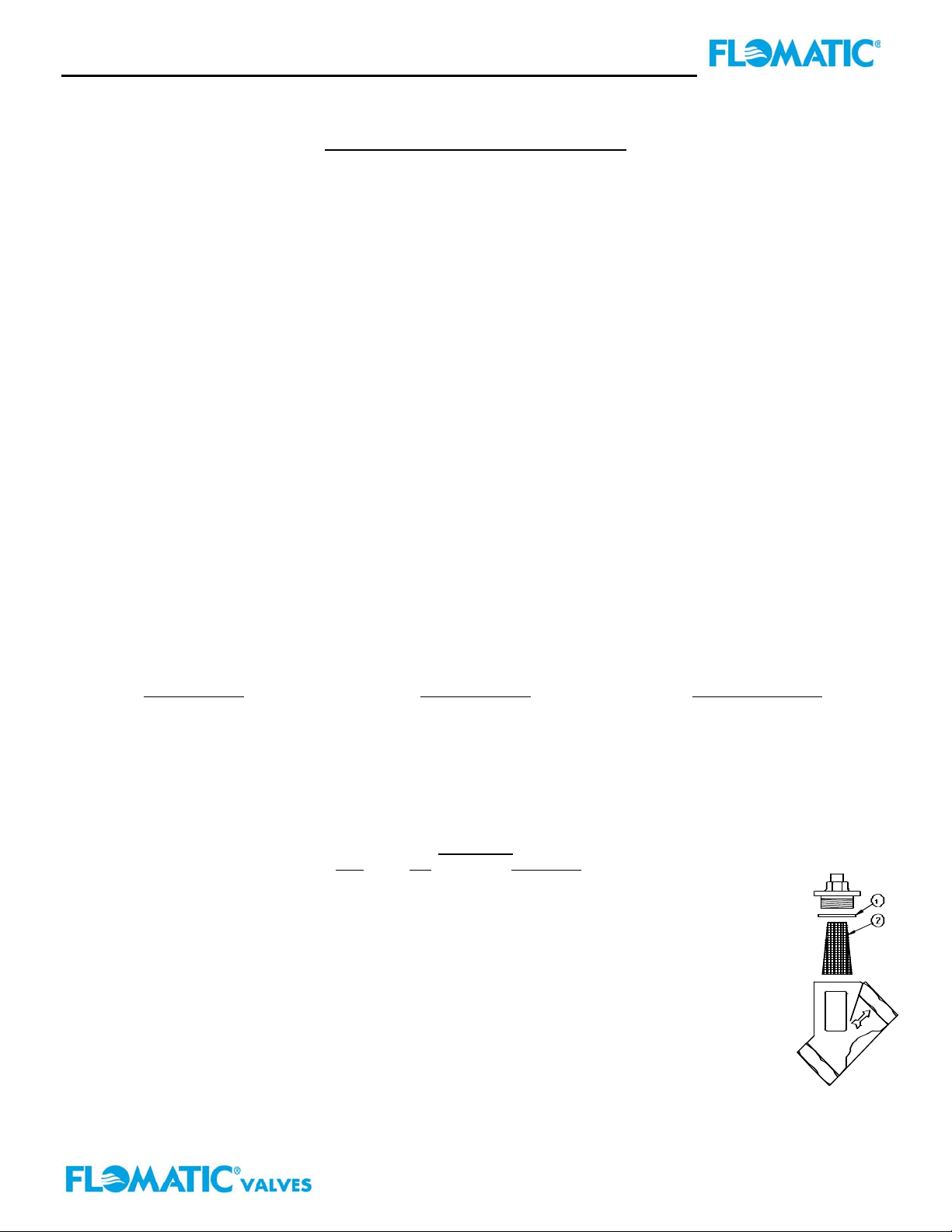

Kit Contains

Item

Qty Description

1 1 Gasket

2 1 Screen

Procedure:

1. Before attempting to repair the strainer, put on proper clothing, gloves and eye protection.

2. Completely drain system of all fluids and/or pressure.

3. Remove cap, screen and gasket.

4. Thoroughly clean body cavity area, strainer seat and cap. Install screen (TAPER END IN

CAP SEE PICTURE) and gasket. Refer to figure above.

5. Screw in cap slowly to insure proper alignment of the screen.

6. Tighten cap to torque specified in table above.

Flomatic Corporation

Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

February 19, 2002 Rev: D

Cv30-000-03

Page 2

Ward Strainer Installation Instructions

Model 16 & 16FL

EXCESSIVE HEAT WILL HARM SEAT

CAUTION:

It is the installers and/or system designers responsibility to insure that theses valves are installed in

accordance with applicable and current ANSI standards.

INSTALLATION:

FAILURE TO FOLLOW THESE INSTRUCTION WILL VOID ANY WARRANTY

1. Ward strainer are designed to be installed at any angle.

2. Remove cap, screen and gasket.

3. Before attempting to install (weld) the valve, put on proper clothing, gloves and eye protection.

4. After valve has cooled, install screen and new gasket (supplied) per installation instructions listed above.

5. Tighten cap to torque specified in table above.

6. Pressure and temperature rating of strainer shall not be exceeded.

MAINTENANCE:

1. Ward strainers are designed to be virtually maintenance free.

2. If a problem should arise, do not disassemble the strainer while the line is under pressure.

3. Repair kits are available should the screen need replacing.

FREEZING:

1. Provide means to protect the strainer from freezing and bursting when used with liquids.

FLUID COMPATIBILITY:

1. Consider the corrosive, erosive and adhesive effects of fluids on the strainer and piping components. It is

your responsibility to insure that the strainer is compatible with the material(s) used in the system.

Repair Kit Installation Instructions

Valve Size (in) Kit Part Number Cap Torque (ft/lbs)

¼, ⅜ & ½ CV24-000-06 30

¾ CV24-000-07 38

1 CV24-000-08 45

1-¼ CV24-000-09 50

1-½ CV24-000-09 55

2 CV24-000-11 60

Replace 000 (in Kit Part Number) with screen mesh size 020, 040, 060, 080 or 100

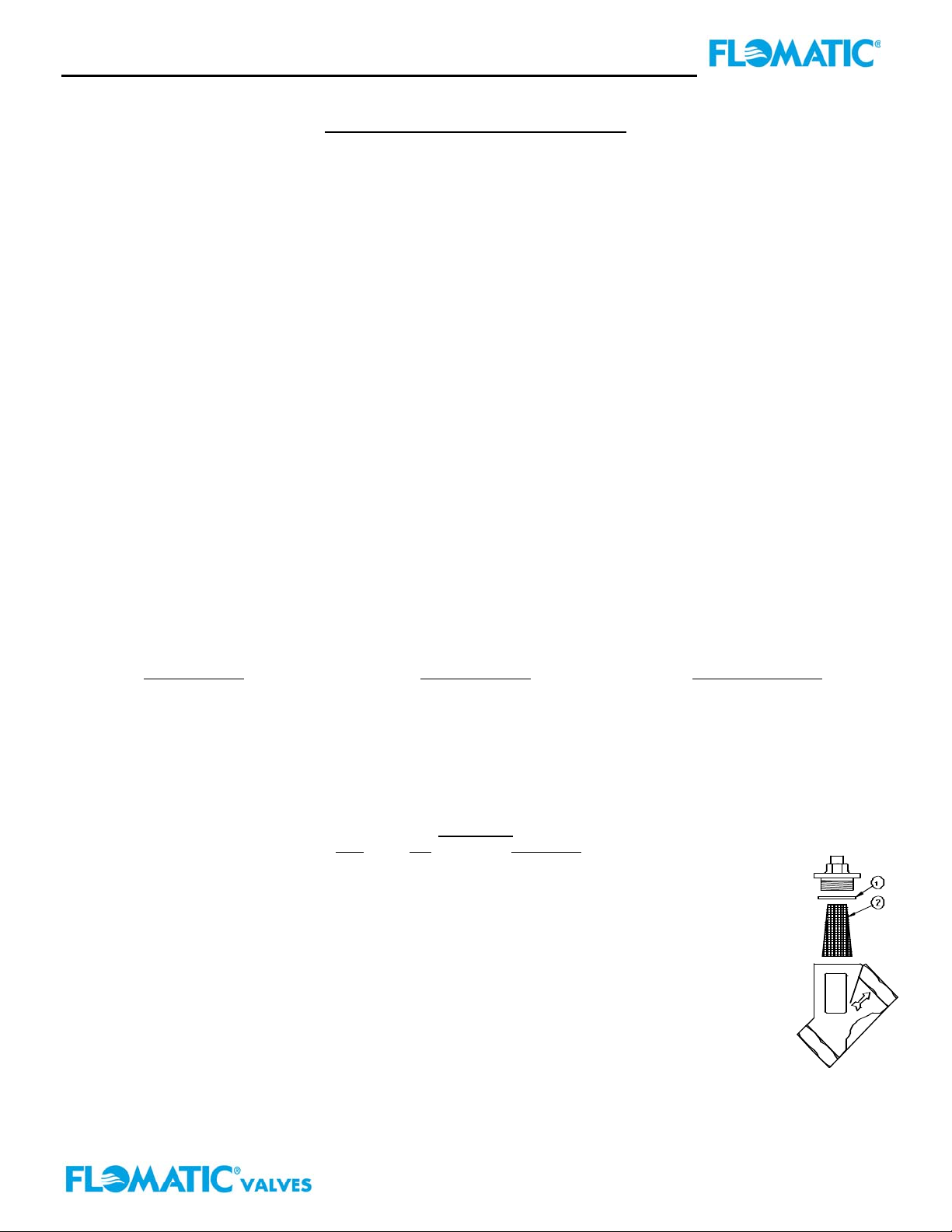

Kit Contains

Qty Description

Item

1 1 Gasket

2 1 Screen

Procedure:

1. Before attempting to repair the strainer, put on proper clothing, gloves and eye protection.

2. Completely drain system of all fluids and/or pressure.

3. Remove cap, screen and gasket.

4. Thoroughly clean body cavity area, strainer seat and cap. Install screen (TAPER END IN

CAP SEE PICTURE) and gasket. Refer to figure above.

5. Screw in cap slowly to insure proper alignment of the screen.

6. Tighten cap to torque specified in table above.

Flomatic Corporation

Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

February 19, 2002 Rev: D

Cv30-000-03

Loading...

Loading...