Page 1

FLOMAG s.r.o.

V Aleji 180/20a

CZ-620 00 Brno

Czech Republic

tel: +420 541212539

fax: +420 549240356

e-mail: info@flomag.com

www.flomag.com

Magnetic Flowmeter

FLOMAG

®

3000

Installation and Operation

Page 2

FLOMAG 3000 -

Installation and Operation Manual

2

Page 3

FLOMAG 3000 -

Installation and Operation Manual

3

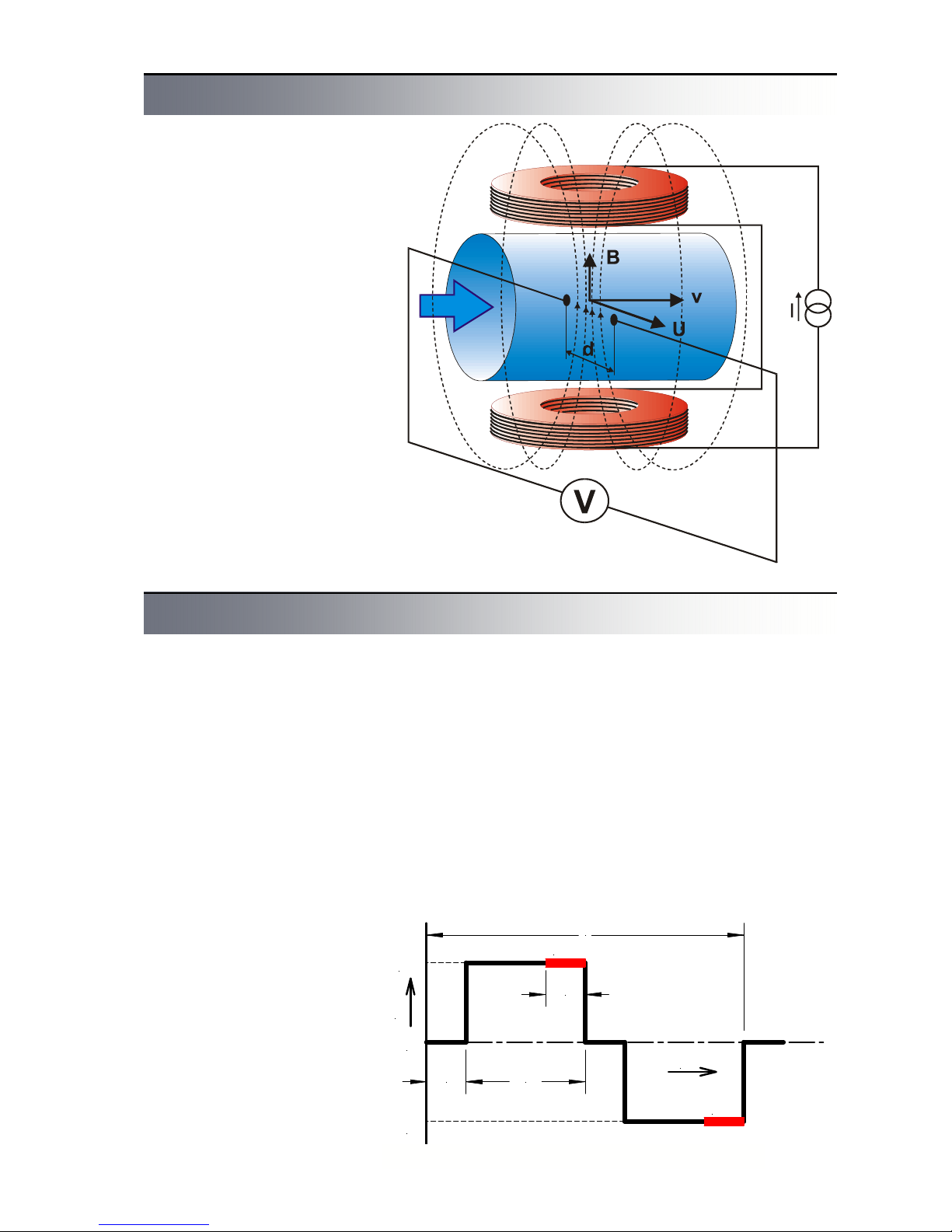

An magnetic flowmeter is used

for volume flow measurement of

electrically conductive liquids.

Measurement principle is based

on Faraday law on electromagnetic induction. A sensor consists of a non-magnetic tube

with non-conductive lining,

measuring electrodes and two

coils generating electromagnetic field. Flowing liquid forms

a conductor. Magnetic field induces voltage U in this conductor that is proportional to magnetic induction B, distance between electrodes d and flow

velocity v.

U = B x d x v

As magnetic induction and distance between electrodes are

constant, induced voltage is

proportional to velocity of liquid

flow in the tube. Volume flow

rate is product of flow velocity

and tube cross section.

Q = v x S

Fig.1 - Principle of measurement

Principle of measurement

Technical solution

The magnetic flowmeter itself

consists of two basic parts – a

flow sensor and a converter.

The converter can be either an

integral part of the sensor

(compact version) or separated,

connected with the sensor using a cable (remote version).

The sensor consists of a nonmagnetic tube with nonconductive lining, measuring

electrodes, excitation coils and

cables. There are various sensor versions available enabling

connection to adjacent tubes

with flanges (type P) and fittings

(gas fitting type G or food industry fitting type V) or wafer which

are installed between flanges

using clamps (type B). Nonconductive lining can be made

of technical rubber (types TG,

MG or NG) or Teflon (type T).

The converter is used for generating excitation current in coils,

processing of signal from measuring electrodes, displaying of

measured data and generating

output signals. Current in excitation coils has constant value

250 mA or 125 mA and is pulse

generated with alternating polarity to avoid permanent magnetization of the sensor. Excitation pulse frequency can be

chosen from six values – 25 Hz,

12,5 Hz, 8,33 Hz, 6,25 Hz,

3,125 Hz and 1,56 Hz. Excitation current of 250 mA with excitation frequency 3,125 Hz is

suitable for all standard applications. Other settings can be

used for specific applications.

Excitation current and frequency are factory set before

sensor calibration and their later

modifications are not allowed.

Voltage induced in measuring

electrodes is measured always

on the end of excitation pulse

when magnetic field is steady.

Each excitation pulse is followed by refreshing period. Signal processing and parameter

setting are performed digitally

and the converter contains no

setting controls or other moving

parts what ensures its high reliability and long-term stability.

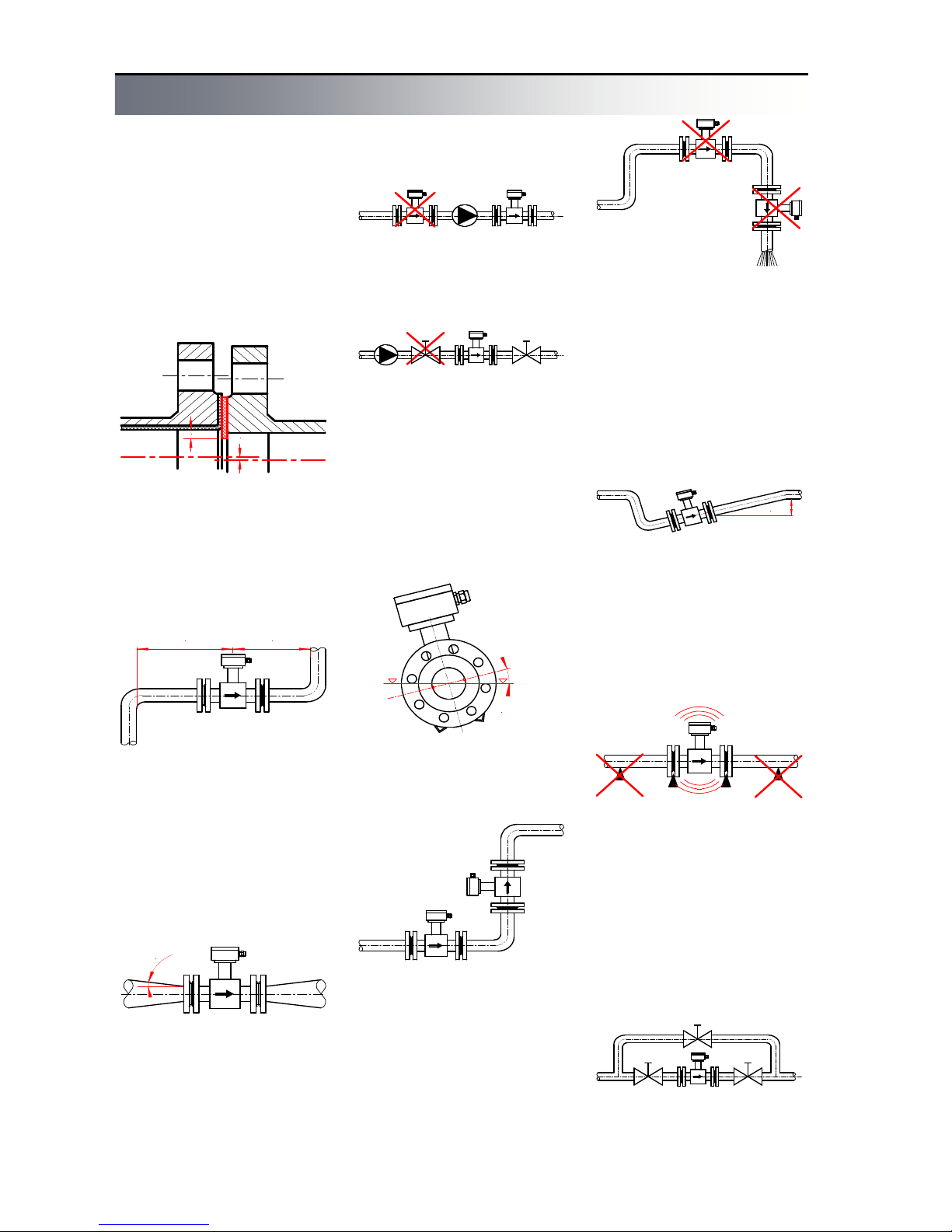

T

t

I

+I

-I

m

m

1/8T 3/8T

1/8T

0

Fig. 2 - Excitation pulse form

Page 4

FLOMAG 3000 -

Installation and Operation Manual

4

min 5 x DN min 3 x DN

The flowmeter will give the best

results when flow of liquid is

steady. Therefore a few basic

recommendations should be

observed for its locating in a

pipeline. There should be no

transitions between the sensor

and the adjacent pipeline that

could be a source of turbulence.

Correct axial alignment should

be observed during installation.

A gasket should not exceed

internal edges of tubes.

If more interfering elements are

present near the sensor (e.g.

bends, fittings), required steady

length should be multiplied by

number of these interfering elements.

Reductions with slopes up to 8°

can be included in steady

lengths.

x

x

Minimum straight steady

lengths of pipeline are required

on both sides of the flow sensor. Their lengths have to be

proportional to pipeline internal

diameter.

Fig. 3 - Overlaps

Fig.4 - Steady lengths

8

°

m

a

x

m

a

x

4

5

°

min 2 x DN

Fig.5 - Reduction

If water in the pipeline is

pumped by a water pump, the

sensor should be always located behind the pump to avoid

low pressure that can damage

the sensor. Steady length of at

least 25DN is required between

the pump and the sensor.

Fig. 6 - A water pump

For the same reason, never

locate stop valves behind the

sensor.

Fig. 7 - Stop valves

The sensor can work both in

horizontal and vertical positions;

only axis of measuring electrodes inside the sensor must

always remain in horizontal position and tapping of the sensor

should be directed upwards at

horizontal installations.

Fig. 8 - Electrode axis

For vertical installations, liquid

should flow upwards.

Fig. 9 - Vertical installation

To ensure correct measurement

and to avoid air lock, whole

sensor cross section should be

flooded. Therefore never locate

the sensor in upper parts of the

pipeline or in vertical positions

with liquid flowing downwards.

Fig.10 - Danger of air lock

If permanent flooding of whole

pipeline cross section cannot be

ensured, it is possible to locate

the sensor in a low water trap

so that it can be always completely flooded. Free water discharge should be located 2DN

higher than the sensor.

Fig.11 - Permanent flooding

To avoid vibrations that could

damage the sensor, ensure that

the adjacent pipeline is always

supported as near to the sensor

as possible.

Fig.12 - Danger of vibrations

Where continuous flow of fluid

is required and removal of the

sensor is impossible, a bypass

should be installed. The same

applies for locations where sensor removal would require

draining of too long part of the

pipeline.

Fig. 13 - A bypass

Installation instructions

Page 5

FLOMAG 3000 -

Installation and Operation Manual

5

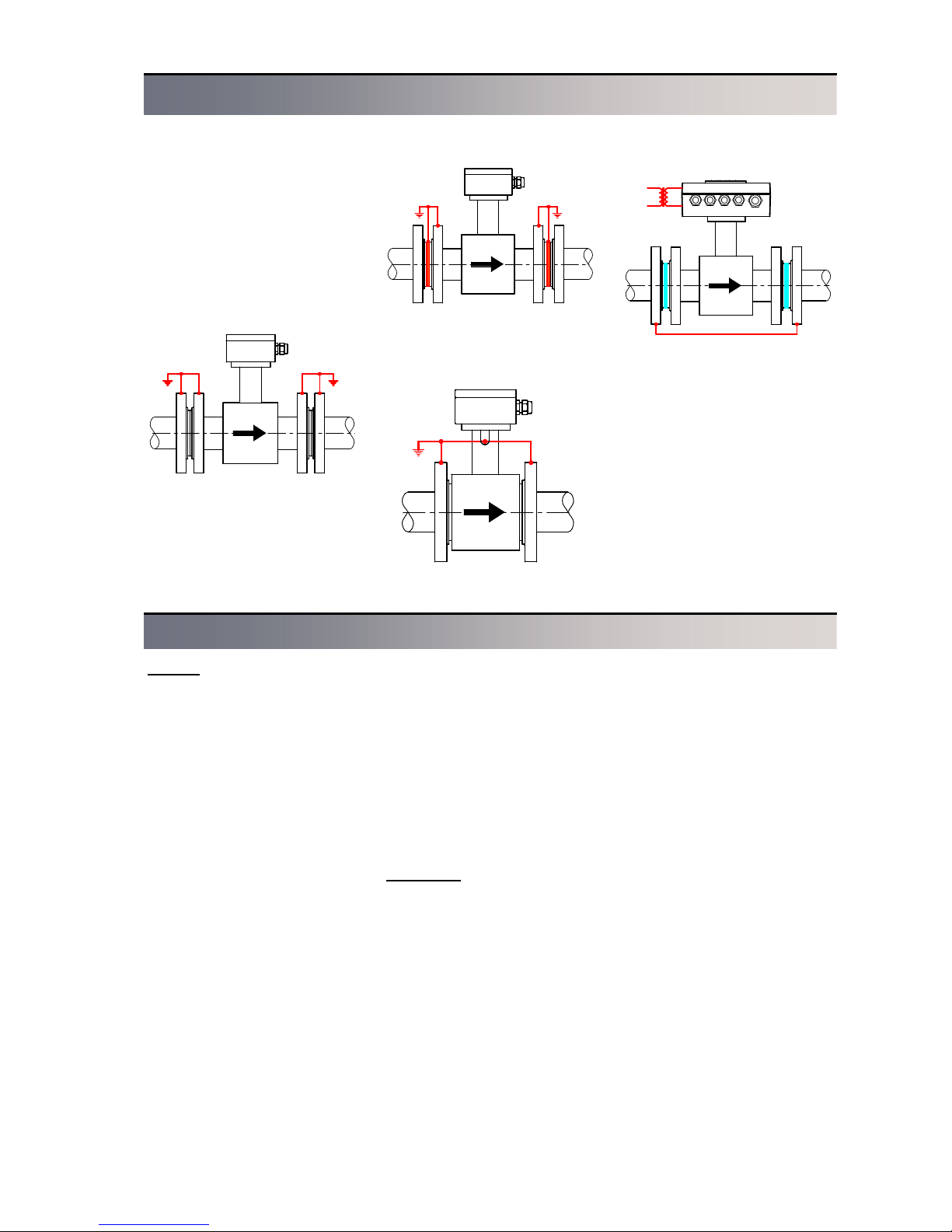

Correct function of the magnetic

flowmeter requires perfect electrical connection between the

sensor and the adjacent pipeline, grounding potential and the

power supply protective wire.

For the flanged sensor with the

adjacent conducting pipeline,

flanges should be electrically

connected and the pipeline

grounded.

If the adjacent pipeline is

non-conductive, grounding rings

should be inserted in it or

equivalent method should be

Fig.16: Grounding rings

Fig.17. The wafer sensor

Fig.18: Cathodic protection

Fig.15: Grounding of flanges

connection of sensor clamping

flanges with grounding point of

the sensor.

If electric current flows through

the pipeline, e.g. for pipeline

cathodic protection against corrosion, the sensor should be

electrically isolated from the

adjacent pipeline. The sensor

should be bridged over using a

wire and galvanic isolation of

the flowmeter power supply

should be provided so that the

flowmeter can be isolated from

all other devices.

Sensor grounding

Selection of suitable sensor lining and electrode material

Linings

Sensors have a non-conductive

lining from various materials.

Choice of material depends on

measured fluid characteristics.

· Technical rubber

Technical rubber is suitable for

low aggressive fluids with operational temperatures from 0.1

°C to 70 °C. It fits for most water management and sewage

treatment applications. It is

manufactured in two variants

“TG” – with hard structure and

“MG” – with soft structure. Soft

structure is used for fluids with

higher content of abrasive particles (e.g. sand). It is not suitable for drinking water.

· Resistant rubber

Type “NG” is suitable for medium aggressive fluids with operational temperatures from 0.1

°C to 90 °C. It can be used for

measurement of hot service

water, condensate etc., as well

as for drinking water. If tem-

perature 100 °C can be exceeded, Teflon (PTFE) lining is

recommended.

· Teflone or Hallar

Type “T” is the most universal

lining for aggressive fluids with

operational temperatures from 20 °C to 150 °C. It is suitable for

chemical and food industry applications.

Electrodes

Choice of material of measuring

electrodes also depends on

measured fluid characteristics.

· Stainless steel – “Ss”

Standard electrodes are made

of stainless steel AISI 316Ti.

They are suitable for all usual

water based fluids and for lower

concentrations of acids and

caustics.

· Hastelloy C-22 – “Ha”

For some special applications,

material of higher quality should

be used. Hastelloy C-276 elec-

trodes are characterized by increased resistance against acids and caustics and usually are

suitable for most of industrial

applications.

· Titanium - „Ti“

Suitable for some acids,

lyes, chlorine, urea and sewage.

· Platinum – “Pt”

For particularly aggressive fluids like concentrated acids and

caustics, chemically extremely

resistant material should be

chosen – platinum. However,

high cost of this material is its

essential drawback.

* Note – We can recommend

suitable lining and electrode

materials for your particular application.

used to connect measured fluid

electrical potential with ground.

For the wafer sensor, grounding

can be provided by electrical

Page 6

FLOMAG 3000 -

Installation and Operation Manual

6

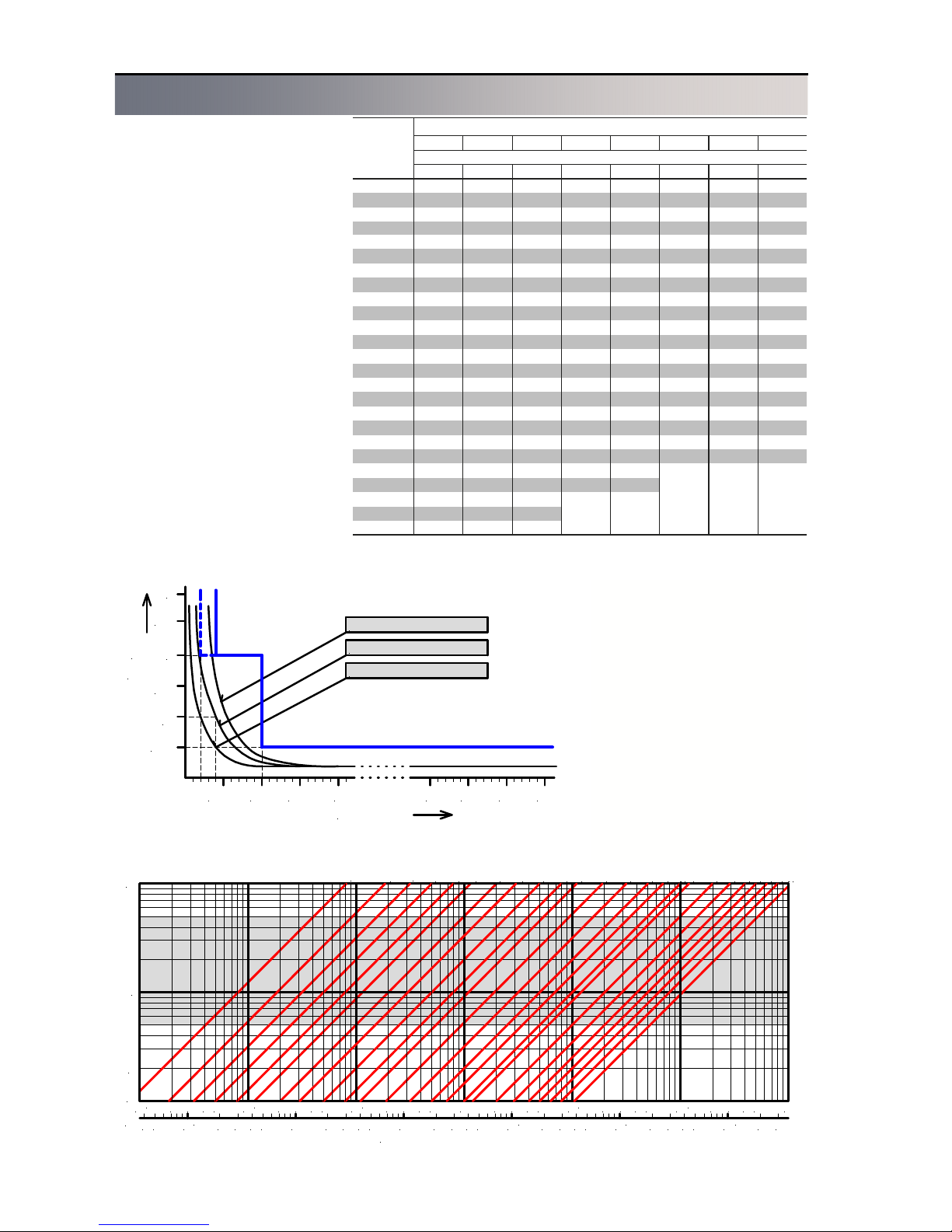

Converter is capable to detect

flow rates as low as 0.1 m/s.

Upper limit is determined by

capability of liquid to maintain

continuous flow at higher velocities. This is usually true for flow

rates up to 12 m/s.

Measurement error rapidly

increases for too low flow rates,

as can be seen in the diagram.

It shows limits of maximum relative measurement error as function of liquid flow rate.

On the other side, too high

flow rate causes discontinuity of

flow and results in chaotic turbulence and vacuum traps. This

results in instable measurement

and too high drift of flow rate

values.

Ideal operational range of the

sensor is in range from 0.5 to 5

m/s. This range is highlighted in

the diagram for correct size selection.

Flow rate ranges for individual

sizes are chosen to meet EN

14154 standard and they are

shown in table. Preferred

ranges are highlighted in bold.

For non-specified working meters, other range can be also

specified on request.

If range is not specified in a

purchase order, the sensor will

be calibrated in preferred range

in accordance with the table

above.

Correct sensor size selection

10

1

0.1

Flow velocity [ m/s ]

Volume flow rate

10 2 3 4 5 10 2 3 4 5 10 2 3 4 5 10 2 3 4 5 10 2 3 4 5 10

-2

-1

0

2

3

DN 10

D

N 20

DN 25

D

N 32DN

4

0

D

N 50DN 65DN 80

D

N

100

DN 125

D

N

1

50

D

N 15

D

N

20

0

D

N

25

0

DN 300

D

N 350DN

400

DN 500

D

N

600

D

N

700

D

N 800DN

900

D

N 1000

DN 1200

2 3 4 5 10

10 2 3 4 5 10 2 3 4 5 10 2 3 4 5 10 2 3 4 5 10 2 3 4 5 10

-1

3

4

2 34 5

3

2

Tab. Sensor ranges in m3/h according to their sizes

Fig. Limit of maximum relative error of measurement

Diagram for correct sensor size selection.

DN

S10 A25 B25 C25 C50 D25 D50 D100

Range Q3/Q1

R10 R25 R25 R25 R50 R25 R50 R100

10

1 0.63

1

1.6 1.6 2.5 2.5 2.5

15

2.5 1.6

2.5

4 4 6.3 6.3 6.3

20

4 2.5

4

6.3 6.3 10 10 10

25

6.3 4

6.3

10 10 16 16 16

32

10 6.3

10

16 16 25 25 25

40

16 10

16

25 25 40 40 40

50

25 16

25

40 40 63 63 63

65

40 25

40

63 63 100 100 100

80

63 40

63

100 100 160 160 160

100

100 63

100

160 160 250 250 250

125

160 100

160

250 250 400 400 400

150

250 160

250

400 400 630 630 630

200

400 250

400

630 630 1000 1000 1000

250

630 400

630

1000 1000 1600 1600 1600

300

1000 630

1000

1600 1600 2500 2500 2500

350

1000 630

1000

1600 1600 2500 2500 2500

400

1600 1000

1600

2500 2500 4000 4000 4000

450

1600 1000

1600

2500 2500 4000 4000 4000

500

2500 1600

2500

4000 4000 6300 6300 6300

600

2500

4000

6300 6300 10000 10000 10000

700

2500

4000

6300 6300 10000 10000 10000

800

4000

6300

10000 10000

900

4000

6300

10000 10000

1000 6300

10000

1200 6300

10000

Range marking

0.25 0.5

0.5

1

1.5

2

2.5

3

0.75 1

±F

10 11 12

[ % ]

v [ m/s ]

9

DN400..1200

DN10..25, 250..350

DN32..200

Page 7

FLOMAG 3000 -

Installation and Operation Manual

7

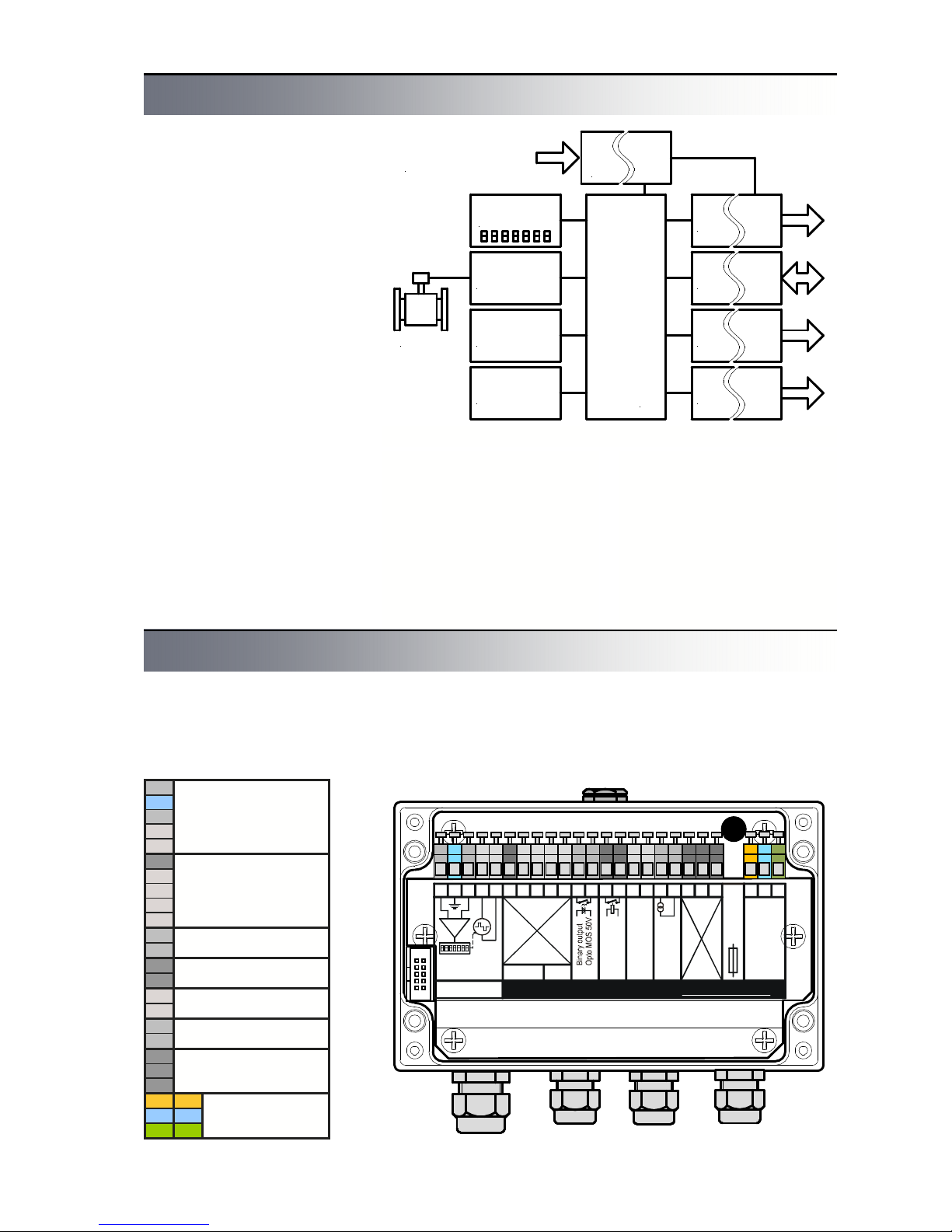

Volba výstelky snímače Block diagram of the flowmeter

Main advantage of the magnetic flowmeter FLOMAG3000

is its significant variability. Flowmeter converter in basic version

consists only of power supply,

microcomputer and sensor input module (module 1). Display,

outputs and other optional features are available as plug-in

modules. Thus, customer pays

only for features that he really

uses. Plug-in modules contain

memories where all configuration data is stored. In this way,

optional features can be added

or modified as required anytime

during the service life of the

flowmeter.

There are 4 free positions

available (module 4, 5, 6 and 7)

for binary and analog output

modules. Their signals are usually processed by connected

technological devices. All output

modules have galvanic isolation. At the same time, up to 4

binary output modules can be

fitted. These can operate either

as pulse or frequency outputs

for flow rate indication. Alterna-

Power

supply

module 4 B1

Binary output

module V1

Display

module 1 S1

Sensor input

module 2 F1

Electrode cleaning

module 5 B1

Binary output

module 6 C1

RS 232 interface

module 7 A3

Analog. output

Microcontroller

module 3 M1

Data logger

Sensor

85 - 265 VAC

(24V, 12V, AC/DC)

Fig. 19: Block diagram of the flowmeter

tively, they can serve for indication of flowmeter limit conditions. Galvanic isolation is ensured by an optoelement or a

relay. One position (module 7)

is dedicated for the active analog output module. Modules

with various accuracy and

ranges are available. One position (module 6) is designed for

the serial communication module. RS 232, RS 485 or MBus interface can be plugged

in.

Position (module 2) is for the

electrochemical electrodes

cleaning module.

A

Module 1

B

Sensor connection

C

Connected

D

internally

E

for compact version

1

module 2 F2 - F3

2

3

Not connected

4

5

6

module 4

7

A4, B1-B5, E1

8

module 5

9

A4, B1-B5, E1

10

module 6

11

A4, B1-B5, C1, D1, D2, E1

12

module 7

13

A1 - A5, B1-B5, E1

14

15

Not connected

16

17

L

18

N

Power supply

19

PE

Terminal connections

T0,5A

250V

ABCDE

12345678910111213141516PELN

B1B5C1A1

+

-

S1

V1

--

Magnetic flowmeter www.flomag.com

FLOMAG3000

Display

Sensor

connection

Relay ou

tpu

t

250VAC/

1

A

RS 232

0(4)..20mAAnalog o

utput

85 - 2

40

V

50 - 6

0 H

z

Power

T0,5A / 250V

Tab. Converter terminals Fig. 20 Converter – location of terminals

The converter is integrated in a

rugged aluminium box. After

opening the box you will gain

access to terminals. Terminals

17, 18 and 19 are for power

supply. Terminals A, B, C, D

and E are used for the sensor.

For compact version, the sensor is connected internally and

terminals remain free. Termi-

nals 1 to 16 are used for connection of inputs and outputs of

optional modules (binary outputs, current output, RS232,

RS485 etc.)

Page 8

FLOMAG 3000 -

Installation and Operation Manual

8

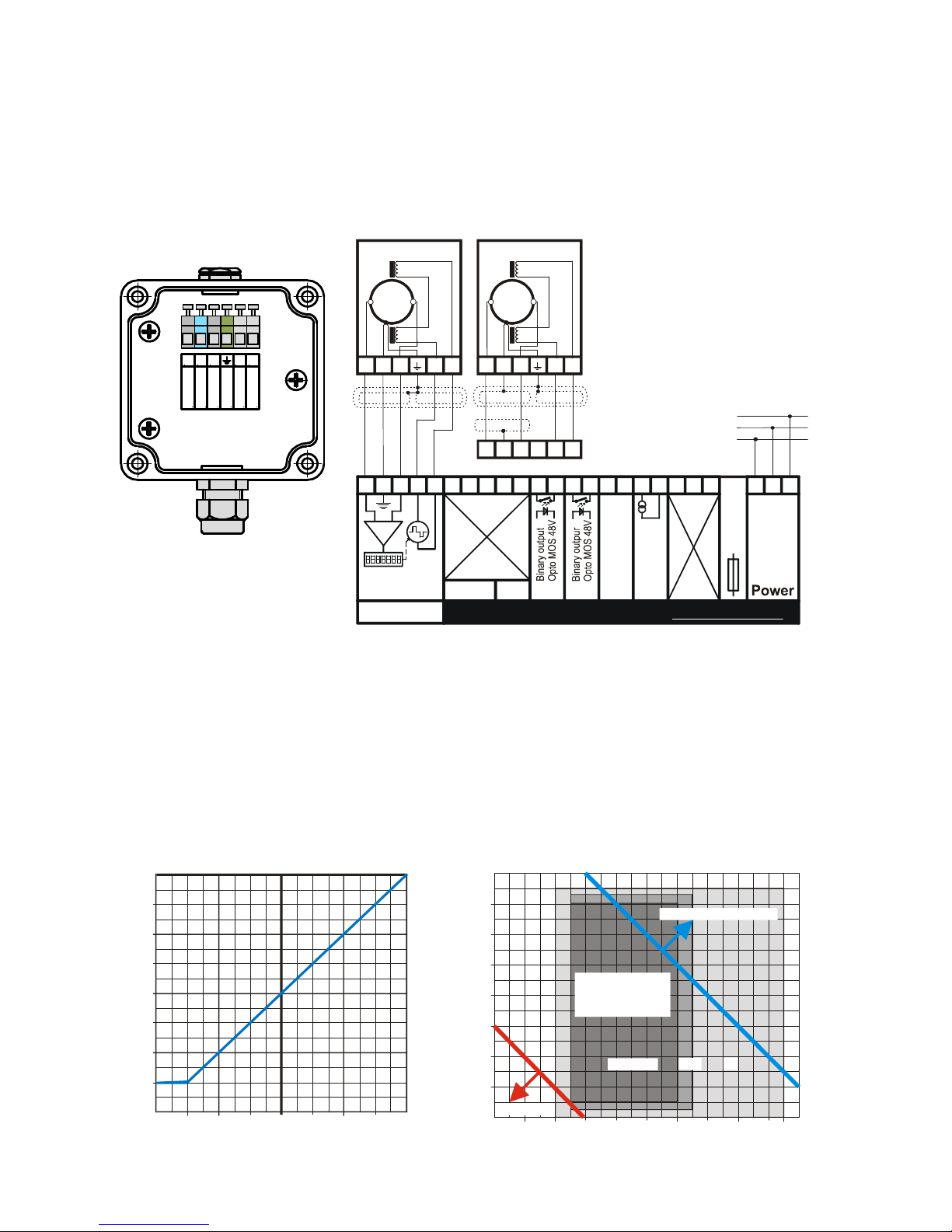

For the remote sensor, there

is a terminal box in its tapping

(see figure 21). The sensor

should be connected to the converter using a double shielded

cable. You can use our special

sensor cable PAAR-LiYCY-CY

[1X(2X0,25 LiYCY)+1X(2X0,75

LiYCY)+1X0,75]CY (length up

to 200 m) or standard double

Maximum length of the cable

between evaluation unit and the

sensor is significantly limited by

conductivity of measured fluid,

as shown in Figure 23.

Remote version should be used

when measured fluid is too hot

to avoid heat transfer to converter. See Figure 24 for assessment of remote version

utilization.

Parallel running of power and

0

25

50

100

200

0255075

100125150175200

Maximum length of cable

[ m ]

Fluid conductivity

[ S/cm ]

m

shielded cable Lapp UNITRONIC Cy PiDy 2x2x0.25 or

Alpha 1243/2C (length up to 50

m).

Fig. 21: Sensor terminal box Fig. 22: Remote sensor connection

signal wires is highly inappropriate; especially in case of the

cable that connects the sensor

with the remote converter. If the

instrument is used in environment with strong electromagnetic interference, cables

should be rather as short as

possible.

For connection of electronic

converter input and output terminals, shielded cables are suit-

able.

For connection of mains voltage, a standard three-core cable, e.g. CYKY 3x1,5 (wire) or

VM03VQ-F 3x1 (wire strand) is

recommended. The instrument

has no switch so it should be

fused and switched using other

device.

Fig. 23: Maximum length of the cable and conduc-

tivity

Fig. 24: Selection of version according to temperature

A B C D E

Yellow/Green

Yellow

Red

White

Brown

Green

AB

CDE12345678910111213141516PEL

N

B1B1C1A3

+

-

S1

V1

Magnetic flowmwter www.flomag.com

FLOMAG3000

Display

Sensor

input

RS 232

4..20mA

Analog. output

85 - 265 V

48 - 63 Hz

T0,5A / 250

V

AABBCCDDEE

PE

N

L

M1F

1

17181

9

AABBCCDDEE

Sensor

Sensor

ABCDEABCDE

Cable

PAAR-LiYCY-CY

[1X(2X0,25 LiYCY)

+1X(2X0,75 LiYCY)

+1X0,75]CY

Cable

Lapp UNITRONIC

Cy PiDy 2x2x0.25

or

Alpha 1243/2C

-20

-10

0

10

20

30

40

50

60

-60-40-20

0204080

100

120

140

160

Fluid temperature [ °C ]

Ambient temperature [ °C

]

TG, MG

NG

T

Remote version

Heating

Remote or

compact

version

Page 9

FLOMAG 3000 -

Installation and Operation Manual

9

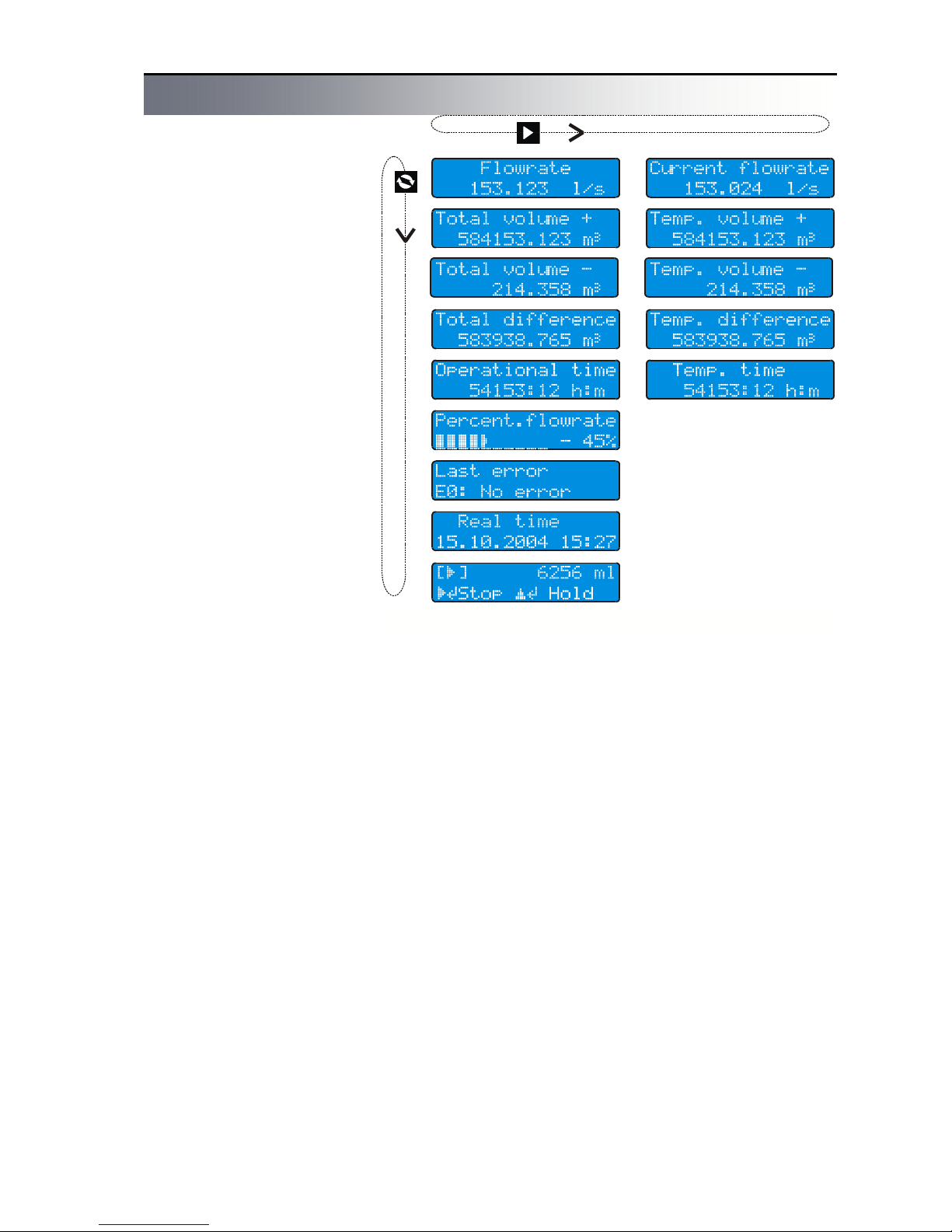

Displayed data

Fig. 25: Displayed data

The instrument is equipped with

a high quality backlit two-line

alphanumerical display with

character height 9.6 mm (2x16

characters) providing good

readability even from longer

distances. Backlight function

works in energy saving mode.

Backlight time is limited to 254

seconds after last pressing of

any key. If backlight is off,

pressing of any key will switch it

on again. Backlight time can be

set in menu from 20 seconds to

254 seconds. Setting to 0

switches backlight permanently

off; setting to 255 switches it

permanently on.

Up to 8 basic readings can be

read from the converter display.

You can alternate them using

1 key. Additional information

accessible via 2 key is avail-

able for some displayed data.

Flow rate

- Flow rate value treated by

floating averaging. Number of

averaging steps can be

changed in range from 1 to 256.

Flow rate units can be changed

as required.

Number of displayed decimal

places can be set in range from

0 to 4.

Total volume (+)

- Total volume of liquid flowed

in direction of arrow on the sensor from start of measurement.

Total volume (-)

- Total volume of liquid flowed

in opposite direction of arrow on

the sensor from start of measurement.

Volume difference

- Difference between positive

and negative volumes flowed

from start of measurement.

Operation time

- Total time of operation from

initial switching instrument on in

hours and minutes.

Percent. flow rate

- Flow rate information indicated

by horizontal bar (its width corresponds to flow rate) and as

numeric value in per cents of

chosen maximum value.

Last error

- Abbreviated text of the last

error message.

Current flow rate

- Flow rate value untreated by

floating averaging.

Temporary volume +

- User resettable value of volume flowed in direction of arrow

on the sensor.

Temporary volume -

- User resettable value of volume flowed in opposite direction of arrow on the sensor.

Temporary difference

- User resettable value of difference between volumes flowed

in direction and in opposite direction of arrow on the sensor.

Temporary time

- User resettable value of volume flowed in direction of arrow

on the sensor.

Values of temporary counters

can be reset by holding 3 key

and simultaneous pressing 4

key. This will reset all counters

at the same time – both volumes and time.

Batching

- Shows information about the

running batch. Detailed information is given in chapter Batching.

Page 10

FLOMAG 3000 -

Installation and Operation Manual

10

Archiving

Electromagnetic flowmeter

FLOMAG3000 automatically

saves in fixed time intervals ,

the value of the flowed volume.

There are three archives.

Hour archive where it is possible to find the flowed volumes

about the last 192 hours (8

days).

Daily archive where it is possible to find the flowed volumes

about the last 192 days (more

than half year).

Month archive where it is possible to find the flowed volumes

about the last 12 months.

Upper line shows always time

interval of the item in the archive. Second line shows the

flowed volume in the fixed time

interval and the power off time

in the fixed time interval (the

flowmeter was without power

supply).

Listing in archive

Pushing key 1, roll to item

Total volume+. By repeated

pushing of key 2 you can find

gradually Flow rate +, hour archive, day archive and month

archive.

By repeated pushing of key

3, in the hour archive you can

see gradually the saved sam-

ples from the previous hour,

totally 192 hours back.

By repeated pushing of key

3, in the daily archive you can

see gradually the saved sam-

ples from the previous day, totally 192 days back.

By repeated pushing of key

3, in the month archive you

can see gradually the saved

samples from the previous

month, totally 12 months back.

If you want to go back to the

last saved sample, please push

and hold key 3 and together

with it push key 4.

Fig. Hour archive

Fig. Daily archive

Fig. Month archive

Fig. Legend

Fig. Hour archive moving

Fig. Daily archive moving

Fig. Month archive moving

Ok - without power off

-#s - power off time in secunds

-#m - power off time in minutes

-#h - power off time in hours

-#d - power off time in days

Error messages

Fig. Error messages

In case of a fault, an error

message with short description of the fault is

shown immediately at the

LCD.

The error message begins

with character E followed

by error's number. If the

error is connected with a

defect of a module than it is

followed also by character

M and the number of the

module. After pushing but-

ton 1 the flowmeter returns to value display mode

and at the same time the error message is saved to last

error register. During the indication of the error message,

the flowmeter is measuring.

In case of error E-7, E-8 and E

-13, the flowmeter indicates 0

if the mentioned error message is not forbidden in the

menu.

Error messages are listed

below together with recommendation how to repair.

E0: No error

E1: EEPROM Checksum

error

Checksum error saved in

the module - re-check data

in the module and save

again

E2: Stack overflow

For module „B“ in pulse

mode - the time constants

are too long, the flow rate is

higher than it is possible to

send pulses, stack overflow

of un-sent pulses - change

pulse length and space

length or volume for 1 pulse

E3: Frequency limit ex-

ceeded

For module „B“ in frequency mode, it is required

higher output frequency than

the module is able to send,

flow rate is higher than it

was assumed - set higher

flow rate value for 1kHz.

E4: Power fail

Page 11

FLOMAG 3000 -

Installation and Operation Manual

11

Appears for short after

power fail

E5: Old software

For proper operation of the

module is required newer

firmware version than it is

installed in the convertor –

upgrade firmware.

E6: Can't use this mode

For module B placed in

position 6 and 7 is not possible to use frequence mode

(it is possible only in position

4 and 5) – change the position of the module or change

the mode to pulse.

E7: Sensor loop disconnected

No current to the coils – for

remote version check cables

and terminals

E8: Empty pipe

For modules F2 and F3,

indicates that the controlling

electrode is not submerged

E9: Low medium conductiv-

ity

For modules F1 and F3 in

electrodes cleaning mode,

no current in the electrodes,

sensor is not submerged,

electrodes are furred or low

medium conductivity - clean

the sensor

E10: MBus conflict

Module D3 – exist two stations M-Bus with same address – change the setting of

module D3

E11: Current output

overrange

For module A it is required

higher output current than

20mA, flowrate is higher

than it was assumed – set

higher flow rate value for

Imax

E12: Serial line fail -

communication error

Communication module

C1 or Dx sends data but

does not receive confirmation for receipt of data –

check cables, could be

caused also by external interference, high capacity of

the cables or too long cables.

E13: Sensor signal over-

range

Signal from the sensor is

overrange of the convertor electrodes are not submerged or there is short circuit of the cables – check

the sensor and the cables

User outputs – plug-in modules

T0,5A

250V

position 8

position 1

position 2

position 3

position 4

position 5

position 6

position 7

Flowmeter converter in basic

configuration contains the

power supply and boards required for measurement functions. All other inputs, outputs

and display units can be added

as plug-in modules. Customer

pays only for features that he

really uses. At the same time,

this concept allows using of

various types of inputs and outputs tailored to customer needs.

Following table and figure

indicate positions and functions

of individual modules.

Fig. Module positions

Tab. Module positions

Positio

n

Modules

Terminals

1

S1 sensor input

module, always

plugged in

A, B, C,

D, E

2

F1-F3 module for

sensor full pipe

checking and electrode cleaning

1, 2, 3,

4,

5,

3

M1 extended memory

module of measured

data

-

4

A4,A7 passive cur-

rent output 4 - 20 mA

B1-B5 binary outputs

incl. frequency up to

12 kHz

E1 binary input

6, 7

5

A4, A7 passive cur-

rent output 4 - 20 mA

B1-B5 binary outputs

incl. frequency up to

1,2 kHz

E1 binary input

8, 9

6

A4, A7 passive c.o.

B1-B5 except for

frequencies,

C1, D1, D2, D3, G1,

H1 data communica-

tion

E1 binary input

10, 11

7 A1-A3, A5, A6 active

current output

A4, A7 passive c.o.

B1-B5 except for

Frequencies

E1 binary input

12, 13

8

V1 display and key-

pad

10 pin

connector

Page 12

FLOMAG 3000 -

Installation and Operation Manual

12

Parameter setting

The magnetic flowmeter converter can be configured in two

ways, as required: either using

a PC connected via serial interface, or using keys.

Press 4 to switch the display

to programming mode. Programming mode is password

protected against unauthorized

access. Correct password (4digit number) must be entered

to obtain access to main menu.

Password of a new instrument

is always set to 0000.

Fig. Enter password

This is also initial value displayed as default. Simply confirm it to enter in menu.

Password can be changed as

required before you leave the

programming mode.

Warning! You can switch the

instrument to data display mode

anytime by pressing 1 and

check current parameter settings. However, the instrument

is not password protected

against unauthorized access

until you enter EXIT command.

Programming runs in background and with only a few exceptions has no influence to

measurement.

Fig. Cursor movement

2 key moves cursor to the

right. When the utmost right

position is reached, the cursor

returns to the left.

Fig. Character changing

system returns to the first available character.

Character set is always selected with regard to possibility

of character occurrence in text:

[0..9] for integers, [0..9,- , .] for

decimals and complete alphabet for text variables (including

Czech characters).

Confirm your selection by 4

key to finish editing.

A status message will be displayed. If your password is not

accepted, program returns to

editing mode. If correct password was entered, you will get

to main menu.

Use 3 to move in menu. This

key moves the lower line item to

upper line. In all menus, the

upper line with blinking first

character is always the active

line.

Press 4 to enter in submenu

or to edit item. Pressing 2

in submenu brings you always

back to previous menu

(“Escape” function). If you are in

main menu, pressing of this key

will offer exit from programming

mode.

Menu legend

Some menu items can be

used only for viewing and do

not allow change of values.

Fig. Movement in menu

Fig. Status message

+ Noise filter

+ Dynamic filter

» Enter password

○ 125 mA

● 250 mA

¤ Production date

3 key changes character at

cursor position. When the last

available character is reached,

Fig. Read only

Fig. Enter value

Press 4 to return to previous

menu.

Other menu items can be

used to enter value directly.

When you enter the value and

press 4, a status message will

be displayed.

If the value entered is accepted, press any key to return

to previous menu or to edit next

item.

If the value entered is out of

range, an error message will be

displayed; press any key to edit

the value.

In some cases, one of listed

values has to be selected.

Fig. Selection of one value

Use 3 to select required item.

When the required value is in

the upper line, press 4 to con-

firm your selection. A status

message will be displayed to

confirm that your selection has

been accepted. Press any key

to return to previous menu or to

edit next item.

In some cases, more of listed

values can be selected.

Fig. Selection of more items

There is a sign “+” (indicating

that the item is selected) or ““ (indicating that the item is not

selected) before each of items.

Fig. Selection of more items

Press 2 to change selection

for the item displayed in the

upper line. Press 4 to finish

your selection. A status message will be displayed to confirm that your selection has

been accepted. Press any key

to return to previous menu.

Page 13

FLOMAG 3000 -

Installation and Operation Manual

13

Flowmeter menu

» Enter password

↓

0.Production data → Production date → ¤ Production date

Serial number → ¤ Serial number

Software → ¤ Software

Meter's type → ¤ Meter's type

Modules used → ¤ Embeded modules

Date setting → » Date

Time setting → » Time

Permit upgrade → » Upgrade PIN

Delete history → » Delete PIN

Reset volumes → » Reset PIN

1.Sensor → Sensor constants → Constatnt 1 → » Sensor constant1

Constant 2 → » Sensor constant2

Excitation freq. →○ 2.775 Hz

● 3.125 Hz

○ 5.55 Hz

○ 6.66 Hz

○ 12.5 Hz

○ 25 Hz

Excitation curr. →○ 125 mA

● 250 mA

Supressed flow → » Do not meas. Q<

Samples → » Samples

Filters →√ Noise filter

√ Dynamic filter

Zero setting → » Autozero PIN

2.Module 2 → Specific settings for individual modules

…

7.Module 7 → Specific settings for individual modules

8.Display → Language →● [CZ] Česky

○ [D] Deutsch

○ [GB] English

○ [PL] Polski

○ [I] Italiano

○ [NL] Nederlands

○ [S] Svenska

○ [E] Espanol

○ [F] Francais

100 per cent → » 100 per cent

Flowrate units →● l/s

…

○ m3/h

…

○ User's → » Flowrate multipl

» Unit's name

Decimal places → » Decimal places

Backlight → » Backlight time

Display select →√ Flowrate

√ Total volume +

√ Total volume +

√ Total difference

√ Operation time

√ Percent flowrate

√ Last error

√ Real time

Error messages →√ E1

√ …

√ E13

9.Exit → Exit menu

Exit menu

New password → » Access password

Page 14

FLOMAG 3000 -

Installation and Operation Manual

14

0. Production data

This submenu relates to the

flowmeter converter.

·Production date – of con-

verter

·Serial number – of con-

verter

·Software – current soft-

ware version

·Type of meter – type num-

ber of flowmeter converter

·Modules used – types of

currently used modules

(Above listed items are only for

information and user cannot

change them)

·Date setting – setting of

current date

·Time setting – setting of

current time

·Upgrade enabled – a new

firmware version can be

uploaded after entering PIN

·Delete history – archives

will be deleted after entering

PIN

·Reset volumes – All total-

izers will be reset after entering PIN

1. Sensor

This submenu relates to the

sensor.

·Sensor constants – sen-

sor calibration constants

·Excitation frequency – of

sensor coils

·Excitation current – of

sensor coils

·Suppressed flow rate –

when flow rate is lower than

this value, it is considered

for zero. This setting is used

to suppress creeping flows.

·Number of samples – for

floating averaging that filters

measured flow rate value.

Higher number of samples

provides more stable flow

rate value, however it increases time constant and

causes delayed reaction to

flow rate changes.

·Filters

¨Noise filter partially re-

duces jump changes but

mainly removes lower periodical interference. Transient edges are rounded as

can be seen in figure of response to unit jump. The

filter is applied already on

input and thus influences

immediate flow rate value

and cumulated volume calculated from it. The noise

filter introduces only negligi-

ble delay (about 0.3 sec)

and can be used almost at

all circumstances.

¨Dynamic filter reduces

rapid jump changes of flow

rate. It protects very effectively against high short

peaks caused by interference. Unlike averaging, dynamic filter cuts input signal

and interference is not included in cumulated volume. It can however cause

delay of flow rate jump

change indication. This fact

should be considered if the

flowmeter is used for dosing

applications. Response to

unit jump can be seen in

figure.

8. Display

This submenu relates to data

shown on the display.

·Language – language of

displayed data. You can

select from 9 languages.

·100 per cent – 100 % flow

rate for bar diagram. It is

Fig. Dynamic filter

Fig. Noise filter

used only for percentage

bar diagram display; it is not

meant as range of the meter.

·Flow rate units – You can

select from 12 preset units

or add your own user defined unit. In such case you

have to enter multiple of

flow rate in l/s and a unit

name.

·Decimal places – Number

of decimal places of displayed flow rate. You can

enter 0-4 decimal places. If

5 places are entered, number of decimal places will be

dynamically changed to 4

valid decimal places.

·Time of backlight – Time

of display backlight in seconds. When you press any

key, backlight of display

goes on. When time period

set in seconds expires since

you pressed the last key,

the backlight goes off. You

can set time period from 1

to 254 seconds. If you set 0,

backlight will never be on. If

you set 255, the display will

be permanently backlit.

·Displayed values – De-

fines what items will be displayed. You can select any

of available items. These

will be alternately displayed

on the flowmeter display.

Press 1 to alternate displayed values.

·Error messages – Enable

or disable displaying of individual error messages.

9. Exit

·Exit menu – When you

finish editing, you have to

exit menu because only after that settings are permanently stored in module

memories. If you will not exit

the menu and power failure

occurs, previously entered

settings will be loaded. Also

access to menu is password

protected only when you

exit menu.

·New password – You can

change the access password before you finish your

editing.

Time

NtN

Sampling moments

Current flow rate

Flow rate

Average flow rate

Fig. Averaging

Page 15

FLOMAG 3000 -

Installation and Operation Manual

15

Modules A – analog current

output – are used for flow data

transmission. There are 4 different types available with various

ranges, accuracy and functions.

Outputs of A1 to A3, A5 and

A6 modules are active (forced

current) and are galvanically

isolated from other flowmeter

parts. Outputs can be loaded up

to 1000 Ω. They can be plugged

only in position 7.

A4 and A7 modules have passive current output (it has to be

powered externally) and are

also galvanically isolated.

Unlike A1-A3, A5, A6 modules,

it can be plugged in positions 4,

5 and 6.

0..+Q output

0..-Q output

IQI output

-Q..+Q output

Fixed current 0..20

Depending on flow rate (see

diagrams), output can work in 5

modes:

The first four modes generate

output current dependent on

flow rate, the fifth mode enables

direct entering of current. Following 4 ranges can be selected for all modes (except for

the fixed current mode):

A3, A4, A6 and A7 modules can

work only with range 4..20 mA.

0..20mA output

4..20mA output

0..10mA output

0..5mA output

Range

4..20mA 0..10mA 0..5mA

Flow rate / current

-Q

max

0 Q

max -Qmax

0 Q

max -Qmax

0 Q

max -Qmax

0 Q

max

0..+Q output 0 0 20 4 4 20 0 0 10 0 0 5

0..-Q output 20 0 0 20 4 4 10 0 0 5 0 0

0..IQI output 20 0 20 20 4 20 10 0 10 5 0 5

-Q.+Q output 0 10 20 4 12 20 0 5 10 0 2,5 5

0..20mA

A1

Range 0(4)..20 mA

Resolution 12 bit

Accuracy ± 0.2%, ± 0.2mA

Active - replaced by A5

A2

Range 0(4)..20 mA

Resolution 16 bit

Accuracy ± 0.1%, ± 0.1mA

Active - replaced by A5

A3

Range 4..20 mA

Resolution 16 bit

Accuracy ± 0.1%, ± 0.1mA

Active - replaced by A6

A4

Range 4..20 mA

Resolution 16 bit

Accuracy ± 0.1%, ± 0.1mA

Passive - replaced by A7

A5

Range 0(4)..20 mA

Resolution 16 bit

Accuracy ± 0.1%, ± 0.1mA

Active

A6

Range 4..20 mA res. 16 bit

Accuracy ± 0.1%, ± 0.1mA

Active - compatible with

module H1 ( HART )

A7

Range 4..20 mA res. 16 bit

Accuracy ± 0.1%, ± 0.1mA

Passive - compatible with

module H1 ( HART )

Current output modules A1 – A4

Fig. 0..+Q output

Fig. 0..+Q output

Fig. IQI output

Fig. -Q..+Q output

Fig. Menu structure of A modules

7.Current output →● 0..+Q output ○ 0..20mA output»Imax flowrate

○ 0..-Q output ● 4..20mA output

○ 0..|Q| output ○ 0..10mA output

○ -Q..+Q output ○ 0..5 mA output

○ Fixed current»Fixed current [mA]

1213

A5

0..20 mA

Current output

+

-

A

+

-

1011

A7

4..20 mA

Current output

+

-

A

+

+

-

Modules A6 and A7 enables

with module H1 (Bell 202 modem) to communicate through

current loop with a protocol

compatable with HART (only

Universal Commands)

Page 16

FLOMAG 3000 -

Installation and Operation Manual

16

B1

Passive (max 4 kHz)

Max. voltage 350 V

p-p

Max. perm. current 120 mA

Max. pulse current 300 mA

Resistance 27 Ω

B2

Passive (max 12 kHz)

Max. voltage 60 V

p-p

Max. perm. current 300 mA

Max. pulse current 500 mA

Resistance 5 Ω

B3

Active

Voltage 5 V

Max. current 10 mA

Max. frequency 12 kHz

B4

Active

Voltage 24 V

Max. current 40 mA

Max. frequency 12 kHz

B5

Relay contacts

Max. voltage 250 VAC

Max. current 1 A

Binary output modules B1 - B5

Flowmeter converter can control up to 4 multifunctional binary outputs in positions 4 – 7.

Following table indicates differences between individual modules:

Outputs can work as pulse,

frequency or status outputs.

Individual functions are explained in detail in following

section.

Binary module functions

· Normally closed/open

These modes are used for service purposes.

· Pulse outputs (not)

In this mode, a pulse is generated immediately after preset

volume has flowed. Pulse generation is determined by three

factors: pulse length “tu”, mini-

Tab. Binary output modules

mal delay between two pulses

“tD” and volume per pulse “V”.

Flow rate values are time integrated. Immediately after preset

volume per pulse has flowed,

the pulse of length tu is generated. After the pulse, there is a

delay of length at least tD. If the

delay expires and the preset

volume has not flowed again,

the output remains inactive;

otherwise, another pulse and

delay are generated immediately. If the preset volume flows

through sooner than the previous pulse is finished, the unsent

pulse will be stored in a buffer

with maximum capacity of 255

pulses. If buffer overflow occurs, an error message will be

generated. It follows from above

mentioned that parameters of

pulse output should be set such

that expected pulse frequency

cannot exceed limit frequency

determined by pulse length and

delay.

It applies: Maximum pulse

frequency [s-1] = 1 / (tu + tD)

Volume per pulse can be set in

range from 1 to 109 ml with 1 ml

step, i.e. from 1 ml to 1000 m3.

Delay and pulse lengths can be

set in range form 10 ms to 2550

ms with 10 ms step. It follows

from above mentioned that the

maximum pulse frequency is 50

s-1.

Pulses can be generated in

three modes depending on flow

rate, and pulse polarity can be

set (output is closed during

pulse or open in not modes).

Fig. Pulse generation

Fig. IQI pulses

Fig. Q+ pulses

Fig. Q- pulses

· Frequency outputs

In this mode of operation, frequency is generated on output

modules. Pulse to delay ratio is

always 1:1. Warning! Only two

frequency generators in positions 4 and 5 are available for

the converter. This function is

blocked in positions 6 and 7.

Maximum frequency in position

4 is 12 kHz and in position 5

only 1.2 kHz. If these limit frequencies are exceeded, output

frequency will be limited and an

error message will be generated.

Frequency outputs can work in

three modes of frequency dependence on flow rate.

Setting is done by selecting of

flow rate corresponding to 1

kHz output frequency.

Fig. Q+ frequency

Fig. Q- frequency

Fig. IQI frequency

Page 17

FLOMAG 3000 -

Installation and Operation Manual

17

Fixed frequency mode is used

for service purposes. Required

frequency is set directly in Hz in

range 1-120000 Hz in position 4

and 1-1200 Hz in position 5.

· Negative/non-negative

flow rate

This mode is used for flow direction differentiation. Output is

closed/open for negative flow

rate.

· Failure occurred/not oc-

curred

If failure with mode set to active

(see error messages) occurs,

the output closes/opens for at

least 5 seconds. If failure persists, output is closed/open for

whole period of failure duration.

· Limit flow rate exceeded/

undergone (not)

If flow rate is higher/lower than

limit value set, the output closes

(opens). When flow rate returns

to limits, the output opens

(closes) again taking in account

preset hysteresis. This function

Fig. Q > Qlimit

Fig. Q < Qlimit

Fig. IQI > Qlimit

Fig. IQI < Qlimit

Fig. Menu structure of B modules

Fig. Terminal connection

6

7

B1

Bi nar y o utput

Opt oMOS 35 0V

8

9

B2

Bi nar y out pu t

ac tiv e 5V/ 100mA

+

-

8

9

B5

Bi nar y out pu t

Re lay

4.Binary output ─►● Permanently open

○ Perm. Closed

○ IQI pulses » Pulse length [10ms]

○ IQI not pulses » Pause length [10ms]

○ Q+ pulses » Vol./ pulse [ml]

○ Q+ not pulses

○ Q- pulses

○ Q- not pulses

○ Q+ frequency » Flowrate at 1 kHz

○ Q- frequency

○ IQI frequency

○ Fixed frequency » Fixed frequency [ Hz ]

○ Negative flow

○ Non-neg. flow

○ 'Error occured √ E1

○ 'No error occured √ …

√ E13

○ Q>Qlim. » Flow limit

○ Q>Qlim. not » Hysteresis

○ Q<Qlim.

○ Q<Qlim. not

○ IQI>Qlim.

○ IQI>Qlim. not

○ IQI<Qlim.

○ IQI<Qlim. not

○ Cleaning

○ Not cleanig

○ Batch Opened » Volume Advance [ml]

○ Batch Opened not » Time Advance [ms]

○ Batch Stop puls » Pulse length [10ms]

○ Batch Stop /puls » Volume Advance [ml]

» Time Advance [ms]

works in four modes of dependence on flow rate with output

polarity differentiation.

· Electrode cleaning/no

cleaning

The output is closed/open during cleaning.

· Batch Opened

· Batch /Opened

Output is switched on /

switched off during the batch

running. It is possible to set the

advance of the output before

batch ending. Advance could be

set by time or volume. Detailed

information is given in chapter

Batching.

· Batch Stop pulse

· Batch Stop /pulse

Output generates pulse for

ending of the batch. It is possible to set pulse length (10ms 2,5s) and pulse advance before

batch ending. Advance could be

set by time or volume. Detailed

information is given in chapter

Batching.

Page 18

FLOMAG 3000 -

Installation and Operation Manual

18

C1, D1, D2 and D3 modules

Modules C1, D1, D2 and D3

are used for data communication. All these modules are galvanically isolated from flowmeter circuits. They can be installed only in position 6 and

their signals are output to terminals 10 and 11. Interface

RS232 is the only exception, as

it needs 3 wires.

C1 – RS232 interface

It is used primarily for

service purposes, because maximum cable

length from the converter

to a computer is 15 meters and only one converter can be connected

to a single link.

Connection to the computer equipped with RS232 interface is done using an included cable. Thread one end

of the cable through a cable

bushing and connect it to 3-pin

connector behind terminals 10-

11. The other end of the cable

is equipped with CANON 9M

connector. This ensures leading

of RS232 interface signals out

of converter box while protection level IP66 is maintained.

The interface is connected to

the computer using a crosslink

cable Laplink 9F-9F.

D1 – RS485 interface

It is used for permanent connection of multiple converters to

the computer. It enables con-

C1

RS232

D1

RS485 (MODBUS)

D2

0/20mA data current loop

D3

M-BUS

G1

GSM modem

H1

HART modem (with A6,7)

12345

6789

CANON 9F

12345

6789

CANON 9M

1011

C1

RS 232

Fig.RS232 cable connection

necting of up to 31 stations in a

communication network using a

twisted pair link cable with total

length of 1200 meters. Number

of stations and length of cables

can be increased by using re-

peaters. Stations are connected

to the link in parallel. The most

distant ends of line have to be

equipped with terminating resistors 120 Ω.

When setting stations, be

sure to set the same baud rate

for all of them and to set a

unique address for each of

them. MASTER address is always set to “0” and addresses

of individual stations can be set

in range 1-254.

D2 – Data current loop

interface 0/20 mA

It is used for permanent connection of multiple converters to

the computer. It enables connecting of multiple stations on

long distances. Data transfer

via current coding 0/20 mA is

highly resistant against interference and is suitable for indus-

Fig. RS485 network connection

Fig.Data current loop 0/20 mA

network connection

trial environment. Individual stations are connected in series.

Disadvantage of this configuration is that if one station fails,

then whole network breaks

down.

D3 – M-BUS interface

Standard M-Bus (Meter-Bus)

is designed for applications of

data acquisition from various

media consumption meters. It

enables connecting of many

devices (hundreds of them) on

distance of several kilometers.

Fig. M-Bus network connection

Fig. Communication module menu

M-BUS

DEVICE 1

DEVICE 2

DEVICE

3

M-BUS

M-BUS

M-BUS

MASTER

10

1110111011

6.RS232 ─► Baudrate ─►○ 300 Bd

○ 600 Bd

○ 1200 Bd

○ 2400 Bd

○ 4800 Bd

● 9600 Bd

○ 19200 Bd

○ 38400 Bd

○ 57600 Bd

○ 76800 Bd

○ 115200 Bd

Adress ─► »Own adress

Protocol ─►● FLOMAG

○ M-BUS

○ MODBUS-RTU

○ MODBUS-ASCII

○ HART

Parity ─►● No parity

○ Odd parity

○ Even parity

Word order ─►● Low word first

○ High word first

Page 19

FLOMAG 3000 -

Installation and Operation Manual

19

Modul E1

Module E1 is galvanically

separated active binary input for

nonvolatile contacts or open

collector. Input has SW transient immunity. It is necessary

min pulse length of 60 ms for

switching .

Functions of the binary

input

· Switch Off

· Batch Start

Starts the batch (see section

Batching).

· Batch Hold

Stops and holds the batch.

Counted batch can be continued after restarting it (see section Batching).

· Batch Stop

Asynchronously finishes the

batch and sets again the preset

batch volume (see section

Batching).

· Reset Volumes

Enables reset of the chosen

totalizers and working time.

· Cleaning Start

Starts electrochemical electrodes cleaning in modules F1

or F3 (requires plug-in modules

Fig Menu of module E1 Fig. Terminal connection

2. Electrode cleaning

─►

● OFF

○ Only once

○ During Power ON

○ Periodiccally

─►

»Clean every x [h]

»Time of start [h:m]

F1, F2 and F3 modules

F1 – F3 modules are used for

full pipe check and for electrochemical cleaning of electrodes.

F1-Electrochemical

electrode cleaning mod-

ule

During operation of the flowmeter, a non-conductive layer

can be formed on sensor electrodes. This layer increases

contact resistance between

electrodes and measured fluid

and results in lower measurement accuracy.

F1 module enables measuring electrode cleaning without

need of sensor deinstallation.

The method is based on electrochemical effect. Alternating

voltage is connected to electrodes and the deposited layer

dissolves in liquid. This cleaning

should be performed periodi-

F1

Electrochemical electrode cleaning module

F2

Empty pipe detection

module

F3

Module with combined

functions F1+F2

cally.

The cleaning cycle takes 1

minute. During cleaning, no real

measurement is performed.

Flow rate measured before start

of cleaning is simulated. Cleaning cycle duration can be indicated using binary outputs.

Running cleaning process is

indicated on display by moving

full character on upper line.

The instrument offers several

possibilities of cleaning cycle

start:

If ONCE is selected, a single

cleaning cycle is immediately

performed and then the instrument returns to Off mode.

If AFTER SWITCH-ON is selected, the cleaning cycle will be

always started if power supply

is switched on. Option PERIODIC starts cleaning in regular

intervals that can be set by user

in range from 1 to 255 hours.

Timer starts counting after time

value is entered. Starting time

of cleaning can be set to match

to real time. It makes sense

only if cleaning period is set in

multiples of 24 hours. Then

cleaning will be performed always in preset time. F1 module

has no wires connected to the

terminal block.

F2 - Full pipe check

module

Correct measurement of flow

rate by the magnetic flowmeter

is conditioned by full flooding of

the whole sensor cross section

by measured liquid. If flooding

is only partial, the magnetic

flowmeter will indicate flow rate

higher than real. However, if

both electrodes are not immersed in liquid, interfering voltage can be generated on elec-

OFF

Only once

During power ON

Periodically

Fig. F1 module menu

4. Binary input ─►● Off

○ Batch Start

○ Batch Hold

○ Batch Stop

○ Reset Counters

─►

√ Total volume +

○ Cleaning Start

√ Total volume -

√ Operational time

√ Temp. volume +

√ Temp. volume -

√ Temporary time

Page 20

FLOMAG 3000 -

Installation and Operation Manual

20

trode wires and the flowmeter

can indicate totally random values. To avoid this situation, the

sensor can be equipped with

checking electrode and converter with full pipe check module. The module continuously

checks if the checking electrode

is immersed in liquid. If it is not,

an error message will be displayed and zero flow rate will be

indicated. The checking electrode is connected to terminal 1.

This electrode cannot be retro-

fitted and should be considered on initial order.

Fig. F2 module menu

F3 - Electrode cleaning

and full pipe check module

This module combines functions of modules F1 and F2.

Besides different menu, all

above mentioned information

applies for this module.

Fig. F3 module menu

2. Full pipe check

─►

√ ON

2. Clean/Full pipe

─►

Electrode cleaning

─►

● Off

○ Once

○ During Power ON

○ Periodiccally

─►

»Clean every x [h]

»Time of start [h:m]

Full pipe check

─►

√ ON

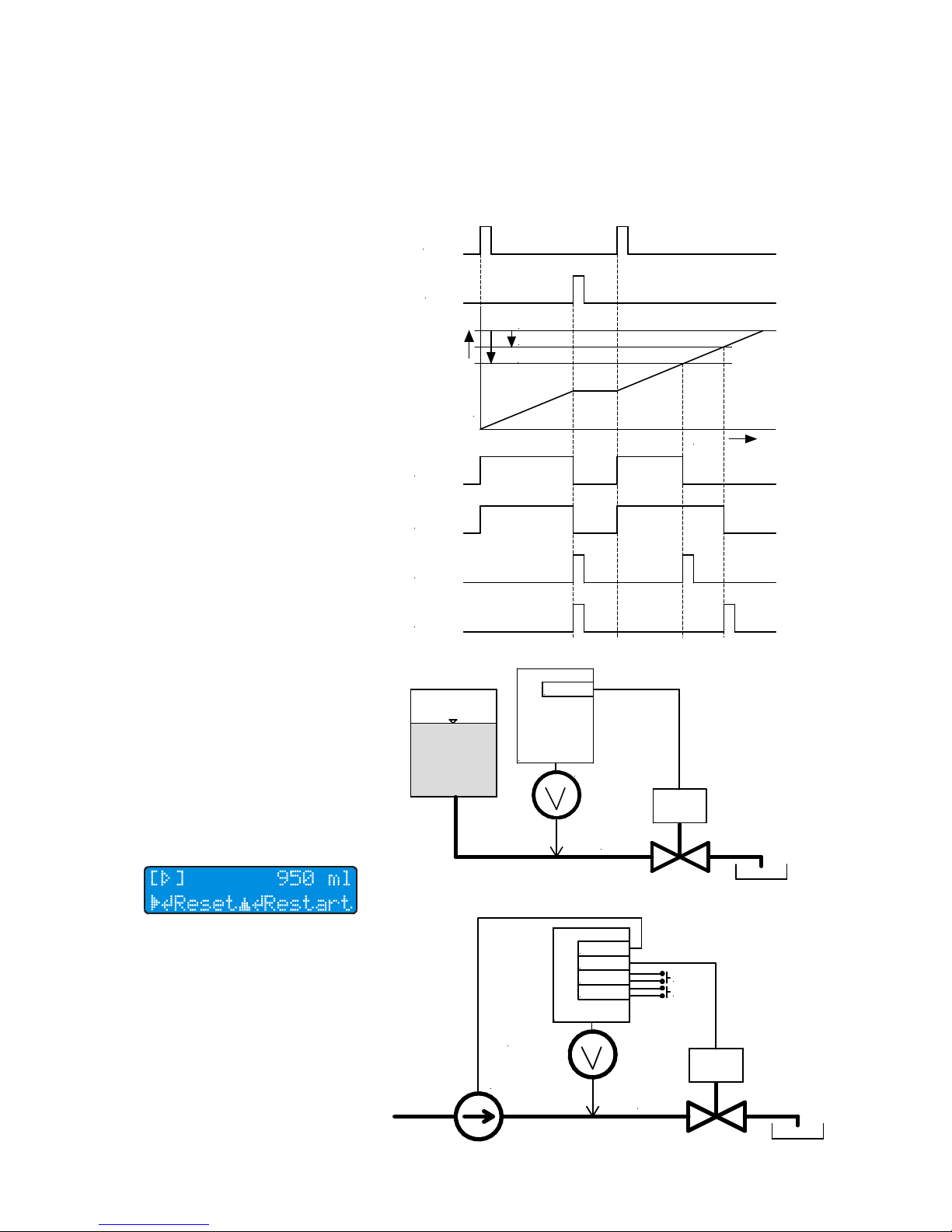

Batching

Batching mode is used for

control of external equipment

( valves, pumps) in order to

measure repeatedly the preset

volume (batch). It is not recommended for batching of very

small volumes. The period of

one batch has to be min 30 s.

Electromagnetic flowmeter

FLOMAG3000 has very sophisticated batching functions. It

enables simple batching with

manual starting but also fully

automatic batching by remote

control.

Batching process is divided

into 4 phases. Single phases

are distinguished on LCD by a

symbol in square brackets. Upper line shows remaining volume in ml to the end of the

batch. Bottom line shows help

for manual batch control.

Phase 0 - Stop

During phase 0 outputs are

inactive, no batching runs, waiting for start of the batching

process. Manual start is real-

ized by holding button 3 and

simultaneous pushing of button

4 or from outside with the help

of module E in Batch Start

mode. During that phase the

batch volume is set. To enter

edit mode it is necessary to

hold button 2 and simultaneously push button 4.

Phase 1 - Hold

Phase 1 temporary batch in-

terruption. Outputs give signal

for interruption of the batch

(close valve, switch off pump).

Counted batch could ve continued again by manual start

choosing Restart or from outside with the help of module E

in Batch Start mode. It is possible also to abort the batch by

choosing Reset or from outside

with the help of module E in

Batch Stop mode.

Phase 2 - Run

During that phase runs the

measuring of the batch (valve is

open, pump is running). This

mode can be interrupted using

Phase 1 (Hold) activated manually or with the help of module E

in Batch Stop mode. It is possible also to abort it choosing Re-

Fig. Batching phase 0

Fig. Batching phase 1

Fig. Batching phase 2

Module G1

Module H1

Module G1 is a GSM modem

enabling sending by SMS messages on preset numbers, in

preselect intervals (or on re-

quest) inforamtion about the

status of the flowmeter and the

measured values. Detailed description of the module func-

tions is given in a separate

document.

Module H1 is Bell 202 modem, extensioning the function

of modules A6 and A7. It enables data communication

through current loop with a pro-

tocol compatible with HART

(only Universal Command). Assigning the variables of the

flowmeter is following:

PV - Flow rate [ l/s ]

SV - Current flow rate [ l/s ]

TV - Total volume + [ m3/h ]

QV - Total volume - [ m3/h ]

Page 21

FLOMAG 3000 -

Installation and Operation Manual

21

Fig. Batching phase 3

Fig. Batch running

Fig. Minimum batching option

Fig. More complex batching option

event which first takes place.

The advantage is that you can

set different advance for each

output. This way it is possible to

switch off a pump and later

close the valve.

Binary outputs have 4 options

for setting in batch mode. They

set or from outside with the

help of module E in Batch Stop

mode. During this phase there

is no reaction to external signal

Batch Start. If there is no any

preset outputs' advance, after

flowing of the set batch volume

comes switching to phase 0

(Stop). Outputs will send signal

for batch stop (switch off pump,

close valve). Because of the

late reaction to the output signal

a partial overflow of the set

batch volume will take place

and display will show negative

volume. That's why it is suitable

to send a signal for batch stop

in advance as it is described

below.

Phase 3 - Finish

In practice we need to send a

signal for batch stop in advance. It is mainly because of

the inertia of the technical

equipment (valves, pumps).

Phase 3 represents time when

one of the outputs have sent in

advance signal for batch stop.

According to the ability to forecast exactly the advance, the

batch can slightly overflow

which means to go to phase 0

or the batch will not finish and

will go to phase 3. In this case it

is possible to go to phase 0 by

choosing Reset or from outside

with the help of module E in

Batch Stop mode. In the same

time takes place presetting of

the volume batch accroding to

the preset value. Second possibility is to start new batch

choosing restart or from outside

with the help of module E in

Batch Start mode.

The binary outputs in batch

mode enable setting of the advance by volume when the output is activated, if the remaining

batch volume is smaller than

the preset volume advance.

Second possibility is to set time

advance when the flowmeter's

logic calculates what time remains to the end of the batch

according to the actual flow.

Both possibilites can be combined. Output reacts to the

time

volume

output 1

output 2

output 2 (puls)

output 1 (puls)

start

hold

volume - advance 2

volume - advance 1

volume of batch

Flowmeter

Electrically

controled

valve

module B

FLOMAG3000

Pump

Flowmeter

Electrically

controled

valve

module B

module B

module E

module E

FLOMAG3000

Start

Hold

can indicate condition when

runs the batch (phase 2) or to

sent a pulse for batch finish/

interuption. Pulse length can be

set from 10 ms up to 2550 ms,

step 10 ms. Both output modes

can work in both polarities.

Page 22

FLOMAG 3000 -

Installation and Operation Manual

22

L

A

DN

o D

o d

l

160

168

80

114

58

65

70

75

100

136

* Standard construction length meets ISO 13359, different construction lengths should be indicated, e.g.

“l=215”

Construction length tolerance for DN£200: +0/-2 mm

DN³200: +0/-3 mm

** Weight of PDIN sensor without converter and terminal box

- weight of terminal box has to be added for remote version – 0.25 kg

- weight of converter has to be added for compact version – 0.9 kg

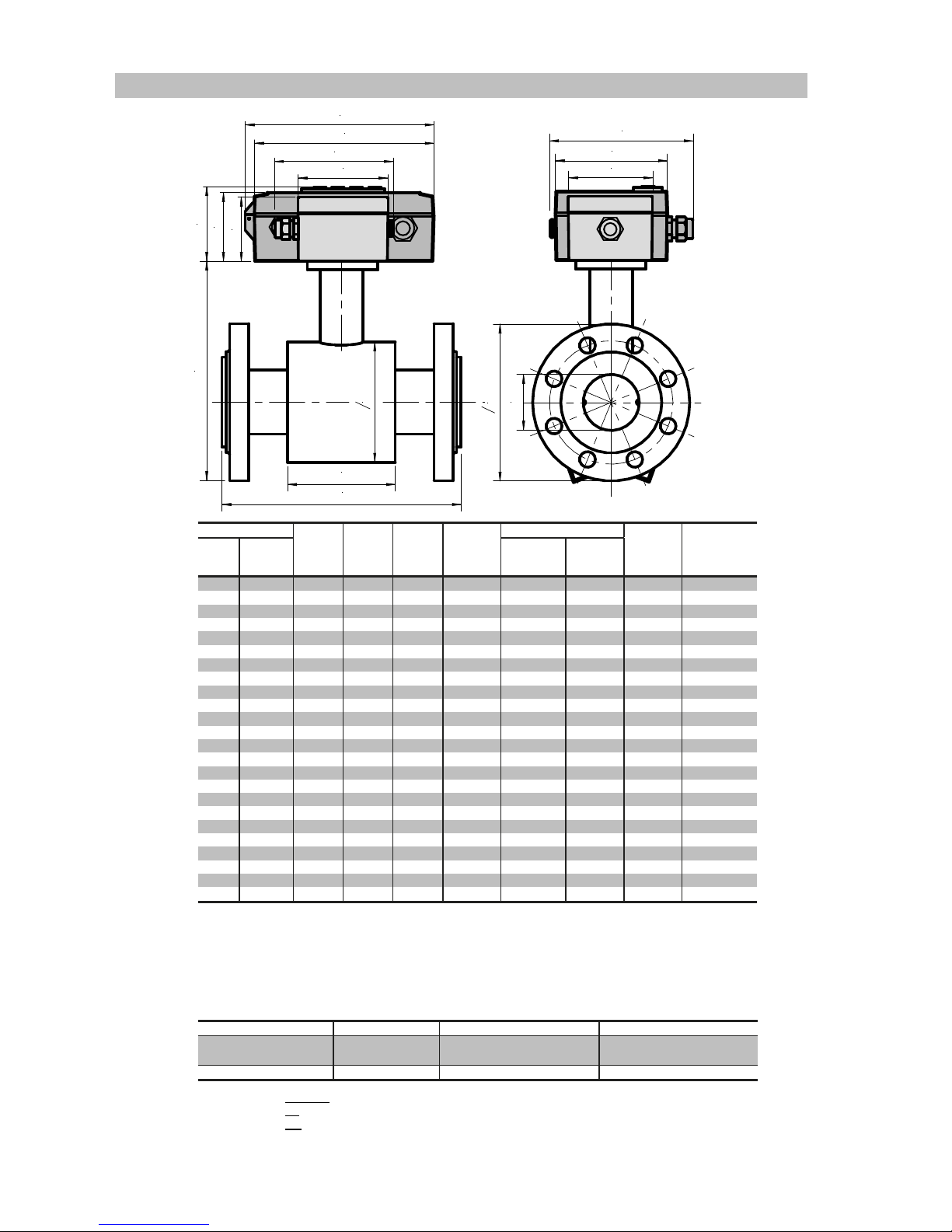

Flowmeter dimensions – flanged versions “P”, “PDIN” and “PANSI”

DN PN D d A l Weight**

ISO 13359

EN 14154

Optional

[mm] [inches] [mm] [mm] [ kg ]

15 1/2

16 95 62 164 200 138 66 3.5

20 3/4

16 105 62 170 200 138 66 3.5

25 1

16 115 72 180 200 215 96 3.5

32 1 1/4

16 135 82 199 200 215 96 6

40 1 1/2

16 145 92 209 200 215 96 7

50 2

16 160 107 223 200 215 96 8

65 2 1/2

16 180 127 244 200 215 96 10

80 3

16 195 142 260 200 215 96 12

100 4

16 215 162 280 250 215 96 16

125 5

16 245 192 310 250 305 126 21

150 6

16 280 218 340 300 305 126 28

200 8

16 335 274 398 350 380 211 35

250 10

10 405 370 480 450 380 211 42.5

300 12

10 440 420 535 500 515 320 55

350 14

10 500 480 584 550 515 320 65

400 16

10 565 530 642 600 515 320 94

450 18

10 565 530 642 600 515 320 94

500 20

10 670 640 752 600 515 320 122

600 24

10 780 760 870 600 615 320 158

700 28

10 895 880 990 700 715 420 230

800 32

6 1010 980 1100 800 815 420 325

900 36

6 1115 1040 1185 900 815 520 420

1000 40

6 1220 1140 1290 1000 1015 520 510

1200 48

6 1455 1340 1510 1200 1015 520 680

L*

[Bar] [mm] [mm] [mm]

[mm]

Type acc. to Flance DN PN Flange dimensions meet

PDIN

15..1200 2.5, 6, 10, 16, 25, 40, 63 EN 1092-1

BS 4504

PANSI

1/2“..40“ 150lb, 300lb ASA / ANSI B 16.5

Protection: compact version IP66, remote version IP67 (optionally IP68)

Electrodes: Ss – stainless steel AISI316Ti, Ha - Hastelloy C22, Ti - Titanium, Pt – platinum

Lining: TG – hard rubber, MG – soft rubber, NG – resistant rubber, PTFE – Teflon

Accessories: optional for a surcharge – grounding rings or grounding electrodes for nonconductive tube

Page 23

FLOMAG 3000 -

Installation and Operation Manual

23

L

A

DN

o d

160

168

80

114

58

65

70

75

100

136

DN D A L* Weight**

lining

TG, MG

lining

NG

lining

PTFE

[mm] [inches] [mm [mm] [mm] [mm] [mm] [ kg ]

10 3/8

62 145 - - 62 0.8

15 1/2

62 145 74 72 70 0.9

20 3/4

62 145 74 72 70 1.1

25 1

72 158 104 102 100 1.5

32 1 1/4

82 168 104 102 100 1.8

40 1 1/2

92 179 104 102 100 2.2

50 2

107 192 104 102 100 2.8

65 2 1/2

127 212 104 102 100 3.2

80 3

142 227 104 102 100 3.5

100 4

162 247 104 102 100 4

125 5

192 277 134 132 130 6

150 6

218 303 134 132 130 8

Flowmeter dimensions – wafer version “B”

* Standard construction length meets ISO 13359, different construction lengths should be indicated, e.g.

“l=215”

Construction length tolerance: +0/-2 mm

** Weight of the sensor without converter and terminal box

- weight of terminal box has to be added for remote version – 0.25 kg

- weight of converter has to be added for compact version – 0.9 kg

The sensor is designed for installation between flanges and for fastening by clamps (not included in

delivery). For sensor sizes DN20..DN120, flanges with corresponding dimensions are used. For sensor

sizes DN10..D15 the flange DN20 has to be used, because the sensor body is bigger than space

between openings of corresponding flanges.

Protection: compact version IP66, remote version IP67 (optionally IP68)

Electrodes: Ss – stainless steel AISI316Ti, Ha - Hastelloy C22, Ti - Titanium, Pt – platinum

Lining: TG – hard rubber, MG – soft rubber, NG – resistant rubber, PTFE – Teflon

Pressure: PN16, PN25, PN40, PN63

Accessories: optional for a surcharge – grounding rings or grounding electrodes for nonconductive

tube

Page 24

FLOMAG 3000 -

Installation and Operation Manual

24

L

A

DN

o d

l

160

168

80

114

58

65

70

75

100

136

DN d l A* Weight**

ISO 13359

EN 14154

Optional

[mm] [inches] [mm] [mm] [mm] [mm] [mm] [ kg ]

15 1/2

62 66 145 200 134 0.9

20 3/4

62 66 145 200 150 1.1

25 1

72 96 158 200 213 1.5

32 1 1/4

82 96 168 200 213 1.8

40 1 1/2

92 96 179 200 213 2.2

50 2

107 96 192 200 213 2.8

65 2 1/2

127 96 212 200 213 3.2

80 3

142 96 227 200 213 3.5

100 4

162 96 247 250 213 4

125 5

192 126 277 250 301 6

150 6

218 126 303 300 301 8

L*

Flowmeter dimensions – version with aseptic screwed fitting “B” (DIN 11851)

* Standard construction length meets ISO 13359, different construction lengths should be indicated,

e.g. “l=213”

Construction length tolerance: +0/-2 mm

** Weight of the sensor without converter and terminal box

- weight of terminal box has to be added for remote version – 0.25 kg

- weight of converter has to be added for compact version – 0.9 kg

The sensor is connected to the pipeline using an aseptic screwed fitting that meets DIN 11 851 standard. Part of the fitting with cap nut is firmly fixed to the sensor. Welded counterpart with male thread

and sealing are part of delivery. This sensor version is suitable for foodstuff flow. Non-conducting lining

of the sensor extends over its edges to avoid both leakage and depositing of measured fluid on edges.

Due to cap nuts, the sensor can be easily deinstalled and comfortably cleaned.

Screwed fitting: DIN 11 851

Protection: compact version IP66, remote version IP67 (optionally IP68)

Electrodes: Ss – stainless steel AISI316Ti, Ha - Hastelloy C22, Ti - Titanium, Pt – platinum

Lining: NG – resistant rubber (for drinking water), PTFE – Teflon (for foodstuff)

Pressure: PN16, PN25, PN40, PN63

Accessories: optional for a surcharge – grounding electrodes for nonconductive tube

Page 25

FLOMAG 3000 -

Installation and Operation Manual

25

L

A

DN

o d

l

160

168

80

114

58

65

70

75

100

136

G

DN G d l A L* Weight**

thread

ISO 13359

EN 14154

Optional

[mm] [inches] [inches] [mm] [mm] [mm] [mm] [mm] [ kg ]

15 1/2

1“ 62 66 145 200 134 0.9

20 3/4

1 1/4“ 62 66 145 200 150 1.1

25 1

1 1/2“ 72 96 158 200 213 1.5

32 1 1/4

2“ 82 96 168 200 213 1.8

40 1 1/2

2 1/2“ 92 96 179 200 213 2.2

50 2

3“ 107 96 192 200 213 2.8

65 2 1/2

3 1/2“ 127 96 212 200 213 3.2

80 3

4“ 142 96 227 200 213 3.5

Flowmeter dimensions – version with tube thread “G” (DIN ISO 228 )

The sensor is connected to the pipeline using a fitting with a cap nut and a gasket. Both ends of measuring tube are equipped with male tube thread. Adjacent tubes have to be equipped with fitting with cap

nut (not included in delivery) and sealed using gasket (not included in delivery).

Protection: compact version IP66, remote version IP67 (optionally IP68)

Electrodes: Ss – stainless steel AISI316Ti, Ha - Hastelloy C22, Ti - Titanium, Pt – platinum

Lining: TG – hard rubber, MG – soft rubber, NG – resistant rubber, PTFE – Teflon

Pressure: PN16, PN25, PN40, PN63

Accessories: optional for a surcharge – grounding electrodes for nonconductive tube

* Standard construction length meets ISO 13359, different construction lengths should be indicated, e.g.

“l=213”

Construction length tolerance: +0/-2 mm

** Weight of the sensor without converter and terminal box

- weight of terminal box has to be added for remote version – 0.25 kg

- weight of converter has to be added for compact version – 0.9 kg

Page 26

FLOMAG 3000 -

Installation and Operation Manual

26

PDIN 50 16 TG Ss Ge Fe Cv

Cv

compact version

Rvx

remote version (x = cable length in m)

_

without full pipe check electrode

Fe

optional full pipe check electrode

_

without grounding electrode

Ge

optional grounding electrode

Ss

stainless steel electrodes

Ha

Hastelloy electrodes

Pt

platinum electrodes

TG

hard rubber lining

MG

soft rubber lining

NG

resistant rubber lining

PTFE

Teflon lining

6, 10, 16, 25, 40

nominal pressure [bars]

150lb, 300lb

nominal pressure [lb]

10..1200

nominal bore diameter [mm]

3/8"..50"

nominal bore diameter [inches]

PDIN

flanged version – flanges according to DIN

PANSI

flanged version – flanges according to ANSI

B

wafer version

V

version with aseptic fittings for food industry

G

threaded version

Ti

Titanium electrodes

Sensor – marking and label

Tab. Sensor marking

Fig. Sensor label

Page 27

FLOMAG 3000 -

Installation and Operation Manual

27

FLOMAG 3 0 0 0 S1 F1 -- B1 B1 C1 A1 V1

--

module not fitted

V1

display and keypad

--

module not fitted

A1

active output module 0(4)..20 mA (12 bit) - replaced by A5

A2

active output module 0(4)..20 mA (16 bit) - replaced by A5

A3

active output module 4..20 mA (16 bit) - replaced by A6

A4

passive output module 4..20 mA (16 bit) - replaced by A7

A5