Flo Fab 2FFSTEP Installation, Operation & Maintenance Manual

Submersible Euent Pumps

2FFSTEP

0.5 & 1 HP @ 3450 RPM

Installation, Operation &

Maintenance Manual

IMPORTANT! - Read all instructions in this manual before operating or servicing

a pump.

General Safety Information

Before installation, read the following

instructions carefully. Failure to

follow instruction and safety

information could cause serious

bodily injury, death and/or property

damage. Each Flo Fab product is

carefully inspected to insure proper

performance. Closely following these

instructions will eliminate potential

operating problems, assuring years

of trouble-free service.

DANGER

"Danger" indicates an

imminently hazardous situation

which, if not avoided, WILL result in

death or serious injury.

WARNING

"Warning" indicates

an imminenty hazardous situation

which, if not avoided, MAY result in

death or serious injury.

CAUTION

"Caution" indicates a

potentially hazardous situation

which, if not avoided, MAY result in

minor or moderate injury.

IMPORTANT! - Flo Fab Pumps is not

responsible for losses, injur y or

death r e sulting from failure to

observe these safety precautions,

misuse, abuse or misapplication of

pumps or equipment.

ALL R E TURNED

P R ODUC T S MUST B E

CLEANED, SANITIZED, OR

DECONTAMINATED PRIOR TO

SHIPMENT, TO INSURE EMPLOYEES

WILL NOT BE EXPOSED TO HEALTH

HA Z ARDS IN HANDLING SAID

MATERIAL. ALL APPLICABLE LAWS

AND REGULATIONS SHALL APPLY.

WARNING

junc tion connec tions must be in

accordance with the National Electric

Code and all applicable state and local

codes. Requirements may vary depending

on usage and location.

Installation, wiring, and

WARNING

I nstalla tion and

servicing is to be conducted by

qualied personnel only.

Keep clear of suction and

discharge openings. Do not

insert ngers in pump with

power connected; the impeller can

cause serious injury.

Always wear eye protection

when working on pumps. Do

not wear loose clothing that

may become entangled in moving

parts.

DANGER

Pumps build up heat

and pressure during

operation. Allow time

for pumps t o c ool

before handling or servicing the

pump or a ny accessor y i tems

associated with or near the pump.

DANGER

T his pump is not

i n t ended f or use in

swimming pools or water

installations where there is

human contact with pumped uid.

DANGER

Risk of electric shock. To

reduce risk of electric shock,

always disconnec t pump

from power source before

handling any aspect of the pumping

system. Lock out power and tag.

WARNING

Do not use these

pumps in water over 104º F. Do not

exceed manufacturers recommended

maximum performance, as this could

cause the motor to overheat.

DANGER

Do not lift, carry or

hang pump by the electrical

cables. Damage to the

electrical cables can cause

shock, burns or death. Never handle

connected power cords with wet

hands. Use appropriate lifting device.

WARNING

Sump and sew age

pumps often handle materials which

could cause illness or disease. Wear

adequate protective clothing when

working on a used pump or piping.

Never enter a basin after it has been

used.

DANGER

Failure to permanently

ground the pump, motor and

controls before connecting

to power can cause shock,

burns or death.

DANGER

These pumps are not to

be installed in locations

classied as hazardous in

accordance with the National

Electric Code, ANSI/NFPA 70.

WARNING

The Uniform Plumbing

Code ( UPC ) sta tes that sewage

systems shall have an audio and visual

alarm that signals a malfunction of the

systems, that are required to reduce

the potencial for property damage.

IMPORTANT! - Prior to installation,

record Model Number, Serial, Amps,

Voltage, Phase and HP from pump

name plate for the future reference.

Also record the Voltage and Current

Readings at Startup:

Model Number: ____________________

Serial: ____________________

Amps:_______ Voltage:_______

Phase:_______ HP:_______

01

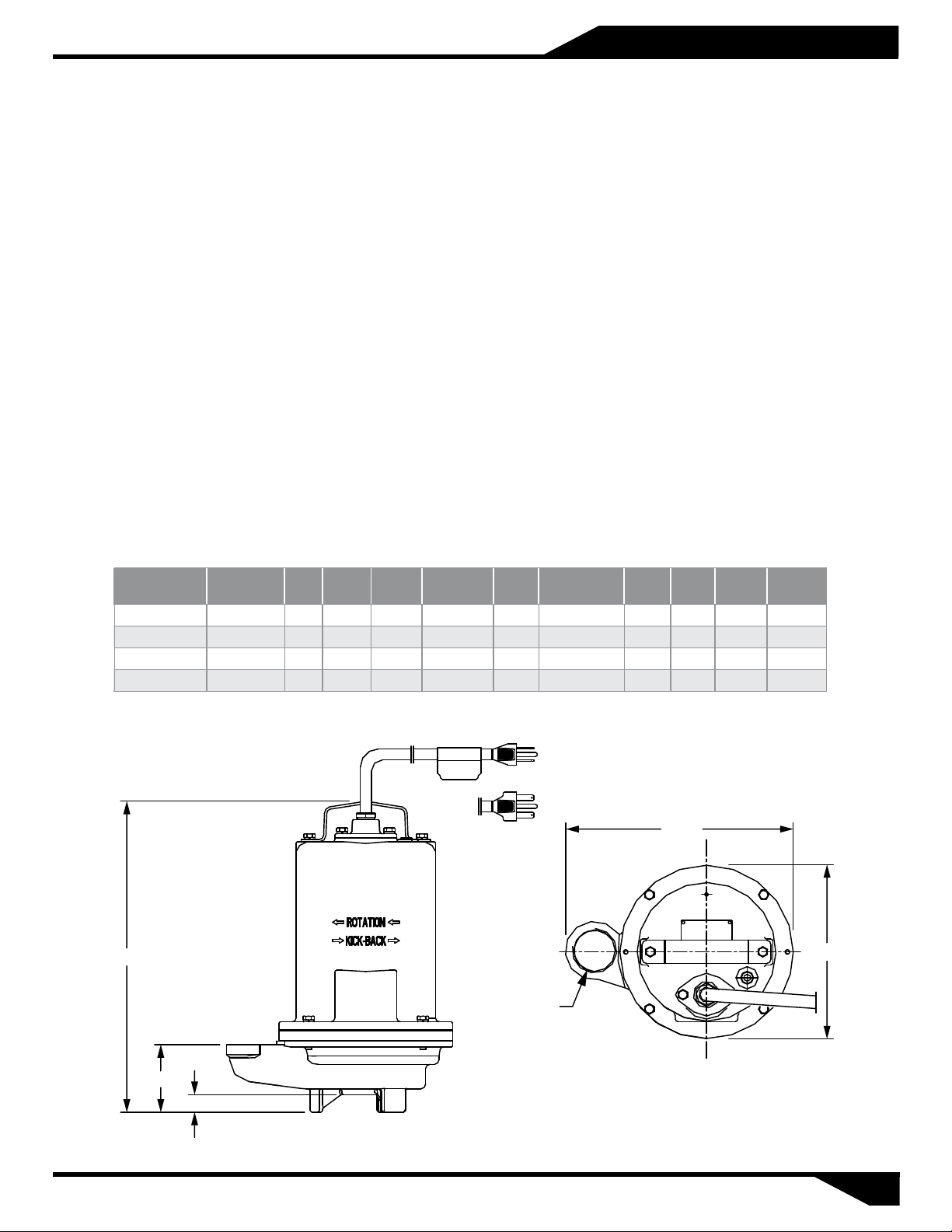

Specications & Dimensions

DISCHARGE: 2" NPT, vertical.

SPHERICAL SLD HNDLG: 3/4"

LIQUID TEMPERATURE: 104° F (40° C) continuous.

VOLUTE: Cast iron ASTM A-48 class 30.

MOTOR HOUSING: Cast iron ASTM A-48 class 30.

SEAL PLATE: Cast iron ASTM A-48 class 30.

IMPELLER: Single vane enclosed. Polypropylene with stainless steel insert.

SHAFT: Stainless steel.

O-RINGS: Square shaped Buna-N.

PAINT: Air dry enamel, water based.

SEAL: Outboard single mechanical, oil lled chamber. carbon / ceramic / Buna-N, with

stainless steel hardware.

HARDWARE: 300 series stainless steel.

CORD ENTRY: 20 ft of neoprene cord, sealed against moisture.

BEARINGS: Ball, single row, oil lubricated.

MOTOR: NEMA L, single phase, permanent split capacitor, oil lled, with

overload

in motor.

OPTIONAL EQUIPMENT: Additional cord, seal material, impeller trims, slide rail coupling (SRC-2).

protection

MODEL PART No. HP VOLTS PHASE

2FFSTEP

2FFSTEP

2FFSTEP

2FFSTEP

A = Automatic Float Switch.

16.53"

512 0.5 115 1 3450 13.1 26.2 G 14/3 SOW 80

512A 0.5 115 1 3450 13.1 26.2 G 14/3 SOW 80

522 0.5 230 1 3450 5.6 13.2 E 14/3 SOW 80

1022

-

-

-

- 1 230 1 3450 9.1 23.5 f 14/3 SOW 80

RPM

(Nominal)

MAX

AMPS

2" NPT

LOCKED

ROTOR AMPS

NEMA

CODE

CORD

SIZE

12.16"

CORD

TYPE

WEIGHT

(pounds)

9.25"

3.6"

0.94"

02

Recommendations and Warnings

Receiving inspection

Upon receiving the pump, it should

be inspected for damage or

shortages. If damage has occurred,

le a claim immediately with the

company that delivered the pump. If

the manual is removed from the

packaging, do not lose or misplace.

Storage

Any product that is stored for a

period longer than six (6) months

from the date of purchase should be

bench tested prior to installation. A

bench test consists of, checking the

impeller to assure it is free turning

and a run test to assure the motor

(and switch if provided) operate

properly.

Controls

Manual models require a separate

approved pump control device or

panel for automatic operation. Be

sure the ele

control selected properly match the

electrical specications of the pump.

ctrical specication of the

Installation

There are two methods of installing

euent pumps:

1. In a Flex-Hose system, most

commonly used in interceptor

tanks, and

2. A slide rail in a package system or

concrete wet well, which allows

the pump(s) to be installed or

removed without requiring

personnel to enter the wet well.

The sump, basin or lift station shall

be sealed and vented in accordance

with local plumbing codes. This

pump is designed to pump

sewage, euent or wastewater,

non-explosive and non-corrosive

liquids and shall NOT be installed

in locations classied as hazardous

in accordance with the National

Electrical Code (NEC) ANS

70 or Canadian Electric Code (CEC).

The pump should never be installed

in a trench, ditch, or hole with a dirt

bottom. The legs will sink into the

dirt and the suction will become

plugged.

I/NFPA

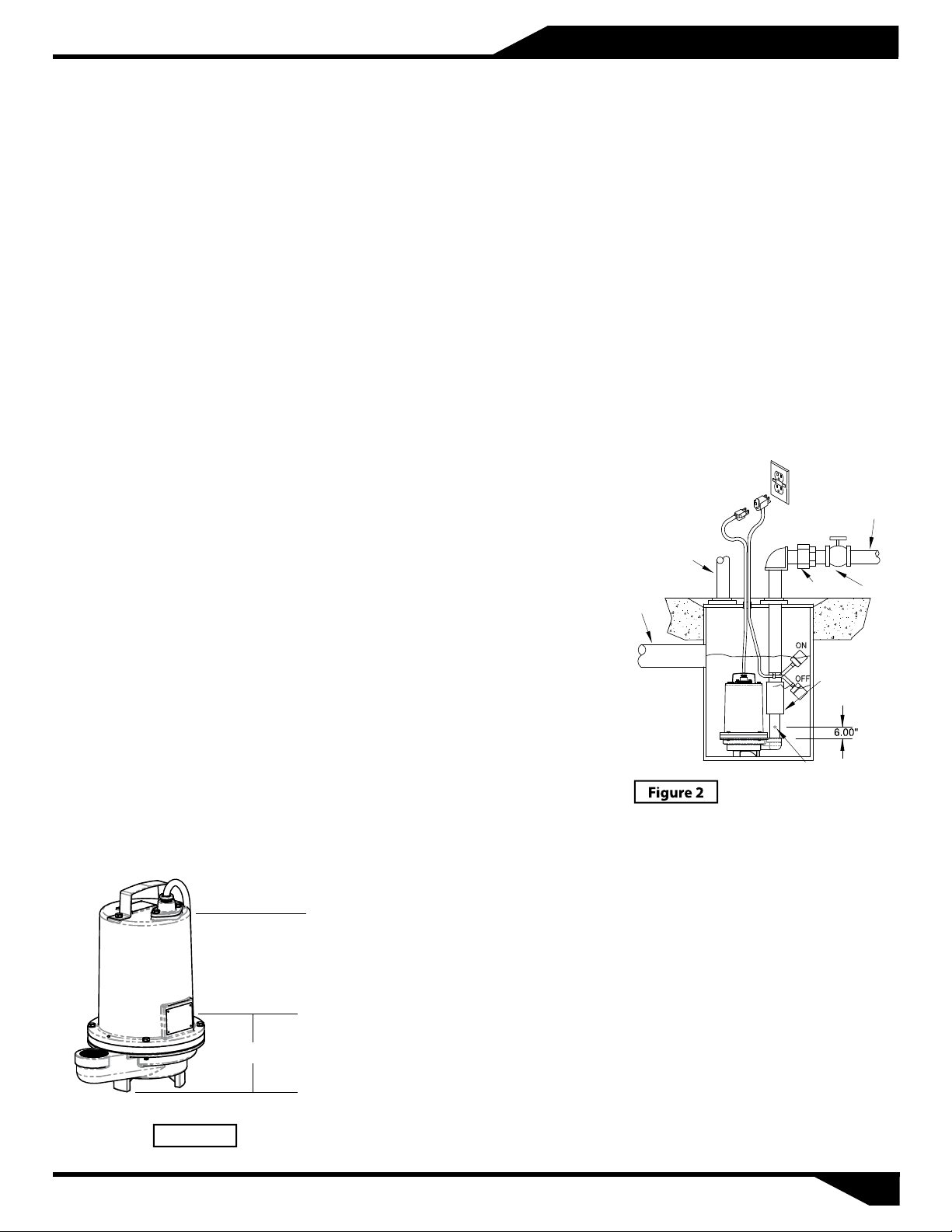

Liquid Level Controls

Typical Discharge Pipe Mounted:

Refer to Figure 2 below which shows

a typical installation of a 1 phase 120

or 240 volt pump using a level

control mounted to the discharge

piping with a piggy-back plug. The

level control should have adequate

clearance so it cannot hang up in it’s

swing and that the pump is

completely submerged when the

level control is in the "O" mode. By

adjusting the cord tether the control

level can be changed.

Typical Installation with Wide

Angle Level Control

DISCHARGE

VENT

UNION

INLET

GATE

VALVE

CHECK VALVE

Submergence

The pump should always be

operated in the submerged

condition. The minimum sump liquid

level should never be less than above

the pump’s volute (See Figure 1).

Recommended

Submergence

Level

Minimum

Submergence

Level

6"

Bottom of Feet

Figure 1

The installation should be at a

sucient depth to ensure that all

plumbing is below the frost line. If

this is not feasible, remove the check

valve and size the basin to

accommodate the additional

backow volume.

Discharge Piping

Discharge piping should be as short

as possible and sized no smaller than

the pump discharge. Do not reduce

the discharge pipe size below that

which is provided on the pump.

Both a check valve and a shut-o

valve are recommended for each

pump. The check valve is used to

prevent backow into the sump. The

shut-o valve is used to manually

stop system low during pump

servicing.

Drill ¼" dia. vent hole

to prevent air locking

Level Control Basic Instructions:

Plug the level control plug into the

GFI receptacle, then plug the pump

into the piggy-back plug (See Figure

3). One cycle of operation should be

observed, so that any potential

problems can be corrected.

It is recommended that the level

control oat should be set to insure

that the liquid in the sump never

drops below the top of the motor

housing or a minimum level of 6

inches above the basin oor.

03

Loading...

Loading...