Page 1

Submersible Euent Pumps

2FFSTEP

0.5 & 1 HP @ 3450 RPM

Installation, Operation &

Maintenance Manual

IMPORTANT! - Read all instructions in this manual before operating or servicing

a pump.

Page 2

General Safety Information

Before installation, read the following

instructions carefully. Failure to

follow instruction and safety

information could cause serious

bodily injury, death and/or property

damage. Each Flo Fab product is

carefully inspected to insure proper

performance. Closely following these

instructions will eliminate potential

operating problems, assuring years

of trouble-free service.

DANGER

"Danger" indicates an

imminently hazardous situation

which, if not avoided, WILL result in

death or serious injury.

WARNING

"Warning" indicates

an imminenty hazardous situation

which, if not avoided, MAY result in

death or serious injury.

CAUTION

"Caution" indicates a

potentially hazardous situation

which, if not avoided, MAY result in

minor or moderate injury.

IMPORTANT! - Flo Fab Pumps is not

responsible for losses, injur y or

death r e sulting from failure to

observe these safety precautions,

misuse, abuse or misapplication of

pumps or equipment.

ALL R E TURNED

P R ODUC T S MUST B E

CLEANED, SANITIZED, OR

DECONTAMINATED PRIOR TO

SHIPMENT, TO INSURE EMPLOYEES

WILL NOT BE EXPOSED TO HEALTH

HA Z ARDS IN HANDLING SAID

MATERIAL. ALL APPLICABLE LAWS

AND REGULATIONS SHALL APPLY.

WARNING

junc tion connec tions must be in

accordance with the National Electric

Code and all applicable state and local

codes. Requirements may vary depending

on usage and location.

Installation, wiring, and

WARNING

I nstalla tion and

servicing is to be conducted by

qualied personnel only.

Keep clear of suction and

discharge openings. Do not

insert ngers in pump with

power connected; the impeller can

cause serious injury.

Always wear eye protection

when working on pumps. Do

not wear loose clothing that

may become entangled in moving

parts.

DANGER

Pumps build up heat

and pressure during

operation. Allow time

for pumps t o c ool

before handling or servicing the

pump or a ny accessor y i tems

associated with or near the pump.

DANGER

T his pump is not

i n t ended f or use in

swimming pools or water

installations where there is

human contact with pumped uid.

DANGER

Risk of electric shock. To

reduce risk of electric shock,

always disconnec t pump

from power source before

handling any aspect of the pumping

system. Lock out power and tag.

WARNING

Do not use these

pumps in water over 104º F. Do not

exceed manufacturers recommended

maximum performance, as this could

cause the motor to overheat.

DANGER

Do not lift, carry or

hang pump by the electrical

cables. Damage to the

electrical cables can cause

shock, burns or death. Never handle

connected power cords with wet

hands. Use appropriate lifting device.

WARNING

Sump and sew age

pumps often handle materials which

could cause illness or disease. Wear

adequate protective clothing when

working on a used pump or piping.

Never enter a basin after it has been

used.

DANGER

Failure to permanently

ground the pump, motor and

controls before connecting

to power can cause shock,

burns or death.

DANGER

These pumps are not to

be installed in locations

classied as hazardous in

accordance with the National

Electric Code, ANSI/NFPA 70.

WARNING

The Uniform Plumbing

Code ( UPC ) sta tes that sewage

systems shall have an audio and visual

alarm that signals a malfunction of the

systems, that are required to reduce

the potencial for property damage.

IMPORTANT! - Prior to installation,

record Model Number, Serial, Amps,

Voltage, Phase and HP from pump

name plate for the future reference.

Also record the Voltage and Current

Readings at Startup:

Model Number: ____________________

Serial: ____________________

Amps:_______ Voltage:_______

Phase:_______ HP:_______

01

Page 3

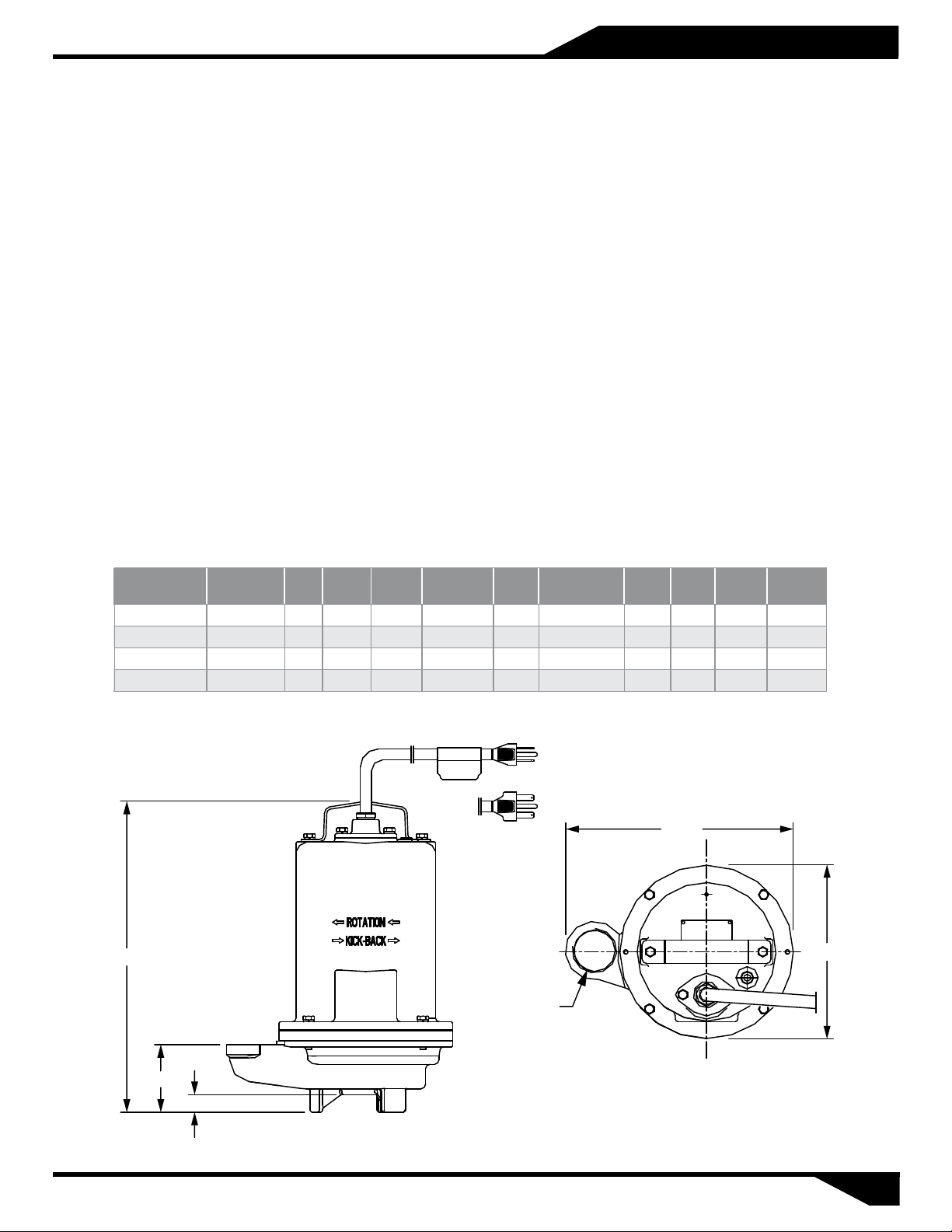

Specications & Dimensions

DISCHARGE: 2" NPT, vertical.

SPHERICAL SLD HNDLG: 3/4"

LIQUID TEMPERATURE: 104° F (40° C) continuous.

VOLUTE: Cast iron ASTM A-48 class 30.

MOTOR HOUSING: Cast iron ASTM A-48 class 30.

SEAL PLATE: Cast iron ASTM A-48 class 30.

IMPELLER: Single vane enclosed. Polypropylene with stainless steel insert.

SHAFT: Stainless steel.

O-RINGS: Square shaped Buna-N.

PAINT: Air dry enamel, water based.

SEAL: Outboard single mechanical, oil lled chamber. carbon / ceramic / Buna-N, with

stainless steel hardware.

HARDWARE: 300 series stainless steel.

CORD ENTRY: 20 ft of neoprene cord, sealed against moisture.

BEARINGS: Ball, single row, oil lubricated.

MOTOR: NEMA L, single phase, permanent split capacitor, oil lled, with

overload

in motor.

OPTIONAL EQUIPMENT: Additional cord, seal material, impeller trims, slide rail coupling (SRC-2).

protection

MODEL PART No. HP VOLTS PHASE

2FFSTEP

2FFSTEP

2FFSTEP

2FFSTEP

A = Automatic Float Switch.

16.53"

512 0.5 115 1 3450 13.1 26.2 G 14/3 SOW 80

512A 0.5 115 1 3450 13.1 26.2 G 14/3 SOW 80

522 0.5 230 1 3450 5.6 13.2 E 14/3 SOW 80

1022

-

-

-

- 1 230 1 3450 9.1 23.5 f 14/3 SOW 80

RPM

(Nominal)

MAX

AMPS

2" NPT

LOCKED

ROTOR AMPS

NEMA

CODE

CORD

SIZE

12.16"

CORD

TYPE

WEIGHT

(pounds)

9.25"

3.6"

0.94"

02

Page 4

Recommendations and Warnings

Receiving inspection

Upon receiving the pump, it should

be inspected for damage or

shortages. If damage has occurred,

le a claim immediately with the

company that delivered the pump. If

the manual is removed from the

packaging, do not lose or misplace.

Storage

Any product that is stored for a

period longer than six (6) months

from the date of purchase should be

bench tested prior to installation. A

bench test consists of, checking the

impeller to assure it is free turning

and a run test to assure the motor

(and switch if provided) operate

properly.

Controls

Manual models require a separate

approved pump control device or

panel for automatic operation. Be

sure the ele

control selected properly match the

electrical specications of the pump.

ctrical specication of the

Installation

There are two methods of installing

euent pumps:

1. In a Flex-Hose system, most

commonly used in interceptor

tanks, and

2. A slide rail in a package system or

concrete wet well, which allows

the pump(s) to be installed or

removed without requiring

personnel to enter the wet well.

The sump, basin or lift station shall

be sealed and vented in accordance

with local plumbing codes. This

pump is designed to pump

sewage, euent or wastewater,

non-explosive and non-corrosive

liquids and shall NOT be installed

in locations classied as hazardous

in accordance with the National

Electrical Code (NEC) ANS

70 or Canadian Electric Code (CEC).

The pump should never be installed

in a trench, ditch, or hole with a dirt

bottom. The legs will sink into the

dirt and the suction will become

plugged.

I/NFPA

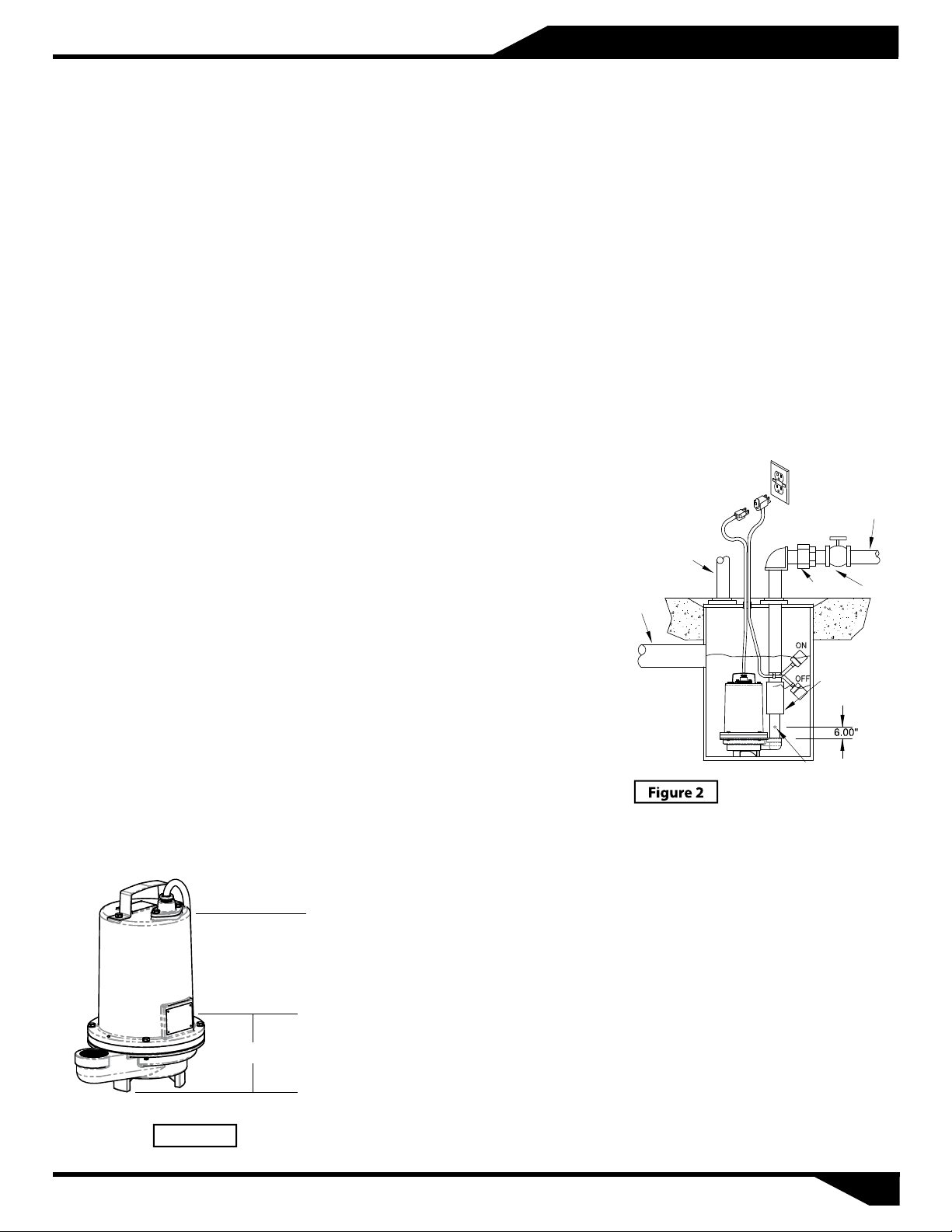

Liquid Level Controls

Typical Discharge Pipe Mounted:

Refer to Figure 2 below which shows

a typical installation of a 1 phase 120

or 240 volt pump using a level

control mounted to the discharge

piping with a piggy-back plug. The

level control should have adequate

clearance so it cannot hang up in it’s

swing and that the pump is

completely submerged when the

level control is in the "O" mode. By

adjusting the cord tether the control

level can be changed.

Typical Installation with Wide

Angle Level Control

DISCHARGE

VENT

UNION

INLET

GATE

VALVE

CHECK VALVE

Submergence

The pump should always be

operated in the submerged

condition. The minimum sump liquid

level should never be less than above

the pump’s volute (See Figure 1).

Recommended

Submergence

Level

Minimum

Submergence

Level

6"

Bottom of Feet

Figure 1

The installation should be at a

sucient depth to ensure that all

plumbing is below the frost line. If

this is not feasible, remove the check

valve and size the basin to

accommodate the additional

backow volume.

Discharge Piping

Discharge piping should be as short

as possible and sized no smaller than

the pump discharge. Do not reduce

the discharge pipe size below that

which is provided on the pump.

Both a check valve and a shut-o

valve are recommended for each

pump. The check valve is used to

prevent backow into the sump. The

shut-o valve is used to manually

stop system low during pump

servicing.

Drill ¼" dia. vent hole

to prevent air locking

Level Control Basic Instructions:

Plug the level control plug into the

GFI receptacle, then plug the pump

into the piggy-back plug (See Figure

3). One cycle of operation should be

observed, so that any potential

problems can be corrected.

It is recommended that the level

control oat should be set to insure

that the liquid in the sump never

drops below the top of the motor

housing or a minimum level of 6

inches above the basin oor.

03

Page 5

Installation & Service

115V, 1Ph

230V, 1Ph

Overload Protection:

Single Phase - The stator in-winding

overload protector used is referred to

as an inherent overheating protector

and operates on the combined eect

of temperature and current. This

means that the overload protector

will trip out and shut the pump o

the

windings become too hot, or the

load current passing through them

becomes too high.

IMPORTANT! - The overload will then

automatically reset and start the

pump up after the motor cools to a

safe temperature. In the event of an

o verload, the source of this condition

should be determined and corrected

immediately.

WARNING

PUMP TO CYCLE OR RUN IF AN

OVERLOAD CONDITION OCCURS.

DO NOT ALLOW THE

if

2.Check Pump Rotation - Improper

motor rotation can result in poor

pump performance and can

damage the motor and/or pump.

Check rotation on three phase

units by momentarily applying

power and observe the "kickback".

3.Name Plate - Record the

information from the pump name

plate to drawing in front of manual

for future reference.

4.Insulation Test - An insulation

(megger) test should be performed

on the motor. Before

into service. The resistance values

(ohms) as well as the voltage (volts)

and current (amps) should be

recorded.

the pump

is put

Figure 3

Electrical Connections

Power cable:

The power cable mounted to the

pump must not be modied in any

way except for shortening to a

specic application. Any splice

between the pump and the control

panel must be made in accordance

with the electric codes. It is

recommended that a junction box, if

used, be mounted outside the sump

or be of at a minimum Nema 4

construction if located within the wet

well. DO NOT USE THE POWER

CABLE TO LIFT PUMP.

Always rely upon a Certied

Electrician for installation.

If current through the temperature

sensor exceeds the values listed, an

intermediate control circuit relay

must be used to reduce the current

or the sensor will not work properly.

TEMPERATURE SENSOR ELECTRICAL

RATINGS

Volts Continuous

Amperes

110-120 3.00 30.0

220-240 1.50 15.0

Wire Size:

If longer power cable is required

c a qualied electrician for onsult

proper wire size.

Inrush

Amperes

Pre-Operation

1.Check Voltage and Phase -

Compare the voltage and phase

information stamped on the

pump name plate.

5.Pump-Down Test - Be sure pump

has been properly wired, lowered

into the basin, sump or lift station,

check the system by lling with liquid

and allowing the pump to operate

through its pumping cycle. The time

needed to empty the system, or

pump-down time along with the

volume of water, should be recorded.

Maintenance

No lubrication or maintenance is

required. Perform the following

checks when pump is removed from

operation or when pump

performance deteriorates:

a)Inspect motor chamber for oil

level and contamination.

b)Inspect impeller and body for

excessive build-up or clogging.

c)Inspect motor, bearings and shaft

seal for wear or leakage.

04

Page 6

Service

Servicing

Cooling Oil - Anytime the pump is

removed from operation, the cooling

oil in the motor housing should be

checked visually for oil level and

contamination. To check oil, set unit

upright. Remove pipe plug from

housing. With a ashlight, visually

inspect the oil in the housing to make

sure it is clean and clear, light amber

in color and free from suspended

particles. Milky white oil indicates the

presence of water. Oil level should be

just above the motor when pump is

in vertical position.

Oil Testing

Drain oil into a clean, dry container

by placing pump on it’s side,

remove pipe plug (20), from

housing (10).

Check oil for contamination using

an oil tester with a range to 30 kV

breakdown.

If oil is found to be clean and

uncontaminated (measuring

above 15 V breakdown), re ill the k f

housing.

If oil is found to be dirty or

contaminated (or measures below

15 breakdown), the pump must kV

be carefully inspected for leaks at

the shaft seal, conduit box, o-rings,

pipe plug and pressure valve,

before re illing with oil. To locate f

the leak, perform a pressure test.

After leak is repaired, dispose of old

oil properly, and re ill with new oil.f

Pressure Test (If oil has been

drained) - Remove pipe plug from

housing. Apply pipe sealant to

pressure gauge assembly and tighten

into hole. Pressurize motor housing

to 10 PSI. Use soap solution around

the sealed areas and inspect joints

for "air bubbles".

If, after ve minutes, the pressure is

still holding constant, and no

"bubbles" are observed, slowly bleed

the pressure and remove the gauge

assembly. Replace oil. Leek must be

ted and repaired if pressure does

loca

not hold.

Pressure Test (If oil has NOT been

drained) - Oil should be at normal

level. Remove pipe plug from

housing. Apply pipe sealant to

pressure gauge assembly and tighten

into hole. Pressurize motor housing to

10 PSI. Use soap solution around the

sealed areas above the oil level and

inspect joints for "air bubbles". For

sealed areas below oil level, leeks will

seep oil. If, after ve minutes, the

pressure is still holding constant, and

no "bubbles"/oil seepage is observed,

slowly bleed the pressure and remove

the gauge assembly. Replace oil. Leek

must be located and repaired if

pressure does not hold.

Pressure builds up extremely

fast, increase pressure by

"TAPPING" air nozzle. Too

much pressure will damage

seal. DO NOT exceed 10 PSI.

Oil Replacement - Set unit upright

and rell with new cooling oil as per

table below . Fill to just above motor,

but below capacitor as an air space

must remain in the top of the housing

to compensate for oil expansion.

Apply pipe thread compound to

threads of pipe plug then assemble

to housing.

DO NOT overll oil.

Overlling of housing with oil

can create excessive and

dangerous hydraulic pressure

which can destroy the pump

and create a hazard.

Overlling oil voids warranty.

Cooling Oil

Recommended Supplier/Grade

BP Enerpar SE100

Conoco Pale Paran 22

Mobile D.T.E. Oil Light

Shell Canada Transformer-10

Texaco Diala-Oil-AX

Disassembly & Assembly

Impeller U-cup, V-ring and Volute:

Disconnect power. Remove cap

screws and lock washers vertically lift

motor, housing and seal plate

assembly from volute. Clean out

volute if necessary. Inspect gasket

and replace if cut or damaged. Check

U-cup for damage. If replacement is

needed, cut the U-cup from the

volute and clean surface of bore.

Clean and examine impeller, for

cracks or breakage and replace if

required. To remove impeller, place a

at screwdriver in the slot of the end

of the shaft to hold the shaft

stationary while unscrewing the

impeller.

05

Page 7

Service

To reassemble, clean the threads with

thread locking compound cleaner.

Apply removable Loctite® 242 or

equivalent to shaft threads. Screw

impeller onto the shaft hand tight

while using a screwdriver in the slot

at the end of the shaft to hold it

stationary. Rotate impeller to check

for binding. Install U-cup by applying

adhesive to bore of volute. Be sure

not to get adhesive on inside

diameter of U-cup.

Position gasket on volute ange and

position impeller and motor housing

assembly on volute.

CAUTION

the U-cup is not pushed out of place

when assembling volute to rest of the

pump.

Position lock washer on cap screw

and screw into volute. Torque to 100

in/lbs. Check for free rotation of

impeller.

Shaft Seal:

To examine or replace shaft seal,

disassemble volute and impeller as

stated. Remove retaining ring, spring

and rotating member from shaft.

Inspect seal for signs of uneven wear

pattern on stationary members, chips

and scratches on either seal face. DO

NOT interchange seal components,

eplace the entire shaft seal . If

r

replacing seal, remove stationary by

prying out with lat screwdrive . f r

To reassemble, clean seal cavity in

seal plate and oil. Press seal’s

stationary member rmly into seal

plate, use a seal tool or pipe.

Be sure the inside lip of

Handle seal parts with

extreme care. DO NOT

damage lapped surfaces.

Nothing should come in contact with

the seal face except the seal tool. Be

sure the stationary is in straight.

Lightly oil (Do not use grease) shaft

and inner surface of bellows. Slide

rotating member onto stationary

using a seal tool. Place spring and

retaining ring onto rotating member.

Assemble impeller and volute as

described.

Motor, Capacitor and Bearings:

Remove volute and impeller as

previously stated and drain oil from

housing. Remove shaft seal. Position

unit upright, using blocks to avoid

resting unit on shaft. Unscrew cable

cap screws and remove compression

ange and power cord. Remove snap

ring with a at head screwdriver.

Pull the terminal block out of the

housing using a T-bolt or a pair of

pliers and a .25-20 screw in the

threads of the terminal block. Leave

slack on the motor leads connected

underneath. Use needle nose pliers

to pull each female connector o of

the pins on the underside of the

terminal block. The voltage should be

noted.

Remove cap screws from seal plate

and lift housing from seal plate.

Remove square ring, replace if cut or

damaged. Disconnect capacitor leads

from capacitor. Remove motor bolts,

lift cover, body and stator assembly

from seal plate. Remove snap ring to

remove rotor assembly. Remove

bearings and with a wheel puller.

Check motor capacitor with an Ohm

meter by rst grounding the

capacitor by placing a screwdriver

across both terminals and then

removing screwdriver. Connect Ohm

meter (set on high scale) to terminals.

If needle moves to innity (∞) then

drifts back, the capacitor is good.

If needle does not mov

innity (∞) and does not drift back,

replace capacitor. Inspect motor

winding for shorts and check

resistance values. Check rotor for

wear. If rotor or the stator windings

are defective, the complete motor

must be replaced.

Slide rotor/shaft with bearings and

into seal plate until bearing seats into

seal plate. Install snap ring into seal

plate.

Place stator over rotor, lining up

motor bolts with holes in seal

Place spring washer on bearing and

cover onto rotor/stator assembly.

Position capacitor so that it will lay on

the opposite side of the cable entry

boss of the housing. Install bracket

and reconnect capacitor leads.

Torque motor bolts to in/lbs. Set

square ring in grove on seal plate.

Lower housing down onto seal plate

while aligning holes and stringing

motor leads through the cord entry

bore. Place cap screws through seal

plate into housing and torque to 60

in/lbs. Reconnect motor leads to the

underside of the terminal block.

Place o-ring into groove in terminal

block and lubricate with dielectric oil.

Press the terminal block into the

housing so it seats completely below

the snap ring groove. Place snap ring

into groove in cord entry bore of

housing.

Power Cable Connection:

Check pow

damage and replace if required. Rell

the cooling oil. Insert female end of

cord plug into housing bore aligning

timing markwith hole in terminal

block. Compress cord plug with

compression ange by tightening

cap screws with lock washers into the

housing. Torque to 132 in/lbs.

er cord for cracks or

e or moves to

plate.

06

Page 8

FFBPSTEP

Repair Parts

For Repair Part Please supply: Model Number and Serial as shown on

Name Plate, and Part Description and Part Number as shown on Parts List.

07

Page 9

FFBPSTEP

ITEM DESCRIPTION QTY MATERIAL

1 Cable Assembly 20 ft SOW

2 O-ring Ø4.5" x 3.1" 1 NBR40

3 Pump body 1 HT200

4 Capacitor 25uf/370V 90 °C 1 Aluminium

5 Upper bearing plate 1 ZL102

6 Bearing 6203 2

7 Wave washer 39 1 65Mn

8 Temperature protector 1

9 Stator 1

10 Rotor component 1

11 Stator component 1

12 Hex head bolt 5/16" 4 304

13 Spring washer 8 304

14 Lower bearing plate O-ring 1 NBR40

15 Lower bearing plate 1 HT200

16 Impeller Ø117.3 1 Polypropylene

17 Casing 1 HT200

18 "U" shpe ring Ø31.5

19 Casing sealing washer 1 Rubber

20 Hex socket cap screws 1/4" - 20UNCx28 2 304

21 "V" shape ring 1 NBR40

22 Mechanical seal Ø31.8 x Ø15.9 x 32.5 1 SiC/SiC

23 Elastic collar 40 1 65Mn

24 Elastic collar 17 2 65Mn

25 Lengthern bolt #8-32 x 140 4 Q235A

26 Flat washer 4 4 Q235A

27 Spring washer 4 4 65Mn

28 Capacitor clamp 1 08F

29 Cross recessed pan head screw M4x8 2 Q235A

30 Ground lead 1

31 Hex bolt 5/16" - 18UNCx25 4 304

32 Hex socket pipe stopper 3/8" - 18 NPT 1 304

33 Handle 1 3

34 Name plate 1 304

35 Nail for name plate 2x4 4 Cu

36 Float switch (optional) 1

37 Clamp (optional) 1 2Cr13+NBR40

38 Cross recess pan head screw #10-32UNFx12 (optional) 1 304

39 Trademark signs 1 304

x Ø44.3 x 6.5 1 NBR40

04

Parts List

For Repair Part Please supply: Model Number and Serial as shown on

Name Plate, and Part Description and Part Number as shown on Parts List.

08

Page 10

Troubleshooting Chart

Risk of electric shock. Always disconnect the pump from the power source before handling inspections or repairs.

Symptom Possible Cause(s) Corrective Action

1. Poor electrical connection, blown fuse, tripped

breaker or other interruption of power;

improper power supply

2. Motor or switch inoperative (go to manual

Pump will not run

Pump will not turn o

Pump hums but doesn’t run

Pump delivers insucient capacity

Pump cycles too frequently or runs periodically

when f ixtures are not in use

Pump shuts of f and turns on independent of

switch, (trips thermal overload protector).

CAUTION! Pump may start unexpectedly.

Disconnect power supply.

Pump operates noisily or vibrates excessively

NOTE: Flo Fab Pumps assumes no responsibility for damage or injury due to disassembly in the eld. Disassembly of the pumps or supplied accessories other

than at Flo Fab Pumps or its authorized service centers, automatically voids warranty.

operation)

2a. Float movement restricted

2b. Switch will not activate pump or is defective

2c. Defective motor

3. Insu cient liquid level

2a. Float movement restricted

2b. Switch will not activate pump or is defective

4. Excessive inow or pump not properly sized for

application

9. Pump may be air locked causing pump not to ow

14. H-O-A switch on panel is in "HAND" position

1. Incorrect low voltage

8. Impeller jammed or loose on shaft, or inlet

plugged

1. Incorrect low voltage

4. Excessive inow or pump not properly sized for

application

5. Discharge restricted

6. Check valve partially closed or installed backwards

7. Shut-o valve closed

8. Impeller jammed or loose on shaft, or inlet

plugged

9. Pump may be air locked causing pump not to ow

10. Piping xtures leaking or discharge be

nozzle

6. Check valve partially closed or installed backwards

11. Fixtures are leaking

15. Ground water entering basin

1. Incorrect low voltage

4. Excessive inow or pump not properly sized for

application

8. Impeller jammed or loose on shaft, or inlet

plugged

12. Excessive water temperature (internal

protection only)

2c. Worn bearings, motor shaft bent

5. Debris in impeller cavity or broken impeller

10. Pump running backwards

13. Piping attachments to building structure too

loose or rigid

fore the

1. Check all electrical connections for security.

Have electrician measure current in motor leads,

if current is within ± 20% of locked rotor Amps,

impeller is probably locked. If current is 0,

overload may be tripped. Remove power, allow

pump to cool, then re-check current.

2a. Reposition pump or clean basin as required to

provide adaquate clearance for oat

2b. Disconnect level control. Set ohmmeter for a

low rang, such as 100 ohms full scale and

connect to level control leads. Actuate level

control manually and check to see that

ohmmeter shows zero ohms for closed switch

and full scale for open switch. (Float Switch)

2c. Check winding insulation (Megger Test) and

winding resistance. If check is outside of range,

dry and re-check. If still defective, replace per

service instructions.

3. Make sure liquid level is above the pump

4. Re-check all sizing calculations to determine

proper pump size.

5. Check discharge line for restrictions, including

ice if line passes through or into cold areas.

6. Remove and examine check valve for proper

installation and freedom of operation

7. Open valve

8. Check impeller for freedom of operation,

security and condition. Clean impeller cavity

and inlet of any obstruction

9. L

oosen union slightly to allow trapped air to

escape. Verify that turn-o level of switch is set

so that the suction is always ooded. Clean vent

hole

10. Check rotation. If power supply is three phase,

reverse any two of three power supply leads to

ensure proper impeller rotation

11. Repair xtures as required to eliminate leakage

12. Check pump temperature limits and uid

temperature

13. Replace portion of discharge pipe with exible

connector or tighten existing piping.

14. Turn to automatic position

15. Check for leaks around basin inlet and outlets

09

Page 11

Loading...

Loading...