Floe V-3600, V-2602 Assembly Instructions Manual

FLOE V

-

36

00

119”

BOAT LIFT

P/N 511-36080-00

WITH PATENTED EASY LEVEL LEG SYSTEM

ASSEMBLY INSTRUCTIONS

© Manufactured by:

Floe International Inc.

48473 State Hwy. 65

McGregor, MN 55362

www.floeintl.com

Instructions P/N 611

-

36080

-00

Issued 3/4/19

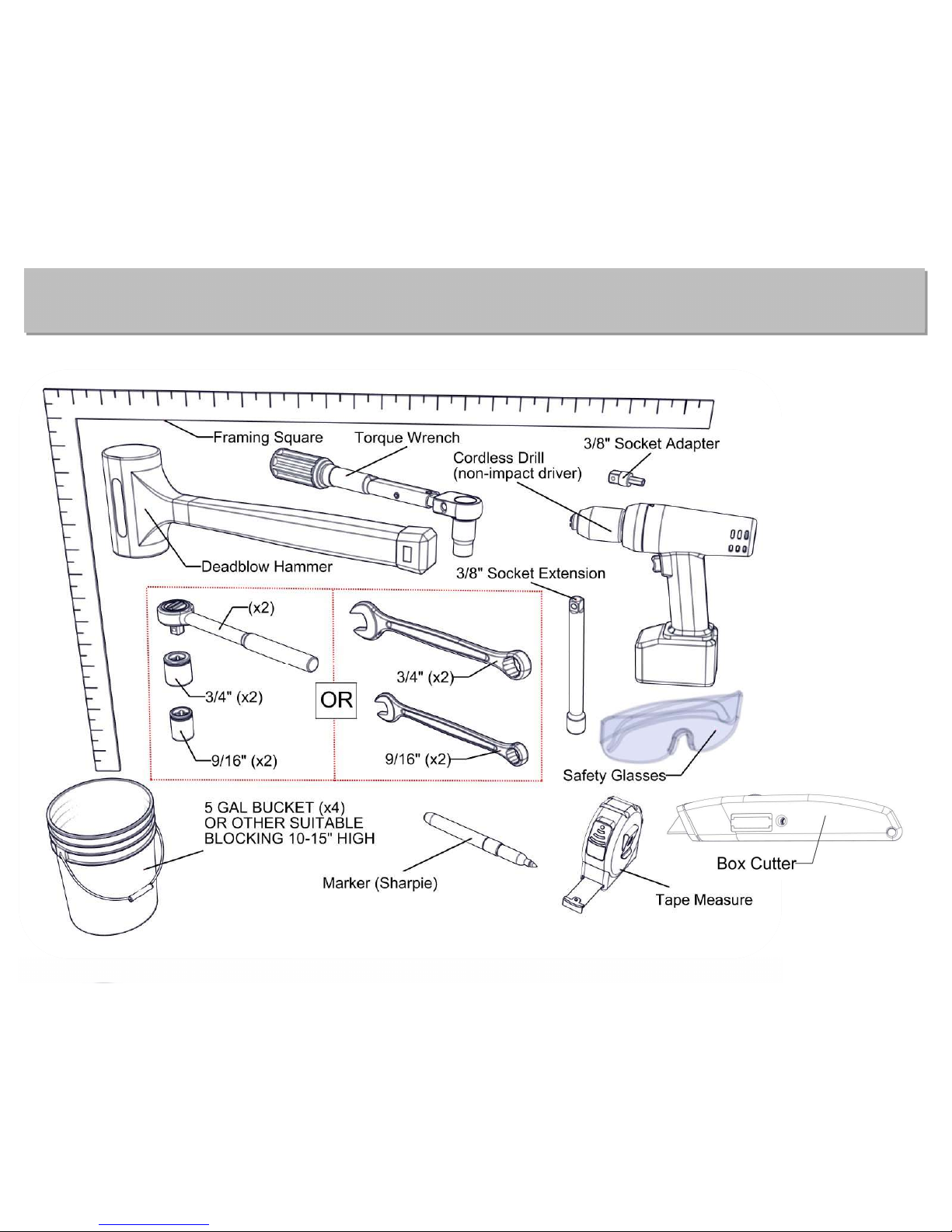

Required Tools

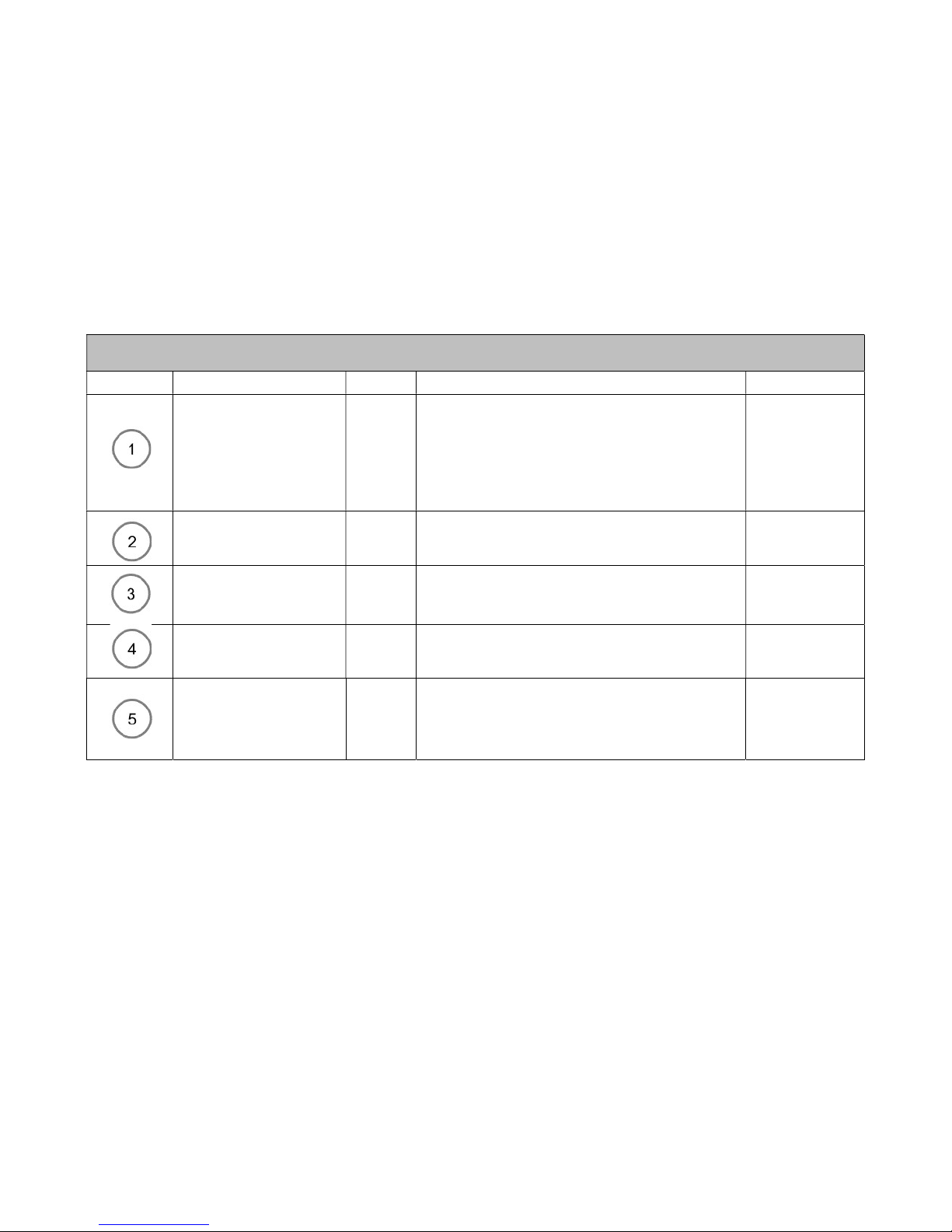

Card Contents (511-04265-00)

Step

Part Numbers

QTY Descriptions Torques

001-70215-00

001-70217-00

001-70210-00

001-70219-00

001-71023-00

001-76072-00

6

8

8

2

48

24

HHCS, 1/2-13 x 3” SS 18-8

HHCS, 1/2-13 x 3 1/2” ss 18-8

HHCS, 1/2-13 x 1 3/4” ss 18-8

HHCS, 1/2-13 x 4” ss 18-8

FLAT WASHER, .5 ID x .75 OD ss

NUT, 1/2-13 ALUMINUM NYLOCK

60 ft. lbs.

45 ft. lbs.

45 ft. lbs.

60 ft. lbs.

001-70218-00

001-76072-00

4

4

HHCS, 1/2-13 x 3 3/4” ss 18-8

NUT, 1/2-13 ALUMINUM NYLOCK

25 ft. lbs.

001-76071-00

001-70115-00

001-70117-00

8

4

4

NUT, 3/8-16 ALUMINUM NYLOCK

HHCS, 3/8-16 x 3” ss 18-8

HHCS, 3/8-16 x 3 ½” ss 18-8

35 ft. lbs.

001-70209-00

001-76350-00

8

8

HHCS, 1/2-13 x 1 1/2” ss 18-8

NUT, 1/2-13 ALUMINUM

45 ft. lbs.

001-70211-00

001-76072-00

002-04140-00

007-06201-00

5

5

1

1

HHCS, 1/2-13 x 2” ss 18-8

NUT, 1/2-13 ALUMINUM NYLOCK

HOLDER, CABLE

SHEAVE, 3” FRONT CABLE ½” ID

45 ft. lbs.

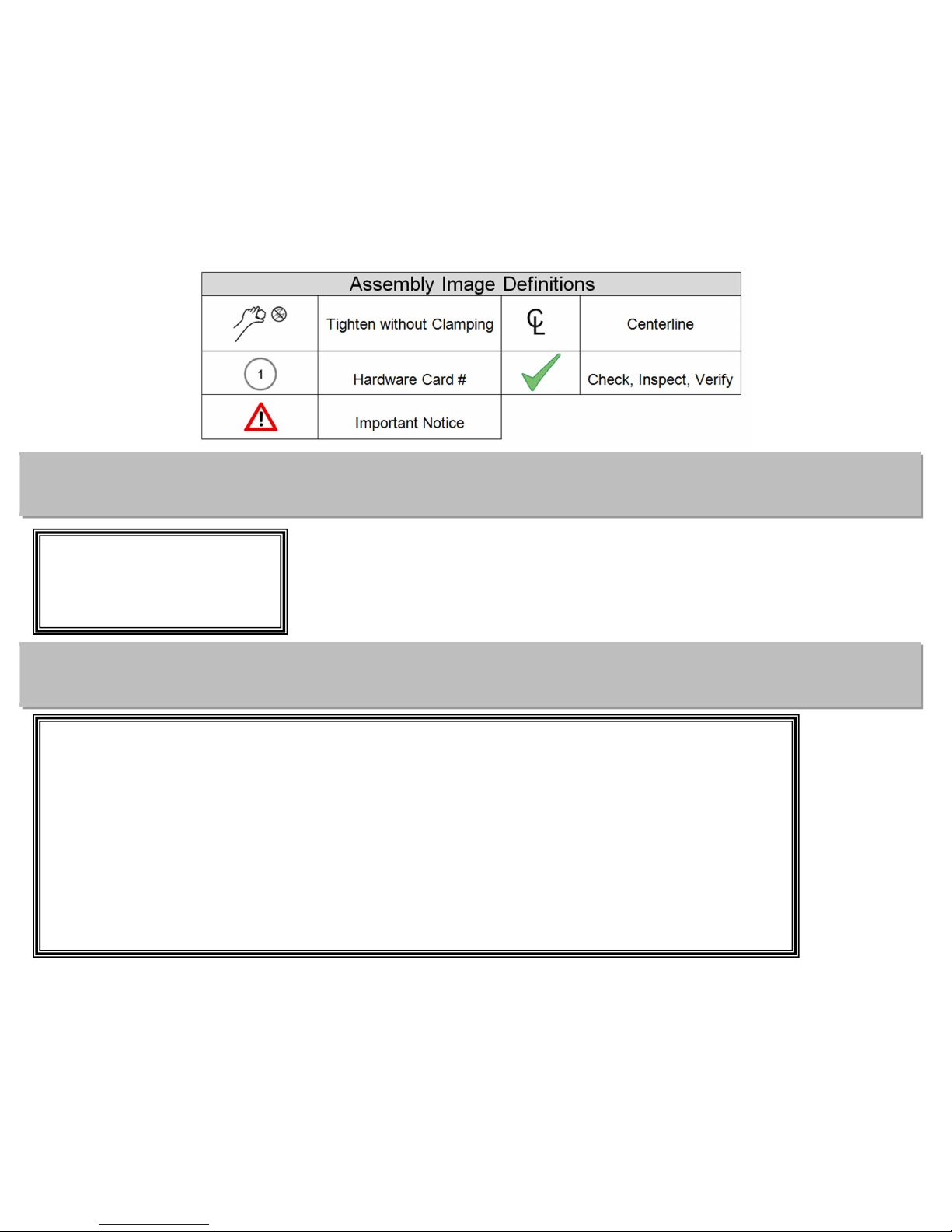

IMPORTANT NOTE:

DO NOT USE IMPACT WRENCH

WHEN ADJUSTING THE EASY

LEVEL LEGS

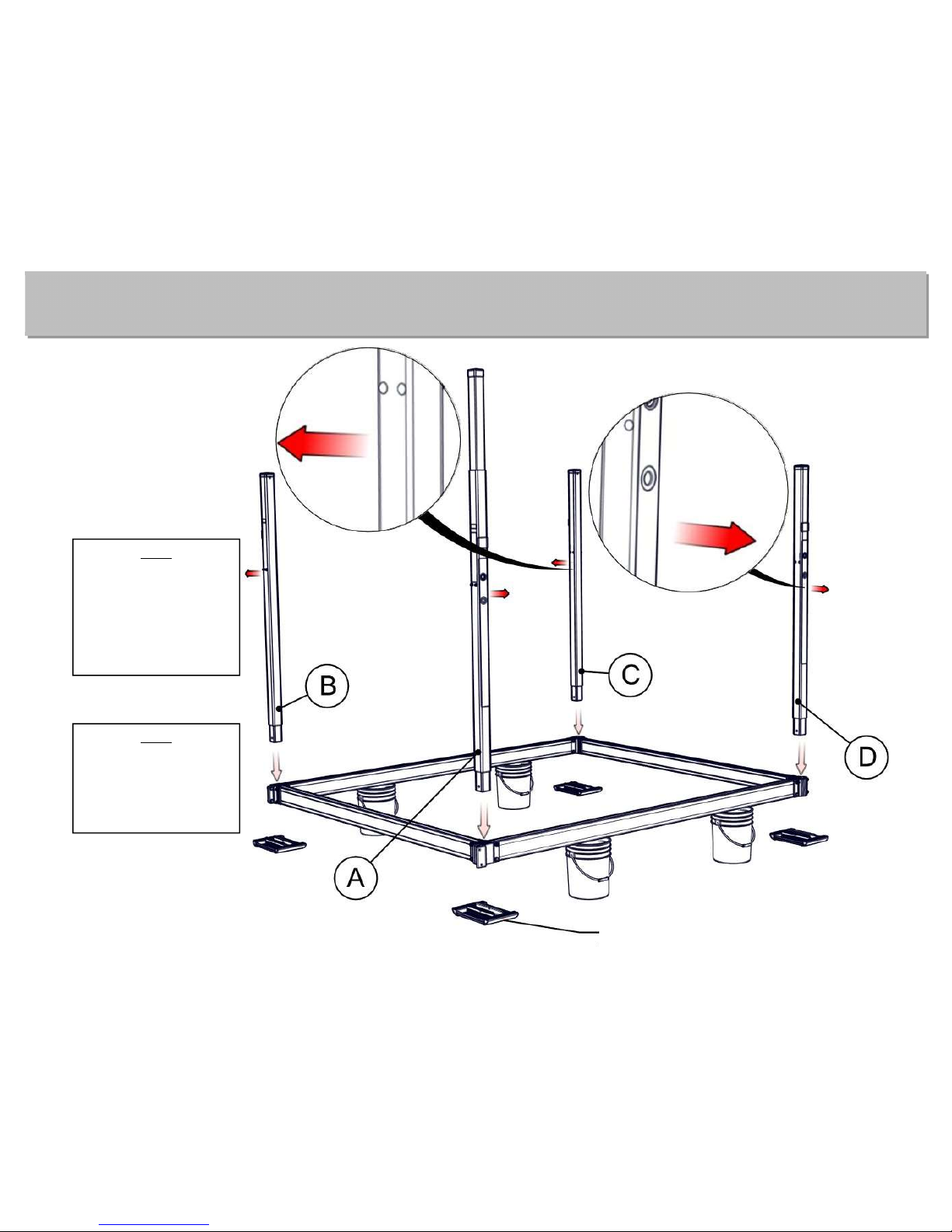

Warnings

Tips

Torque nuts to specification, not bolts.

Place parts and fasteners in designated locations prior to each step.

Before tightening fasteners to specified torque, ensure that the lift is square.

Measure from corner to corner (A to C/B to D) to verify that the lift is square.

Measure distance between corner posts (A to B, B to C, C to D, A to D) above frame beam and at the

top of the corner post to verify that the lift is square.

Ensure that the lift is level and square before proceeding to install the V-Brace or Ball Screw Tube.

Assemble cradle clamps with given bolt and nut before installing onto cradle beam.

Use a marker to denote fasteners which have been tightened to the specified torque.

Read instructions and understand them before attempting assembly.

Lift Dimensions

Length: 114”

Width: 135 3/8”

Height: 104”

Work Space

Level work space

Allow space to organize parts

Material

Blocking may be anything 10”-15” in height.

(5 gallon bucket, jack stands, blocks, saw horses)

QTY

4 (2 for each side)

Purpose

Blocking used to support lift during assembly steps

1 and 2

Pre-Assembly Prep

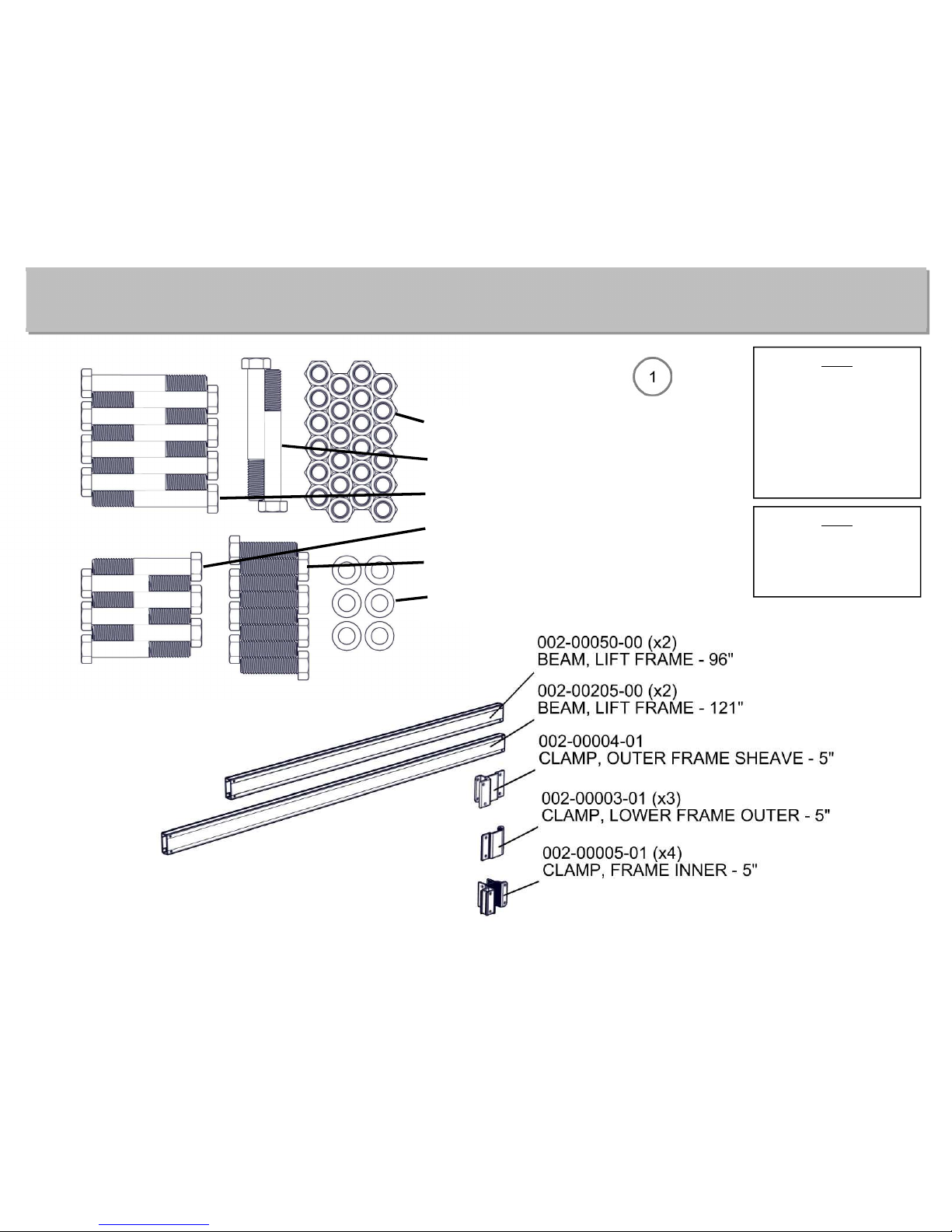

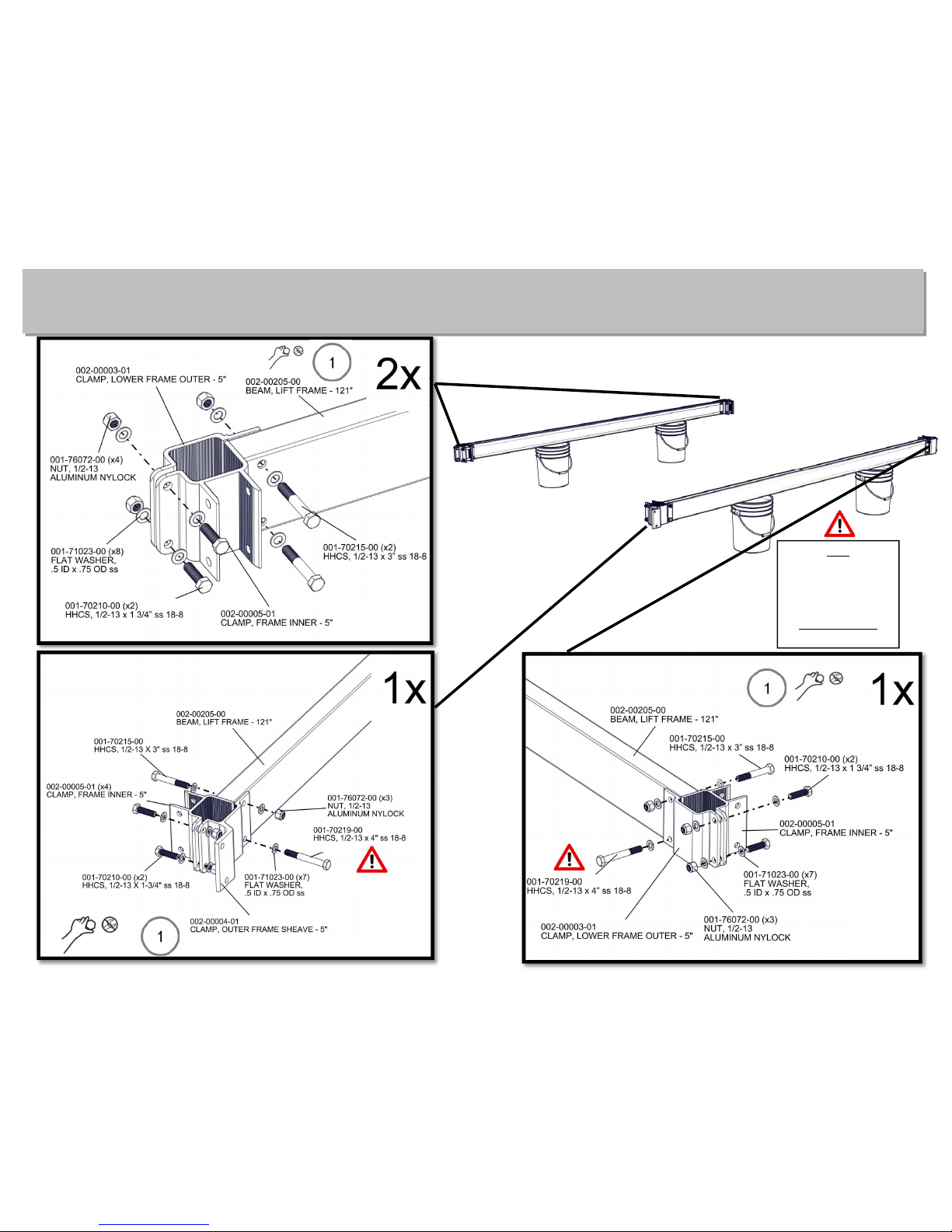

Contents for Step 1

(24) 1/2” Alum. Nylock Nuts

(6) 1/2 x 4” ss Bolts

(8) 1/2 x 3 1/2” ss Bolts

(6) 1/2 x 3” ss Bolts

(8) 1/2 x 1 3/4” ss Bolts

(48) 1/2” ID x 7/8” OD ss Washers

NOTE

(2) ½” Nylock Nuts

and (2) ½” Washers

are used in Step 5-A

to attach lifting

cables to (2) ½” x 4”

Bolts.

NOTE

ALL FASTENERS IN

STEP 1 ARE HAND-

TIGHTENED ONLY.

Assembly for Step 1

1-A 1-B

1-C

A

B

C D

NOTE

(2) ½” Nylock Nuts

and (2) ½” Washers

ARE NOT used for

(2) ½” x 4” Bolts on

corners A and D

until Step 6

-A.

1-E 1-D

A B C

D

IMPORTANT NOTE:

FRAME BEAMS MUST

BE IN THIS

ORIENTATION

BEFORE CONTINUING.

FRONT/REAR

FRONT/REAR

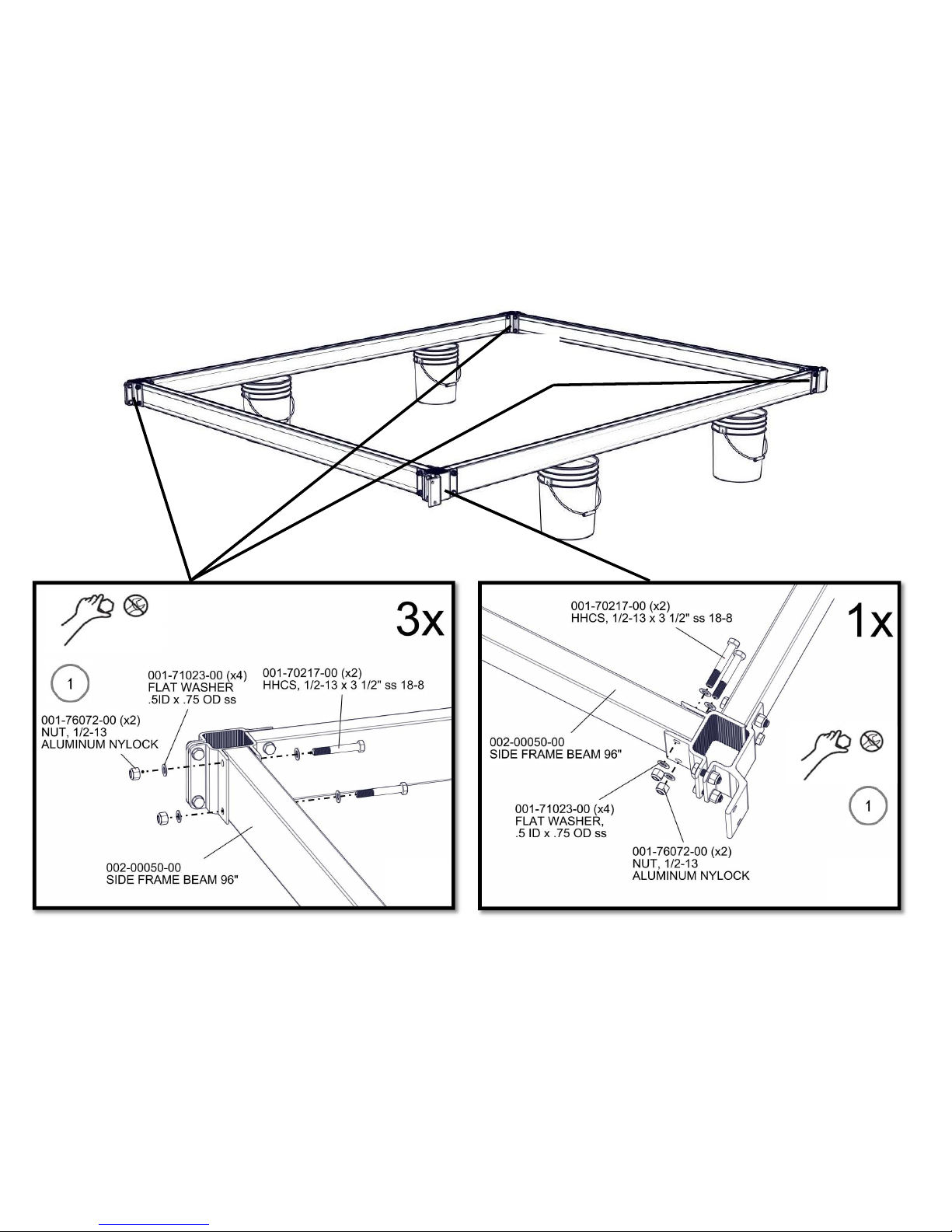

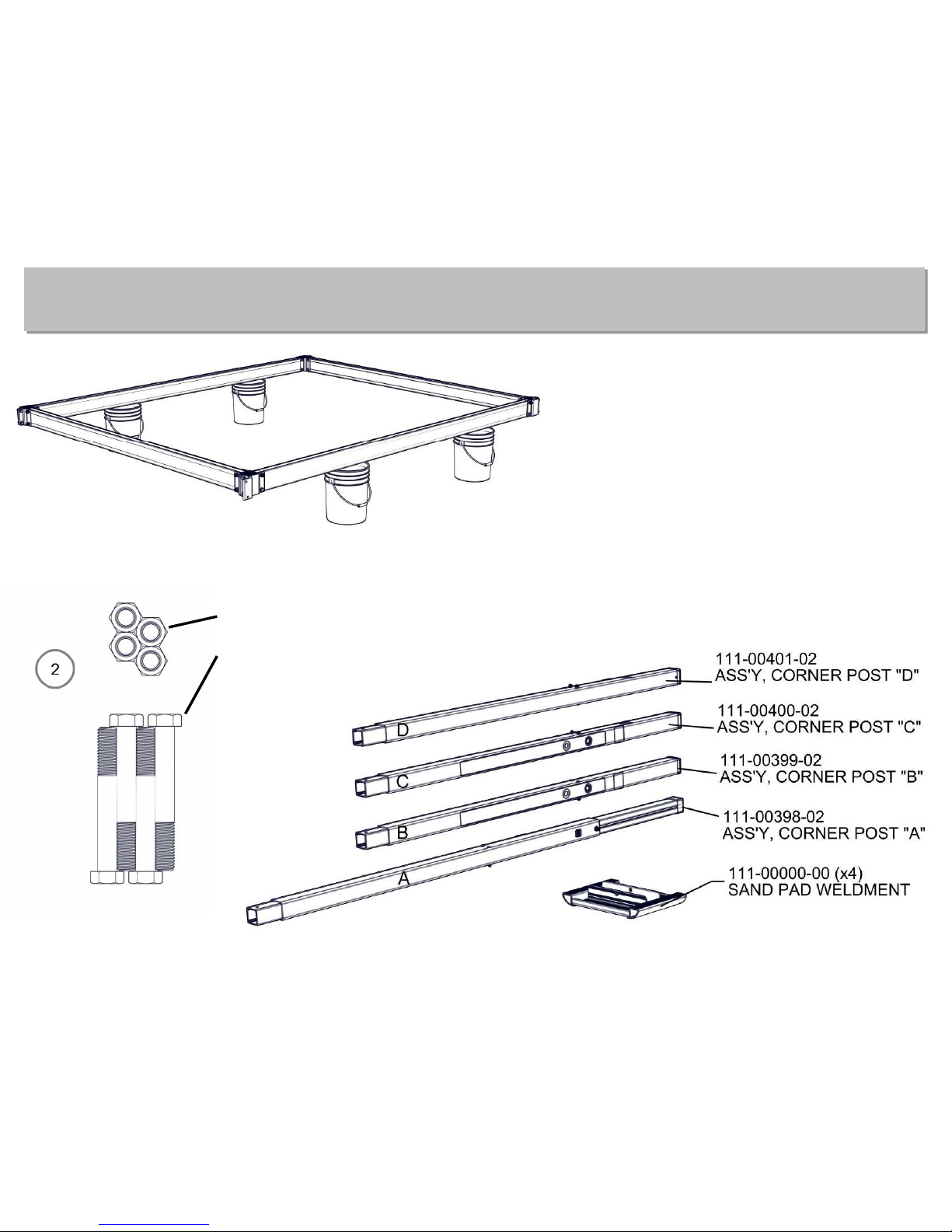

Contents for Step 2

(4) 1/2” Alum. Nylock Nuts

(4

) 1/2 x

3 3/4

” ss Bolts Torque to

20 ft. lbs.

Assembly of Step 2

NOTE

CARRIDGE BOLT

HEADS MUST FACE

INSIDE OF LIFT.

NUTS MUST FACE

OUTSIDE OF LIFT.

NOTE

WATER DEPTH

STICKERS MUST FACE

OUT ON FRONT AND

REAR OF LIFT.

110-00000-00 (x4)

SAND PAD WELDMENT

Loading...

Loading...