Floe 500-95500-00 Owner's Manual

OWNER’S MANUAL

8’

ATV Pro

Tilt Trailer

8’ & 10’

All-Terrain Pro

Utility Trailers

10’ & 12’

Versa-Max

Tilt Trailers

Featuring FLOE’s exclusive Versa-Track System™

Page 1

Congratulations!

Dear Customer,

We appreciate your business and hope you are proud of your new Floe aluminum trailer – a pride that will continue

throughout the years. If you shopped trailers before deciding on the Floe, you probably concluded that our trailer has

numerous features not commonly found on others.

At FLOE INTERNATIONAL, we take great pride in providing the highest quality trailer, with the latest state-of-the-art

features, at an affordable price. Each year we implement improvements to our product lines to ensure that we are on the

“leading edge” and providing the best available trailer.

We are condent your Floe trailer will provide you with years of trouble free trailering, and that if you decide to buy another

trailer, it is because you want another Floe model.

Please take the time to read and understand this owner’s manual before towing your new trailer. The information offered here

will have a direct impact on your safety, the safety of others, and the dependability of your trailer.

Thank you for choosing Floe.

Sincerely,

Wayne Floe

CEO, Floe International

Contents

Important Safety Information .............................................. 3

Reporting Safety Defects ...............................................3

Procedure for Vortex Hub / Spindle ...................................... 4

Adding & Changing Grease .......................................... 4

Removing/Remounting .................................................. 5

Axle Assembly ............................................................... 6

Using Your FLOE Trailer ...................................................... 7

Hitch Selection ............................................................... 7

Hitch Coupler Adjustment..............................................8

Tilt Clamp ......................................................................8

Proper Loading & Unloading ......................................... 9

Securing Ramp ............................................................... 9

Trailer Safety

Securing the Load ...................................................10-12

Trailer Lighting ................................................................... 12

Changing Tires ............................................................. 13

Care & Maintenance .................................................... 13

Tire Safety ...............................................................14-30

Accessory Installation ....................................................32-33

Common Questions and Answers ....................................... 34

Specications Chart ............................................................ 35

Warranty ......................................................................... 36-38

Page 2

Important

Safety Information

READ THIS INFORMATION BEFORE USING TRAILER!

It is the owner’s/operator’s responsibility to

check the following items each time before

towing trailer:

• Wheel bearings are properly tightened and oiled.

• Tires are inated to correct pressure.

• Lug nuts on each wheel are tight.

• Trailer is level with tow vehicle and load is

positioned to apply equal weight to all tires.

• Bed locking system (tilt clamp) is properly

secured.

• Ensure safety chains cross each other and open

end of “S” hook faces the trailer.

• Ensure any cables are secure.

• Trailer coupler is properly adjusted and securely

attached to the hitch ball.

• If equipped, brake system is working properly

and breakaway cable is securely attached.

• Trailer electrical connector is properly connected

and all lights are operating correctly.

- - - - - - - - - - - - - - IMPORTANT- - - - - - - - - - - - - Whether you are using your trailer for

hauling snowmobiles, ATVs or other items,

it is important that you take simple safety

precautions every time you use your trailer.

WARNING

may result in damage to your trailer or vehicle,

and could cause severe or fatal injury to you

or others.

Reporting Safety Defects

If you believe that your trailer has a defect

which could cause a crash or could cause injury

or death, you should immediately inform the

National Highway Trafc Safety Administration

(NHTSA) in addition to notifying FLOE

INTERNATIONAL, INC. at 1-800-336-6337.

• Load is secure. Monitor load at regular intervals

once underway.

• Trailer capacity and tongue weight are not

exceeded.

• The width of the trailer in proportion to your

vehicle. Take mental note if trailer width

exceeds that of your towing vehicle and drive

accordingly.

• No structural damage to trailer exists. Do not use

if damaged.

Page 3

If NHTSA receives similar complaints, it may

open an investigation, and if it nds that a safety

defect exists in a group of vehicles, it may

order a recall and remedy campaign. However,

NHTSA cannot become involved in individual

problems between you, your dealer, or FLOE

INTERNATIONAL, INC.

To contact NHTSA, you may either call the Auto

Safety Hotline toll-free at 1-888-327-4236 (TTY:

1-800-424-9153); go to http://www.safercar.gov; or

write to: NHTSA, US Department of Transportation,

1200 New Jersey SE, Washington, D.C. 20590. You

can also obtain other information about motor vehicle

safety from http://www.safercar.gov.

Procedure for

Vortex Hub

Owners Manual

Old

Out

Out

New

Grease

In

Old

Out

Out

New

Grease

In

Vortex Hub/Spindle

Simple is best when it comes to Wheel bearing lubrication. Tie Down

has adapted the best features of grease and oil lubrication to develop the

Vortex hub. The Vortex hub bearing lubrication system provides long

term continuous bearing lubrication and ease of service or inspection.

Your trailer is equipped with Vortex hubs/spindles from Tie Down

Engineering. The hubs are pre-grease and assembled at the factory

and should not require any additional adjustments, The Vortex hub

uses tapered roller bearings adjusted to a maximum .006 end play.

The twelve sided castle nut easily maintains this maximum .006 end

play. The conguration requires a minimal amount of end-play that is

factored in at the time of assembly.

Vortex Features:

• Stainless steel wear sleeve on factory assembled spindle/hub units

• Vortex internal through the spindle lubrication system

• Super strong threaded removable grease cap

• Premium grade Lucas Oil Marine grease (100,000 miles)

WHAT MAKES THE VORTEX THE BEST

The rear seal rides on a stainless steel wear sleeve. This provides longer life for the seal as the surface

does not corrode. Corroded or rusted seal surfaces act like sandpaper on the seal causing premature

failure. Vortex lubrication makes changing or adding grease easy with no need to remove the hub. The

threaded grease cap is easy to remove and replace. No more knocking the cap off with a hammer. Lucas

Oil Marine grease is a premium lithium based complex fortied with rust and oxidation inhibitors, high

pressure additives and provides a high degree of moisture resistance and washout properties. These

features allow Tie Down Engineering to offer a 6 year, 100,000 mile limited warranty. See separate

warranty sheet for details.

The Vortex hub/spindle is designed to be a no maintenance hub for 6 years. If you should need to add

grease or remove the hubs for any reason, follow the instructions listed in this owner’s manual.

TO MAINTAIN THE FACTORY WARRANTY, LUCAS OIL MARINE GREASE MUST BE

USED WHEN ADDING OR REPLACING GREASE IN THE VORTEX HUB.

ADDING OR CHANGING GREASE IN YOUR VORTEX HUB

Your Vortex hub/spindle is equipped with the Vortex Lubrication System. Should the hub/bearings

require additional lubrication for any reason, the Vortex lubrication system allows you to do so without

removing the hub or having to re-adjust the bearings. New Lucas Oil Marine grease is pumped into the

zerc tting at the end of the spindle, travels to the rear bearing where the new grease pushes out the old

grease through the rear bearing, center of hub and through the front bearing.

1. Remove the Vortex grease cap, un-screwing in a counter clockwise rotation.

2. Use a standard grease gun loaded with Lucas Oil marine grease to pump grease into the zerc tting

located on the end of the spindle.

Page 4

3. Pump the Lucas Oil Marine grease into

the zerc tting while slowly rotating the

wheel. Grease will ow out of the hub

around the front bearing.

4. When the grease appears to be the new

clean grease, remove the grease gun.

5. Replace the Vortex grease cap. Turn

in a clock-wise rotation until the o-ring

on the cap is in contact with the hub

surface. Turn an additional 1/4 turn to

seal the Vortex cap to the hub. (This is

similar to installing an oil lter in an

automobile)

REMOVING/REMOUNTING FOR THE VORTEX HUB

Removing the Vortex hub for inspection or maintenance should be done in a safe location away from

moving vehicles.

1. Elevate the trailer on level ground using the

manufacturers instructions. Always use jack

stands or other solid supports. Do not rely on

wrench. This “seats” the bearings.

11. Lossen the spindle nut to remove the torque

applied. DO NOT ROTATE THE HUB.

a jack to support the trailer. Block wheels to

keep the trailer from rolling.

12. Tighten the spindle nut until snug, backing off

only enough to line up the cotter pin with the

2. Remove the tire/wheel assembly.

3. Place a newspaper or cloth on the ground under

hole in the spindle.

13. Bend the cotter pin into place.

the hub to keep any parts from falling onto a

dirty surface.

14. LOAD HUB WITH LUCAS OIL MARINE

GREASE USING THE INSTRUCTIONS

4. Remove the Vortex grease cap by un-screwing

FOR ADDING OR CHANGING GREASE.

in a counter clockwise rotation.

15. Replace the Vortex grease cap. Turn in a

5. Remove the cotter pin, castle nut (in a counter

clockwise rotation) and washer.

6. Remove the hub from the spindle. If you have

disc brakes, you will need to remove the brake

caliper to remove the rotor. Follow separate

instructions for disc brake rotor removal.

7. Be careful not to allow the bearings to fall out

of the hub.

8. Clean bearing and cup surfaces.

9. To re-install, coat bearings with Lucas Oil

Marine grease before re-installing.

10. Install bearings and place hub on spindle

clock-wise rotation until the o-ring on the

cap in contact with the hub surface. Turn an

additional 1/4 turn to seal the Vortex cap to the

hub. (This is similar to installing an oil lter in

an automobile)

16. Replace tire/wheel, torque lug nuts according

to wheel manufacturers instructions.

17. Test hub for proper end play by grabbing

the tire and pulling the tire from side to side.

Readjust if necessary.

18. VERY IMPORTANT: RE-CHECK LUG

NUTS AFTER 25 MILES OF USE.

in reverse order as listed above. Rotate the

hub while applying approximately 50 ft lbs

of torque to the spindle nut. This translates

into a full hand pressure load with a 12” long

Page 5

Procedure for

Axle Assembly

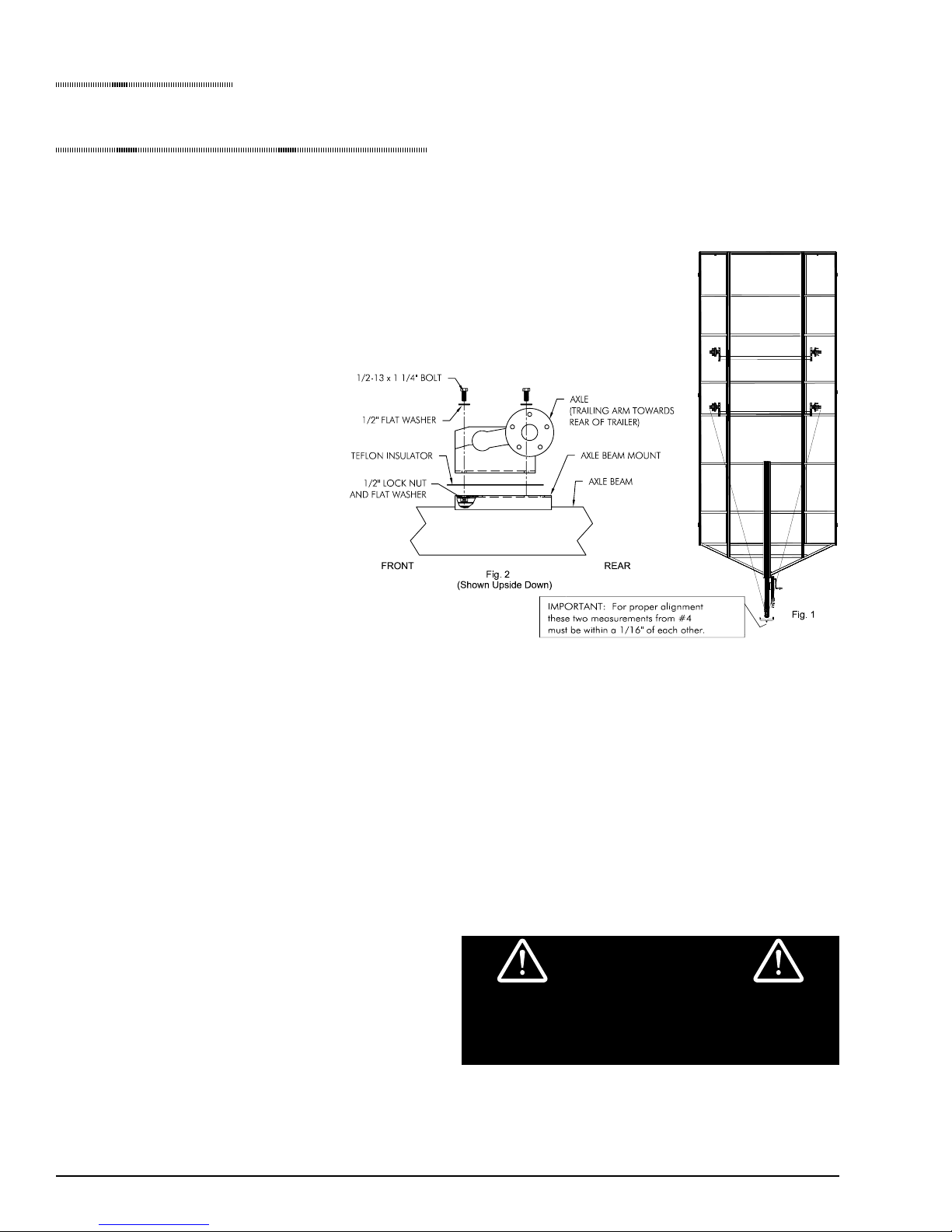

1. Place teon insulators on the axle beam mount and line up holes.

Some trailers will have two sets of holes with the front set as the

standard location. The rear set can be used to add tongue weight.

2. Set axle(s) on top of Teon insulators so trailing arm taper is to the

rear of trailer. Start each of the four bolts but do not snug up yet. See

Fig. 1 and Fig. 2

3. Pick a point on the outer edge

of the axle(s) that can be easily

measured to on both sides. Measure

from the center of the coupler to

these points (g. 3). Adjust axles so

these two measurements are equal

to within 1/16”. If mounting more

than one axle, start with the rear

and work forward.

4. Tighten all four bolts to 75 ft/

Ibs. Recheck alignment.

WARNING

Multi axle trailers must be level when towing.

Failure to do so will result in excessive tire

wear and reduced braking power.

Page 6

Using your FLOE trailer

Hitch Selection

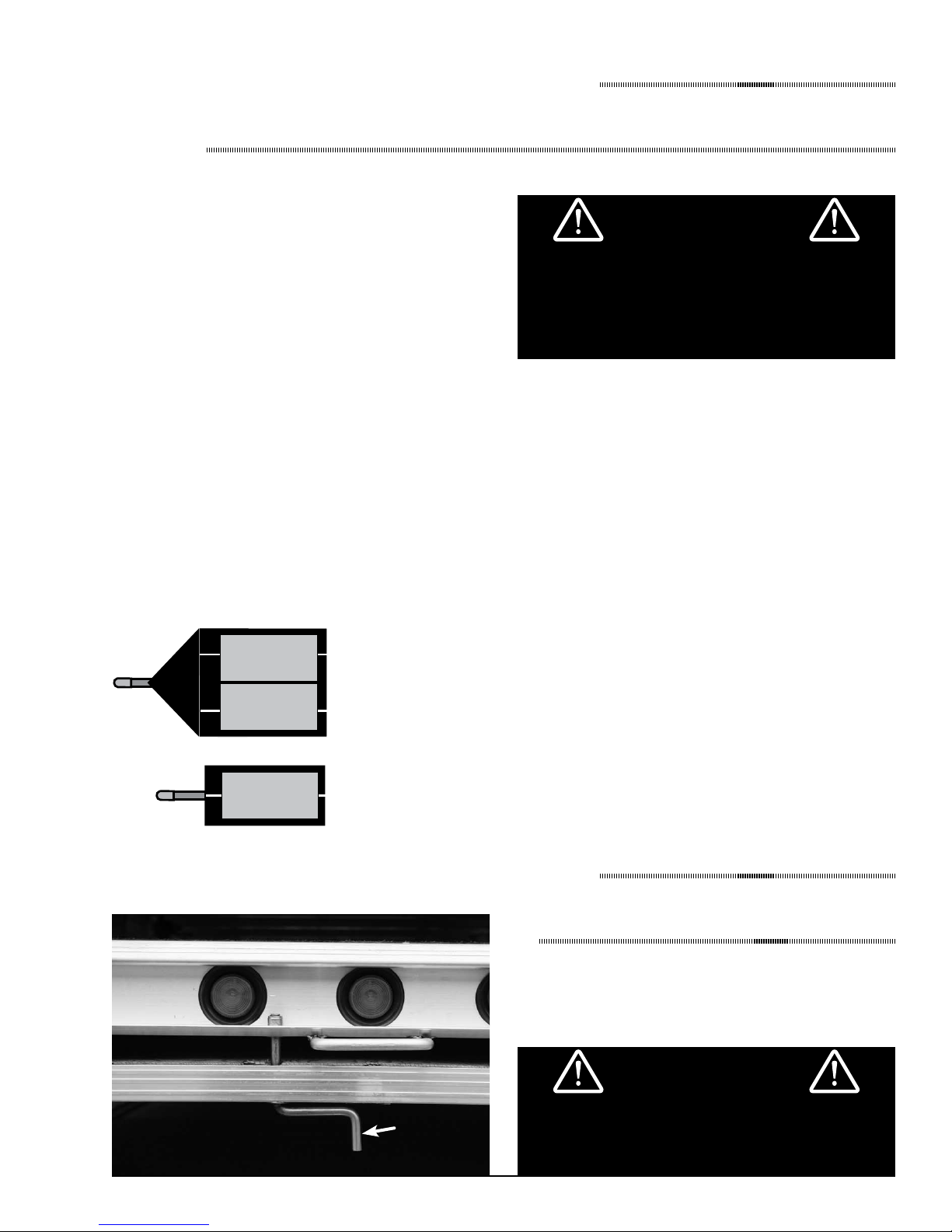

When selecting a hitch, there are four important

things to keep in mind:

• Ball size -- All FLOE tilt trailers use 2”

couplers.

• Load capacity -- Load should never exceed the

load capacity of your hitch.

• In-set or out-set hitch -- FLOE recommends an

out-set or receiver-type hitch (See below).

• Hitch Height -- Hitch should be set so the trailer

is level.

- - - - - - - - - - - - - - IMPORTANT- - - - - - - - - - - - - -

Pulling a trailer that is not level could greatly

an uncomfortable and dangerous situation

while towing. It could also create excessive or

negative tongue weight which can cause either

tongue or axle damage.

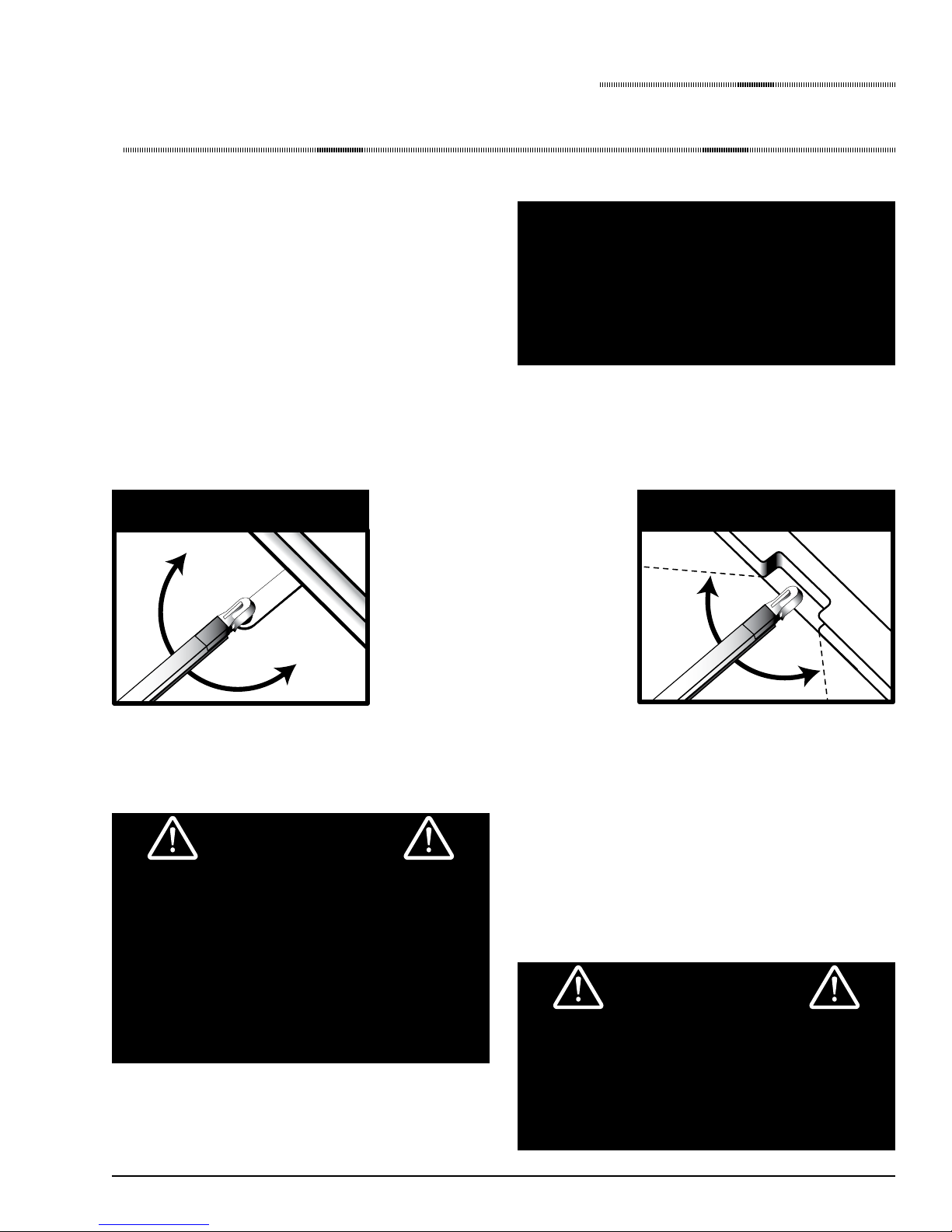

Out-set Hitch (Recommended) In-set Hitch (NOT Recommended)

These illustrations show that

a trailer’s turning radius is

signicantly reduced when

towed by vehicles equipped

with an “in-set” hitch. To

reduce the risk of damage, we

recommend the use of an

“out-set” or “receiver-type”

hitch.

WARNING

When connecting your trailer to the towing

vehicle, it is important that your hitch coupler

is adjusted with the correct amount of force

for both smooth and safe trailer performance.

A loose connection may cause the coupler to

disconnect or to rattle. An over-tight coupler

This can also transmit unnecessary vibration to

your towing vehicle.

When turning or backing up, the towing vehicle

operator must exercise good judgement.

The manufacturer will not be responsible for

damage that results from the tongue or trailer

coming in contact with towing vehicle!

CAUTION

Page 7

Using your FLOE trailer

Hitch Coupler Adjustment

All FLOE models have a lever lock hitch coupler. On the lever lock coupler, the amount of locking force

can be adjusted to the diameter of the hitch ball. To change the amount of locking force against the hitch

ball:

1. Release the hitch coupler locking lever (to its straight up position).

2. Locate the adjustment nut on the bottom of the hitch coupler.

3. Rotate the nut on the threaded shaft counter clockwise to decrease tightness, or clockwise to increase

tightness.

4. Re-mount the trailer coupler on the hitch ball.

5. Push down the hitch coupler locking lever to its original locking position.

6. Repeat steps 1 through 5 until a snug t is obtained. (If you are unfamiliar with how tight to adjust

your coupler, consult your FLOE dealer.)

Using your FLOE trailer

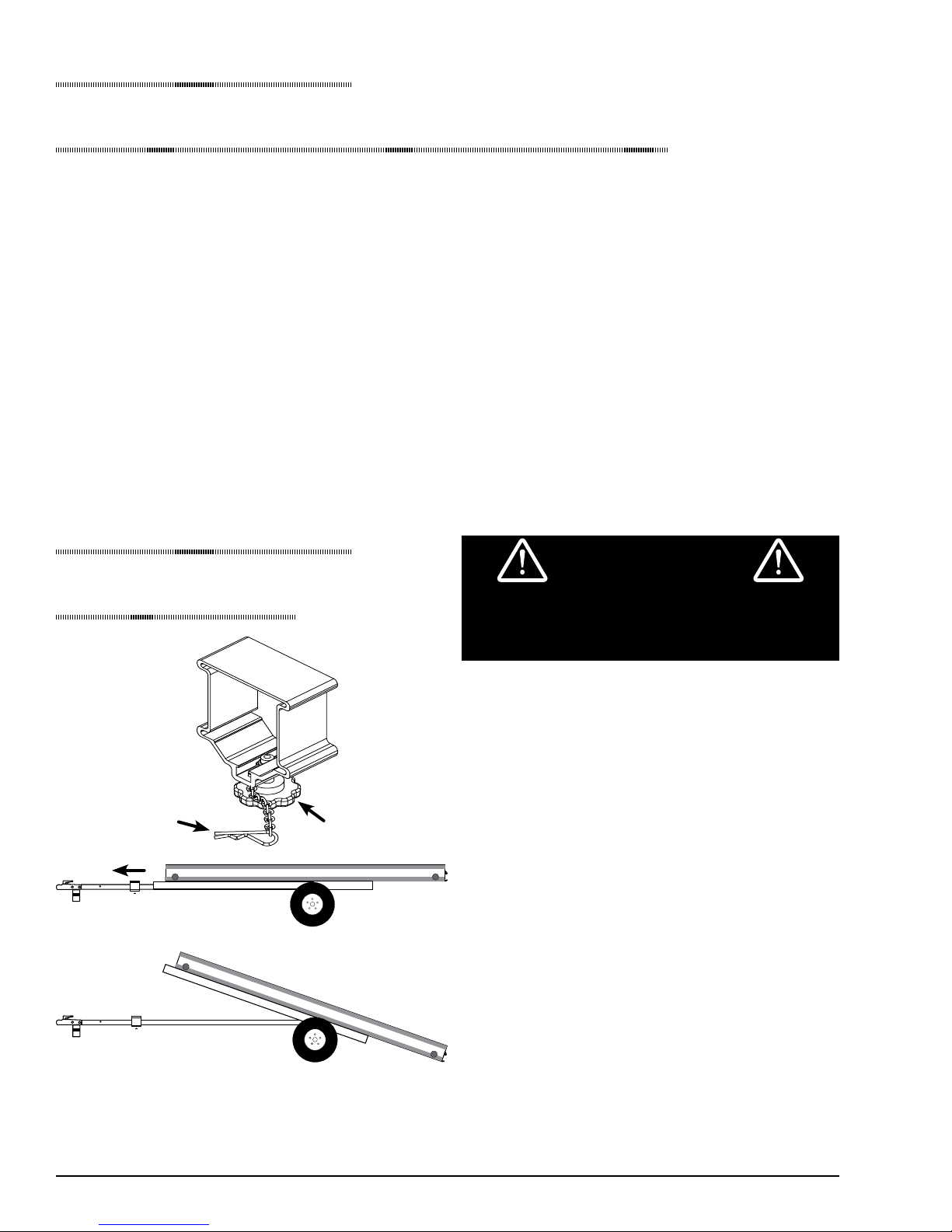

Tilt Clamp

Safety-pin

Slide clamp forward to tilt

Knob

WARNING

Failure to tighten tilt clamp and secure safety

pin before towing trailer could cause the trailer

to tilt while in transit.

The Floe tilt clamp eliminates the hassle and rattle

of a hitch pin design. To tilt, simply loosen Tbolt, remove the safety cotter pin, and slide clamp

forward. Slide back on, replace cotter pin, and

tighten when nished loading or unloading.

1. Loosen Knob on underside of tilt clamp.

2. Remove safety cotter pin.

3. Slide clamp forward.

4. To tilt trailer bed, either lift up on front of

trailer, or push down on rear of trailer.

5. Load trailer (see “Proper Loading and

Unloading” on page 7)

Trailer in tilted position

Note: If your trailer does not stay in the tilted position:

1. The tongue mounting bolt may not be tightened to

optimal tension.

2. A tilt-assist shock assembly is available as an accessory

for your FLOE tilt trailer. See page 18.

Page 8

6. Tilt trailer back to horizontal position by lifting

up on rear of trailer, or pushing down on front of

trailer.

7. Slide tilt clamp back to original position,

replace cotter pin and tighten Knob.

8. Secure your load before towing. (see pages 7-9)

Proper Loading & Unloading

Loads should be placed on the trailer so that

proper weight is applied to the tongue. Increase

or decrease the tongue weight by moving the

load forward or backward. When possible, loads

should also be placed to distribute equal weight to

all tires to prevent poor towing, axle damage, and

unequal or premature tire wear. See the diagrams

below for suggested load placement and tongue

weight. Unlike many trailers, the advanced design

of your FLOE trailer requires very little tongue

weight in order to minimize sway and to track

smoothly behind your tow vehicle.

The illustrations below are for typical placement

of snowmobiles. Use this information and

common sense for placing other loads as well.

Tongue weights are not strict maximums or

minimums, they are recommended ranges that

work well for the illustrated loads.

10’ & 12’ Tilt

Tongue Wt. 45-100 lbs

Ideal: 70 lbs.

Using your FLOE trailer

CAUTION

Failure to follow the steps below when loading

or unloading could result in damage to your

trailer, tow vehicle, snowmobile, and/or cause

possible severe or fatal injury to yourself and

others.

1. Never load or unload your trailer unless it is

properly connected to your tow vehicle.

2. It is imperative that your tow vehicle and trailer

are parked on level, even ground. Loading while

parked on an incline or uneven ground could

cause your trailer bumper to be at an improper

angle. This could catch your ski and cause

damage to your trailer, snowmobile and/or cause

severe or fatal injury.

3. Never load at speeds greater than 5 mph.

4. Ensure the trailer is fully tilted and that it will

stay in the tilted position until you have driven

on to it.

Be sure to securely

tighten crank handle

before each trip.

Utility

Tongue Wt. 25-80 lbs

Ideal: 50 lbs.

Crank Handle

5. After loading, make sure the tilt clamp is secure

and will not work itself loose while being

towed. Make sure the safety pin is attached.

6. Always test your footing before walking on the

trailer’s deck. It may get very slippery in cold,

wet and snowy weather.

Using your FLOE trailer

Securing Ramp

Be sure that you tighten the crank handle rmly in

place each time you travel and each time the ramp

is put into it’s storage position.

WARNING

the crank handle may result in the trailer ramp

becoming loose and falling out.

Page 9

Safety

Securing The Load

- - - - - - - - - - - - - - IMPORTANT- - - - - - - - - - - - - Although your FLOE trailer is equipped

with certain load securing features, it is the

responsibility of the operator to decide what is

necessary to properly secure the load for the

travel conditions.

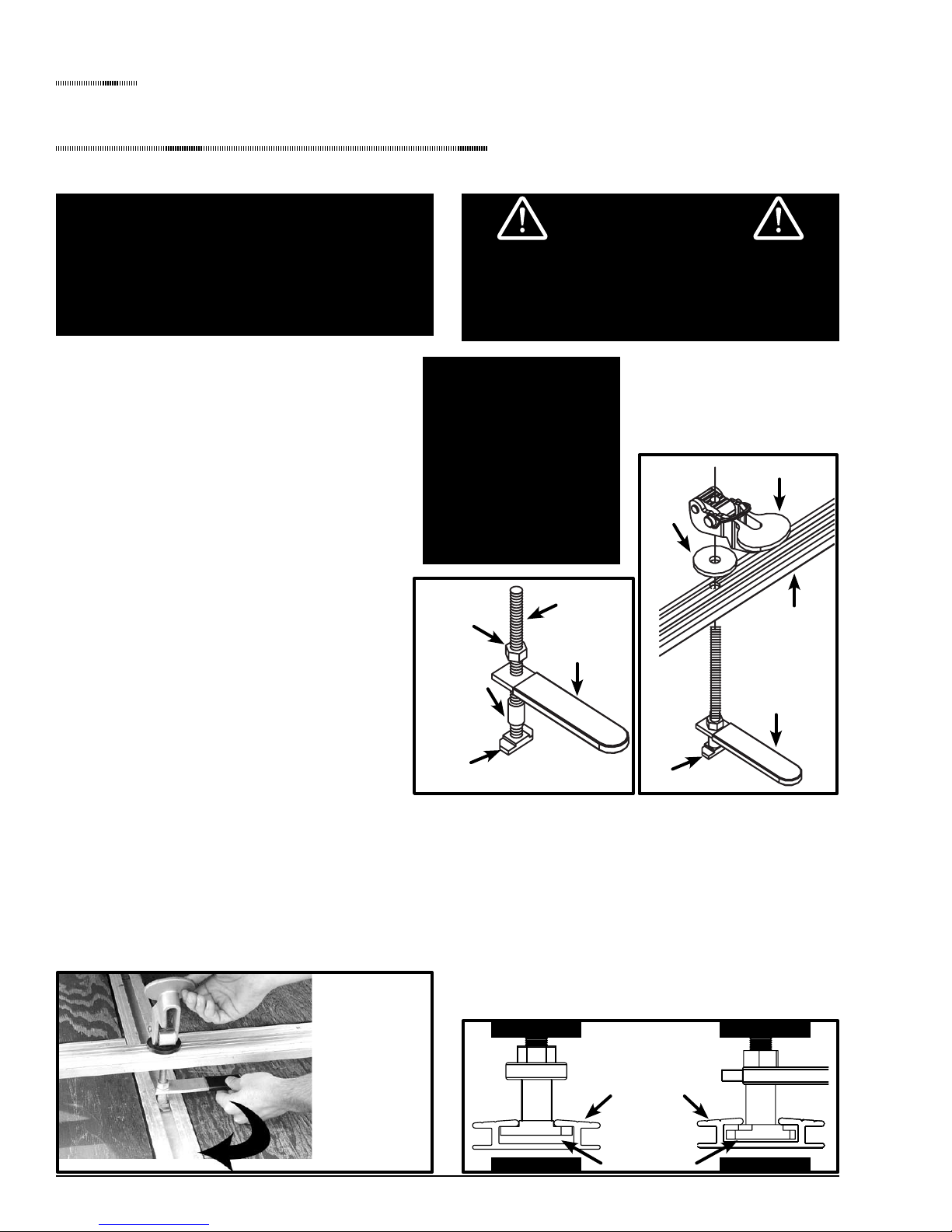

VERSA-LOCK ASSEMBLY INSTRUCTIONS

1. Slide spacer tube and handle over threaded

rod. Thread 1/2” nut down to handle and

tighten so handle is perpendicular (90º) to tie

down lock. Torque to 60 ft. lbs. See Fig. 4

2. Insert threaded rod through tie down bar

from the bottom. The tie down lock and

handle assembly should be on the bottom

(at) side of bar. Slide the plastic disc over

rod. Apply a liberal amount of anti-seize

lubricant onto the threaded rod. Screw the

lever assembly onto the rod until 1” of thread

is sticking out the top of lever assembly. See

Fig. 5.

3. Before using the Versa-Lock to secure a

load, read and understand the instructions on

how to use it.

Failure to read the Versa-Lock use instructions

prior to using it could result in severe damage

to the cargo it is meant to hold, cause a road

hazard, or even death.

- - - - IMPORTANT - - - Anti-seize lubricant

MUST be applied on

the threaded rod of

the Versa-Lock when

time and annually or

as needed to provide

peak performance.

FIG. 4

1/2” 20 Nut

Spacer Tube

Tie Down Lock

Threaded Rod

Handle

WARNING

FIG. 5

Plastic

Disc

Tie Down Lock

Lever Assembly

Tie Down Bar

Handle

VERSA-LOCK USE INSTRUCTIONS

1. With the snowmobile loaded on the trailer, place the tie-down bar on the skis, insert the tie-down lock

into the Versa-Track™ on the trailer and turn handle 90º. See Fig. 6. The handle should be parallel (in

line) with Versa-Track and directly below the lever assembly. Ensure tie-down lock is properly seated

as shown in Fig. 7, by lifting handle and moving from side to side until lock is completely square

across track.

Insert tie down

lock and turn 90º

Page 10

FIG. 6

CONTINUED NEXT PAGE

FIG. 7

Versa-Track

Tie down lock

IncorrectCorrect

IncorrectCorrect

Safety

Securing The Load

CONTINUED FROM PREVIOUS PAGE

2. Crank the lever assembly down until it is a

maximum of 3/8” from the plastic disc when the

tie-down bar is sitting on the skis. See Fig. 8.

3. To clamp tie down bar in place, pull up on

handle and move side to side to make sure tie

down lock is seated properly in Versa-Track.

See Fig. 7. Use your other hand to push down

on lever assembly while still pulling up on

handle. Pulling the handle up keeps the tie-down

assembly in vertical position and allows it to

clamp down much easier. See Fig. 9. If more

or less holding pressure is desired, simply lift

lever up and turn clockwise to tighten or counter

clockwise to loosen.

4. With the Versa-Lock in the clamped position,

insert the safety snap pin to hold the lever

assembly down. See Fig. 10. A padlock (not

included) may be used instead of the snap pin

for added security. Failure to insert the safety

snap pin or padlock will result in the load

becoming unsecured.

Lever Assembly

3/8” Max.

Plastic Disc

Handle

FIG. 8

FIG. 9

FIG. 10

5. A recommended Quick Loop and strap for rear

tie-down is shown in Fig. 11. Fig 12 shows a

properly installed Versa-Lock with tie-down bar.

Note: If the Versa-Lock is used on a different

snowmobile, it may need to be adjusted up or

down for varying ski heights.

CAUTION

As with any tie-down system, the ultimate

responsibility for ensuring that the load is

adequately secured lies with the driver. At

a minimum, FLOE recommends the use of a

properly tensioned tie-down bar and a means

to secure the rear of the snowmobile (as

shown in Figs. 11 & 12). You may choose to

do more or less, based on road conditions and

when determining load-securing measures,

and periodically check your load to ensure

security is maintained.

FIG. 11

FIG. 12

Page 11

Safety

Securing The Load

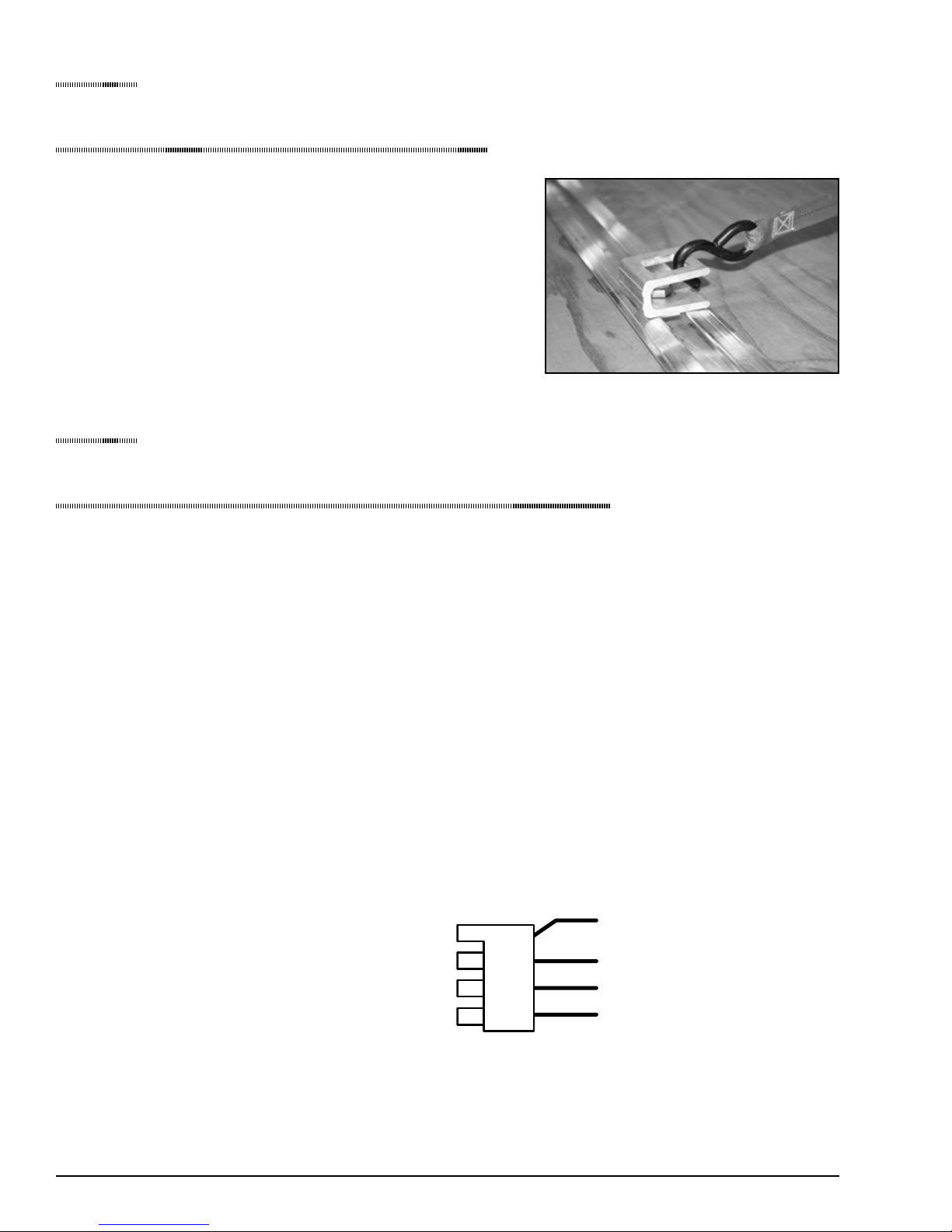

QUICK-LOOP™ INSTALLATION

Lubricate the threads of the bolt with Anti-seize.

Insert the Quick Looop assembly into the Versa-Track. Rotate

the cam until the insert catches in the Versa-Track. While

pulling up on the Quick Loop, tighten until insert stays engaged

with slot. Slide the Quick Loop to the desired location and

nish tightening the bolt. Quick Loops should be installed so

that the pull is as close to perpendicular as possible.

Safety

Trailer Lighting System

Special emphasis has been placed on the design of

your FLOE trailer’s lighting and wiring system to

ensure that it is long-lasting and maintenance-free.

FLOE uses high quality lights that are commonly

found on commercial over-the-road trailers.

SIDE MARKER LIGHTS (Amber and Red)

• Shock-mounted (on replaceable rubber

grommets)

• Waterproof sealed units (for longer life)

• Easy to replace

• Small enough to carry spares

REAR TAIL/BRAKE/TURN SIGNAL LIGHTS

• Standard size

• Easy to replace and to carry spares

TONGUE CONNECTOR AND HARNESS

• Electrical connector has a molded harness for

long lasting durability. Your trailer is equipped

with a plug-in receptacle to keep the electrical

connector protected when not in use.

• Tongue portion of wiring harness can be replaced

without having to splice or replace the remaining

wiring harness.

• Wire harness is run through the trailer frame to

keep it protected from the elements.

• To ensure trouble-free use, periodically inspect

all connections for tight, corrosion-free contact

and apply an electrical grease as necessary to

prevent future corrosion.

White - Grounds all lights

Brown - Front & rear marker lights

3 light ID bar & tail lights

Yellow - Left turn / brakes

REAR ID MARKER LIGHTS, FRONT/REAR

CLEARANCE LIGHTS

• Standard size

• Easy to replace and to carry spares

Page 12

Green - Right turn / brakes

The wiring diagram provides the information

needed for wiring the towing vehicle harness/

connector. It is important that the proper

connections be made and that the system is tested

before using your trailer.

Loading...

Loading...