Flo Corp TRACER 1000 LTT1 Operating Instructions Manual

OPERATING INSTRUCTIONS

TRACER 1000™ LTT1

GUIDED WAVE RADAR LEVEL TRANSMITTER

(877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 1

Introduction

Please read carefully! No liability can be accepted for damage caused by improper use or installation of the Tracer 1000 Level Transmitter.

Featuring TDR (Time Domain Reectometry) technology, the Tracer 1000™ provides continuous radar level measurement

and point level detection in liquids and solids, with analog and switching output. This innovative radar device has almost

no installation restrictions – the 1” radar beam can be mounted in small tanks, tall and narrow nozzles and it measures

precisely even with difcult tank geometries or close to interfering structures. Factory settings may be congured via

HART® Communication protocol. Tracer 1000 is ideal for various types of processing and storage applications and has

an exceptional performance in liquids even with low reectivity such as light oils and hydrocarbons.

Safety Precautions

If you are unsure of the suitability of a Tracer 1000 for your installation, please consult your FLO-CORP representative for

further information.

NOTE: REMOVE ALL PACKING INSERTS BEFORE OPERATING LEVEL TRANSMITTER.

Authorized Personnel

All operations described in this operating instructions manual must be carried out only by trained specialist personnel

authorized by the plant operator. During work on and with the device the required personal protection equipment must

always be worn.

Warning about misuse

Inappropriate or incorrect use of the instrument can give rise to application-specic hazards, e.g. vessel over ll or damage

to system components through incorrect mounting or adjustment.

General Safety Instructions

The user must take note of the safety instructions in this operating instructions manual , the country specic installation

standards as well as all prevailing safety regulations and accident prevention rules. The instrument must only be operated

in a technically awless and reliable condition. The operator is responsible for trouble-free operation of the instrument.

During the entire duration of use, the user is obliged to determine the compliance of the required occupational safety

measures with the current valid rules and regulations and also take note of new regulations.

Disclaimer

The information contained in this document is subject to change without notice. FLO-CORP makes no representations or

warranties with respect to the contents hereof and specically disclaims any implied warranties of merchantability or tness

for a particular purpose.

(877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 2

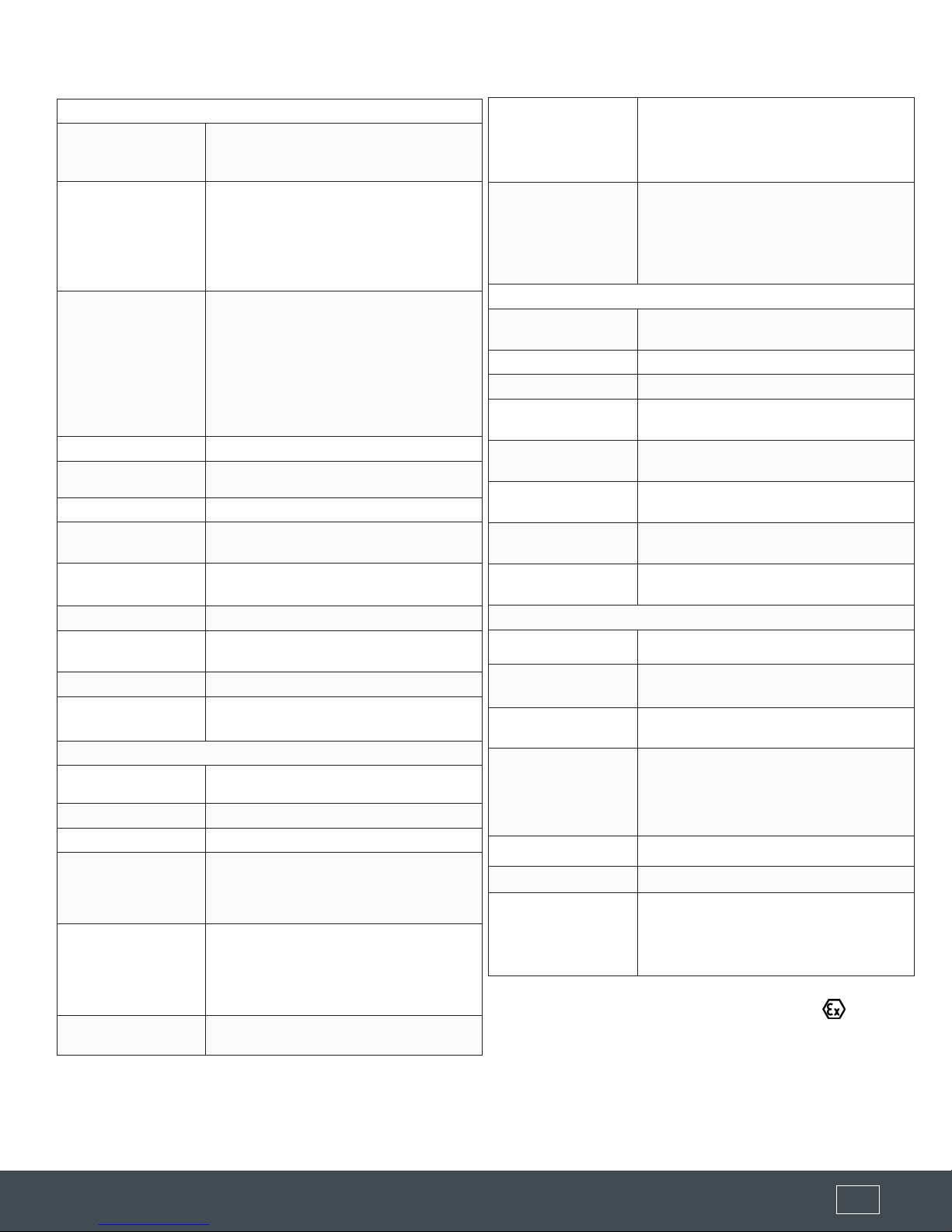

SPECIFICATION

Output Functions

Analog Output

(Active)

Total Load

Resistance

Lower Range Value

Upper Range Span

Response Time

Temperature Drift

Switch Output

Supply Voltage

Current

Consumption

Start-Up Time

Cable Terminals

Measurement Specications

Accuracy

Repeatability

Resolution

Probe Type

Probe Length [L]

Top Dead Band

Electrical Specications

The Tracer 1000 is an active, single

ended, non-isolated, 3 or 4 wire analog

output transmitter.

Current output 4-20mA: The span

between the lower range value [4mA]

and the upper range value [20mA]

is equal to 0-100% of the continuous

level measurement reading as a factory

default. Output can be inverted.

< 500Ω: HART resistor approx. 250Ω

+ load resistance approx. 250Ω if the

current output is connected to a device

with an inner resistance of approx. 250Ω,

then there is no additional external HART

resistor necessary. In that case, the

HART modem is connected in parallel to

the current output wires.

4.0mA (span 0%)

20.0mA (span 100%)

0.5s (default), 2s 5s (selectable)

Less than .0078 in/ºF change in ambient

temperature

DC Switch, PNP, Active, Max. Load 200

mA Current.

12-30VDC (reverse-polarity protected)

< 50mA at 24 VDC (no burden)

< 6s

Screwless, cage clamp terminal block for

stranded and solid wires AWG 22-14.

± 0.12” or 0.03% of measured distance,

whichever is greatest

< .08”

< .04”

316 SS Rod: 1/4” Dia. (Coated Rod; 3/8” Dia.)

316 SS Coaxial: 3/8” Dia.

Wire Cable: 1/2” Dia.

316 SS Rod: 2.41” - 120”

316 SS Coaxial: 0” - 120”

Wire Cable: 2.41” - 480”

(Length must be specied when ordering - The reference point

is always the sealing surface of the connection thread - See

dimensional drawings)

0” Coaxial Probe

2.41” Rod or Wire Probe

Measuring Range

[M]

Up to 780” depending on probe type

Freely positionable within the measuring

range [M] Hysteresis can be set by

Switching Point [S]

dening seperate upper and lower

thresholds; if those are set at the same

position, the minimum hysteresis of .11”

applies

Application Specications

Dielectric Constant

[ɛr]

Conductivity

Density

Standard

Application Temp.

Optional

Application Temp.

Ambient

Temperature

Application

Pressure

Velocity of Level

Change

Wire & Cable Probe: Congurable

Coaxial Probe: 0

No restrictions

No restrictions

F: -40º to 410º

C: -40 to 150º

F: -320º to 500º

C: -195 to 260º

F: -13º to 176º

C: -25º to 80º

-14.50 PSI to 580 PSI

< 3.2 fps

Mechanical Specications

Wetted Materials

Enclosure Material

Enclosure Rating

1.4404 / 316L and PEEK, PTFE

Aluminum alloy EN AC-AISi9Cu3 (DIN EN

1706), Epoxy Spray (~70µm)

Standard: NEMA 6 (IP68)

Explosion Proof Option: ATEX NEMA 7

1/2” NPT (2) or

Cable Glands/Screw

Plugs

Cable Glands (2) or

1/2” NPT (1) & Cable Gland (1) or

M20 x 1.5 (2) or

M20 X 1.5 (1) & Cable Gland (1)

Connection Thread

Weight (Less Probe)

3/4” NPT (US) or 3/4” G (Metric)

1.99 lbs. (903.8 g)

FM: Class I Groups A,B,C,D

Certication

Class II Groups E,F,G; Class III; Type 4X

Class I, Div. I, AEx D IIC; IP66

Class I, Div. I, Ex d II C

Specications are subject to change without notice.

(877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 3 (877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 4

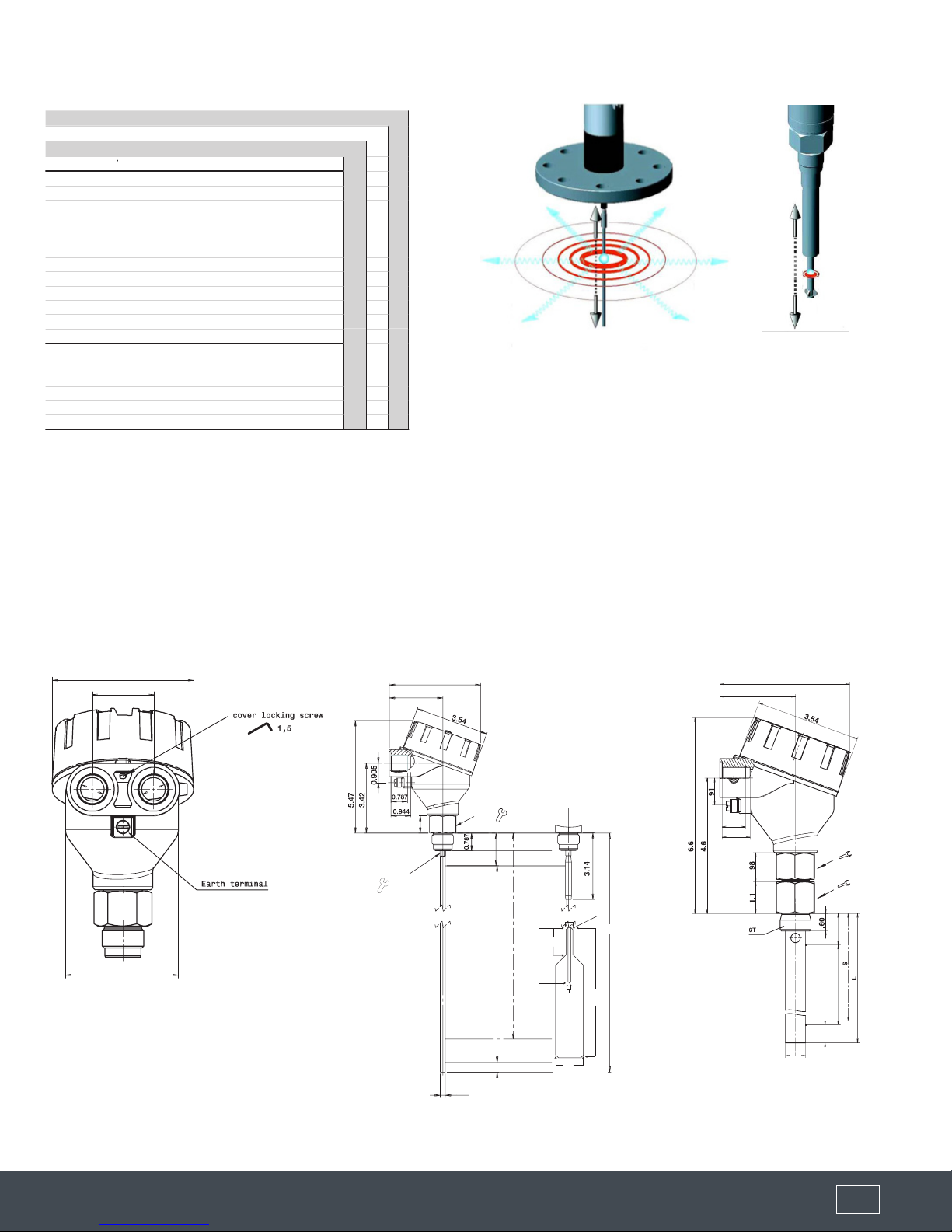

PROBE TYPE RECOMMENDATIONS

Probe Type Recommendations

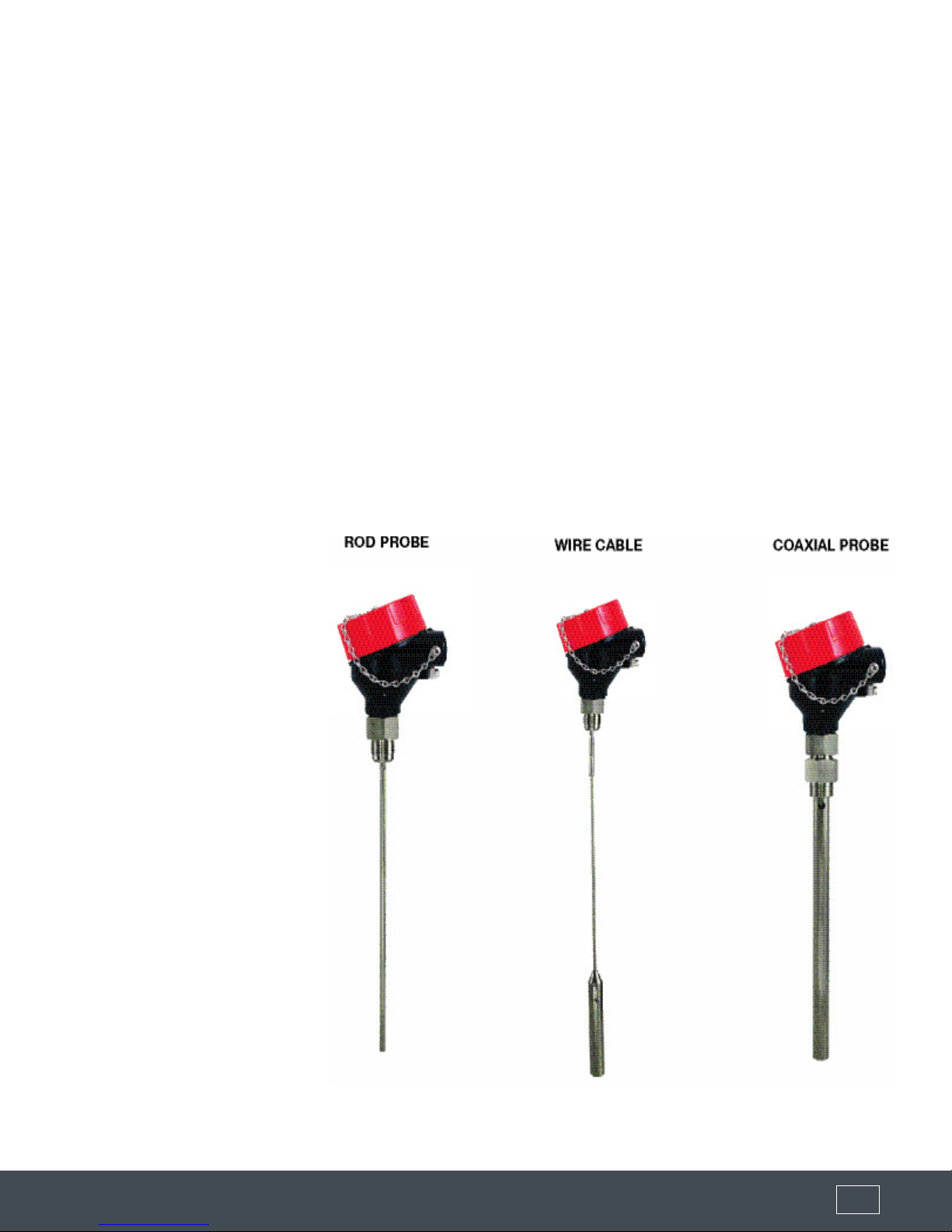

WIRE CABLE PROBE

316 SS ROD PROBE

316 SS COAXIAL PROBE

PROBE MOUNTING

Tall & narrow nozzles

Difficult tank or nozzle geometries

Close to internal tank structures or tank wall

Probe might move or touch internal tank structures/tank wall

Liquid spray may touch probe above the liquid surface

Non-stationary interface targets, e.g. agitator blades

Measurement readings at the very top or bottom of the tank

Non-metallic tanks

Bypass chambers and stilling wells

Limited headroom for installation

MEDIA CHARACTERISTICS

Measuring low reflectivity liquids (i.e. low dielectric constant)

Viscous, crystallizing, adhesive, coating, or sticky liquids

Fibrous liquids, sludge, slurry, pulp

Liquids containing solid particles

Clean-ability of probe is important

= Recommended

= Possible, maybe with configuration and/or mounting adjustments

= Not recommended

WIRE CABLE PROBE

316 SS ROD PROBE

316 SS COAXIAL PROBE

Tall tanks

Cable Probe Coaxial Probe

+ • •

+ • •

+ • •

+ • •

+ • •

+ • •

+ • •

+ • •

• + -

• • +

• • +

Bulk solids

+

•

-

DIMENSIONS (Inches)

Housing

3.5

1.54

- - +

+ • •

- + +

- + +

- + +

- + +

316 SS Rod Probe / Wire Cable Probe 316 SS Coaxial Probe

2.55

65

4.4

D

3

90

39

cover locking screw

1.5

2

D

4.41

2.56

2.8

1/4”

72

Earth therminal

.79

.94

1.26

1.26

3/8”

1.259

CT

.375

(wire cable 7x19)

0.157

480 (wire rope 7x19)

0.236

1

1.5

M6x10, DIN914

set screw

0.47

12 M

6

.166

.75

5

M12x1.75

0.86

22

L

150

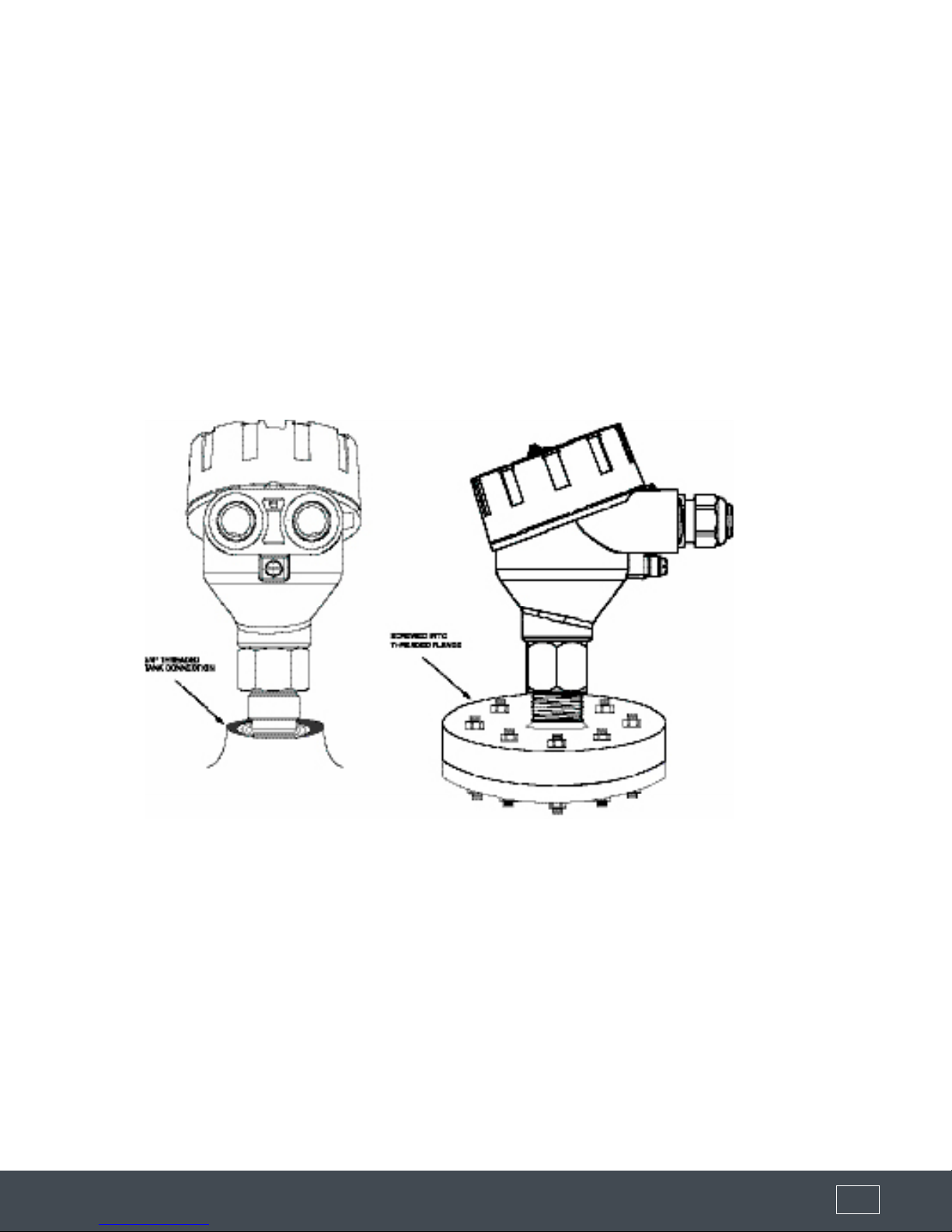

Installation/Mounting

Handling and Mounting:

The Tracer 1000 generally comes supplied with a 3/4” MNPT process connection used for mounting.

The Tracer 1000 is mounted vertically at the top of the tank via the process connection thread. The threaded

process connection can be screwed directly into a standard female threaded tank connection. We recommend

using Teon tape on the process connection. Please ensure proper sealing of the sensor connection and take into

consideration temperature, pressure and other process conditions. The tank connection can be either anged

or non-anged, standard tank nozzle or pipe union. The Tracer 1000 should never be welded onto the tank

connections. Welding directly on the metal parts of the Tracer 1000 will cause serious damage to the transmitter

and void the warranty. The G tting thread of the Tracer 1000 is supplied with a gasket made of Klingersil C-4400,

thickness 0.0787”. The suggested tightening torque is 25 Nm (max. permissible torque is 45 Nm) with a max.

pressure of 580 PSIG.

Preparation:

FLO-CORP’s Tracer 1000 level transmitters are ready to install as-is, and are completely pre-congured per the

application data sheet or customer application information at time of order. The Tracer 1000 is shipped with a

Figure 1: Mounting

calibration tag secured to the safety chain of the transmitter head. The calibration tag indicates the 4 mA equivalent

in level (usually 0.0”) and 20 mA equivalent in level (high level reading). If changes are to be made with this

conguration, please see section Operation and section Programming and Conguration.

Things to Avoid:

Avoid lifting or handling the Tracer 1000 by its probe; this can potentially damage the probe or the probe

connection. The Tracer 1000 should be handled by the hexagon connection or the lower section of the housing.

Avoid using the housing to screw the Tracer 1000 into the process connection. Use the hexagon tting to tighten

using a 1.25” wrench.

Avoid installing the Tracer 1000 probe so it is not directly impacted by liquids owing out of the lling inlet. This

may cause erroneous readings from the transmitter. If this situation is unavoidable, please consider the use of the

Coaxial Probe option.

Avoid installing the Tracer 1000 probe so it is touching or swaying towards other objects inside the tank, including

(877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 5 (877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 6 (877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 7 (877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 8 (877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 9 (877) 356-5463 | (p) 330-331-7331 | (f) 330-331-7172 | www.FLO-CORP.com | © 2017 FLO-CORP | REVA 1116 10

the tank nozzle. This may cause erroneous readings from the transmitter. Anchoring xtures are permissible and

supplied by the end-user. Please contact FLO-CORP for further details about using anchoring xtures.

Since the Tracer 1000 has an energy signature that is approximately a 1.5” to 2.0” radius from the center of the probe,

considerations should be made when engineering the proper probe location for mounting. If it is not possible to mount

the probe in a location that will be free of any objects that might interfere with the signal, than set-up conguration

changes can be made to possibly accommodate the mounting location (See Conguration Section).

Probe Selection

Probes for Liquids and Paste Applications:

The Tracer 1000 uses 1 of 2 possible probe congurations. The Rod probe is the most common. It can be used for

most liquids and is recommended for use with stilling wells and bypass chambers with a minimum inside diameter of

2.0”. The maximum length of the rod probe is 10 feet. The Rod probe is made of 316L Stainless Steel, 1/4” diameter.

The Rod probe can be ordered with an optional teon isolation sleeve and connections. Both congurations have a

threaded female connection on one end and bare end on the other. To install, thread the threaded connection into the

male threaded adapter on the Tracer 1000 transmitter.

The Coaxial probe is the second probe type available with the Tracer 1000. The Coaxial probe is typically used with

extremely low ∑r (dielectric) strength. It is also used if the agitation caused by inuent ow or mixing blades make the

level signal to erratic to read. The maximum length of the Coaxial probe is 10 feet. The Coaxial probe is made of 316

Stainless Steel, 1/2” diameter. To install, thread the threaded end of the inner rod into the threaded adapter of the Tracer

1000. Please make sure that the centering rod isolators are installed with approx. 20” space between each spacer.

The outer tube will now be ready

to slide over the inner rod, upward

towards the transmitter head. Next,

thread the threaded connection of

the outer tube into the upper hex

threaded connection. The Coaxial

probe assembly should now be

complete with the 3/4” male process

connection and is now ready to be

threaded into the 3/4” female tank

connection.

Figure 2: Probes

Wiring

Wiring Diagrams:

Loading...

Loading...