FLM CP30-M4L6, CP30-S3S, CP30-XL4S, CP30-XL4L6, CP26-L4S User manual

...

E-mail: info@flm-gmbh.de

R

Your Dealer

Accessories for Photography,

Lighting Engineering and Metrology

79312 Emmendingen - Germany

Schützenstraße 18

Tel.: +49 (0) 76 41-57 17 22

Fax: +49 (0) 76 41-57 17 23

Homepage: www.flm-gmbh.com

Operating Instructions

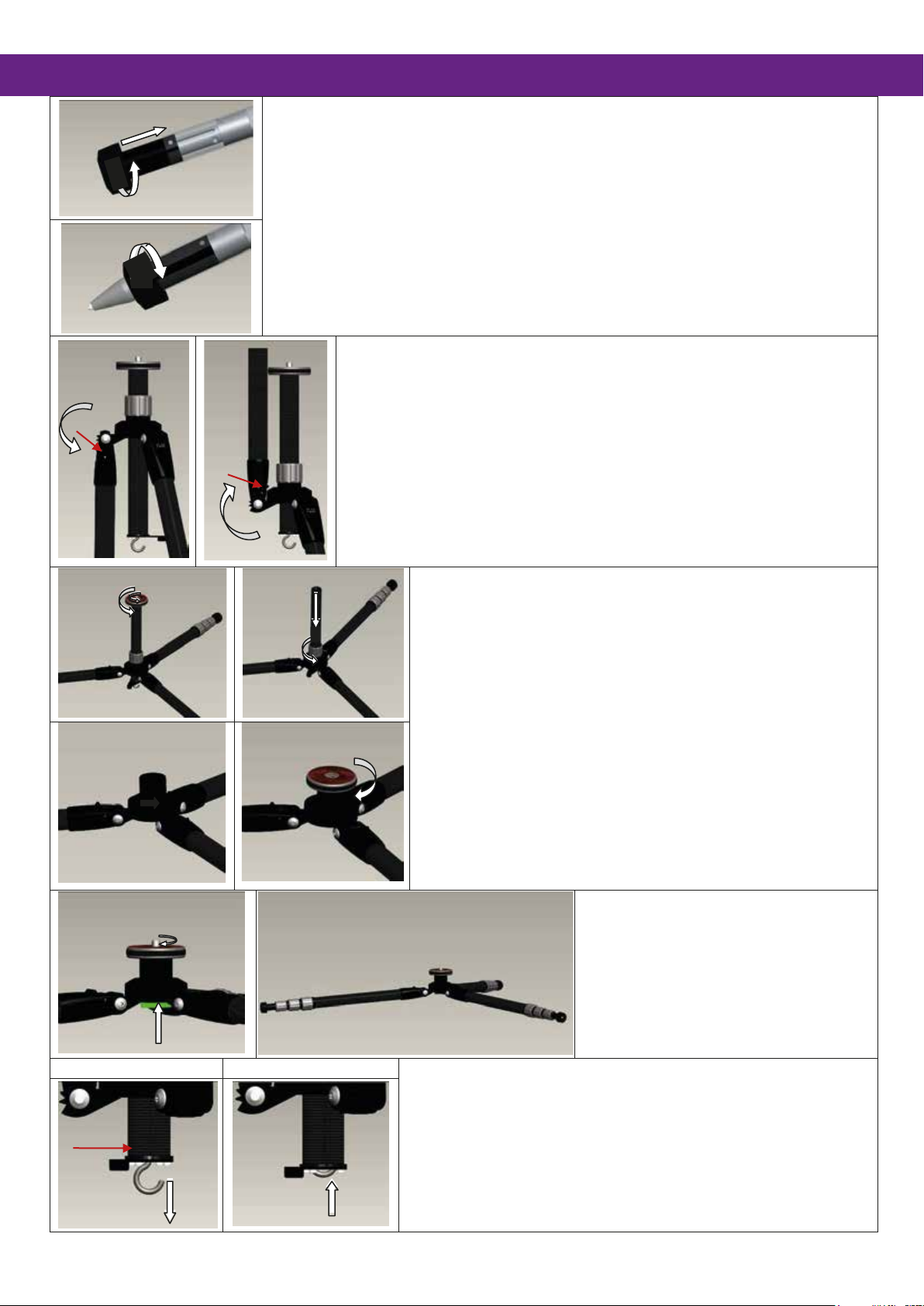

Quick Change Tips

The changing of a hardened steel tip to replace it with a rubber tip for the FLM-Centerpod is

Automatic Leg Locking System

Very Stable Position with High Flexibility

Now, the plate can be screwed on in the place

Clever Hook System

1

2

2

3

"Click"

"Click"

Fig. 3

Fig. 4

Fig. 1

Fig. 2

6

7

Fig. 9

Fig. 10

1

2

3

4

5

Fig. 5

Fig. 6

Fig. 7

Fig. 8

"Click"

Fig. 12

Fig. 13

very simple, fast and secure due to the new bayonet catch.

The rubber tip is released by turning counterclockwise (Fig. 1, Pos. 1) and can then be simply

shoved over the steel tip (Fig 1, Pos. 2). By turning clockwise (Fig. 2, Pos. 3), the rubber tip is

locked in place and when this is done it then forms a water tight connection with the metal

and the carbon tube. Due to this, the inside of the tripod is always protected against water and

dirt in an outside area.

However, if water should enter the tripod leg then this can be drained out by turning the tripod

upside down.

With the automatic locking system, the unfolding and the folding up of the FLMCenterpod is accomplished with just a few movements.

To fold up the tripod, the legs are swiveled downwards (Fig. 3) and then moved

upwards 180° in one movement (Fig. 4) so they are folded together. When they are

folded together in this way, the stored dimensions of the FLM-Centerpod are very

small.

tip

To set up the tripod, the legs are simpl

automatically in the desired position.

y rotated downwards and they are then locked

The FLM-Centerpod has a plate and tripod head locking system, which

insures that you always have firm control of your camera. In spite of

this, the tripod is very flexible and due to the removable center column

is very well suited even for difficult macroshots.

The antitwist protection is provided by screwing the plate into the center

tube and then fixing this in place with the 3/8" set screw. In addition,

using a headless screw in th

fits, can be protected against becoming loose.

To remove the center column, first unscrew the 3/8" set screw with an

Allen wrench (Fig. 5, Pos. 1). After this is done, the plate be rotated out

of the center column.

Now, the tightening device for the center column is loosened and the

center tube pulled downwards and out (Fig. 6, Pos. 3 + 4). The device is

then completely unscrewed (Fig. 7).

e bottom of the plate, any ball head, which

of the tightening device (Fig. 8, Pos. 5) and

by inserting the antitwist protection (Fig. 9,

Pos. 6) it is fixed in place with the 3/8" screw

so that it is protected against twisting (Fig. 9,

Pos. 7).

The rubber tips insure a stable footing in this

position (Fig. 10).

The hook is pulled downwards out of the center column and is held in the

end position (Fig. 12). In this way, it is easier to attach additional weight

to dampen vibrations or level the LB head.

By tapping lightly on the hook, this snaps back into the center column.

This then reduces the stored dimensions of the FLM-Centerpod and the

hook is properly stored.

Loading...

Loading...