Page 1

®

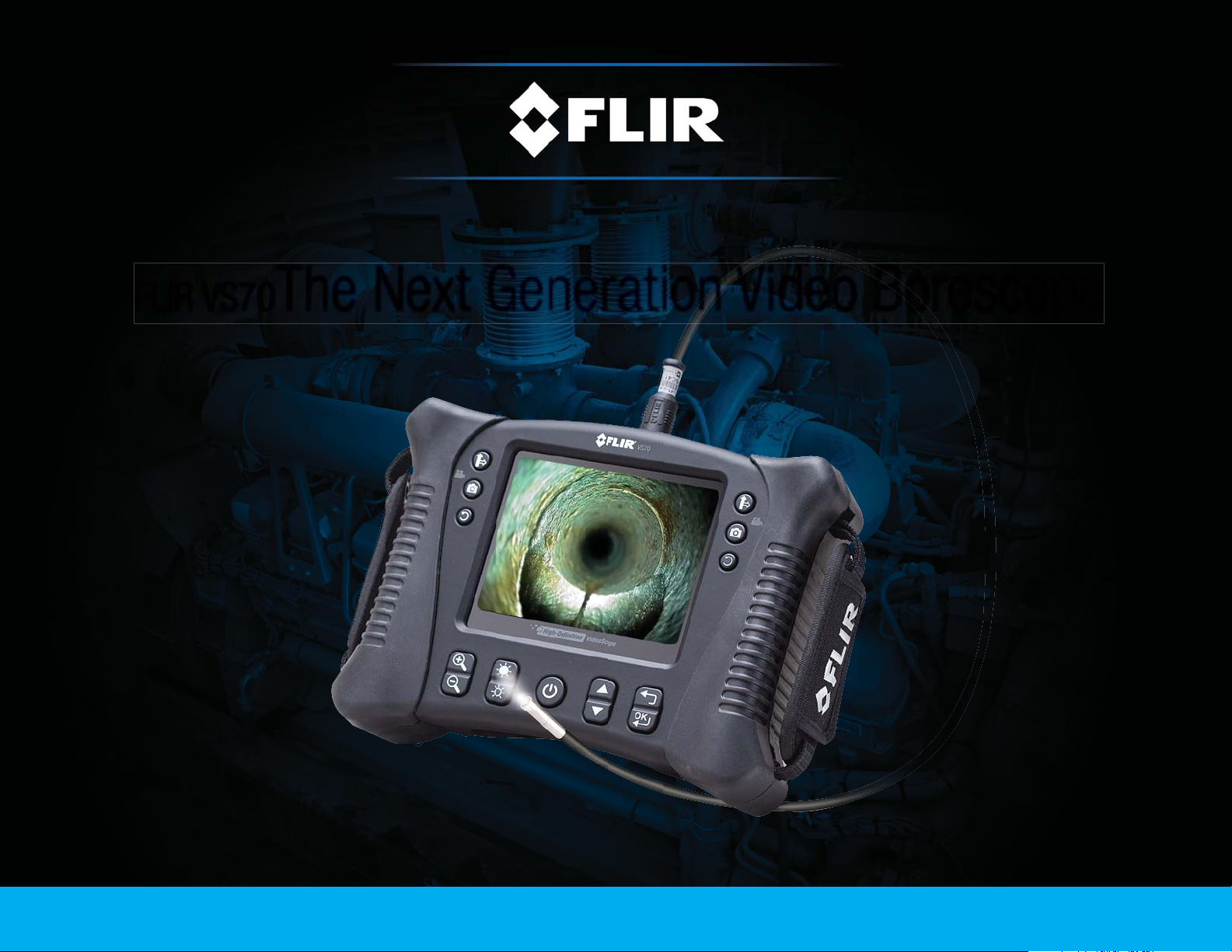

FLIR VS70The Next Generation Video Borescope

Industrial Maintenance | Power Plants | Petrochemical | Aviation & Marine MRO

HVAC | Vehicle Fleet Service | Building Inspections | Site Investigations

Page 2

TWO YEAR

FLIRVS70

Patent# US D6971215

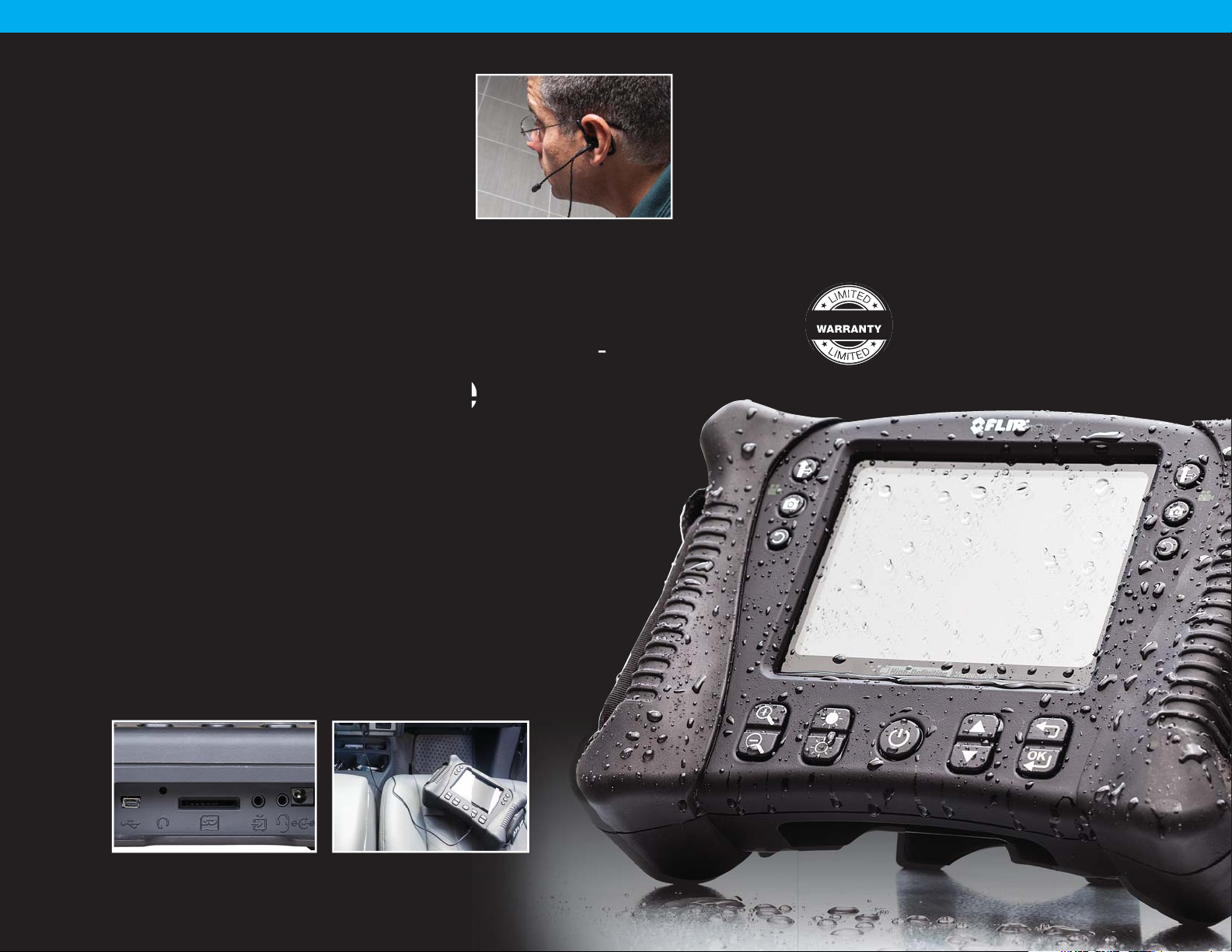

High Tech, Waterproof

and Versatile

Let the VS70 take you where few have gone before.

Bring hidden problems into clear view by accessing extremely

confined areas. The new FLIR VS70 is a rugged, waterproof

videoscope featuring user-friendly, ambidextrous handset controls

that help you easily maneuver the narrow camera probe into extremely

tight spaces to uncover hidden problems.

• Record thousands of images and hours of

video on a standard SD card

• Grab still images from captured video

directly on the base unit

• Add voice annotations to clarify findings

and reduce note-taking

2

View clear video and images on the durable 5.7” (145mm) color LCD

display that is easy to see, even in bright outdoor areas. All cameras

are equipped with adjustable LED lights to illuminate dark inspection

targets. On-screen menus include support for 26 languages.

Inputs include USB port, SD card slot,

video out, earphone and AC power jacks

Includes a car charger to keep your

VS70 working all day long

p your

Page 3

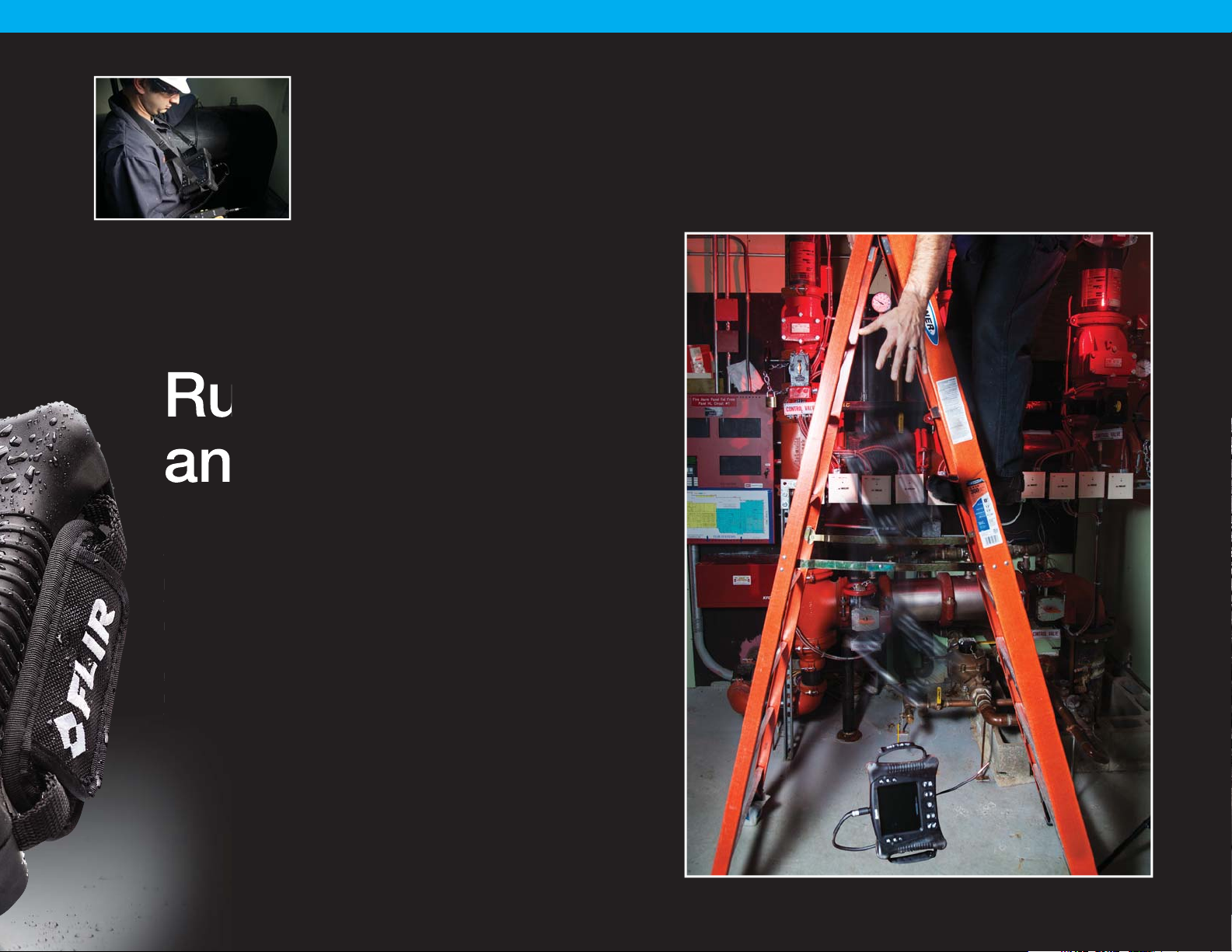

• Waterproof base unit

World

6

o

e

a

• Drop-proof to 2 meters (6.5’)

• Oil and chemical resistant

• Tungsten reinforced cameras

Rugged

and Reliable

VS70Heavy Duty

World-class features that meet your real-world needs

The FLIR VS70’s rubber-reinforced case is waterproof and dust-

The FLIR

proof (IP67-rated) – as well as oil and chemical resistant. Drop-

proof (IP

tested from a height of 2 meters (6.5 feet), the VS70 is built for

tested fr

rough use in harsh environments.

rough us

Designed for on-the-job endurance, the VS70 has a

rechargeable lithium battery that lasts 6 to 8 hours. Flexible USB

recharge

recharging options and the included vehicle charger means your

rechargin

VS70 will work all day long.

VS70 will

-c

esigned

3

Page 4

FLIRFlexibility

Flexible For Various

Industries & Applications

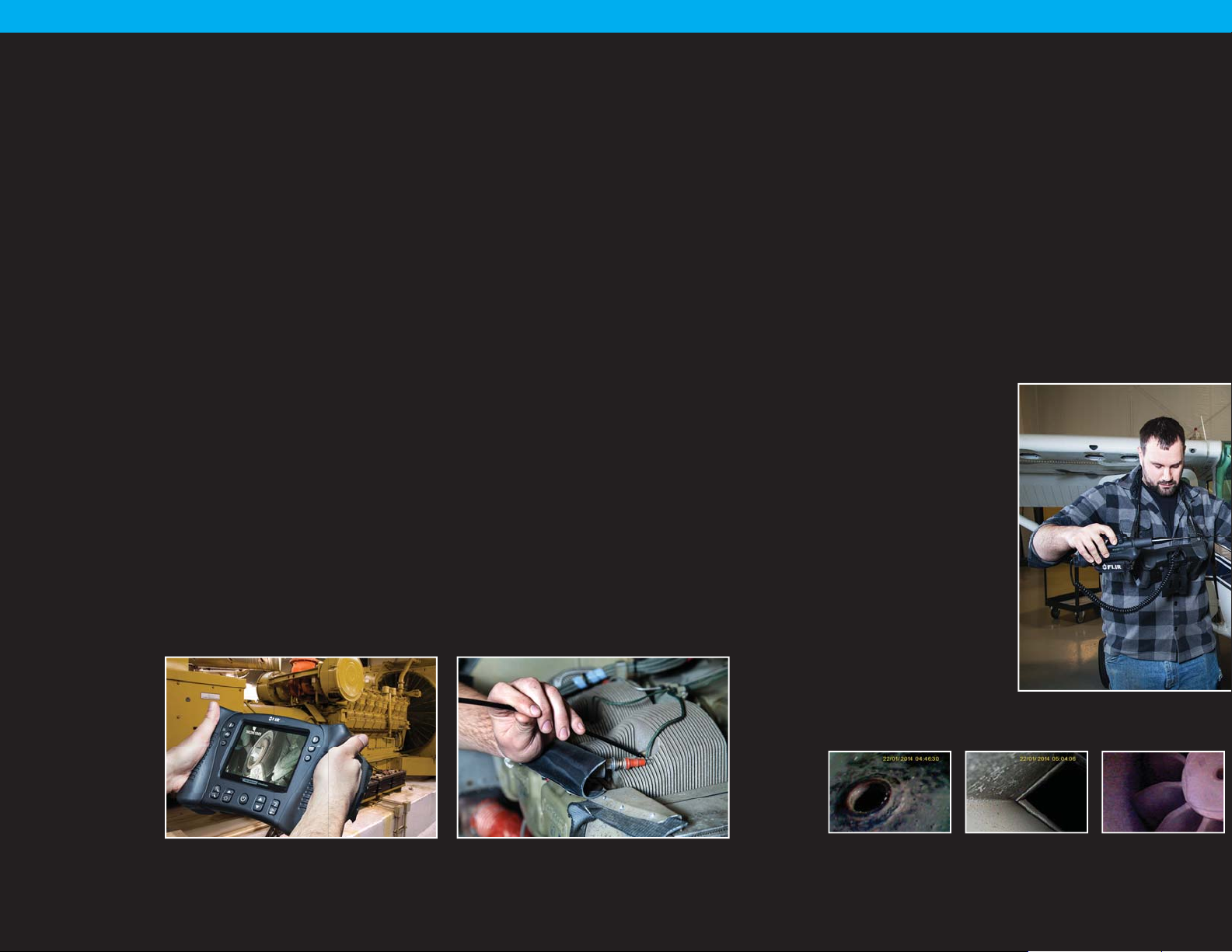

Industrial Maintenance – Check weld integrity, process equipment, machinery and storage tanks.

Aircraft Inspections – Inspect airframes/systems for cracks, wear, debris, and contamination.

Building Inspections – Access wall cavities to find wiring, pipes, leaks, mold growth, insect infestations.

Vehicle Service – See inside and around engines, transmissions, and other hard-to-reach vehicle areas.

• Industrial Maintenance

• Power Generation Plants

• Petrochemical & Refineries

• Government & Security

• Aircraft & Marine Inspections

• Vehicle Diagnostics

• HVAC Troubleshooting

• Building Inspections

HVAC Repairs – Look inside duct work, behind motors and compressors, and within piping and walls.

Inspection bore of tank

Generator inspection Inspecting cylinder in aircraft motor with VSA2-1M

4

using 6mm Long Focus

camera (VSA2-1)

Internal duct work using

28mm detachable

camera head (VSC28)

Exhaust fan blades

using 6mm Long Focus

camera (VSA2-1)

Page 5

Thermostat valve using

6mm Short Focus

camera (VSA2-1M-W)

Checking aircraft engines and airframes

for cracks, wear, defects and debris;

Inspecting oil tank for corrosion

5

Page 6

VS70Cameras

• Cameras from 3.9 to 28mm

• Short & long focal lengths

• Integrated LED lights

• Tungsten-reinforced tips

3.9mm (0.15 in)

VSC39-1FM

4.1mm (0 .16 in)

VSC41-2RM

25mm (1 in),

72° Field of View

VSC25

28mm (1.1 in),

110° Field of View

VSC28

5.8mm (0.23 in)

Dual Camera

VSC2-58-1FM

6.5mm (0.26 in)

90° Mirror Tube

VSC65-12S**

8mm (0.32 in)

VSC80-1R***

5.8mm (0.23 in)

VSC58-20M*

Customizable

Camera Options

Camera Probes and Camera Lenses

A wide variety of camera probe diameters (from 3.9mm to 28mm) enable

users to gain access into otherwise inaccessible areas. Probe sizes are

selected based on the width of access points.

Long Focus (65mm/2.36” to ∞) Lenses enable you to see further within

confined areas. They are ideal for accessing larger areas where the

inspection targets are viewed at longer distances from the camera tip.

Short Focus (20 to 65mm / 0.59” to 2.36”) Lenses let you perform inspections

in areas where close-up viewing of detailed features is essential, such as

when inspecting turbine blades or boiler tubes.

Circles represent camera diameters and are to scale.

6

* Comes with 20 meter cable. Also available with 30 meter cable (VSC58-30M) **Comes with 12” probe. Also available with 17” probe (VSC65-17S) ***Comes with 1 meter cable. Also available with 2 meter (VSC80-2R)

Page 7

Camera 1

Camera 2

Dual Ca mera let s you swit ch

bet ween a wide -angle

180-deg ree o r standar d

90- degr ee ang le lens by simply

pres sing a b ut ton on eit her

side of the ba se uni t.

VS70Accessories

VSC65-17S

VSC2-58-1FM

Specialty Tools

The wireless handset transmits more than 30 meters to the base unit, making inspections easier

in tight spots or when you want to mount the VS70 on a tripod. Wired and wireless handsets make

it easier to manipulate the camera probe and keep the display in a stable position.

For even more camera control, two-way, 240-degree articulation enables you to look around

within confined areas. Articulating 6mm cameras are available on dedicated wired or wireless

handsets, with short and long focus lenses, and semi-rigid cables in one- and two-meter lengths.

Nickel Plated

Copper Housing

Outer Steel

Mesh

Polyurethane Layer

Inner Steel Mesh

Nickel Plated Coil

Polyethylene Layer

Steel Monocoil

Signal Wires + Articulating

Cables

VSA2-1-W

Camera Head Bending Neck Insertion Tube

Detachable 25 and 28mm “pl umbing” camera head s are

designed for u se with 20 - and 30 -mete r fi bergl ass ca bles

on weara ble spo ols to make plumbi ng insp ectio ns a snap.

Availab le brus h kits e nable u sers to c enter t heir pl umbing

camer as insi de larg er pipe s and ducts.

VSS-20

VSC25 & VSC28

VS-BR25

7

Page 8

FLIRPre-Packaged Kits

The FLIR VS70 is available in seven pre-bundled kits to

simplify the selection process. The seven kits we offer

address the most common videoscope applications.

KIT COMPONENTS DESCRIPTION

Wired articulated camera probe VSA2-1 Videoscope Transmitter (VST)

VS70-1

VS70-1W

VS70-2

VS70-3

VS70-3W

VS70-Kit

VS70-Kit-W

VS70 + VSC8.0-1R

+ accessories + case

VS70 + VST + VSC8.01R

+ accessories + case

VS70 + VSC5.8-1RM

+ accessories + case

VS70 + VSA2-1

+ accessories + case

VS70 + VSA2-1-w

+ accessories + case

VS70 + VSA2-1 + VSC80-1R

+ accessories + case

VS70 + VSA2-1-W + VSC80-1R

+ accessories + case

General Purpose (Wired) Long Focus Combo Kit includes the VS70, base kit and 8mm long focus camera on a 1-meter

semi-rigid cable. This kit enables users to perform basic inspections and add options as needs grow.

Wireless General Purpose Combo Kit includes the VS70, wireless handset (VST), and a non-dedicated 8mm long focus

camera on a 1-meter semi-rigid cable. The wireless handset makes it easy to manipulate the camera probe while keeping

the display in clear view.

Small Opening Short Focus Combo Kit includes the VS70, base kit, and a 5.8mm short focus camera on a 1-meter

semi-rigid cable. Allows close-up inspections.

Wired Articulation Combo Kit includes VS70 and wired handset with dedicated 6mm long focus camera with 2-way

articulation on a 1-meter semi-rigid cable. Long focus offers farther viewing distances and articulation provides greater

internal camera control.

Wireless Articulation Combo Kit includes VS70 and wireless handset with a dedicated 6mm long focus camera and

2-way articulation on a 1-meter semi-rigid cable. Offers farther viewing and greater internal camera control.

Starter Bundle includes the VS70 and a wired handset with a dedicated 6mm long locus camera with 2-way articulation

on a 1-meter semi-rigid cable, and an 8mm long focus camera on a 1 meter semi-rigid cable.

Wireless Bundle includes the VS70 and a wired handset with a dedicated 6mm long focus, 2-way articulation camera on a

1-meter semi-rigid cable, and an 8mm long focus camera on a 1-meter cable.

All camera s are available in y our ow n cus tom c onfi gura tions – please re fer t o page 10 under “Mix-and-Ma tch O pti ons”

8

Page 9

All cameras come with 3 screw-on Accessory Tips

• Anti-Snag Ball helps prevent cameras from

hanging up on rough surfaces

• Magnet Tip retrieves small steel objects

• Mirror Tip creates 90° side views

VS70Kit Components

What’s in

the Box

The VS70 base kit comes with:

• VS70 Videoscope

Items incl uded w ith the pu rcha se of t he VS70 main uni t

• 4GB SD card

• USB/video out cables

• Power adapters

• Vehicle charger

• Audio headset

• Shoulder strap

• Cleaning kit

• Hard case

• User manual (printed and on CD).

9

Page 10

Mix-and-Match

Options

SELECTION GUIDE

Customized Solutions

The FLIR VS70 is available with a wide range of probes and other

accessories that enable users to create custom-configured

solutions that meet their specific needs. One such accessory is

the Videoscope Transmitter (VST), a general purpose wireless

transmiter designed to work with all cameras.

Choose the right optical camera tip available with the VS70—long

focus or macro focus—that’s right for your job requirements.

ACCESSORIES

Wireless

General Meter Accessories

Detachable Camera Accessories

VST Wireless 2.4Ghz VS70 transmitter

VSA-AP Accessory Pouch for VS70 including

universal battery charger and cleaning kit

VS-2PC 2 Meter Patch Cable

VS-NS Hands Free Neck Strap Harness for VS70

VS-BR25 Centering Brush for VSC25

VS-BR28 Centering Brush for VSC28

VS-RB Replacement Centering Brush

Answer the below questions to begin the selection

process. Match up the colored circles in the Selection

Guide to the VS70 options that best meet your needs.

Smallest opening sizes?

Smallest diameter cameras for

•

openings less than 5mm

Smaller diameter cameras for

•

openings less than 10mm (3/8”) in size

Larger diameter cameras for openings

•

more than 10mm (3/8”) in size

Distance to inspection targets?

Short Focus Cameras to check for

•

fine details from 20 to 60mm away

Long Focus Cameras to see distances

•

from 65mm to

Typical target distances?

1-Meter Cables for shorter distances

•

2-Meter Cables for distances greater

•

than 1 meter

20- or 30-Meter Cables for longer distances

•

Need More Viewing Options?

2-Way Articulation Camera

•

Dual Camera (180/90°) Camera

•

Rigid Probe with Rotating Mirror

•

∞

10

Page 11

TYPE PART NUMBER SOLUTION DIAMETER (MM)LENGTH (M)RESOLUTION (PX)FIELD OF VIEW (°) FOCAL LENGTH (MM)WIRELESS

ARTICULATING CAMERAS

2-Way Articulation Wireless Handset with

integrated cable and camera

2-Way Articulation Wired Handset with

integrated cable and camera

GENERAL INSPECTIONS

Small Diameter Cameras with cables

General Purpose Cameras with cables

SPECIALTY INSPECTIONS

Dual Camera with cable

Rigid Probe Cameras with handle

PLUMBING INSPECTIONS

Small Opening Camera on Long-Reach Cable

Detachable Cameras for use with Plumbing Spool Cables

Plumbing Spool Cables for use with Detachable Cameras

VSA2-2M-W

VSA2-2-W

VSA2-1M-W

VSA2-1-W

VSA2-2

VSA2-2M

VSA2-1

VSA2-1M

VSC41-2RM

VSC39-1FM

VSC58-2R

VSC58-2RM

VSC58-1R

VSC58-1RM

VSC80-2R

VSC80-1R

VSC2-58-1FM

VSC65-17S

VSC65-12S

VSC58-30M

VSC58-20M

VSC25

VSC28

VSS-30

VSS-20

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • •

• • • •

• • • •

• • • •

• • •

• • •

• •

• •

•

•

6 2 307,200 56 20 to 60 Yes

6 2 307,200 56 65 to ∞ Yes

6 1 307,200 56 20 to 60 Yes

6 1 307,200 56 65 to ∞ Yes

6 2 307,200 56 65 to ∞ With VST

6 2 307,200 56 20 to 60 With VST

6 1 307,200 56 65 to ∞ With VST

6 1 307,200 56 20 to 60 With VST

4.1 2 76,800 53 20 to 60 With VST

3.9 1 76,800 53 20 to 60 With VST

5.8 2 307,200 56 65 to ∞ With VST

5.8 2 307,200 56 20 to 60 With VST

5.8 1 307,200 56 65 to ∞ With VST

5.8 1 307,200 56 20 to 60 With VST

8 2 307,200 56 65 to ∞ With VST

8 1 307,200 56 65 to ∞ With VST

5.8 1 307,200 56 20 to 60 With VST

6.5 .43 307,200 56 20 to 60 With VST

6.5 .30 307,200 56 20 to 60 With VST

5.8 30 76,800 56 20 to 60 With VST

5.8 20 76,800 56 20 to 60 With VST

25 — 307,200 72 60 to 600 —

28 — 307,200 110 60 to 600 —

— 30 — — — With VST

— 20 — — — With VST

11

Page 12

BOSTON

FLIR Systems, Inc.

9 Townsend West

Nashua, NH 03063

USA

PH: +1 866.477.3687

PORTLAND

Corporate Headquar ters

FLIR Systems, Inc.

27700 SW Park way Ave.

Wilsonville, OR 97070

USA

PH: +1 866.477.3687

SANTA BARBARA

FLIR Systems, Inc.

70 Castilian Dr.

Goleta, CA 93117

USA

PH: +1 866.477.3687

CANADA

FLIR Systems, Ltd.

920 Sheldon Cour t

Burlington, ON L7L 5K6

Canada

PH: +1 800.613.0507

PH: +1 603.324.7611

For more information about FLIR’s new line of test & measurement products, please visit www.fl ir.com/test.

NASDAQ: FLIR

Equipment d escr ibed here in may r equi re US Go ver nmen t aut hori zat ion f or ex por t pur pose s. Div ersion contr ary t o US law is pro hibi ted. S peci fi cations are s ubject to c hange wit hout

notice. For the mo st up -t o-date spec s, visit our w ebsi te: w w w.fl ir.com. ©2014 FLIR Sys te ms, Inc. All other brand and p roduct na mes ar e tradema rks o f FLIR Sy st ems, Incorp ora ted.

Imagery us ed for illus tr ati on pur pose s only. (brv s70R4.14)

Loading...

Loading...