Page 1

User’s manual

FLIR Kx3 series

Page 2

Page 3

User’s manual

FLIR Kx3 series

#T810170; r. AE/41948/41948; en-US

iii

Page 4

Page 5

Table of contents

1 Legal disclaimer ....... ....... ....... .......................... ....... ....... .....................1

1.1 Legal disclaimer .... ....... ............ ....... ....... ....... ....... ....... ..... ....... ... 1

1.2 Usage statistics .................... ....... ....... ....... ....... ....... ..... ....... ....... 1

1.3 Changes to registry ............. ....... ....... ....... .......................... ....... ..1

1.4 U.S. Government Regulations.......................... ....... ....... ................1

1.5 Copyright . ....... .......................... ....... ....... .......................... ....... . 1

1.6 Quality assurance ......... ....... ....... .......................... ....... ....... ....... . 1

1.7 Patents.... ....... ....... ....... ....... ....... .......................... ....... ....... ...... 1

1.8 EULA Terms ............... ....... ....... .......................... ....... ....... .........1

2 Safety information .... ....... ....... ....... ................... ....... ....... ....... ..............2

3 Notice to user .. ....... ....... .......................... ....... ....... ................... ....... ... 6

3.1 User-to-user forums ..... .......................... ....... ....... .......................6

3.2 Disposal of electronic waste . .......................... ....... ....... ................. 6

3.3 Training ..... ..... ....... ....... ....... ....... ....... .......................... ....... ...... 6

3.4 Documentation updates .... .......................... ....... ....... ....... ............ 6

3.5 Important note about this manual.. ....... ....... ....... ....... ..... .. ..... ....... ... 6

3.6 Note about authoritative versions.... .......................... ....... ....... ....... . 7

4 Customer help ................................. ....... ....... .......................... ....... ....8

4.1 General ..... ....... ....... ....... ..... ....... ....... ....... ....... ....... ............ ...... 8

4.2 Submitting a question .......................... ....... ....... ....... ....... ............ 8

4.3 Downloads ............... ....... ....... ....... ....... ............ ....... ....... ....... ....9

5 Important information about FLIR Kx3 series service..... ....... ....... .......... 10

6 Quick start guide ..... ....... ................... ....... ....... ....... ................... ....... . 11

6.1 Quick start guide, FLIR K33 ....... ....... ....... .......................... ....... .. 11

6.2 Quick start guide, FLIR K53 ....... ....... ....... .......................... ....... .. 11

7 List of accessories and services ........... ........................................ ...... 12

8 System configuration overview ............................ ....... ....... ....... .......... 13

8.1 Figure .. ....... .......................... ....... ....... .......................... ....... .. 13

8.2 Explanation ..... ....... ....... .......................... ....... ....... .................. 13

9 System parts..... ....... ................... ....... ....... ....... ................................. 15

9.1 Camera parts ... ....... ....... .......................... ....... ....... .................. 15

9.1.1 Figure.... ....... ....... ..... ....... ....... ....... ....... ....... ............ .... 15

9.1.2 Explanation..... ....... .......................... ....... ....... ............... 15

9.2 Lanyard strap and retractable lanyard............... ....... ....... ....... ........ 16

9.3 Handle strap and retractable lanyard. ....... .......................... ....... .... 16

9.4 Neck strap... ....... ....... ....... ....... ................... ....... ....... ....... ........ 17

10 Screen elements ..... ................... ....... ....... ....... ................... ....... ....... . 18

10.1 Figure .. ....... .......................... ....... ....... .......................... ....... .. 18

10.2 Explanation ..... ....... ....... .......................... ....... ....... .................. 18

10.3 Battery condition indicator ....... ....... ....... ................................. .... 18

11 Operation .... ................................. ....... ....... ....... ................... ....... ..... 19

11.1 Removing the battery.. ....... ....... ....... ..... ....... ....... ....... ....... ....... .. 19

11.1.1 Charging the battery . ....... ....... ....... ....... ....... ................... 19

11.2 Turning on and turning off the camera...... ..... .. ..... ....... ....... ....... ..... 20

11.3 Basic mode ... ....... ....... ................... ....... ....... ....... ....... ....... ..... . 20

11.3.1 Automatic temperature range selection ....... ....... ..... ....... ..... 21

11.4 Saving an image (FLIR K53).... ....... ....... ....... ....... ....... ..... ....... ..... 21

11.4.1 General........ ....... .......................... ....... ....... ....... .......... 21

11.4.2 Figure....... ....... .......................... ....... ....... ....... ....... ...... 22

#T810170; r. AE/41948/41948; en-US

v

Page 6

Table of contents

11.4.3 Procedure .............. ....... ....... .......................... ....... ....... 22

11.5 Recording a video clip (FLIR K53) .... ....... ....... ....... ....... ............ .... 22

11.5.1 General........ ....... .......................... ....... ....... ....... .......... 22

11.5.2 Figure....... ....... .......................... ....... ....... ....... ....... ...... 22

11.5.3 Procedure .............. ....... ....... .......................... ....... ....... 22

11.6 Continuous video recording (FLIR K53) ............ ....... ....... ............... 23

11.6.1 General........ ....... .......................... ....... ....... ....... .......... 23

11.7 Freezing the image. ....... ............ ....... ....... ....... ....... ....... ..... ....... . 23

11.7.1 General........ ....... .......................... ....... ....... ....... .......... 23

11.7.2 Figure....... ....... .......................... ....... ....... ....... ....... ...... 23

11.7.3 Procedure .............. ....... ....... .......................... ....... ....... 23

11.8 Changing the temperature unit ....... .......................... ....... ....... ...... 24

11.9 Connecting the camera to a computer ....... .......................... ....... ... 24

11.9.1 General........ ....... .......................... ....... ....... ....... .......... 24

11.9.2 Procedure .............. ....... ....... .......................... ....... ....... 25

11.10 Changing settings in FLIR Tools ..... .......................... ....... ....... ...... 26

11.10.1 The General settings tab..................... ....... ....... ............... 26

11.10.2 The User interface tab . ....... ....... ..... ....... ....... ....... ....... ..... 27

12 In-truck charger (optional accessory) ........................................ .......... 29

12.1 Introduction ....... ....... ....... ....... ....... ....... ..... ....... ....... ....... ....... .. 29

12.2 Parts and functions .... ....... ....... ..... ....... ....... ....... ....... ....... ..... .... 30

12.3 Choosing a suitable position. ....... ................... ....... ....... ....... ........ 30

12.4 Recommended cable area and fuse ....... .......................... ....... ...... 31

12.5 Mounting instructions. .......................... ....... ....... ....... ....... .......... 31

12.6 Charging the camera ...... ....... ....... ..... ....... ....... ....... ....... ....... ..... 31

12.7 Charging a battery separately ... .......................... ....... ....... ........... 31

12.8 Cleaning ........ ....... ....... ....... ..... ....... ....... ....... ....... ....... ............ 32

12.9 Customer support ....... .......................... ....... ....... ...................... 32

13 Technical data ... ....... ................... ....... ....... ....... ................................. 33

13.1 Online field-of-view calculator ...... ................... ....... ....... ....... ........ 33

13.2 Note about technical data .............................. ....... ...................... 33

13.3 Note about authoritative versions.... .......................... ....... ....... ...... 33

13.4 FLIR K33 ....... ................... ....... ....... ....... .......................... ....... 34

13.5 FLIR K53 ....... ................... ....... ....... ....... .......................... ....... 38

13.6 In-truck charger .... .......................... ....... ....... .......................... .. 42

14 Mechanical drawings ................................................. ....... ....... .......... 44

15 CE Declaration of conformity ................... ........................................ ... 48

16 Cleaning, decontamination and disinfection ......................................... 50

16.1 Cleaning ........ ....... ....... ....... ..... ....... ....... ....... ....... ....... ............ 50

16.1.1 Camera housing, cables, and other items ............................ 50

16.1.2 Infrared lens................. ....... ....... .......................... ....... .. 50

16.2 Decontamination and disinfection.. ....... ....... ....... .......................... 51

17 Maintenance, inspection, and service ... ....... ....... ....... .......................... 52

17.1 Maintenance... ....... ....... ..... ....... ....... ....... ....... ....... ................... 52

17.2 Inspection .. ....... ....... ..... ....... ....... ....... ....... ....... ................... .... 52

17.3 Service ....... ....... ....... ....... ....... ................... ....... ....... ....... ........ 52

18 Storage conditions ............................... ....... ....... ....... ................... ..... 53

19 About FLIR Systems ....... ....... .......................... ....... ....... ....... ............. 54

19.1 More than just an infrared camera ........................ ....... ....... .......... 55

#T810170; r. AE/41948/41948; en-US

vi

Page 7

Table of contents

19.2 Sharing our knowledge ....................... ....... ....... ......................... 56

19.3 Supporting our customers. ....... ....... .......................... ....... ....... .... 56

20 History of infrared technology... ........................................ .................. 57

#T810170; r. AE/41948/41948; en-US

vii

Page 8

Page 9

1

Legal disclaimer

1.1 Legal disclaimer

All products manufactured by FLIR Systems are warranted against defective

materials and workmanship for a period of one (1) year from the delivery date

of the original purchase, provided such products have been under normal storage, use and service, and in accordance with FLIR Systems instruction.

Uncooled handheld infrared cameras manufactured by FLIR Systems are warranted against defective materials and workmanship for a period of two (2)

years from the deliverydate of the original purchase, provided such products

have been under normal storage, use and service, and in accordance with

FLIR Systems instruction, and provided that the camera has been registered

within 60 days of original purchase.

Detectors for uncooled handheld infrared cameras manufactured by FLIR Systems are warranted against defective materials and workmanship for a period

of ten (10) years from the delivery date of the original purchase,provided such

products have been under normal storage, use and service, and in accordance

with FLIR Systems instruction, and provided that the camera has been registered within 60 days of original purchase.

Products which are not manufactured by FLIR Systems but included in systems delivered by FLIR Systems to the original purchaser, carry the warranty, if

any, of the particular supplieronly. FLIR Systems has no responsibility whatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It

is not applicable to any product which has been subjected to misuse, neglect,

accident or abnormal conditions of operation. Expendable parts are excluded

from the warranty.

In the case of a defect in a product covered by this warranty the product must

not be further used in order to prevent additional damage. The purchaser shall

promptly report any defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, atits option, repair or replace any such defective product

free of charge if, upon inspection, it proves to be defective in material or workmanship and provided that it is returned to FLIR Systems within the said oneyear period.

FLIR Systems has no other obligation or liability for defects than those set forth

above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims

the implied warranties of merchantability and fitnessfor a particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidental or

consequential loss or damage, whether based on contract, tort or any other legal theory.

This warranty shall be governed by Swedish law.

Any dispute, controversy or claim arising out of or in connection with this warranty, shall be finally settled by arbitration in accordance with the Rules of the

Arbitration Institute of the Stockholm Chamber of Commerce. The place of arbitration shall be Stockholm. The language to be usedin the arbitral proceedings shall be English.

1.2 Usage statistics

FLIR Systems reserves the right to gather anonymous usage statistics to help

maintain and improve the quality of our software and services.

1.3 Changes to registry

The registry entry HKEY_LOCAL_MACHINE\SYSTEM\CurrentControlSet

\Control\Lsa\LmCompatibilityLevel will be automatically changed to level 2 if

the FLIR Camera Monitor service detects a FLIR camera connected to the

computer with a USB cable. The modification will only be executedif the camera device implements aremote network service that supports network logons.

1.4 U.S. Government Regulations

This product may be subject to U.S. Export Regulations. Please send any inquiries to exportquestions@flir.com.

1.5 Copyright

© 2016, FLIR Systems, Inc. All rights reserved worldwide. No parts of the software including source code may be reproduced, transmitted, transcribed or

translated into any language or computer language in any form or by any

means, electronic, magnetic, optical, manual or otherwise, without the prior

written permission of FLIR Systems.

The documentation must not, in whole or part, be copied, photocopied, reproduced, translated or transmitted to any electronic medium or machine readable form without priorconsent, in writing, from FLIRSystems.

Names and marks appearing on the products herein are either registered

trademarks or trademarks of FLIR Systems and/or its subsidiaries. All other

trademarks, trade names or company names referenced herein are used for

identification only and arethe property of their respective owners.

1.6 Quality assurance

The Quality Management System under which these products are developed

and manufactured has been certified in accordance with the ISO 9001

standard.

FLIR Systems is committed to a policy of continuous development; therefore

we reserve the right to make changes and improvements on any of the products without prior notice.

1.7 Patents

000439161; 000653423; 000726344; 000859020; 001707738; 001707746;

001707787; 001776519; 001954074; 002021543; 002021543-0002;

002058180; 002249953; 002531178; 002816785; 002816793; 011200326;

014347553; 057692; 061609; 07002405; 100414275; 101796816;

101796817; 101796818; 102334141; 1062100; 11063060001; 11517895;

1226865; 12300216; 12300224; 1285345; 1299699; 1325808; 1336775;

1391114; 1402918; 1404291; 1411581; 1415075; 1421497; 1458284;

1678485; 1732314; 17399650; 1880950; 1886650; 2007301511414;

2007303395047; 2008301285812; 2009301900619; 20100060357;

2010301761271; 2010301761303; 2010301761572; 2010305959313;

2011304423549; 2012304717443; 2012306207318; 2013302676195;

2015202354035; 2015304259171; 204465713; 204967995; 2106017;

2107799; 2115696; 2172004; 2315433; 2381417; 2794760001; 3006596;

3006597; 303330211; 4358936; 483782; 484155; 4889913; 4937897;

4995790001; 5177595; 540838; 579475; 584755; 599392; 60122153;

6020040116815; 602006006500.0; 6020080347796; 6020110003453;

615113; 615116; 664580; 664581; 665004; 665440; 67023029; 6707044;

677298; 68657; 69036179; 70022216; 70028915; 70028923; 70057990;

7034300; 710424; 7110035; 7154093; 7157705; 718801; 723605; 7237946;

7312822; 7332716; 7336823; 734803; 7544944; 7606484; 7634157;

7667198; 7809258; 7826736; 8018649; 8153971; 8212210; 8289372;

8340414; 8354639; 8384783; 8520970; 8565547; 8595689; 8599262;

8654239; 8680468; 8803093; 8823803; 8853631; 8933403; 9171361;

9191583; 9279728; 9280812; 9338352; 9423940; 9471970; 9595087;

D549758.

1.8 EULA Terms

• You have acquired a device (“INFRARED CAMERA”) that includes software licensed by FLIR Systems AB from Microsoft Licensing, GP or its affiliates (“MS”). Those installed software products of MS origin, as well as

associated media, printed materials, and “online” or electronic documentation (“SOFTWARE”) are protected by international intellectual property

laws and treaties. The SOFTWARE is licensed, not sold. All rights

reserved.

• IF YOU DO NOTAGREE TO THIS END USER LICENSE AGREEMENT

(“EULA”), DO NOT USE THEDEVICE OR COPY THE SOFTWARE. INSTEAD, PROMPTLYCONTACT FLIR Systems AB FOR INSTRUCTIONS

ON RETURN OF THE UNUSED DEVICE(S) FOR A REFUND. ANY USE

OF THE SOFTWARE, INCLUDING BUT NOT LIMITED TO USE ON

THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT TOTHIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

• GRANT OF SOFTWARE LICENSE. This EULA grants you the following

license:

◦ You may use the SOFTWARE only on the DEVICE.

◦ NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLER-

ANT. FLIR Systems AB HAS INDEPENDENTLY DETERMINED

HOW TO USE THE SOFTWARE IN THE DEVICE, AND MS HAS

RELIED UPON FLIR Systems AB TO CONDUCT SUFFICIENT

TESTING TO DETERMINE THAT THE SOFTWARE IS SUITABLE

FOR SUCH USE.

◦ NO WARRANTIES FOR THE SOFTWARE. THE SOFTWAREis

provided “AS IS” and with all faults. THE ENTIRE RISK AS TO SATISFACTORY QUALITY, PERFORMANCE, ACCURACY, AND EFFORT (INCLUDING LACK OF NEGLIGENCE) IS WITH YOU.

ALSO, THERE IS NO WARRANTY AGAINST INTERFERENCE

WITH YOUR ENJOYMENT OF THE SOFTWARE OR AGAINST INFRINGEMENT. IF YOU HAVE RECEIVED ANY WARRANTIES RE-

GARDING THE DEVICE OR THE SOFTWARE, THOSE

WARRANTIES DO NOT ORIGINATE FROM, AND ARE NOT

BINDING ON, MS.

◦ No Liability for Certain Damages. EXCEPTAS PROHIBITED BY

LAW,MS SHALL HAVE NO LIABILITY FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING

FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE SOFTWARE. THIS LIMITATION SHALL APPLY

EVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE. IN

NO EVENT SHALL MS BE LIABLE FOR ANY AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS (U.S.$250.00).

◦ Limitations on Reverse Engineering, Decompilation, and Dis-

assembly. You may not reverse engineer, decompile, or disassem-

ble the SOFTWARE, except and only to the extent that such activity

is expressly permitted by applicable law notwithstanding this

limitation.

◦ SOFTWARE TRANSFER ALLOWED BUT WITH RESTRICTIONS.

Youmay permanently transfer rights under this EULA only as part of

a permanent sale or transfer of the Device, and only if the recipient

agrees to this EULA. If the SOFTWARE is an upgrade, any transfer

must also include all prior versions of the SOFTWARE.

◦ EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is

subject to U.S. export jurisdiction. You agree to comply with all applicable international and national laws that apply to the SOFTWARE,

including the U.S. Export Administration Regulations, as well as

end-user, end-use and destination restrictions issued by U.S. and

other governments. For additional information see http://www.microsoft.com/exporting/.

#T810170; r. AE/41948/41948; en-US

1

Page 10

2

Safety information

WARNING

Applicability: Cameras with one or more batteries.

Do not disassemble or do a modification to the battery. The battery contains safety and protection devices

which, if damage occurs, can cause the battery to become hot, or cause an explosion or an ignition.

WARNING

Applicability: Cameras with one or more batteries.

If there is a leak from the battery and you get the fluid in your eyes, do not rub your eyes. Flush well with

water and immediately get medical care. The battery fluid can cause injury to your eyes if you do not do

this.

WARNING

Applicability: Cameras with one or more batteries.

Do not continue to charge the battery if it does not become charged in the specified charging time. If you

continue to charge the battery, it can become hot and cause an explosion or ignition. Injury to persons

can occur.

WARNING

Applicability: Cameras with one or more batteries.

Only use the correct equipment to remove the electrical power from the battery. If you do not use the correct equipment, you can decrease the performance or the life cycle of the battery. If you do not use the

correct equipment, an incorrect flow of current to the battery can occur. This can cause the battery to become hot, or cause an explosion. Injury to persons can occur.

WARNING

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and warning labels on containers before you use a liquid. The liquids can be dangerous. Injury to persons can occur.

CAUTION

Do not point the infrared camera (with or without the lens cover) at strong energy sources, for example,

devices that cause laser radiation, or the sun. This can have an unwanted effect on the accuracy of the

camera. It can also cause damage to the detector in the camera.

CAUTION

Applicability: Cameras with one or more batteries.

Do not attach the batteries directly to a car’s cigarette lighter socket, unless FLIR Systems supplies a specific adapter to connect the batteries to a cigarette lighter socket. Damage to the batteries can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not connect the positive terminal and the negative terminal of the battery to each other with a metal

object (such as wire). Damage to the batteries can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not get water or salt water on the battery, or permit the battery to become wet. Damage to the batteries

can occur.

#T810170; r. AE/41948/41948; en-US

2

Page 11

2

Safety information

CAUTION

Applicability: Cameras with one or more batteries.

Do not make holes in the battery with objects. Damage to the battery can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not hit the battery with a hammer. Damage to the battery can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not put your foot on the battery, hit it or cause shocks to it. Damage to the battery can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not put the batteries in or near a fire, or into direct sunlight. When the battery becomes hot, the built-in

safety equipment becomes energized and can stop the battery charging procedure. If the battery becomes hot, damage can occur to the safety equipment and this can cause more heat, damage or ignition

of the battery.

CAUTION

Applicability: Cameras with one or more batteries.

Do not put the battery on a fire or increase the temperature of the battery with heat. Damage to the battery

and injury to persons can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not put the battery on or near fires, stoves, or other high-temperature locations. Damage to the battery

and injury to persons can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not solder directly onto the battery. Damage to the battery can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not use the battery if, when you use, charge, or put the battery in storage, there is an unusual smell

from the battery, the battery feels hot, changes color, changes shape, or is in an unusual condition. Speak

with your sales office if one or more of these problems occurs. Damage to the battery and injury to persons can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Only use a specified battery charger when you charge the battery. Damage to the battery can occur if you

do not do this.

#T810170; r. AE/41948/41948; en-US

3

Page 12

2

Safety information

CAUTION

Applicability: Cameras with one or more batteries.

Only use a specified battery for the camera. Damage to the camera and the battery can occur if you do

not do this.

CAUTION

Applicability: Cameras with one or more batteries.

The temperature range through which you can charge the battery is 0°C to +45°C (+32°F to +113°F). If

you charge the battery at temperatures out of this range, it can cause the battery to become hot or to

break. It can also decrease the performance or the life cycle of the battery.

CAUTION

Applicability: Cameras with one or more batteries.

The temperature range through which you can remove the electrical power from the battery is -15°C to

+50°C (+5°F to +122°F), unless other information is specified in the user documentation or technical data.

If you operate the battery out of this temperature range, it can decrease the performance or the life cycle

of the battery.

CAUTION

Applicability: Cameras with one or more batteries.

When the battery is worn, apply insulation to the terminals with adhesive tape or equivalent materials before you discard it. Damage to the battery and injury to persons can occur if you do not do this.

CAUTION

Applicability: Cameras with one or more batteries.

Remove any water or moisture on the battery before you install it. Damage to the battery can occur if you

do not do this.

CAUTION

Do not apply solvents or equivalent liquids to the camera, the cables, or other items. Damage to the battery and injury to persons can occur.

CAUTION

Be careful when you clean the infrared lens. The lens has an anti-reflective coating which is easily damaged. Damage to the infrared lens can occur.

CAUTION

Do not use too much force to clean the infrared lens. This can cause damage to the anti-reflective

coating.

Note The encapsulation rating is only applicable when all the openings on the camera

are sealed with their correct covers, hatches, or caps. This includes the compartments for

data storage, batteries, and connectors.

CAUTION

Do not change the standard fire-fighting procedures when you use a FLIR K series camera. The FLIR K

series camera is not a replacement technology.

#T810170; r. AE/41948/41948; en-US

4

Page 13

2

Safety information

CAUTION

Do not use the FLIR K series camera without the correct training. If the persons that operate the camera

do not have the correct training, an incorrect analysis of the infrared images can occur. Thus, incorrect

decisions during the firefighting can be made.

The training must include:

• How a thermal camera operates and its limits

• How to interpret an image

• How to work safely with the camera.

#T810170; r. AE/41948/41948; en-US

5

Page 14

3

Notice to user

3.1 User-to-user forums

Exchange ideas, problems, and infrared solutions with fellow thermographers around the

world in our user-to-user forums. To go to the forums, visit:

http://forum.infraredtraining.com/

3.2 Disposal of electronic waste

As with most electronic products, this equipment must be disposed of in an environmentally friendly way, and in accordance with existing regulations for electronic waste.

Please contact your FLIR Systems representative for more details.

3.3 Training

To read about infrared training, visit:

• http://www.infraredtraining.com

• http://www.irtraining.com

• http://www.irtraining.eu

3.4 Documentation updates

Our manuals are updated several times per year, and we also issue product-critical notifications of changes on a regular basis.

To access the latest manuals, translations of manuals, and notifications, go to the Download tab at:

http://support.flir.com

It only takes a few minutes to register online. In the download area you will also find the latest releases of manuals for our other products, as well as manuals for our historical and

obsolete products.

3.5 Important note about this manual

FLIR Systems issues generic manuals that cover several cameras within a model line.

This means that this manual may contain descriptions and explanations that do not apply

to your particular camera model.

#T810170; r. AE/41948/41948; en-US

6

Page 15

Notice to user3

3.6 Note about authoritative versions

The authoritative version of this publication is English. In the event of divergences due to

translation errors, the English text has precedence.

Any late changes are first implemented in English.

#T810170; r. AE/41948/41948; en-US

7

Page 16

4

Customer help

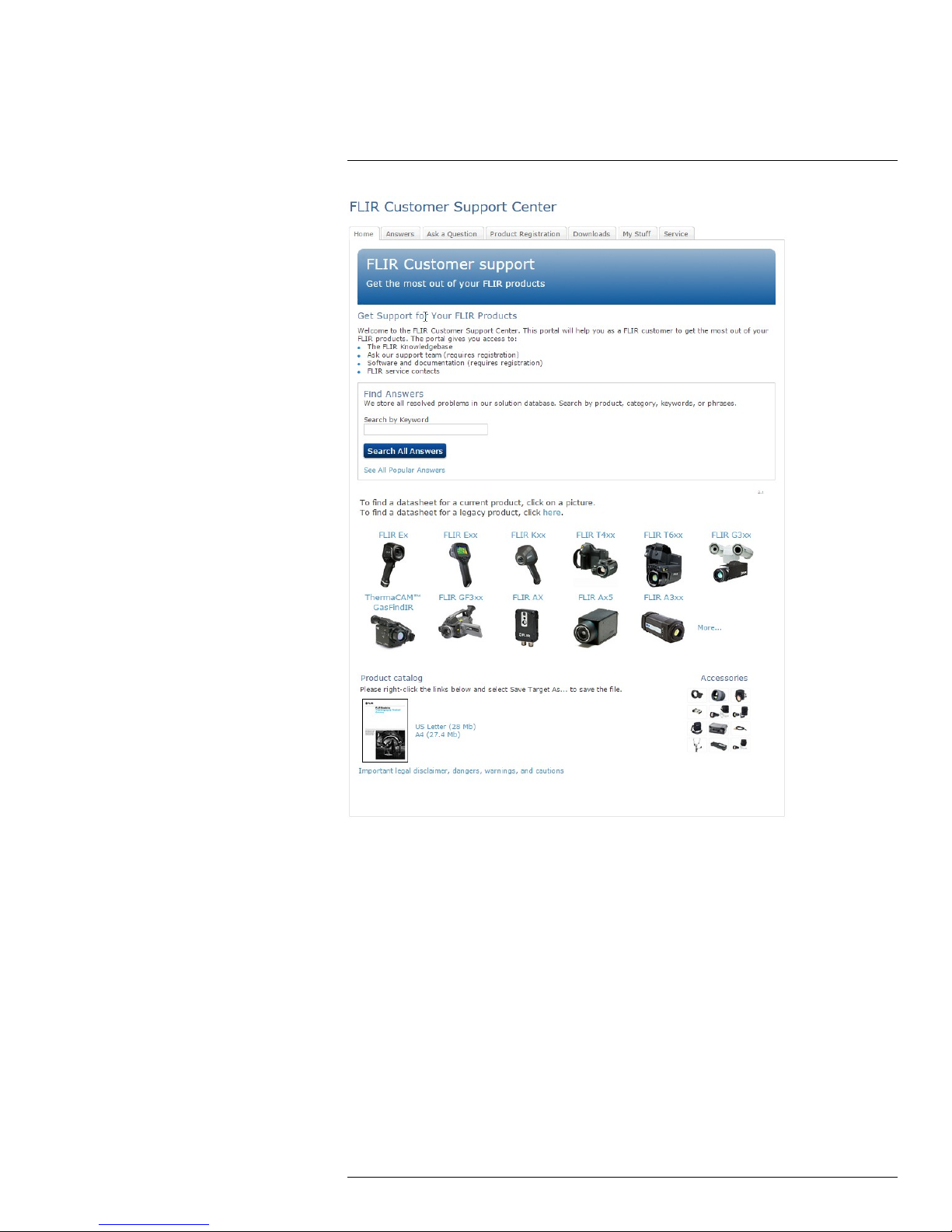

4.1 General

For customer help, visit:

http://support.flir.com

4.2 Submitting a question

To submit a question to the customer help team, you must be a registered user. It only

takes a few minutes to register online. If you only want to search the knowledgebase for

existing questions and answers, you do not need to be a registered user.

When you want to submit a question, make sure that you have the following information to

hand:

• The camera model

#T810170; r. AE/41948/41948; en-US

8

Page 17

4

Customer help

• The camera serial number

• The communication protocol, or method, between the camera and your device (for example, SD card reader, HDMI, Ethernet, USB, or FireWire)

• Device type (PC/Mac/iPhone/iPad/Android device, etc.)

• Version of any programs from FLIR Systems

• Full name, publication number, and revision number of the manual

4.3 Downloads

On the customer help site you can also download the following, when applicable for the

product:

• Firmware updates for your infrared camera.

• Program updates for your PC/Mac software.

• Freeware and evaluation versions of PC/Mac software.

• User documentation for current, obsolete, and historical products.

• Mechanical drawings (in *.dxf and *.pdf format).

• Cad data models (in *.stp format).

• Application stories.

• Technical datasheets.

• Product catalogs.

#T810170; r. AE/41948/41948; en-US

9

Page 18

5

Important information about FLIR

Kx3 series service

• Contact the service department before shipping the camera. Many problems can be resolved on the phone—if so, the camera does not need to be shipped.

• The camera must be thoroughly cleaned, decontaminated and disinfected before shipping to our service department. No hazardous residues are allowed on cameras. Such

residues include—but are not limited to—chemical fire-extinguishing compounds, radioactivity, biohazardous materials, and residues from chemical fires.

• FLIR Systems reserves the right to charge the full cost for the decontamination and disinfection of contaminated cameras that are shipped to our service department.

#T810170; r. AE/41948/41948; en-US

10

Page 19

6

Quick start guide

6.1 Quick start guide, FLIR K33

Follow this procedure:

1. Charge the battery for 4 hours before starting the camera for the first time, or until the

blue battery condition LED glows continuously.

2. Push the on/off button to turn on the camera.

3. Aim the camera toward the object of interest.

4. To freeze the image, pull and hold the trigger.

5. To return to the live image, release the trigger.

Note The function of the trigger is configured by a setting in FLIR Tools, see section

11.10.2 The User interface tab, page 27.

6.2 Quick start guide, FLIR K53

Follow this procedure:

1. Charge the battery for 4 hours before starting the camera for the first time, or until the

blue battery condition LED glows continuously.

2. Push the on/off button to turn on the camera.

3. Aim the camera toward the object of interest.

4. Pull the trigger to save an image.

5. Pull and hold the trigger to record a video clip.

6. Connect the camera to a computer, using the USB cable.

7. Do one of the following:

• Move the image to the computer using a drag-and-drop operation in Microsoft Windows Explorer.

Note Moving an image using a drag-and-drop operation does not delete the image in the camera.

• Move the image to the computer using FLIR Tools. In FLIR Tools you can analyze

the images and create PDF reports.

Note The function of the trigger is configured by a setting in FLIR Tools, see section

11.10.2 The User interface tab, page 27.

#T810170; r. AE/41948/41948; en-US

11

Page 20

7

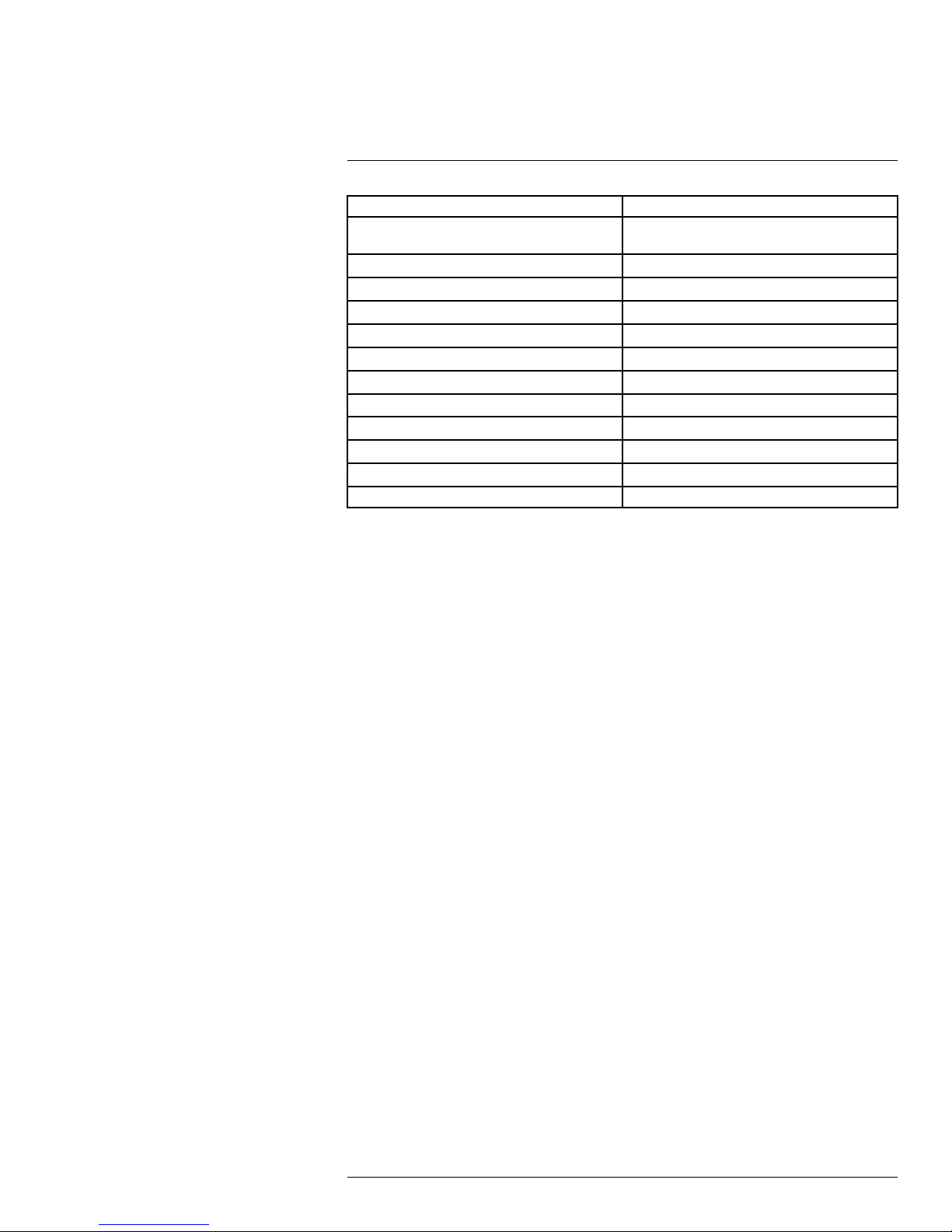

List of accessories and services

Product name Part no.

Battery charger, incl. power supply with multi plugs

(Exx, Kxx)

Battery Li-ion 3.6 V, 4.4 Ah, 16 Wh

Carabiner strap T129915ACC

Cigarette lighter adapter kit, 12 VDC, 1.2 m/3.9 ft. T198509

In-truck charger

Lanyard strap T198416ACC

Li-Ion Battery pack 3.6 V 16 Wh T198310ACC

Neck strap

Retractable lanyard T127722ACC

Transport case Kxx

Tripod Adapter, Kxx T198457ACC

USB cable Std A <-> Mini-B

T198125

T199368ACC

T198322ACC

T127724ACC

T198441ACC

1910423

#T810170; r. AE/41948/41948; en-US

12

Page 21

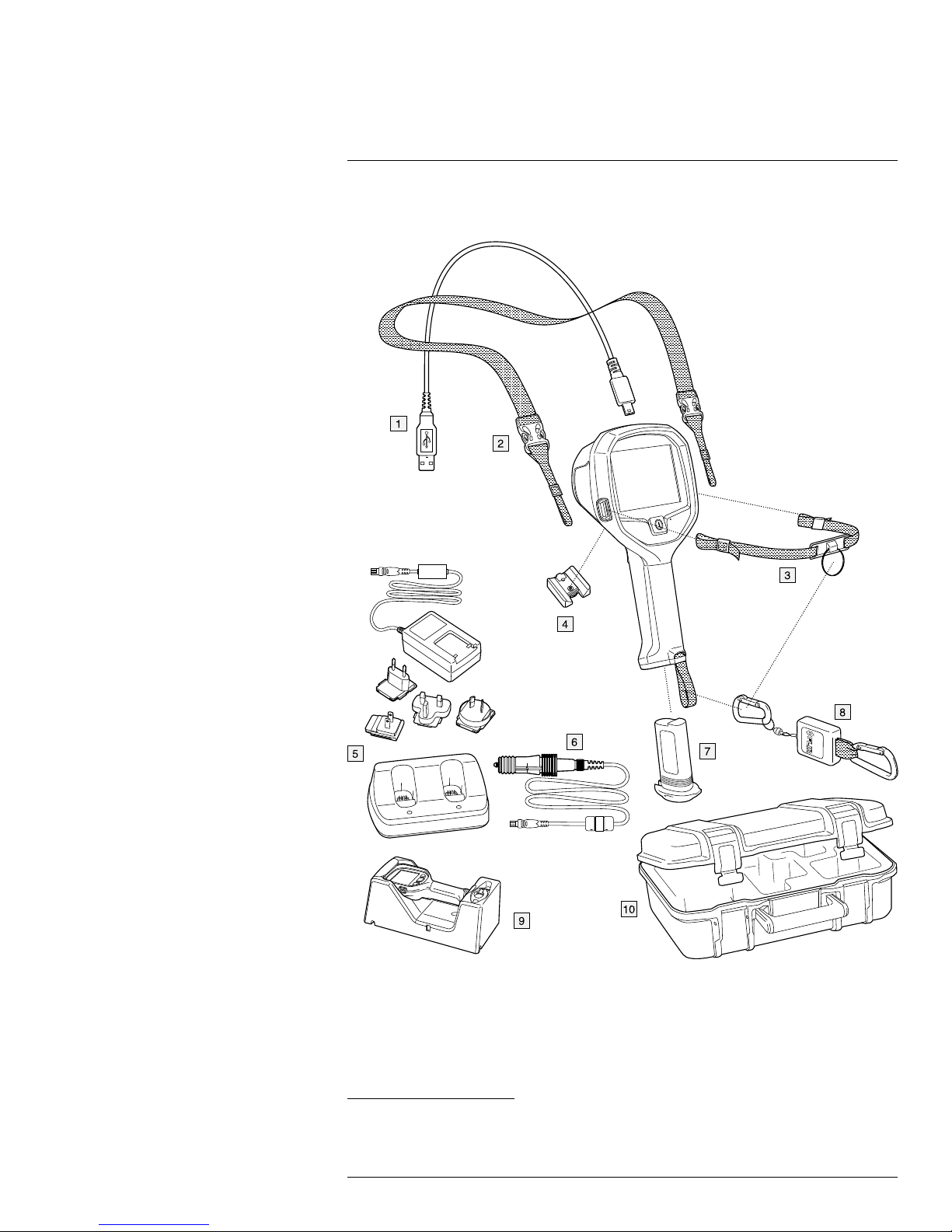

8

System configuration overview

8.1 Figure

8.2 Explanation

1. FLIR P/N: 1910423, USB cable Std A <-> Mini-B

2. FLIR P/N: T127724ACC, Neck strap

1. The inclusion of this item is dependent on model.

#T810170; r. AE/41948/41948; en-US

1

13

Page 22

8

System configuration overview

3. FLIR P/N: T198416ACC, Strap lanyard

4. FLIR P/N: T198457ACC, Tripod Adapter, Kxx

2

2

5. FLIR P/N: T198125, Battery charger, incl. power supply with multi plugs

6. FLIR P/N: T198509, Cigarette lighter adapter kit, 12 VDC, 1.2 m/3.9 ft

7. FLIR P/N: T198310ACC, Li-Ion Battery pack 3.6 V 16 Wh

8. FLIR P/N: T127722ACC, Retractable lanyard

2

9. FLIR P/N: T198322ACC, In-truck charger

10. FLIR P/N: T198441ACC, Transport case Kxx

2. The inclusion of this item is dependent on model.

#T810170; r. AE/41948/41948; en-US

14

Page 23

9

System parts

9.1 Camera parts

9.1.1 Figure

9.1.2 Explanation

1. USB Mini-B connector: Connect to a computer to download images (FLIR K53 only)

and change settings using FLIR Tools.

2. Attachment point for the lanyard strap/neck strap (left and right sides).

3. Eccentric latch to secure the battery.

4. On/off button. This button has three functions:

• Push the on/off button to turn on the camera.

• Push and hold the on/off button for more than 3 seconds but less than 10 seconds

to put the camera into standby mode. The camera then automatically turns off after

6 hours.

• Push and hold the on/off button for more than 10 seconds to turn off the camera.

5. Pin hole for setting of the temperature unit (°C/°F).

6. Connectors for the in-truck charger.

7. Trigger.

8. Mount for the tripod adapter.

9. Attachment point for the retractable lanyard.

10. Battery.

#T810170; r. AE/41948/41948; en-US

15

Page 24

9

System parts

9.2 Lanyard strap and retractable lanyard

9.3 Handle strap and retractable lanyard

#T810170; r. AE/41948/41948; en-US

16

Page 25

9

System parts

9.4 Neck strap

#T810170; r. AE/41948/41948; en-US

17

Page 26

10

Screen elements

10.1 Figure

10.2 Explanation

1. Low-sensitivity mode indicator. The indicator is displayed when the camera identifies a

hot area and automatically switches to the low-sensitivity mode.

2. Overheating indicator. The indicator provides a visual warning to the user that the thermal imager is about to shut down due to internal overheating.

3. Reference bar.

4. Temperature bar.

5. Spotmeter temperature.

6. Battery condition indicator.

7. Spotmeter.

10.3 Battery condition indicator

Battery condition indicator Explanation

75% power.

50% power.

25% power.

Flashing indicator. At least 5 minutes of available

power remains.

#T810170; r. AE/41948/41948; en-US

18

Page 27

11

Operation

CAUTION

Do not use the FLIR K series camera without the correct training. If the persons that operate the camera

do not have the correct training, an incorrect analysis of the infrared images can occur. Thus, incorrect

decisions during the firefighting can be made.

The training must include:

• How a thermal camera operates and its limits

• How to interpret an image

• How to work safely with the camera.

11.1 Removing the battery

Follow this procedure:

1. Pull the eccentric latch.

2. Pull out the battery from the battery compartment.

11.1.1 Charging the battery

WARNING

Make sure that you install the socket-outlet near the equipment and that it is easy to get access to.

#T810170; r. AE/41948/41948; en-US

19

Page 28

11

Operation

11.1.1.1 General

Charge the battery for 4 hours before starting the camera for the first time, or until the blue

battery condition LED glows continuously.

11.1.1.2 Procedure

Follow this procedure:

1. Put the battery in the standalone battery charger.

2. Connect the power supply cable plug to the connector on the standalone battery

charger.

3. Connect the power supply mains-electricity plug to a mains socket.

4. Disconnect the power supply cable plug when the blue battery condition LED glows

continuously.

11.2 Turning on and turning off the camera

• Push the on/off button to turn on the camera.

• Push and hold the on/off button for more than 3 seconds but less than 10 seconds to

put the camera into standby mode. The camera then automatically turns off after 6

hours.

• Push and hold the on/off button for more than 10 seconds to turn off the camera.

11.3 Basic mode

The camera features one camera mode: Basic mode. This is a multipurpose mode for the

initial fire attack with life-saving operations and control of the fire. The camera automatically switches between the high-sensitivity range and the low-sensitivity range, to maintain

an optimal infrared image while at the same time maintaining a safe and consistent heat

colorization of the fire scene. This automatic switching of ranges occurs when objects with

a temperature above 150°C (302°F) enter the field of view of the camera.

• Automatic range.

• Colorization of heat: +150 to +650°C (+302 to +1202°F).

• High-sensitivity range: –20 to +150°C (–4 to +302°F).

• Low-sensitivity range: 0 to +650°C (+32 to +1202°F).

#T810170; r. AE/41948/41948; en-US

20

Page 29

11

Operation

11.3.1 Automatic temperature range selection

11.3.1.1 General

The automatic temperature range selection is based on a measured area defined by a rectangle covering (x1, y1) = (15% of the width, 15% of the height) to (x2, y2) = (85% of the

width, 85% of the height) of the LCD area. See the figure in section 11.3.1.2.

An automatic change from the high-sensitivity range to the low-sensitivity range occurs if

more than 2% of the pixels within the measured area constantly (for more than 1 second)

have a temperature above the maximum temperature of the high-sensitivity range.

An automatic change from low-sensitivity range to high-sensitivity range occurs if more

than 98% of the pixels within the measured area constantly have, for more than 1 second,

a temperature lower than 50°C (122°F) below the maximum temperature of the high-sensitivity range.

11.3.1.2 Figure

11.3.1.3 Explanation

1. LCD area.

2. Area activating the automatic range change.

11.4 Saving an image (FLIR K53)

11.4.1 General

You can save images to the camera’s archive.

Note The maximum number of images that can be saved in the archive is 200. When

the number of images exceeds 200, images are deleted on a first-in, first-out basis, i.e.,

the 201st image will delete the 1st image, the 202nd image will delete the 2nd image, and

so on.

#T810170; r. AE/41948/41948; en-US

21

Page 30

11

Operation

11.4.2 Figure

11.4.3 Procedure

Note The function of the trigger is configured by a setting in FLIR Tools, see section

11.10.2 The User interface tab, page 27.

Follow this procedure:

1. Aim the camera toward an object of interest.

2. To save an image, pull the trigger.

11.5 Recording a video clip (FLIR K53)

11.5.1 General

You can record video clips and save them to the camera’s archive.

11.5.2 Figure

11.5.3 Procedure

Note The function of the trigger is configured by a setting in FLIR Tools, see section

11.10.2 The User interface tab, page 27.

#T810170; r. AE/41948/41948; en-US

22

Page 31

11

Operation

Follow this procedure:

1. Aim the camera toward an object of interest.

2. Depending on the Trigger button setting in FLIR Tools, do one of the following to start

the recording:

• With the Rec. on/off setting, pull the trigger.

• With the Record video setting, pull and hold the trigger.

3. A blinking circle in the middle left part of the screen indicates that the camera is currently recording a video clip.

4. Depending on the Trigger button setting in FLIR Tools, do one of the following to stop

the recording:

• With the Rec. on/off setting, pull the trigger.

• With the Record video setting, release the trigger.

11.6 Continuous video recording (FLIR K53)

11.6.1 General

You can configure the camera to start a continuous video recording when you turn on the

camera. The recording cannot be stopped.

Note The continuous video recording functionality is configured by a setting in FLIR

Tools, see section 11.10.2 The User interface tab, page 27.

11.7 Freezing the image

11.7.1 General

You can freeze the image.

11.7.2 Figure

11.7.3 Procedure

Note The function of the trigger is configured by a setting in FLIR Tools, see section

11.10.2 The User interface tab, page 27.

#T810170; r. AE/41948/41948; en-US

23

Page 32

11

Operation

Follow this procedure:

1. Aim the camera toward an object of interest.

2. Do the following:

• To freeze the image, pull and hold the trigger.

• To return to the live image, release the trigger.

11.8 Changing the temperature unit

The camera displays temperatures in ℃ or ℉. You change the temperature unit by pushing a button behind the pin hole.

Note It is also possible to change the temperature unit using FLIR Tools. See section

11.10.2 The User interface tab, page 27.

Follow this procedure:

1. Turn on the camera.

2. Use a paper clip or a similar small item to push the button behind the pin hole.

11.9 Connecting the camera to a computer

11.9.1 General

You can connect the camera to a computer, using the USB cable.

Once connected, you can do the following:

• Change the camera settings using the FLIR Tools software. See section 11.10 Chang-

ing settings in FLIR Tools, page 26.

• Applicable to FLIR K53: Move the images and video clips from the camera’s archive to

the computer.

• Applicable to FLIR K53: Import the images into the FLIR Tools software.

#T810170; r. AE/41948/41948; en-US

24

Page 33

11

Operation

11.9.2 Procedure

Follow this procedure:

1. Fold up the rubber cover at the top of the camera.

2. Hold the metal ring firmly.

3. Rotate the ring about 90° counter-clockwise.

4. Pull out the plastic insert.

CAUTION

The plastic insert has an O-ring seal. Do not damage the O-ring seal.

5. Connect the USB cable to the USB Mini-B connector in the connector bay.

#T810170; r. AE/41948/41948; en-US

25

Page 34

11

Operation

6. Applicable to FLIR K53:

• Move the images to the computer using a drag-and-drop operation in Microsoft

Windows Explorer.

Note Moving an image using a drag-and-drop operation does not delete the image in the camera.

• Move the images to the computer using FLIR Tools.

11.10 Changing settings in FLIR Tools

11.10.1 The General settings tab

11.10.1.1 Figure

11.10.1.2 Explanation

Regional settings area: To synchronize the camera’s date and time settings with the computer, select the checkbox.

Firmware info area: To check whether a newer version of the camera firmware exists, click

Check for updates and follow the on-screen instructions.

Restore to factory default area: To restore all camera settings to the factory defaults, click

Restore.

#T810170; r. AE/41948/41948; en-US

26

Page 35

11

Operation

11.10.2 The User interface tab

11.10.2.1 Figure

11.10.2.2 Explanation

Camera mode area: The camera features one camera mode: Basic mode. For more information, see section 11.3 Basic mode, page 20.

Trigger button area: The camera has a trigger button. With the settings in the Trigger button area, you can select the function of the trigger button. You select what will happen

when you click (short press) the trigger button and what will happen when you hold (long

press) the trigger button.

• No action, No action: Select to disable any functionality of the trigger button. Nothing

will happen when you press the trigger.

• No action, Freeze image: Select to make the camera freeze the image when you press

and hold the trigger. The image will unfreeze when you release the trigger. Nothing will

happen when you press the trigger momentarily.

• No action, Record video (not applicable to the FLIR K33): Select to make the camera

start a recording when you press and hold the trigger. The recording will stop when you

release the trigger. Nothing will happen when you press the trigger momentarily.

• Save image, No action (not applicable to the FLIR K33): Select to make the camera

save an image when you press the trigger momentarily. Nothing will happen when you

press and hold the trigger.

• Save image, Freeze image (not applicable to the FLIR K33): Select to make the camera

save an image when you press the trigger momentarily and freeze the image when you

press and hold the trigger. The image will unfreeze when you release the trigger.

• Save image, Record video (not applicable to the FLIR K33): Select to make the camera

save an image when you press the trigger momentarily and start a recording when you

press and hold the trigger. The recording will stop when you release the trigger.

• Rec. on/off, No action (not applicable to the FLIR K33): Select to make the camera start

a recording when you press the trigger and stop the recording when you press the trigger again. Nothing will happen when you press and hold the trigger.

• Continuous rec. (trigger disabled) (not applicable to the FLIR K33): Select to make the

camera start a continuous video recording when you turn on the camera. The recording

cannot be stopped. Nothing will happen when you press the trigger.

#T810170; r. AE/41948/41948; en-US

27

Page 36

11

Operation

Gain mode area:

• Auto gain mode: Select to make the camera automatically switch between the high-

sensitivity range and the low-sensitivity range, depending on the scene temperature.

The temperature level at which the camera switches between the two modes is 150°C

(302°F).

• Low gain mode: Select to make the camera operate in the low-sensitivity range only.

This has the advantage that the camera does not perform a non-uniformity correction

(NUC) when an object with a temperature higher than 150°C (302°F) enters the scene.

However, the disadvantage is lower sensitivity and a higher level of signal noise.

Temperature unit area: To select a different temperature unit, click Celsius or Fahrenheit.

Thermal indication area:

• Digital readout only: Select to display the thermal information in the image as the tem-

perature of the spotmeter only. In modes with automatic heat colorization, the colorization of the image will remain but the static heat color reference icon will not be

displayed.

• Reference bar: In modes with automatic heat indication colorization, a vertical heat col-

or reference bar is displayed in the thermal indication area. This static icon shows how

heat colors are applied to the range of the camera mode. The colors yellow, orange,

and red correspond to a temperature-dependent change in hue as the temperature

increases.

• Temp bar: Select to display the thermal information in the image as a temperature bar,

similar to a thermometer. This displays a dynamic vertical temperature bar on the righthand side of the image. The top of the dynamic bar represents the temperature of the

measured spot. In modes with automatic heat colorization, the colorization of the image

will remain, with a static heat color reference bar displayed next to the temperature bar.

Add custom boot image area: To select an image of your choice to appear during start-up,

click Browse, and navigate to the image file. This is useful for, for example, identifying your

fire department’s cameras. By incorporating your fire department’s logo, and a unique

identity number in the image, you can keep track of your cameras. This image can also be

accessed from the camera menu.

#T810170; r. AE/41948/41948; en-US

28

Page 37

12

In-truck charger (optional

accessory)

12.1 Introduction

Thank you for choosing the FLIR Kx3 series in-truck charger from FLIR Systems.

The in-truck charger is intended to be mounted on a flat surface in the cab, in one of the

equipment lockers, or in another suitable compartment on the fire engine. The in-truck

charger has five ports for cable routing—one through the rear of the metal bracket and

one port on each side of the in-truck charger.

The in-truck charger can also be powered using a standard FLIR Systems power supply,

and has a battery charger located at the lower front of the unit.

#T810170; r. AE/41948/41948; en-US

29

Page 38

12

In-truck charger (optional accessory)

12.2 Parts and functions

1. Top cover.

2. LED indicator for the camera charger.

3. Hole for attaching the charger housing to the metal bracket.

4. Connectors in the cradle.

5. Connector to power the charger using a standard FLIR Systems power supply.

6. Hole for attaching the charger housing to the metal bracket.

7. LED indicator for the battery charger.

8. Battery slot.

9. Eccentric latch to secure the battery during charging.

10. Cable port (1 of 4).

Note There is also one port through the rear of the metal bracket.

11. Routing support.

12. 12–24 VDC cable plinth.

13. Recess for the cable.

14. Routing support.

12.3 Choosing a suitable position

Before mounting the in-truck charger, take a few minutes to think about a suitable position.

The mounting position should be protected from rain and road splash, and it should be

reasonably easy to install a permanent cable running from the fire engine’s 12–24 VDC

system to the in-truck charger.

Additional considerations may be important, e.g., getting access to panels and equipment

behind the in-truck charger.

#T810170; r. AE/41948/41948; en-US

30

Page 39

12

In-truck charger (optional accessory)

12.4 Recommended cable area and fuse

Cable area 1.5 mm2(No. 15 AWG)

Fuse 5 A

12.5 Mounting instructions

Follow this procedure:

1. Permanently install a cable running from the fire engine’s 12–24 VDC system to the selected mounting position of the in-truck charger. Do not connect this cable to the 12–

24 VDC system at this time. The routing must include a fuse installed close to the battery. See above for the fuse recommendation.

2. Remove the two screws that hold the metal bracket.

3. Remove the metal bracket.

4. Use the metal bracket as a template to mark where the mounting holes should be

drilled.

5. Drill the holes.

6. Mount the metal bracket using the rivets and/or screws that come with the in-truck

charger.

7. Connect the cable to the cable plinth on the rear of the in-truck charger.

Note Take note of the polarity when you connect the cable to the cable plinth.

8. Route the cable so that it exits through the cable port of your choice.

9. Mount the in-truck charger to the metal bracket using the two screws that you removed

in Step 2 above.

10. Permanently connect the cable to the fire engine’s 12–24 VDC system.

12.6 Charging the camera

Follow this procedure:

1. Pull up the top cover of the in-truck charger.

2. Push the camera into position.

3. Push down the top cover.

The charging of the camera has now started, and is finished when the blue light glows

continuously. Charging a fully depleted camera takes approximately 4 hours.

12.7 Charging a battery separately

FLIR Kx3 series batteries can be charged separately using the battery charger at the lower

front of the unit.

Follow this procedure:

1. Pull the eccentric latch on the bottom of the camera.

2. Pull out the battery from the camera.

3. Push the battery into the slot at the lower front of the charger.

4. Secure the battery using the eccentric latch on the charger.

The charging of the battery has now started, and is finished when the blue light glows

continuously. Charging a fully depleted battery takes approximately 4 hours.

#T810170; r. AE/41948/41948; en-US

31

Page 40

12

In-truck charger (optional accessory)

12.8 Cleaning

CAUTION

Disconnect the in-truck charger from the fire engine’s 12–24 VDC system before cleaning.

The in-truck charger can be cleaned using warm water or a weak detergent solution. Do

not use solvents or similar liquids.

12.9 Customer support

Should you experience any problems, do not hesitate to contact our Customer Support at

http://support.flir.com.

#T810170; r. AE/41948/41948; en-US

32

Page 41

13

Technical data

Table of contents

13.1 Online field-of-view calculator....................................................... ...... 33

13.2 Note about technical data ................................................................... 33

13.3 Note about authoritative versions.............................................. .......... 33

13.4 FLIR K33 .. ....... ....... ....... ................... ....... ....... ....... ................... ....... . 34

13.5 FLIR K53 .. ....... ....... ....... ................... ....... ....... ....... ................... ....... . 38

13.6 In-truck charger ................................................................................ 42

13.1 Online field-of-view calculator

Please visit http://support.flir.com and click the photo of the camera series for field-of-view

tables for all lens–camera combinations.

13.2 Note about technical data

FLIR Systems reserves the right to change specifications at any time without prior notice.

Please check http://support.flir.com for latest changes.

13.3 Note about authoritative versions

The authoritative version of this publication is English. In the event of divergences due to

translation errors, the English text has precedence.

Any late changes are first implemented in English.

#T810170; r. AE/41948/41948; en-US

33

Page 42

Technical data13

13.4 FLIR K33

P/N: 72203-0411

Rev.: 41168

General description

The FLIR K33 is a robust and reliable infrared camera designed to perform under extremely severe conditions. The FLIR K33 has an intuitive interface with a design that makes it easy to control even with a

gloved hand. The crisp and clear image helps you to navigate through smoke and to make quick and accurate decisions.

Benefits:

• Robust and reliable: The FLIR K33 is designed to meet tough operating conditions. It can withstand a

drop from 2 m (6.5 ft.) onto a concrete floor, is water resistant to IP67, and is fully operational up to

+85°C (+185°F), or +260°C (+500°F) for 5 min.

• Clear and crisp thermal images: The maintenance-free uncooled microbolometer sensor produces

clear and detail-rich images of 240 × 180 pixels which have been further improved with FSX, a digital

image processing enhancement technique. Thermal images are presented on a large, bright 4″ display, helping you to navigate and to make quick and accurate decisions.

• Easy-to-use—also in a gloved firefighter’s hand: An intuitive and simple user interface allows you to focus on the job. The FLIR K33 can be controlled by just one large button on top of the unit. Ideal for a

gloved firefighter’s hand.

Imaging and optical data

IR resolution 240 × 180 pixels

Thermal sensitivity/NETD < 40 mK @ +30°C (+86°F)

Field of view (FOV)

Depth of field 0.84 m to infinity (33 in. to infinity)

Focal length 9 mm (0.35 in.)

Spatial resolution (IFOV)

F-number 1.25

Image frequency 60 Hz

Focus Fixed

Detector data

Detector type Focal plane array (FPA), uncooled microbolometer

Spectral range

Pitch 25 µm

Image presentation

Display 4 in. LCD, 320 × 240 pixels, backlit

Auto range Yes, selectable on/off using FLIR Tools

Contrast optimization Digital image enhancement using FSX

Image presentation modes

Image modes TI Basic fire-fighting mode

51° × 38°

3.6 mrad

7.5–13 µm

#T810170; r. AE/41948/41948; en-US

34

Page 43

Technical data13

Measurement

Object temperature range

Accuracy ±4°C (±7.2°F) or ±4% of reading, for ambient tem-

Measurement analysis

Spotmeter

Isotherm Yes

Set-up

Set-up commands Local adaptation of units, date and time formats

Languages English

Video streaming

Non-radiometric IR video streaming Uncompressed colorized video using USB

• –20°C to +150°C (–4°F to +302°F)

• 0°C to +650°C (+32°F to +1202°F)

perature 10°C to 35°C (+50°F to 95°F)

1

USB

USB USB Mini-B

Compatibility

Compatible with FLIR software FLIR Tools

Data communication interfaces

Interfaces

Power system

Battery type Li Ion

Battery voltage 3.6 V

Battery capacity

Battery operating time

Charging system

Charging time 2 h to 85% capacity, charging status indicated by

Charging temperature 0°C to +45°C (+32°F to +113°F)

Power management Automatic shutdown and sleep mode

Start-up time from sleep mode

Start-up time < 17 s. (IR image, no GUI)

• Update from PC devices

• Data transfer to and from PC

4.4 Ah, at +20°C to +25°C (+68°F to +77°F)

Approx. 4 hours at +25°C (+77°F) ambient temperature and typical use

• Battery is charged inside the camera

• 2-bay charger

• Optional In-truck charger

LEDs

< 4 s.

Environmental data

Operating temperature range

Storage temperature range –40°C to +85°C (–40°F to +185°F)

#T810170; r. AE/41948/41948; en-US

• –20°C to +85°C (–4°F to +185°F)

• +150°C (+302°F): 15 min.

• +260°C (+500°F): 5 min.

35

Page 44

Technical data13

Environmental data

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

Relative humidity 95% relative humidity +25°C to +40°C (+77°F to

Directives Designed to meet NFPA 1801:2013 specification:

EMC

Magnetic fields EN 61 000-4-8, Test level 5 for continuous field (se-

Encapsulation

Shock 25 g (IEC 60068-2-27)

Vibration 2 g (IEC 60068-2-6)

Drop 2 m (6.6 ft.) on concrete floor (IEC 60068-2-31)

Safety (power supply) CE/EN/UL/CSA/PSE 60950-1

to +40°C (+77°F to +104°F) / 2 cycles

+104°F) non-condensing

• Vibration

• Impact acceleration resistance

• Corrosion

• Viewing surface abrasion

• Heat resistance

• Heat and flame

• Product label durability

• EN 61000-6-2:2005 (Immunity)

• EN 61000-6-3: 2011 (Emission)

• FCC 47 CFR Part 15 B (Emission)

vere industrial environment)

IP 67 (IEC 60529)

Physical data

Camera weight, incl. battery 1.1 ±0.05 kg (2.4 ±0.1 lb.)

Battery weight 0.152 kg (0.3 lb.)

Camera size (L × W × H) 120 × 125 × 280 mm (4.7 × 4.9 × 11 in.)

Tripod mounting UNC ¼"-20 (adapter needed)

Material

Shipping information

List of contents

Packaging, weight 5.7 kg (12.6 lb.)

Packaging, size 500 × 190 × 370 mm (19.7 × 7.5 × 14.6 in.)

EAN-13 7332558011515

UPC-12

Country of origin

• PPSU

• Silicon rubber

• Aluminium, cast

• Flame-resistant magnesium alloy

• Infrared camera

• Battery (2 ea.)

• Battery charger

• Hard transport case

• Lanyard strap

• Neck strap

• Power supply

• Printed documentation

• Retractable lanyard

• USB cable

845188012465

Estonia

#T810170; r. AE/41948/41948; en-US

36

Page 45

Technical data13

Supplies & accessories:

• 1910423; USB cable Std A <-> Mini-B

• T198509; Cigarette lighter adapter kit, 12 VDC, 1.2 m/3.9 ft.

• T198125; Battery charger, incl. power supply with multi plugs (Exx, Kxx)

• T198310ACC; Li-Ion Battery pack 3.6 V 16 Wh

• T127724ACC; Neck strap

• T127722ACC; Retractable lanyard

• T198416ACC; Lanyard strap

• T198457ACC; Tripod Adapter, Kxx

• T198441ACC; Transport case Kxx

• T198322ACC; In-truck charger

• T199368ACC; Battery Li-ion 3.6 V, 4.4 Ah, 16 Wh

• T129915ACC; Carabiner strap

#T810170; r. AE/41948/41948; en-US

37

Page 46

Technical data13

13.5 FLIR K53

P/N: 72203-0511

Rev.: 41168

General description

The FLIR K53 is a robust and reliable infrared camera designed to perform under extremely severe conditions. The FLIR K53 has an intuitive interface with a design that makes it easy to control even with a

gloved hand. The crisp and clear image helps you to navigate through smoke and to make quick and accurate decisions.

Benefits:

• Robust and reliable: The FLIR K53 is designed to meet tough operating conditions. It can withstand a

drop from 2 m (6.5 ft.) onto a concrete floor, is water resistant to IP67, and is fully operational up to

+85°C (+185°F), or +260°C (+500°F) for 5 min.

• Clear and crisp thermal images: The maintenance-free uncooled microbolometer sensor produces

clear and detail-rich images of 320 × 240 pixels which have been further improved with FSX, a digital

image processing enhancement technique. Thermal images are presented on a large, bright 4″ display, helping you to navigate and to make quick and accurate decisions.

• Easy-to-use—also in a gloved firefighter’s hand: An intuitive and simple user interface allows you to focus on the job. The FLIR K53 can be controlled by just one large button on top of the unit. Ideal for a

gloved firefighter’s hand.

• Recording

Imaging and optical data

IR resolution 320 × 240 pixels

Thermal sensitivity/NETD < 30 mK @ +30°C (+86°F)

Field of view (FOV)

Depth of field 0.84 m to infinity (33 in. to infinity)

Focal length 9 mm (0.35 in.)

Spatial resolution (IFOV)

F-number 1.25

Image frequency 60 Hz

Focus Fixed

Detector data

Detector type Focal plane array (FPA), uncooled microbolometer

Spectral range

Pitch 25 µm

Image presentation

Display 4 in. LCD, 320 × 240 pixels, backlit

Auto range Yes, selectable on/off using FLIR Tools

Contrast optimization Digital image enhancement using FSX

Image presentation modes

Image modes TI Basic fire-fighting mode

51° × 38°

2.8 mrad

7.5–13 µm

#T810170; r. AE/41948/41948; en-US

38

Page 47

Technical data13

Measurement

Object temperature range

Accuracy ±4°C (±7.2°F) or ±4% of reading, for ambient tem-

Measurement analysis

Spotmeter

Isotherm Yes

Set-up

Set-up commands Local adaptation of units, date and time formats

Languages English

Storage of images

Image storage

Storage media Internal flash memory

Image storage capacity 200 files in total

• –20°C to +150°C (–4°F to +302°F)

• 0°C to +650°C (+32°F to +1202°F)

perature 10°C to 35°C (+50°F to 95°F)

1

Standard JPEG

NOTE

The total number of files is co-dependent on the

number of saved video clips.

Image storage mode IR only

File formats Standard JPEG

Image annotations

Report generation Separate software (FLIR Tools)

Video recording in camera

Non-radiometric IR video recording MPEG-4 to internal flash memory

Storage capacity 200 files in total, with a maximum duration of 5 mi-

Video streaming

Non-radiometric IR video streaming

USB

USB USB Mini-B

Compatibility

Compatible with FLIR software FLIR Tools

nutes each.

NOTE

The total number of files is co-dependent on the

number of saved images.

Uncompressed colorized video using USB

Data communication interfaces

Interfaces

#T810170; r. AE/41948/41948; en-US

• Update from PC devices

• Data transfer to and from PC

39

Page 48

Technical data13

Power system

Battery type Li Ion

Battery voltage 3.6 V

Battery capacity 4.4 Ah, at +20°C to +25°C (+68°F to +77°F)

Battery operating time Approx. 4 hours at +25°C (+77°F) ambient temper-

Charging system

Charging time

Charging temperature 0°C to +45°C (+32°F to +113°F)

Power management Automatic shutdown and sleep mode

Start-up time from sleep mode

Start-up time < 17 s. (IR image, no GUI)

ature and typical use

• Battery is charged inside the camera

• 2-bay charger

• Optional In-truck charger

2 h to 85% capacity, charging status indicated by

LEDs

< 4 s.

Environmental data

Operating temperature range

Storage temperature range –40°C to +85°C (–40°F to +185°F)

Humidity (operating and storage) IEC 60068-2-30/24 h 95% relative humidity +25°C

Relative humidity 95% relative humidity +25°C to +40°C (+77°F to

Directives Designed to meet NFPA 1801:2013 specification:

EMC

Magnetic fields EN 61 000-4-8, Test level 5 for continuous field (se-

Encapsulation IP 67 (IEC 60529)

Shock 25 g (IEC 60068-2-27)

Vibration

Drop

Safety (power supply) CE/EN/UL/CSA/PSE 60950-1

• –20°C to +85°C (–4°F to +185°F)

• +150°C (+302°F): 15 min.

• +260°C (+500°F): 5 min.

to +40°C (+77°F to +104°F) / 2 cycles

+104°F) non-condensing

• Vibration

• Impact acceleration resistance

• Corrosion

• Viewing surface abrasion

• Heat resistance

• Heat and flame

• Product label durability

• EN 61000-6-2:2005 (Immunity)

• EN 61000-6-3: 2011 (Emission)

• FCC 47 CFR Part 15 B (Emission)

vere industrial environment)

2 g (IEC 60068-2-6)

2 m (6.6 ft.) on concrete floor (IEC 60068-2-31)

Physical data

Camera weight, incl. battery 1.1 ±0.05 kg (2.4 ±0.1 lb.)

Battery weight 0.152 kg (0.3 lb.)

Camera size (L × W × H) 120 × 125 × 280 mm (4.7 × 4.9 × 11 in.)

#T810170; r. AE/41948/41948; en-US

40

Page 49

Technical data13

Physical data

Tripod mounting

Material

Shipping information

List of contents

Packaging, weight 5.7 kg (12.6 lb.)

Packaging, size 500 × 190 × 370 mm (19.7 × 7.5 × 14.6 in.)

EAN-13 7332558011522

UPC-12

Country of origin Estonia

UNC ¼"-20 (adapter needed)

• PPSU

• Silicon rubber

• Aluminium, cast

• Flame-resistant magnesium alloy

• Infrared camera

• Battery (2 ea.)

• Battery charger

• Hard transport case

• Lanyard strap

• Neck strap

• Power supply

• Printed documentation

• Retractable lanyard

• USB cable

845188012472

Supplies & accessories:

• 1910423; USB cable Std A <-> Mini-B

• T198509; Cigarette lighter adapter kit, 12 VDC, 1.2 m/3.9 ft.

• T198125; Battery charger, incl. power supply with multi plugs (Exx, Kxx)

• T198310ACC; Li-Ion Battery pack 3.6 V 16 Wh

• T127724ACC; Neck strap

• T127722ACC; Retractable lanyard

• T198416ACC; Lanyard strap

• T198457ACC; Tripod Adapter, Kxx

• T198441ACC; Transport case Kxx

• T198322ACC; In-truck charger

• T199368ACC; Battery Li-ion 3.6 V, 4.4 Ah, 16 Wh

• T129915ACC; Carabiner strap

#T810170; r. AE/41948/41948; en-US

41

Page 50

Technical data13

13.6 In-truck charger

P/N: T198322

Rev.: 28825

Power system

Charging time

Charging temperature 0°C to +45°C (+32°F to +113°F)

External power, connector type Screw terminal or HRS_UK60-3PT

DC operation 12/ 24 V DCnominal (11.1 - 28.0 V DC)

Power

Environmental data

Operating temperature range –40°C to +85°C (–40°F to +185°F)

Storage temperature range –40°C to +85°C (–40°F to +185°F)

Relative humidity Operational for non-condensing humidity between

EMC

Encapsulation IP 20

Bump

Vibration

< 4 hours

Max 36 Watts or 3000 mA at 12 VDC (5 amps

fuse)

5% and 95%.

• EN61000-6-3 Emission

• EN61000-6-2 Immunity

• FCC47CFR part 15 class B

• NFPA requirements

• ISO 7637-2 Road vehicles - Electrical disturbances from conduction and coupling Part 2:

Electrical transient conduction along supply

lines only

Operational after exposed to: 5 pulses/ in each axis/ direction (30 total) of 30g 11ms half sine profile

Operational after exposed to: 4, 3g rms random

profile. 8 hours in each axis.

Physical data

Weight 1.050 kg

Size (L × W × H) 380 mm × 180 mm × 153 mm (15 in. × 7.1 in. × 6

Material PC / ABS

Color Grey / black

Shipping information

List of contents

Packaging, weight 3.2 kg (7.0 lb.)

Packaging, size 435 × 245 × 167 mm (17.1 × 9.6 × 6.6 in.)

EAN-13 7332558005446

#T810170; r. AE/41948/41948; en-US

in.)

• Charger

• Documentation

• Card board box

4743254001282 (Estonia plant)

42

Page 51

Technical data13

Shipping information

UPC-12

Country of origin

Compatible with the following products

• 72201-0106; FLIR K45

• 72201-0206; FLIR K55

• 72202-0303; FLIR K65

845188005368

Estonia

#T810170; r. AE/41948/41948; en-US

43

Page 52

14

Mechanical drawings

[See next page]

#T810170; r. AE/41948/41948; en-US

44

Page 53

[6.36]

161,50

[4.46]

113

[8.04]

204

[11.08]

281,50

[3.29]

83,5

[2.5]

63,5

[4.87]

123,7

Basic dimension drawing

Kx3

Där ej annat anges/Unless otherwise stated

Kanter brutna

Edges broken

Hålkälsradier

Ra µm

Fillet radii

Ytjämnhet/Roughness

Blad/Sheet

Rev

Ritn nr/Drawing No

ArtNo.

Skala/Scale

Size

Datum/Date

Kontr/Check

Konstr/Drawn

Material

Ytbehandling/Surface treatment

Gen tol

Benämning/Denomination

Denna handling får ej delges annan, kopieras i

sin helhet eller delar utan vårt medgivande .

Överträdelse härav beivras med stöd av gällande lag.

FLIR SYSTEMS AB

This document must not be communicated or

copied completely or in part, without our permission.

Any infringement will lead to legal proceedings.

FLIR SYSTEMS AB

A3

Utdrag ur/Excerpt from ISO 2768-m

±0,1

±0,2

±0,3

±0,5

±0,8

(400)-1000

(120)-400

(30)-120

(6)-30

0,5-6

ISO 2768-mK

1(2)

1:2

A. LUND

2016-03-23

2016-03-29

A. LUND

Ändrad av/Modified by

Ändrad/Modified

1 2 3 4 5 6 7 8 9 10

A

B

C

D

E

F

G

H

1 32 54

C

F

B

D

G

E

A

Page 54

1/4"-20

Tripod adapter

13,5°

[0.55]

14

[0.98]

25

Kx3

Basic dimension drawing

Där ej annat anges/Unless otherwise stated

Kanter brutna

Edges broken

Hålkälsradier

Ra µm

Fillet radii

Ytjämnhet/Roughness

Blad/Sheet

Rev

Ritn nr/Drawing No

ArtNo.

Skala/Scale

Size

Datum/Date

Kontr/Check

Konstr/Drawn

Material

Ytbehandling/Surface treatment

Gen tol

Benämning/Denomination

Denna handling får ej delges annan, kopieras i

sin helhet eller delar utan vårt medgivande .

Överträdelse härav beivras med stöd av gällande lag.

FLIR SYSTEMS AB

This document must not be communicated or

copied completely or in part, without our permission.

Any infringement will lead to legal proceedings.

FLIR SYSTEMS AB

A3

Utdrag ur/Excerpt from ISO 2768-m

±0,1

±0,2

±0,3

±0,5

±0,8

(400)-1000

(120)-400

(30)-120

(6)-30

0,5-6

ISO 2768-mK

2(2)

1:2

-

A. LUND

2016-03-23

2016-03-29

A. LUND

Ändrad av/Modified by

Ändrad/Modified

1 2 3 4 5 6 7 8 9 10

A

B

C

D

E

F

G

H

1 32 54

C

F

B

D

G

E

A

Page 55

14,96

±0,04

380

±1

7,08

±0,04

180

±1

6,02

±0,04

153

±1

Mounting hole

6x ø6,3

Mounting hole

10x ø5,0

A

Basic dimensions

1(1)

T127865

ISO 2768-mK

0,5-6

(6)-30

(30)-120

(120)-400

±0,5

±0,3

±0,2

±0,1

Utdrag ur/Excerpt from ISO 2768-m

Där ej annat anges/Unless otherwise stated

Kanter brutna

Edges broken

Hålkälsradier

Ra µm

Fillet radii

Ytjämnhet/Roughness

Blad/Sheet

Rev

Ritn nr/Drawing No

Art.No.

Size

Kontr/Check

Konstr/Drawn

Material

A4

Ytbehandling/Surface treatment

Gen tol

Benämning/Denomination

Denna handling får ej delges annan, kopieras i

sin helhet eller delar utan vårt medgivande .