Page 1

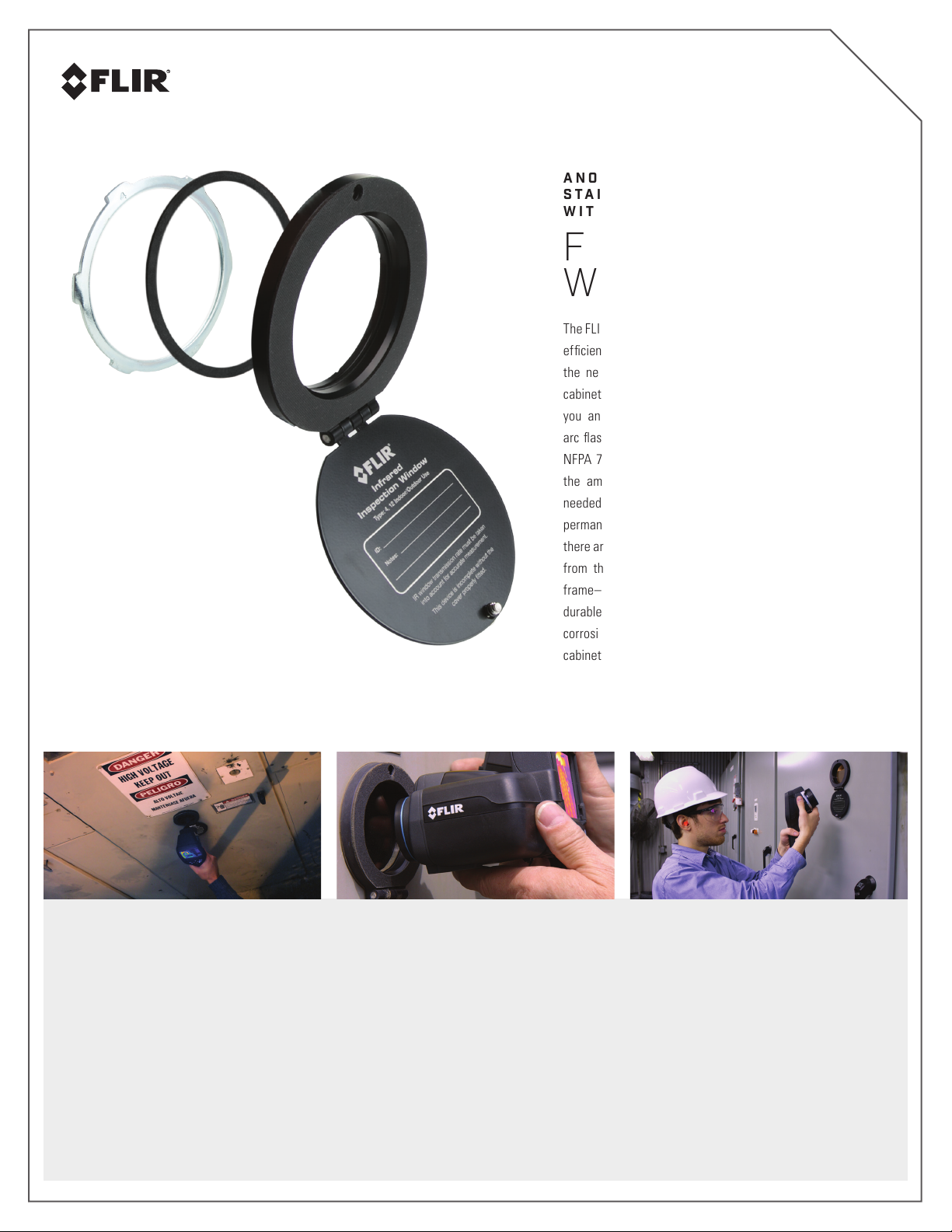

ANODIZED ALUMINUM OR

STAINLESS STEEL WINDOWS

WITH PIRMA-LOCK

TM

FLIR IR

WINDOWS

The FLIR IRW-Series inspection windows allow for fast,

efcient inspections of electrical gear by eliminating

the need to remove panel covers or open electrical

cabinets. IR Windows add a protective barrier between

you and energized equipment to reduce the risk of

arc ash. They also help keep you in compliance with

NFPA 70E requirements and may allow you to reduce

the amount of personal protective equipment (PPE)

needed. The windows are easy to install and feature a

permanent, hinged cover that ips open effortlessly, so

there are no loose parts to drop, mix up, or lose. Choose

from the standard anti-corrosion anodized aluminum

frame–or if there are mixed-metal concerns–opt for

durable stainless steel. This helps prevent galvanic

corrosion from contact between the stainless steel

cabinet and window frame.

WORK SAFELY

Avoid arc flash incidents

• Keep panel covers on for a protective barrier

from energized equipment, and to prevent nuts

or bolts from dropping into energized cabinets

• Work condently with the knowledge that IRWSeries windows meet NFPA 70E safet y requirements

• Inspect more frequently to ensure equipment is in

good condition, and reduce the potential of incidents

www.ir.com/instruments/ir-windows

INCREASE EFFICIENCY

Improve productivity and ROI

• Saves time and labor by eliminating the

need to remove panel covers, so just one

person can complete the inspection

• May reduce the number of protective

layers inspectors need to wear

• Supports thermal, MSX®, and visual inspections

with broadband crystal IR window that also allows

laser pointers and illumination to shine through

DECREASE DOWNTIME

Install easily, with no detachable parts

• Uses standard punch tools for knockouts

for single hole installation

• PIRma-Lock™ ring nut speeds installation,

automatically grounds, and locks window tight

• Stainless steel option avoids contact between

dissimilar metals to resist corrosion

Page 2

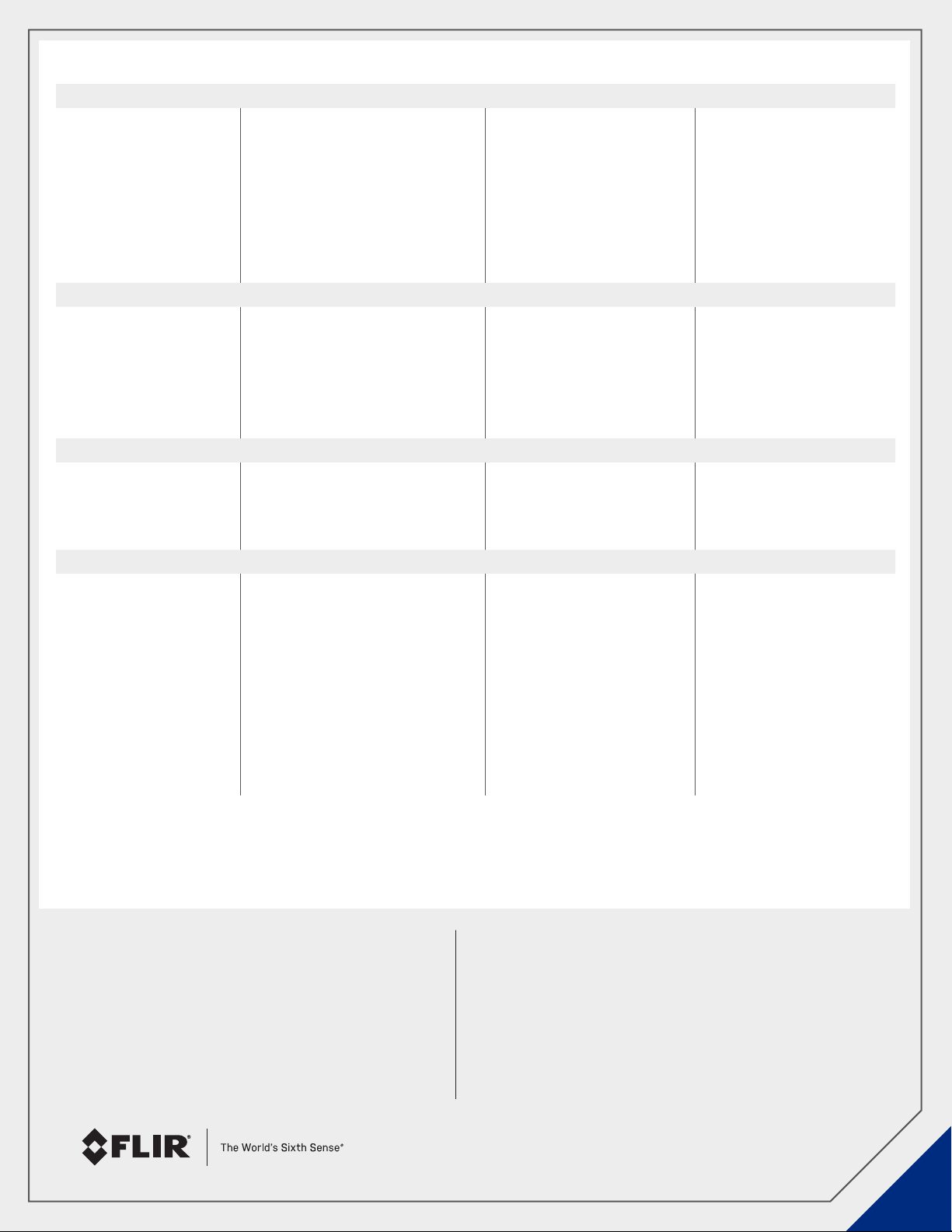

SPECIFICATIONS

Model/Size IRW-2C/2S 2” Window IRW-3C /3 S 3” W indow IRW-4C/4 S 4” Window

NEMA Environment Type Type 4/12 (outdoor/indoor) Type 4/12 (outdoor/indoor) Type 4/12 (outdoor/indoor)

Voltage Range Any Any Any

Automaticall y Grounded Yes Yes Yes

Maximum Operating Temperature 260°C/500°F 260°C/500°F 260°C/500°F

Body Material - IRW-xC Type Anodized aluminum Anodized aluminum Anodized aluminum

Body Material - IRW-xS Type AISI-grade 316 stainless steel AISI-grade 316 stainless steel AISI-grade 316 stainless steel

Gasket Material Silicone Silicone Silicone

Hardware Material Steel Steel Steel

Size Specifications

Overall Height 85.5 mm (3.36 in) 107.4 mm (4.22 in) 136.5 mm (5.37 in)

Overall Width 73 mm (2.87 in) 99 mm (3.89 in) 127.44 mm (5.01 in)

Overall Thickness 25.5 mm (1.0 0 in) 26.8 6 mm (1.05 in) 29.25 mm (1.15 in)

Required Hole Diameter (Nominal) 60.3 mm (2 3/8 in) 88.9 mm (3 1/2 in) 114.3 mm (4 1/2 in)

Greenlee Punch 76BB 739BB 742BB

Recommended Max. Panel Thickness 3.2 mm (1/8 in) 3.2 mm (1/8 in) 3.2 mm (1/8 in)

Optic Specifications

Optic Diameter 50 mm (1.97 in) 75 mm (2.95 in) 95 mm (3.74 in)

Viewing Aper ture Diameter 45 mm (1.77 in) 69 mm (2.71 in) 89 mm (3.50 in)

Viewing Aperture Area 1590 mm ² (2.46 in²) 3739 mm² (5.79 in²) 6221 mm² (9.6 4 in²)

Optic Maximum Temp erature 1355.6° C (2474°F ) 1355.6 °C (2474°F) 1355.6° C (2474°F )

Ratings & Testing

UL Component Recognition (UL 5 0V) Yes Yes Yes

UL 50 / NE MA Environment Rating Type 4/12 Type 4/12 Type 4/12

Arc Flash Testing, IEC 62271-200

(KEMA)*

IP Rating, IEC 60529 ( TUV )* IP67 IP67 IP67

Vibration Testing, IEC 60068-2-6 (TUV )* 100 m/s² vibration withstand 100 m/s² vibration withs tand 100 m/s² vibration withstand

Humidit y Testing, IEC 60068-2-3 (TUV)* Extreme humidity withstand Extreme humidity withstand Extreme humidity withstand

Mechanical Testing, ANSI/IEEE C37.20.2

Section A3.6 (TUV)*

Maximum Pullout Strength 657 kg (1450 lbs) 1655 kg (3 650 lbs) 1678 kg (3700 lbs)

CSA Certi cation, C22.2 No. 14 or 508 Yes Yes Yes

5 kV, 63 kA for 30 cycles at 60 Hz 5 kV, 63 kA for 30 cycles at 60 Hz 5 kV, 63 kA for 30 cycles at 60 Hz

Impac t and load r esistant cover Impac t and load r esistant cover Impact and load resistant cover

*Test results valid for IRW-2C, IRW-3C, and IRW-4C only.

CORPORATE

HEADQUARTERS

27700 SW Parkway Ave.

Wilsonville, OR 97070

PH: +1 877.773.3547

CHINA

RM 1613-16, Tower II

Grand Central Plaza

138 Shatin Rural Committee Rd.

Shatin, New Territories

Hong Kong

NASHUA

PH: +852 2792 8 955

9 Townsend West

Nashua, NH 06063

USA

PH: +1 603. 324.7611

EUROP E

Luxemburgstraat 2

2321 Meer

Belgium

PH: +32 ( 0) 36 65 5100

www.ir.com

NASDAQ: FLIR

Equipme nt described herein is subject to US ex port

regulat ions and may re quire a license prior to export.

Diversi on contrary to US law is p rohibited . Imager y for

illustration purp oses only. Sp ecic ations are subject to

change w ithout not ice. ©2017 FLIR Systems , Inc. All

rights reserved. 11/09/17

17- 3170 -IN S

Loading...

Loading...