Page 1

User’s manual – Benutzerhandbuch – Manual del usuario – Manuel de l’utilisateur – Manuale dell’utente – Manual do utilizador – Felhas-

ználói kézikönyv – Käyttäjän opas –

Betjeningsvejledning – Brukerveiledning – Instrukcja obsługi – Bruksanvisning – Kullanım

Kılavuzu – Uživatelská příručka –

Gebruikershandleiding

User’s manual

FLIR i5

FLIR i7

T559382Publ. No.

a358Revision

English (EN)Language

June 23, 2009Issue date

Page 2

Page 3

User’s manual

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 4

Legal disclaimer

All products manufactured by FLIR Systemsarewarranted against defectivematerialsandworkmanship for aperiodof one(1)year from the

delivery date of the original purchase, provided such products have been under normal storage, use and service, and in accordance with

FLIR Systems instruction.

All products not manufactured by FLIR Systems included in systemsdelivered by FLIRSystems to the original purchaser carrythe warranty,

if any, of the particular supplier only and FLIR Systems has no responsibilitywhatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It is not applicable to any product which has been subjected to

misuse, neglect, accident or abnormal conditions of operation. Expendable parts are excluded from the warranty.

In the case of adefect inaproduct coveredbythis warrantytheproduct must notbe furtherusedin order toprevent additional damage.The

purchaser shall promptly report any defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, at its option, repair or replace any such defective product free of charge if, upon inspection, it proves to be defective in

material or workmanship and provided that it is returned to FLIR Systems within the said one-year period.

FLIR Systems has no other obligation or liability for defects than those set forth above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims the implied warranties of merchantability and fitness for a

particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidentalor consequential loss or damage, whether basedon contract, tort

or any other legal theory.

Copyright

© FLIR Systems,2009. All rights reservedworldwide. No parts ofthesoftware including source codemaybe reproduced, transmitted, transcribed

or translated into any language or computer language in any form or by any means, electronic, magnetic, optical, manual or otherwise,

without the prior written permission of FLIR Systems.

This manual must not, in whole or part, be copied, photocopied, reproduced,translated ortransmitted to any electronic medium or machine

readable form without prior consent, in writing, from FLIR Systems.

Names and marks appearing on the products herein are eitherregistered trademarksor trademarksof FLIR Systems and/or its subsidiaries.

All othertrademarks,trade names or companynames referenced herein areusedfor identification only andarethe property of theirrespective

owners.

Quality assurance

The Quality Management System under which these products are developed and manufactured has been certified in accordance with the

ISO 9001 standard.

FLIR Systems is committed to a policy of continuous development; therefore we reserve the right to make changes and improvements on

any of the products described in this manual without prior notice.

Patents

One or several of the following patents or design patents apply to the products and/or features described in this manual:

0002258-2; 000279476-0001;000439161;000499579-0001; 000653423; 000726344; 000859020;0101577-5; 0102150-0; 0200629-4; 0300911-

5; 0302837-0; 1144833;1182246;1182620; 1188086; 1263438; 1285345; 1287138; 1299699;1325808;1336775;1678485;200530018812.0;

2106017; 235308; 3006596; 3006597; 466540; 483782; 484155; 518836; 60004227.8; 60122153.2; 602004011681.5-08; 6707044; 68657;

7034300; 7110035; 7154093; 7157705; 7237946; 7312822; 7332716; 7336823; 75530; D540838; D549758; DI6702302-9; DI6703574-4;

DM/057692; DM/061609;ZL00809178.1;ZL01823221.3; ZL01823226.4; ZL02331553.9; ZL02331554.7;ZL200530120994.2; ZL200630130114.4;

ZL200730151141.4.

EULA Terms

You have acquired a device (“INFRARED CAMERA”) that includes software licensed by FLIR Systems AB from Microsoft Licensing, GP

■

or its affiliates (“MS”). Those installed software products of MS origin, as well as associated media, printed materials, and “online” or

electronic documentation(“SOFTWARE”)are protected by internationalintellectualproperty laws and treaties.TheSOFTWARE is licensed,

not sold. All rights reserved.

IF YOU DO NOTAGREE TO THISENDUSER LICENSE AGREEMENT(“EULA”), DO NOTUSETHE DEVICE ORCOPYTHESOFTWARE.

■

INSTEAD, PROMPTLY CONTACT FLIR Systems AB FOR INSTRUCTIONS ON RETURN OF THE UNUSED DEVICE(S) FOR A REFUND.

ANY USE OF THE SOFTWARE, INCLUDING BUT NOT LIMITED TO USE ON THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT

TO THIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

GRANT OF SOFTWARE LICENSE. This EULA grants you the following license:

■

You may use the SOFTWARE only on the DEVICE.

■

NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLERANT. FLIR Systems AB HAS INDEPENDENTLY DETERMINED

■

HOW TOUSE THE SOFTWAREIN THE DEVICE,AND MS HASRELIED UPON FLIRSystems AB TOCONDUCT SUFFICIENT TESTING

TO DETERMINE THAT THE SOFTWARE IS SUITABLE FOR SUCH USE.

iv Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 5

NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is provided “AS IS” and with all faults. THE ENTIRE RISK AS TO SAT-

■

ISFACTORY QUALITY, PERFORMANCE, ACCURACY, AND EFFORT (INCLUDING LACK OF NEGLIGENCE) IS WITH YOU. ALSO,

THERE ISNO WARRANTY AGAINSTINTERFERENCE WITH YOURENJOYMENT OF THESOFTWAREOR AGAINST INFRINGEMENT.

IF YOU HAVE RECEIVED ANY WARRANTIES REGARDING THE DEVICE OR THE SOFTWARE, THOSE WARRANTIES DO NOT

ORIGINATE FROM, AND ARE NOT BINDING ON, MS.

No Liability for Certain Damages. EXCEPT AS PROHIBITED BY LAW, MS SHALL HAVE NO LIABILITY FOR ANY INDIRECT,

■

SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE SOFTWARE. THIS LIMITATION SHALL APPLY EVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE.

IN NO EVENT SHALL MS BE LIABLE FOR ANY AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS (U.S.$250.00).

Limitations on Reverse Engineering, Decompilation, and Disassembly. Youmay not reverse engineer, decompile, ordisassemble

■

the SOFTWARE, exceptand only to the extentthat such activity isexpresslypermitted by applicable lawnotwithstandingthis limitation.

SOFTWARE TRANSFER ALLOWED BUT WITH RESTRICTIONS. Youmaypermanentlytransferrights under this EULA only aspart

■

of a permanent sale or transfer of the Device, and only if the recipient agrees to this EULA. If the SOFTWARE is an upgrade, any

transfer must also include all prior versions of the SOFTWARE.

EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is subject to U.S. export jurisdiction. You agree to comply with all

■

applicable international andnationallawsthatapplytotheSOFTWARE, includingthe U.S. Export Administration Regulations,aswell

as end-user, end-use and destination restrictions issued by U.S. and other governments. For additional information see

http://www.microsoft.com/exporting/.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 6

vi Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 7

Table of contents

11 Warnings & Cautions .....................................................................................................................

32 Notice to user ..................................................................................................................................

43 Customer help ................................................................................................................................

54 Documentation updates .................................................................................................................

65 Important note about this manual .................................................................................................

76 Quick Start Guide ...........................................................................................................................

97 Packing list ......................................................................................................................................

108 Camera parts ..................................................................................................................................

139 Screen elements ............................................................................................................................

1510 Connectors and storage media ....................................................................................................

1611 Using the camera ............................................................................................................................

1611.1 Installing the battery .............................................................................................................

1711.2 Charging the battery .............................................................................................................

1911.3 Saving an image ...................................................................................................................

2011.4 Recalling an image ...............................................................................................................

2111.5 Opening the image archive ..................................................................................................

2211.6 Deleting an image .................................................................................................................

2311.7 Deleting all images ...............................................................................................................

2411.8 Measuring a temperature using a spotmeter .......................................................................

2511.9 Measuring a temperature using an area ..............................................................................

2611.10 Marking all areas above or below a set temperature level ..................................................

2711.11 Changing the color palette ...................................................................................................

2811.12 Changing the settings ..........................................................................................................

2911.13 Changing the image mode ...................................................................................................

3011.14 Setting the surface properties ..............................................................................................

3111.15 Changing the emissivity .......................................................................................................

3211.16 Changing the reflected apparent temperature ....................................................................

3311.17 Resetting the camera ............................................................................................................

3411.18 Finding the serial number of the camera .............................................................................

3512 Cleaning the camera ......................................................................................................................

3512.1 Camera housing, cables, and other items ...........................................................................

3612.2 Infrared lens ..........................................................................................................................

3713 Technical data .................................................................................................................................

3713.1 Camera data .........................................................................................................................

4013.2 Additional data ......................................................................................................................

4213.3 Accessories data ..................................................................................................................

4314 Dimensions ......................................................................................................................................

4314.1 Camera (front) ......................................................................................................................

4414.2 Camera (side) .......................................................................................................................

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 vii

Page 8

16.2.1.2 Guidelines for moisture detection, mold detection & detection of

water damages ..................................................................................

16.3.8 Excerpt from Technical Note ‘Assessing thermal bridging and insulation

continuity’ (UK example) ......................................................................................

4515 Application examples .....................................................................................................................

4515.1 Moisture & water damage ....................................................................................................

4615.2 Faulty contact in socket ........................................................................................................

4715.3 Oxidized socket ....................................................................................................................

4815.4 Insulation deficiencies ..........................................................................................................

4915.5 Draft ......................................................................................................................................

5016 Introduction to building thermography ........................................................................................

5016.1 Important note ......................................................................................................................

5016.2 Typical field investigations ....................................................................................................

5016.2.1 Guidelines .............................................................................................................

5016.2.1.1 General guidelines ............................................................................

51

5116.2.1.3 Guidelines for detection of air infiltration & insulation deficiencies ...

5216.2.2 About moisture detection .....................................................................................

5216.2.3 Moisture detection (1): Low-slope commercial roofs ..........................................

5216.2.3.1 General information ...........................................................................

5316.2.3.2 Safety precautions ............................................................................

5416.2.3.3 Commented building structures .......................................................

5516.2.3.4 Commented infrared images ............................................................

5716.2.4 Moisture detection (2): Commercial & residential façades ..................................

5716.2.4.1 General information ...........................................................................

5716.2.4.2 Commented building structures .......................................................

5916.2.4.3 Commented infrared images ............................................................

5916.2.5 Moisture detection (3): Decks & balconies ..........................................................

5916.2.5.1 General information ...........................................................................

6016.2.5.2 Commented building structures .......................................................

6216.2.5.3 Commented infrared images ............................................................

6216.2.6 Moisture detection (4): Plumbing breaks & leaks ................................................

6216.2.6.1 General information ...........................................................................

6316.2.6.2 Commented infrared images ............................................................

6516.2.7 Air infiltration .........................................................................................................

6516.2.7.1 General information ...........................................................................

6516.2.7.2 Commented building structures .......................................................

6716.2.7.3 Commented infrared images ............................................................

6816.2.8 Insulation deficiencies ..........................................................................................

6816.2.8.1 General information ...........................................................................

6816.2.8.2 Commented building structures .......................................................

7016.2.8.3 Commented infrared images ............................................................

7216.3 Theory of building science ...................................................................................................

7216.3.1 General information ..............................................................................................

7316.3.2 The effects of testing and checking .....................................................................

7416.3.3 Sources of disruption in thermography ................................................................

7616.3.4 Surface temperature and air leaks .......................................................................

7616.3.4.1 Pressure conditions in a building .....................................................

8216.3.5 Measuring conditions & measuring season .........................................................

8216.3.6 Interpretation of infrared images ..........................................................................

8416.3.7 Humidity & dew point ...........................................................................................

8416.3.7.1 Relative & absolute humidity ............................................................

8516.3.7.2 Definition of dew point ......................................................................

85

viii Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 9

8516.3.8.1 Credits ...............................................................................................

8616.3.8.2 Introduction .......................................................................................

8616.3.8.3 Background information ...................................................................

8716.3.8.4 Quantitative appraisal of thermal anomalies ....................................

9016.3.8.5 Conditions and equipment ...............................................................

9116.3.8.6 Survey and analysis ..........................................................................

9216.3.8.7 Reporting ...........................................................................................

9416.4 Disclaimer .............................................................................................................................

9416.4.1 Copyright notice ...................................................................................................

9416.4.2 Training & certification ..........................................................................................

9416.4.3 National or regional building codes .....................................................................

9517 Introduction to thermographic inspections of electrical installations ......................................

9517.1 Important note ......................................................................................................................

9517.2 General information ..............................................................................................................

9517.2.1 Introduction ...........................................................................................................

9617.2.2 General equipment data .......................................................................................

9717.2.3 Inspection .............................................................................................................

9717.2.4 Classification & reporting ......................................................................................

9817.2.5 Priority ...................................................................................................................

9817.2.6 Repair ....................................................................................................................

9917.2.7 Control ..................................................................................................................

10017.3 Measurement technique for thermographic inspection of electrical installations ...............

10017.3.1 How to correctly set the equipment .....................................................................

10017.3.2 Temperature measurement ...................................................................................

10217.3.3 Comparative measurement ..................................................................................

10317.3.4 Normal operating temperature .............................................................................

10417.3.5 Classification of faults ...........................................................................................

10617.4 Reporting ..............................................................................................................................

10817.5 Different types of hot spots in electrical installations ...........................................................

10817.5.1 Reflections ............................................................................................................

10817.5.2 Solar heating .........................................................................................................

10917.5.3 Inductive heating ...................................................................................................

10917.5.4 Load variations ......................................................................................................

11017.5.5 Varying cooling conditions ...................................................................................

11117.5.6 Resistance variations ............................................................................................

11117.5.7 Overheating in one part as a result of a fault in another ......................................

11317.6 Disturbance factors at thermographic inspection of electrical installations ........................

11317.6.1 Wind ......................................................................................................................

11317.6.2 Rain and snow ......................................................................................................

11417.6.3 Distance to object .................................................................................................

11517.6.4 Object size ............................................................................................................

11717.7 Practical advice for the thermographer ................................................................................

11717.7.1 From cold to hot ...................................................................................................

11717.7.2 Rain showers ........................................................................................................

11717.7.3 Emissivity ..............................................................................................................

11817.7.4 Reflected apparent temperature ...........................................................................

11817.7.5 Object too far away ...............................................................................................

11918 About FLIR Systems .......................................................................................................................

12018.1 More than just an infrared camera .......................................................................................

12018.2 Sharing our knowledge ........................................................................................................

12018.3 Supporting our customers ...................................................................................................

12118.4 A few images from our facilities ...........................................................................................

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 ix

Page 10

12319 Glossary ...........................................................................................................................................

12720 Thermographic measurement techniques ...................................................................................

12720.1 Introduction ..........................................................................................................................

12720.2 Emissivity ..............................................................................................................................

12820.2.1 Finding the emissivity of a sample .......................................................................

12820.2.1.1 Step 1: Determining reflected apparent temperature .......................

13020.2.1.2 Step 2: Determining the emissivity ...................................................

13120.3 Reflected apparent temperature ..........................................................................................

13120.4 Distance ................................................................................................................................

13120.5 Relative humidity ..................................................................................................................

13120.6 Other parameters ..................................................................................................................

13221 History of infrared technology ......................................................................................................

13622 Theory of thermography ................................................................................................................

13622.1 Introduction ...........................................................................................................................

13622.2 The electromagnetic spectrum ............................................................................................

13722.3 Blackbody radiation ..............................................................................................................

13822.3.1 Planck’s law ..........................................................................................................

13922.3.2 Wien’s displacement law ......................................................................................

14122.3.3 Stefan-Boltzmann's law .........................................................................................

14222.3.4 Non-blackbody emitters .......................................................................................

14422.4 Infrared semi-transparent materials .....................................................................................

14623 The measurement formula .............................................................................................................

15224 Emissivity tables .............................................................................................................................

15224.1 References ............................................................................................................................

15224.2 Important note about the emissivity tables ..........................................................................

15324.3 Tables ....................................................................................................................................

x Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 11

1 Warnings & Cautions

This equipment generates, uses, and can radiate radio frequency energy and if

WARNING

■

not installed and used in accordance with the instruction manual, may cause interference to radio communications. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designedto providereasonable protection againstsuch interference when operated in a commercial environment. Operation of this equipment

in a residential area is likely to cause interference in which case the user at his

own expense will be required to take whatever measures may be required to

correct the interference.

(Applies only to cameras with laser pointer:) Do not look directly into the laser

■

beam. The laser beam can cause eye irritation.

Applies only to cameras with battery:

■

Do not disassemble or do a modification to the battery. The battery contains

■

safety and protection devices which, if they become damaged, can cause the

battery to become hot, or cause an explosion or an ignition.

If there is a leak from the battery and the fluid gets into your eyes, do not rub

■

your eyes.Flush well withwater and immediatelyget medical care. Thebattery

fluid can cause injury to your eyes if you do not do this.

Do not continue to charge the battery if it does not become charged in the

■

specified charging time. If you continue to charge the battery, it can become

hot and cause an explosion or ignition.

Only use the correct equipment to discharge the battery. If you do not use the

■

correct equipment, you can decrease the performance or the life cycle of the

battery. If you do not use the correct equipment, an incorrect flow of current

to the battery can occur. This can cause the battery to become hot, or cause

an explosion and injury to persons.

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and

■

warning labelson containersbeforeyou usea liquid: theliquids can bedangerous.

Do not point theinfrared camera (withor without the lens cover)at intensive energy

CAUTION

■

sources, for example devices that emit laser radiation, or the sun. This can have

an unwanted effect on the accuracy of the camera. It can also cause damage to

the detector in the camera.

Do not use the camera in a temperature higher than +50°C (+122°F), unless

■

specified otherwise in the technical data section. High temperatures can cause

damage to the camera.

(Applies only to cameras with laser pointer:) Protect the laser pointer with the

■

protective cap when you do not operate the laser pointer.

Applies only to cameras with battery:

■

Do not attach the batteries directly to a car’s cigarette lighter socket, unless a

■

specific adapter for connecting the batteries to a cigarette lighter socket is

provided by FLIR Systems.

Do not connect the positive terminal and the negative terminal of the battery

■

to each other with a metal object (such as wire).

Do not get water or salt water on the battery, or permit the battery to get wet.

■

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 1

Page 12

1 – Warnings & Cautions

■

■

■

Do not make holes in the battery with objects. Do not hit the battery with a

■

hammer. Do not step on the battery, or apply strong impacts or shocks to it.

Do not put thebatteries inor near a fire, orinto direct sunlight. When thebattery

■

becomes hot, the built-in safety equipment becomes energized and can stop

the battery charging process. If the battery becomes hot, damage can occur

to the safety equipment and this can cause more heat, damage or ignition of

the battery.

Do not put the battery on a fire or increase the temperature of the battery with

■

heat.

Do not put the battery on or near fires, stoves, or other high-temperature loca-

■

tions.

Do not solder directly onto the battery.

■

Do not use the battery if, when you use, charge, or store the battery, there is

■

an unusual smell fromthe battery,the battery feelshot, changes color, changes

shape, or is in an unusual condition. Contact your sales office if one or more

of these problems occurs.

Only use a specified battery charger when you charge the battery.

■

The temperature range through which you can charge the battery is ±0°C to

■

+45°C (+32°F to +113°F). If you charge the battery at temperatures outof this

range, it can cause thebattery to become hot or to break. It can also decrease

the performance or the life cycle of the battery.

The temperature range through which you can dischargethe battery is −15°C

■

to +50°C (+5°F to +122°F). Use of the battery out of this temperature range

can decrease the performance or the life cycle of the battery.

When the battery is worn, apply insulation to the terminals with adhesive tape

■

or similar materials before you discard it.

Do not apply solvents or similar liquids to the camera, the cables, or other items.

This can cause damage.

Be careful when you cleanthe infraredlens. The lens has a delicate anti-reflective

coating.

Do not clean the infrared lens too vigorously. This can damage the anti-reflective

coating.

2 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 13

2 Notice to user

Typographical

conventions

User-to-user

forums

Calibration

Accuracy

Disposal of

electronic waste

This manual uses the following typographical conventions:

Semibold is used for menu names, menu commands and labels, and buttons in

■

dialog boxes.

Italic is used for important information.

■

Monospace is used for code samples.

■

UPPER CASE is used for names on keys and buttons.

■

Exchange ideas,problems, and infraredsolutions with fellowthermographers around

the world in our user-to-user forums. To go to the forums, visit:

http://www.infraredtraining.com/community/boards/

(This notice only applies to cameras with measurement capabilities.)

We recommend that you send in the camera for calibration once a year. Contact

your local sales office for instructions on where to send the camera.

(This notice only applies to cameras with measurement capabilities.)

For very accurate results, we recommend that you wait 5 minutes after you have

started the camera before measuring a temperature.

For cameras where the detector is cooled by a mechanical cooler, this time period

excludes the time it takes to cool down the detector (usually 5–7 minutes).

10742803;a1

As with most electronic products, this equipment must be disposed of in an environmentally friendlyway, and inaccordance with existingregulations for electronicwaste.

Please contact your FLIR Systems representative for more details.

Training

To read about infrared training, visit:

http://www.infraredtraining.com

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 3

Page 14

3 Customer help

General

Submitting a

question

Downloads

For customer help, visit:

http://flir.custhelp.com

To submit a question to the customer help team, you must be a registered user. It

only takes a fewminutes to registeronline. If you only wantto search the knowledgebase for existing questions and answers, you do not need to be a registered user.

When you want to submit a question, makesure thatyou have the following information to hand:

The camera model

■

The camera serial number

■

The communication protocol, or method, between the camera and your PC (for

■

example, HDMI, Ethernet, USB™, or FireWire™)

Operating system on your PC

■

Microsoft®Office version

■

Full name, publication number, and revision number of the manual

■

On the customer help site you can also download the following:

Firmware updates for your infrared camera

■

Program updates for your PC software

■

User documentation

■

Application stories

■

Technical publications

■

4 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 15

4 Documentation updates

General

Our manuals are updated several times per year, and we also issue product-critical

notifications of changes on a regular basis.

To access the latest manuals and notifications, go to the Download tab at:

http://flir.custhelp.com

It only takes a few minutes to register online. In the download area you will also find

the latest releases of manuals for our other products, as well as manuals for our

historical and obsolete products.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 5

Page 16

5 Important note about this manual

General

NOTE

FLIR Systems issues generic manuals that cover several cameras within a model

line.

This means that this manual may contain descriptions and explanations that do not

apply to your particular camera model.

FLIR Systemsreserves therightto discontinuemodels,software, parts oraccessories,

and other items, or to change specifications and/or functionality at any time without

prior notice.

6 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 17

6 Quick Start Guide

Procedure

Follow this procedure to get started right away:

Remove the protective film from the LCD.1

You must charge the battery inside the camera for four full hours (or until

2

the battery charging indicator displays a green light) before you use the

camera for the first time.

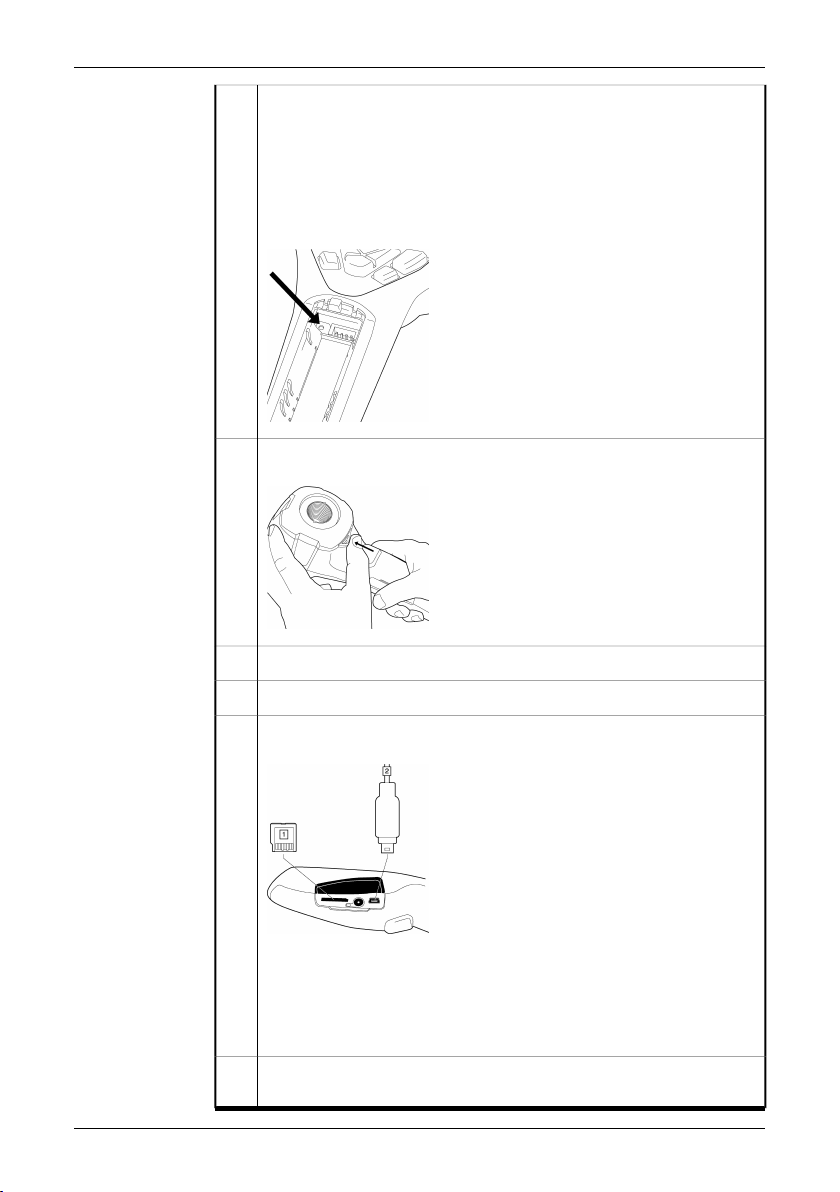

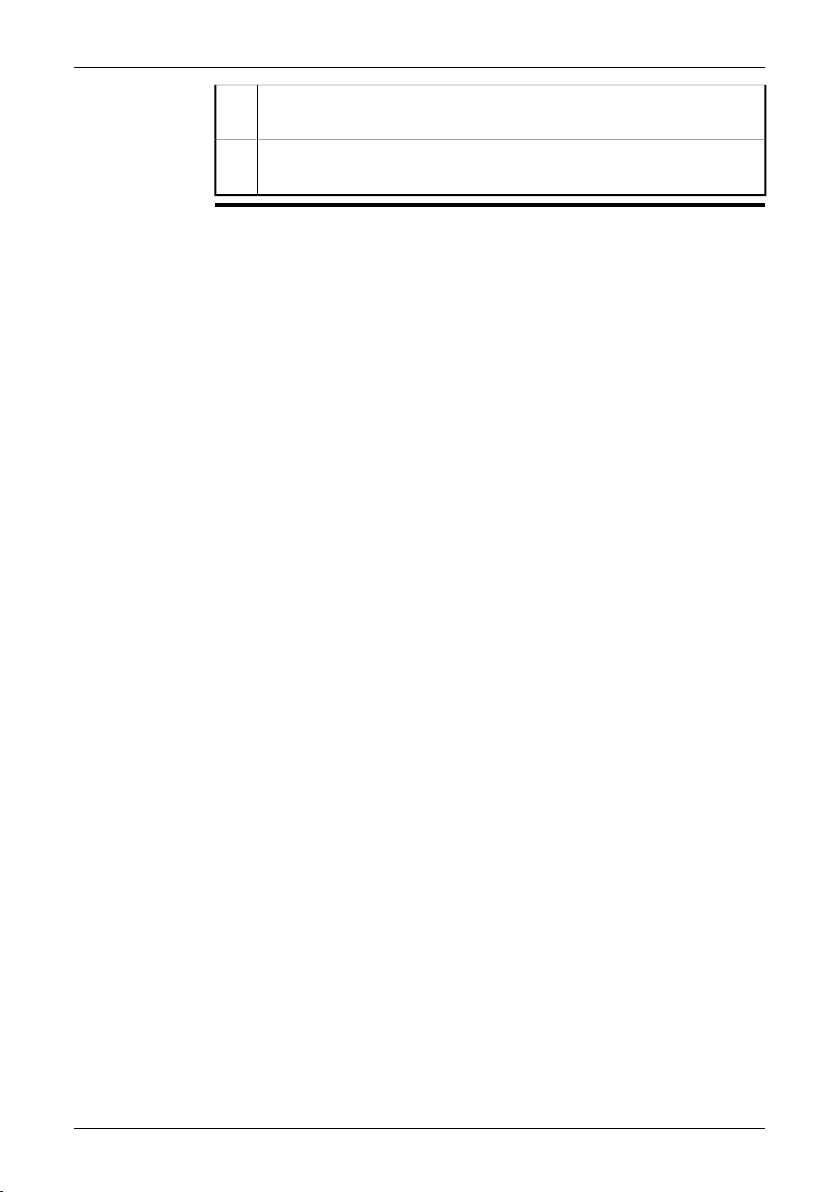

Charge thebatteryby connecting thepowersupply to the powerconnector

on the camera. Make sure that you use the correct AC plug.

Note: The first time you charge a factory-new battery you must turn on and

then turn off the camera after you have connected the power supply to the

power connector on the camera.

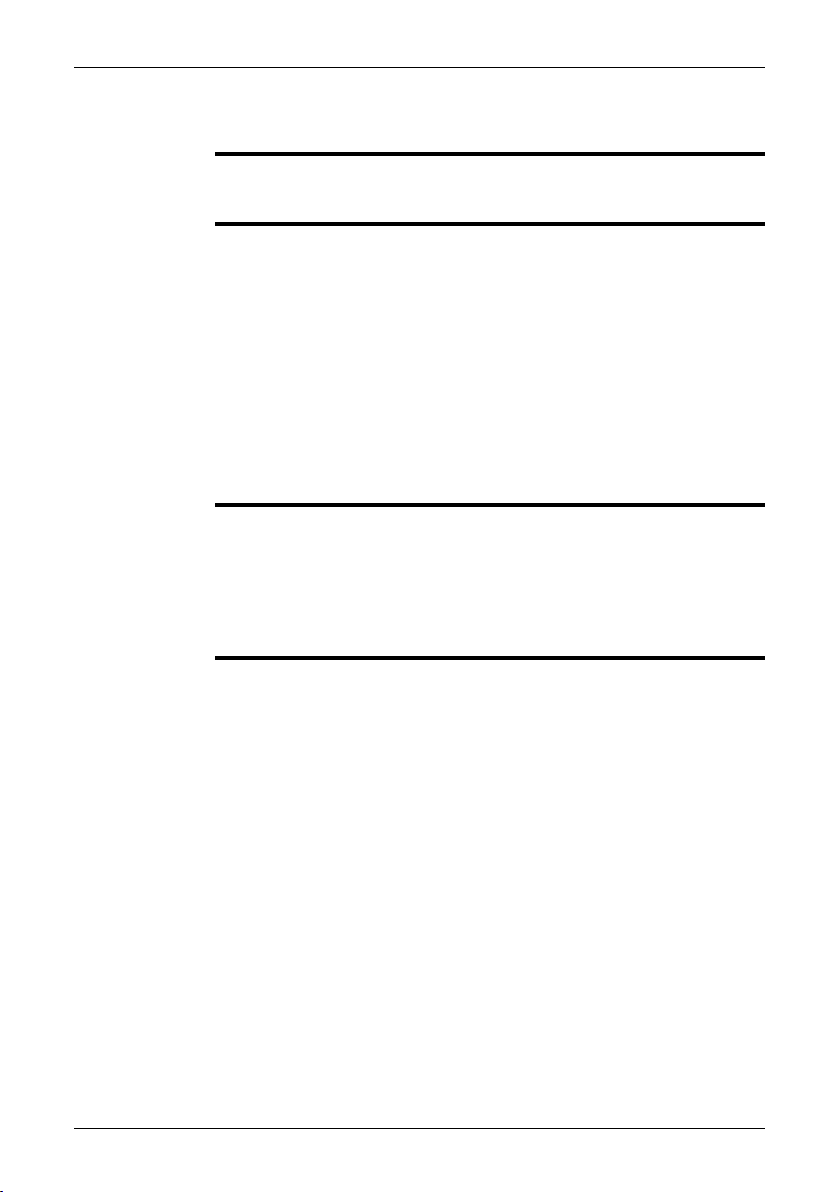

T630175;a1

1 Battery charging indicator

2 Power supply cable

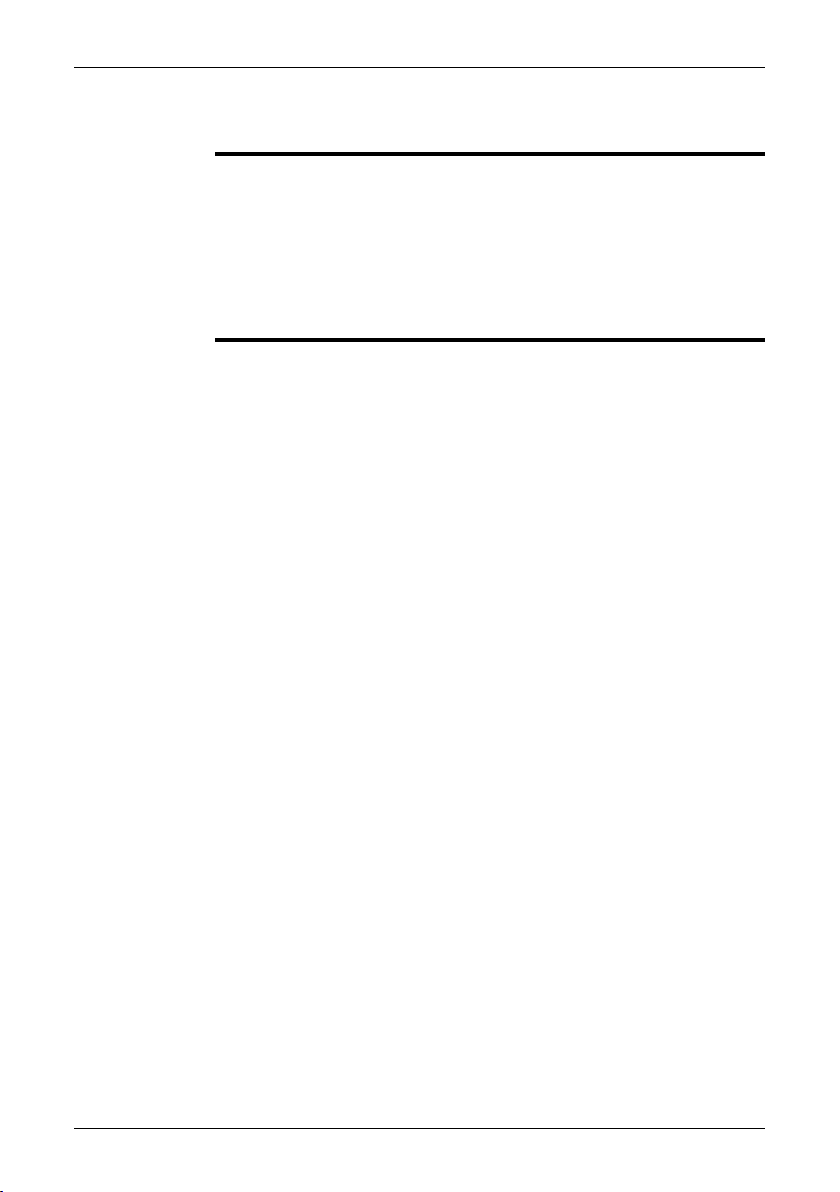

Insert a miniSD™ memory card into the card slot.

3

T630176;a1

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 7

Page 18

6 – Quick Start Guide

Push the On/Off button to turn on the camera.

4

Note: If the camera does not start after you have charged thebattery, push

the reset button with a non-conductive tool. The reset button is located

beside the battery connector, inside the battery compartment. Then press

the On/Off button again.

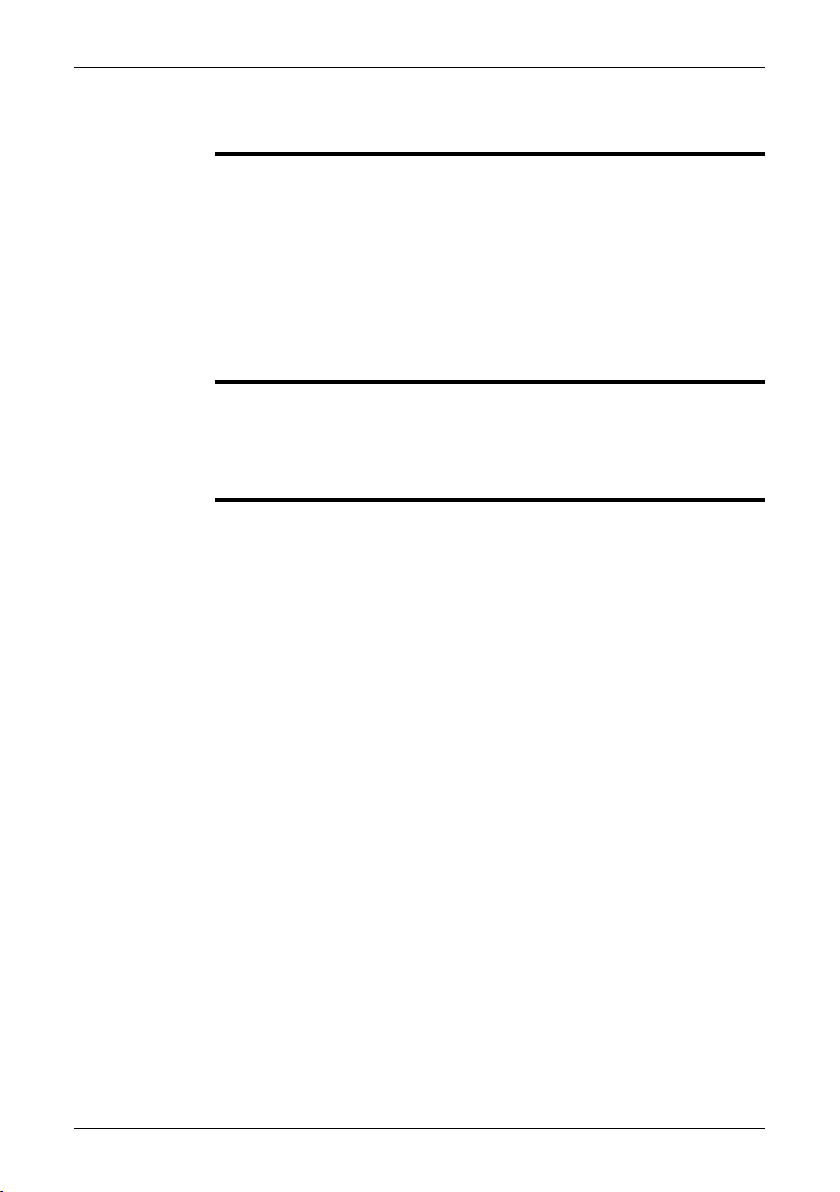

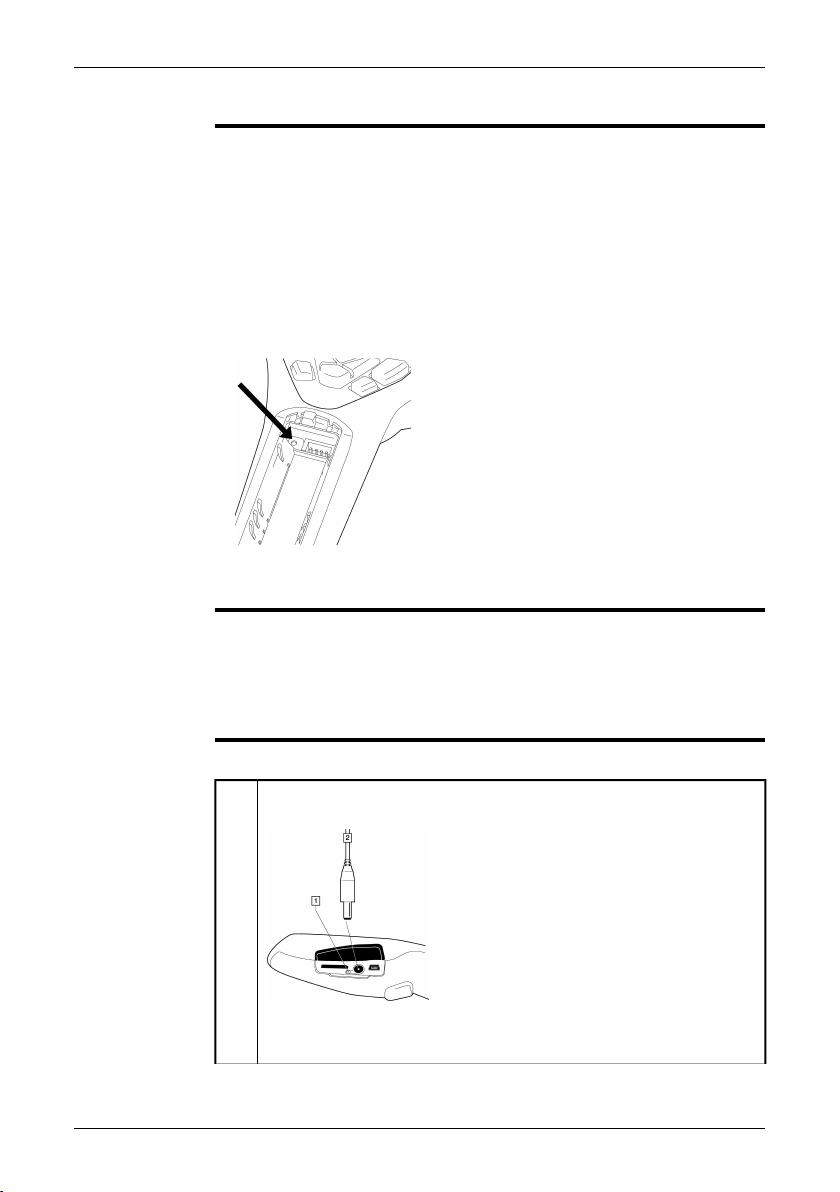

The reset button:

T630179;a1

Open the lens cap by pushing the lens cap lever.

5

T630177;a1

Aim the camera toward your target of interest.6

Pull the Save trigger to save the image.7

To move the image to a computer, do one of the following:

8

T630178;a1

(Fig. 1 above) Remove the miniSD™ memory card and insert it into a

■

card readerconnected to a computer. A miniSD™ cardadapter is included with your camera.

(Fig. 2 above) Connect a computer to the camera using a USB™ Mini-

■

B cable.

In Windows®Explorer, move the image from the card or camera using a

9

drag-and-drop operation.

8 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 19

7 Packing list

Battery (inside camera)

Contents

NOTE

■

Calibration certificate

■

FLIR QuickReport CD

■

Hand strap

■

Infrared camera

■

miniSD card (512 MB), with SD adapter

■

Power supply/charger with EU, UK, US and Australian plugs

■

Printed Getting Started Guide

■

USB cable

■

User documentation CD-ROM

■

Contact your local sales office if any item is damaged or missing. You can find

■

the addresses and telephone numbers of local sales offices on the back cover of

this manual.

FLIR Systems reserves the rightto discontinue models, parts or accessories, and

■

other items, or to change specifications at any time without prior notice.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 9

Page 20

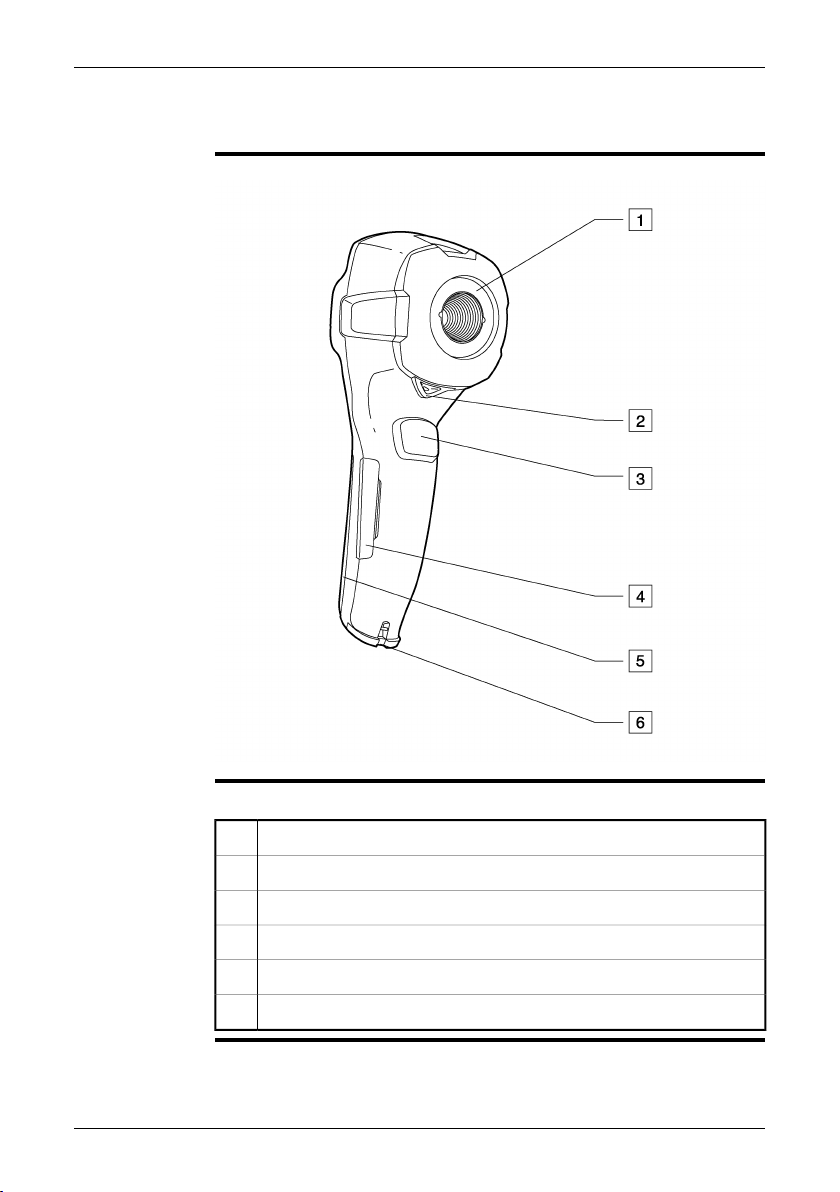

8 Camera parts

Figure

10780903;a1

Explanation

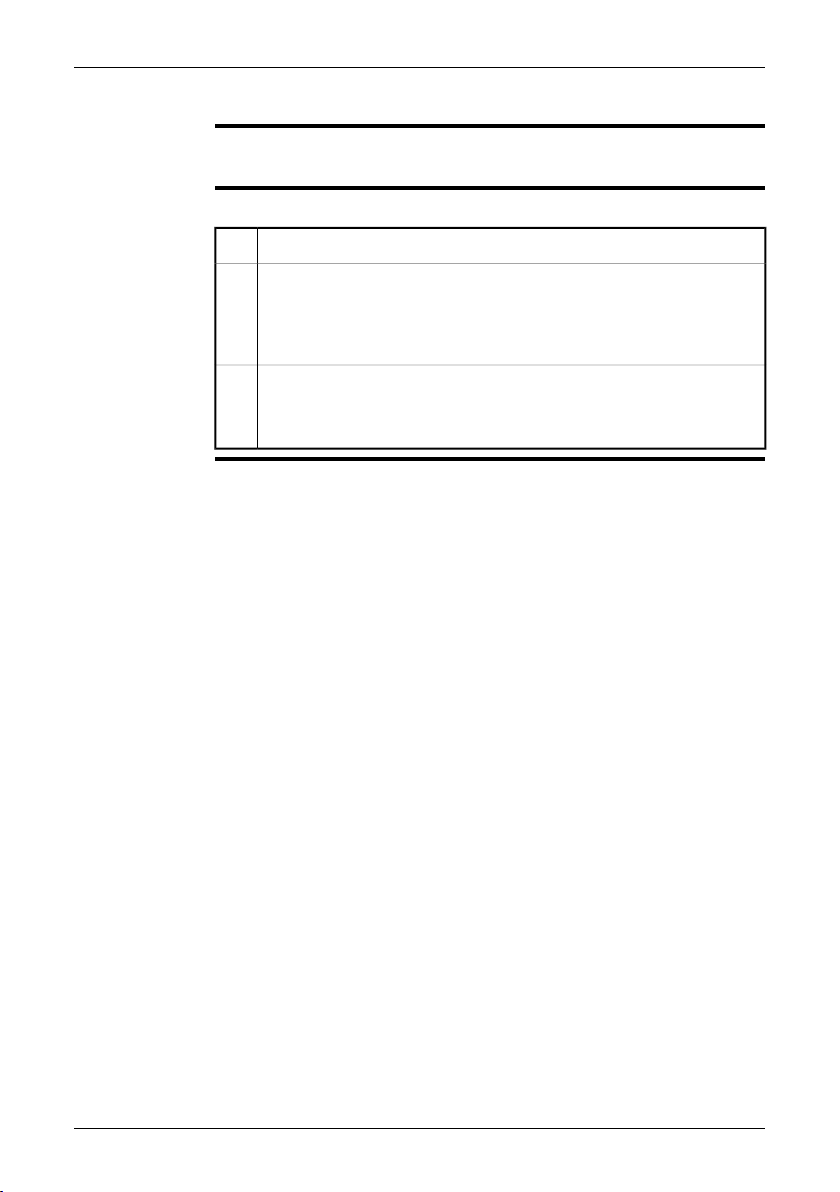

This table explains the figure above:

Infrared lens1

Lever to open and close the lens cap2

Trigger to save images3

Cover to connectors and the miniSD™ memory card slot4

Cover to the battery compartment5

Attachment point for the hand strap6

10 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 21

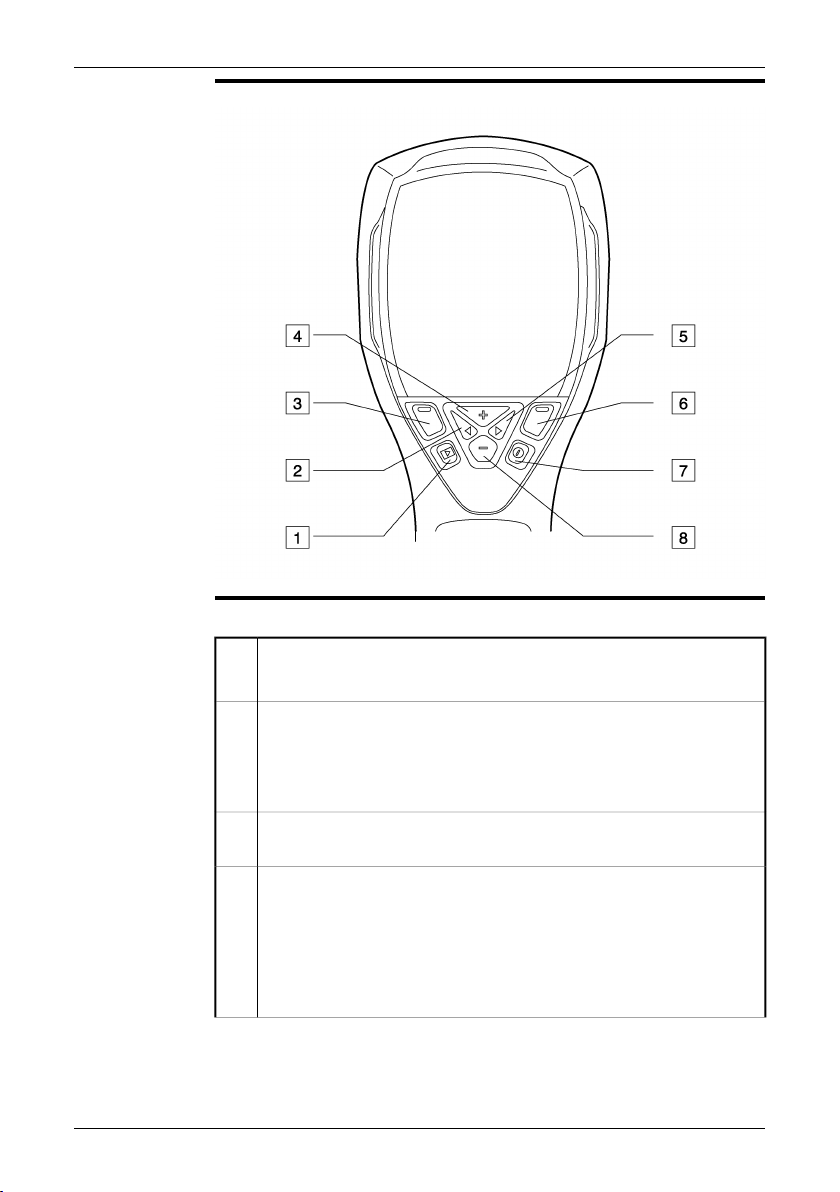

8 – Camera parts

Figure

Explanation

10781003;a1

This table explains the figure above:

Archive button

1

Function: Push to open the image archive.

Left arrow button (on the navigation pad)

2

Function:

Push to go left in menus, submenus, and dialog boxes

■

Push to navigate in the image archive

■

Left selection button. This button is context-sensitive, and the current

3

function is displayed above the button on the screen.

+ button (on the navigation pad)

4

Function:

Push to go up in menus, submenus, and dialog boxes.

■

Push to display the image archive (after having pushed the Archive

■

button).

Push to increase/change the value.

■

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 11

Page 22

8 – Camera parts

Right arrow button (on the navigation pad)

5

Function:

Push to go right in menus, submenus, and dialog boxes.

■

Push to navigate in the image archive.

■

Right selection button. This button is context-sensitive, and the current

6

function is displayed above the button on the screen.

On/Off button

7

Function:

Push to turn on the camera.

■

Push and hold down for more than one second to turn off the camera.

■

– button (on navigation pad)

8

Function:

Push to go down in menus, submenus, and dialog boxes.

■

Push to decrease/change the value.

■

12 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 23

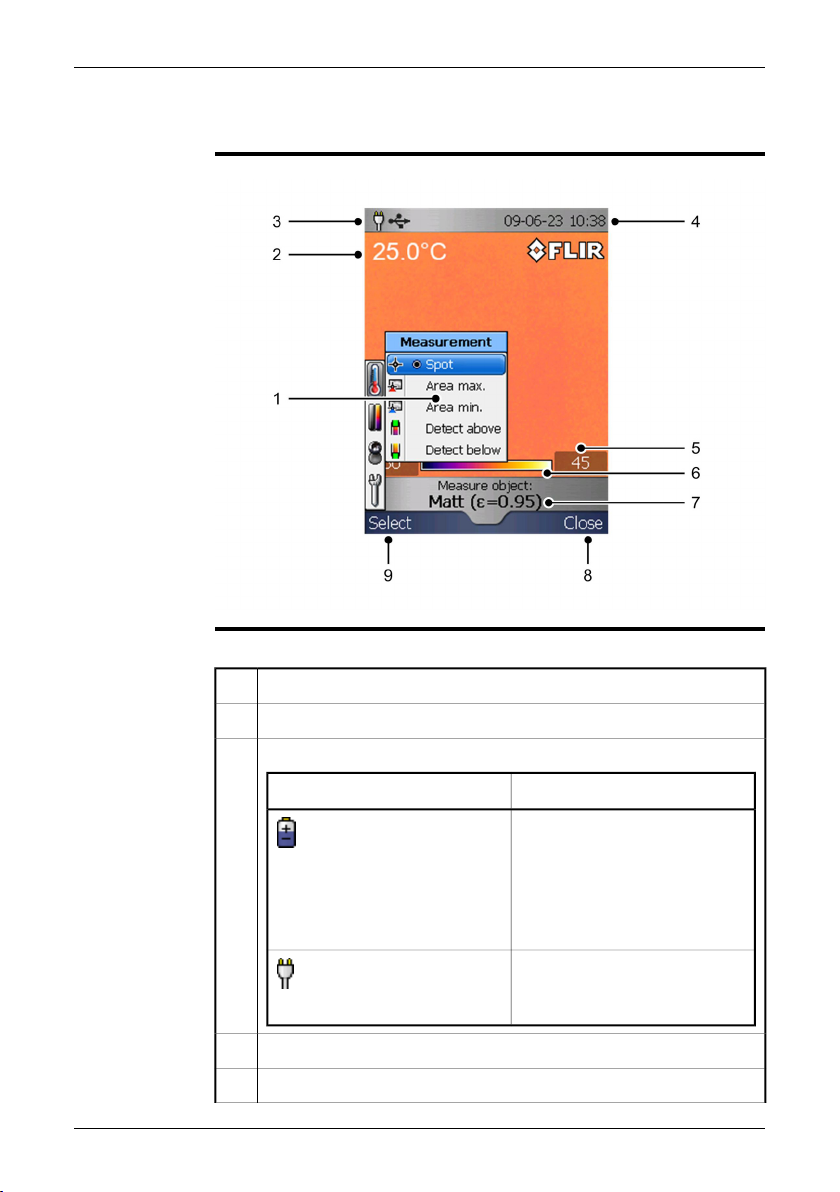

9 Screen elements

Figure

Explanation

10781203;a2

This table explains the figure above:

Menu system1

Measurement result2

Power indicator

3

MeaningIcon

One of the following:

The camera is powered using

■

the battery.

The battery is being charged

■

(indicated by a refilling battery

animation).

The battery is fullycharged and the

camera is powered using the

power supply.

Date and time4

Limit value for the temperature scale5

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 13

Page 24

9 – Screen elements

Temperature scale6

Currently set emissivity value or material properties7

Current function for the right selection button8

Current function for the left selection button9

14 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 25

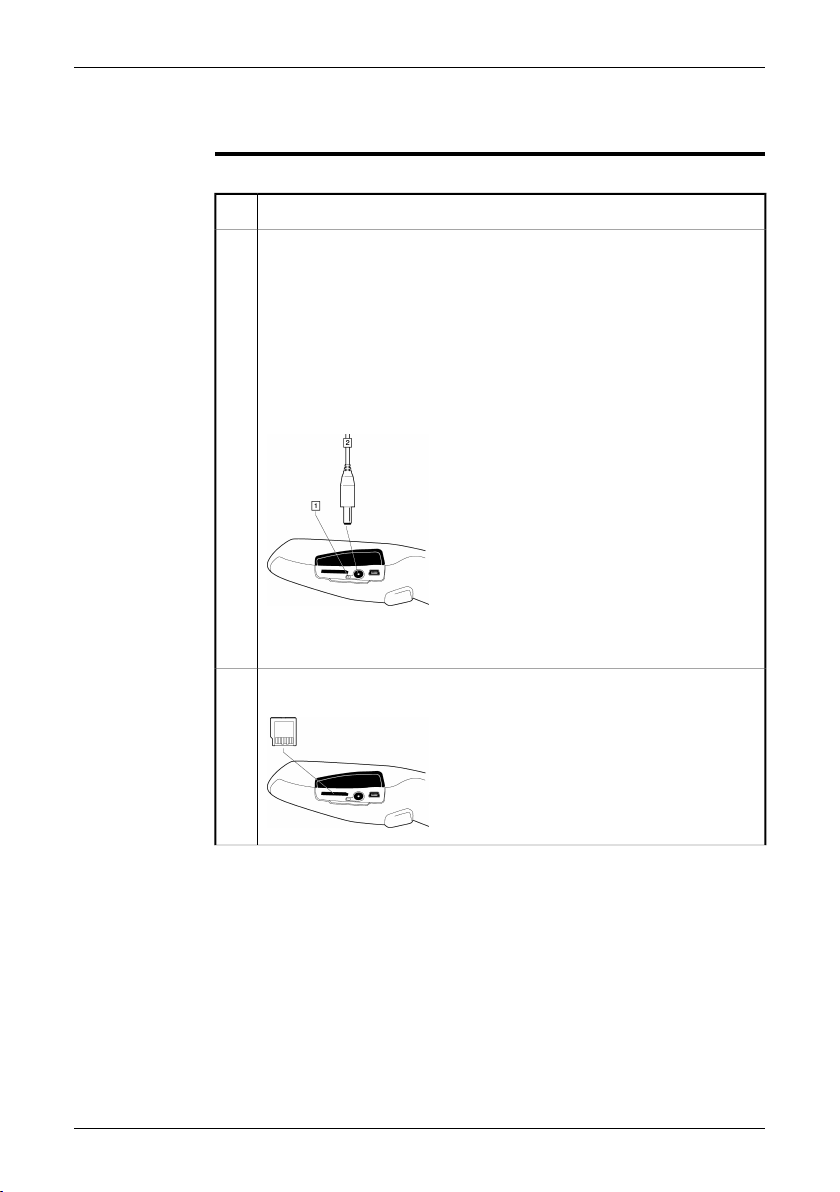

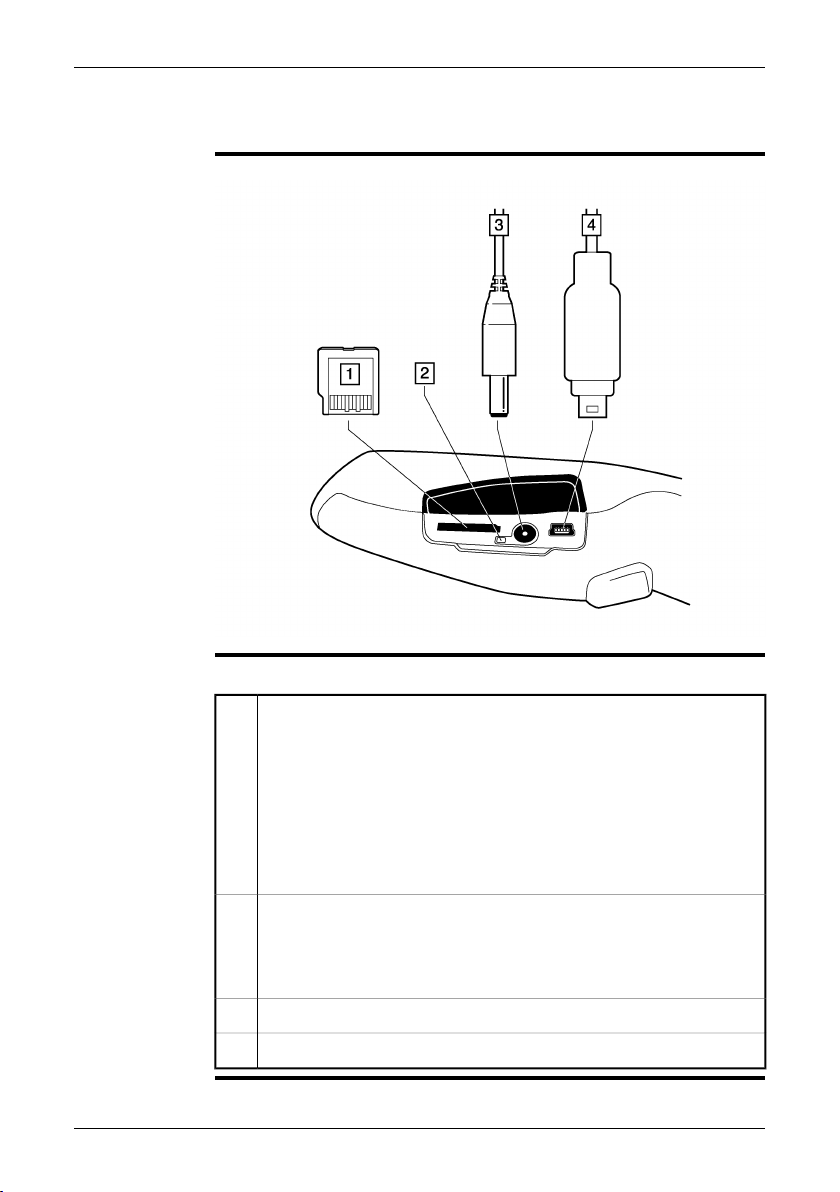

10 Connectors and storage media

Figure

Explanation

10780803;a1

This table explains the figure above:

miniSD™ memory card

1

We recommend that you do not save more than 5,000 images on the miniSD™ memory card.

Although a memory card may have a higher capacity than 5,000 images,

saving more than that number ofimages severelyslows down file management on the miniSD™ memory card.

Note: There is no upper limit to the memory size of the miniSD™ memory

card.

Battery charging indicator:

2

No light: The power supply is not connected.

■

Orange light: The battery is being charged.

■

Green light: The charging of the battery is completed.

■

Power supply cable3

USB cable with USB Mini-B connector4

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 15

Page 26

11 Using the camera

11.1 Installing the battery

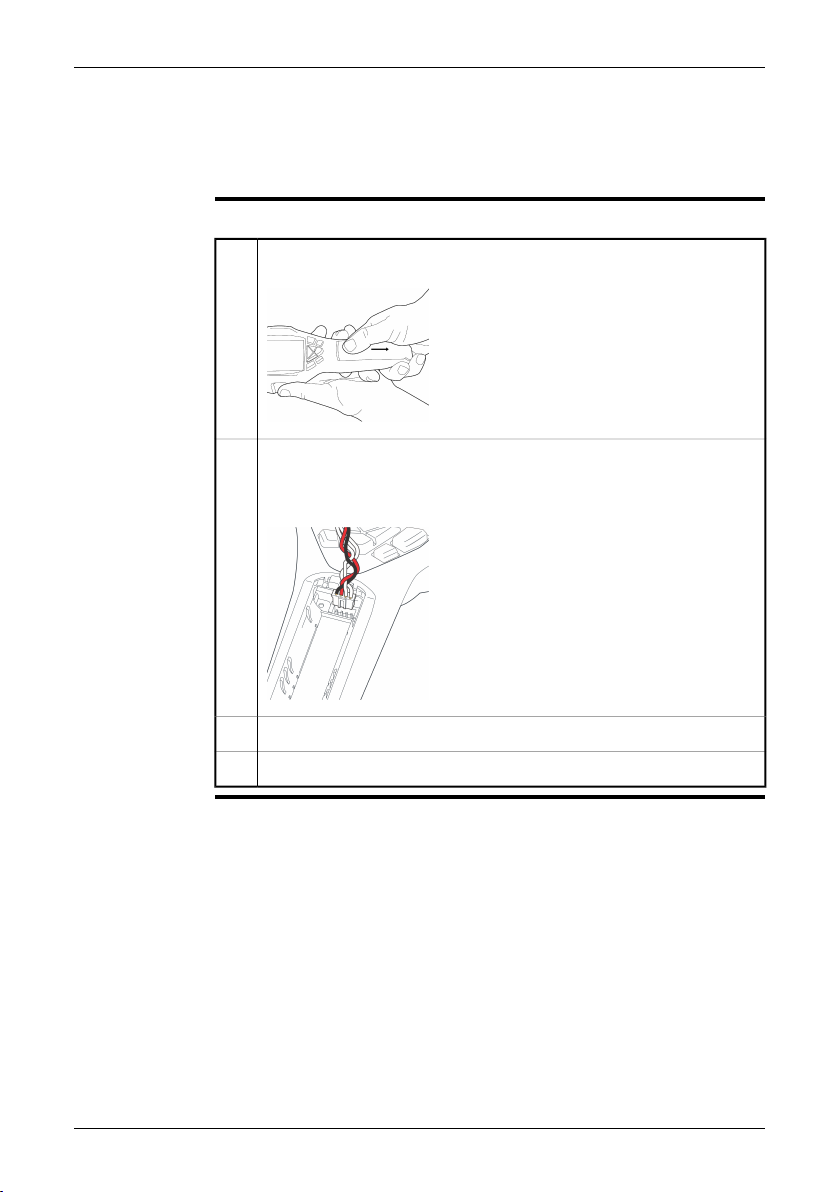

Procedure

Follow this procedure to install the battery:

Remove the battery compartment cover.

1

T630174;a1

Connect the cable that is attached to the battery to the connector inside

2

the battery compartment. Note: Do not use conductive tools when doing

this.

T630173;a2

Push the battery into place.3

Replace the cover to close the battery compartment.4

16 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 27

11.2 Charging the battery

You must charge the battery inside the camera for four full hours (or until the

NOTE

■

battery indicator displays a green light) before you use the camera for the first

time.

The first time you charge a factory-new battery you must turn on and then turn off

■

the camera after you have connected the power supply to the power connector

on the camera.

If the camera does not start after you have charged the battery, push the reset

■

button with a non-conductive tool. The reset button is located beside the battery

connector, inside the battery compartment. Then press the On/Off button again.

The reset button:

T630179;a1

Do not replace the battery on a frequent basis. Only replace the battery when it

■

is worn out.

11 – Using the camera

About the battery

charging indicator

Procedure

The battery charging indicator is an LED beside the power connector. It displays the

following signals:

No light: The power supply is not connected.

■

Orange light: The battery is being charged.

■

Green light: The charging of the battery is completed.

■

Follow this procedure to charge the battery:

Connect the power supply to the power connector on the camera.

1

T630175;a1

1 Battery charging indicator

2 Power supply cable

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 17

Page 28

11 – Using the camera

Connect the power supply mains-electricity plug to a mains socket. Make

2

sure that you use the correct AC plug.

Disconnect thepower supply cableplug when thebattery charging indicator

3

displays a green light.

18 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 29

11.3 Saving an image

11 – Using the camera

General

Image capacity

Formatting

memory cards

Naming

convention

You can save multiple images to the miniSD™ memory card.

We recommend that you do not save more than 5,000 images on the miniSD™

memory card.

Although amemory card mayhave a highercapacity than 5,000images, saving more

than that number of images severely slows down file management on the memory

card.

Note: There is no upper limit to the memory size of the miniSD™ memory card.

For best performance, memory cards should be formatted to the FAT (FAT16) file

system. Using FAT32-formatted memory cards may result in inferior performance.

To format a memory card to FAT (FAT16), follow this procedure:

Insert the memory card into a card reader that is connected to your com-

1

puter.

In Windows®Explorer, select My Computer and right-click the memory

2

card.

Select Format.3

Under File system, select FAT.4

Click Start.5

The naming convention for images is IR_xxxx.jpg, where xxxx is a unique counter.

When you select Restore, the cameraresets the counterand assigns thenext highest

free file name for the new file.

Procedure

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 19

To save an image, pull the Save trigger.

Page 30

11 – Using the camera

11.4 Recalling an image

General

Procedure

When you save an image, it is stored on the removable miniSD™ memory card. To

display the image again, you can recall it from the miniSD™ memory card.

Follow this procedure to recall an image:

Push the Archive button.1

Do one of the following:

2

Push the navigation pad left/right to select the image you want to view.

■

Push the + button, use the navigation pad to selectthe image you want

■

to see, then push the right selection button (Open).

To return to live mode, do one of the following:

3

Push the Archive button.

■

Push the right selection button (Close).

■

20 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 31

11.5 Opening the image archive

11 – Using the camera

General

Procedure

The image archive is a thumbnail gallery of all the images on the miniSD™ memory

card.

Follow this procedure to open the image archive:

Push the Archive button.1

Push the + button on the navigation pad.

2

This will display the image archive. You can now use the navigation pad to

navigate in the archive.

To open a selected image, push the right selection button (Open).3

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 21

Page 32

11 – Using the camera

11.6 Deleting an image

General

Alternative 1

Alternative 2

You can delete one or more images from the miniSD™ memory card.

Follow this procedure to delete an image:

Push the Archive button.1

Push the + button. This will display the image archive.2

Select the image you want to delete by using the navigation pad.3

Push the left selection button (Options).4

Use the navigation pad to select Delete image.5

Push the left selection button (Select).6

Push the right selection button to confirm (Delete).7

To return to live mode, do one of the following:

8

Push the Archive button.

■

Push the right selection button (Close).

■

Follow this procedure to delete an image:

Push the Archive button.1

Select the image you want to delete by using the navigation pad.2

Push the left selection button (Delete).3

Push the right selection button to confirm (Delete).4

To return to live mode, do one of the following:

5

Push the Archive button.

■

Push the right selection button (Close).

■

22 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 33

11.7 Deleting all images

11 – Using the camera

General

Procedure

You can delete all images from the miniSD™ memory card.

Follow this procedure to delete all images:

Push the Archive button.1

Push the + button. This will display the image archive2

Push the left selection button (Options).3

Use the navigation pad to select Delete all images.4

Push the left selection button (Select).5

Push the right selection button to confirm (Delete).6

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 23

Page 34

11 – Using the camera

11.8 Measuring a temperature using a spotmeter

General

Procedure

You can measure a temperature using a spotmeter. This will display the temperature

at the position of the spotmeter on the screen.

Follow this procedure:

Push the left selection button (Menu).1

Use the navigation pad to select Measurement.2

Push the left selection button (Select).3

Use the navigation pad to select Spot.4

Push the left selection button (Select).

5

The temperature at the position of the spotmeter will now displayed in the

top left corner of the screen.

24 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 35

11.9 Measuring a temperature using an area

11 – Using the camera

General

Procedure

You can continuouslyindicate the highestor lowest temperature within anarea, using

a continuously moving cursor.

Follow this procedure:

Push the left selection button (Menu).1

Use the navigation pad to select Measurement.2

Push the left selection button (Select).3

Use the navigation pad to select one of the following:

4

Area max.

■

Area min.

■

Push the left selection button (Select).

5

The highest or lowest temperature within the area will now be indicated by

a continuously moving cursor.

The temperature will also be displayed in the top left corner of the screen.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 25

Page 36

11 – Using the camera

11.10 Marking all areas above or below a set temperature level

General

Procedure

You can mark all areas above or below a set temperature level.

Follow this procedure:

Push the left selection button (Menu).1

Use the navigation pad to select Measurement.2

Push the left selection button (Select).3

Use the navigation pad to select one of the following:

4

Detect above

■

Detect below

■

Push the left selection button (Select).5

To change the temperature level above or below which you want to mark

6

the areas, use the navigation pad.

26 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 37

11.11 Changing the color palette

11 – Using the camera

General

Procedure

You can change the color palette that the camera uses to display different temperatures. A different palette can make it easier to analyze an image.

Follow this procedure to change the color palette:

Push the left selection button (Menu).1

Use the navigation pad to go to Color palette.2

Push the left selection button (Select). This will display the Color palette

3

submenu.

Use the navigation pad to select the new color palette.4

Push the left selection button (Select) to confirm the choice and leave the

5

submenu.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 27

Page 38

11 – Using the camera

11.12 Changing the settings

General

Procedure

You can change a variety of settings for the camera. These include the following:

Auto shutdown

■

Display intensity

■

Language

■

Unit

■

Time format

■

Set time

■

Time stamp

■

Firmware (to download program updates for your camera. See http://flir.cus-

■

thelp.com for more information.)

Restore

■

Follow this procedure to change a setting:

Push the left selection button (Menu).1

Use the navigation pad to go to Settings.2

Push the left selection button (Select). This will display the Settings sub-

3

menu.

Use the navigation pad to select the setting you want to change.4

Push the left selectionbutton (Select), then usethe navigationpad to select

5

a new setting.

Push the left selection button (Select) to confirm the choice and leave the

6

submenu, or push the right selection button (Close) to leave the menu.

28 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 39

11.13 Changing the image mode

11 – Using the camera

General

When to use

Locked mode

Procedure

The camera can operate in two different image modes:

ExplanationIconImage mode

[None]Auto

Locked

A typical situation when you would want to use Locked mode is when looking for

temperature anomalies in two items of similar design or construction.

For example, if you are looking at two cables, where you suspect one is overheated,

working inLocked mode willclearly show that oneis overheated. Thehighertemperature in that cable would create a lighter color for the higher temperature.

If you use Auto mode instead, the color for the two items will appear the same.

To switch between Auto mode and Locked mode, push the right selection button

(Auto/Locked). A padlock icon ( ) indicates the Locked mode.

In Auto mode, the camera is continuously autoadjusted for best image

brightness and contrast.

In Locked mode, the

camera locksthe temperature span and the temperature level.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 29

Page 40

11 – Using the camera

11.14 Setting the surface properties

General

Procedure

SEE ALSO

To measure temperatures accurately, the camera must know what kind of surface

you are measuring.

The easiest way to do this is to set the surface property on the Measure menu. You

can choose between the following surface properties:

Matt

■

Semi-matt

■

Semi-glossy

■

Glossy

■

Follow this procedure to set the surface property:

Push the left selection button (Menu).1

Use the navigation pad to go to Measure.2

Push the left selection button (Select). This will display the Measure sub-

3

menu.

On the Measure menu, use thenavigation pad to select asurface property.4

Push the left selection button (Select) to confirm the choice and leave the

5

menu.

For more precise measurements, see the following sections:

Section 11.15 – Changing the emissivity on page 31

■

Section 11.16 – Changing the reflected apparent temperature on page 32

■

30 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 41

11.15 Changing the emissivity

11 – Using the camera

General

Procedure

For very precise measurements, you may need to set the emissivity, instead of selecting a surface property. You also need to understand how emissivity and reflectivity affect measurements, rather than just simply selecting a surface property.

Emissivity is a property that indicates how much radiation originates from an object

as opposed to being reflected by it. A lower value indicates that a larger proportion

is beingreflected, while ahigh value indicates thata lower proportionis being reflected.

Polished stainless steel, for example, has an emissivity of 0.14, while a structured

PVC floor typically has an emissivity of 0.93.

Follow this procedure to set the emissivity:

Push the left selection button (Menu).1

Use the navigation pad to go to Measure.2

Push the left selection button (Select). This will display the Measure sub-

3

menu.

Use the navigation pad to select Advanced.4

Push the left selection button (Select). This will display the Advanced sub-

5

menu.

Use the navigation pad to do either of the following:

6

Set a value for emissivity

■

Select a material in the list of materials

■

Push the left selection button (Select) to confirm the choice and leave the

7

menu.

SEE ALSO

To read more about emissivity, see section 20 – Thermographic measurement techniques on page 127.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 31

Page 42

11 – Using the camera

11.16 Changing the reflected apparent temperature

General

Procedure

SEE ALSO

This parameter is used to compensate for the radiation reflected by the object. If the

emissivity is low and the object temperature relatively far from that of the reflected

temperature it will be important to set and compensate for the reflected apparent

temperature correctly.

Follow this procedure to set the reflected apparent temperature:

Push the left selection button (Menu).1

Use the navigation pad to go to Measure.2

Push the left selection button (Select). This will display the Measure sub-

3

menu.

Use the navigation pad to select Advanced.4

Push the left selection button (Select). This will display the Advanced sub-

5

menu.

Use the navigation pad to set the reflected apparent temperature.6

Push the left selection button (Select) to confirm the choice and leave the

7

menu.

To read more about the reflected apparent temperature, see section 20 – Thermographic measurement techniques on page 127.

32 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 43

11.17 Resetting the camera

11 – Using the camera

General

NOTE

Procedure

If you need toreset the camera,there is areset buttoninside the batterycompartment.

Do not use a metal or other conductive tool to reset the camera.

Follow this procedure to reset the camera:

Open the battery compartment cover.1

To locate the reset button, see the figure below.

2

T630179;a1

Use a non-conductive tool to push reset button. The camera will now be

3

reset.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 33

Page 44

11 – Using the camera

11.18 Finding the serial number of the camera

General

When you communicate with our service departments, you may need to state the

serial number of the camera.

The serial number is printed on a label inside the battery compartment, behind the

battery.

34 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 45

12 Cleaning the camera

12.1 Camera housing, cables, and other items

Liquids

Equipment

Procedure

CAUTION

Use one of these liquids:

Warm water

■

A weak detergent solution

■

A soft cloth

Follow this procedure:

Soak the cloth in the liquid.1

Twist the cloth to remove excess liquid.2

Clean the part with the cloth.3

Do not apply solvents or similar liquids to the camera, the cables, or other items.

This can cause damage.

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 35

Page 46

12 – Cleaning the camera

12.2 Infrared lens

Liquids

Equipment

Procedure

WARNING

CAUTION

Use one of these liquids:

96% isopropyl alcohol.

■

A commercial lens cleaning liquid with more than 30% isopropyl alcohol.

■

Cotton wool

Follow this procedure:

Soak the cotton wool in the liquid.1

Twist the cotton wool to remove excess liquid.2

Clean the lens one time only and discard the cotton wool.3

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and

warning labels on containers before you use a liquid: the liquids can be dangerous.

Be careful when you cleanthe infraredlens. The lens has a delicate anti-reflective

■

coating.

Do not clean the infrared lens too vigorously. This can damage the anti-reflective

■

coating.

36 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 47

13 Technical data

13.1 Camera data

Imaging and

optical data

Detector data

Image

presentation

Measurement

Field of view (FOV) Dependent on the camera:

17° × 17° (FLIR i5 (2009 model))

■

25° × 25° (FLIR i7)

■

0.6 m (2 ft.)Minimum focus distance

3.71 mradSpatial resolution (IFOV)

< 0.1°C (0.18°F)Thermal sensitivity/NETD

9 HzImage frequency

Focus freeFocus

Detector type Focal plane array (FPA), uncooled microbolometer

7.5–13 µmSpectral range

IR resolution

Display 2.8 in. color LCD

Object temperature

range

Dependent on the camera:

80 × 80 pixels (FLIR i5 (2009 model))

■

120 × 120 pixels (FLIR i7)

■

Automatic adjust/lock imageImage adjustment

0°C to +250°C (+32° to +482°F)

Accuracy

Measurement

analysis

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 37

Spotmeter Center spot

Area

Isotherm

±2°C (±3.6°F)or ±2% ofreading, for ambienttemperature 10°C to 35°C (+50°F to 95°F)

Dependent on the camera:

Not applicable (FLIR i5 (2009 model))

■

Box with max./min. (FLIR i7)

■

Dependent on the camera:

Not applicable (FLIR i5 (2009 model))

■

Above/below (FLIR i7)

■

Variable from 0.1 to 1.0Emissivity correction

Page 48

13 – Technical data

Emissivity table of predefined materialsEmissivity table

Automatic, based on input of reflected temperatureReflected apparent tem-

perature correction

Set-up

Storage of images

Data

communication

interfaces

Power system

Environmental

data

Color palettes Black and white, iron and rainbow

Set-up commands

Local adaptation of units, language, date and time

formats

Image storage type miniSD card

Standard JPEG, 14-bit measurement data includedFile formats

Interfaces USB Mini-B: Data transfer to and from PC

Battery type Rechargeable Li Ion battery

3.6 VBattery voltage

Battery operating time

Approx. 5 hours at +25°C (+77°F) ambient temperature and typical use

Battery is charged inside the camera.Charging system

3 h to 90% capacityCharging time

Automatic shut-downPower management

AC adapter, 90–260 VAC input, 5 V output to cameraAC operation

Operating temperature

0°C to +50°C (+32°F to +122°F)

range

–40°C to +70°C (–40°F to +158°F)Storage temperature

range

IEC 60068-2-30/24 h 95% relative humidityHumidity (operating and

storage)

EMC

EN 61000-6-2:2005 (Immunity)

■

EN 61000-6-3:2007 (Emission)

■

FCC 47 CFR Part 15 Class B (Emission)

■

Camera housing and lens: IP 43 (IEC 60529)Encapsulation

25 g (IEC 60068-2-29)Bump

2 g (IEC 60068-2-6)Vibration

38 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 49

13 – Technical data

Physical data

Certifications

Scope of delivery

Camera weight, incl. bat-

0.34 kg (0.75 lb.)

tery

223 × 79 × 83 mm (8.8 × 3.1 × 3.3 in.)Camera size(L× W × H)

Material

Polycarbonate + acrylonitrile butadiene styrene (PCABS)

Thixomold magnesium

Thermoplastic elastomer (TPE)

Blue and grayColor

Certification UL, CSA, CE, PSE and CCC

Packaging, type Hard case

Packaging, contents

FLIR QuickReport CD

■

Printed Getting Started Guide

■

User documentation CD-ROM

■

Calibration certificate

■

Hand strap

■

Battery (inside camera)

■

Power supply/charger with EU, UK, US and Aus-

■

tralian plugs

USB cable

■

miniSD card (512 MB), with SD card adapter

■

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 39

Page 50

13 – Technical data

13.2 Additional data

Field of view &

distance (FLIR i5)

10780503;a1

Figure 13.1 Relationship between the fieldof viewand distance. 1: Distance to target;

2: VFOV =vertical field ofview; 3: HFOV =horizontal field of view, 4: IFOV = instan-

taneous field of view (size of one detector element).

This table gives examples ofthe field of view for different target distances. Note: The

table does not take into account the minimum focus distance.

10781103;a1

40 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 51

Field of view &

distance (FLIR i7)

13 – Technical data

10780503;a1

Figure 13.2 Relationship between the fieldof viewand distance. 1: Distance to target;

2: VFOV =vertical field ofview; 3: HFOV =horizontal field of view, 4: IFOV = instan-

taneous field of view (size of one detector element).

This table gives examples ofthe field of view for different target distances. Note: The

table does not take into account the minimum focus distance.

T638201;a1

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 41

Page 52

13 – Technical data

13.3 Accessories data

USB cable Std A

↔ Mini B, 2 m/6.6

ft.

Battery

Power

supply/charger

with EU, UK, US

and AU plugs

Memory card, 512

MB miniSD

Cable length 2.0 m (6.6 ft.)

Standard USB-A to USB Mini-BConnector

Battery type Rechargeable Li Ion battery

3.6 VBattery voltage

Approximate lithium content: 0.7 gBattery note

Battery is charged inside the cameraCharging system

AC operation 100–240 V, 50/60 Hz output 5.0 VAC, 1.2 A

6 WPower

69.2 × 43.3 × 29.8 mm (2.7 × 1.7 × 1.2 in.)Size (L × W × H)

1.8 m (5.9 ft.)Cable length

Packaging, contents

Power supply/Battery charger

■

EU, UK, US and Australian plugs

■

512 MBMemory card, size

21.5 × 20 × 1.4 mm (0.85 × 0.79 × 0.06 in.)Size (L × W × H)

Packaging, contents

miniSD card

■

Adapter from miniSD Card to SD Memory Card

■

42 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 53

14 Dimensions

14.1 Camera (front)

Figure

10780603;a1

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 43

Page 54

14 – Dimensions

14.2 Camera (side)

Figure

10780703;a1

44 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 55

15 Application examples

15.1 Moisture & water damage

General

NOTE

Figure

It is often possible to detect moisture and water damage in a house by using an infrared camera. This ispartly becausethe damaged area has adifferent heat conduction property and partly because it has a differentthermal capacity to storeheat than

the surrounding material.

Many factors can come into play as to how moisture or water damage will appear in

an infrared image.

For example,heating and coolingof these parts takes placeat different ratesdepending on the material and the time of day. For this reason, it is important that other

methods are used as well to check for moisture or water damage.

The imagebelow shows extensive waterdamage on anexternalwall where thewater

has penetrated the outer facing because of an incorrectly installed window ledge.

10739503;a1

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 45

Page 56

15 – Application examples

15.2 Faulty contact in socket

General

NOTE

Figure

Depending on the type of connection a socket has, an improperly connected wire

can result in local temperature increase. This temperature increase is caused by the

reduced contact area between the connection point of the incoming wire and the

socket , and can result in an electrical fire.

A socket’s construction may differ dramatically from one manufacturer to another.

For this reason, different faults in a socket can lead to the same typical appearance

in an infrared image.

Local temperature increase can also result from improper contact between wire and

socket, or from difference in load.

The image below shows aconnection ofa cable to a socket where improper contact

in the connection has resulted in local temperature increase.

10739603;a1

46 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 57

15.3 Oxidized socket

15 – Application examples

General

NOTE

Figure

Depending on the typeof socket andthe environment in which thesocket is installed,

oxides may occur on the socket's contact surfaces. These oxides can lead to locally

increased resistance when the socket is loaded, which can be seen in an infrared

image as local temperature increase.

A socket’s construction may differ dramatically from one manufacturer to another.

For this reason, different faults in a socket can lead to the same typical appearance

in an infrared image.

Local temperature increase can also result from improper contact between a wire

and socket, or from difference in load.

The image below shows a series of fuses where one fuse has a raised temperature

on the contact surfaces against the fuse holder. Because of the fuse holder’s blank

metal, the temperature increase is not visible there, while it is visible on the fuse’s

ceramic material.

10739703;a1

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 47

Page 58

15 – Application examples

15.4 Insulation deficiencies

General

NOTE

Figure

Insulation deficiencies may result from insulation losing volume over the course of

time and thereby not entirely filling the cavity in a frame wall.

An infraredcamera allowsyou to seethese insulation deficienciesbecause they either

have a different heat conduction property than sections with correctly installed insulation, and/or show the area where air is penetrating the frame of the building.

When you are inspecting a building, the temperature difference between the inside

and outside should be at least 10°C (18°F). Studs, water pipes, concrete columns,

and similar components may resemble an insulation deficiency in an infrared image.

Minor differences may also occur naturally.

In the image below, insulation in the roof framing is lacking.. Due to the absence of

insulation, air has forcedits way into the roof structure, whichthus takes on a different

characteristic appearance in the infrared image.

10739803;a1

48 Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

Page 59

15.5 Draft

15 – Application examples

General

NOTE

Figure

Draft can be found under baseboards, around door and window casings, and above

ceiling trim. This type of draft is often possible to see with an infrared camera, as a

cooler airstream cools down the surrounding surface.

When youare investigating draftin a house,there should besub-atmosphericpressure

in the house. Close all doors, windows, and ventilation ducts, and allow the kitchen

fan to run for a while before you take the infrared images.

An infrared image of draft often shows a typical stream pattern. You can see this

stream pattern clearly in the picture below.

Also keep in mind that drafts can be concealed by heat from floor heating circuits.

The image below shows a ceiling hatch where faulty installation has resulted in a

strong draft.

10739903;a1

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009 49

Page 60

16 Introduction to building

thermography

16.1 Important note

All camera functions and features that are described in this section may not be supported by your particular camera configuration.

16.2 Typical field investigations

16.2.1 Guidelines

As will be noted in subsequent sections there are a number of general guidelines the

user should take heed of when carrying out building thermography inspection. This

section gives a summary of these guidelines.

16.2.1.1 General guidelines

■ The emissivity of the majority of building materials fall between 0.85 and 0.95.

Setting the emissivity value in the camera to 0.90 can be regarded as a good

starting point.

■ An infrared inspection alone should never be used as a decision point for further