Page 1

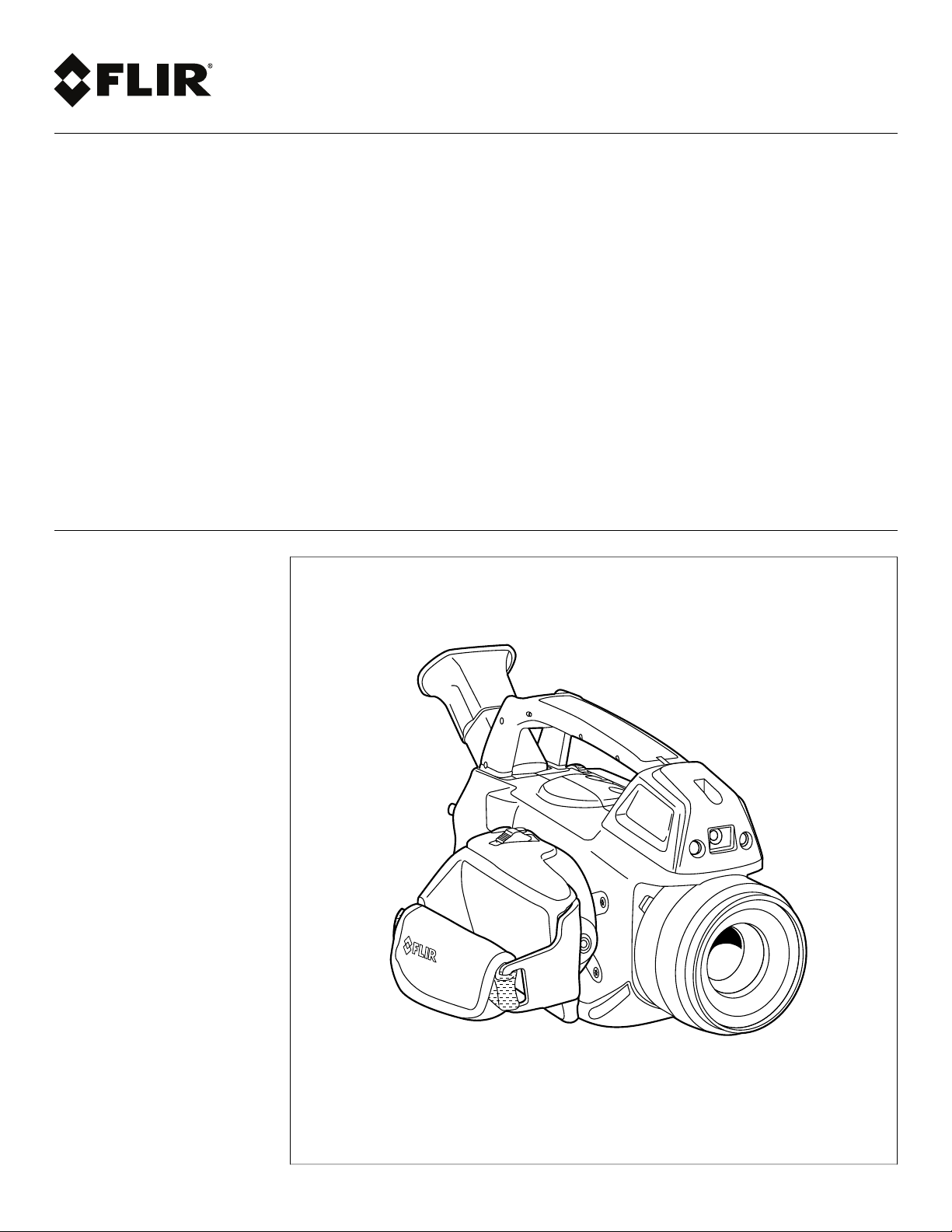

User’s manual

FLIR GF3xx series

Page 2

Page 3

User’s manual

FLIR GF3xx series

#T559157; r. AH/45951/45951; en-US

iii

Page 4

Page 5

Table of contents

1 Disclaimers ........................... ................................. ............................1

1.1 Legal disclaimer ......................................................................... 1

1.2 U.S. Government Regulations........................................................1

1.3 Level 1 statement........................................................................1

1.4 Copyright ..................................................................................2

1.5 Quality assurance .......................................................................2

1.6 Patents..................................................................................... 2

1.7 EULA Terms ..............................................................................2

1.8 EULA Terms ..............................................................................3

2 Safety information ......................... ................................. .....................5

3 Notice to user ............................ ............................... .. ...................... 10

3.1 User-to-user forums .................................................................. 10

3.2 Calibration............................................................................... 10

3.3 Accuracy ................................................................................ 10

3.4 Disposal of electronic waste........................................................ 10

3.5 Training .................................................................................. 10

3.6 Documentation updates ............................................................. 11

3.7 Note about authoritative versions.................................................. 11

4 Customer help ........................... ............................... .. ...................... 12

4.1 General .................................................................................. 12

4.2 Submitting a question ................................................................ 12

4.3 Downloads .............................................................................. 13

5 Important note about training and applications............. .. ...................... 14

5.1 General .................................................................................. 14

6 List of accessories and services ........ .. ............................... ................ 15

7 Introduction................... .. ............................... ................................. . 17

7.1 FLIR GF300............................................................................. 17

7.1.1 Optical gas imaging of methane and other volatile organic

7.1.2 Benefits ....................................................................... 17

7.2 FLIR GF304............................................................................. 17

7.2.1 Optical gas imaging of refrigerant gases.............................. 17

7.2.2 Benefits ....................................................................... 17

7.3 FLIR GF306............................................................................. 18

7.3.1 Optical gas imaging especially of SF6 and ammonia .............. 18

7.3.2 Benefits ....................................................................... 18

7.4 FLIR GF309............................................................................. 18

7.4.1 IR camera for furnace and high temperature

7.4.2 Benefits ....................................................................... 19

7.5 FLIR GF320............................................................................. 19

7.5.1 Optical gas imaging of methane and other volatile organic

7.5.2 Benefits ....................................................................... 19

7.6 FLIR GF335............................................................................. 20

7.6.1 Benefits ....................................................................... 20

7.7 FLIR GF343............................................................................. 20

7.7.1 The new FLIR GF343 is an optical gas camera for

7.7.2 Main applications ........................................................... 20

compounds (VOCs) ........................................................ 17

inspection..................................................................... 18

compounds (VOCs) ........................................................ 19

visualizing carbon dioxide (CO

......................................... 20

2

#T559157; r. AH/45951/45951; en-US

v

Page 6

Table of contents

7.8 FLIR GF346............................................................................. 21

7.8.1 Optical gas imaging especially of carbon monoxide (CO)

and other harmful gases .................................................. 21

7.8.2 Benefits ....................................................................... 21

8 Example images ...... .. ............................... ............................... .. ........ 22

8.1 General .................................................................................. 22

8.2 Images ................................................................................... 22

9 Quick Start Guide .................. .. ............................... .... ....................... 23

9.1 Detecting a temperature............................................................. 23

9.1.1 Procedure .................................................................... 23

9.1.2 Related topics ............................................................... 24

9.2 Detecting a gas leak .................................................................. 24

9.2.1 Procedure .................................................................... 24

9.2.2 Related topics ............................................................... 25

10 FLIR GF3xx series series general instrument check.. ............................. 26

11 A note about ergonomics .......................... ............................... .. ........ 27

11.1 General .................................................................................. 27

11.2 Figure .................................................................................... 27

11.3 Related topics .......................................................................... 28

12 Camera parts ........ ............................... ................................. ............ 29

12.1 View from the left ...................................................................... 29

12.1.1 Figure.......................................................................... 29

12.1.2 Explanation................................................................... 29

12.2 View from the right .................................................................... 30

12.2.1 Figure.......................................................................... 30

12.2.2 Explanation................................................................... 30

12.3 View from the rear..................................................................... 31

12.3.1 Figure.......................................................................... 31

12.3.2 Explanation................................................................... 31

12.4 Battery condition LED indicator .................................................... 32

12.4.1 Figure.......................................................................... 32

12.4.2 Explanation................................................................... 32

12.5 Power LED indicator .................................................................. 32

12.5.1 Figure.......................................................................... 32

12.5.2 Explanation................................................................... 33

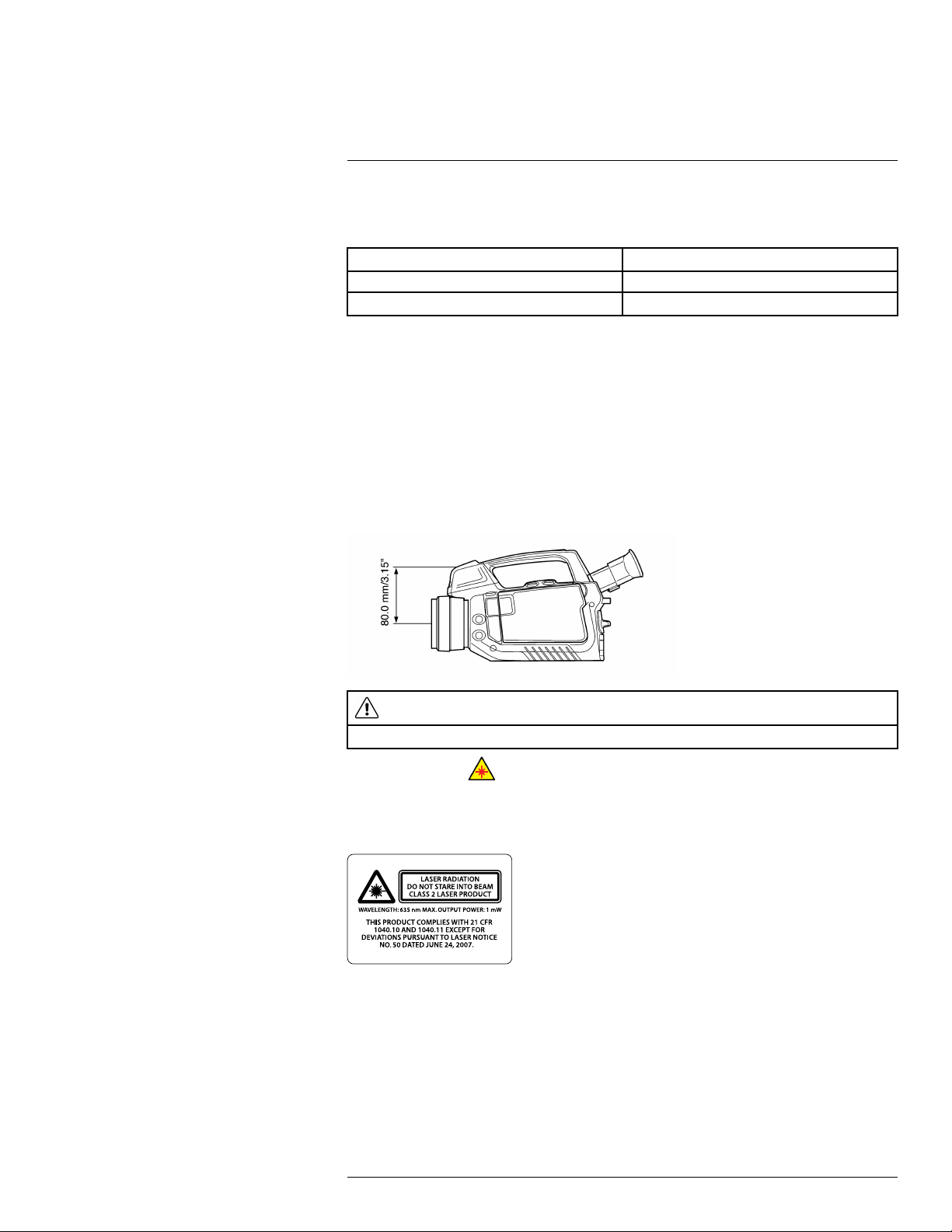

12.6 Laser pointer ........................................................................... 33

12.6.1 General........................................................................ 33

12.6.2 Figure.......................................................................... 33

12.6.3 Laser warning label......................................................... 33

12.6.4 Laser rules and regulations .............................................. 33

13 Screen elements .. ................................. ............................... ............. 34

13.1 Mode selector .......................................................................... 34

13.1.1 Figure.......................................................................... 34

13.1.2 Explanation................................................................... 34

13.2 Result table and measurement tools ............................................. 34

13.2.1 Figure.......................................................................... 34

13.2.2 Explanation................................................................... 34

13.3 Toolbox, indicators, and other objects............................................ 35

13.3.1 Figure.......................................................................... 35

13.3.2 Explanation................................................................... 35

#T559157; r. AH/45951/45951; en-US

vi

Page 7

Table of contents

14 Achieving a good image .................. ............................... .................... 36

14.1 General .................................................................................. 36

14.2 Adjusting the infrared camera focus manually ................................. 36

14.2.1 Figure.......................................................................... 36

14.2.2 Procedure .................................................................... 36

14.3 Adjusting the infrared camera focus .............................................. 37

14.3.1 Figure.......................................................................... 37

14.3.2 Procedure .................................................................... 37

14.4 Adjusting an image.................................................................... 37

14.4.1 General........................................................................ 37

14.4.2 Explanation of the adjustment methods ............................... 37

14.4.3 Procedure (Auto)............................................................ 37

14.4.4 Figure.......................................................................... 38

14.4.5 Procedure (HSM) ........................................................... 38

14.4.6 Procedure (Manual) ........................................................ 38

14.5 Selecting a suitable temperature range .......................................... 38

14.5.1 About temperature ranges................................................ 38

14.5.2 Understanding the temperature scale ................................. 39

14.5.3 Changing the temperature range ....................................... 40

14.6 Selecting a suitable color palette .................................................. 40

14.6.1 Procedure .................................................................... 40

14.7 Enabling or disabling histogram mode ........................................... 40

14.7.1 General........................................................................ 40

14.7.2 Procedure .................................................................... 40

14.8 Enabling or disabling inverted color palette ..................................... 41

14.8.1 Procedure .................................................................... 41

14.9 Changing object parameters ....................................................... 41

14.9.1 General........................................................................ 41

14.9.2 Types of parameters ....................................................... 41

14.9.3 Recommended values..................................................... 41

14.9.4 Procedure .................................................................... 42

14.9.5 Related topics ............................................................... 42

15 Connecting external devices................... ............................... ............. 43

15.1 General .................................................................................. 43

15.2 Related topics .......................................................................... 43

15.3 Connecting devices to the rear connectors ..................................... 43

15.3.1 Figure.......................................................................... 43

15.3.2 Explanation................................................................... 43

15.3.3 Figure.......................................................................... 44

15.3.4 Explanation................................................................... 44

15.4 Inserting SD Memory Cards ........................................................ 44

15.4.1 Figure.......................................................................... 44

15.4.2 Explanation................................................................... 44

15.4.3 Formatting memory cards ................................................ 45

16 Handling the camera.......................... .. .. ........................... .. .. ............. 46

16.1 Charging the camera battery ....................................................... 46

16.1.1 Charging the battery using the power supply cable ................ 46

16.1.2 Charging the battery using the stand-alone battery

charger ........................................................................ 46

16.2 Installing and removing the camera battery..................................... 47

16.2.1 Installing the battery........................................................ 47

#T559157; r. AH/45951/45951; en-US

vii

Page 8

Table of contents

16.2.2 Removing the battery ...................................................... 48

16.3 Turning on the camera ............................................................... 49

16.3.1 Procedure .................................................................... 49

16.4 Turning off the camera ............................................................... 49

16.4.1 Procedure .................................................................... 49

16.5 Adjusting the viewing angle of the viewfinder................................... 49

16.5.1 General........................................................................ 49

16.5.2 Figure.......................................................................... 49

16.5.3 Procedure .................................................................... 49

16.6 Adjusting the viewfinder’s dioptric correction ................................... 50

16.6.1 General........................................................................ 50

16.6.2 Figure.......................................................................... 50

16.6.3 Procedure .................................................................... 50

16.7 Adjusting the camera grip ........................................................... 50

16.7.1 General........................................................................ 50

16.7.2 Figure.......................................................................... 51

16.7.3 Procedure .................................................................... 51

16.8 Opening the display................................................................... 51

16.8.1 Figure.......................................................................... 51

16.9 Adjusting the viewing angle of the display....................................... 52

16.9.1 General........................................................................ 52

16.9.2 Figure.......................................................................... 52

16.9.3 Procedure .................................................................... 52

16.10 Installing an infrared lens ............................................................ 52

16.10.1 Procedure .................................................................... 52

16.11 Removing an infrared lens .......................................................... 53

16.11.1 Procedure .................................................................... 53

16.12 Mounting the heatshield ............................................................. 54

16.12.1 General........................................................................ 54

16.12.2 Procedure .................................................................... 54

16.13 Adjusting the infrared camera focus manually ................................. 56

16.13.1 Figure.......................................................................... 56

16.13.2 Procedure .................................................................... 56

16.14 Adjusting the infrared camera focus .............................................. 57

16.14.1 Figure.......................................................................... 57

16.14.2 Procedure .................................................................... 57

16.15 Autofocusing the infrared camera and the digital camera ................... 58

16.15.1 Figure.......................................................................... 58

16.15.2 Procedure .................................................................... 58

16.16 Operating the laser pointer.......................................................... 59

16.16.1 Figure.......................................................................... 59

16.16.2 Procedure .................................................................... 59

16.16.3 Laser warning label......................................................... 59

16.17 Using the zoom function ............................................................. 59

16.17.1 General........................................................................ 59

16.17.2 Procedure .................................................................... 59

17 Working with views and images. ...... ................................. ................... 60

17.1 Saving infrared images............................................................... 60

17.1.1 General........................................................................ 60

17.1.2 Image capacity .............................................................. 60

#T559157; r. AH/45951/45951; en-US

viii

Page 9

Table of contents

17.1.3 Saving an infrared image directly to an SD Memory

Card............................................................................ 60

17.1.4 Previewing and saving an infrared image to an SD

Memory Card ................................................................ 60

17.2 Opening an image..................................................................... 61

17.2.1 General........................................................................ 61

17.2.2 Procedure .................................................................... 61

17.3 Changing settings related to image presentation.............................. 61

17.3.1 General........................................................................ 61

17.3.2 Procedure .................................................................... 62

17.4 Editing a saved image ................................................................ 62

17.4.1 General........................................................................ 62

17.4.2 Procedure .................................................................... 62

17.5 Deleting a file........................................................................... 63

17.5.1 Procedure .................................................................... 63

18 Working with measurement tools .... ................................. ................... 64

18.1 Laying out a measurement tool .................................................... 64

18.1.1 General........................................................................ 64

18.1.2 Procedure .................................................................... 64

18.2 Moving or resizing a measurement tool .......................................... 64

18.2.1 General........................................................................ 64

18.2.2 Procedure .................................................................... 64

18.3 Creating & setting up a difference calculation .................................. 64

18.3.1 General........................................................................ 64

18.3.2 Procedure .................................................................... 65

18.4 Changing object parameters ....................................................... 65

18.4.1 General........................................................................ 65

18.4.2 Types of parameters ....................................................... 65

18.4.3 Recommended values..................................................... 66

18.4.4 Procedure .................................................................... 66

18.4.5 Related topics ............................................................... 67

19 Programming the camera ...................... ................................. ............ 68

19.1 General .................................................................................. 68

19.2 Procedure ............................................................................... 68

20 Recording video clips ........................... ................................. ............ 69

20.1 General .................................................................................. 69

20.2 Procedure ............................................................................... 69

21 Changing settings . ............................... ................................. ............ 70

21.1 General .................................................................................. 70

21.2 Procedure ............................................................................... 70

21.3 Connecting the camera using a peer-to-peer (ad hoc) WLAN

network .................................................................................. 70

21.3.1 General........................................................................ 70

21.3.2 Procedure .................................................................... 70

21.3.3 Related topics ............................................................... 71

21.4 Connecting the camera using a infrastructure WLAN network ............. 71

21.4.1 General........................................................................ 71

21.4.2 Procedure .................................................................... 71

21.4.3 Related topics ............................................................... 71

21.5 Changing Wi-Fi settings ............................................................. 71

21.5.1 General........................................................................ 71

#T559157; r. AH/45951/45951; en-US

ix

Page 10

Table of contents

21.5.2 Procedure .................................................................... 71

21.5.3 Related topics ............................................................... 72

22 Technical data ........................ .. .. ............................. .. .. ...................... 73

22.1 Online field-of-view calculator ...................................................... 73

22.2 Note about technical data ........................................................... 73

22.3 Note about authoritative versions.................................................. 74

22.4 FLIR GF300 14.5°..................................................................... 75

22.5 FLIR GF300 14.5° Fixed lens....................................................... 80

22.6 FLIR GF300 24° ....................................................................... 85

22.7 FLIR GF300 24° Fixed lens ......................................................... 90

22.8 FLIR GF304 14.5°..................................................................... 95

22.9 FLIR GF304 14.5° Fixed lens..................................................... 101

22.10 FLIR GF304 24° ..................................................................... 106

22.11 FLIR GF304 24° Fixed lens ....................................................... 112

22.12 FLIR GF306 14.5°................................................................... 117

22.13 FLIR GF306 14.5° Fixed lens..................................................... 123

22.14 FLIR GF306 24° ..................................................................... 129

22.15 FLIR GF306 24° Fixed lens ....................................................... 135

22.16 FLIR GF309 14.5°................................................................... 141

22.17 FLIR GF309 14.5° Fixed lens..................................................... 147

22.18 FLIR GF309 24° ..................................................................... 152

22.19 FLIR GF309 24° Fixed lens ....................................................... 158

22.20 FLIR GF320 14.5°................................................................... 163

22.21 FLIR GF320 14.5° Fixed lens..................................................... 169

22.22 FLIR GF320 24° ..................................................................... 175

22.23 FLIR GF320 24° Fixed lens ....................................................... 181

22.24 FLIR GF335 24° ..................................................................... 187

22.25 FLIR GF343 24° Fixed lens ....................................................... 192

22.26 FLIR GF346 14.5°................................................................... 197

22.27 FLIR GF346 14.5° Fixed lens..................................................... 203

22.28 FLIR GF346 24° ..................................................................... 209

22.29 FLIR GF346 24° Fixed lens ....................................................... 215

23 Mechanical drawings ............................... .. .. ............................. .. .. ... 221

24 CE Declaration of conformity ........................... .. ............................... 227

25 Cleaning the camera......................... .. ............................... .............. 229

25.1 Camera housing, cables, and other items..................................... 229

25.1.1 Liquids....................................................................... 229

25.1.2 Equipment.................................................................. 229

25.1.3 Procedure .................................................................. 229

25.2 Infrared lens .......................................................................... 229

25.2.1 Liquids....................................................................... 229

25.2.2 Equipment.................................................................. 229

25.2.3 Procedure .................................................................. 229

26 Cooler maintenance.......................... .. .. ............................. .. .. .......... 231

26.1 General ................................................................................ 231

26.2 Signs to watch for ................................................................... 231

27 Detectable gases......... .. .. ............................... .. ............................... 232

27.1 General ................................................................................ 232

27.2 Gases that can be detected by FLIR GF300.................................. 232

27.3 Coolants that can be detected by FLIR GF304 .............................. 235

#T559157; r. AH/45951/45951; en-US

x

Page 11

Table of contents

27.4 Gases that can be detected by FLIR GF306.................................. 235

27.5 Gases that can be detected by FLIR GF320.................................. 239

27.6 Gases that can be detected by FLIR GF343.................................. 242

27.7 Gases that can be detected by FLIR GF346.................................. 242

28 Why do some gases absorb infrared energy? ............................. .. ...... 246

29 About FLIR Systems ....................... ............................... .................. 249

29.1 More than just an infrared camera .............................................. 250

29.2 Sharing our knowledge ............................................................ 251

29.3 Supporting our customers......................................................... 251

30 Terms, laws, and definitions.......................... ................................. ... 252

31 About calibration................... .. ............................... ......................... 254

31.1 Introduction ........................................................................... 254

31.2 Definition—what is calibration? .................................................. 254

31.3 Camera calibration at FLIR Systems ........................................... 254

31.4 The differences between a calibration performed by a user and

that performed directly at FLIR Systems....................................... 255

31.5 Calibration, verification and adjustment........................................ 255

31.6 Non-uniformity correction.......................................................... 256

31.7 Thermal image adjustment (thermal tuning) .................................. 256

32 Thermographic measurement techniques ............. .. ........................... 257

32.1 Introduction .......................................................................... 257

32.2 Emissivity.............................................................................. 257

32.2.1 Finding the emissivity of a sample.................................... 257

32.3 Reflected apparent temperature ................................................. 261

32.4 Distance ............................................................................... 261

32.5 Relative humidity .................................................................... 261

32.6 Other parameters.................................................................... 261

33 History of infrared technology...... .. .. ............................... .................. 262

34 Theory of thermography.. .. ............................... ................................ 265

34.1 Introduction ........................................................................... 265

34.2 The electromagnetic spectrum................................................... 265

34.3 Blackbody radiation................................................................. 266

34.3.1 Planck’s law ................................................................ 267

34.3.2 Wien’s displacement law................................................ 268

34.3.3 Stefan-Boltzmann's law ................................................. 269

34.3.4 Non-blackbody emitters................................................. 270

34.4 Infrared semi-transparent materials............................................. 272

35 The measurement formula.................. ............................... .. ............. 273

36 Emissivity tables .. ................................. ............................... ........... 277

36.1 References............................................................................ 277

36.2 Tables .................................................................................. 277

#T559157; r. AH/45951/45951; en-US

xi

Page 12

Page 13

1

Disclaimers

1.1 Legal disclaimer

All products manufactured by FLIR Systems are warranted against defective materials

and workmanship for a period of one (1) year from the delivery date of the original purchase, provided such products have been under normal storage, use and service, and in

accordance with FLIR Systems instruction.

Uncooled handheld infrared cameras manufactured by FLIR Systems are warranted

against defective materials and workmanship for a period of two (2) years from the delivery

date of the original purchase, provided such products have been under normal storage,

use and service, and in accordance with FLIR Systems instruction, and provided that the

camera has been registered within 60 days of original purchase.

Detectors for uncooled handheld infrared cameras manufactured by FLIR Systems are

warranted against defective materials and workmanship for a period of ten (10) years from

the delivery date of the original purchase, provided such products have been under normal

storage, use and service, and in accordance with FLIR Systems instruction, and provided

that the camera has been registered within 60 days of original purchase.

Products which are not manufactured by FLIR Systems but included in systems delivered

by FLIR Systems to the original purchaser, carry the warranty, if any, of the particular supplier only. FLIR Systems has no responsibility whatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It is not applicable to any product which has been subjected to misuse, neglect, accident or abnormal

conditions of operation. Expendable parts are excluded from the warranty.

In the case of a defect in a product covered by this warranty the product must not be further used in order to prevent additional damage. The purchaser shall promptly report any

defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, at its option, repair or replace any such defective product free of charge

if, upon inspection, it proves to be defective in material or workmanship and provided that

it is returned to FLIR Systems within the said one-year period.

FLIR Systems has no other obligation or liability for defects than those set forth above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims the implied

warranties of merchantability and fitness for a particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidental or consequen-

tial loss or damage, whether based on contract, tort or any other legal theory.

This warranty shall be governed by Swedish law.

Any dispute, controversy or claim arising out of or in connection with this warranty, shall be

finally settled by arbitration in accordance with the Rules of the Arbitration Institute of the

Stockholm Chamber of Commerce. The place of arbitration shall be Stockholm. The language to be used in the arbitral proceedings shall be English.

1.2 U.S. Government Regulations

This product may be subject to U.S. Export Regulations. Please send any inquiries to exportquestions@flir.com.

1.3 Level 1 statement Applicability: Flir GF3xx.

This document is controlled to Flir Technology Level 1. The information contained in this

document pertains to a defense article controlled for export by the International Traffic in

#T559157; r. AH/45951/45951; en-US

1

Page 14

Disclaimers1

Arms Regulations (ITAR). Flir trade secrets contained herein are subject to disclosure restrictions as a matter of law. Diversion contrary to US law is prohibited. US Government

authorization for public release has been obtained from the Office of Security Review, authorization No. 10-S-2672. Additional US Department of State authorization is not required

prior to export or transfer to foreign persons or parties, unless otherwise prohibited.

1.4 Copyright

© 2016, FLIR Systems, Inc. All rights reserved worldwide. No parts of the software including source code may be reproduced, transmitted, transcribed or translated into any language or computer language in any form or by any means, electronic, magnetic, optical,

manual or otherwise, without the prior written permission of FLIR Systems.

The documentation must not, in whole or part, be copied, photocopied, reproduced, translated or transmitted to any electronic medium or machine readable form without prior consent, in writing, from FLIR Systems.

Names and marks appearing on the products herein are either registered trademarks or

trademarks of FLIR Systems and/or its subsidiaries. All other trademarks, trade names or

company names referenced herein are used for identification only and are the property of

their respective owners.

1.5 Quality assurance

The Quality Management System under which these products are developed and manufactured has been certified in accordance with the ISO 9001 standard.

FLIR Systems is committed to a policy of continuous development; therefore we reserve

the right to make changes and improvements on any of the products without prior notice.

1.6 Patents

000439161; 000653423; 000726344; 000859020; 001707738; 001707746; 001707787;

001776519; 001954074; 002021543; 002021543-0002; 002058180; 002249953;

002531178; 002816785; 002816793; 011200326; 014347553; 057692; 061609;

07002405; 100414275; 101796816; 101796817; 101796818; 102334141; 1062100;

11063060001; 11517895; 1226865; 12300216; 12300224; 1285345; 1299699; 1325808;

1336775; 1391114; 1402918; 1404291; 1411581; 1415075; 1421497; 1458284;

1678485; 1732314; 17399650; 1880950; 1886650; 2007301511414; 2007303395047;

2008301285812; 2009301900619; 20100060357; 2010301761271; 2010301761303;

2010301761572; 2010305959313; 2011304423549; 2012304717443; 2012306207318;

2013302676195; 2015202354035; 2015304259171; 204465713; 204967995; 2106017;

2107799; 2115696; 2172004; 2315433; 2381417; 2794760001; 3006596; 3006597;

303330211; 4358936; 483782; 484155; 4889913; 4937897; 4995790001; 5177595;

540838; 579475; 584755; 599392; 60122153; 6020040116815; 602006006500.0;

6020080347796; 6020110003453; 615113; 615116; 664580; 664581; 665004; 665440;

67023029; 6707044; 677298; 68657; 69036179; 70022216; 70028915; 70028923;

70057990; 7034300; 710424; 7110035; 7154093; 7157705; 718801; 723605; 7237946;

7312822; 7332716; 7336823; 734803; 7544944; 7606484; 7634157; 7667198; 7809258;

7826736; 8018649; 8153971; 8212210; 8289372; 8340414; 8354639; 8384783;

8520970; 8565547; 8595689; 8599262; 8654239; 8680468; 8803093; 8823803;

8853631; 8933403; 9171361; 9191583; 9279728; 9280812; 9338352; 9423940;

9471970; 9595087; D549758.

1.7 EULATerms

• You have acquired a device (“INFRARED CAMERA”) that includes software licensed by

FLIR Systems AB from Microsoft Licensing, GP or its affiliates (“MS”). Those installed

software products of MS origin, as well as associated media, printed materials, and

#T559157; r. AH/45951/45951; en-US

2

Page 15

Disclaimers1

“online” or electronic documentation (“SOFTWARE”) are protected by international intellectual property laws and treaties. The SOFTWARE is licensed, not sold. All rights

reserved.

• IF YOU DO NOT AGREE TO THIS END USER LICENSE AGREEMENT (“EULA”), DO

NOT USE THE DEVICE OR COPY THE SOFTWARE. INSTEAD, PROMPTLY CONTACT FLIR Systems AB FOR INSTRUCTIONS ON RETURN OF THE UNUSED DEVICE(S) FOR A REFUND. ANY USE OF THE SOFTWARE, INCLUDING BUT NOT

LIMITED TO USE ON THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT TO

THIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

• GRANT OF SOFTWARE LICENSE. This EULA grants you the following license:

◦ You may use the SOFTWARE only on the DEVICE.

◦ NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLERANT. FLIR Sys-

tems AB HAS INDEPENDENTLY DETERMINED HOW TO USE THE SOFTWARE

IN THE DEVICE, AND MS HAS RELIED UPON FLIR Systems AB TO CONDUCT

SUFFICIENT TESTING TO DETERMINE THAT THE SOFTWARE IS SUITABLE

FOR SUCH USE.

◦ NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is provided “AS IS”

and with all faults. THE ENTIRE RISK AS TO SATISFACTORY QUALITY, PERFORMANCE, ACCURACY, AND EFFORT (INCLUDING LACKOF NEGLIGENCE)

IS WITH YOU. ALSO, THERE IS NO WARRANTYAGAINST INTERFERENCE

WITH YOUR ENJOYMENT OF THE SOFTWARE OR AGAINST INFRINGEMENT.

IF YOU HAVE RECEIVED ANY WARRANTIES REGARDING THE DEVICE OR

THE SOFTWARE, THOSE WARRANTIES DO NOT ORIGINATE FROM, AND ARE

NOT BINDING ON, MS.

◦ No Liability for Certain Damages. EXCEPTAS PROHIBITED BY LAW, MS SHALL

HAVE NO LIABILITY FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING FROM OR IN CONNECTION WITH THE USE

OR PERFORMANCE OF THE SOFTWARE. THIS LIMITATION SHALL APPLY

EVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE. IN NO EVENT

SHALL MS BE LIABLE FOR ANY AMOUNT IN EXCESS OF U.S. TWO HUNDRED

FIFTY DOLLARS (U.S.$250.00).

◦ Limitations on Reverse Engineering, Decompilation, and Disassembly. You

may not reverse engineer, decompile, or disassemble the SOFTWARE, except and

only to the extent that such activity is expressly permitted by applicable law notwithstanding this limitation.

◦ SOFTWARE TRANSFER ALLOWED BUT WITH RESTRICTIONS. You may perma-

nently transfer rights under this EULA only as part of a permanent sale or transfer of

the Device, and only if the recipient agrees to this EULA. If the SOFTWARE is an upgrade, any transfer must also include all prior versions of the SOFTWARE.

◦ EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is subject to U.S. ex-

port jurisdiction. You agree to comply with all applicable international and national

laws that apply to the SOFTWARE, including the U.S. Export Administration Regulations, as well as end-user, end-use and destination restrictions issued by U.S. and

other governments. For additional information see http://www.microsoft.com/exporting/.

1.8 EULATerms

Qt4 Core and Qt4 GUI, Copyright ©2013 Nokia Corporation and FLIR Systems AB. This

Qt library is a free software; you can redistribute it and/or modify it under the terms of the

GNU Lesser General Public License as published by the Free Software Foundation; either

version 2.1 of the License, or (at your option) any later version. This library is distributed in

the hope that it will be useful, but WITHOUTANY WARRANTY; without even the implied

warranty of MERCHANTABILITYor FITNESS FOR A PARTICULAR PURPOSE. See the

GNU Lesser General Public License, http://www.gnu.org/licenses/lgpl-2.1.html. The

#T559157; r. AH/45951/45951; en-US

3

Page 16

Disclaimers1

source code for the libraries Qt4 Core and Qt4 GUI may be requested from FLIR Systems

AB.

#T559157; r. AH/45951/45951; en-US

4

Page 17

2

Safety information

WARNING

Applicability: Class A digital devices.

This equipment generates, uses, and can radiate radio frequency energy and if not installed and used in

accordance with the instruction manual, may cause interference to radio communications. It has been

tested and found to comply with the limits for a Class A computing device pursuant to Subpart J of Part

15 of FCC Rules, which are designed to provide reasonable protection against such interference when

operated in a commercial environment. Operation of this equipment in a residential area is likely to cause

interference in which case the user at his own expense will be required to take whatever measures may

be required to correct the interference.

WARNING

Applicability: Class B digital devices.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

WARNING

Applicability: Digital devices subject to 15.19/RSS-210.

NOTICE: This device complies with Part 15 of the FCC Rules and with RSS-210 of Industry Canada. Op-

eration is subject to the following two conditions:

1. this device may not cause harmful interference, and

2. this device must accept any interference received, including interference that may cause undesired

operation.

WARNING

Applicability: Digital devices subject to 15.21.

NOTICE: Changes or modifications made to this equipment not expressly approved by FLIR Systems

may void the FCC authorization to operate this equipment.

WARNING

Applicability: Digital devices subject to 2.1091/2.1093/OET Bulletin 65.

Radiofrequency radiation exposure Information: The radiated output power of the device is below

the FCC/IC radio frequency exposure limits. Nevertheless, the device shall be used in such a manner that

the potential for human contact during normal operation is minimized.

WARNING

Applicability: Cameras with one or more laser pointers.

Do not look directly into the laser beam. The laser beam can cause eye irritation.

#T559157; r. AH/45951/45951; en-US

5

Page 18

2

Safety information

WARNING

Applicability: Cameras with one or more batteries.

Do not disassemble or do a modification to the battery. The battery contains safety and protection devices

which, if damage occurs, can cause the battery to become hot, or cause an explosion or an ignition.

WARNING

Applicability: Cameras with one or more batteries.

If there is a leak from the battery and you get the fluid in your eyes, do not rub your eyes. Flush well with

water and immediately get medical care. The battery fluid can cause injury to your eyes if you do not do

this.

WARNING

Applicability: Cameras with one or more batteries.

Do not continue to charge the battery if it does not become charged in the specified charging time. If you

continue to charge the battery, it can become hot and cause an explosion or ignition. Injury to persons

can occur.

WARNING

Applicability: Cameras with one or more batteries.

Only use the correct equipment to remove the electrical power from the battery. If you do not use the correct equipment, you can decrease the performance or the life cycle of the battery. If you do not use the

correct equipment, an incorrect flow of current to the battery can occur. This can cause the battery to become hot, or cause an explosion. Injury to persons can occur.

WARNING

Make sure that you read all applicable MSDS (Material Safety Data Sheets) and warning labels on containers before you use a liquid. The liquids can be dangerous. Injury to persons can occur.

CAUTION

Do not point the infrared camera (with or without the lens cover) at strong energy sources, for example,

devices that cause laser radiation, or the sun. This can have an unwanted effect on the accuracy of the

camera. It can also cause damage to the detector in the camera.

CAUTION

Do not use the camera in temperatures more than +50°C (+122°F), unless other information is specified

in the user documentation or technical data. High temperatures can cause damage to the camera.

CAUTION

Applicability: Cameras with one or more laser pointers.

To prevent damage, put the protective cap on the laser pointer when you do not operate the laser pointer.

Damage to the laser pointer can occur if you do not do this.

CAUTION

Applicability: Cameras with one or more batteries.

Do not attach the batteries directly to a car’s cigarette lighter socket, unless FLIR Systems supplies a specific adapter to connect the batteries to a cigarette lighter socket. Damage to the batteries can occur.

#T559157; r. AH/45951/45951; en-US

6

Page 19

2

Safety information

CAUTION

Applicability: Cameras with one or more batteries.

Do not connect the positive terminal and the negative terminal of the battery to each other with a metal

object (such as wire). Damage to the batteries can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not get water or salt water on the battery, or permit the battery to become wet. Damage to the batteries

can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not make holes in the battery with objects. Damage to the battery can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not hit the battery with a hammer. Damage to the battery can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not put your foot on the battery, hit it or cause shocks to it. Damage to the battery can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not put the batteries in or near a fire, or into direct sunlight. When the battery becomes hot, the built-in

safety equipment becomes energized and can stop the battery charging procedure. If the battery becomes hot, damage can occur to the safety equipment and this can cause more heat, damage or ignition

of the battery.

CAUTION

Applicability: Cameras with one or more batteries.

Do not put the battery on a fire or increase the temperature of the battery with heat. Damage to the battery

and injury to persons can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not put the battery on or near fires, stoves, or other high-temperature locations. Damage to the battery

and injury to persons can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Do not solder directly onto the battery. Damage to the battery can occur.

#T559157; r. AH/45951/45951; en-US

7

Page 20

2

Safety information

CAUTION

Applicability: Cameras with one or more batteries.

Do not use the battery if, when you use, charge, or put the battery in storage, there is an unusual smell

from the battery, the battery feels hot, changes color, changes shape, or is in an unusual condition. Speak

with your sales office if one or more of these problems occurs. Damage to the battery and injury to persons can occur.

CAUTION

Applicability: Cameras with one or more batteries.

Only use a specified battery charger when you charge the battery. Damage to the battery can occur if you

do not do this.

CAUTION

Applicability: Cameras with one or more batteries.

Only use a specified battery for the camera. Damage to the camera and the battery can occur if you do

not do this.

CAUTION

Applicability: Cameras with one or more batteries.

The temperature range through which you can charge the battery is 0°C to +45°C (+32°F to +113°F). If

you charge the battery at temperatures out of this range, it can cause the battery to become hot or to

break. It can also decrease the performance or the life cycle of the battery.

CAUTION

Applicability: Cameras with one or more batteries.

The temperature range through which you can remove the electrical power from the battery is -15°C to

+50°C (+5°F to +122°F), unless other information is specified in the user documentation or technical data.

If you operate the battery out of this temperature range, it can decrease the performance or the life cycle

of the battery.

CAUTION

Applicability: Cameras with one or more batteries.

When the battery is worn, apply insulation to the terminals with adhesive tape or equivalent materials before you discard it. Damage to the battery and injury to persons can occur if you do not do this.

CAUTION

Applicability: Cameras with one or more batteries.

Remove any water or moisture on the battery before you install it. Damage to the battery can occur if you

do not do this.

CAUTION

Do not apply solvents or equivalent liquids to the camera, the cables, or other items. Damage to the battery and injury to persons can occur.

CAUTION

Be careful when you clean the infrared lens. The lens has an anti-reflective coating which is easily damaged. Damage to the infrared lens can occur.

#T559157; r. AH/45951/45951; en-US

8

Page 21

2

Safety information

CAUTION

Do not use too much force to clean the infrared lens. This can cause damage to the anti-reflective

coating.

CAUTION

Applicability: Cameras with a heatshield.

When you operate the camera in high-temperature conditions, you must install a heatshield on the camera. If you use the camera in high-temperature conditions without a heatshield, damage to the camera

can occur.

Note The encapsulation rating is only applicable when all the openings on the camera

are sealed with their correct covers, hatches, or caps. This includes the compartments for

data storage, batteries, and connectors.

CAUTION

Applicability: FLIR GF309.

The exceptionally wide temperature range of the FLIR GF309 infrared camera is designed for performing

highly accurate electrical and mechanical inspections and can also “see through flames” for inspecting

gas-fired furnaces, chemical heaters and coal-fired boilers. IN ORDER TO DERIVE ACCURATE TEMPERATURE MEASUREMENTS IN THESE ENVIRONMENTS THE FLIR GF309 OPERATOR MUST

HAVE A STRONG UNDERSTANDING OF RADIOMETRIC FUNDAMENTALS AS WELL AS THE PRODUCTS AND CONDITIONS OF COMBUSTION THAT IMPACT REMOTE TEMPERATURE MEASUREMENT. The Infrared Training Center (ITC) offers a wide range of world class infrared training for

thermography professionals including FLIR GF309 operators. For more information about obtaining the

training and certification you require, contact your FLIR Systems sales representative or ITC at http://www.

infraredtraining.com.

CAUTION

Applicability: Cameras with a viewfinder.

Make sure that the beams from the intensive energy sources do not go into the viewfinder. The beams

can cause damage to the camera. This includes the devices that emit laser radiation, or the sun.

#T559157; r. AH/45951/45951; en-US

9

Page 22

3

Notice to user

3.1 User-to-user forums

Exchange ideas, problems, and infrared solutions with fellow thermographers around the

world in our user-to-user forums. To go to the forums, visit:

http://forum.infraredtraining.com/

3.2 Calibration

Gas detection: no re-calibration recommendation. The ability to detect gases is not influenced by the calibration and will not degrade over time.

Temperature measurement: annual re-calibration recommended.

3.3 Accuracy

For very accurate results, we recommend that you wait 5 minutes after you have started

the camera before measuring a temperature.

For cameras where the detector is cooled by a mechanical cooler, this time period excludes the time it takes to cool down the detector.

3.4 Disposal of electronic waste

Electrical and electronic equipment (EEE) contains materials, components and substances that may be hazardous and present a risk to human health and the environment when

waste electrical and electronic equipment (WEEE) is not handled correctly.

Equipment marked with the below crossed-out wheeled bin is electrical and electronic

equipment. The crossed-out wheeled bin symbol indicates that waste electrical and electronic equipment should not be discarded together with unseparated household waste,

but must be collected separately.

For this purpose all local authorities have established collection schemes under which residents can dispose waste electrical and electronic equipment at a recycling centre or other

collection points, or WEEE will be collected directly from households. More detailed information is available from the technical administration of the relevant local authority.

3.5 Training

To read about infrared training, visit:

• http://www.infraredtraining.com

• http://www.irtraining.com

• http://www.irtraining.eu

#T559157; r. AH/45951/45951; en-US

10

Page 23

Notice to user3

3.6 Documentation updates

Our manuals are updated several times per year, and we also issue product-critical notifications of changes on a regular basis.

To access the latest manuals, translations of manuals, and notifications, go to the Download tab at:

http://support.flir.com

It only takes a few minutes to register online. In the download area you will also find the lat-

est releases of manuals for our other products, as well as manuals for our historical and

obsolete products.

3.7 Note about authoritative versions

The authoritative version of this publication is English. In the event of divergences due to

translation errors, the English text has precedence.

Any late changes are first implemented in English.

#T559157; r. AH/45951/45951; en-US

11

Page 24

4

Customer help

4.1 General

For customer help, visit:

http://support.flir.com

4.2 Submitting a question

To submit a question to the customer help team, you must be a registered user. It only

takes a few minutes to register online. If you only want to search the knowledgebase for

existing questions and answers, you do not need to be a registered user.

When you want to submit a question, make sure that you have the following information to

hand:

• The camera model

• The camera serial number

• The communication protocol, or method, between the camera and your device (for example, SD card reader, HDMI, Ethernet, USB, or FireWire)

• Device type (PC/Mac/iPhone/iPad/Android device, etc.)

• Version of any programs from FLIR Systems

• Full name, publication number, and revision number of the manual

#T559157; r. AH/45951/45951; en-US

12

Page 25

4

Customer help

4.3 Downloads

On the customer help site you can also download the following, when applicable for the

product:

• Firmware updates for your infrared camera.

• Program updates for your PC/Mac software.

• Freeware and evaluation versions of PC/Mac software.

• User documentation for current, obsolete, and historical products.

• Mechanical drawings (in *.dxf and *.pdf format).

• Cad data models (in *.stp format).

• Application stories.

• Technical datasheets.

• Product catalogs.

#T559157; r. AH/45951/45951; en-US

13

Page 26

5

Important note about training and applications

5.1 General

Infrared inspection of gas leaks, furnaces, and high-temperature applications—including

infrared image and other data acquisition, analysis, diagnosis, prognosis, and reporting—

is a highly advanced skill. It requires professional knowledge of thermography and its applications, and is, in some countries, subject to certification and legislation.

Consequently, we strongly recommend that you seek the necessary training before carrying out inspections. Please visit the following site for more information:

http://www.infraredtraining.com

#T559157; r. AH/45951/45951; en-US

14

Page 27

6

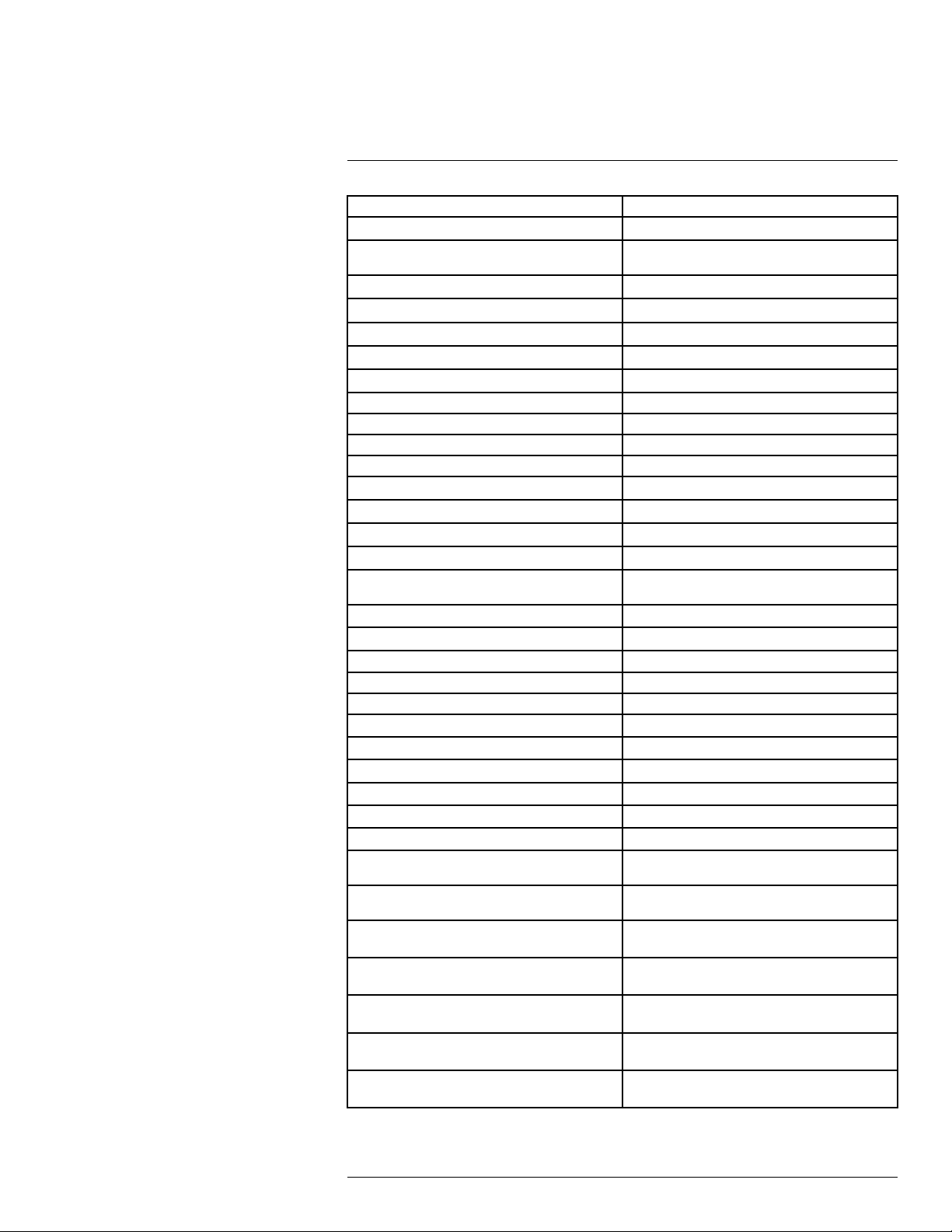

List of accessories and services

Product name Part number

Battery charger, incl. power supply with multi plugs T197692

Calibration including General maintenance GF3xx

series

Cigarette lighter adapter kit, 12 VDC, 1.2 m/3.9 ft. T198509

FLIR IR Camera Player DSW-10000

FLIR Reporter Professional (license only) T198586

FLIR ResearchIR 3 (license only) T198578

FLIR ResearchIR 3 Max (license only) T198574

FLIR ResearchIR Max + HSDR 4 T198697

FLIR ResearchIR Max 4 T198696

FLIR ResearchIR Standard 4

FLIR Tools T198584

FLIR Tools Mobile (Android Application) APP-10002

FLIR Tools Mobile (iPad/iPhone Application) APP-10003

FLIR Tools+ (license only) T198583

FLIR VideoReport T198585

Furnace IR lens extender, 14.5° with case for

GF309

Furnace IR lens extender, 24° with case for GF309 T198360

Hard transport case for FLIR GF3xx-Series T197555

HDMI to DVI cable 1.5 m T910816ACC

HDMI to HDMI cable 1.5 m

Heat Shield for FLIR GF309

IR lens, 14.5° with case for GF300, GF309, GF320 T197385

IR lens, 14.5° with case for GF304, GF306 T197384

IR lens, 14.5° with case for GF335, GF346 T198298

IR lens, 24° with case for GF300, GF309, GF320 T197387

IR lens, 24° with case for GF304, GF306 T197386

IR lens, 24° with case for GF335, GF346 T198267

IR lens, 6° with case for GF300, GF309, GF320,

GF346.

ITC Advanced Furnace Application Course - additional student to on site class

ITC Advanced Furnace Application Course - attendance, 1 pers. (3 days)

ITC Advanced Furnace Applications Course group up to 10 pers. (3 days)

ITC Advanced Furnace Applications Course group up to 6 persons (3 days)

ITC Advanced Gas Detection Course - additional

student to on site class, 1 pers.

ITC Advanced Gas Detection Course - attendance,

1 pers.

T199834

T198731

T198361

T910815ACC

T197482

T197388

ITC-ADV-3055

ITC-ADV-3051

ITC-ADV-3059

ITC-ADV-3056

ITC-ADV-3035

ITC-ADV-3031

#T559157; r. AH/45951/45951; en-US

15

Page 28

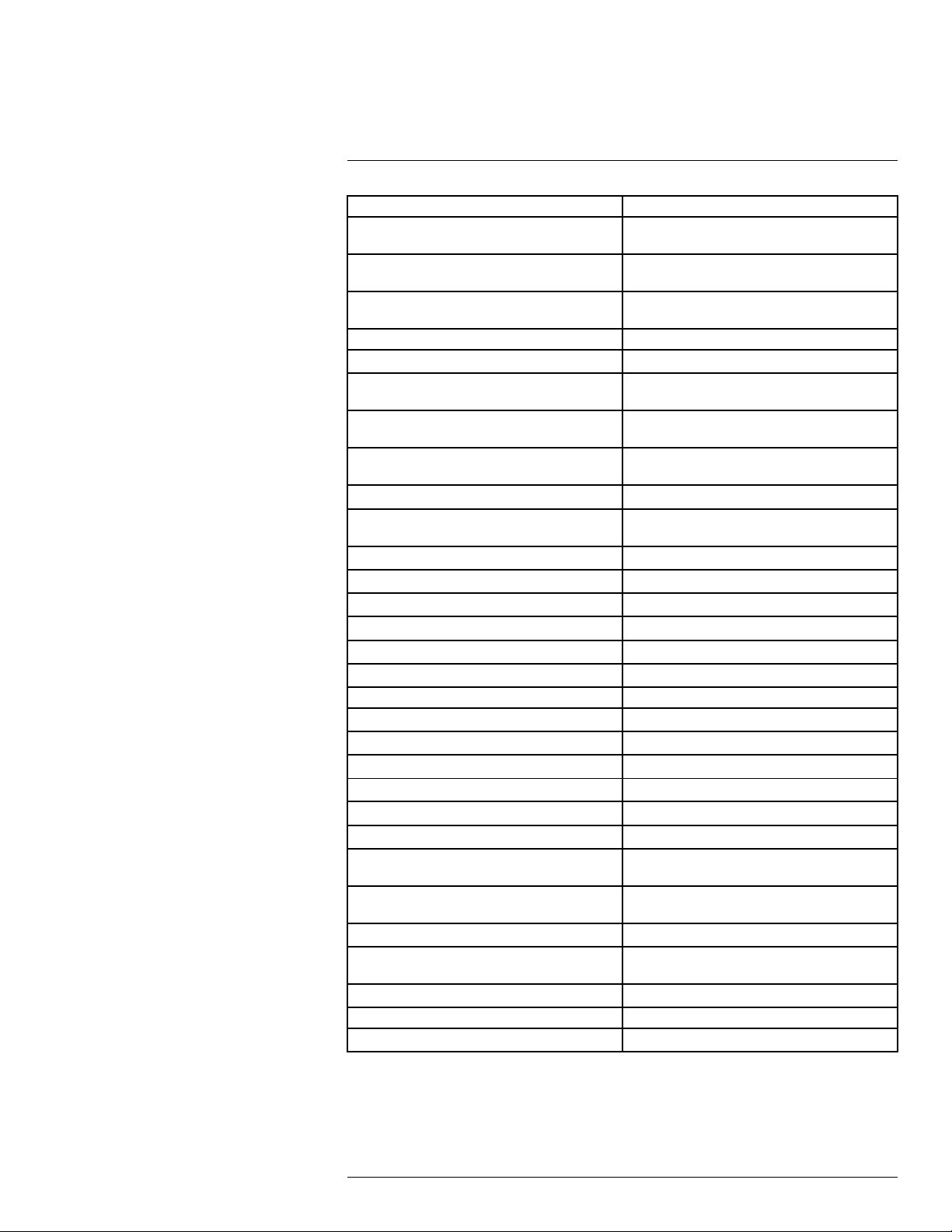

6

List of accessories and services

Product name Part number

ITC Advanced Gas Detection Course - group of up

to 6 pers. (3 days)

ITC Advanced Gas Detection Course – group of 10

pers.

ITC Advanced training - group of max. 6 pers, additional day 4 for on-site training

ITC conference fee ITC-CON-1001

ITC Customized workshop - per person (per day) ITC-EXP-1041

ITC In-house training - additional attendance 1

pers. (per day)

ITC In-house training - group up to 10 pers. (per

day)

ITC Infrared application and system consultancy

(per day)

ITC Software course - attendance 1 pers. (per day) ITC-SOW-0001

ITC Software course - group up to 10 pers. (per

day)

ITC Training 1 day - attendance 1 pers. ITC-EXP-1001

ITC Training 1 day - group up to 10 pers. ITC-EXP-1009

ITC Training 2 days - attendance 1 pers. ITC-EXP-2001

ITC Training 2 days - group up to 10 pers. ITC-EXP-2009

ITC Training 3 days - attendance 1 pers. ITC-EXP-3001

ITC Training 3 days - group up to 10 pers. ITC-EXP-3009

ITC travel time for instructor ITC-TFT-0100

Li-Ion Battery pack 7.4V 33Wh T198511

Memory card SDHC 4 GB T911230ACC

One year extended warranty for GF3xx series T199825

Power supply, incl. multi plugs T910814

ThermoVision™ LabVIEW® Digital Toolkit Ver. 3.3 T198566

ThermoVision™ System Developers Kit Ver. 2.6

Travel and lodging expenses instructor (Center

and South Africa)

Travel and lodging expenses instructor (Europe,

Balcans, Turkey, Cyprus)

Travel and lodging expenses instructor (other) ITC-TOL-1005

Travel and lodging expenses instructor (Russia/

GUS, Middle East, North Africa)

Travel and lodging expenses instructor (various) ITC-TOL-1004

USB cable Std A <-> Mini-B

Wi-Fi USB micro adapter T951387

ITC-ADV-3036

ITC-ADV-3039

ITC-ADV-4006

ITC-EXP-1021

ITC-EXP-1029

ITC-EXP-1050

ITC-SOW-0009

T198567

ITC-TOL-1003

ITC-TOL-1001

ITC-TOL-1002

1910423

Note FLIR Systems reserves the right to discontinue models, parts or accessories, and

other items, or to change specifications at any time without prior notice.

#T559157; r. AH/45951/45951; en-US

16

Page 29

7

Introduction

7.1 FLIR GF300

7.1.1 Optical gas imaging of methane and other volatile organic compounds

(VOCs)

The FLIR GF300 is an IR camera for optical gas imaging (OGI) that visualizes and pinpoints leaks of VOCs, without the need to shut down the operation. The portable camera

also greatly improves operator safety, by detecting emissions at a safe distance, and helps

to protect the environment by tracing leaks of environmentally harmful gases.

The FLIR GF300 is used in industrial settings such as oil refineries, natural gas processing

plants, offshore platforms, chemical/petrochemical industries, and biogas and power generation plants.

7.1.2 Benefits

• Improved efficiency: The FLIR GF300 reduces revenue loss by pinpointing even small

gas leaks quickly and efficiently, and from a distance. It also reduces the inspection

time by allowing a broad area to be scanned rapidly and without the need to interrupt

the industrial process.

• Increased worker safety: OGI allows gas leaks to be detected in a non-contact mode

and from a safe distance. This reduces the risk of the inspector being exposed to invisible and potentially harmful or explosive chemicals. With a FLIR GF300 gas imaging

camera it is easy to scan areas of interest that are difficult to reach with conventional

methods. The camera is ergonomically designed, with a bright LCD and tiltable viewfinder, which facilitates its use over a full working day.

• Protecting the environment: Several VOCs are dangerous to human health or cause

harm to the environment, and are usually governed by regulations. Even small leaks

can be detected and documented using theFLIR GF300 camera.

7.2 FLIR GF304

7.2.1 Optical gas imaging of refrigerant gases

The FLIR GF304 is an IR camera for optical gas imaging (OGI) that visualizes and pinpoints leaks of refrigerant gases, without the need to shut down the operation. This portable camera also greatly improves operator safety, by detecting gases at a safe distance,

and helps to protect the environment by tracing leaks of environmentally harmful gases.

Refrigerant gases are found in, for example, the food, chemical/petrochemical and automotive industries, as well as in air-conditioning systems.

7.2.2 Benefits

• Improved efficiency: The FLIR GF304 reduces revenue loss by pinpointing even small

gas leaks quickly and efficiently, and from a distance. It also reduces the inspection

time by being able to scan a broad area rapidly without the need to interrupt the industrial process. The wireless connectivity of the camera allows you to connect to smart

phones or tablet PCs for the wireless transfer of images or the remote control of the

camera. The FLIR GF304 can also be used for temperature measurement, which

makes it even more useful for predictive maintenance.

• Increased worker safety: The leak detection of gases can be performed in noncontact

mode, and from a safe distance. This reduces the risk of the inspector being exposed

to invisible and potentially harmful or explosive chemicals. With a FLIR GF304 gasimaging camera it is easy to scan areas of interest that are difficult to reach with

#T559157; r. AH/45951/45951; en-US

17

Page 30

7

Introduction

conventional methods. The camera is ergonomically designed with a bright LCD and a

tiltable viewfinder, which facilitates its use over a full working day.

• Protecting the environment: Several refrigerant gases have a high global warming potential and are usually governed by regulations. Even small leaks can be detected and

documented using the FLIR GF304 camera.

7.3 FLIR GF306

7.3.1 Optical gas imaging especially of SF6 and ammonia

The FLIR GF306 is an IR camera for optical gas imaging (OGI) that visualizes and pinpoints gas leaks of SF6 and ammonia, without the need to de-energize high-voltage

equipment or shut down the operation. The portable camera also greatly improves operator safety, by detecting emissions at a safe distance, and helps to protect the environment

by tracing leaks of environmentally harmful gases.

SF6 is used in the electric power industry as an insulator and quenching medium for gasinsulated substations and circuit breakers. The gas is also used in magnesium production

and semiconductor manufacture. Ammonia is produced in ammonia plants, and is used

mainly for the production of fertilizers.

7.3.2 Benefits

• Improved efficiency: The FLIR GF306 reduces revenue loss by pinpointing even small

gas leaks quickly and efficiently, and from a distance. It also reduces the inspection

time by allowing a broad area to be scanned rapidly and without the need to de-energize components in the high-voltage area. The wireless connectivity of the camera allows you to connect to smart phones or tablet PCs for the wireless transfer of images or

remote control of the camera. The FLIR GF306 can also be used for temperature measurement, which makes it even more useful for predictive maintenance of high-voltage

equipment.

• Increased worker safety: OGI allows gas leaks to be detected in a non-contact mode

and from a safe distance. This prevents electrical exposure to personnel working in a

high-voltage area. With a FLIR GF306 gas imaging camera it is easy to scan areas of

interest that are difficult to reach with conventional methods. The camera is ergonomically designed, with a bright LCD and tiltable viewfinder, which facilitates its use over a

full working day.

• Protecting the environment: SF6 is a well-known greenhouse gas that can cause harm

to the environment, and is usually governed by regulations. SF6 has a global warming

potential 24,000 times higher than CO2. Even small leaks can be detected and documented using the FLIR GF306 camera.

7.4 FLIR GF309

7.4.1 IR camera for furnace and high temperature inspection

The FLIR GF309 is an IR camera for the high-temperature measurement of industrial furnaces, chemical heaters, and coal-fired boilers, without the need to shut down the operation. The portable camera also greatly improves operator safety, by measuring through

flames at a safe distance, for all types of furnaces. A good knowledge of the furnace condition can avert failures and unscheduled shutdowns

Industrial furnaces, heaters, and boilers are found in the chemical, petrochemical, and utility industries.

#T559157; r. AH/45951/45951; en-US

18

Page 31

7

Introduction

7.4.2 Benefits

• Improved efficiency: The FLIR GF309 reduces inspection time by measuring the temperature through flames without the need to interrupt the industrial process or await

scheduled service shutdowns. A furnace camera can help you to determine how to run

a furnace/boiler efficiently to give the best fuel economy and maximize production output and quality. As the FLIR GF309 has a wide temperature range, high-accuracy electrical and mechanical inspections can be performed, which makes the camera even

more useful for predictive maintenance.

• The wireless connectivity of the camera allows you to connect to smart phones or tablet

PCs for the wireless transfer of images or the remote control of the camera—a useful

function if regulations require a second person to accompany the furnace inspector or

thermal images needs to be sent quickly for a second opinion.

• Increased worker safety: High-temperature measurement can be performed through

flames in a non-contact mode, and from a safe distance. Custom-built, the FLIR GF309

also features a detachable heat-shield designed to reflect heat away from the camera

and the camera operator, providing increased protection. The camera is ergonomically

designed with a bright LCD and tiltable viewfinder, which facilitates its use over a full

working day.

• Increased furnace safety: Good knowledge of furnace/boiler condition and operating

parameters can provide the information needed to avert catastrophic failures and prevent unscheduled shutdowns.

7.5 FLIR GF320

7.5.1 Optical gas imaging of methane and other volatile organic compounds

(VOCs)

The FLIR GF320 is an IR camera for optical gas imaging (OGI) that visualizes and pinpoints leaks of VOCs, without the need to shut down the operation. The portable camera

also greatly improves operator safety, by detecting emissions at a safe distance, and helps

to protect the environment by tracing leaks of environmentally harmful gases.

The FLIR GF320 is used in industrial settings such as oil refineries, natural gas processing

plants, offshore platforms, chemical/petrochemical industries, and biogas and power generation plants.

7.5.2 Benefits

• Improved efficiency: The FLIR GF320 reduces revenue loss by pinpointing even small

gas leaks quickly and efficiently, and from a distance. It also reduces the inspection

time by allowing a broad area to be scanned rapidly and without the need to interrupt

the industrial process. The wireless connectivity of the camera allows you to connect to

smart phones or tablet PCs for the wireless transfer of images or remote control of the

camera. The FLIR GF320 is also used for temperature measurement, which makes it

even more useful for predictive maintenance.

• Increased worker safety: OGI allows gas leaks to be detected in a non-contact mode

and from a safe distance. This reduces the risk of the inspector being exposed to invisible and potentially harmful or explosive chemicals. With a FLIR GF320 gas imaging

camera it is easy to scan areas of interest that are difficult to reach with conventional

methods. The camera is ergonomically designed, with a bright LCD and tiltable viewfinder, which facilitates its use over a full working day.

• Protecting the environment: Several VOCs are dangerous to human health or cause

harm to the environment, and are usually governed by regulations. Even small leaks

can be detected and documented using the FLIR GF320 camera.

#T559157; r. AH/45951/45951; en-US

19

Page 32

7

Introduction

7.6 FLIR GF335

The FLIR GF335 is a high-sensitivity, low-noise, cooled infrared camera for applications

requiring a portable camera able to detect very subtle temperature differences. The high

performance of the camera makes it perfect for the detection of faint heat signatures as

well as for non-destructive testing and quality control applications.

7.6.1 Benefits

• High performance: The FLIR GF335 features a cooled 3–5 µm InSb detector that produces razor-sharp thermal images. Its high sensitivity of <15 mK and high accuracy of

±1°C (±1.8°F) or 1% allow the user to detect very subtle temperature differences with

astounding clarity.

• Improved efficiency: The wireless connectivity of the FLIR GF335 allows connection to

smart phones and tablets for the wireless transfer of images or the remote control of

the camera—a useful function if a second person is required to accompany the inspector . The camera also features built-in radiometric video recording, and can store

MPEG-4 thermal and/or standard video on an SD card. The camera has an integrated

GPS and a digital camera, and is compatible with Flir Tools, Flir Reporter, and Flir Researcher software.

• Thought-through ergonomics for everyday use:The FLIR GF335 is ergonomically designed, with a bright LCD and tiltable viewfinder, which facilitates its use over a full

working day. A multi-angle handle with integrated direct access buttons also improves

the ergonomics.

7.7 FLIR GF343