Installation

Manual

FC-Series T

Tra f f i c C a m e ra

© 2012 FLIR Systems, Inc. All rights reserved worldwide. No parts of this manual, in whole or in part, may be

copied, photocopied, translated, or transmitted to any electronic medium or machine readable form without

the prior written permission of FLIR Systems, Inc.

Names and marks appearing on the products herein are either registered trademarks or trademarks of FLIR

Systems, Inc. and/or its subsidiaries. All other trademarks, trade names, or company names referenced

herein are used for identification only and are the property of their respective owners.

This product is protected by patents, design patents, patents pending, or design patents pending.

The contents of this document are subject to change.

FLIR Systems, Inc.

70 Castilian Drive

Goleta, CA 93117

Phone: 888.747.FLIR (888.747.3547)

International: +1.805.964.9797

http://www.flir.com

Important Instructions and Notices to the User:

Modification of this device without the express authorization of FLIR Commercial Systems, Inc. may void the

user’s authority under FCC rules to operate this device.

Note 1: This equipment has been tested and found to comply with the limits for a Class B digital device,

purs uant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that the interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna;

• Increase the separation between the equipment and receiver;

• Connect the equipment into an outlet on a circuit different from that of the receiver; and/or

• Consult the dealer or an experienced radio/television technician for help.

Note 2: This equipment was tested for compliance with the FCC limits for a Class B digital device using a

shielded cable for connecting the equipment to an analog video output to a monitor and using a shielded USB

cable for connecting the equipment to a personal computer. When making such connections, shielded cables

must be used with this equipment.

Industry Canada Notice:

This Class B digital apparatus complies with Canadian ICES-003.

Avis d’Industrie Canada:

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Proper Disposal of Electrical and Electronic Equipment (EEE)

came with the product) should be responsibly discarded or recycled.

To identify a responsible disposal method where you live, please contact your local waste collection or recycling service, your

original place of purchase or product supplier, or the responsible government authority in your area. Business users should

contact their supplier or refer to their purchase contract.

427-0070-11-12, Rev. 100—FC-Series T Installation Manual, April 2012 ii

The European Union (EU) has enacted Waste Electrical and Electronic Equipment Directive 2002/96/EC

(WEEE), which aims to prevent EEE waste from arising; to encourage reuse, recycling, and recovery of EEE

waste; and to promote environmental responsibility.

In accordance with these regulations, all EEE products labeled with the “crossed out wheeled bin” either on the

product itself or in the product literature must not be disposed of in regular rubbish bins, mixed with regular

household or other commercial waste, or by other regular municipal waste collection means. Instead, and in

order to prevent possible harm to the environment or human health, all EEE products (including any cables that

Table of Contents

1 FC-Series T Camera Installation

1.1 Warnings and Cautions 1-1

1.2 References 1-1

1.3 Installation Overview 1-2

1.4 Installation Components 1-2

1.5 Location Considerations 1-2

1.5.1 Prior to Cutting/Drilling Holes 1-3

1.5.2 Sunshield 1-3

1.6 Camera Mounting 1-4

1.7 Removing the Cover 1-5

1.8 Cable Gland Sealing 1-6

1.8.1 Cable Gland Seal Inserts 1-6

1.9 Camera Connections 1-7

1.9.1 Connecting power 1-7

1.9.2 Video Connection 1-8

1.9.3 Camera Grounding 1-9

1.10 Bench Testing 1-9

2 Basic Operation

2.1 Troubleshooting Tips 2-3

2.1.1 Image freezes momentarily 2-3

2.1.2 No video 2-3

2.1.3 Noisy image 2-3

2.1.4 Image too dark or too light 2-4

2.1.5 Performance varies with time of day 2-4

2.1.6 Eastern or Western Exposure 2-5

2.2 Camera specifications 2-6

427-0070-11-12, version 100 April 2012 -iii

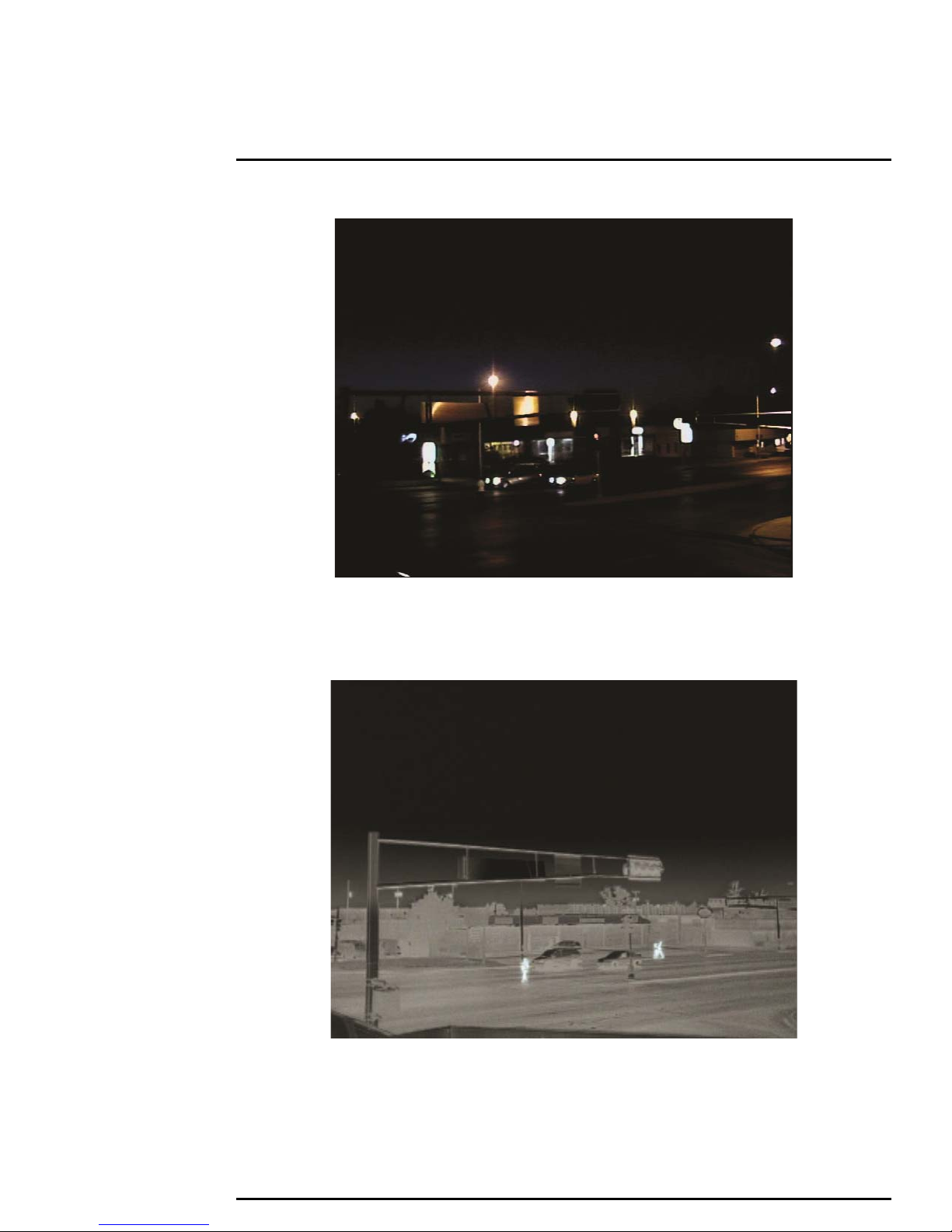

Figure 1: Image from a standard camera

Figure 2: Image from a thermal camera

427-0070-11-12, Rev. 100—FC-Series T Installation Manual, April 2012 iv

1 FC-Series T Camera Installation

1FC-Series T Camera Installation

This manual describes the installation of the FC-Series T cameras. If you need help during the

installation process, contact your local FLIR service representative or, call 877-773-3547 inside the US.

All installers and integrators are encouraged to take advantage of the training offered by FLIR; visit

http://www.flir.com/training for more information.

This manual includes the following topics:

• Installation overview

• Mounting the camera and its components

• Connecting the electronics

• Bench testing the camera

• Basic configuration and operation of the camera

• Camera Specifications

For safety, and to achieve the highest levels of performance from the FC-Series T camera system,

always follow the warnings and cautions in this manual when handling and operating the camera.

1.1 Warnings and Cautions

Warning!

If mounting the F-Series camera on a pole, tower or any elevated location, use industry standard safe

practices to avoid injuries.

Caution!

Except as described in this manual, do not open the FC-Series T camera for any reason. Damage to

the camera can occur as the result of careless handling or electrostatic discharge (ESD). Always

handle the camera with care to avoid damage to electrostatic-sensitive components.

Prior to making any connections, ensure the power supply or circuit breaker is switched off.

Be careful not to leave fingerprints on the FC-Series T camera’s infrared optics.

The FC-Series T camera requires a power supply of 90-240 VAC. Operating the camera outside of

the specified input voltage range or the specified operating temperature range can cause permanent

damage.

1.2 References

FLIR FC-Series T ICD, Doc # 427-00XX-XX-19 - The FC-Series T Interface Control Document (ICD),

available on the documentation CD or from the FLIR website, provides further details regarding

mechanical dimensions and mounting for the FC-Series T cameras. These documents are provided for

reference only.

NEMA Standards Publication TS 2-2003 v02.06 Traffic Controller Assemblies with NTCIP Requirements

UL 60950 Safety of Information Technology Equipment (ITE)

427-0070-11-12, version 100 April 2012 1-1

1

FC-Series T Camera Installation

1.3 Installation Overview

The FC-Series T Camera is an infrared thermal imaging camera intended for outdoor traffic

applications, and can be installed in a fixed location or on a pan/tilt mechanism.The FC-Series T

camera is intended to be mounted on a medium-duty fixed pedestal mount or wall mount commonly

used in the Traffic industry. Cables will exit from the back of the camera housing. The mount must

support up to 5 LBS (2.3 KG).

The camera requires a power connection and a video connection, both of which enter the camera via

conduit or a cable gland on the back of the camera. In order to access the electrical connections and

install the cables, it is necessary to temporarily remove the top cover of the camera housing. The

camera has an external ground connection on the outside back of the camera.

The power connects to a screw terminal block and the camera operates on 90-240 VAC single phase

50-60 Hz. The camera automatically adjusts to the input voltage - it is not necessary to set the input

voltage with a dip switch or other mechanism. The camera accepts an unterminated coax video

connection, which is clamped in place, or optionally a BNC-terminated video cable.

The FC-Series T is an analog camera and the video from the camera can be viewed over a traditional

analog video network. Analog video will require a connection to a video monitor or an analog video

matrix switch.

1.4 Installation Components

The FC-Series T camera includes these standard components:

• Fixed Camera Unit with sunshield and cable gland

• FC-Series T Camera Documentation Package

The installer will need to supply the following items (cable lengths are specific to the installation.)

• Electrical wire, for system power; (3-conductor, shielded, gauge determined by cable length and

supply voltage; Refer to paragraph 1.8.1 “Cable Gland Seal Inserts” on page 1-6 for additional

information)

• Camera grounding strap

• Coaxial RG59U video cables (unterminated cable at the camera end, or alternatively BNC

connector can be used) for analog video

•Camera mount

• Miscellaneous electrical hardware, connectors, and tools, including 3mm hex wrench (T-Handle),

small blade screwdriver, coax wire strip tool

1.5 Location Considerations

The camera will require connections for power and video. Ensure that cable distances do not exceed

the specifications and that cables adhere to all local and Industry Standards, Codes, and Best

Practices. The FC-Series T camera must be mounted upright, either on top of the mounting surface.

or underneath an overhanging mounting surface such as eaves or an awning. The unit should not be

mounted upside down.

Note

If the camera is to be mounted on a pole or tower or other hard-to-reach location, it may be a good

idea to connect and operate the camera as a bench test at ground level prior to mounting the camera

in its final location.

427-0070-11-12, version 100 April 2012 1-2

1

FC-Series T Camera Installation

1.5.1 Prior to Cutting/Drilling Holes

When selecting a mounting location for the FC-Series T camera, consider cable lengths and cable

routing. Ensure the cables are long enough, given the proposed mounting locations and cable routing

requirements, and route the cables before you install the components.

Use cables that have sufficient dimensions to ensure safety (for power cables) and adequate signal

strength (for video and communications). Allow space behind the camera so each cable does not

exceed its recommended minimum bend radius.

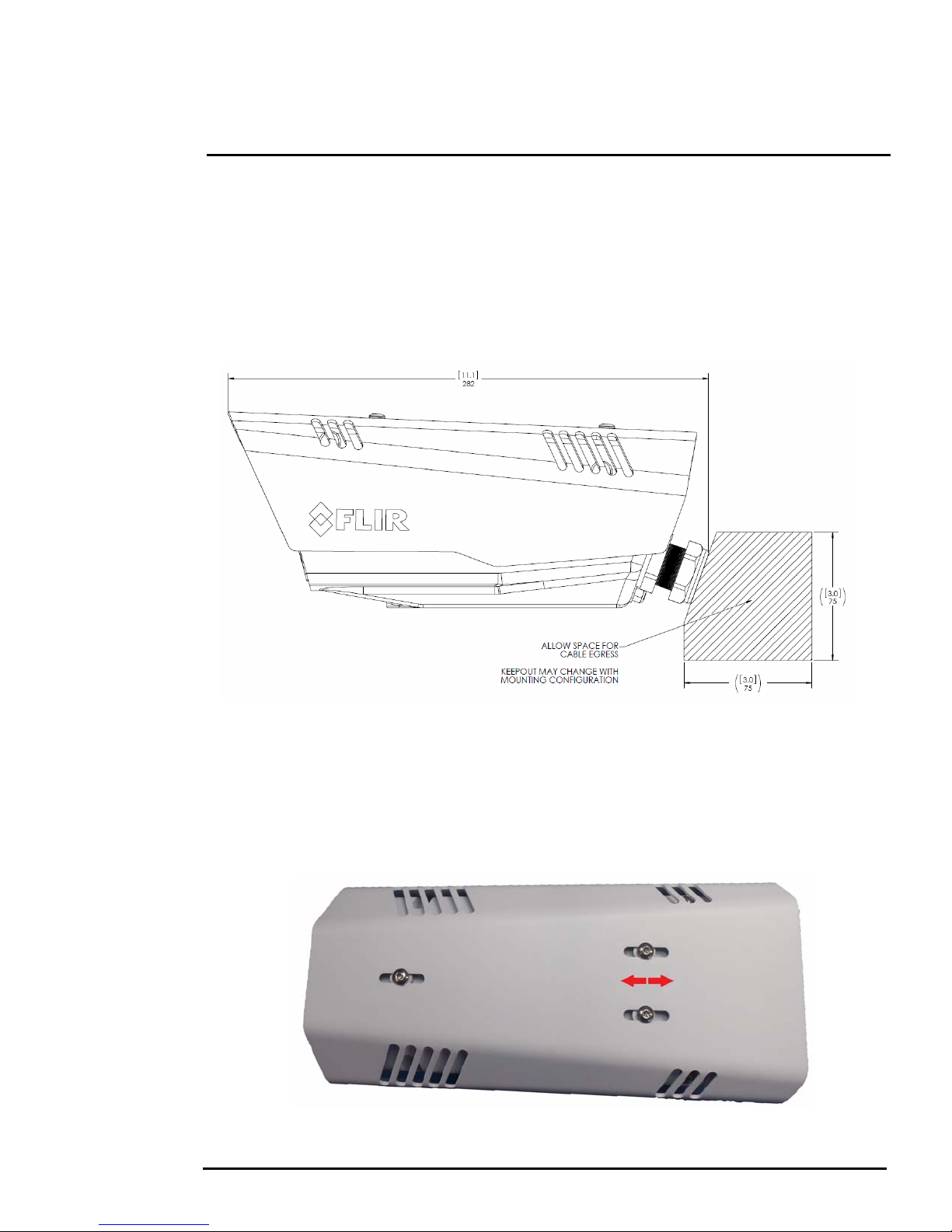

1.5.2 Sunshield

The camera includes a sunshield which should be used for any installation where the camera is

exposed to direct sunlight or precipitation, If the camera is mounted with the top mounting holes, the

sunshield is not used. Depending on the needs of the installation, the sunshield can be positioned in

the neutral (middle) position, or slightly forward or rearward.To change the position of the sunshield,

temporarily loosen the three 3mm hex screws on top, slide the sunshield forward or backward, and

retighten the screws.

427-0070-11-12, version 100 April 2012 1-3

1

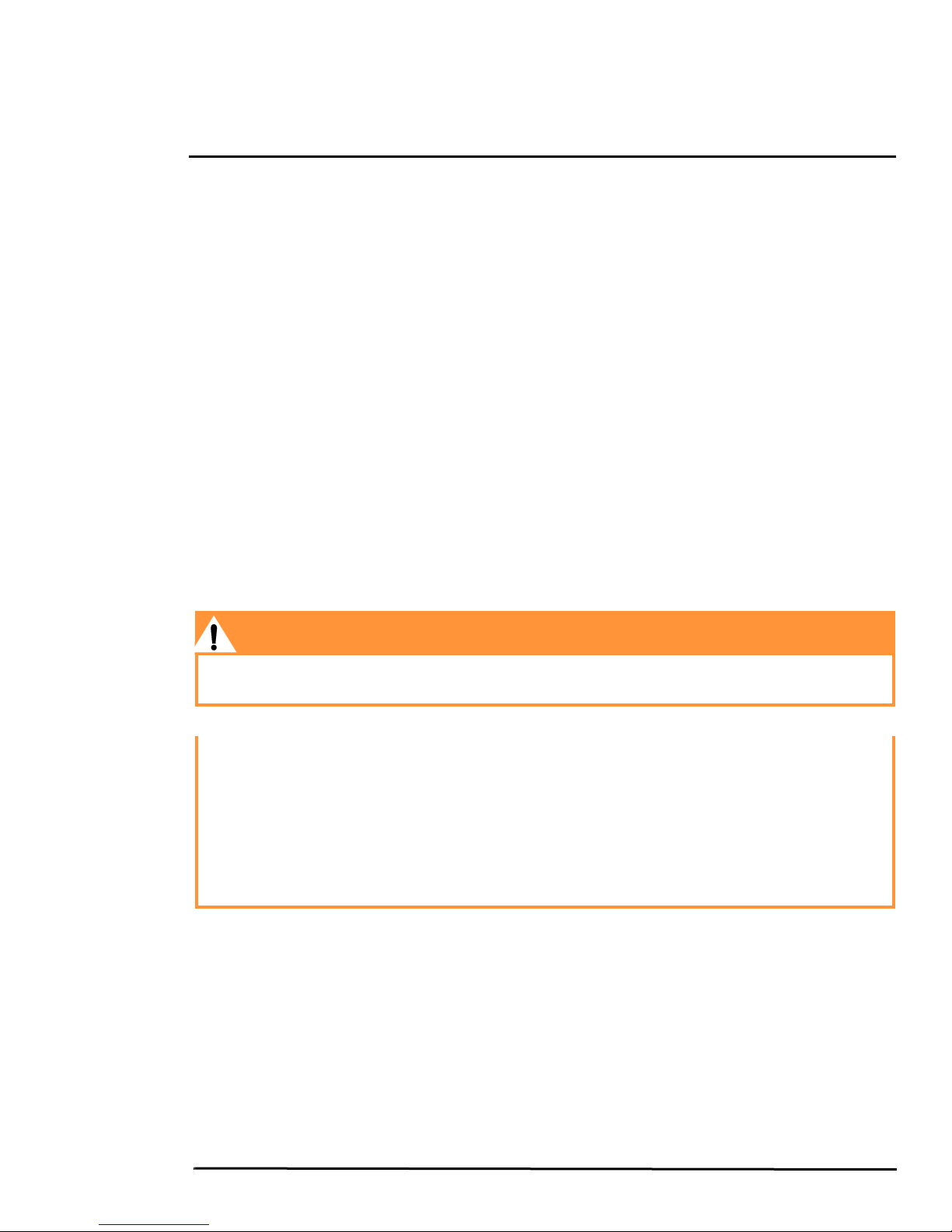

Not to scale

Figure 1-1: FC-Series T Camera Mounting Holes

FC-Series T Camera Installation

1.6 Camera Mounting

The FC-Series T camera can be secured to the mount with two in-line 1/4-20 threaded fasteners on

the top or bottom of the camera. Alternatively the camera can be mounted with four M5 x 0.8 threaded

fasteners to the bottom of the camera. Use Loctite 222 low strength threadlocker for the top mount

fasteners (can be used with the bottom mount fasteners also). Refer to the FC-Series T ICD, FLIR

Doc. # 427-00XX-XX-19 for additional information and specific dimensions.

427-0070-11-12, version 100 April 2012 1-4

1

Not to scale

Figure 1-2: Top Side Mounting Holes

FC-Series T Camera Installation

Once the mounting location has been selected, verify both sides of the mounting surface are

accessible. Install the threaded fasteners into the camera with thread-locking compound.

1.7 Removing the Cover

The top cover of the camera is held in place with four 3mm hex screws. The screws are accessible

through slots in the sunshield, so the sunshield does not need to be removed from the top cover. Use

a 3 mm hex key to loosen the four captive screws, exposing the connections inside the camera

enclosure. There is a grounding wire connected inside the case to the top cover, as shown. If it (or any

of the grounding wires) is temporarily disconnected during the installation, it must be reconnected to

ensure proper grounding of the camera.

427-0070-11-12, version 100 April 2012 1-5

1

Cable Gland

FC-Series T Camera Installation

1.8 Cable Gland Sealing

Proper installation of cable sealing gland and use of appropriate elastomer inserts is critical to long

term reliability. Cables enter the camera mount enclosure through a liquid-tight compression gland.

Be sure to insert the cables through the cable gland on the enclosure before connecting them. If using

a BNC video connection, insert the cable through the gland before terminating the cable (terminated

connectors will not fit through the cable gland). Leave the gland nut loosened until all cable installation

has been completed, and ensure the manufacturer’s recommended cable bend radius is observed

within the enclosure. Do not forget to tighten the cable gland seal nut to ensure a watertight seal and

provide strain relief for cables.

1.8.1 Cable Gland Seal Inserts

The FC-Series T camera comes with a single 3/4” NPT cable gland installed in the camera, with a

two-hole gland seal insert. The gland includes a sealing washer and is secured to the camera with a

nut on the inside of the enclosure. The gland insert has one hole for the power cable (the larger hole)

and another for the video cable. Typically the power cable is inserted in the hole on the left and the

video is inserted through the right, so the cables line up with the connections inside the camera.

Table 1-1: Cable Min/Max Dimensions

Cable Minimum Maximum

Power cable (3 conductor) 6.8mm [ .27 IN ] 9.4 mm [ .37 IN ]

RG 59 Video cable 5.3 mm [ .21 IN ] 6.4 mm [ .25 IN ]

If non-standard cable diameters are used, an appropriate cable gland and insert should be used to fit

the desired cable and to fit the hole in the enclosure. FLIR Systems, Inc. does not provide cable gland

inserts other than the insert supplied with the system.

If a replacement is used, inspect and install the gland fitting in the back cover with suitable leak seal or

sealant and tighten to ensure water tight fittings. To fit the 1.05” (26.7mm) hole in the enclosure, the

thread size should be 3/4” NPT or M25. The gland should be installed with a sealing washer (for

example, Heyco p/n 3261 or equivalent) between the gland and the external surface of the enclosure.

427-0070-11-12, version 100 April 2012 1-6

1

Primary video

connection

Alternate video

connection

Not used

Power

connection

FC-Series T Camera Installation

1.9 Camera Connections

..

1.9.1 Connecting power

Prior to making any connections, ensure the power supply or circuit breaker is switched off. The

camera itself does not have an on/off switch. Generally the FC-Series T camera will be connected to a

circuit breaker and the circuit breaker will be used to apply or remove power to the camera. If power is

supplied to it, the camera will be powered on and operating.

The power cable supplied by the installer must use wires that are sufficient size gauge for the supply

voltage and length of the cable run, to ensure adequate current carrying capacity (18 AWG

recommended for most installations). Always follow local building/safety codes.

Refer to the diagram below for recommended dimensions for cable jacket and wire stripping.

Note

The terminal blocks for power connections will accept 16 AWG to 20 AWG wire size.

427-0070-11-12, version 100 April 2012 1-7

1

FC-Series T Camera Installation

1.9.2 Video Connection

The primary analog video connection of the camera is an open bare-wire connection that does not

require any crimping or termination. Alternatively, the camera also provides a BNC video connector.

Only one or the other connection should be used on a permanent basis to ensure adequate video

quality. The BNC connection can be used to temporarily monitor the video output, without

disconnecting the primary connection.

The video clamp connection is designed to be used with RG-59 solid center coax cable, such as

Belden part number 9244 or equivalent. The video cable used should be rated as RG-59/U or better

to ensure a quality video signal.

Note

Insert the cables through the cable glands on the enclosure before terminating and connecting them.

In general, terminated connectors will not fit through the cable gland. If a terminated cable is required,

it is possible to make a clean and singular cut in the gland seal to install the cable into the gland seal.

Strip the RG-59 cable similar to the way it would be prepared for a crimp-type BNC connector. This is

easily accomplished with a 3-level coaxial stripper that produces the correct stripped dimensions in

one operation, such as Ideal Industries Inc. Coaxial Stripper, part number 45-521 or equivalent.

427-0070-11-12, version 100 April 2012 1-8

1

Camera Ground

FC-Series T Camera Installation

1.9.3 Camera Grounding

Ensure the camera is properly grounded. Failure to properly ground the camera can lead to

permanent damage to the camera. Typical to good grounding practices, the camera chassis ground

should be connected to the lowest resistance path possible. The camera has an external ground

connection on the outside back of the camera.FLIR requires a grounding strap anchored to the

grounding lug and connected to the nearest earth-grounding point.

If, during installation, any ground connections inside the camera are disconnected, they should be

reconnected prior to closing the camera.

1.10 Bench Testing

If mounting the F-Series camera on a pole, tower or any elevated or difficult to access location, it may

be a good idea to bench test the camera prior to final installation. Connect the power and video, and

confirm the video can be displayed on a monitor when the power is turned on. Refer to section 2.1

“Troubleshooting Tips” on page 2-3 if there is a problem.

427-0070-11-12 Rev100 April 2012 1-9

1 FC-Series T Camera Installation

427-0070-11-12, version 100 April 2012 1-10

2Basic Operation

Splash Screen

2 Basic Operation

When power is applied to the FC-Series camera, a FLIR splash screen is displayed for less than two

seconds, and then the camera outputs the live video image. No operator action or intervention is

required - “power in, video out”. No configuration of the camera is necessary.

The thermal camera makes an image based on temperature differences. In the thermal image, the

hottest item in the scene appears as white and the coldest item is black, and all other items are

represented as a grey scale value between white and black.

It may take some time to get used to he thermal imagery from the camera, especially for someone who

only has experience with normal daylight cameras. Having a basic understanding of the differences

between thermal and daylight cameras can help with getting the best performance from the thermal

camera.

Both thermal and daylight cameras have detectors (pixels) that detect energy. One difference between

thermal and daylight cameras has to do with where the energy comes from to create an image. When

viewing an image with an ordinary camera, there has to be some source of visible light (something hot,

such as the sun or lights) that reflects off the objects in the scene to the camera. The same is true with

human eyesight; the vast majority of what people see is based on reflected light energy.

On the other hand, the thermal camera detects energy that is directly radiated from objects in the

scene. Most objects in typical surroundings are not hot enough to radiate visible light, but they easily

radiate the type of infrared energy that the thermal camera can detect. Even very cold objects, like ice

and snow, radiate this type of energy.

The camera is capable of sensing very small temperature differences, and produces a video image that

typically has dramatic contrast in comparison to daylight cameras. This high contrast level from the

thermal video enables intelligent video analytics software to perform more reliably.

427-0070-11-12, version 100 April 2012 2-1

2

Basic Operation

The performance of the camera will likely vary throughout the day. Right after sunset, objects warmed

by the sun will appear warmest. Early in the morning, many of these objects will appear cooler than

their surroundings, so be sure to look for subtle differences in the scene, as opposed to just hot

targets.

Originally developed for the military, thermal imaging cameras are now deployed in numerous

commercial applications where it is impractical or too expensive to use active illumination (lights).

They are perfect for a wide variety of applications including transportation, maritime, security, fire

fighting, and medical applications. The cameras often provide improved daytime viewing in

environments where traditional video camera performance suffers, such as in shadows or backlit

scenes.

The FC-Series T camera is a state-of-the-art thermal imaging system that will provide excellent night

visibility and situational awareness, without any form of natural or artificial illumination. The system is

easy to use, but it is useful to understand how to interpret what is displayed on the monitor.

While the imagery on the monitor may at first look similar to ordinary black and white daylight video,

experience with the camera in varying conditions and seasons will lead to an appreciation of the

characteristics that make thermal imaging distinct. A few tips on how to interpret some of the imagery

may help you to make the most of your system.

The thermal imager inside the camera does not sense light like conventional cameras; it senses heat

or temperature differences. Observe the system during daylight and nighttime operation, and notice

the differences in the picture quality, which are expected. The camera senses small “differences” in

apparent radiation from the objects in view, and displays them as either white (or lighter shades of

grey) for warmer objects, and black (or darker shades of grey) for colder objects.

The thermal imaging camera relies on the fact that all objects, even very cold objects like ice, emit

thermal energy in the portion of the infrared spectrum that this camera can "see", the long wave

infrared (LWIR). Therefore, unlike an illuminated infrared camera, a thermal imaging camera does not

need an additional active illumination source, and creates video based on directly radiated rather than

reflected energy.

This is why hot objects such as parts on an engines and exhaust pipes appear white, while the sky,

puddles of water and other cold objects appear dark (or cool). Scenes with familiar objects will be

easy to interpret with some experience. The camera automatically optimizes the image to provide you

with the best contrast in most conditions.

427-0070-11-12, version 100 April 2012 2-2

2

Basic Operation

2.1 Troubleshooting Tips

If you need help during the installation process, contact your local FLIR representative or, call 877773-3547 inside the US. FLIR Systems, Inc. offers a comprehensive selection of training courses to

help you to get the best performance and value from your thermal imaging camera. Find out more at

the FLIR training web page:

http://www.flir.com/training.

2.1.1 Image freezes momentarily

By design, the camera image will freeze momentarily on a periodic basis during the Flat Field

Correction (FFC) cycle (also known as Non-Uniformity Correction or NUC). Periodically the image will

momentarily freeze for a fraction of a second while the camera performs a flat field correction. A

shutter activates inside the camera and provides a target of uniform temperature, allowing the camera

to correct for ambient temperature changes and provide the best possible image. Just prior to the

FFC, a small green square will appear in the corner of the screen.

2.1.2 No video

If the camera will not produce an image, check the video connection at the camera and at your

display. If the connectors appear to be properly connected but the camera still does not produce an

image, ensure that power has been properly applied to the camera and the circuit breaker is set

properly. If a fuse was used, be sure the fuse is not blown. If the video cabling is suspected as a

possible source of the problem, plug a monitor into the BNC connection inside the camera and

determine if it produces an image.

When the camera is powered on, it will do a NUC operation shortly after startup. If you are uncertain if

the camera is receiving power, it may be useful to listen to the camera to hear if the click-click of the

shutter mechanism can be heard. It may be only be possible to perform this test when the camera is

on a work bench rather than in its installed position.

If the camera still does not produce an image, contact the FLIR dealer or reseller who provided the

camera, or contact FLIR directly (contact information is provided on the rear cover of this manual).

2.1.3 Noisy image

A noisy image is usually attributed to a cable problem (too long or inferior quality) or the cable is

picking up electromagnetic interference (EMI) from another device. Although coax cable has built-in

losses, the longer the cable is (or the smaller the wire gauge/thickness), the more severe the losses

become; and the higher the signal frequency, the more pronounced the losses. Unfortunately this is

one of the most common and unnecessary problems that plagues video systems in general.

Cable characteristics are determined by a number of factors (core material, dielectric material and

shield construction, among others) and must be carefully matched to the specific application.

Moreover, the transmission characteristics of the cable will be influenced by the physical environment

through which the cable is run and the method of installation. Use only high quality cable and ensure

the cable is suitable to the marine environment.

427-0070-11-12, version 100 April 2012 2-3

2

Images at night from standard camera (left) and thermal camera (right)

Basic Operation

Check cable connector terminations. Inferior quality connections may use multiple adapters which

can cause unacceptable noise. Use a high-quality video distribution amplifier when splitting the signal

to multiple monitors.

2.1.4 Image too dark or too light

By default the FC-Series T thermal camera uses an Automatic Gain Control (AGC) setting that has

proven to be superior for most applications, and the camera will respond to varying conditions

automatically. The installer should keep in mind that the sky is quite cold and can strongly affect the

overall image. It may be possible to solve this type of problem by slightly moving the camera up or

down to include (or exclude) items with hot or cold temperatures that influence the overall image. For

example, a very cold background (such as the sky) could cause the camera to use a wider

temperature range than appropriate.

2.1.5 Performance varies with time of day

You may observe differences in the way the camera performs at different times of the day, due to the

diurnal cycle of the sun. Recall that the camera produces an image based on temperature differences.

At certain times of the day, such as just before dawn, the objects in the image scene may all be

roughly the same temperature, compared to other times of the day. Compare this to imagery right

after sunset, when objects in the image may be radiating heat energy that has been absorbed during

the day due to solar loading. Greater temperature differences in the scene generally will allow the

camera to produce high-contrast imagery.

Performance may also be affected when objects in the scene are wet rather than dry, such as on a

foggy day or in the early morning when everything may be coated with dew. Under these conditions, it

may be difficult for the camera to show the temperature the object itself, rather than of the water

coating.

427-0070-11-12, version 100 April 2012 2-4

2

Basic Operation

2.1.6 Eastern or Western Exposure

Once installed, the camera may point directly east or west, and this may cause the sun to be in the

field of view during certain portions of the day. We do not recommend intentionally viewing the sun,

but looking at the sun will not permanently damage the sensor. In fact the thermal imaging camera

often provides a considerable advantage over a conventional camera in this type of back-lit situation.

However, the sun may introduce image artifacts that will eventually correct out. and it may take some

time for the camera to recover. The amount of time needed for recovery will depend on how long the

camera was exposed to the sun. The longer the exposure, the longer the recovery time needed.

427-0070-11-12, version 100 April 2012 2-5

2

Basic Operation

2.2 Camera specifications

Camera Model FC-Series T

Camera Platform Type Fixed

Composite Video NTSC or PAL (switch selectable)

Thermal Camera

Array Format 320x240 (NTSC), 3??x2?? (PAL)

Detector Type Long-Life, Uncooled VOx Microbolometer

Effective Resolution 76,800

Pixel Pitch 25 µm

Field Of View (Focal Length) FC-348 T = 48° × 37° (9 mm)

FC-334 T = 34° × 26° (13 mm)

FC-324 T = 24° × 18° (19 mm)

Spectral Range 7.5 to 13.5 μm

Lens Athermalized, focus-free

Ge n e r a l

Weight 4.2 lb with sun shield

Dimensions (L,W,H) 10.8" x 5.4" x 4.4" with sun shield

Input Voltage 90-240VAC single phase 50-60Hz

Power Consumption 1.7W nominal at 110VAC

18W Peak Power with heaters

Mounting Provisions Two 1/4-20" threaded holes on top and bottom,

1" spacing along center line front to back

Shipping weight 5.9 lbs (2.7kg) does this include the box, or ?

Shipping Dimensions 143/4”(L) x 73/4”(W) x 73/4”(H)

Environmental

IP rating IP66

Operating temperature range -50C to 75C (continuous operation)

-40C to 75C (cold start)

Storage Temperature range -55C to 85C

Humidity 0-95% relative

Shock MIL-STD-810F "Transportation"

Vibration 10g shock pulse with a 11ms half- sine profile

NEMA TS2 Tested in accordance with Section 2.1 of NEMA TS 2-

2003 for the following categories: Operating Voltage,

Operating Frequency, Ambient Temperature, Humidity,

Vibration & Shock

Approvals FCC Part15, Subpart B, Class B, EN 55022 Class B,

EN 50130 - 4, EN 50130-4

427-0070-11-12, version 100 April 2012 2-6

2Basic Operation

427-0070-11-12, version 100 April 2012 2-7

FLIR Systems, Inc.

70 Castilian Drive

Goleta, CA 93117

USA

PH: + 1 805.964.9797

PH: + 1 877.773.3547

(Sales)

PH: + 1 888.747.3547

(Support)

FX: + 1 805.685.2711

www.flir.com

Corporate Headquarters

FLIR Systems, Inc.

27700 SW Parkway Ave.

Wilsonville, OR 97070

USA

PH: +1 503.498.3547

FX: +1 503.498.3153

sales@flir.com

Document:

427-0070-11-12

Version: 100

Date: April 2012

Loading...

Loading...