Page 1

User’s manual

FLIR A310 ex

nbn Austria GmbH

Page 2

Page 3

User’s manual

FLIR A310 ex

#T559891; r. AE/57789/57789; en-US

iii

Page 4

Page 5

Table of contents

1 Disclaimers ............ .. ..................................... .. ................................. 1

1.1 Legal disclaimer ................................ .. .. .. ................................. 1

1.2 Usage statistics .......................... .. ..................................... ....... 1

1.3 U.S. Government Regulations....................... .. .. .. ......................... 1

1.4 Copyright ..... .. .. .. ................................. .. .. ................................ 1

1.5 Quality assurance .. .. .. .. ................................. .. .. .. ......................1

1.6 Patents...................... .. .. ................................. .. .. .. ..................1

1.7 EULA Terms ......... .. .. .. ................................. .. .. .. ......................1

1.8 EULA Terms ......... .. .. .. ................................. .. .. .. ......................1

2 Safety information .......... .. ..................................... .. ..........................2

3 Notice to user ......... .. ..................................... .. ................................. 3

3.1 Calibration................................. .. .. .. ................................. .. .. .. . 3

3.2 Accuracy ................ .. .. .. ................................. .. .. .. ................... 3

3.3 Disposal of electronic waste ............................... .. .. .. ................... 3

3.4 Training .... .. .. .. ................................. .. .. .. ................................. 3

3.5 Documentation updates .................................... .. .. .. ................... 3

3.6 Important note about this manual........... .. .. .. ................................. 4

3.7 Note about authoritative versions. .. ................................... .. .. ........4

4 Customer help .............. .. .. .. ............................... .. .. .. ......................... 5

4.1 General ............... .. .. .. ................................. .. .. .. ......................5

4.2 Submitting a question .............. .. .. .. ................................. .. .. ....... 5

4.3 Downloads ........... .. .. .. ................................. .. .. .. ......................5

5 What is FLIR A310 ex?..................................... .. ................................. 6

6 Typical system overview.......................... ..................................... .. ....7

7 Typical system setup procedure................ .. .. .. ................................. .. .8

8 Technical data ..... .. .. .. ................................. .. .. .. ................................. 9

8.1 Online field-of-view calculator ............ .. .. .. ................................. .. . 9

8.2 Note about technical data . ................................. .. .. .. ................... 9

8.3 Note about authoritative versions. .. ................................... .. .. ........9

8.4 FLIR A310 ex 25°.......... .. .. .. ................................. .. .. .. ............. 10

8.5 FLIR A310 ex 45°.......... .. .. .. ................................. .. .. .. ............. 14

9 Mechanical drawings .. .. ..................................... .............................. 18

10 EC Type Examination Certificate........................... .. ........................... 20

11 EC Type Examination Certificate, 1st supplement................................ 23

12 EC Type Examination Certificate, 2nd supplement. .............................. 26

13 EC Type Examination Certificate, 3rd supplement . .............................. 28

14 EC Declaration of conformity (enclosure) ..................... .. .................... 31

15 Certiticate of conformity (camera) ..... ....................................... ......... 33

16 Thermographic measurement techniques .............................. .. .......... 35

16.1 Introduction .. .. .. .. ................................. .. .. .. ........................... 35

16.2 Emissivity....................... .. .. .. ................................. .. .. .. .......... 35

16.2.1 Finding the emissivity of a sample. ............................... .. .. 35

16.3 Reflected apparent temperature ......... .. .. .. ................................. . 39

16.4 Distance .. ................................. .. .. .. ................................. .. .. . 39

16.5 Relative humidity ... .. .. .. ................................. .. .. .. .................... 39

16.6 Other parameters............. .. .. .. ................................. .. .. .. .......... 39

17 About FLIR Systems .................. .. ..................................... .. ............. 40

17.1 More than just an infrared camera ............. .. .. .. ........................... 41

17.2 Sharing our knowledge ............. .. .. .. ................................. .. .. .. .. 41

17.3 Supporting our customers........................... .............................. 42

A OEM manual (German)....... .. .. .. ................................. .. .. .. ................. 43

B OEM manual (English) ....... .. ..................................... ....................... 67

#T559891; r. AE/57789/57789; en-US

v

Page 6

Page 7

1

Disclaimers

1.1 Legal disclaimer

For warranty terms, please refer to https://www.flir.com/warranty.

1.2 Usage statistics

FLIR Systems reserves the right to gather anonymous usage statistics to help

maintain and improve the quality of our software and services.

1.3 U.S. Government Regulations

This product may be subject to U.S. Export Regulations. Please send any inquiries to exportquestions@flir.com.

1.4 Copyright

© 2019, FLIR Systems, Inc. All rights reserved worldwide. No parts of the

software including source code may be reproduced, transmitted, transcribed

or translated into any language or computer language in any form or by any

means, electronic, magnetic, optical, manual or otherwise, without the prior

written permission of FLIR Systems.

The documentation must not, in whole or part, be copied, photocopied, reproduced, translated or transmitted to any electronic medium or machine

readable form without prior consent, in writing, from FLIR Systems.

Names and marks appearing on the products herein are either registered

trademarks or trademarks of FLIR Systems and/or its subsidiaries. All other

trademarks, trade names or company names referenced herein are used for

identification only and are the property of their respective owners.

1.5 Quality assurance

The Quality Management System under which these products are developed

and manufactured has been certified in accordance with the ISO 9001

standard.

FLIR Systems is committed to a policy of continuous development; therefore

we reserve the right to make changes and improvements on any of the products without prior notice.

1.6 Patents

This product is protected by patents, design patents, patents pending, or design patents pending. Please refer to the FLIR Systems’ patent registry:

https://www.flir.com/patentnotices.

1.7 EULA Terms

Qt4 Core and Qt4 GUI, Copyright ©2013 Nokia Corporation and FLIR Systems AB. This Qt library is a free software; you can redistribute it and/or modify it under the terms of the GNU Lesser General Public License as published

by the Free Software Foundation; either version 2.1 of the License, or (at your

option) any later version. This library is distributed in the hope that it will be

useful, but WITHOUT ANY WARRANTY; without even the implied warranty of

MERCHANTABILITYor FITNESS FOR A PARTICULAR PURPOSE. See the

GNU Lesser General Public License, http://www.gnu.org/licenses/lgpl-2.1.

html. The source code for the libraries Qt4 Core and Qt4 GUI may be requested from FLIR Systems AB.

1.8 EULA Terms

• Youhave acquired a device (“INFRARED CAMERA”) that includes software licensed by FLIR Systems AB from Microsoft Licensing, GP or its

affiliates (“MS”). Those installed software products of MS origin, as well

as associated media, printed materials, and “online” or electronic documentation (“SOFTWARE”) are protected by international intellectual

property laws and treaties. The SOFTWARE is licensed, not sold. All

rights reserved.

• IF YOU DO NOT AGREE TO THIS END USER LICENSE AGREEMENT

(“EULA”), DO NOT USE THE DEVICE OR COPY THE SOFTWARE. INSTEAD, PROMPTLY CONTACT FLIR Systems AB FOR INSTRUCTIONS ON RETURN OF THE UNUSED DEVICE(S) FOR A REFUND.

ANY USE OF THE SOFTWARE, INCLUDING BUT NOT LIMITED TO

USE ON THE DEVICE, WILL CONSTITUTE YOUR AGREEMENT TO

THIS EULA (OR RATIFICATION OF ANY PREVIOUS CONSENT).

• GRANT OF SOFTWARE LICENSE. This EULA grants you the following

license:

◦ Youmay use the SOFTWARE only on the DEVICE.

◦ NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOL-

ERANT.FLIR Systems AB HAS INDEPENDENTLY DETERMINED

HOW TO USE THE SOFTWARE IN THE DEVICE, AND MS HAS

RELIED UPON FLIR Systems AB TO CONDUCT SUFFICIENT

TESTING TO DETERMINE THAT THE SOFTWARE IS SUITABLE

FOR SUCH USE.

◦ NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is

provided “AS IS” and with all faults. THE ENTIRE RISK AS TO

SATISFACTORY QUALITY, PERFORMANCE, ACCURACY, AND

EFFORT (INCLUDING LACK OF NEGLIGENCE) IS WITH YOU.

ALSO, THERE IS NO WARRANTYAGAINST INTERFERENCE

WITH YOUR ENJOYMENT OF THE SOFTWARE OR AGAINST

INFRINGEMENT.IF YOU HAVE RECEIVED ANY WARRANTIES

REGARDING THE DEVICE OR THE SOFTWARE, THOSE WARRANTIES DO NOT ORIGINATE FROM, AND ARE NOT BINDING

ON, MS.

◦ No Liability for Certain Damages. EXCEPT AS PROHIBITED BY

LAW,MS SHALL HAVE NO LIABILITY FOR ANY INDIRECT,

SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES

ARISING FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE SOFTWARE. THIS LIMITATION SHALL

APPLYEVEN IF ANY REMEDY FAILS OF ITS ESSENTIAL PURPOSE. IN NO EVENT SHALL MS BE LIABLE FOR ANY

AMOUNT IN EXCESS OF U.S. TWO HUNDRED FIFTY DOLLARS (U.S.$250.00).

◦ Limitations on Reverse Engineering, Decompilation, and Dis-

assembly. You may not reverse engineer, decompile, or disas-

semble the SOFTWARE, except and only to the extent that such

activity is expressly permitted by applicable law notwithstanding

this limitation.

◦ SOFTWARE TRANSFER ALLOWED BUT WITH RESTRIC-

TIONS. You may permanently transfer rights under this EULA only

as part of a permanent sale or transfer of the Device, and only if

the recipient agrees to this EULA. If the SOFTWARE is an upgrade,

any transfer must also include all prior versions of the SOFTWARE.

◦ EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is

subject to U.S. export jurisdiction. You agree to comply with all applicable international and national laws that apply to the SOFTWARE, including the U.S. Export Administration Regulations, as

well as end-user, end-use and destination restrictions issued by U.

S. and other governments. For additional information see http://

www.microsoft.com/exporting/.

#T559891; r. AE/57789/57789; en-US

1

Page 8

2

Safety information

CAUTION

Do not point the infrared camera (with or without the lens cover) at strong energy sources, for example,

devices that cause laser radiation, or the sun. This can have an unwanted effect on the accuracy of the

camera. It can also cause damage to the detector in the camera.

CAUTION

Applicability: Cameras with an automatic shutter that can be disabled.

Do not disable the automatic shutter in the camera for a long time period (a maximum of 30 minutes is

typical). If you disable the shutter for a longer time period, damage to the detector can occur.

#T559891; r. AE/57789/57789; en-US

2

Page 9

3

Notice to user

3.1 Calibration

We recommend that you send in the camera for calibration once a year. Contact your local sales office for instructions on where to send the camera.

3.2 Accuracy

For very accurate results, we recommend that you wait 5 minutes after you have started

the camera before measuring a temperature.

3.3 Disposal of electronic waste

Electrical and electronic equipment (EEE) contains materials, components and substances that may be hazardous and present a risk to human health and the environment

when waste electrical and electronic equipment (WEEE) is not handled correctly.

Equipment marked with the below crossed-out wheeled bin is electrical and electronic

equipment. The crossed-out wheeled bin symbol indicates that waste electrical and electronic equipment should not be discarded together with unseparated household waste,

but must be collected separately.

For this purpose all local authorities have established collection schemes under which

residents can dispose waste electrical and electronic equipment at a recycling centre or

other collection points, or WEEE will be collected directly from households. More detailed information is available from the technical administration of the relevant local

authority.

3.4 Training

To read about infrared training, visit:

• http://www.infraredtraining.com

• http://www.irtraining.com

• http://www.irtraining.eu

3.5 Documentation updates

Our manuals are updated several times per year, and we also issue product-critical notifications of changes on a regular basis.

To access the latest manuals, translations of manuals, and notifications, go to the Download tab at:

http://support.flir.com

It only takes a few minutes to register online. In the download area you will also find the

latest releases of manuals for our other products, as well as manuals for our historical

and obsolete products.

#T559891; r. AE/57789/57789; en-US

3

Page 10

Notice to user3

3.6 Important note about this manual

FLIR Systems issues generic manuals that cover several cameras within a model line.

This means that this manual may contain descriptions and explanations that do not apply

to your particular camera model.

3.7 Note about authoritative versions

The authoritative version of this publication is English. In the event of divergences due to

translation errors, the English text has precedence.

Any late changes are first implemented in English.

#T559891; r. AE/57789/57789; en-US

4

Page 11

4

Customer help

4.1 General

For customer help, visit:

http://support.flir.com

4.2 Submitting a question

To submit a question to the customer help team, you must be a registered user. It only

takes a few minutes to register online. If you only want to search the knowledgebase for

existing questions and answers, you do not need to be a registered user.

When you want to submit a question, make sure that you have the following information

to hand:

• The camera model

• The camera serial number

• The communication protocol, or method, between the camera and your device (for example, SD card reader, HDMI, Ethernet, USB, or FireWire)

• Device type (PC/Mac/iPhone/iPad/Android device, etc.)

• Version of any programs from FLIR Systems

• Full name, publication number, and revision number of the manual

4.3 Downloads

On the customer help site you can also download the following, when applicable for the

product:

• Firmware updates for your infrared camera.

• Program updates for your PC/Mac software.

• Freeware and evaluation versions of PC/Mac software.

• User documentation for current, obsolete, and historical products.

• Mechanical drawings (in *.dxf and *.pdf format).

• Cad data models (in *.stp format).

• Application stories.

• Technical datasheets.

#T559891; r. AE/57789/57789; en-US

5

Page 12

5

What is FLIR A310 ex?

Explosive atmospheres need to be protected from ignition sources by selecting equipment and protective systems that meet the requirements of the ATEX product directives

and similar regulations.

The FLIR A310 ex is an ATEX-proof solution, with a thermal imaging camera mounted in

an enclosure, making it possible to monitor critical and other valuable assets in explosive

atmospheres. Process monitoring, quality control, and fire detection in potentially explosive locations are typical applications for the FLIR A310 ex.

Key features:

• Thermography monitoring and early fire detection in explosion hazard areas.

• Enclosures for infrared cameras in classification zones 1, 2, 21, and 22.

• ATEX certified to the latest standards.

• Rated to protection class IP67.

• Plug and play installation, with the enclosure delivered ready for use.

#T559891; r. AE/57789/57789; en-US

6

Page 13

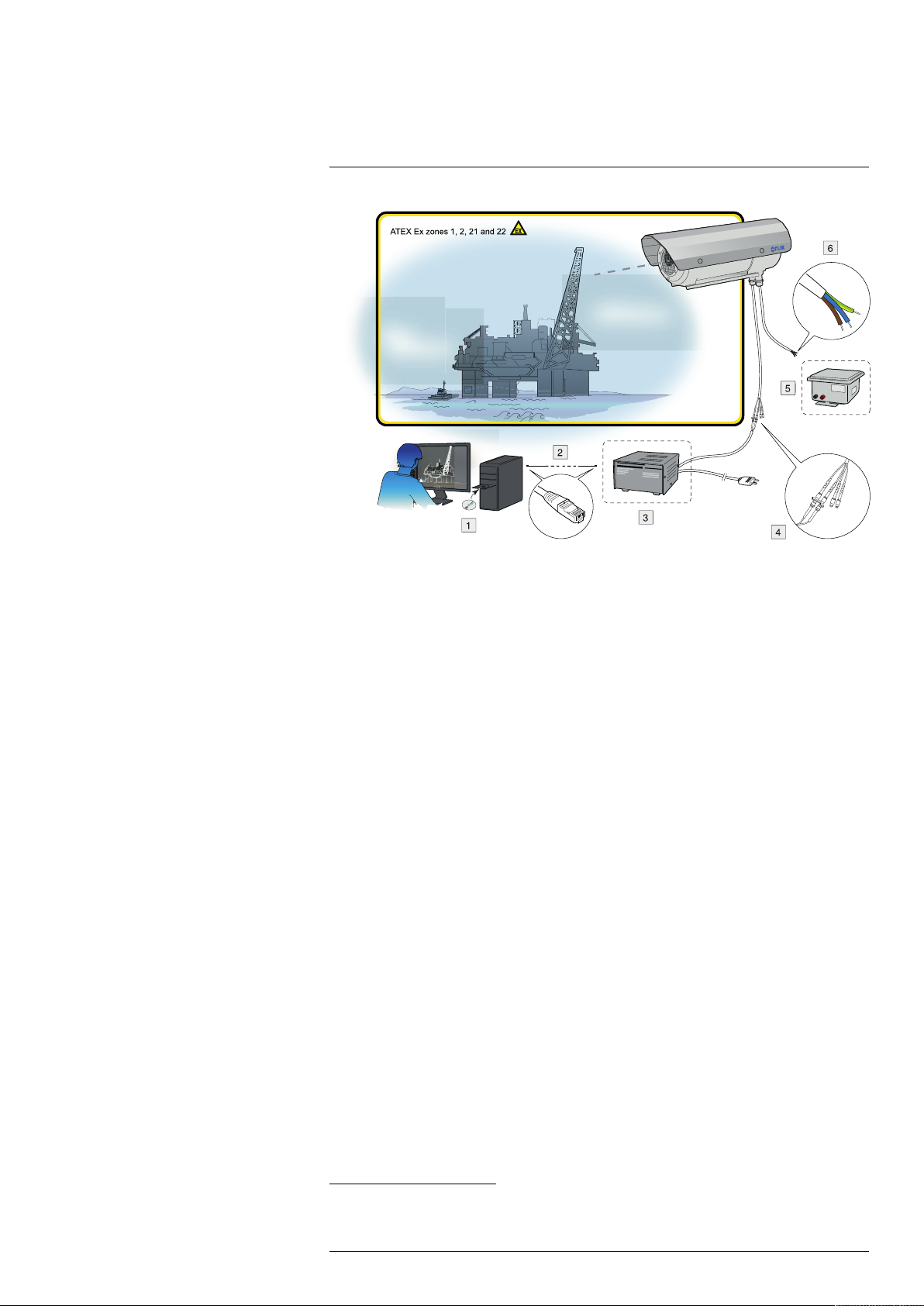

6

Typical system overview

1. Thermovision System Tools & Utilities CD-ROM.

2. Ethernet cable.

3. Optical-to-Ethernet converter.

4. FC connectors from the camera housing (including two spares).

5. 24 V DC power supply.

6. Pigtail cable from the housing. The color coding of the pigtail cable is:

• Brown: positive (+).

• Blue: negative (–).

• Green/yellow: earth.

1

1

1

1. Not supplied with the camera unit.

#T559891; r. AE/57789/57789; en-US

7

Page 14

7

Typical system setup procedure

1. Unpack the camera unit from the cardboard box.

2. Install the camera unit at the intended location. It is the responsibility of the installer

to meet all applicable safety standards required by the authorities of the region in

which the unit will be operating in.

3. Connect the camera unit to an external power supply.

The color coding of the pigtail cable is:

• Brown: positive +.

• Blue: negative –.

• Green/yellow: earth.

Note The external power supply must not be inside the classified zone.

4. Connect the camera unit to an optical-to-Ethernet converter.

Note The optical-to-Ethernet converter must not be inside the classified zone.

5. Install the Thermovision System Tools & Utilities CD-ROM on a computer connected

to the network. This will install the following software:

• FLIR IP Config.

• FLIR IR Monitor.

• FLIR IR Camera Player.

6. Start FLIR IP Config to identify the unit in the network and automatically assign or

manually set IP addresses, etc. For more information, see the FLIR IP Config manual

on the User Documentation CD-ROM or on the Help menu in FLIR IP Config.

7. Start FLIR IR Monitor to control the camera, e.g., laying out measurement tools and

setting up alarms. For more information, see the FLIR IR Monitor manual on the User

Documentation CD-ROM or on the Help menu in FLIR IR Monitor.

2

The unit requires 24 V DC in.

2

2. Not supplied with the camera unit.

#T559891; r. AE/57789/57789; en-US

8

Page 15

8

Technical data

Table of contents

8.1 Online field-of-view calculator.......................... .. ................................. 9

8.2 Note about technical data................. ....................................... ...........9

8.3 Note about authoritative versions.............. .. ..................................... .. .9

8.4 FLIR A310 ex 25° .................. ..................................... .. .................... 10

8.5 FLIR A310 ex 45° .................. ..................................... .. .................... 14

8.1 Online field-of-view calculator

Please visit http://support.flir.com and click the photo of the camera series for field-of-

view tables for all lens–camera combinations.

8.2 Note about technical data

FLIR Systems reserves the right to change specifications at any time without prior notice.

Please check http://support.flir.com for latest changes.

8.3 Note about authoritative versions

The authoritative version of this publication is English. In the event of divergences due to

translation errors, the English text has precedence.

Any late changes are first implemented in English.

#T559891; r. AE/57789/57789; en-US

9

Page 16

Technical data8

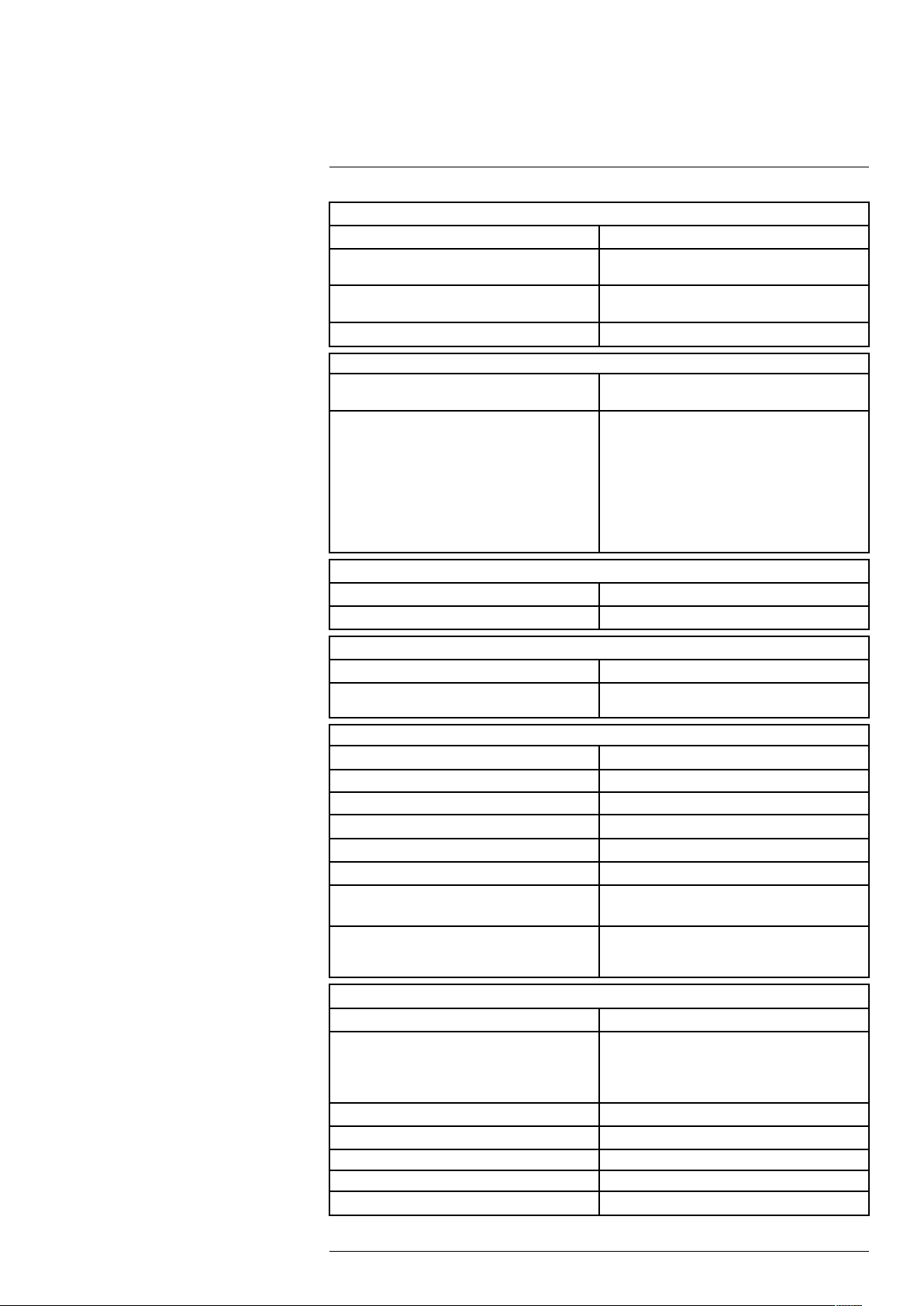

8.4 FLIR A310 ex 25°

P/N: 71001-1103

Rev.: 51350

Introduction

The FLIR A310 ex is an ATEX-proof solution, with a thermal imaging camera mounted in

an enclosure—making it possible to monitor critical and other valuable assets in explosive atmospheres. Process monitoring, quality control, and fire detection in potentially

explosive locations are typical applications for the FLIR A310 ex.

• Thermographic monitoring and early fire detection in an explosion–hazard area.

• Enclosures for infrared cameras in Ex zones 1, 2, 21, 22.

• ATEX certified.

• Protection class IP67.

• Plug-and-play installation with the enclosure delivered ready for use.

• Available with additional options.

The certification covers the entire system, which includes the enclosure as well as all

components inside of it, such as the infrared camera, heater, and integrated controller.

This means that no additional certification is required for operation.

The integrated controller is equipped with two fiber optic and two Ethernet ports. This enables a flexible network integration in star ring topologies.

In addition, the integrated controller features several digital I/O channels and sensors for

temperature, humidity, and pressure. Among other functions, the I/O channels enable

the user to switch on/off the camera and the heater via remote control. Access is through

an integrated web interface or Modbus TCP/IP.

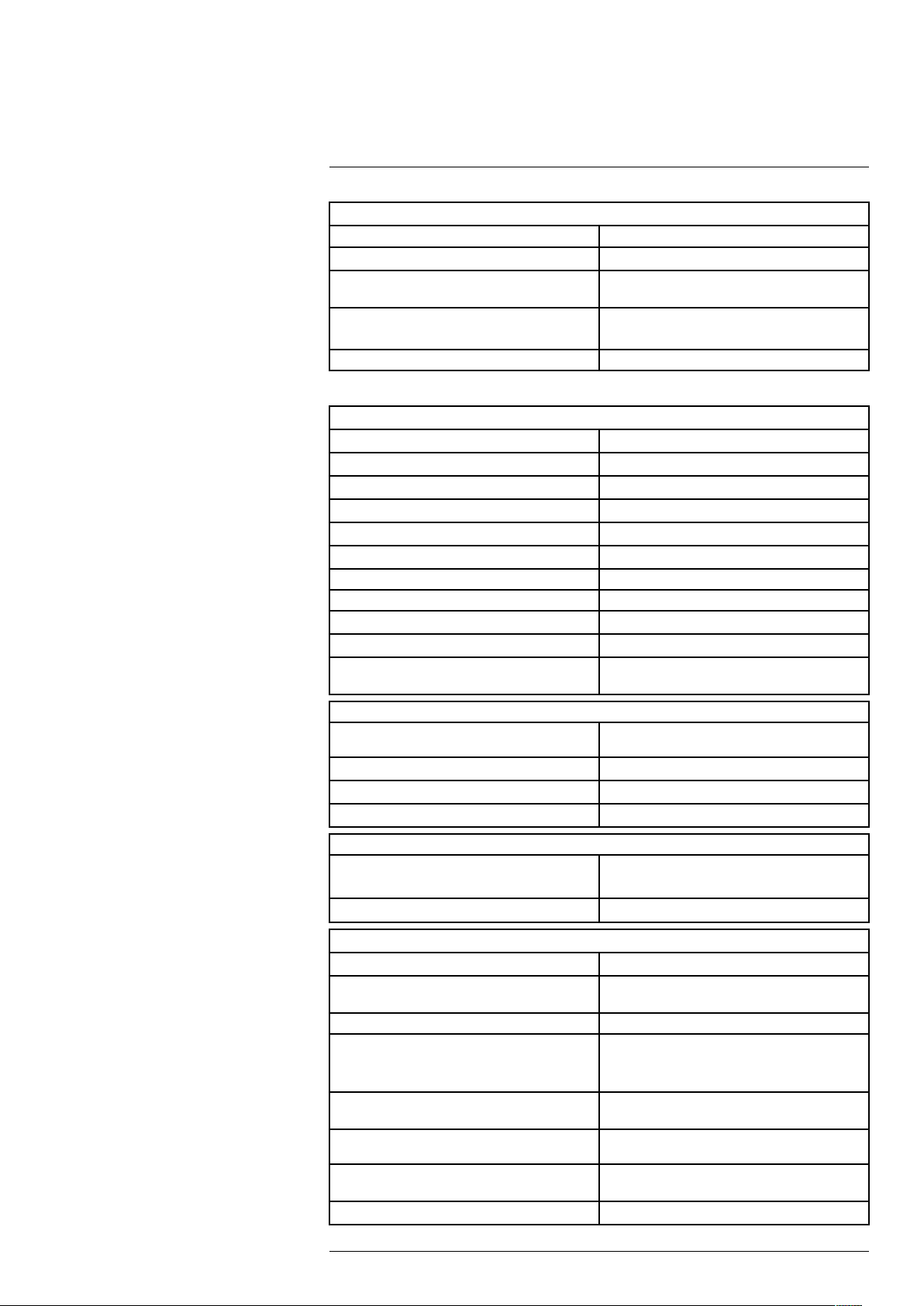

Explosion-proof housing

General data

Ambient temperature range for operation –40°C to +60°C (–40°F to +140°F)

Protection class IP67

Weight 6.7 kg (without camera and lens)

Empty volume 5.06 l

External dimensions (without sun shield) D = 170 mm, L = 408 mm

Housing material Nickel-plated aluminium

Surface

Protection window Germanium, double-sided AR Coated, externally

Maximum power of the additional heater 16 W

Operating voltage 24 V DC

Maximum electric connection power 60 W

Power cable Helukabel 37264

Length of power cable 4 m (13 ft.)

Power cable configuration Pigtail

Powder coated

with additional hard-carbon layer

Ethernet medium Multi-mode breakout fiber AT-V(ZN)Y(ZN)Y 4G50/

125 OM2

Length of Ethernet cable 4 m (13 ft.)

Ethernet configuration Pigtail with FC connector

#T559891; r. AE/57789/57789; en-US

10

Page 17

Technical data8

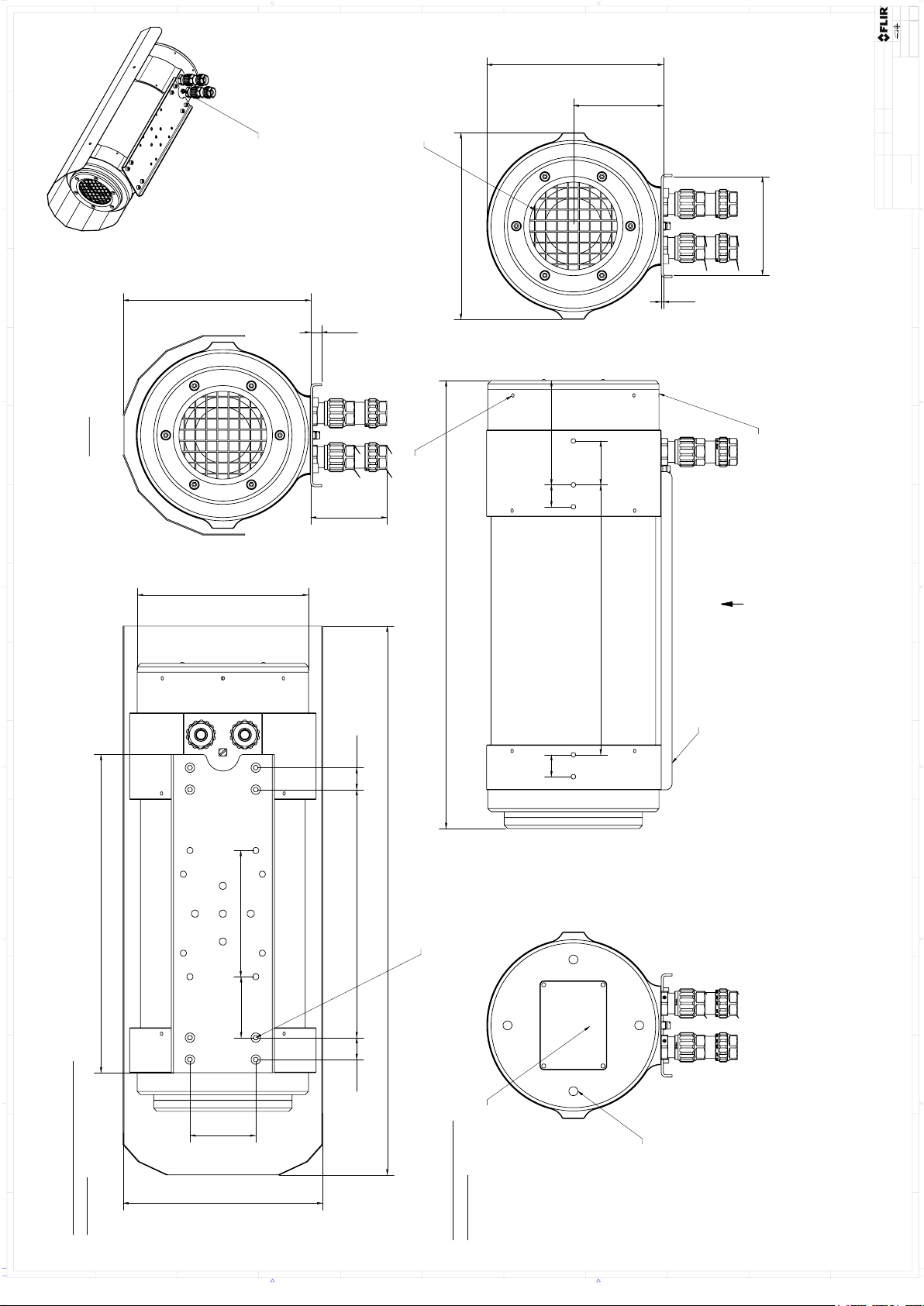

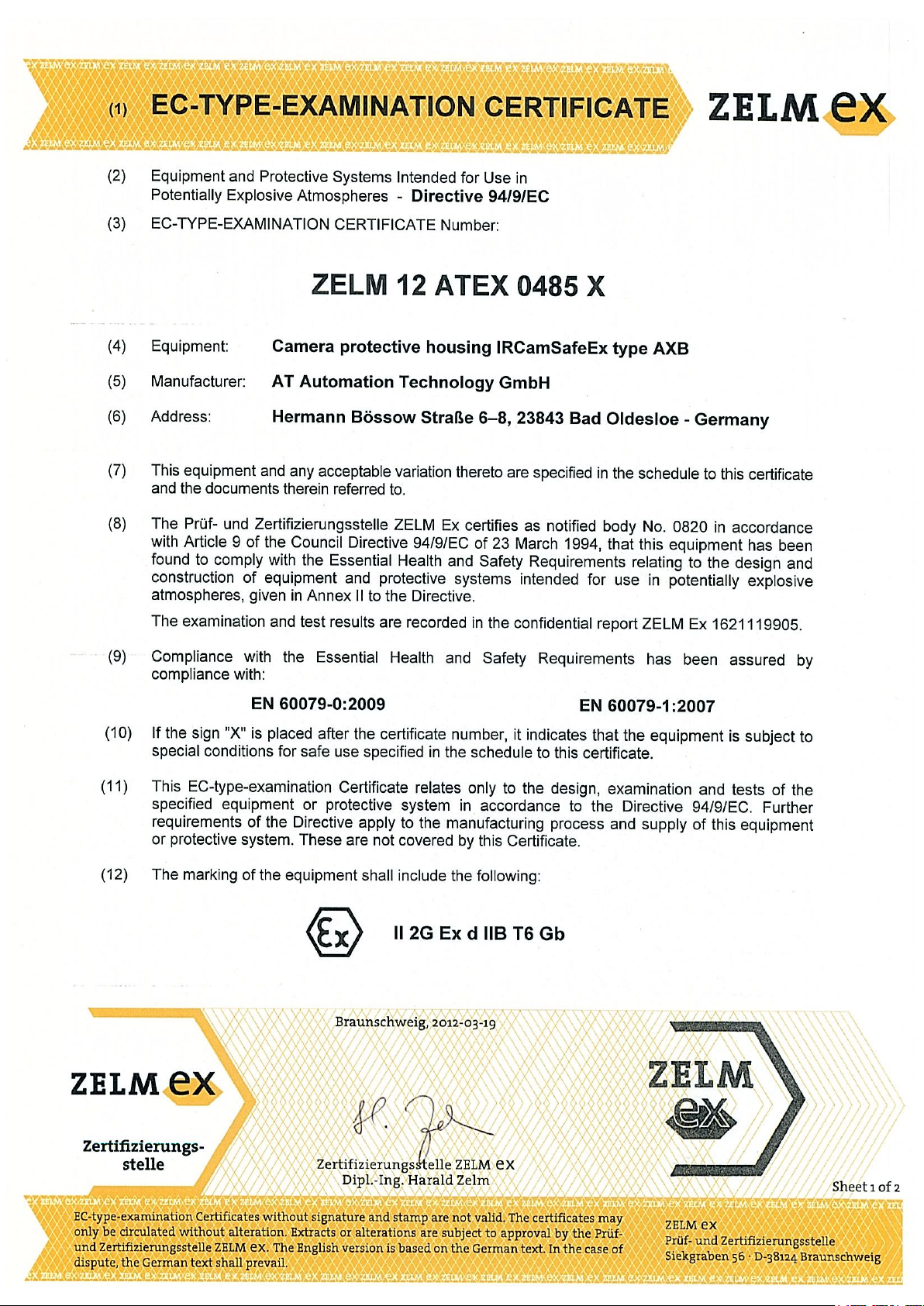

Explosion protection-specific data

For use in EX zone 1, 2, 21, 22

Ignition protection category Flame-proof enclosure “d”

Maximum surface temperature (according to temperature class T6)

ATEX certification (version -AXC)

Verification certificate ZELM 12 ATEX 0485 X

Maximum 85°C

• II 2G Ex db IIC T6 / T5

• II 2D Ex tb IIIC T85° / T100

Camera system

Imaging and optical data

IR resolution 320 × 240 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Minimum focus distance 0.4 m (1.31 ft.)

Focal length 18 mm (0.7 in.)

Spatial resolution (IFOV)

Lens identification Automatic

F-number 1.3

Image frequency 30 Hz

Focus Automatic or manual (built in motor)

Zoom 1–8× continuous, digital, interpolating zooming on

25° × 18.8°

1.36 mrad

images

Detector data

Detector type Focal plane array (FPA), uncooled

Spectral range

Detector pitch 25 µm

Detector time constant Typical 12 ms

Measurement

Object temperature range

Accuracy ±4°C (±7.2°F) or ±4% of reading

Measurement analysis

Spotmeter 10 (with no image streaming)

Area 10 boxes with max./min./average/position (with no

Isotherm 1 with above/below/interval

Measurement option Measurement Mask Filter

Difference temperature Delta temperature between measurement func-

Reference temperature Manually set or captured from any measurement

Atmospheric transmission correction Automatic, based on inputs for distance, atmos-

Optics transmission correction Automatic, based on signals from internal sensors

microbolometer

7.5–13 µm

• –20 to +120°C (–4 to +248°F)

• 0 to +350°C (+32 to +662°F)

image streaming)

Schedule response: File sending (ftp), email

(SMTP)

tions or reference temperature

function

pheric temperature and relative humidity

#T559891; r. AE/57789/57789; en-US

11

Page 18

Technical data8

Measurement analysis

Emissivity correction Variable from 0.01 to 1.0

Reflected apparent temperature correction Automatic, based on input of reflected

External optics/windows correction Automatic, based on input of optics/window trans-

Measurement corrections Global and individual object parameters

Alarm

Alarm functions 6 automatic alarms on any selected measurement

Alarm output Log, store image, file sending (ftp), email notifica-

temperature

mission and temperature

function, Digital In, Camera temperature, timer

tion (SMTP).

With an additional FLIR I/O module (T130090 or

T130091), the system can provide up to 8 digital

outputs and 8 analog outputs that can be connected to any camera analytic function or the

cameras status. These outputs can be connected

to existing alarm infrastructure, PLCs, or data

loggers.

Set-up

Color palettes Color palettes (BW, BW inv, Iron, Rain)

Set-up commands Date/time, Temperature (°C/°F)

Storage of images

Storage media Built-in memory for image storage

File formats Standard JPEG, 16-bit measurement data

Ethernet

Ethernet

Ethernet, type 100 Mbps

Ethernet, standard IEEE 802.3

Ethernet, configuration Pigtail with FC-connector (fiber)

Ethernet, communication TCP/IP socket-based FLIR proprietary

Ethernet, video streaming

Ethernet, image streaming 16-bit 320 × 240 pixels @ 7-8 Hz

Ethernet, protocols

Shipping information

Packaging, type

List of contents

Packaging, weight

Packaging, size 495 × 370 × 192 mm (19.5 × 14.6 × 7.6 in.)

EAN-13 7332558008355

UPC-12

Country of origin Sweden

included

Control, result and image

MPEG-4, ISO/IEC 14496-1 MPEG-4 ASP@L5

• Radiometric

Ethernet/IP, Modbus TCP, TCP, UDP, SNTP, RTSP,

RTP, HTTP, ICMP, IGMP, ftp, SMTP, SMB (CIFS),

DHCP, MDNS (Bonjour), uPnP

Cardboard box

• Infrared camera with lens, in explosion-proof

housing

• Printed documentation

• Utility CD-ROM

845188008703

#T559891; r. AE/57789/57789; en-US

12

Page 19

Technical data8

Supplies & accessories:

• T129252; Special temperature range -20 to +700 deg C

• T129253; Special temperature range -20 to +500 deg C

• T129254; High temperature measurement option -20 to +2000 deg C

• T130151; Special temperature range -20 to +2000 deg C

• T130090; I/O module MIO-A310-1

• T130091; I/O module MIO-A310-7

• T911288ACC; Pole mount adapter for wall mount kit

• T199713; ThermoVision CM Panel, max. 4 cameras

• T199712; ThermoVision CM Panel, max. 9 cameras

• T130169; Thermovision CM, max. 4 cameras

• T130170; Thermovision CM, max. 9 cameras

• T911263ACC; Wall mount kit

• INST-EW-0165; Extended Warranty 1 Year for A6xx, A310ex, T640/bx, T650sc, T660

• INST-EWGM-0175; Premium Service Package for A310ex, A3xxf, A6xx, T620-T660

• INST-GM-0155; General Maintenance Package for A3xxf, A310ex, A310pt, A6xx

#T559891; r. AE/57789/57789; en-US

13

Page 20

Technical data8

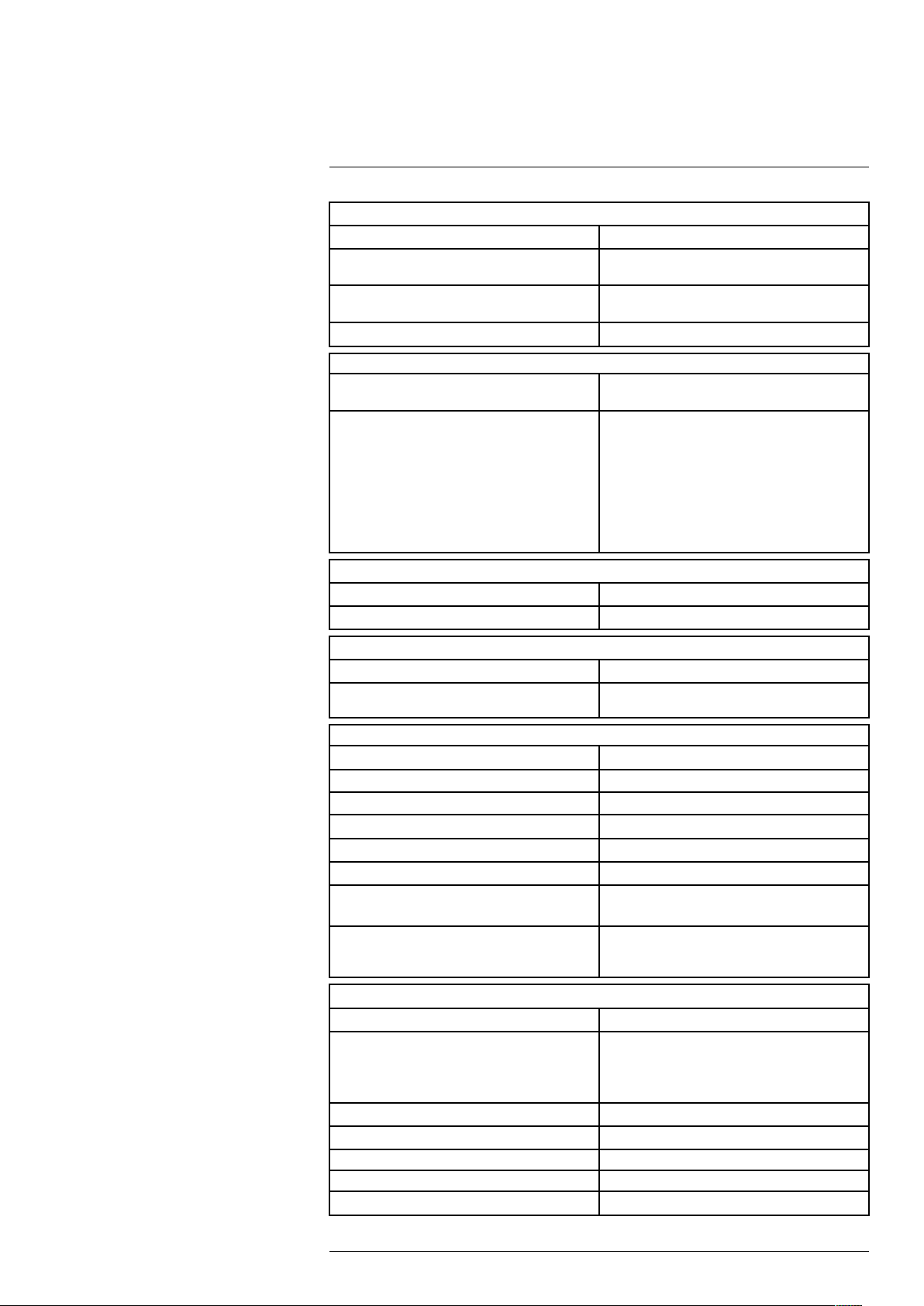

8.5 FLIR A310 ex 45°

P/N: 71001-1104

Rev.: 51351

Introduction

The FLIR A310 ex is an ATEX-proof solution, with a thermal imaging camera mounted in

an enclosure—making it possible to monitor critical and other valuable assets in explosive atmospheres. Process monitoring, quality control, and fire detection in potentially

explosive locations are typical applications for the FLIR A310 ex.

• Thermographic monitoring and early fire detection in an explosion–hazard area.

• Enclosures for infrared cameras in Ex zones 1, 2, 21, 22.

• ATEX certified.

• Protection class IP67.

• Plug-and-play installation with the enclosure delivered ready for use.

• Available with additional options.

The certification covers the entire system, which includes the enclosure as well as all

components inside of it, such as the infrared camera, heater, and integrated controller.

This means that no additional certification is required for operation.

The integrated controller is equipped with two fiber optic and two Ethernet ports. This enables a flexible network integration in star ring topologies.

In addition, the integrated controller features several digital I/O channels and sensors for

temperature, humidity, and pressure. Among other functions, the I/O channels enable

the user to switch on/off the camera and the heater via remote control. Access is through

an integrated web interface or Modbus TCP/IP.

Explosion-proof housing

General data

Ambient temperature range for operation –40°C to +60°C (–40°F to +140°F)

Protection class IP67

Weight 6.7 kg (without camera and lens)

Empty volume 5.06 l

External dimensions (without sun shield) D = 170 mm, L = 408 mm

Housing material Nickel-plated aluminium

Surface

Protection window Germanium, double-sided AR Coated, externally

Maximum power of the additional heater 16 W

Operating voltage 24 V DC

Maximum electric connection power 60 W

Power cable Helukabel 37264

Length of power cable 4 m (13 ft.)

Power cable configuration Pigtail

Ethernet medium

Length of Ethernet cable 4 m (13 ft.)

Ethernet configuration Pigtail with FC connector

Powder coated

with additional hard-carbon layer

Multi-mode breakout fiber AT-V(ZN)Y(ZN)Y 4G50/

125 OM2

#T559891; r. AE/57789/57789; en-US

14

Page 21

Technical data8

Explosion protection-specific data

For use in EX zone 1, 2, 21, 22.

Ignition protection category Flame-proof enclosure “d”

Maximum surface temperature (according to temperature class T6)

ATEX certification (version -AXC)

Verification certificate ZELM 12 ATEX 0485 X

Maximum 85°C

• II 2G Ex db IIC T6 / T5

• II 2D Ex tb IIIC T85° / T100

Camera system

Imaging and optical data

IR resolution 320 × 240 pixels

Thermal sensitivity/NETD < 0.05°C @ +30°C (+86°F) / 50 mK

Field of view (FOV)

Minimum focus distance 0.20 m (0.66 ft.)

Focal length 9.66 mm (0.38 in.)

Spatial resolution (IFOV)

Lens identification Automatic

F-number 1.3

Image frequency 30 Hz

Focus Automatic or manual (built in motor)

Zoom 1–8× continuous, digital, interpolating zooming on

45° × 33.8

2.59 mrad

images

Detector data

Detector type Focal plane array (FPA), uncooled

Spectral range

Detector pitch 25 µm

Detector time constant Typical 12 ms

Measurement

Object temperature range

Accuracy ±4°C (±7.2°F) or ±4% of reading

Measurement analysis

Spotmeter 10 (with no image streaming)

Area 10 boxes with max./min./average/position (with no

Isotherm 1 with above/below/interval

Measurement option Measurement Mask Filter

Difference temperature Delta temperature between measurement func-

Reference temperature Manually set or captured from any measurement

Atmospheric transmission correction Automatic, based on inputs for distance, atmos-

Optics transmission correction Automatic, based on signals from internal sensors

microbolometer

7.5–13 µm

• –20 to +120°C (–4 to +248°F)

• 0 to +350°C (+32 to +662°F)

image streaming)

Schedule response: File sending (ftp), email

(SMTP)

tions or reference temperature

function

pheric temperature and relative humidity

#T559891; r. AE/57789/57789; en-US

15

Page 22

Technical data8

Measurement analysis

Emissivity correction Variable from 0.01 to 1.0

Reflected apparent temperature correction Automatic, based on input of reflected

External optics/windows correction Automatic, based on input of optics/window trans-

Measurement corrections Global and individual object parameters

Alarm

Alarm functions 6 automatic alarms on any selected measurement

Alarm output Log, store image, file sending (ftp), email notifica-

temperature

mission and temperature

function, Digital In, Camera temperature, timer

tion (SMTP).

With an additional FLIR I/O module (T130090 or

T130091), the system can provide up to 8 digital

outputs and 8 analog outputs that can be connected to any camera analytic function or the

cameras status. These outputs can be connected

to existing alarm infrastructure, PLCs, or data

loggers.

Set-up

Color palettes Color palettes (BW, BW inv, Iron, Rain)

Set-up commands Date/time, Temperature (°C/°F)

Storage of images

Storage media Built-in memory for image storage

File formats Standard JPEG, 16-bit measurement data

Ethernet

Ethernet

Ethernet, type 100 Mbps

Ethernet, standard IEEE 802.3

Ethernet, configuration Pigtail with FC connector

Ethernet, communication TCP/IP socket-based FLIR proprietary

Ethernet, video streaming

Ethernet, image streaming 16-bit 320 × 240 pixels @ 7-8 Hz

Ethernet, protocols

Shipping information

Packaging, type

List of contents

Packaging, weight

Packaging, size 495 × 370 × 192 mm (19.5 × 14.6 × 7.6 in.)

EAN-13 7332558008362

UPC-12

Country of origin Sweden

included

Control, result and image

MPEG-4, ISO/IEC 14496-1 MPEG-4 ASP@L5

• Radiometric

Ethernet/IP, Modbus TCP, TCP, UDP, SNTP, RTSP,

RTP, HTTP, ICMP, IGMP, ftp, SMTP, SMB (CIFS),

DHCP, MDNS (Bonjour), uPnP

Cardboard box

• Infrared camera with lens, in explosion-proof

housing

• Printed documentation

• Utility CD-ROM

845188008710

#T559891; r. AE/57789/57789; en-US

16

Page 23

Technical data8

Supplies & accessories:

• T129252; Special temperature range -20 to +700 deg C

• T129253; Special temperature range -20 to +500 deg C

• T129254; High temperature measurement option -20 to +2000 deg C

• T130151; Special temperature range -20 to +2000 deg C

• T130090; I/O module MIO-A310-1

• T130091; I/O module MIO-A310-7

• T911288ACC; Pole mount adapter for wall mount kit

• T199713; ThermoVision CM Panel, max. 4 cameras

• T199712; ThermoVision CM Panel, max. 9 cameras

• T130169; Thermovision CM, max. 4 cameras

• T130170; Thermovision CM, max. 9 cameras

• T911263ACC; Wall mount kit

• INST-EW-0165; Extended Warranty 1 Year for A6xx, A310ex, T640/bx, T650sc, T660

• INST-EWGM-0175; Premium Service Package for A310ex, A3xxf, A6xx, T620-T660

• INST-GM-0155; General Maintenance Package for A3xxf, A310ex, A310pt, A6xx

#T559891; r. AE/57789/57789; en-US

17

Page 24

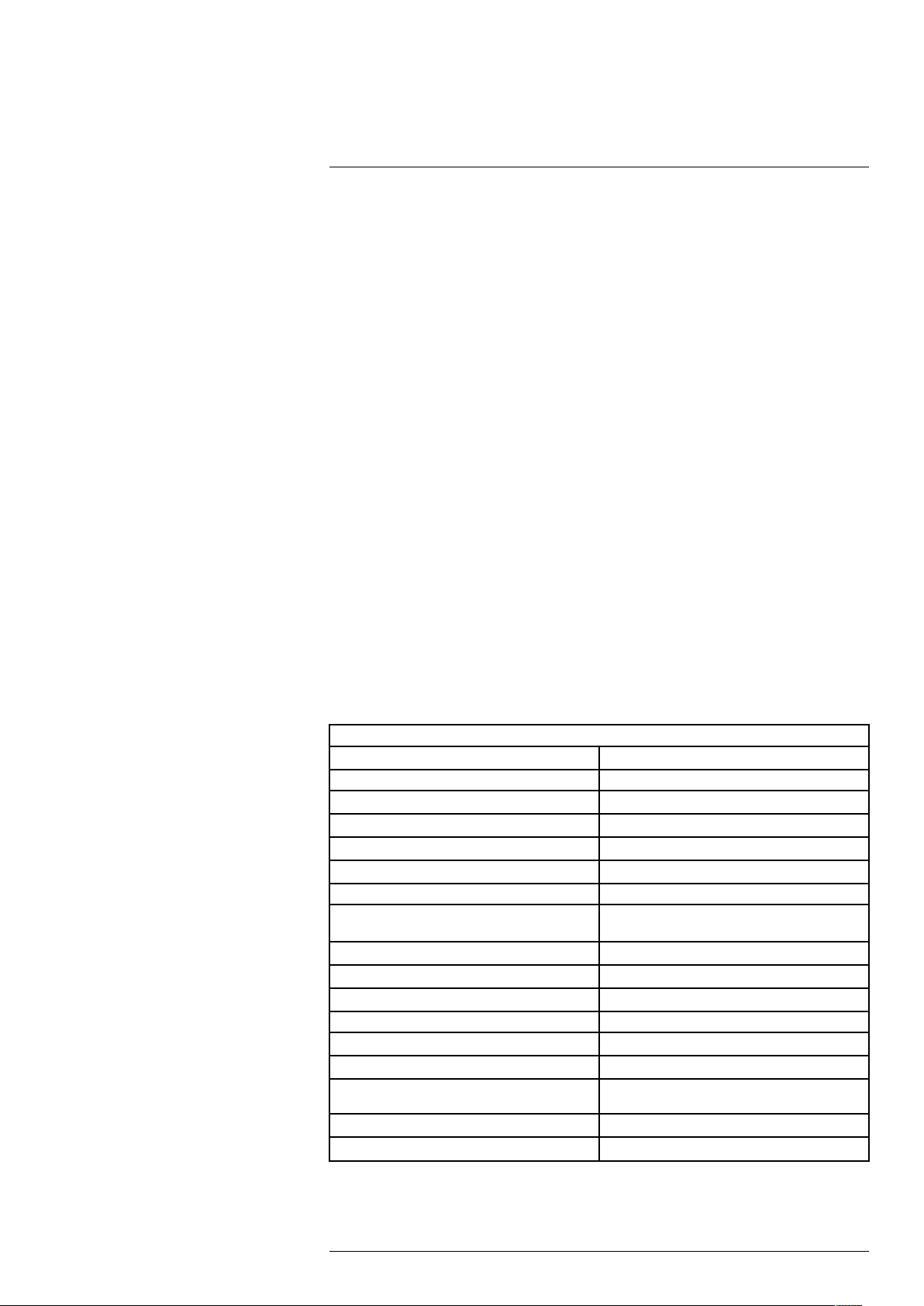

9

Mechanical drawings

[See next page]

#T559891; r. AE/57789/57789; en-US

18

Page 25

408,20

156,00

60,00

20,00 226,00

170,00

40,00

20,0020,00 95,00

246,00

82,00

2,00

55,50

20,00

115,00

161,00

90,00

290,00

500,00

182,00

171,00

10,00

70mm depending on

EX cable gland

A

A ( 1 : 2 )

Type

label

Mounting

rail

Protective

grid

8x Mounting holes with

M5x8 deep

for Mounting rail or

mounting plate

Overview with Sunshield

installed

Drawing without

Sunshield

Earthing

connection

Hole for

installation

wrench

4x Clamping

screws

Index

screw

All dimensions in

mm

Denna handling får ej delges annan, kopieras i

sin helhet eller delar utan vårt medgivande .

Överträdelse härav beivras med stöd av gällande lag.

FLIR SYSTEMS AB

This document must not be communicated or

copied completely or in part, without our permission.

Any infringement will lead to legal proceedings.

FLIR SYSTEMS AB

Där ej annat anges/Unless otherwise stated

Kanter brutna

Edges broken

Hålkälsradier

Fillet radii

Ytjämnhet/Roughness

Blad/Sheet

Rev

Ritn nr/Drawing No

Art.No.

Skala/Scale

Size

Datum/Date

Kontr/Check

Konstr/Drawn

Material

Ytbehandling/Surface treatment

Gen tol

Benämning/Denomination

A0

Utdrag ur/Excerpt from

ISO 2768-m

±0,1

±0,2

±0,3

±0,5

±0,8

(400)-1000

(120)-400

(30)-120

(6)-30

0,5-6

ISO 2768-mK

1(1)

2:1

H. ÖSTLING

A

T128183

A3xxEx

Basic Dimensions

JAMA

2014-04-14

2014-05-15

H. ÖSTLING

Ändrad av/Modified by

Ändrad/Modified

Ra µm

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

101 11732 1284 1395 6

A

B

C

D

E

F

G

H

I

J

K

B

J

F

G

C

H

D

A

I

E

K

-

Page 26

10

EC Type Examination Certificate

[See next page]

#T559891; r. AE/57789/57789; en-US

20

Page 27

Page 28

Page 29

11

EC Type Examination Certificate, 1st supplement

[See next page]

#T559891; r. AE/57789/57789; en-US

23

Page 30

Page 31

Page 32

12

EC Type Examination Certificate, 2nd supplement

[See next page]

#T559891; r. AE/57789/57789; en-US

26

Page 33

Page 34

13

EC Type Examination Certificate, 3rd supplement

[See next page]

#T559891; r. AE/57789/57789; en-US

28

Page 35

Page 36

Page 37

14

EC Declaration of conformity (enclosure)

[See next page]

#T559891; r. AE/57789/57789; en-US

31

Page 38

EG-Konformitätserklärung

EC-Declaration of Conformity

Déclaration de Conformité CE

AT – Automation Technology GmbH • Hermann-Bössow-Strasse 6 – 8 • D-23843 Bad Oldesloe, Germany

erklärt in alleiniger Verantwortung,

declares in its sole responsibility,

déclare sous sa seule responsabilité

dass das Produkt

that the product

que le produit

IRCamSafeEX-AXB

IRCamSafeEX-AXC

Kennzeichnung, marking, marquage (-AXB):

Kennzeichnung, marking, marquage (-AXC):

II 2G Ex d IIB T6 Gb

II 2G Ex d IIC T6 Gb

II 2D Ex tb IIIC T85° Db

mit der EG-Baumusterprüfbescheinigung:

under EC-Type Examination Certificate:

avec Attestation d’examen CE de type:

ZELM 12 ATEX 0485 X

(ZELM Ex e.K.

Siekgraben 56, 38124 Braunschweig)

Kenn-Nr. der benannten Stelle:

Notified Body number:

No de l’organisme de certification:

0820

auf das sich diese Erklärung bezieht, mit den folgenden Normen oder normativen Dokumenten übereinstimmt

which is the subject of this declaration, is in conformity with the following standards or normative documents

auquel cette déclaration se rapporte, est conforme aux normes ou aux documents normatifs suivants

Bestimmungen der Richtlinie

Terms of the directive

Prescription de la directive

Nummer sowie Ausgabedatum der Norm

Number and date of issue of the standard

Numéro ainsi que date d’émission de la norme

94/9/EG: ATEX-Richtlinie

94/9/EC: ATEX Directive

94/9/CE: Directive ATEX

EN 60079-0: 2009

EN 60079-1: 2007

EN 60079-14: 2009

EN 60079-17: 2008

EN 60079-28: 2007

EN 60079-31: 2009

2006/95/EG: Niederspannungsrichtlinie

2006/95/EC: Low Voltage Directive

2006/95/CE: Directive Basse Tension

2004/108/EG: EMV-Richtlinie

2004/108/EC: EMC Directive

2004/108/CE: Directive CEM

Bad Oldesloe, 16. Mai. 2012

Ort und Datum

Place and Date

Lieu et date

Dr. Andrè Kasper

Leiter Qualitätssicherung

Director Quality Management Dept.

Directeur Dept. Assurance de Qualité

Page 39

15

Certiticate of conformity (camera)

[See next page]

#T559891; r. AE/57789/57789; en-US

33

Page 40

Page 41

16

Thermographic measurement techniques

16.1 Introduction

An infrared camera measures and images the emitted infrared radiation from an object.

The fact that radiation is a function of object surface temperature makes it possible for

the camera to calculate and display this temperature.

However, the radiation measured by the camera does not only depend on the temperature of the object but is also a function of the emissivity. Radiation also originates from

the surroundings and is reflected in the object. The radiation from the object and the reflected radiation will also be influenced by the absorption of the atmosphere.

To measure temperature accurately, it is therefore necessary to compensate for the effects of a number of different radiation sources. This is done on-line automatically by the

camera. The following object parameters must, however, be supplied for the camera:

• The emissivity of the object

• The reflected apparent temperature

• The distance between the object and the camera

• The relative humidity

• Temperature of the atmosphere

16.2 Emissivity

The most important object parameter to set correctly is the emissivity which, in short, is a

measure of how much radiation is emitted from the object, compared to that from a perfect blackbody of the same temperature.

Normally, object materials and surface treatments exhibit emissivity ranging from approximately 0.1 to 0.95. A highly polished (mirror) surface falls below 0.1, while an oxidized

or painted surface has a higher emissivity. Oil-based paint, regardless of color in the visible spectrum, has an emissivity over 0.9 in the infrared. Human skin exhibits an emissivity 0.97 to 0.98.

Non-oxidized metals represent an extreme case of perfect opacity and high reflexivity,

which does not vary greatly with wavelength. Consequently, the emissivity of metals is

low – only increasing with temperature. For non-metals, emissivity tends to be high, and

decreases with temperature.

16.2.1 Finding the emissivity of a sample

16.2.1.1 Step 1: Determining reflected apparent temperature

Use one of the following two methods to determine reflected apparent temperature:

#T559891; r. AE/57789/57789; en-US

35

Page 42

Thermographic measurement techniques16

16.2.1.1.1 Method 1: Direct method

Follow this procedure:

1. Look for possible reflection sources, considering that the incident angle = reflection

angle (a = b).

Figure 16.1 1 = Reflection source

2. If the reflection source is a spot source, modify the source by obstructing it using a

piece if cardboard.

Figure 16.2 1 = Reflection source

#T559891; r. AE/57789/57789; en-US

36

Page 43

Thermographic measurement techniques16

3. Measure the radiation intensity (= apparent temperature) from the reflection source

using the following settings:

• Emissivity: 1.0

• D

: 0

obj

You can measure the radiation intensity using one of the following two methods:

Figure 16.3 1 = Reflection source Figure 16.4 1 = Reflection source

You can not use a thermocouple to measure reflected apparent temperature, because a

thermocouple measures temperature, but apparent temperatrure is radiation intensity.

16.2.1.1.2 Method 2: Reflector method

Follow this procedure:

1. Crumble up a large piece of aluminum foil.

2. Uncrumble the aluminum foil and attach it to a piece of cardboard of the same size.

3. Put the piece of cardboard in front of the object you want to measure. Make sure that

the side with aluminum foil points to the camera.

4. Set the emissivity to 1.0.

#T559891; r. AE/57789/57789; en-US

37

Page 44

Thermographic measurement techniques16

5. Measure the apparent temperature of the aluminum foil and write it down. The foil is

considered a perfect reflector, so its apparent temperature equals the reflected apparent temperature from the surroundings.

Figure 16.5 Measuring the apparent temperature of the aluminum foil.

16.2.1.2 Step 2: Determining the emissivity

Follow this procedure:

1. Select a place to put the sample.

2. Determine and set reflected apparent temperature according to the previous

procedure.

3. Put a piece of electrical tape with known high emissivity on the sample.

4. Heat the sample at least 20 K above room temperature. Heating must be reasonably

even.

5. Focus and auto-adjust the camera, and freeze the image.

6. Adjust Level and Span for best image brightness and contrast.

7. Set emissivity to that of the tape (usually 0.97).

8. Measure the temperature of the tape using one of the following measurement

functions:

• Isotherm (helps you to determine both the temperature and how evenly you have

heated the sample)

• Spot (simpler)

• Box Avg (good for surfaces with varying emissivity).

9. Write down the temperature.

10. Move your measurement function to the sample surface.

11. Change the emissivity setting until you read the same temperature as your previous

measurement.

12. Write down the emissivity.

Note

• Avoid forced convection

• Look for a thermally stable surrounding that will not generate spot reflections

• Use high quality tape that you know is not transparent, and has a high emissivity you

are certain of

• This method assumes that the temperature of your tape and the sample surface are

the same. If they are not, your emissivity measurement will be wrong.

#T559891; r. AE/57789/57789; en-US

38

Page 45

Thermographic measurement techniques16

16.3 Reflected apparent temperature

This parameter is used to compensate for the radiation reflected in the object. If the

emissivity is low and the object temperature relatively far from that of the reflected it will

be important to set and compensate for the reflected apparent temperature correctly.

16.4 Distance

The distance is the distance between the object and the front lens of the camera. This

parameter is used to compensate for the following two facts:

• That radiation from the target is absorbed by the atmosphere between the object and

the camera.

• That radiation from the atmosphere itself is detected by the camera.

16.5 Relative humidity

The camera can also compensate for the fact that the transmittance is also dependent

on the relative humidity of the atmosphere. To do this set the relative humidity to the correct value. For short distances and normal humidity the relative humidity can normally be

left at a default value of 50%.

16.6 Other parameters

In addition, some cameras and analysis programs from FLIR Systems allow you to compensate for the following parameters:

• Atmospheric temperature – i.e. the temperature of the atmosphere between the cam-

era and the target

• External optics temperature – i.e. the temperature of any external lenses or windows

used in front of the camera

• External optics transmittance – i.e. the transmission of any external lenses or windows

used in front of the camera

#T559891; r. AE/57789/57789; en-US

39

Page 46

17

About FLIR Systems

FLIR Systems was established in 1978 to pioneer the development of high-performance

infrared imaging systems, and is the world leader in the design, manufacture, and marketing of thermal imaging systems for a wide variety of commercial, industrial, and government applications. Today, FLIR Systems embraces five major companies with

outstanding achievements in infrared technology since 1958—the Swedish AGEMA Infrared Systems (formerly AGA Infrared Systems), the three United States companies Indigo Systems, FSI, and Inframetrics, and the French company Cedip.

Since 2007, FLIR Systems has acquired several companies with world-leading

expertise:

• NEOS (2019)

• Endeavor Robotics (2019)

• Aeryon Labs (2019)

• Seapilot (2018)

• Acyclica (2018)

• Prox Dynamics (2016)

• Point Grey Research (2016)

• DVTEL (2015)

• DigitalOptics micro-optics business (2013)

• MARSS (2013)

• Traficon (2012)

• Aerius Photonics (2011)

• TackTick Marine Digital Instruments (2011)

• ICx Technologies (2010)

• Raymarine (2010)

• Directed Perception (2009)

• OmniTech Partners (2009)

• Salvador Imaging (2009)

• Ifara Tecnologías (2008)

• Extech Instruments (2007)

Figure 17.1 Patent documents from the early 1960s

FLIR Systems has three manufacturing plants in the United States (Portland, OR, Boston,

MA, Santa Barbara, CA) and one in Sweden (Stockholm). Since 2007 there is also a

manufacturing plant in Tallinn, Estonia. Direct sales offices in Belgium, Brazil, China,

#T559891; r. AE/57789/57789; en-US

40

Page 47

17

About FLIR Systems

France, Germany, Great Britain, Hong Kong, Italy, Japan, Korea, Sweden, and the USA

—together with a worldwide network of agents and distributors—support our international customer base.

FLIR Systems is at the forefront of innovation in the infrared camera industry. We anticipate market demand by constantly improving our existing cameras and developing new

ones. The company has set milestones in product design and development such as the

introduction of the first battery-operated portable camera for industrial inspections, and

the first uncooled infrared camera, to mention just two innovations.

1969: Thermovision Model 661. The camera

weighed approximately 25 kg (55 lb.), the oscilloscope 20 kg (44 lb.), and the tripod 15 kg (33 lb.).

The operator also needed a 220 VAC generator

set, and a 10 L (2.6 US gallon) jar with liquid nitrogen. To the left of the oscilloscope the Polaroid attachment (6 kg (13 lb.)) can be seen.

2015: FLIR One, an accessory to iPhone and Android mobile phones. Weight: 36 g (1.3 oz.).

FLIR Systems manufactures all vital mechanical and electronic components of the camera systems itself. From detector design and manufacturing, to lenses and system electronics, to final testing and calibration, all production steps are carried out and

supervised by our own engineers. The in-depth expertise of these infrared specialists ensures the accuracy and reliability of all vital components that are assembled into your infrared camera.

17.1 More than just an infrared camera

At FLIR Systems we recognize that our job is to go beyond just producing the best infrared camera systems. We are committed to enabling all users of our infrared camera systems to work more productively by providing them with the most powerful camera–

software combination. Especially tailored software for predictive maintenance, R & D,

and process monitoring is developed in-house. Most software is available in a wide variety of languages.

We support all our infrared cameras with a wide variety of accessories to adapt your

equipment to the most demanding infrared applications.

17.2 Sharing our knowledge

Although our cameras are designed to be very user-friendly, there is a lot more to thermography than just knowing how to handle a camera. Therefore, FLIR Systems has

founded the Infrared Training Center (ITC), a separate business unit, that provides certified training courses. Attending one of the ITC courses will give you a truly hands-on

learning experience.

#T559891; r. AE/57789/57789; en-US

41

Page 48

17

About FLIR Systems

The staff of the ITC are also there to provide you with any application support you may

need in putting infrared theory into practice.

17.3 Supporting our customers

FLIR Systems operates a worldwide service network to keep your camera running at all

times. If you discover a problem with your camera, local service centers have all the

equipment and expertise to solve it within the shortest possible time. Therefore, there is

no need to send your camera to the other side of the world or to talk to someone who

does not speak your language.

#T559891; r. AE/57789/57789; en-US

42

Page 49

This section contains the original manual from the manufacturer of the enclosure.

Page 50

Betriebsanleitung

IRCamSafeEX-AXC Ex-d Gehäuse für

Infrarotkameras

AT – Automation Technology GmbH

Datum: 01.04.2017

Revision: 1.4

© AT – Automation Technology GmbH 2016

Page 51

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 1 AT-Automation Technology GmbH

1 Inhaltsverzeichnis

2 Allgemeine Angaben........................................................................................................................ 2

2.1 Hersteller ................................................................................................................................. 2

2.2 Einleitung ................................................................................................................................. 2

2.3 Kennzeichnung ........................................................................................................................ 3

3 Allgemeine Sicherheitshinweise ...................................................................................................... 4

4 Verwendung und Vorgesehener Einsatzbereich ............................................................................. 5

4.1 Zulässige Einbauten ................................................................................................................. 5

4.2 Zulässige Kabeleinführungen und Steckverbinder .................................................................. 6

4.3 Ausführung mit vorkonfektionierten Anschlusskabeln ........................................................... 6

5 Normenkonformität ........................................................................................................................ 7

6 Technische Daten ............................................................................................................................ 8

7 Transport, Lagerung und Entsorgung ........................................................................................... 10

8 Montage und Demontage ............................................................................................................. 10

9 Installation ..................................................................................................................................... 11

9.1 Installation der Anschlussleitungen ...................................................................................... 12

9.1.1 Hinteren Gehäusedeckel abschrauben ......................................................................... 12

9.1.2 Auflegen der Anschlussleitungen .................................................................................. 12

9.1.3 Hinteren Gehäusedeckel schließen ............................................................................... 13

9.1.4 Erdungsanschluss auflegen ........................................................................................... 13

10 Inbetriebnahme ......................................................................................................................... 14

11 Wartung ..................................................................................................................................... 15

11.1 Regelmäßige Wartungsarbeiten ............................................................................................ 15

11.2 Reinigung ............................................................................................................................... 16

12 Zubehör und Ersatzteile ............................................................................................................ 16

13 EG-Baumusterprüfbescheinigung ............................................................................................. 17

14 EU-Konformitätserklärung......................................................................................................... 24

Page 52

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 2 AT-Automation Technology GmbH

2 Allgemeine Angaben

2.1 Hersteller

AT-Automation Technology GmbH

Hermann-Bössow-Str. 6-8

23843 Bad Oldesloe

Germany

Telefon: +49 4531 88011-0

Telefax: +49 34531 88011-20

Internet: www.AutomationTechnology.de

2.2 Einleitung

Bei den Kameragehäusen der Serie IRCamSafeEX-AXB/C handelt es sich um Schutzgehäuse für

Infrarotkameras. Die Gehäuse sind für den Einsatz von Infrarotkameras der Serie FLIR

A3XX/SC3XX und A615/SC6XX, sowie Flir G300A und AT IRS und Xenics Serval in

explosionsgefährdeten Bereichen konzipiert. Die Variante–AXC ist zudem für den Einsatz in

staubexplosionsgefährlicher Atmosphäre zugelassen.

Die Schutzgehäuse erfüllen die aktuellen EX-Schutz Normen und sind als komplette Einheit mit

allen Einbauten zertifiziert. Eine zusätzliche Zertifizierung nach Einbau der vorgesehenen

Kameras ist somit nicht mehr notwendig.

Page 53

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 3 AT-Automation Technology GmbH

2.3 Kennzeichnung

Gehäusevariante 24V DC:

AT – Automation Technology GmbH

Hermann-Bössow-Straße 6 – 8 • 23843 Bad Oldesloe • Germany

Phone: +49 4531 88011-0 • www.AutomationTechnology.de

Model:

IRCamSafeEX-AXC

Serial No.:

71000260

Year: 2016

Power:

24VDC, 60W

max.

T

amb

-40°C - +40°C / 60°C

Certificate:

ZELM 12 ATEX 0485 X

2572

IP67

WARNUNG / WARNING / ADVERTENCIA / ATTENTION !

NICHT UNTER SPANNUNG ÖFFNEN / DE-ENERGIZE BEFORE OPENING

DESENERGIZAR ANTES DE ABRIR / NE PAS OUVIRIR SOUS TENSION

NACH DEM ABSCHALTEN 10 MINUTEN WARTEN VOR DEM ÖFFNEN.

Gehäusevariante 230V AC:

AT – Automation Technology GmbH

Hermann-Bössow-Straße 6 – 8 • 23843 Bad Oldesloe • Germany

Phone: +49 4531 88011-0 • www.AutomationTechnology.de

Model:

IRCamSafeEX-AXC

Serial No.:

71000260

Year: 2016

Power:

230VAC, 60W

max.

T

amb

-40°C - +40°C / 60°C

Certificate:

ZELM 12 ATEX 0485 X

2572

IP67

WARNUNG / WARNING / ADVERTENCIA / ATTENTION !

NICHT UNTER SPANNUNG ÖFFNEN / DE-ENERGIZE BEFORE OPENING

DESENERGIZAR ANTES DE ABRIR / NE PAS OUVIRIR SOUS TENSION

NACH DEM ABSCHALTEN 10 MINUTEN WARTEN VOR DEM ÖFFNEN.

II 2G Ex db IIC T6 / T5

II 2D Ex tb IIIC T85° / T100°

II 2G Ex db IIC T6 / T5

II 2D Ex tb IIIC T85° / T100°

Page 54

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 4 AT-Automation Technology GmbH

3 Allgemeine Sicherheitshinweise

Die Betriebsanleitung enthält grundlegende Sicherheitshinweise, die bei Aufstellung, Betrieb

und Wartung zu beachten sind. Nichtbeachtung hat eine Gefährdung für Personen, Anlage und

Umwelt zur Folge.

Gefahr durch unbefugte Arbeiten am Gerät!

Montage, Installation, Inbetriebnahme, Betrieb und Wartung dürfen ausschließlich von

dazu befugtem und entsprechend geschultem Personal durchgeführt werden.

Vor Montage/Inbetriebnahme:

Betriebsanleitung lesen.

Montage- und Betriebspersonal ausreichend schulen.

Sicherstellen, dass der Inhalt der Betriebsanleitung vom zuständigen Personal voll

verstanden wird.

Es gelten die nationalen Montage- und Errichtungsvorschriften (z.B. IEC/EN 60079-14).

Bei Unklarheiten:

Mit dem Hersteller Kontakt aufnehmen.

Bei Betrieb der Geräte:

Betriebsanleitung am Einsatzort verfügbar halten.

Sicherheitshinweise beachten.

Nationale Sicherheits- und Unfallverhütungsvorschriften beachten.

Gerät nur entsprechend der Leistungsdaten betreiben.

Wartungsarbeiten bzw. Reparaturen, die nicht in der Betriebsanleitung beschrieben

sind, dürfen nicht ohne vorherige Abstimmung mit dem Hersteller durchgeführt werden.

Beschädigungen können den Explosionsschutz aufheben.

Umbauten und Veränderungen am Gerät, die den Explosionsschutz beeinträchtigen, sind

nicht gestattet.

Gerät nur in unbeschädigtem, trockenem und sauberem Zustand einbauen und

betreiben.

Page 55

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 5 AT-Automation Technology GmbH

4 Verwendung und Vorgesehener Einsatzbereich

Die Schutzgehäuse sind für den Einsatz von Infrarotkameras in explosionsgefährdeten

Bereichen der Zone 1 und 2, sowie 21 und 22 zugelassen.

Gerät nur bestimmungsgemäß einsetzen!

Sonst erlischt Herstellerhaftung und Gewährleistung.

Gerät ausschließlich entsprechend den in dieser Betriebsanleitung festgelegten Betriebs-

bedingungen verwenden.

Das Gerät darf in explosionsgefährdeten Bereichen nur gemäß dieser Betriebsanleitung betrieben

werden.

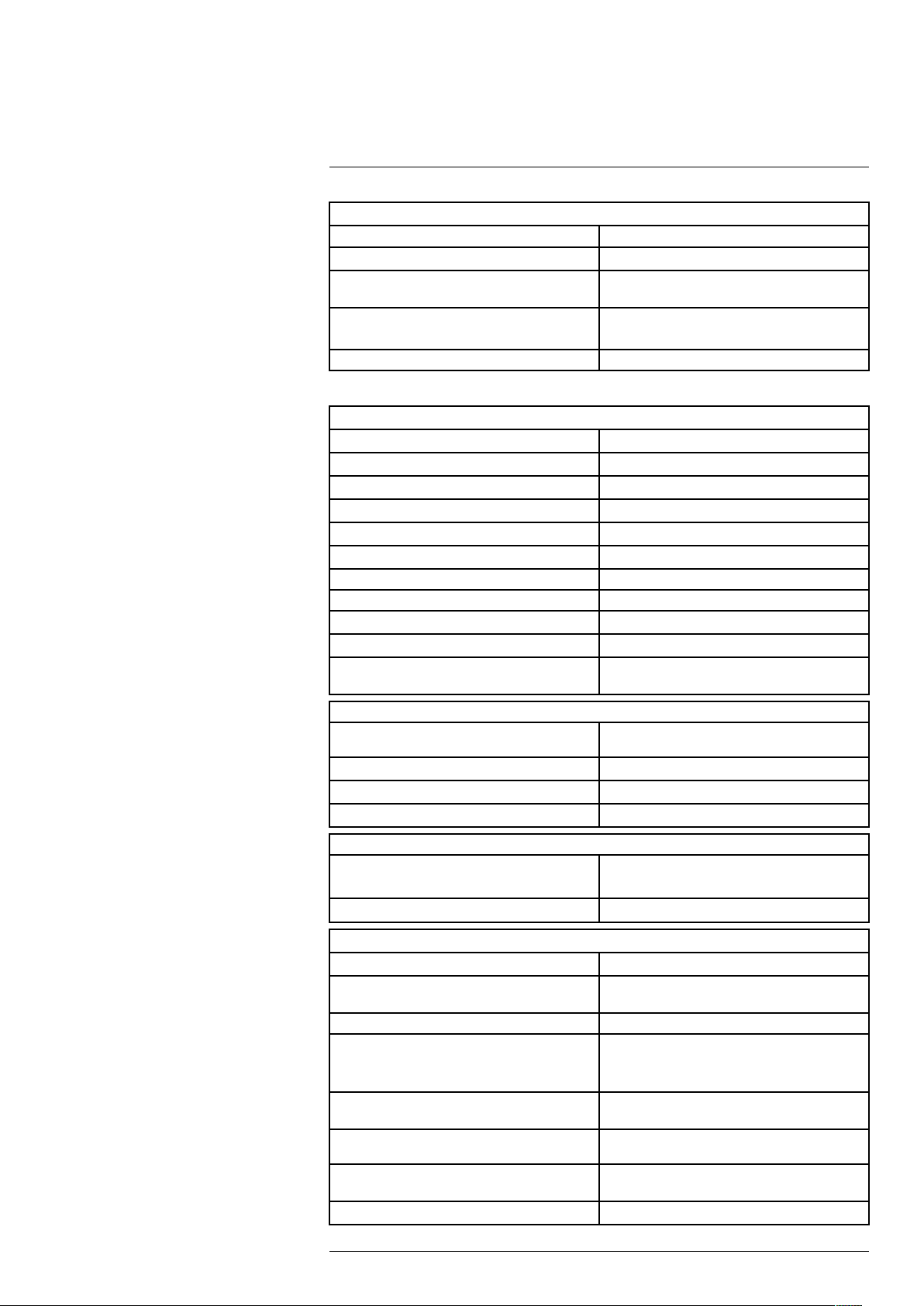

4.1 Zulässige Einbauten

Folgende Kamera und Optikkombinationen können eingesetzt werden.

Kamera

Optik

Variante

- AXC

Flir A3XX,

SC3XX,

A3XXsc

ohne Zusatzoptik

X

45° Zusatzoptik, f‘ = 10mm

X

15° Zusatzoptik, f‘ = 30mm

X

6° Zusatzoptik, f‘ = 76mm

X

90° Zusatzoptik, f‘ = 4mm

X

Flir A615,

SC6XX,

A6XXsc

15° Optik, f‘ = 41,3mm

X

25° Optik, f‘ = 24,6mm

X

45° Optik, f‘ = 13,1mm

X

AT IRS-X-GigE

WFOV Optiken

X

IRS-X-GigE

Xenics Serval-X-GigE

Optik, f‘ = 11mm

X

Optik, f‘ = 25mm

X

Optik, f‘ =35mm

X

Optik, f‘ = 60mm

X

Optik, f‘ = 100mm

X

Optik, f‘=35-105mm

X

Flir AX5

WFOV Optiken

X

Flir G300A

f‘ = 23mm, F=1,5

f‘=38mm, F=1,5

X

Installationsarbeiten nur durch Fachpersonal!

Die Montage der Einbauten erfolgt durch den Hersteller oder durch vom Hersteller autorisiertes

Personal.

Page 56

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 6 AT-Automation Technology GmbH

4.2 Zulässige Kabeleinführungen und Steckverbinder

Für den Anschluss der Stromversorgungsleitung und der Datenübertragungsleitung stehen zwei

druckfeste und zünddurchschlagsichere Kabeleinführungen zur Verfügung. Alternativ können

druckfeste und zünddurchschlagsichere Steckverbindersysteme eingesetzt werden. Die

Kabeleinführungen und Steckverbinderbuchsen sind vom Hersteller vormontiert. Optional wird

vom Hersteller das Gehäuse zusätzlich mit bereits angeschlossenen Anschlusskabeln geliefert.

Folgende EX-Kabeleinführungen sind für die Verwendung mit dem Schutzgehäuse geeignet.

Hersteller

Bezeichnung

Größe

Manteldurchmesser

A1 mm

Max. Anzahl

Einzeladern

Stahl

8163/2-20S/16-PXSS2K-M20

20s/16

3.1– 8.7

15

Stahl

8163/2-20S-PXSS2K-M20

20s

6.1 – 11.7

15

Stahl

8163/2-20-PXSS2K-M20

20

6.5 – 14.0

15

Stahl

8163/2-20S/16-PX2K-M20

20s/16

6.1 - 11.5

15

Stahl

8163/2-20S-PX2K-M20

20s

9.5 – 15.9

15

Stahl

8163/2-20-PX2K-M20

20

12.5 – 20.9

15

Hummel

EXIOS Barrier 1.606.2000.50

20-1

6 – 12

8

Hummel

EXIOS Barrier 1.606.2000.51

20-2

9 – 16

10

Hummel

EXIOS Barrier 1.606.2000.52

20-3

12.5 – 20.5

15

Folgende EX-Steckverbindersysteme sind für die Verwendung mit dem Schutzgehäuse geeignet.

Hersteller

Beschreibung

Bezeichnung

Stahl

Gerätestecker für Stromversorgungsanschluss

2 polig + PE

8591/16.-06-3.00

Stahl

Gerätestecker in Ethernet Ausführung 4 polig

8591/467-01-3022

Hawke

Einbaubuchse für Stromversorgungsanschluss, 4 polig

N-BR1-M-B-P-X-0-3-X-A

Hawke

Einbaubuchse für Ethernetanschluss, 8 polig

N-BR1-M-C-P-X-0-8-X-A

Im Zuge von Aktualisierungen kann sich die Kennzeichnung entsprechend den aktuellen

Normanforderungen ändern.

Installationsarbeiten nur durch Fachpersonal!

Die Montage der Kabeleinführungen und der gehäuseseitigen Steckverbinder erfolgt durch den

Hersteller oder durch vom Hersteller autorisiertes Personal.

4.3 Ausführung mit vorkonfektionierten Anschlusskabeln

Anschluss 1 (Datenverbindung) ist mit einem LWL-Anschlusskabel mit folgenden Eigenschaften

ausgestattet.

Vieradriges LWL Breakoutkabel für den Außeneinsatz, AT-V(ZN)Y(ZN)Y 4G50/125 OM2 oder

62.5/125 OM1 (z.B. Helukabel 803348 mit Manteldurchmesser 8,5mm)

4x LC Stecker auf der Gehäuseinnenseite vorkonfektioniert, Einzelader Innenlänge 450mm

Page 57

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 7 AT-Automation Technology GmbH

Zweite Anschlussseite ist nicht-konfektioniert und zum Spleißen geeignet

Typische Länge 5m

Anschluss 2 (Stromversorgung) ist mit einem 3 adrigen Kupfer-Kabel (z.B. Helukabel 37264) mit

folgenden Eigenschaften ausgestattet:

Manteldurchmesser: 9,8mm

Aderquerschnitt: 3 x 1,5mm

2

feindrähtig

Typische Länge 5m, optional mit Stecker Stahl 8570/12-306 konfektioniert

Kundenspezifische Längen und Konfektionierungen der freien Enden sind auf Anfrage möglich.

5 Normenkonformität

Die Schutzgehäuse entsprechen den folgenden Normen und Richtlinien:

Richtlinie 2014/34/EU

EN 60079-0:2012+A11:2013; „Explosionsfähige Atmosphäre - Teil 0: Geräte - Allgemeine

Anforderungen“

EN 60079-1:2014; „Explosionsfähige Atmosphäre - Teil 1: Geräteschutz durch druckfeste

Kapselung „d““

EN 600079-31:2014; „Explosionsfähige Atmosphäre - Teil 31: Geräte-Staubexplosionsschutz

durch Gehäuse "t"“

Für den Einsatz des Schutzgehäuses sind u.a. folgende Normen zu beachten:

EN 60079-14:2014; „Explosionsfähige Atmosphäre - Teil 14: Projektierung, Auswahl und

Errichtung elektrischer Anlagen“

EN 60079-17:2014; „Explosionsfähige Atmosphäre - Teil 17: Prüfung und Instandhaltung

elektrischer Anlagen“

EN 60079-28:2007; „Explosionsfähige Atmosphäre - Teil 28: Schutz von Einrichtungen und

Übertragungssystemen, die mit optischer Strahlung arbeiten“

Page 58

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 8 AT-Automation Technology GmbH

6 Technische Daten

Allgemeine technische Daten:

Normal-Betriebsumgebungstemperaturbereich T

a

: -40°C … +60°C

Schutzart: IP67

Gewicht: 6,7 kg (ohne Kamera und Optik)

Leervolumen: 5,06l

Außenmaße (ohne Sonnendach und Anschlüsse): D=170mm, L=408mm

Gehäusematerial: Aluminium

Oberfläche: pulverbeschichtet,

Material infrarotdurchlässiges Fenster: Germanium, beidseitig AR beschichtet, außen

zusätzlich hardcarbon beschichtet

Maximale Leistung der Zusatzheizung: 16W + 6W (Fensterheizung)

Optionale Zusatzheizung für kalte Gebiete: 18W

Betriebsspannung: 115VAC 60Hz / 230VAC 50Hz / 24V DC

Maximale elektrische Anschlussleistung: 60W

Integrierter Controller:

o 4 Port Switch mit 2x LWL-LC 100Base-FX oder 2x RJ45(10/100) Up-Links

o Unterstützt Ring-Topologie für reduzierten Verkabelungsaufwand

o 2 interne Temperatursensoren, Luftfeuchte und Drucksensor

o schaltbare Kameraversorgung und Zusatzheizung via Modbus-TCP/IP

o Web-Interface zur Konfiguration

EX-Schutz spezifische Angaben:

Für Einsatz in EX-Zone : 1, 2

Zündschutzart: druckfeste Kapselung „d“

Maximale Oberflächentemperaturen:

o Temperaturklasse T5: maximal +100°C (maximale Umgebungstemperatur +60°C)

o Temperaturklasse T6: maximal +85°C (maximale Umgebungstemperatur +40°C)

ATEX Kennzeichnung

o II 2G Ex db IIC T6 / T5

o II 2D Ex tb IIIC T85° / T100

Prüfbescheinigung: ZELM 12 ATEX 0485 X

Page 59

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 9 AT-Automation Technology GmbH

Abb. 1: Übersicht IRCamSafeEX-AXC (alle Maße in mm) – Änderungen vorbehalten

Page 60

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 10 AT-Automation Technology GmbH

7 Transport, Lagerung und Entsorgung

Transport:

Erschütterungsfrei in der Originalverpackung, nicht stürzen, vorsichtig handhaben.

Lagerung:

Trocken in der Originalverpackung lagern

Entsorgung:

Die umweltgerechte Entsorgung aller Bauteile gemäß den gesetzlichen Bestimmungen ist

sicherzustellen.

8 Montage und Demontage

Vor der Montage den Umgebungstemperaturbereich und die Schutzart gemäß Typenschild auf

Zulässigkeit im Montagebereich prüfen.

Die für die Montage vorgesehenen Befestigungsbohrungen sin der Zeichnung Abb. 1 zu entnehmen.

Für die Befestigung des Schutzgehäuses auf eine Montageplatte erfolgt können die 8x M5 Gewinde

des Schutzgehäuses verwendet werden. Alternativ kann eine Befestigungsschiene zur Montage auf

einer Wandhalterung verwendet werden. Bei der Montage auf festen Sitz der Schrauben achten,

maximal 3.5Nm Anzugsdrehmoment in den M5 – Befestigungsgewinden verwenden. Die Be-

festigungsschrauben sind gegen Selbstlockern mit Sicherungsscheiben zu sichern.

Bei freier Bewetterung wird empfohlen, das Schutzgehäuse mit Sonnenschutzdach

auszurüsten.

Page 61

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 11 AT-Automation Technology GmbH

9 Installation

Installationsarbeiten nur durch Fachpersonal!

Installationsarbeiten dürfen nur von dazu befugtem und entsprechend geschultem Personal

durchgeführt werden. Geltende nationale Bestimmungen im Einsatzland, z.B. EN 60079-14

beachten. Die Montage der Kabeleinführungen oder gehäuseseitigen Steckverbinder und die

Installation der Anschlussleitungen erfolgt durch den Hersteller oder durch vom Hersteller

autorisiertes Personal.

Gefahr durch spannungsführende Teile!

Es ist sicherzustellen, dass alle Zuleitungen spannungsfrei geschaltet sind und gegen unbefugtes

Schalten gesichert sind.

Gefahr durch unzulässige Kabeleinführungen!

Bei Verwendung unzulässiger Kabeleinführungen ist der Explosionsschutz nicht mehr ge-

währleistet. Nur Kabeleinführungen verwenden, die für die geforderte Zündschutzart zugelassen

sind und für das Gehäuse vom Hersteller benannt sind, s. Abschnitt „Zulässige Kabeleinführungen

und Steckverbinder“.

Gefahr durch fehlerhafte Zugentlastung!

Bei Verwendung von Kabeleinführungen ist bei fehlerhafter Zugentlastung der Explosionsschutz

nicht mehr gewährleistet. Kabel und Leitungen fest verlegen. Betriebsanleitung zur Kabel-

durchführung beachten.

Gefahr durch beschädigte Gewinde!

Bei beschädigten Gewinden ist der zünddurchschlagssichere Spalt nicht mehr gewährleistet.

Gehäusedeckel vorsichtig ablegen bzw. vorsichtig auf das Gehäuse aufsetzen. Gehäusedeckel oder

Gehäuse mit beschädigtem Gewinde sofort austauschen!

Gefahr durch fehlerhafte Abdichtung!

Der Explosionsschutz ist in hohem Maße von der Einhaltung der IP-Schutzart abhängig. Bei allen

Arbeiten auf korrekten Sitz und einwandfreien Zustand aller Dichtungen achten.

Page 62

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 12 AT-Automation Technology GmbH

9.1 Installation der Anschlussleitungen

Leitungen

Die Qualität der verwendeten Zuleitung ist so zu wählen, dass sie den thermischen und

mechanischen Anforderungen im Einsatzbereich genügt. Die Kabel müssen den entsprechenden

Richtlinien für direkte Einführung in druckfeste Kapselung nach EN 60079-14 genügen. Die

Kabeleinführung ist mit Vergussmasse zur Abdichtung der Einzeladern auszuführen.

Abb. 2: Darstellung der Anschlüsse am Controllerboard

9.1.1 Hinteren Gehäusedeckel abschrauben

1. 1x Gehäuseindexschraube lösen

2. 4x Gehäuseklemmschraube lösen

3. Montageschlüssel für Deckel hinten aufsetzen und Gehäusedeckel abschrauben

4. Gehäusedeckel vorsichtig ablegen

9.1.2 Auflegen der Anschlussleitungen

Führen Sie die Anschlussleitungen mit der kompletten äußeren Isolation durch die

Kabeleinführungen in den Anschlussraum.

Stellen Sie dabei sicher, dass der Kabeldurchmesser mit dem Klemmquerschnitt auf der

Kabeleinführung übereinstimmt und die Abdichtung mit der Vergussmasse gemäß

Bedienungsanleitung der Kabeleinführung ausgeführt ist.

Ziehen Sie die Sechskantmuttern der Kabeleinführung so fest an, dass die Dichtheit des

Anschlussraumes sowie der Zugentlastungsschutz der Anschlussstellen gesichert sind.

Die Anzugsdrehmomente entnehmen Sie den Betriebsanleitungen der Komponenten.

Verlegen Sie die Anschlussleitungen im Anschlussraum so, dass:

o Die für den jeweiligen Leiterquerschnitt zulässigen minimalen Biegeradien nicht

unterschritten werden.

o Mechanische Beschädigungen der Leiterisolation ausgeschlossen sind.

LWL-LC Anschluss

Anschluss Versorgungsleitung

Page 63

Betriebsanleitung IRCamSafeEX-AXC

Ex-d Gehäuse für Infrarotkameras 13 AT-Automation Technology GmbH

Nicht korrekt durchgeführte Installation!

Bitte beachten Sie die Gewindegrößen für die Leitungseinführungen in der Dokumentation

des Betriebsmittels.

Die Anschlussleistung muss den geltenden Vorschriften entsprechen und über den

erforderlichen Querschnitt verfügen. Der Durchmesser muss mit den Angaben auf der

Kabeldurchführung übereinstimmen.

Durch geeignete Auswahl der verwendeten Leitungen sowie durch die Art der Verlegung

muss sichergestellt sein, dass maximal zulässige Leitertemperaturen nicht überschritten

werden.

Die zulässige Umgebungstemperatur an den eingebauten Komponenten darf nicht

überschritten werden.

Es muss sichergestellt werden, dass beim Abisolieren die Leiterisolation bis an die

Klemmen heranreicht.

Der Leiter darf beim Abisolieren nicht beschädigt werden.

Die Schaltgerätekombination darf nur in trockener und sauberer Umgebung installiert

werden.

9.1.3 Hinteren Gehäusedeckel schließen

1. Korrekten Sitz und einwandfreien Zustand des O-Rings prüfen

2. Gewinde des hinteren Deckels auf einwandfreien Zustand und Sauberkeit prüfen. Bei

Beschädigung des Gewindes muss der Deckel ausgetauscht werden!

3. Prüfen das auf dem Gewinde Montagepaste (z.B. Teflonpaste) aufgebracht ist.

4. Neues Trockenmittel einsetzen

5. Gehäusedeckel vorsichtig aufsetzen und mit Hand zuschrauben

6. Montageschlüssel für Deckel hinten aufsetzen und Gehäusedeckel zuschrauben, bis

Indexposition erreicht ist

7. 1x Gehäuseindexschraube Gewindestift einschrauben und festziehen

8. 4x Gehäuseklemmschraube einschrauben und festziehen

9.1.4 Erdungsanschluss auflegen

Der Erdungsanschluss ist für feindrähtige Kabel bis 1,5mm2 und für eindrähtige Kabel bis 2,5mm2

geeignet. Das abisolierte Ende des Erdungskabels in den Erdungsanschluss einlegen und die M4-

Schraube des Erdungsanschlusses mit einem maximalen Anzugsdrehmoment von 1,2Nm festziehen.

Für größere Erdungsleiter ist der Anschluß über einen Ringkabelschuh möglich. Diese auf das Ende