Page 1

ThermoVision™ Sentinel

Operator’s manual

1 557 544Publ. No.

a121Revision

English (EN)Language

October 6, 2005Issue date

Page 2

Page 3

ThermoVision™

Sentinel

Operator’s manual

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 4

Legal disclaimer

All products manufactured by FLIR Systemsarewarranted against defectivematerialsandworkmanship for aperiodof one(1)year from the

delivery date of the original purchase, provided such products have been under normal storage, use and service, and in accordance with

FLIR Systems instruction.

All products not manufactured by FLIR Systems included in systemsdelivered by FLIRSystems to theoriginal purchaser carrythe warranty,

if any, of the particular supplier only and FLIR Systems has no responsibilitywhatsoever for such products.

The warranty extends only to the original purchaser and is not transferable. It is not applicable to any product which has been subjected to

misuse, neglect, accident or abnormal conditions of operation. Expendable parts are excluded from the warranty.

In the case of adefect inaproduct coveredbythis warrantytheproduct must notbe furtherusedin order toprevent additional damage.The

purchaser shall promptly report any defect to FLIR Systems or this warranty will not apply.

FLIR Systems will, at its option, repair or replace any such defective product free of charge if, upon inspection, it proves to be defective in

material or workmanship and provided that it is returned to FLIR Systems within the said one-year period.

FLIR Systems has no other obligation or liability for defects than those set forth above.

No other warranty is expressed or implied. FLIR Systems specifically disclaims the implied warranties of merchantability and fitness for a

particular purpose.

FLIR Systems shall not be liable for any direct, indirect, special, incidentalor consequential loss or damage, whether basedon contract, tort

or any other legal theory.

Copyright

© FLIR Systems,2005. All rights reservedworldwide. No parts ofthesoftware including source codemaybe reproduced, transmitted, transcribed

or translated into any language or computer language in any form or by any means, electronic, magnetic, optical, manual or otherwise,

without the prior written permission of FLIR Systems.

This manual must not, in whole or part, be copied, photocopied, reproduced,translated ortransmitted to any electronic mediumor machine

readable form without prior consent, in writing, from FLIR Systems.

Names and marks appearing on the products herein are eitherregistered trademarksor trademarksof FLIR Systems and/or its subsidiaries.

All othertrademarks,trade names or companynames referenced herein areusedfor identification only andarethe property of theirrespective

owners.

Quality assurance

The Quality Management System under which these products are developed and manufactured has been certified in accordance with the

ISO 9001 standard.

FLIR Systems is committed to a policy of continuous development; therefore we reserve the right to make changes and improvements on

any of the products described in this manual without prior notice.

Patents

This product is protected by patents, design patents, patents pending, or design patents pending.

Contact details

FLIR Systems AB Imaging Sweden ■ P. O. Box 3 ■ SE-182 11 Danderyd ■ SwedenPostal address

+46 (0)8 753 25 00Telephone

+46 (0)8 731 05 30Telefax

www.flir.com/imagingWeb site

imagingsweden.sales@flir.seE-mail

➲ For contact details for regional offices, see the back cover of this manual.

iv Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 5

Table of contents

11 System description .........................................................................................................................

22 Packing list ......................................................................................................................................

33 Connecting system components ..................................................................................................

33.1 Important notes ....................................................................................................................

43.2 Connection overviews ..........................................................................................................

43.2.1 Imager ...................................................................................................................

63.2.2 Power Box (PB) .....................................................................................................

84 Typical system overview ................................................................................................................

95 Mechanical installation ..................................................................................................................

106 Remote Control (RC) ......................................................................................................................

117 Display symbology .........................................................................................................................

117.1 General information ..............................................................................................................

127.2 System display & symbols ...................................................................................................

127.2.1 System display ......................................................................................................

137.2.2 In-depth explanations of symbols ........................................................................

137.2.2.1 NFOV (narrow field-of-view) reticle ...................................................

137.2.2.2 Crosshair reticle ................................................................................

137.2.2.3 Image polarity ....................................................................................

137.2.2.4 System date ......................................................................................

137.2.2.5 System time .......................................................................................

137.2.2.6 Focus position indicator ....................................................................

137.2.2.7 Active channel indicator ....................................................................

137.2.2.8 Additional indicators not shown in the illustration ............................

147.2.2.9 Declutter function ..............................................................................

158 Operation .........................................................................................................................................

158.1 Checking the system by using the Remote Control (RC) ....................................................

158.2 On-screen menus .................................................................................................................

158.2.1 General information ..............................................................................................

168.2.2 Autofocus ..............................................................................................................

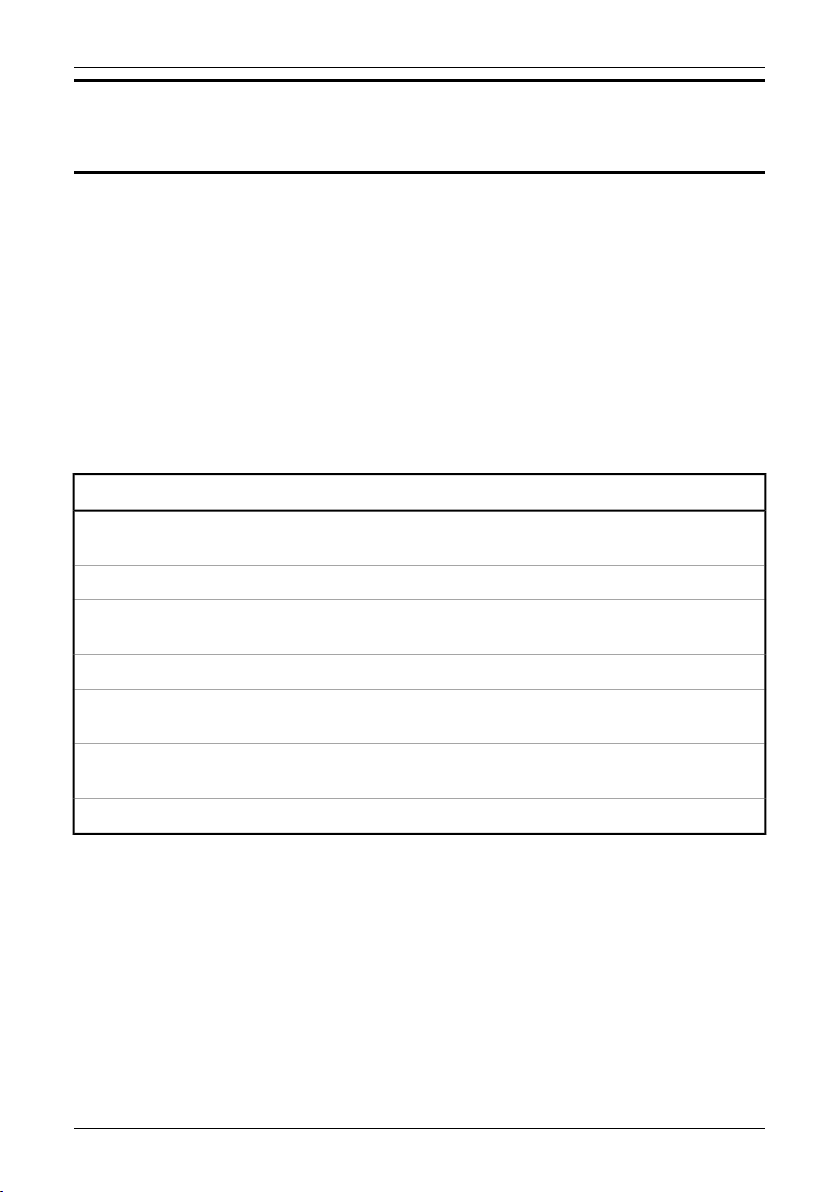

178.2.3 Image menu ..........................................................................................................

178.2.3.1 When IR is selected ...........................................................................

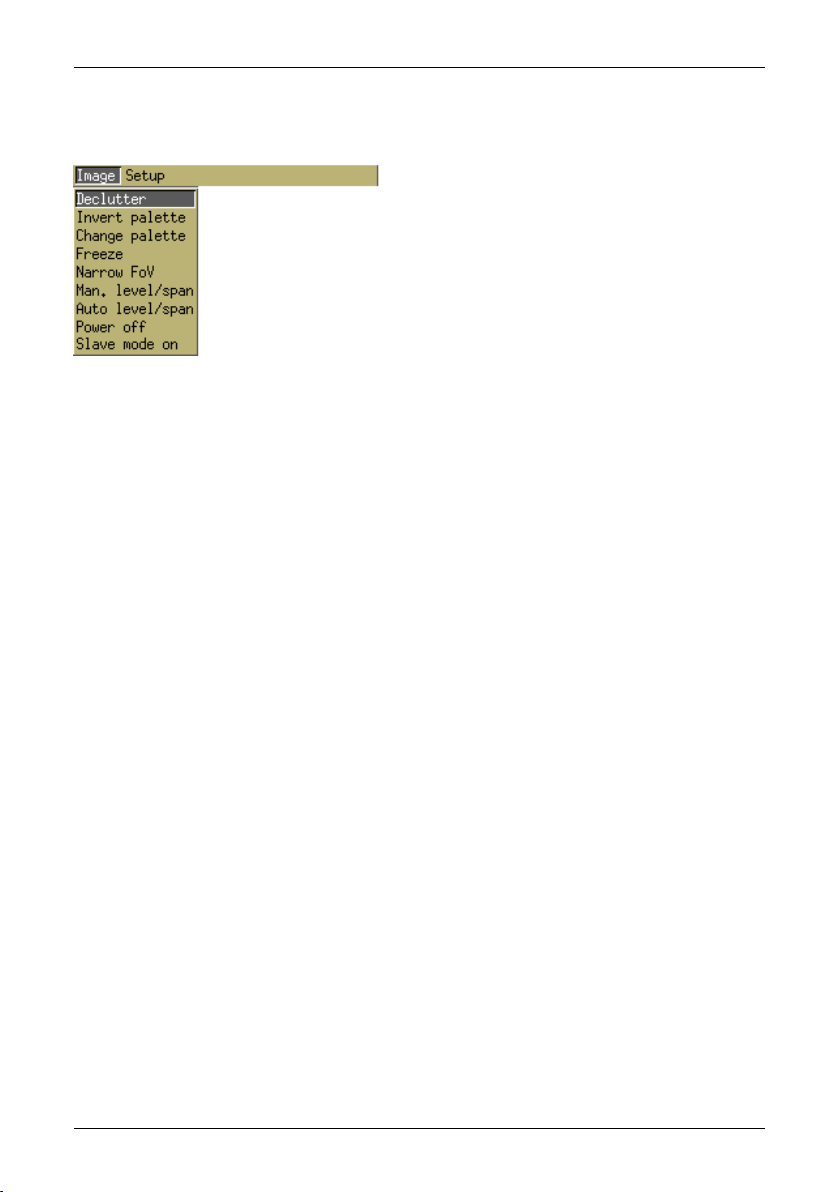

188.2.3.2 When TV is selected ..........................................................................

198.2.4 Setup menu ...........................................................................................................

208.2.4.1 Image ................................................................................................

218.2.4.2 Symbology ........................................................................................

238.2.4.3 Local adapt ........................................................................................

248.2.4.4 Date & Time .......................................................................................

258.2.4.5 Maintenance ......................................................................................

278.2.4.6 System info ........................................................................................

289 Adverse weather conditions ..........................................................................................................

289.1 Built-in heaters ......................................................................................................................

289.2 Precautions under cold weather conditions ........................................................................

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 v

Page 6

2910 Maintenance & cleaning ................................................................................................................

2910.1 Camera body, cables & accessories ....................................................................................

2910.2 Lenses ...................................................................................................................................

3011 Technical support ...........................................................................................................................

3112 Technical specifications .................................................................................................................

3112.1 System specifications ...........................................................................................................

3212.2 Thermal imager specifications .............................................................................................

3312.3 Video camera specifications ................................................................................................

3412.4 List of relevant documents ...................................................................................................

3512.5 Diagnostic tools ....................................................................................................................

3512.5.1 General ..................................................................................................................

3612.6 Troubleshooting guide .........................................................................................................

3712.7 Overview & location of connectors ......................................................................................

3712.7.1 Connectors on Power Box (PB) ............................................................................

3812.7.2 Connectors on imager unit ...................................................................................

3912.8 Pin configuration ...................................................................................................................

3912.8.1 Connectors on Power Box (PB) ............................................................................

3912.8.1.1 J4 – 23-pin connector .......................................................................

4012.8.1.2 J5 – Connector for host computer & remote control ........................

4012.8.1.3 J6 – BNC connector ..........................................................................

4012.8.1.4 J7 – BNC connector ..........................................................................

4012.8.2 Connectors on imager unit ...................................................................................

4012.8.2.1 J1 – 23-pin connector .......................................................................

4212.8.2.2 J3 – Internal service connector .........................................................

4312.9 Basic dimensions – Imager; view from above .....................................................................

4412.10 Basic dimensions – Imager; rear view .................................................................................

4512.11 Basic dimensions – Imager; front view ................................................................................

4612.12 Basic dimensions – Imager; side view .................................................................................

4712.13 Basic dimensions – Imager; view from below ......................................................................

4812.14 Basic dimensions – Remote Control (RC) ...........................................................................

4912.15 Basic dimensions – Power Box (PB) ....................................................................................

5012.16 Basic dimensions – Power Box (PB) ....................................................................................

5113 History of infrared technology ......................................................................................................

5614 Theory of thermal imaging ............................................................................................................

5614.1 Introduction ...........................................................................................................................

5614.2 The electromagnetic spectrum ............................................................................................

5714.3 Blackbody radiation ..............................................................................................................

5814.3.1 Planck’s law ..........................................................................................................

5914.3.2 Wien’s displacement law ......................................................................................

6114.3.3 Stefan-Boltzmann's law .........................................................................................

6114.3.4 Non-blackbody emitters .......................................................................................

6414.4 Infrared semi-transparent materials .....................................................................................

65Index ................................................................................................................................................

vi Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 7

1 System description

The ThermoVision™ Sentinel from FLIR Systems is a high performance thermal

imaging system that incorporates the latest in uncooled detector technology. The

ThermoVision™ Sentinel contains a 320 × 240 uncooled microbolometer focal plane

detector array.

The ThermoVision™ Sentinel features a dual field-of-view (WFOV = 20° × 15°, NFOV

= 5° × 3.75°) for wide area surveillance, and close-up inspections. Electronic zoom

as well as autofocus are included for enhanced target recognition, along with freeze

frame capabilities, and various image enhancement functions.

The systemalso features a side-mounted 1/4" color CCD video camera with autofocus

and 12x electronic zoom / 18x optical zoom, allowing the operator to toggle between

IR imaging and video imaging.

The ThermoVision™ Sentinel can be configured for stand-alone operation, or it can

be fully configured into a comprehensive surface surveillance network. This makes

it an ideal solution for a wide variety of applications including perimeter surveillance,

border surveillance, and force protection.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 1

Page 8

2 Packing list

The ThermoVision™ Sentinel and its accessories are normally delivered in a hard

transport case which typically contains the items below.

On receipt, inspect all items and check them against the delivery note. Any damaged

items must be reported to the local FLIR Systems representative immediately.

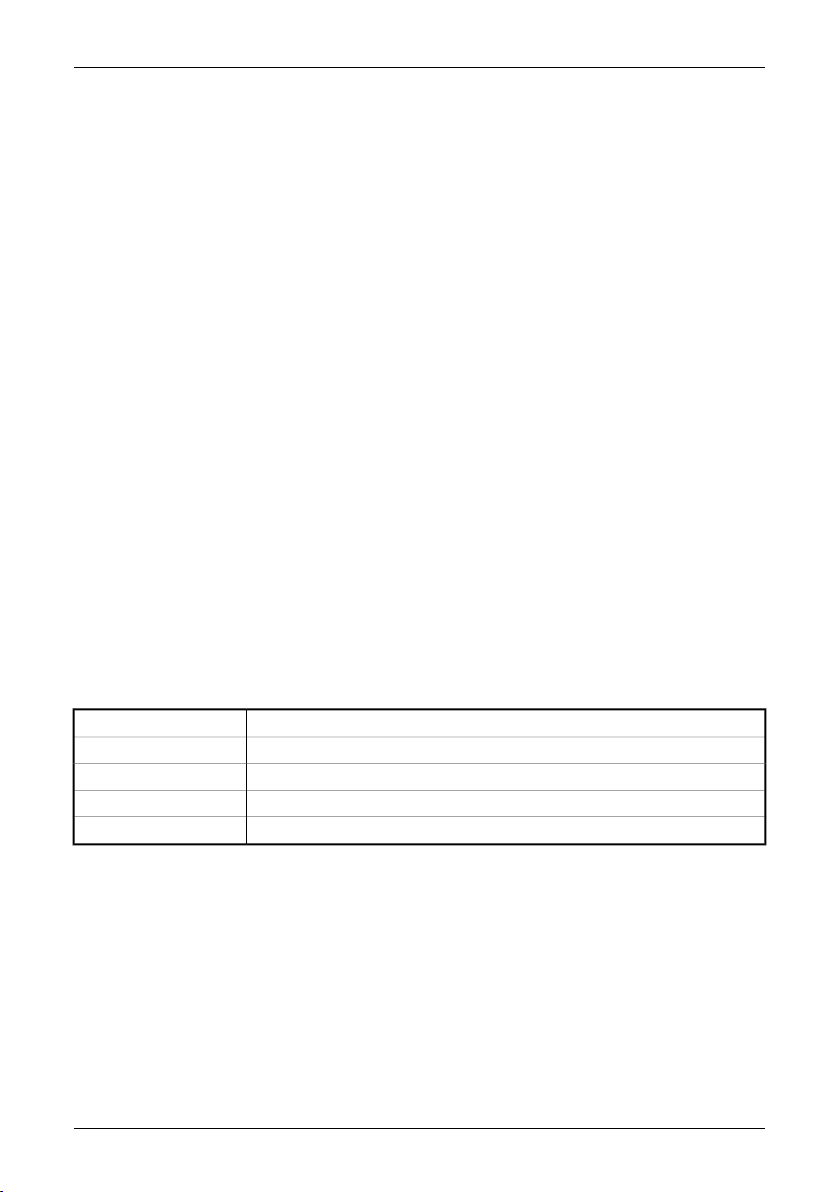

Qty.Part NumberDescription

1614004898ThermoVision™ Sentinel

11 557 544Operator’s manual

■ System cable, 15 m / 50 ft. or

■ System cable, 61 m / 200 ft.

1■ 194 796 (15 m / 50 ft.)

■ 194 797 (61 m / 200 ft.)

11 195 413Power Box (PB)

11 195 367Remote Control (RC)

1908 929Video cable

11 909 824Transport Case

1PP_614004898ATR ThermoVision™ Sentinel

1Certificate of Conformity

2 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 9

3 Connecting system components

3.1 Important notes

Please note the following:

■ Always disconnect the system fromthe mainssupply before connecting or discon-

necting any cables.

■ The connectors should be sealed with the protective caps when not in use.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 3

Page 10

3.2 – Connection overviews

3.2 Connection overviews

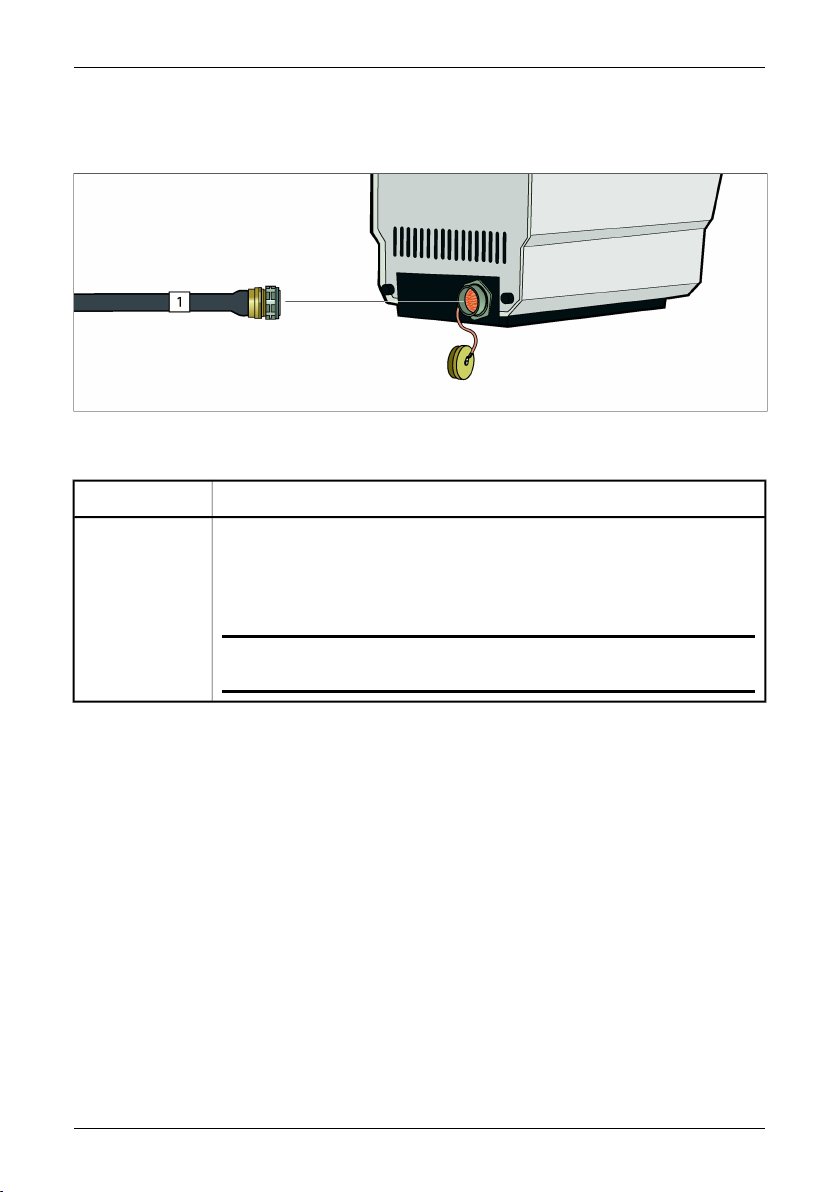

3.2.1 Imager

10597403;a1

Figure 3.1 Main system connector

Figure 3.2 Explanations of callouts

ExplanationCallout

1

■ Cable designation: System cable

■ Part Number: 194 796 (15 m / 49 ft.) or 194 797 (61 m / 200 ft.)

■ Function: Connecting from Power Box (PB) to J1 connector on imager

■ Pin configuration on receptacle connector: See section 12.8.2.1 – J1 – 23-

pin connector on page 40

SEE ALSO: For an example in a typical system overview, see section 4 – Typical

system overview on page 8

4 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 11

3.2 – Connection overviews

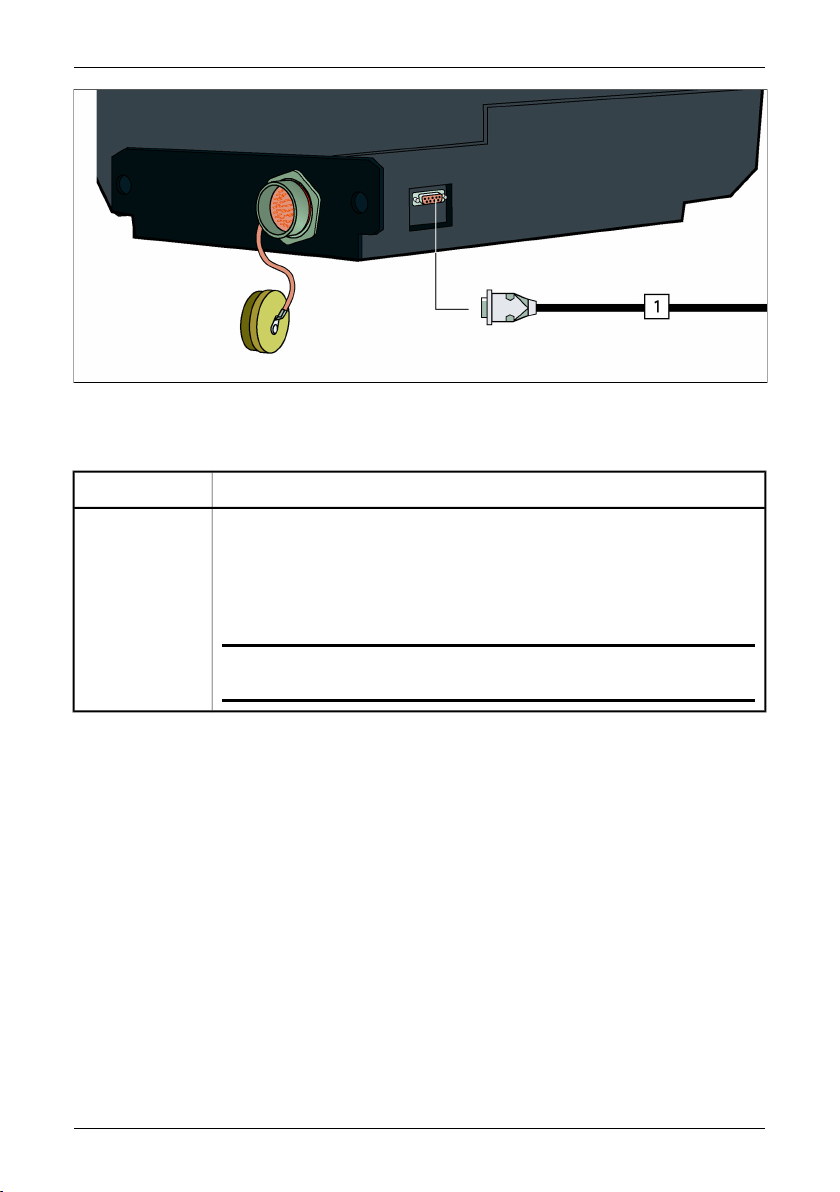

10597503;a1

Figure 3.3 J3 internal service connector. Note that the outer housing must be removed to access the J3

internal service connector.

Figure 3.4 Explanations of callouts

ExplanationCallout

1

■ Cable designation: RS-232 cable(local supplier),orRemote Control (RC)cable

■ Part Number: 1 195 367 (applies only to cable including Remote Control (RC))

■ Function: Either connecting a desktop orlaptop computer tothe J3 connector,

or connecting a Remote Control (RC) to the J3 connector

■ Pin configuration on receptacle connector: See section 12.8.2.2– J3 –Internal

service connector on page 42

SEE ALSO: For an example in a typical system overview, see section 4 – Typical

system overview on page 8

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 5

Page 12

3.2 – Connection overviews

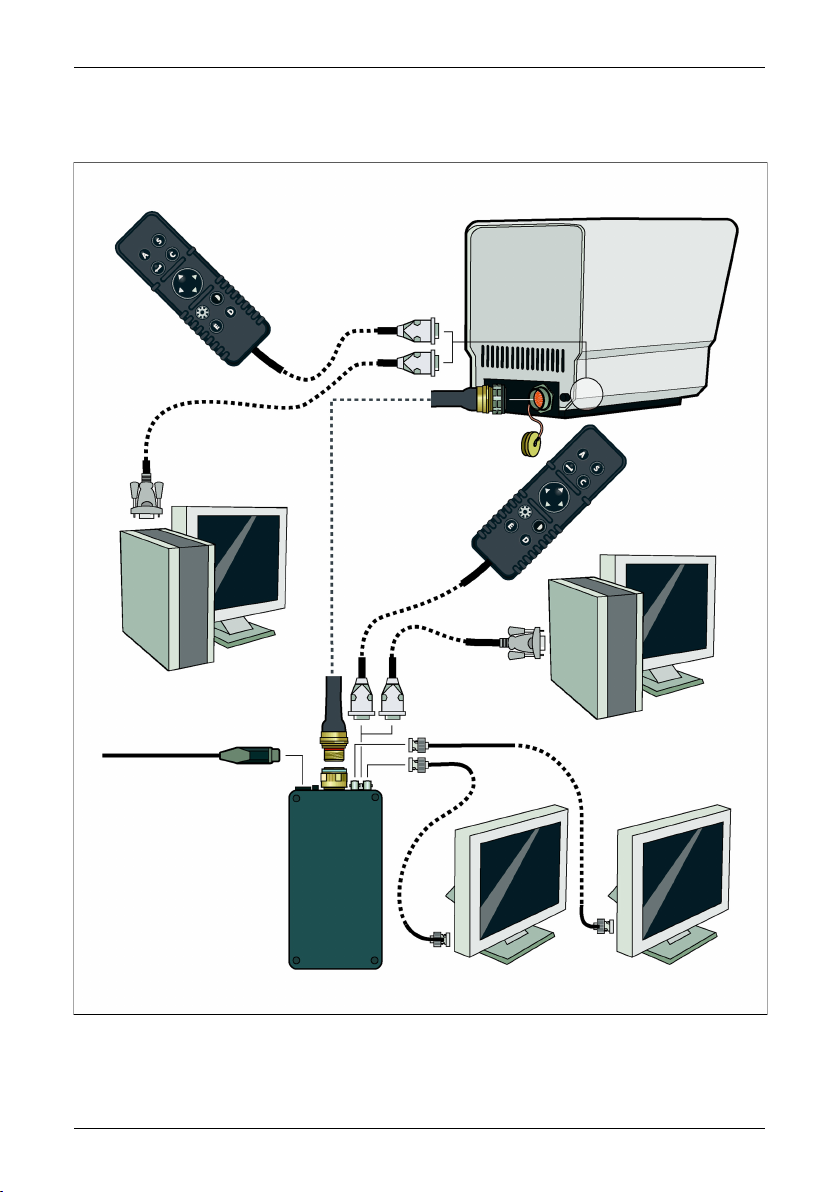

3.2.2 Power Box (PB)

10597603;a1

Figure 3.5 Connecting cables to Power Box (PB)

Figure 3.6 Explanations of callouts

ExplanationCallout

1

■ Cable designation: Video cable

■ Part Number: 908 929

■ Function: Connecting from external video monitor to the J7 connector on the

Power Box (PB)

SEE ALSO: For an example in a typical system overview, see section 4 – Typical

system overview on page 8

2

■ Cable designation: Video cable

■ Part Number: 908 929

■ Function: Connecting from external video monitor to the J6 connector on the

Power Box (PB)

SEE ALSO: For an example in a typical system overview, see section 4 – Typical

system overview on page 8

6 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 13

3.2 – Connection overviews

ExplanationCallout

3

■ Cable designation: RS-232 cable(local supplier),orRemote Control (RC)cable

■ Part Number: 1 195 367 (applies only to cable including Remote Control (RC))

■ Function: Either connecting a desktop or laptop computer to the J5 connector

on thePower Box (PB),orconnecting a RemoteControl (RC) tothe J5 connector

on the Power Box (PB)

■ Pin configuration on receptacle connector: See section 12.8.1.2 – J5 –

Connector for host computer & remote control on page 40

SEE ALSO: For an example in a typical system overview, see section 4 – Typical

system overview on page 8

4

■ Cable designation: System cable

■ Part Number: 194 796 (15 m / 49 ft.) or 194 797 (61 m / 200 ft.)

■ Function: Connecting from imager to J4 connector on Power Box (PB)

■ Pin configuration on receptacle connector: See section 12.8.1.1 – J4 – 23-

pin connector on page 39

SEE ALSO: For an example in a typical system overview, see section 4 – Typical

system overview on page 8

5

■ Cable designation: Mains cable

■ Part Number: N/A

■ Function: Connecting from amains supply tothe unmarked power in connector

on the Power Box (PB)

SEE ALSO: For an example in a typical system overview, see section 4 – Typical

system overview on page 8

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 7

Page 14

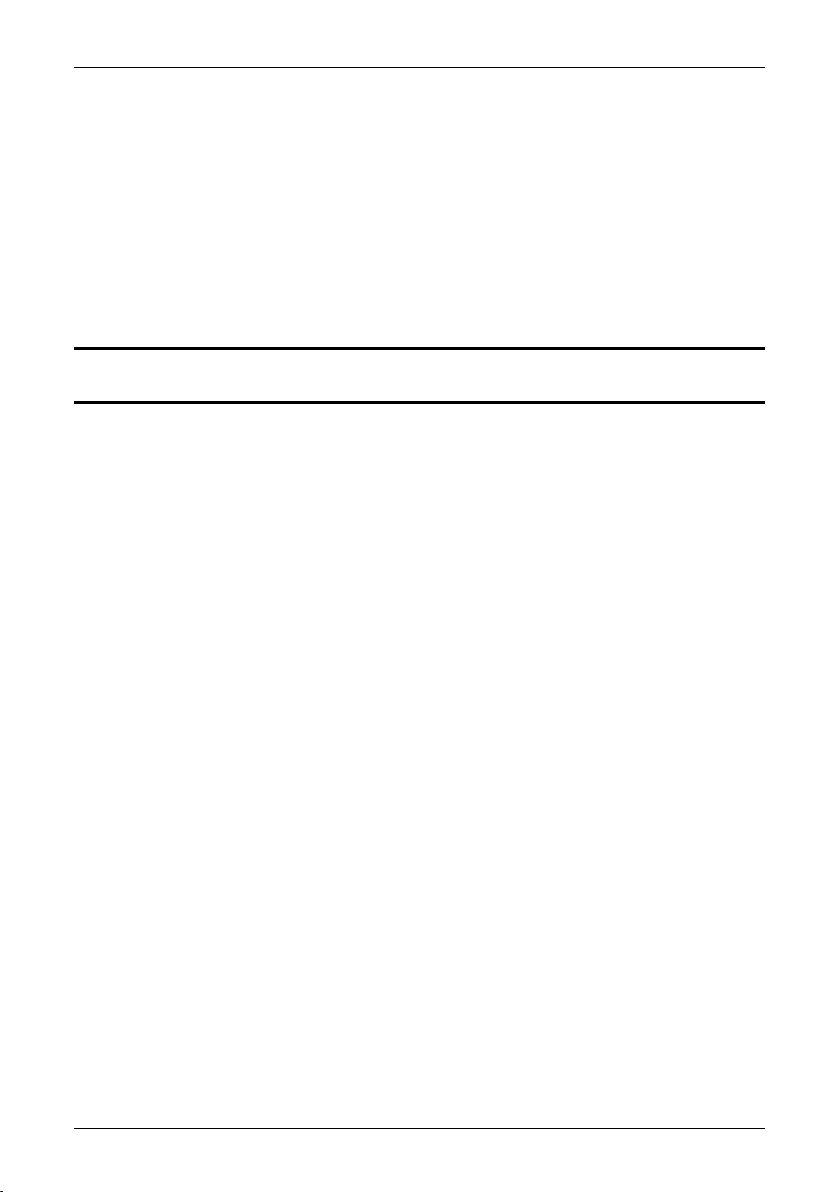

4 Typical system overview

10597303;a1

Figure 4.1 Typical system overview

8 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 15

5 Mechanical installation

Different applications call for different ways of mechanically installing the imager unit

and thereforespecific information regarding the installation can not be given. However,

the imager unit has a mounting plate (with one 3/8"-16 UNC and two 1/4"-20 UNC

threaded holes) on the bottom side of the housing designed to match an existing

platform.

Mounting plates with a different hole layout can be made by custom order at FLIR

Systems AB Imaging Sweden.

SEE ALSO: For more information about mounting plates, see section 12.13 – Basic dimensions – Imager;

view from below on page 47.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 9

Page 16

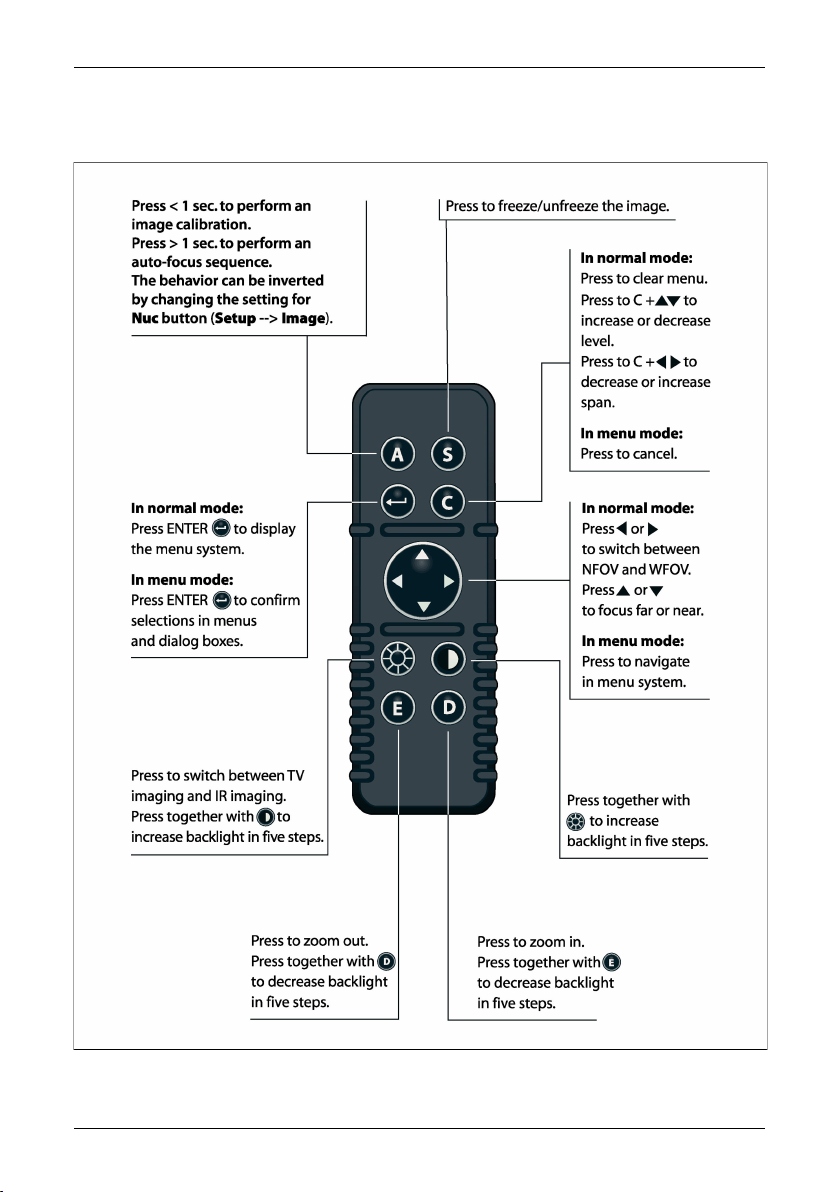

6 Remote Control (RC)

10597003;a2

Figure 6.1 Remote Control (RC)

10 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 17

7 Display symbology

7.1 General information

The ThermoVision™ Sentinel system operates in a number of modes. Each mode is

a combination of settings and functions designed to assist the operator in performing

a particular task. In addition to the operating modes, there are also a number of

controls that can be used to optimize the system’s performance, or enhance system

operation.

The ThermoVision™ Sentinel system takes the thermal video of the area within the

field-of-view and displays it on the video display unit (-s). Symbology is also overlaid

on the imagery and provides system time/date, focus indicator, NFOV brackets,

crosshair, and polarity (White hot or Black hot) indicator.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 11

Page 18

7.2 – System display & symbols

7.2 System display & symbols

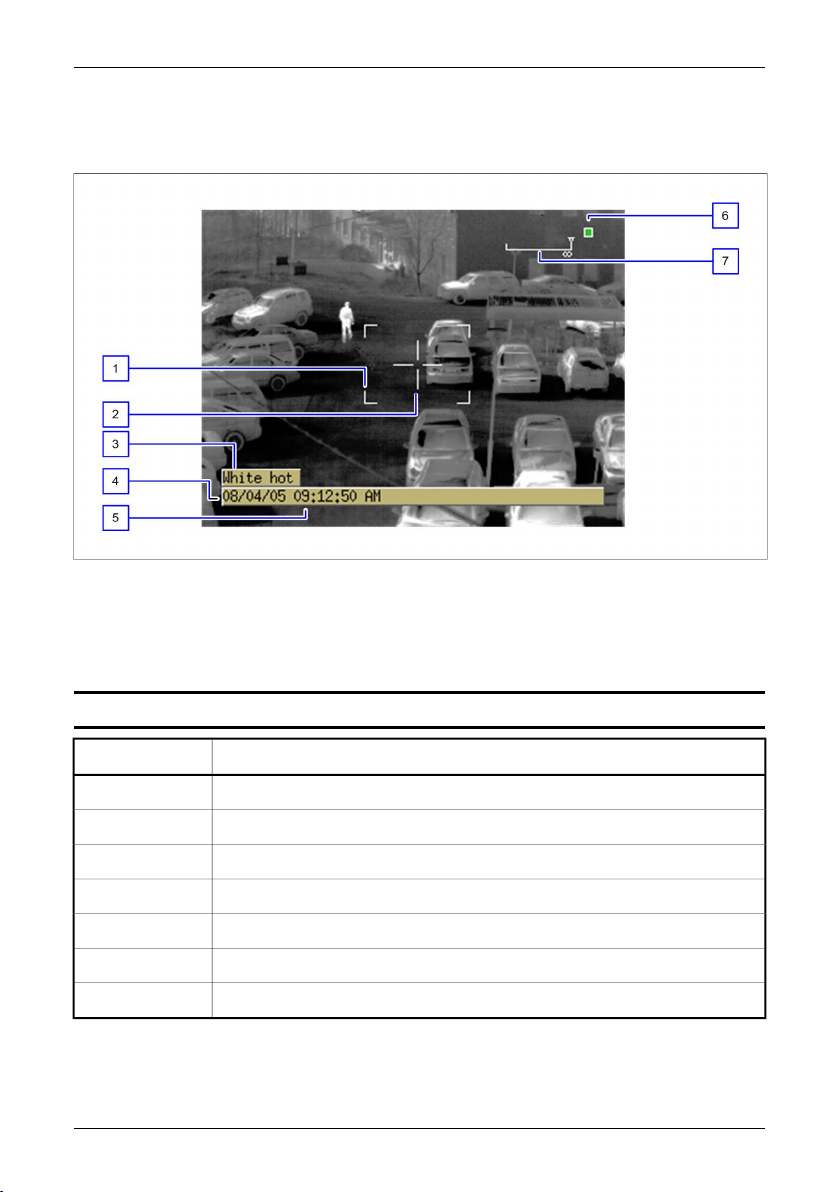

7.2.1 System display

10700103;a1

Figure 7.1 System display

The symbology actually displayed is mode and function dependent, and can be removed from the display by using the Declutter feature if desired.The display is shown

with all of the symbology activated (DECLUTTER mode is not active).

NOTE: The DECLUTTER mode is only active until the operator presses the ENTER key.

DescriptionCallout

NFOV reticule1

Crosshair reticle2

Image polarity3

System date4

System time5

Active channel6

Focus position indicator7

12 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 19

7.2 – System display & symbols

7.2.2 In-depth explanations of symbols

7.2.2.1 NFOV (narrow field-of-view) reticle

The NFOV reticle is displayed when the system is in the WFOV (wide field-of-view),

and provides an indication of the area viewed when the NFOV is selected.

7.2.2.2 Crosshair reticle

The crosshair reticle shows the center of the current field-of-view.

7.2.2.3 Image polarity

The image polarity shows if white is set to represent hot or black is set to represent

hot.

7.2.2.4 System date

The system date is located at the bottom left of the display, and is shown in either

YY-MM-DD, MM/DD/YY or DD/MM/YY format. The system date is set from the Setup

menu (the date format is set from the Local adaptions dialog box, while the actual

date is set from the Date & time dialog box).

7.2.2.5 System time

The system time is located at the bottom of the display and is displayed in either 12

or 24 hour format. The system time is set from the Setup menu (the time format is set

from the Local adaptions dialog box while the actual system time is set fromthe Date

& time dialog box).

7.2.2.6 Focus position indicator

The focus position indicator is located at the upper right corner of the display, and

provides an indication of the focus travel from near (left) to distant (right).

7.2.2.7 Active channel indicator

The active channel indicator is shown on the screen to indicate which channel – i.e.

TV or IR – is active.

7.2.2.8 Additional indicators not shown in the illustration

7.2.2.8.1 Level & span (gain) indicators

The level & span (gain) indicators, are located at the bottom left of the screen (over

the system date and time) when Manual level & span is first selected. They provide

the operator with an indication of the current system level & span settings.

7.2.2.8.2 Other indicators

One or several of the following text strings and / or icons will be displayed when the

functions they represent are triggered:

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 13

Page 20

7.2 – System display & symbols

■ Zooming in

■ Zooming out

■ Focus far

■ Focus near

■ Frozen

■ Zoom box

■ Adjusting

7.2.2.9 Declutter function

At times the operator may want to remove all the symbology from the image. The

system is capable of two levels of symbology display: Declutter none (all symbology

is displayed normally as defined from the Setup → Symbology menu), and the DECLUTTER mode where all of the symbology is removed.

NOTE: The DECLUTTER mode is only active until the operator presses the ENTER key.

14 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 21

8 Operation

8.1 Checking the system by using the Remote Control (RC)

The ThermoVision™ Sentinel is usually controlled from a host computer. However, it

can also be controlled locally – at the imager unit site or ina training center – by using

a remote control.

NOTE: The remote control cable should be connected to the J5 connector on the Power Box

The imager unit is controlled by pressing the direct access buttons and/or using the

navigation pad on the remote control. All buttons on the remote control are backlit.

By pressing the E and D buttons simultaneously the intensity of the backlight for all

buttons on the remote control will decrease in five steps.

By pressing the and buttons simultaneously the intensity of the backlight for all buttons on the

remote control will increase in five steps.

8.2 On-screen menus

8.2.1 General information

NOTE: All commands inthis section canbe initiated usingthe remote controlor imager unitcontrol software.

The system’s software menus provide the operator with a simple interface to define

system features and enter system constants. Access to the MENU mode is made by

pressing the ENTER button located on the remote control. The two main menus are

shown in the menu bar found at the top of the screen with the currently selected

menu/feature highlighted. Features are presented directly as a command (Freeze or

Change palette for example), while selections that do not directly perform an action,

but open a dialog box allowing further selections to be made, are identifiedby a feature

title followed by three periods (Image... or Date & time... for example). Features that

are not currently available for selection will be shaded in the menu.

The left/right arrow buttons on the remote control are used to move between the different menus, and the up/down arrow buttons are used to move between the menu

features or in dialog boxes. When a menu item is highlighted, pressing the ENTER

button will either activate the feature and exit the menu mode, or open the sub-menu

for further selection. To exit a menu (or the menu mode) press the ENTER button to

accept anychanges, oruse the C button to back out of the menu mode without altering

any of the current settings.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 15

Page 22

8.2 – On-screen menus

NOTE: The action to be performed is the one that is displayed in the menu. For example, if the feature

Narrow FOV is listed, the system is currently using the WFOV and the selection will zoom in on the target.

If the system is already using NFOV, the feature would be listed as Wide FOV. Selecting this would return

the system to normal display.

8.2.2 Autofocus

The A button performs an image calibration to correct for image non-uniformities that

arise due to the slightly different gain characteristics that occur from detector to detector within the array.

In IR mode, pressing the A button < 1 second will perform an image calibration. In

both IR and TV mode, pressing the A button > 1 second will perform an auto-focus

sequence. This is the default behavior. The behavior can be inverted by changing

the setting for Nuc button (Setup → Image).

To make it possible for the imager unit to autofocus properly, there are a few things

that the user should think about.

To think about when autofocusing

The area that the imager uses when autofocusing is a 64 × 64 pixel box, centered vertically and horizontally on the screen.

The imager will havedifficulties autofocusing whenthe image haslow contrastsbetween different areas.

To make it possible for theimager to autofocus properly, it isimportant that there are nomoving objects

inside the 64 × 64 pixel box during the autofocus adjustment.

Horizontal or vertical lines in the image should not be parallel to the pixel lines on the screen.

The imager will experience difficulties autofocusing if it is completely out of focus when beginning the

autofocus sequence.

When auto-focusing in NFOV (narrow field-of-view) the distance to target must be more than 15 m

/ 49.2 ft.

When auto-focusing in WFOV (wide field-of-view) the distance to target must be more than 2 m / 6.6 ft.

16 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 23

8.2 – On-screen menus

8.2.3 Image menu

8.2.3.1 When IR is selected

10342903;a1

Figure 8.1 Image menu when IR is selected

The Image menu is used to define appearance of the system video display. The

up/down arrow buttons are used to move between the different menu features;

pressing the ENTER button will activate the currently highlighted feature, and then

exit the MENU mode. To exit the Image menu without making any changes, press

the C (cancel) button.

8.2.3.1.1 Declutter

The Declutter feature allows the operator to temporarily remove all of the displayed

symbology fromthe systemdisplay. The symbology will return the next time the ENTER

button is pressed.

8.2.3.1.2 Invert palette

Highlighting and pressing enter inverts the palette currently in use, and then exits the

MENU mode.

■ Gray (white hot) to Inv gray (black hot), or back;

■ Rainbow to Inv rainbow, or back;

■ Iron to Inv Iron, or back.

8.2.3.1.3 Change palette

Highlighting andpressing ENTERchanges thepalette currentlyin use,and thenexits

the MENU mode. The palettes will ‘rotate’ from Gray to Rainbow to Iron, and then

back to Gray and start over again. If the palette currently in use is inverted, the newly

selected palette will also be inverted.

8.2.3.1.4 Freeze/Live

Changes the display from live image to frozen image, or back. A frozen image is

identified by the text Frozen in the display.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 17

Page 24

8.2 – On-screen menus

8.2.3.1.5 Narrow FoV/Wide FoV

Changes the current field-of-view in use from Wide FoV (normal) to Narrow FoV

(zoomed), or back.

8.2.3.1.6 Man. level/span

When selected, level & span values are locked, and a dialog box is shown at the

bottom left of the display. The left/right arrow buttons are used to select either the

level or span for adjustment, while the up/down arrow buttons adjusts the setting.

Pressing ENTER accepts these setting for the image and removes the control bar.

Pressing the C button will reset the level & span to the previous values. Man. Lev-

el/span can be selected again to continue the adjustments.

NOTE: The system will remain in manual level/span mode until Auto level/span is selected.

8.2.3.1.7 Auto level/span

When selected, the system will automatically select an image enhancement method

for best overall image contrast. The method selected depends on the settings in the

Setup – Image dialog box.

8.2.3.1.8 Power off/Power off

This function switches off the power to the detector module. A test image will be displayed.

8.2.3.1.9 Slave mode on/Slave mode off

When Slave mode on is selected, and the operator switches to TV mode, the same

field of view as in IR mode will be used and the camera will carry out an autofocus

sequence.

8.2.3.2 When TV is selected

10597103;a1

Figure 8.2 Image menu when TV is selected

8.2.3.2.1 Declutter

This is the same function as when IR is selected.

18 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 25

8.2 – On-screen menus

SEE: For information, see section 8.2.3.1.1 – Declutter on page 17.

8.2.3.2.2 Auto focus

Choosing this function executes a momentary auto-focus adjustment. Due to the risk

of mechanical wear, continuous auto-focus is not provided.

8.2.3.2.3 Change FoV

This is the same function as when IR is selected.

8.2.3.2.4 Freeze/Live

This is the same function as when IR is selected.

SEE: For information, see section 8.2.3.1.4 – Freeze/Live on page 17.

8.2.3.2.5 Backlight on/Backlight off

This function offers a backlight compensation. If an object appears in front of a very

light background – or if the object is very dark – selecting this function increases the

image quality. There are two choices – Backlight on and Backlight off.

8.2.3.2.6 Power off/Power on

This function switches the TV camera off, which will turn the image black. When the

TV is switched off, all menu items except Power On in the Image menu are gray and

can not be selected.

8.2.3.2.7 Slave mode on/Slave mode off

When Slave mode on is selected, and the operator switches to IR mode, 5° field of

view will be used for IR mode if the current TV field of view is less than 15°. If not, 20°

field of view for IR mode will be used.

The camera will also carry out an autofocus sequence.

8.2.4 Setup menu

10343103;a1

Figure 8.3 Setup menu

The Setup menu is used to define system constants and symbology. The up/down

arrow buttons are used to move between the different dialog box selections, and the

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 19

Page 26

8.2 – On-screen menus

ENTER button is used to open a dialog box. Within the dialog boxes, the up/down

arrow buttons are used to move between the features while the left/right arrowbuttons

are used to adjust system settings or values.

Pressing the ENTER button will accept any changes made and then exit the MENU

mode, or press C to exit without making any changes to the current settings

8.2.4.1 Image

8.2.4.1.1 When IR is selected

The Setup – Image dialog box is used to define the appearance of the system display

and symbology.

10057003;a3

Figure 8.4 Setup – Image dialog box

ExplanationLabel

Color scale

The Color scale feature allows the operator to select the palette that the display is shown in.

Options include:

■ Gray

■ Gray inv (inverted)

■ Rainbow

■ Rainbow inv (inverted)

■ Iron

■ Iron inv (inverted)

Level/Span

The Level/span feature determines howthesystem

will process the thermalinformation in the generation of the displayed image.

Options include:

■ Manual

■ Auto (linear)

■ Auto (full) = histogram equalization

■ DDE L = Low filtering. Improves details inhigh

contrast images

■ DDE H = High filtering. Improves details in low

contrast images

20 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 27

8.2 – On-screen menus

ExplanationLabel

Nuc button

8.2.4.1.2 When TV is selected

10059003;a1

Figure 8.5 Setup – Image dialog box

Back light comp

Image effect

■ NUC / AF = When pressing the NUC button for

less than 1 second, the camera performs an

image calibration. When pressing and holding

the NUC button for more than 1 second, the

camera performsan auto-focus sequence.This

is the default detting.

■ AF / NUC = When pressing the NUC button for

less than 1 second, the camera performs an

auto-focus sequence. When pressing and

holding theNUC button formore than 1second,

the camera performs an image calibration.

ExplanationLabel

SEE: See section 8.2.3.2.5– Backlight on/Backlight

off on page 19.

The Image effect feature allows the operator to

select between:

■ Off

■ B/W

Selecting Off puts the TV imager in color mode,

while selecting B/W puts it in black & white mode.

Near IR sensitive

This functionoffers increased sensitivity to IRradiation by removing abuilt-in cut-off IRradiation filter.

The feature is especially valuable under twilight

conditions.

NOTE: The normal position of the cut-off filter is

in the raypath of the TV imager.

8.2.4.2 Symbology

From the Setup – Symbology dialog box the operator defines how the overlaid symbology is displayed.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 21

Page 28

8.2 – On-screen menus

8.2.4.2.1 When IR is selected

10700003;a1

Figure 8.6 Setup – Symbology dialog box

ExplanationLabel

Data field

Data background

Status background

Focus indicator

Crosshair retic

The Data field option affects the two lines of information presented at the bottom of the display.

Three choices are available:

■ Normal (both lines are shown)

■ Reduced (only the bottom line is shown, i.e.

date, time, and digital azimuth/elevation)

■ None (both lines are disabled)

The Data background feature can be used to put

a solid background behind thelines ofsymbology,

making them more visible.

The Status background feature can be used to

put a solid background behind the status symbology (Frozen, Autoscan, Near focus etc.), making

it more visible.

Focus indicators affects the presentation of the

analog focus indicator.

Three options are available:

■ On (the indicators are always shown)

■ Off (the indicators are disabled)

■ When changed (the indicator is only shown

during a change of focus).

The Crosshair retic selection controls the presentation of the crosshair indicator.

Two options are available:

■ On (the indicator is always shown)

■ Off (the indicator is disabled)

22 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 29

8.2 – On-screen menus

ExplanationLabel

NFOV brackets

The NFOVbrackets selection controls the presentation of the NFOV reticule that is displayed when

the system is in the WFOV (and is used to provide

an indication of the area viewed when the NFOV

is selected).

Two options are available:

■ On (the indicator is always shown)

■ Off (the indicator is disabled)

8.2.4.2.2 When TV is selected

This is the same dialog box as when IR is selected.

8.2.4.3 Local adapt

10055903;a1

Figure 8.7 Setup – Local adaption dialog box

The Setup – Local adaption dialog box is used to adjust the format that system date,

time, and the language that the symbology is displayed in. Use the up/down arrow

buttons to move the highlight bar between the menu selections, and the left/right arrow

buttons to adjust values/settings. Pressing the ENTER button will accept any changes

made and then exit the MENU mode, or press C to exit without making any changes

to the current settings.

ExplanationLabel

English + optional languagesLanguage

Date format

Time format

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 23

■ MM/DD/YY

■ DD/MM/YY

■ YY-MM-DD

■ HH:MM:SS (24 hour format)

■ HH.MM.SS (24 hour format)

■ HH:MM:SS PM (12 hour format)

Page 30

8.2 – On-screen menus

8.2.4.4 Date & Time

10056003;a1

Figure 8.8 Setup – Date & Time dialog box

The system time and date is set from within the Setup – Date & Time dialog box. The

format that the information is presented in depends onthe settings made in the Local

Adaptions dialog box. For example, if the 12 hour (a.m./p.m.) format has been selected, the time setting can be adjusted from 12 p.m. through12 a.m. If the 24 hour format

is active 1 through 24 can be set. Use the up/down arrow buttons to move the highlighted bar through the selections, and the left/right arrow buttons to adjust values/settings. Pressing the ENTER button will accept any changes made and then exit the

MENU mode, or press C to exit without making any changes to the current settings.

ExplanationLabel

1981--2038Year

1 through 12Month

1 through 31Day

Hour

■ 12 a.m. through 12 p.m.

■ 1 through 24 (format dependent)

00 through 59Minute

24 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 31

8.2 – On-screen menus

8.2.4.5 Maintenance

10058803;a2

Figure 8.9 Setup – Maintenance dialog box

The Setup – Maintenance dialog boxis used to define system constants such as the

system password (if used), and the protocol.

ExplanationLabel

Yes or NoRun diag tool

Baudrate

■ 1200 bps

■ 2400 bps

■ 4800 bps

■ 9600 bps

■ 19200 bps

If the Baudrate is changed, it will be necessary to

restart the system before the change will take effect.

NOTE: For best performance, 9600 bps or 19200

bps should be selected.

NOTE: When using the Remote Control (RC),

19200 bps is required.

1 through 31Device ID

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 25

Page 32

8.2 – On-screen menus

ExplanationLabel

Protocol

Change password

■ 5X0

■ TASS

■ PELCO D (NOTE: By default,a ThermoVision™

Sentinel system is shipped without PELCO D

protocol. The customer must specifically request PELCO D protocol.)

Protocol is selectable to 5X0, TASS or PELCO D.

The 5X0protocol is alsoused in theThermaCAM™

500 seriescamerasand is an ASCIIprotocolusing

‘xon/xoff handshaking’.If the protocolis changed,

it will be necessaryto restartthe system beforethe

change will take effect.

Optional protocols are available upon request.

NOTE: The 5X0 protocol is a point-to-point

protocol. No Device ID can be selected.

NOTE: When using the Remote Control (RC), 5X0

protocol is required.

Yes or No

When the maintenance menu is entered, a pass-

word dialog box will appear (ifthe passwordis the

default system value 0000, the password dialog

box will not be displayed).

To change a value,use the up/downarrowbuttons.

To select another digit, use the left/right arrow

buttons. Whenthe right passwordis present, press

the ENTER button. If the wrong password is entered a warning will appear. When the correct

password is entered the maintenance menu will

appear.

To change the password, set the Change pass-

word selection to Yes, and press the ENTER button. A dialog boxwill appear allowingthe operator

to enter the new password.

26 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 33

8.2 – On-screen menus

ExplanationLabel

IR/TV video swap

Default settings

8.2.4.6 System info

10056203;a1

Yes or No

If Yes is selected the active video signal is

swapped between the two video outputs on the

pan/tilt head when the operator toggles between

IR and TV.

If two monitors are used (one for IR and one for

TV) this means that the images move between the

monitors, instead of only moving the indicator for

active channel between the monitors.

SEE: See section 7.2.2.7– Active channelindicator

on page 13.

Yes or No

NOTE: Selecting Yes resets all parameters to

factory settings.

Figure 8.10 System information dialog box

The System information dialog box contains information about the system, such as:

ExplanationLabel

NTSC or PALVideo mode

Hours and minutesRuntime

Configuration numberSystem check ID

Hardware and firmware information is also available.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 27

Page 34

9 Adverse weather conditions

9.1 Built-in heaters

ThermoVision™ Sentinel is designed and manufactured to meet strict specifications

and can be used under the most demanding weather conditions that may occur in

field situations. Apart from the protection by design – such as sealings and encapsulation — a number of built-in heaters automatically turn on at start-up in cold temperatures to protect the electronics and to defrost the lens. The heating of the camera

may take up to 30 minutes and is indicated by the HEATER ON indicator lamp on the

Power Box (see Figure 3.5 on page 6).

NOTE: The system does not start until it is heated to the factory preset temperature level.

9.2 Precautions under cold weather conditions

Despite the steps that have been taken to secure the operation of the imager under

cold weather conditions – such as heavy snowfall or freezing rain – situations may

arise where the imager unit is exposed to ice and snow build-up. In such situations

it is strongly advised that the operator checks the imager unit on a regular basis.

■ Clear the imager housing from ice and snow. Make sure the ventilation slots on

the rear side of the housing are not obstructed.

■ Clear the area in front of the lens from ice and snow. If the lens needs cleaning,

follow the instructions in the section 10 – Maintenance & cleaning on page 29

■ Check all connectors and make sure the locking rings are secured. Clear the con-

nectors from ice and snow.

■ Check all cables and clear the cables from ice and snow.

28 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 35

10 Maintenance & cleaning

10.1 Camera body, cables & accessories

The camerabody,cables and accessories may be cleaned by wiping with a soft cloth.

To remove stains, wipe with a soft cloth moistened with a mild detergent solution and

wrung dry, then wipe with a dry soft cloth.

NOTE: Do not use benzene, thinner, or any other chemical product on the camera, the cables or the

accessories, as this may cause deterioration.

10.2 Lenses

In order to make the system withstand severe field conditions, all lenses are coated

with a hard carbon thin film coating.

To clean the lenses, any consumer-grade glass cleaner can be used.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 29

Page 36

11 Technical support

For technical support, service inquiries, or comments & questions about the documentation, please contact FLIR Systems Imaging using one of the following two email addresses:

■ imagingboston.support@flir.com (US / North American customers only)

■ imagingsweden.support@flir.se

For telephone numbers to FLIR Systems Imaging offices, see the back cover of this

manual.

30 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 37

12 Technical specifications

12.1 System specifications

254 × 220 × 320 mm (10 × 8.7 × 12.6")Dimensions (H x W x D)

6.7 kg / 14.76 lb.Weight

18–32 VDCPower

Peak current

Power consumption

Vibration

During Operation

Bump

During Operation

See also Doc. No. PM501707

■ 2 A, <0.5 sec, without heaters

■ 5.5 A, with heaters

■ 12 W typical, without heaters

■ 150 W, at 28 VDC, with heaters

RS-232 (all functions)Remote control

< 45 sec.Start-up time

IP 65Environmental protection

-32 °C to +55 °C (-26 °F to +131 °F)Operating temperature

-40 °C to +70 °C (-40 °F to + 158 °F)Storage temperature

Standard IEC 68-2-6 Test F

■ 5–500 Hz

■ ± 0.5 mm / 2 g

■ 1 octave / minute

■ 1 double sweep along each of three mutually

perpendicular axes.

Standard IEC 68-2-29

■ 25 g, 4–6 ms

■ 1000 bumps in one of two attitudes in each of

three mutually perpendicular axes, making a

total of three attitudes and 3000 bumps.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 31

Page 38

12.2 – Thermal imager specifications

12.2 Thermal imager specifications

Detector type

Spectral range

See also Doc. No. PM501708

Focal Plane Array (FPA), uncooled microbolometer,

320 × 240 pixels.

20° × 15°Field of view, WFOV

5° × 3.75°Field of view, NFOV

7.5–13 μm, built-in atmospheric filter with cut-on

@ 7.5 μm.

1× to 4×Electronic zoom

< 0.8 secondsField of view switch time

14-bitDigital image resolution

Auto or manualGain/span (level) adjustment

Linear, histogram equalization, DDEImage processing

Black/white, rainbow, iron (+ inverted)Palettes

32 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 39

12.3 Video camera specifications

1/4" color CCDImage sensor

768 (H) × 494 (V)Picture elements, NTSC

752 (H) × 582 (V)Picture elements, PAL

48° to 2.7°, continuousField of view, FOV

12 times, continuousElectronic zoom

0.7 lx (f/1.4)Minimum sensitivity

> 470 TVLHorizontal resolution, NTSC

> 460 TVLHorizontal resolution, PAL

18x, continuousOptical zoom

< 0.5 m (1.6 ft.)Close focus; wide (48°)

< 0.8 m (2.6 ft.)Close focus, narrow (2.7°)

Serial RS-232 (all functions)Remote control

RS-170 EIA, NTSC or PALVideo format

IP65Environmental protection

12.3 – Video camera specifications

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 33

Page 40

12.4 – List of relevant documents

12.4 List of relevant documents

NameDoc. No.

Outer Dimensions,ThermoVision™ Integrator 5/20MD_614004452

PM501708

PE_614004898

PP_614004898

Technical specification ThermoVision™ Integrator

5/20

Technical specification ThermoVision™ SentinelPM501705

Factory Acceptance Procedure ThermoVision™

Sentinel

Factory Acceptance Record ThermoVision™ Sentinel

Outer dimensions ThermoVision™ Sentinel1 121 716

34 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 41

12.5 – Diagnostic tools

12.5 Diagnostic tools

NOTE: Subject to change without further notice.

12.5.1 General

The processing unit in the ThermoVision™ Sentinel comprises a built-in system of

tests that the operator can initiate. The dialog boxes below show the tests that can

be performed and an example of a result.

10712403;a1

Figure 12.1 Setup – Diag tools: Press the navigation pad left/right for each test to include or exclude it

from the diagnostic test.

10712303;a1

Figure 12.2 Setup – Diag tools: Example of a result

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 35

Page 42

12.6 – Troubleshooting guide

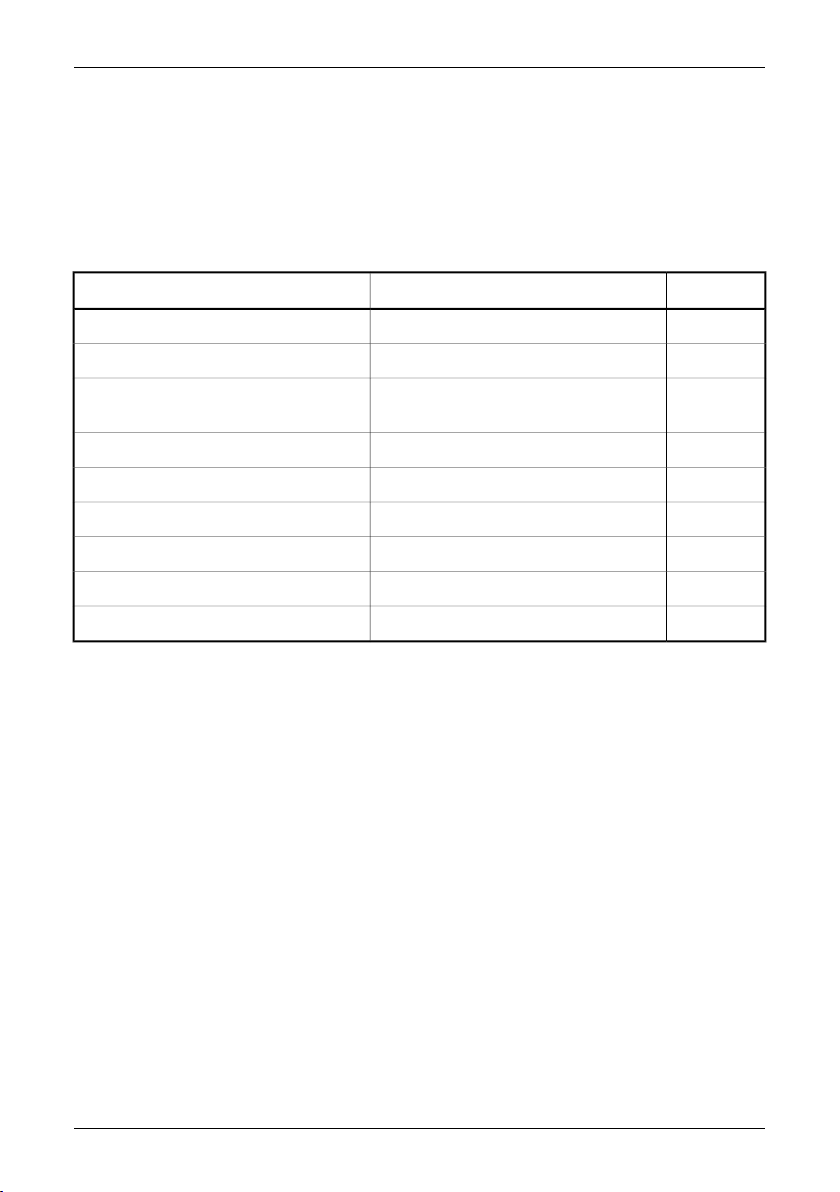

12.6 Troubleshooting guide

The following table is a guide for actions taken to correct simple operational faults

that may occur during normal use of the ThermoVision™ Sentinel.

ActionSymptom

No image appears on the screen at power on, or

the picture is distorted or continually scrolling.

The imager starts normallyand the screen display

appears but no IR image.

The systemstarts up properlyand gives anacceptable image but the imager does not react on

commands from the remote control unit

No video graphics overlay appear on the screen.

Check the video cable connecting the imager to

the video monitor.

The image could be totally out of focus. Adjust focus.

■ Check the cable connecting the imager to the

remote control unit

■ Check that the baud rate is set to 19200 bps

■ Check that the protocol is set to 5X0

Declutter is chosen. Press the Enter button and

check in the Symbology dialog box.

Change the Autoadjust setting.The image is totally black or white.

Press the NUC button.The image is of bad quality.

36 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 43

12.7 – Overview & location of connectors

12.7 Overview & location of connectors

12.7.1 Connectors on Power Box (PB)

10370703;a1

Figure 12.3 Connectors on Power Box (PB)

Figure 12.4 Connectors on Power Box (PB) – explanations

LocationFunctionTypeName

Power Box (PB)Main system connector23-pin MIL C 38999J4

9-pin D-SUBJ5

computer or remote

control

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 37

Power Box (PB)Connector for host

Power Box (PB)Video out (1)Standard BNCJ6

Power Box (PB)Video out (2)Standard BNCJ7

Page 44

12.7 – Overview & location of connectors

12.7.2 Connectors on imager unit

10371003;a1

Figure 12.5 Location of connectors (enclosureremoved): J1 mainsystem connector andJ3 internal service

connector

Figure 12.6 Connectors on imager unit – explanations

LocationFunctionTypeName

23-pin MIL C 38999J1

9-pin D-SUBJ3

Main systemcable connector

Internal serviceconnector forhost computer or

remote control

Back panel on imager

unit

Inside protectiveimager

housing.

38 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 45

12.8 Pin configuration

12.8.1 Connectors on Power Box (PB)

12.8.1.1 J4 – 23-pin connector

NOTE: Pin designations are printed on connector.

RESERVEDR

RESERVEDP

RESERVEDE

12.8 – Pin configuration

Wire typeSignal namePin

AWG 20GNDW

AWG 20+28 VZ

AWG 26HEATER ONV

AWG 26 twisted pairRS485CONSTX_BJ

AWG 26 twisted pairRS485CONSTX_AH

AWG 26 twisted pairRS485CONSRX_BG

AWG 26 twisted pairRS485CONSRX_AF

RESERVEDU

AWG 26SIGNAL GROUNDT

Coax 75 ΩVIDEO POSITIVES

Coax 75 ΩTV VIDEO POSITIVE/GROUNDX

Coax 75 ΩTV VIDEO POSITIVED

Coax 75 ΩVIDEO GROUNDC

VIDEO GROUNDY

RESERVEDA

RESERVEDB

RESERVEDK

RESERVEDL

RESERVEDM

RESERVEDN

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 39

Page 46

12.8 – Pin configuration

12.8.1.2 J5 – Connector for host computer & remote control

10342503;a1

Figure 12.7 J5 pin configuration.

NOTE: Pin designations are printed on connector.

Wire typeSignal namePin

1

AWG26RS-232 Host in (from camera)2

AWG26RS-232 Host out (to camera)3

4

AWG24RS-232 Ground5

AWG24+12 VDC6

7

AWG26HEATER_ON8

9

NOTE: HEATER_ON is positive when the heaters are activated and negative when they are not activated.

12.8.1.3 J6 – BNC connector

Standard configuration.

12.8.1.4 J7 – BNC connector

Standard configuration.

12.8.2 Connectors on imager unit

12.8.2.1 J1 – 23-pin connector

NOTE: Pin designations are printed on connector.

■ Cable connector: MIL C 38999: D38999/26WE99SN

■ Shell size: 17

■ Configuration: 99

40 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 47

12.8 – Pin configuration

Wire typeSignal namePin

AWG 20GNDW

AWG 20+28 VZ

AWG 26HEATER ONV

AWG 26 twisted pairRS485CONSTX_BJ

AWG 26 twisted pairRS485CONSTX_AH

AWG 26 twisted pairRS485CONSRX_BG

AWG 26 twisted pairRS485CONSRX_AF

RS485TX_EN_BR

RS485TX_EN_AP

TERMINATOR DISABLEE

REMOTE PRESENTU

AWG 26SIGNAL GROUNDT

Coax 75 ΩVIDEO POSITIVES

Coax 75 ΩTV VIDEO POSITIVE/GROUNDX

Coax 75 ΩTV VIDEO POSITIVED

Coax 75 ΩGROUNDC

VIDEO GROUNDY

RS232 TxD (from imager)A

RS232 RxD (to imager)B

RESERVEDK

RESERVEDL

RESERVEDM

RESERVEDN

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 41

Page 48

12.8 – Pin configuration

12.8.2.2 J3 – Internal service connector

10342503;a1

Figure 12.8 J3 pin configuration.

NOTE: The outer housing must be removed to access the J3 internal service connector.

NOTE: This connector is normallynot used bytheoperator, butreserved for uploadingsoftware upgrades,

patches, bug fixes etc.

NOTE: Pin designations are printed on connector.

Wire typeSignal namePin

1

AWG26RS-232 Test in (from camera)2

AWG26RS-232 Test out (to camera)3

4

AWG24RS-232 Test ground5

+12 VDC6

7

8

9

NOTE: The +12 VDC wire has a thermal current limiter (PTC resistor). If the limiter triggers, it needs to

cool down before normal operation can be resumed.

NOTE: The communictation parameters are 19200 Bd, 5X0, 8, 1, N, XON/XOFF.

42 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 49

12.9 – Basic dimensions – Imager; view from above

12.9 Basic dimensions – Imager; view from above

10343703;a1

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 43

Page 50

12.10 – Basic dimensions – Imager; rear view

12.10 Basic dimensions – Imager; rear view

10371103;a1

44 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 51

12.11 – Basic dimensions – Imager; front view

12.11 Basic dimensions – Imager; front view

10343803;a1

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 45

Page 52

12.12 – Basic dimensions – Imager; side view

12.12 Basic dimensions – Imager; side view

10343903;a1

46 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 53

12.13 – Basic dimensions – Imager; view from below

12.13 Basic dimensions – Imager; view from below

10371203;a1

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 47

Page 54

12.14 – Basic dimensions – Remote Control (RC)

12.14 Basic dimensions – Remote Control (RC)

10051103;a1

48 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 55

12.15 – Basic dimensions – Power Box (PB)

12.15 Basic dimensions – Power Box (PB)

10370803;a1

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 49

Page 56

12.16 – Basic dimensions – Power Box (PB)

12.16 Basic dimensions – Power Box (PB)

10370903;a1

50 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 57

13 History of infrared technology

Less than 200 years ago the existence of the infrared portion of the electromagnetic

spectrum wasn't even suspected. The original significance of the infrared spectrum,

or simply ‘the infrared’ as it is often called, as a form of heat radiation is perhaps less

obvious today than it was at the time of its discovery by Herschel in 1800.

10398703;a1

Figure 13.1 Sir William Herschel (1738–1822)

The discovery was made accidentally during the search for a new optical material.

Sir William Herschel – Royal Astronomer to King George III of England, and already

famous for his discovery of the planet Uranus – was searching for an optical filter

material to reduce the brightness of the sun’s image in telescopes during solar observations. While testing different samples of colored glass which gave similar reductions

in brightness he was intrigued to find that some of the samples passed very little of

the sun’s heat, while others passed so much heat that he risked eye damage after

only a few seconds’ observation.

Herschel was soon convinced of the necessity of setting up a systematic experiment,

with the objective of finding a single material that would give the desired reduction in

brightness as well as the maximum reduction in heat. He began the experiment by

actually repeatingNewton’s prism experiment, but looking for the heating effect rather

than the visual distribution of intensity in the spectrum. He first blackened the bulb of

a sensitive mercury-in-glass thermometer with ink, and with this as his radiation detector he proceeded to test the heating effect of the various colors of the spectrum

formed on the top of a table by passing sunlight through a glass prism. Other thermometers, placed outside the sun’s rays, served as controls.

As the blackened thermometer was moved slowly along the colors of the spectrum,

the temperature readings showed a steady increase from the violet end to the red

end. This was not entirely unexpected, since the Italian researcher, Landriani, in a

similar experiment in 1777 had observed much the same effect. It was Herschel,

however, who was the first to recognize that there must be a point where the heating

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 51

Page 58

effect reaches a maximum, and that measurements confined to the visible portion of

the spectrum failed to locate this point.

10398903;a1

Figure 13.2 Marsilio Landriani (1746–1815)

Moving the thermometer into the dark region beyond the red end of the spectrum,

Herschel confirmedthat the heating continued to increase. The maximum point, when

he found it, lay well beyond the red end – in what is known today as the ‘infrared

wavelengths’.

When Herschel revealed his discovery, he referred to this new portion of the electromagnetic spectrumas the‘thermometrical spectrum’.The radiationitself hesometimes

referred to as ‘dark heat’, or simply ‘the invisible rays’. Ironically, and contrary to

popular opinion, it wasn't Herschel who originated the term ‘infrared’. The word only

began to appear in print around 75 years later, and it is still unclear who should receive

credit as the originator.

Herschel’s use of glass in the prism of his original experiment led to some early

controversies with his contemporaries about the actual existence of the infrared

wavelengths. Different investigators, in attempting to confirm his work, used various

types of glass indiscriminately, havingdifferent transparenciesin the infrared. Through

his later experiments, Herschel was aware of the limited transparency of glass to the

newly-discovered thermal radiation, and he was forced to conclude that optics for

the infrared would probably be doomed to the use of reflective elements exclusively

(i.e. plane and curved mirrors). Fortunately, this proved to be true only until 1830,

when the Italian investigator, Melloni, made his great discoverythat naturally occurring

rock salt (NaCl) – which was available in large enough natural crystals to be made

into lenses and prisms – is remarkably transparent to the infrared. The result was that

rock salt became the principal infrared optical material, and remained so for the next

hundred years, until the art of synthetic crystal growing was mastered in the 1930’s.

52 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 59

10399103;a1

Figure 13.3 Macedonio Melloni (1798–1854)

Thermometers, as radiation detectors, remained unchallenged until 1829, the year

Nobili invented the thermocouple. (Herschel’s own thermometer could be read to

0.2 °C (0.036 °F), and later models were able to be read to 0.05 °C (0.09 °F)). Then

a breakthrough occurred; Melloni connected a number of thermocouples in series

to form the first thermopile. The new device was at least 40 times as sensitive as the

best thermometer of the day for detecting heat radiation – capable of detecting the

heat from a person standing three meters away.

The first so-called ‘heat-picture’ became possible in 1840, the result of work by Sir

John Herschel, son of the discoverer of the infrared and a famous astronomer in his

own right. Based upon the differential evaporation of a thin film of oil when exposed

to a heat pattern focused upon it, the thermal image could be seen by reflected light

where the interference effects of the oil film made the image visible to the eye. Sir

John also managed to obtain a primitive record of the thermal image on paper, which

he called a ‘thermograph’.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 53

Page 60

10399003;a2

Figure 13.4 Samuel P. Langley (1834–1906)

The improvement of infrared-detector sensitivity progressed slowly. Another major

breakthrough, made by Langley in 1880, was the invention of the bolometer. This

consisted ofa thinblackened strip of platinumconnected in one arm of a Wheatstone

bridge circuit upon which the infrared radiation was focused and to which a sensitive

galvanometer responded. This instrument is said to have been able to detect the heat

from a cow at a distance of 400 meters.

An English scientist, Sir James Dewar, first introduced the use of liquefied gases as

cooling agents (such as liquid nitrogen with a temperature of -196 °C (-320.8 °F)) in

low temperature research. In 1892 he invented a unique vacuum insulating container

in which it is possible to store liquefied gases for entire days. The common ‘thermos

bottle’, used for storing hot and cold drinks, is based upon his invention.

Between the years 1900 and 1920, the inventors of the world‘discovered’ the infrared.

Many patents were issued for devices to detect personnel, artillery, aircraft, ships –

and even icebergs. The first operating systems, in the modern sense, began to be

developed duringthe 1914–18war, when both sides had research programs devoted

to the military exploitation of the infrared. These programs included experimental

systems for enemy intrusion/detection, remote temperature sensing, secure communications, and ‘flying torpedo’ guidance. An infrared search system tested during this

period was able to detect an approaching airplane at a distanceof 1.5 km (0.94 miles),

or a person more than 300 meters (984 ft.) away.

The most sensitive systems up to this time were all based upon variations of the

bolometer idea, but the period between the two wars saw the development of two

revolutionary new infrared detectors: the image converter and the photon detector.

At first, the image converter received the greatest attention by the military, because

it enabled an observer for the first time in history to literally ‘see in the dark’. However,

the sensitivity of the image converter was limited to the near infrared wavelengths,

and the most interesting military targets (i.e. enemy soldiers) had to be illuminated

54 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 61

by infrared search beams. Since this involved the risk of giving away the observer’s

position to a similarly-equipped enemy observer, it is understandable that military

interest in the image converter eventually faded.

The tactical military disadvantages of so-called 'active’ (i.e. search beam-equipped)

thermal imaging systems provided impetus following the 1939–45 war for extensive

secret military infrared-research programs into the possibilities of developing ‘passive’

(no search beam) systems around the extremely sensitive photon detector. During

this period, military secrecy regulations completely prevented disclosure of the status

of infrared-imaging technology. This secrecy only began to be lifted in the middle of

the 1950’s, and from that time adequate thermal-imaging devices finally began to be

available to civilian science and industry.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 55

Page 62

14 Theory of thermal imaging

14.1 Introduction

The subjects of infrared radiation is still new to many who will use an infrared camera.

In this section the theory behind thermal imaging will be given.

14.2 The electromagnetic spectrum

The electromagnetic spectrum is divided arbitrarily into a number of wavelength regions, called bands, distinguished by the methods used to produce and detect the

radiation. Thereis no fundamental difference between radiation in the different bands

of the electromagnetic spectrum. They are all governed by the same laws and the

only differences are those due to differences in wavelength.

10067803;a1

Figure 14.1 The electromagnetic spectrum. 1: X-ray; 2: UV; 3: Visible; 4: IR; 5: Microwaves; 6: Radiowaves.

Thermal imaging makes use of the infrared spectral band. At the short-wavelength

end the boundary lies at the limit of visual perception, in the deep red. At the longwavelength end it merges with the microwave radio wavelengths, in the millimeter

range.

The infrared band is often further subdivided into four smaller bands, the boundaries

of which are also arbitrarily chosen. They include: the near infrared (0.75–3 μm), the

56 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 63

14.3 – Blackbody radiation

middle infrared (3–6 μm), the far infrared (6–15 μm) and the extreme infrared (15–100

μm). Although the wavelengths are given in μm (micrometers), other units are often

still used to measure wavelength in this spectral region, e.g. nanometer (nm) and

Ångström (Å).

The relationships between the different wavelength measurements is:

14.3 Blackbody radiation

A blackbody is defined as an object which absorbs all radiation that impinges on it

at any wavelength. The apparentmisnomer black relating to an object emitting radiation isexplained by Kirchhoff’s Law (after Gustav Robert Kirchhoff, 1824–1887), which

states that a body capable of absorbing all radiation at any wavelength is equally

capable in the emission of radiation.

10398803;a1

Figure 14.2 Gustav Robert Kirchhoff (1824–1887)

The construction of a blackbody source is, in principle, very simple. The radiation

characteristics of an aperture in an isotherm cavity made of an opaque absorbing

material representsalmost exactlythe properties of a blackbody. A practical application

of the principle to the construction of a perfect absorber of radiation consists of a box

that is light tight except for an aperture in one of the sides. Any radiation which then

enters the hole is scattered and absorbed by repeatedreflections so only an infinitesimal fraction can possibly escape. The blackness which is obtained at the aperture

is nearly equal to a blackbody and almost perfect for all wavelengths.

By providing such an isothermal cavity with a suitable heater it becomes what is

termed a cavity radiator. An isothermal cavity heated to a uniform temperature generates blackbody radiation, the characteristics of which are determined solely by the

temperature of the cavity.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 57

Page 64

14.3 – Blackbody radiation

If the temperature of blackbody radiation increases to more than 525 °C (977 °F), the

source begins to be visible so that it appears to the eye no longer black. This is the

incipient red heat temperature of the radiator, which then becomes orange or yellow

as the temperature increases further. In fact, the definition of the so-called color

temperature of an object is the temperature to which a blackbody would have to be

heated to have the same appearance.

Now consider three expressions that describe the radiation emitted from a blackbody.

14.3.1 Planck’s law

10399203;a1

Figure 14.3 Max Planck (1858–1947)

Max Planck (1858–1947) wasable todescribe the spectral distribution of the radiation

from a blackbody by means of the following formula:

where:

λb

NOTE: The factor 10-6is used since spectral emittance in the curves is expressed in Watt/m2m. If the

factor is excluded, the dimension will be Watt/m2μm.

Blackbody spectral radiant emittance at wavelength λ.W

Velocity of light = 3 × 108m/sc

Planck’s constant = 6.6 × 10

Boltzmann’s constant = 1.4 × 10

Absolute temperature (K) of a blackbody.T

Wavelength (μm).λ

-34

Joule sec.h

-23

Joule/K.k

58 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 65

14.3 – Blackbody radiation

Planck’s formula, when plotted graphically for various temperatures, produces a

family of curves. Following any particular Planck curve, the spectral emittance is zero

at λ = 0, then increases rapidly to amaximum at a wavelength λ

and after passing

max

it approaches zero again at very long wavelengths. The higher the temperature, the

shorter the wavelength at which maximum occurs.

10327103;a3

Figure 14.4 Blackbody spectral radiant emittance according to Planck’s law, plotted for various absolute

temperatures. 1: Spectral radiant emittance (W/cm2× 103(μm)); 2: Wavelength (μm)

14.3.2 Wien’s displacement law

By differentiating Planck’s formula with respect to λ, and finding the maximum, we

have:

This is Wien’s formula (after Wilhelm Wien, 1864–1928), which expresses mathematically the common observation that colors vary from red to orange or yellow as the

temperature of a thermal radiator increases. The wavelength of the color is the same

as the wavelength calculated for λ

. A good approximation of the value of λ

max

max

for

a given blackbody temperature is obtained by applying the rule-of-thumb 3 000/T

μm. Thus, a very hot star such as Sirius (11 000 K), emitting bluish-white light, radiates

with the peak of spectral radiant emittance occurring within the invisible ultraviolet

spectrum, at wavelength 0.27 μm.

Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005 59

Page 66

14.3 – Blackbody radiation

10399403;a1

Figure 14.5 Wilhelm Wien (1864–1928)

The sun (approx. 6 000 K) emits yellow light, peaking at about 0.5 μm in the middle

of the visible light spectrum.

At room temperature (300 K) the peak of radiant emittance lies at 9.7 μm, in the far

infrared, while at the temperature of liquid nitrogen (77 K) the maximum of the almost

insignificant amount of radiant emittance occurs at 38 μm, in the extreme infrared

wavelengths.

10327203;a3

Figure 14.6 Planckian curves plottedon semi-log scales from 100 K to1000 K. The dotted line represents

the locus of maximum radiant emittance at each temperature as described by Wien's displacement law.

1: Spectral radiant emittance (W/cm2(μm)); 2: Wavelength (μm).

60 Publ. No. 1 557 544 Rev. a121 – ENGLISH (EN) – October 6, 2005

Page 67

14.3 – Blackbody radiation

14.3.3 Stefan-Boltzmann's law

By integrating Planck’s formula from λ = 0 to λ = ∞, we obtain the total radiant

emittance (Wb) of a blackbody:

This is the Stefan-Boltzmann formula (after Josef Stefan, 1835–1893, and Ludwig

Boltzmann, 1844–1906), which states that the total emissive power of a blackbody is

proportional tothe fourth power of its absolute temperature. Graphically, Wbrepresents

the area below the Planck curve for a particular temperature. It can be shown that the

radiant emittancein the interval λ = 0 to λ

is only 25 % of the total, which represents

max