Flir 427-0097-13-00, 427-0097-23-00, 427-0097-33-00, 427-0097-43-00, 427-0097-63-00 User Manual

...Page 1

Installation

Manual

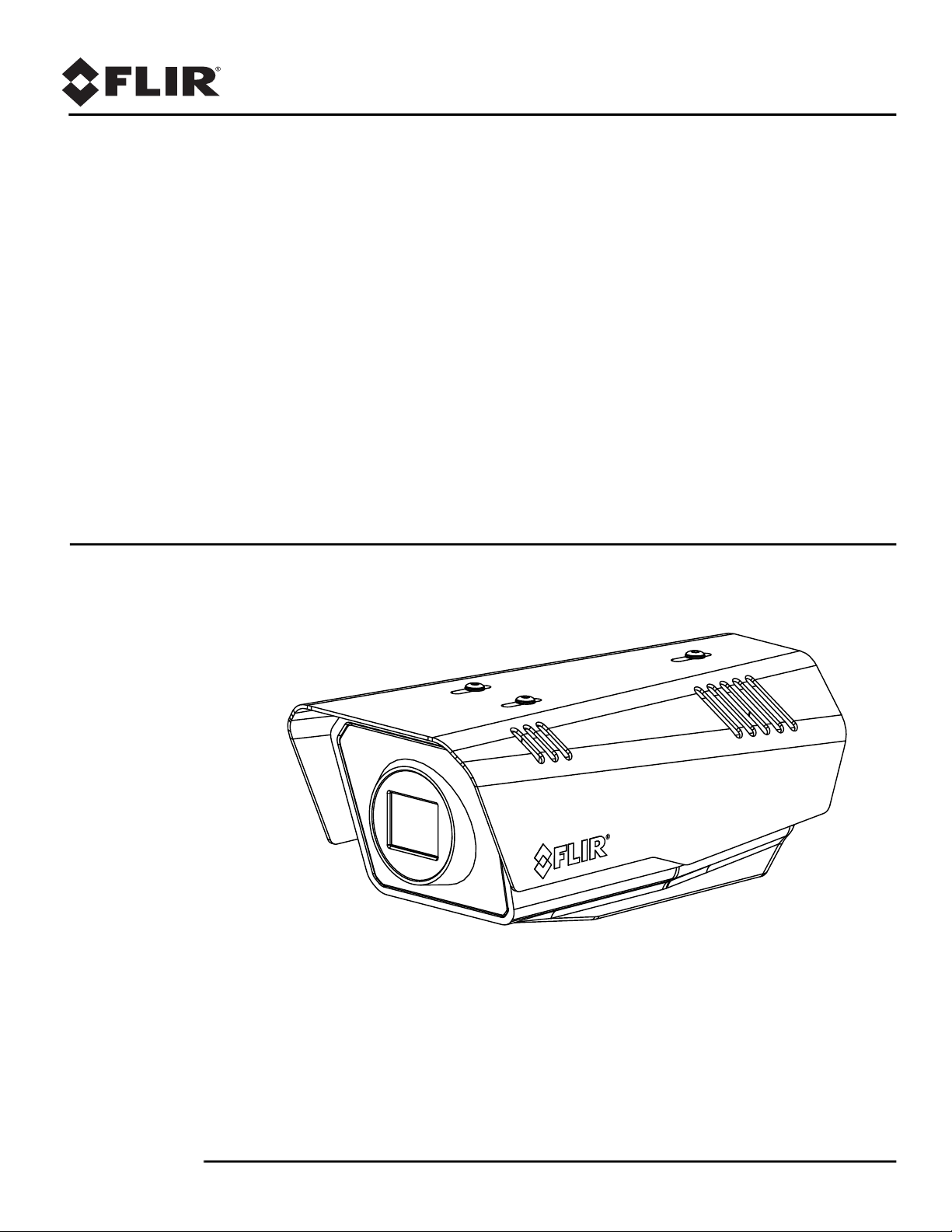

FC-Series

FC-Series O

FC-Series ID

427-0089-00-12 Version 160 March 2019

This document does not contain any export-controlled information.

Page 2

© 2019 FLIR Systems, Inc. All rights reserved worldwide. No parts of this manual, in whole or in part, may be

copied, photocopied, translated, or transmitted to any electronic medium or machine readable form without the

prior written permission of FLIR Systems, Inc.

Names and marks appearing on the products herein are either registered trademarks or trademarks of FLIR

Systems, Inc. and/or its subsidiaries. All other trademarks, trade names, or company names referenced herein are

used for identification only and are the property of their respective owners.

This product is protected by patents, design patents, patents pending, or design patents pending.

The contents of this document are subject to change without notice.

For additional information visit www.flir.com or write to FLIR Systems, Inc.

FLIR Systems, Inc.

6769 Hollister Avenue

Goleta, CA 93117

Support: https://www.flir.com/support-center/support-hq/

Important Instructions and Notices to the User:

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Modification of this device without the express authorization of FLIR Systems, Inc. may void the user’s authority

under FCC rules to operate this device.

Note 1: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at the user’s own expense.

Note 2:

If this equipment came with shielded cables, it was tested for compliance with the FCC limits for

a Class A digital device using shielded cables and therefore shielded cables must be used with the

device

Industry Canada Notice:

This Class A digital apparatus complies with Canadian ICES-003.

Avis d’Industrie Canada:

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Proper Disposal of Electrical and Electronic Equipment (EEE)

The European Union (EU) has enacted Waste Electrical and Electronic Equipment Directive 2002/

96/EC (WEEE), which aims to prevent EEE waste from arising; to encourage reuse, recycling, and

recovery of EEE waste; and to promote environmental responsibility.

In accordance with these regulations, all EEE products labeled with the “crossed out wheeled bin”

either on the product itself or in the product literature must not be disposed of in regular rubbish bins,

mixed with regular household or other commercial waste, or by other regular municipal waste

collection means. Instead, and in order to prevent possible harm to the environment or human

health, all EEE products (including any cables that came with the product) should be responsibly

discarded or recycled.

To identify a responsible disposal method nearby, please contact the local waste collection or recycling service, the

original place of purchase or product supplier, or the responsible government authority in the area. Business users

should contact their supplier or refer to their purchase contract.

Document History

Version Date Comment

100 July 2016 Initial Release

110 August 2016 User Interface Updates

120 January 2017 Setup Temperature/GPIO User Interface Update

130 March 2017 Added support for IEEE 802.1x authentication, Field Service log download, and IOI analytics interface

140 August 2017 Initial release of FC-Series O

150 March 2018 Updated password management, simplified IR graphical user interface

160 March 2019 V2.04.P06

427-0089-00-12 Version 160

This document does not contain any export-controlled information.

Page 3

Table of Contents

Table of Contents

Camera Installation

1.1 Warnings and Cautions ............................................................................................... 5

1.2 References .................................................................................................................. 5

1.3 Installation Overview ................................................................................................... 6

1.3.1 Camera Connection Options .............................................................................. 6

1.3.2 Camera Accessories .......................................................................................... 7

1.3.3 Supplied Components ........................................................................................ 8

1.3.4 Additional Supplies ............................................................................................. 8

1.3.5 Camera Placement ............................................................................................. 8

1.3.6 Camera Mounting for Rear Cable Access .......................................................... 9

1.3.7 Camera Mounting with Concealed Cable Wall Mount ...................................... 11

1.3.8 Sunshield .......................................................................................................... 12

1.3.9 Removing the Cover ......................................................................................... 12

1.4 Camera Connections ................................................................................................. 13

1.4.1 Installing the microSD Card .............................................................................. 13

1.4.2 Bench Testing .................................................................................................. 14

1.4.3 Analog Video Connections ............................................................................... 14

1.4.4 Connecting Power ............................................................................................ 14

1.4.5 GPIO Connections ........................................................................................... 15

1.4.6 Ethernet ............................................................................................................ 16

1.4.7 Camera Grounding ........................................................................................... 16

1.4.8 Rear Access Cable Gland Sealing ................................................................... 17

1.5 Concealed Cable Mount Accessory .......................................................................... 18

1.6 Camera specifications ............................................................................................... 20

Basic Operation and Configuration

2.1 IP Camera, ONVIF Profile S Compliant .................................................................... 22

2.2 Camera Bench Test .................................................................................................. 22

2.3 Set IP Address using the FLIR Discovery Network Assistant (DNA) ........................ 22

2.3.1 Log in to the Camera Web Page ...................................................................... 23

2.3.2 Live Video Page ............................................................................................... 24

2.4 Basic Camera Configuration ..................................................................................... 27

2.4.1 Setup Menu ...................................................................................................... 27

2.4.2 Server Menu ..................................................................................................... 28

2.5 Thermal Imaging Overview ....................................................................................... 37

2.6 Maintenance and Troubleshooting Tips .................................................................... 38

427-0089-00-12 Version 160 March 2019 3

This document does not contain any export-controlled information.

Page 4

Table of Contents

Advanced Configuration

3.1 Setup Menu ............................................................................................................... 42

3.1.1 Temperature Page ............................................................................................43

3.1.2 Video Setup ...................................................................................................... 44

3.1.3 Thermal Image Setup ....................................................................................... 47

3.1.4 Video Analytics Setup—FC-Series ID only ....................................................... 49

3.2 Maintenance Menu .................................................................................................... 54

3.2.1 Sensor Menu .................................................................................................... 55

3.2.2 Files Menu ........................................................................................................ 66

3.2.3 Product Info Menu ............................................................................................ 70

3.3 Restoring the Factory Settings .................................................................................. 70

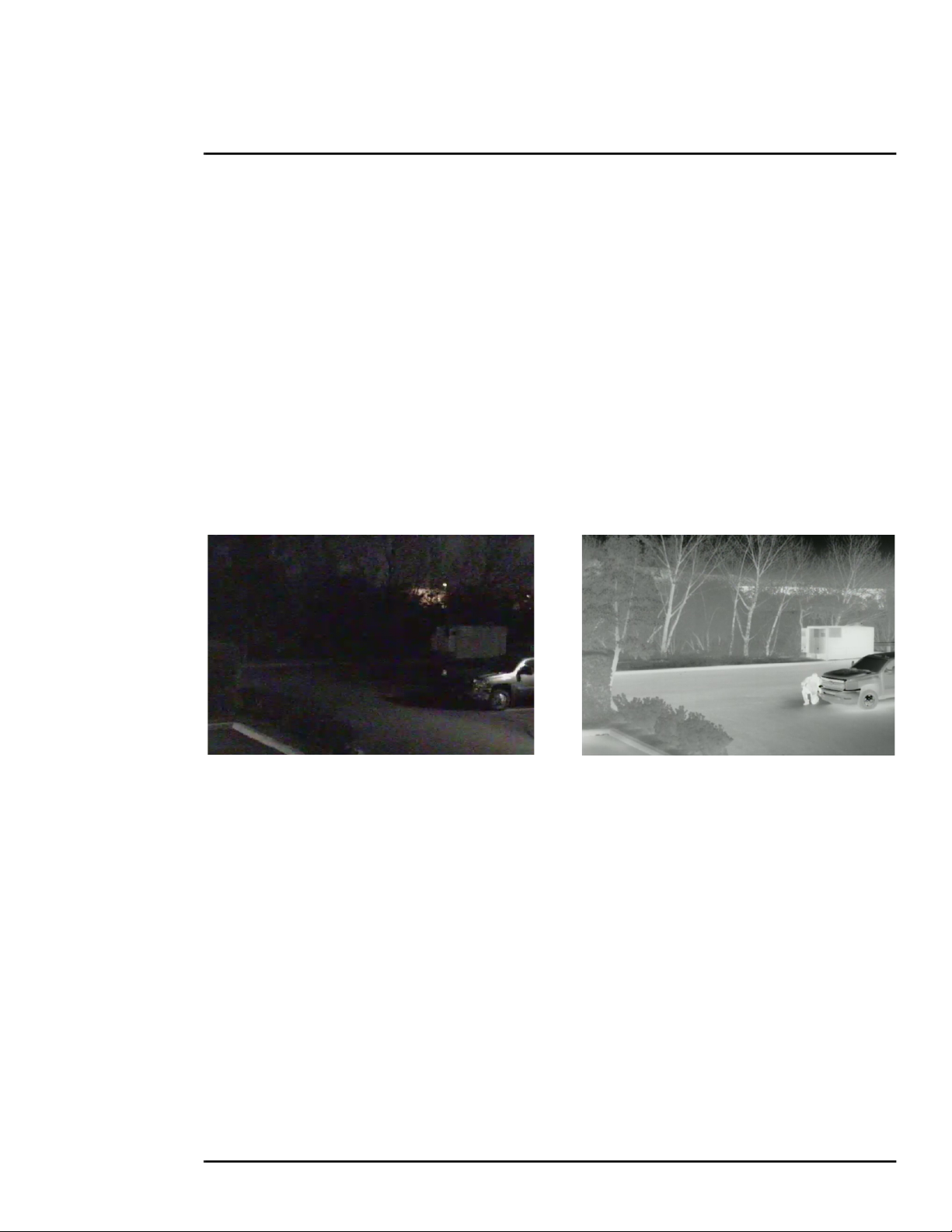

Image from a standard camera in low light

427-0089-00-12 Version 160 March 2019 4

This document does not contain any export-controlled information.

Image from a thermal camera in the same

conditions

Page 5

1

Camera Installation

This manual describes the installation and initial configuration of the FC-Series thermal camera. The

FC-Series ID and the FC-Series O are based on identical hardware. The FC-Series ID camera has

software installed providing for on-board video analytics: setting of detection regions, trip lines, and

classification of detected objects. Refer to Video Analytics Setup—FC-Series ID only, pg. 49.

If help is needed during the installation process, contact the local FLIR service representative or

contact support at: https://www.flir.com/support-center/support-hq/. All installers and integrators are

encouraged to take advantage of the training offered by FLIR; visit

https://www.flir.com/support-center/training/ for more information.

This manual includes the following topics:

• Installation overview

• Mounting the camera and its components

• Connecting the electronics

• Bench testing the camera

• Basic configuration and operation of the camera

• Camera Specifications

For safety, and to achieve the highest levels of performance from the FC-Series camera system,

always follow the warnings and cautions in this manual when handling and operating the camera.

1.1 Warnings and Cautions

Warning!

If mounting the FC-Series camera on a pole, tower or any elevated location, use industry standard

safe practices to avoid injuries.

Caution!

Except as described in this manual, do not open the FC-Series camera for any reason. Damage to

the camera can occur as the result of careless handling or electrostatic discharge (ESD). Always

handle the camera with care to avoid damage to electrostatic-sensitive components.

Prior to making any connections, ensure the power supply or circuit breaker is switched off.

Be careful not to leave fingerprints on the camera’s infrared optics.

Operating the camera outside of the specified input voltage range or the specified operating

temperature range can cause permanent damage.

1.2 References

FLIR Doc # 427-00XX-YY-41 FC-Series Interconnect Document provides further details regarding

mechanical dimensions and mounting for the FC-Series camera.

Documents are available from the FLIR website.

427-0089-00-12 Version 160 March 2019 5

This document does not contain any export-controlled information.

Page 6

Camera Installation

1.3 Installation Overview

The FC-Series camera is an infrared thermal imaging camera intended for outdoor security

applications, and can be installed in a fixed location or on a pan/tilt mechanism. The camera is

intended to be mounted on a medium-duty fixed pedestal mount or wall mount commonly used in the

security industry. The camera mount must support up to 5.4 lbs (2.5 kg).

Cables may exit from the back of the camera housing through the

supplied cable gland or from the bottom of the camera housing when

using the concealed cable wall mount (sold separately). A cable gland

plug is supplied for the rear of the camera housing when cables are

routed using the concealed cable wall mount.

1.3.1 Camera Connection Options

The camera can be installed with an analog or digital (IP) video output (or both). Analog video will

require a connection to a video monitor or an analog video matrix switch. The camera can be

powered using Power over Ethernet Plus (PoE+) or with a conventional 24 Vac or 24 Vdc power

supply. For a PoE+ connection, an accessory PoE+ power supply (PN 4132391, also called a PoE+

injector) is available if the camera is not connected to a PoE+ switch. The maximum Ethernet cable

run is 100 meters including the PoE+ power supply. In installations using PoE+ power and IP video,

only a single Ethernet cable from the camera is required.

In installations using analog video and conventional power (24 Vac is commonly used in many

installations), an RG59U coaxial cable and a three-conductor power cable are installed. It is

recommended an Ethernet cable should also be installed for camera configuration, operation and

troubleshooting. For example, if the camera is mounted on a pole, an Ethernet cable should run at

least to the bottom of the pole, so a laptop could be temporarily connected directly to the camera.

The FC-Series camera does not support serial communications.

Network Security

The camera supports IEEE 802.1x authentication when connected to a network supporting the

following requirements:

• Network device (Authenticator) such as an Ethernet switch configured with 802.1x

• Authentication server supporting TLS

Refer to IEEE 802.1X Security, pg. 29 for information on how to configure the LAN settings.

General Purpose Input/Output (GPIO)

The camera can receive a single input signal and can provide a single output signal. By default the

signals are configured for normally open alarm switch circuits. Refer to GPIO Connections, pg. 15.

Input Signal—When an external alarm device closes a switch to complete the circuit for the

camera, an input alarm is generated by the GPIO for the Alarm Manager.

Output Signal—When an output alarm is generated by the Alarm Manager for the GPIO, the

camera closes its internal switch to complete the circuit for the receiving device.

427-0089-00-12 Version 160 March 2019 6

This document does not contain any export-controlled information.

Page 7

Camera Installation

PoE+ Power Supplies

With PoE+, camera power is delivered to the camera over the Ethernet cable via the camera’s

standard RJ-45 Ethernet connector. The FC-Series camera is a Powered Device compliant with the

IEEE 802.3at-2009 standard, known as PoE+ or PoE Plus. The FC-Series camera is also backward

compatible with the older IEEE 802.3af-2003 standard.

When connected to Power Sourcing Equipment compliant with the earlier, lower power IEEE

802.3af-2003 standard, the limited power available to the FC-Series will typically prevent the

formation of frost and ice. However, the limited power available from 802.3af-2003 may not fully

achieve the camera’s stated specification of de-icing 6 mm of ice from cold start. In all other ways the

camera will operate normally with Ethernet Powered Sourcing Equipment compliant to either IEEE

PoE standard.

Supplemental Lens Heater

The supplemental lens heater is intended to provide lens de-fogging and de-icing in the event of:

• A power interruption which disables the camera for an extended period, and

• Freezing rain which fully covers the lens and obstructs the image.

The FC-Series cameras with lens windows (13 mm, 19 mm, 35 mm) are shipped from the factory

with the supplemental lens heater on. The lens heater is configured to dynamically maintain the

camera window at a constant temperature.

The lens heater may be turned on manually from the Live Video web page (De-Ice button). Refer to

Web Control Panel, pg. 25. The heater, when turned on manually, will run for approximately 2 hours

unless turned off either by the user (De-Ice button) or the thermostat control.

FC-Series cameras with a 60 mm or a 75 mm lens are shipped from the factory with the

supplemental lens heater off. These cameras require the de-ice kit accessory for installations that

require using the supplemental lens heater. After installing the de-ice kit, contact FLIR Technical

Support for configuration instructions for the specific installation.

Note

The 60 mm or 75 mm lenses are not thermally conductive. The de-ice kit provides a lens cover

that will conduct heat to keep the lens free of ice or frost.

1.3.2 Camera Accessories

The following accessories are available for purchase from FLIR Systems, Inc.

• PoE+ power supply (PN 4132391) - For powering a single FC-Series camera using PoE+. In

addition to PoE+ power and communications, the power supply provides surge protection. It

complies with IEEE 802.3at and is backward compatible with the IEEE802.3af standard.

• Concealed Cable Wall Mount (PN 4129742) - Includes camera mount

gasket and hex wrench for adjusting the ball joint controlling the

camera’s view angle. The FC-Series camera is attached to the

mounting arm using the four M5 threaded bottom mounting holes. A

cable gland plug is supplied with the camera for the rear of the camera

housing when cables are routed using the concealed cable accessory.

Refer to Camera Mounting with Concealed Cable Wall Mount, pg. 11.

Concealed Cable

Wall Mount

427-0089-00-12 Version 160 March 2019 7

This document does not contain any export-controlled information.

Page 8

Camera Installation

• Pole Mount Adapter Kit (PN 4132982) - Adapter kit that allows the Concealed Cable Wall Mount

to be mounted to a pole (75 mm [3 in] min to 180 mm [7 in];

larger pole diameter requires use of customer supplied band clamps)

• FC-Series De-Ice Kit (PN 421-0056-00 for 60 mm lens, and PN 421-0057-00 for 75 mm lens)

The 60 mm and 75 mm lenses are not thermally conductive. The de-ice-kit provides a lens cover

that will conduct heat to keep the lens free of ice or frost while also protecting the lens in salt or

other harsh environments. Refer to Supplemental Lens Heater, pg. 7.

1.3.3 Supplied Components

The FC-Series camera package includes these standard components:

• Fixed Camera Unit with sun shield and installed cable gland

• Cable gland plug and gland inserts for sealing camera housing

• Power terminal block plug (installed)

• Accessory terminal block plugs (installed)

• Tools: 3 mm hex wrench (T-Handle), small blade screwdriver

1.3.4 Additional Supplies

The installer will need to supply the following items as required (specific to the installation).

• Optional customer supplied microSD card (up to 64 GB) provides local storage of image files

through power cycles.

• Power supply, 18 Vac to 32 Vac or 11 Vdc to 32 Vdc, if not using PoE power for system power.

• Power cable, 3-conductor, shielded, gauge determined by cable length and supply voltage,

if used for system power

• Accessory cable 6-conductor for GPIO (optional)

• PoE+ power supply or PoE+ switch, if used for system power. Note that the camera will operate

normally with PoE, but lens heaters may not operate to specification in cold environments.

• Cat5e or Cat6 Ethernet cable for digital video and/or PoE+ for system power

• Coaxial RG59U cables (BNC connector at the camera end) for analog video

• Camera grounding strap, camera mount, electrical hardware, connectors, and tools

Be sure to use cables that fit in the cable gland holes, as described below. Refer to Rear Access

Cable Gland Sealing, pg. 17 for more information.

1.3.5 Camera Placement

The FC-Series camera may be mounted upright, either on top of the mounting surface. or

underneath an overhanging mounting surface such as eaves or an awning. The camera may also be

mounted sideways in order to view a scene such as along a fence line or corridor. Adhere to all local

and industry standards, codes, and best practices.

Although the FC-Series O camera does not have on-board video analytics, many video

management systems and video encoders analyze the video signals to send alarm notifications

based on customized rules. Several types of third-party Video Management Systems (VMS) are

427-0089-00-12 Version 160 March 2019 8

This document does not contain any export-controlled information.

Page 9

Camera Installation

supported by FLIR IP cameras. Because these systems tend to evolve and change over time,

contact the local FLIR representative or FLIR Technical Support for information.

α

Camera mounted upright

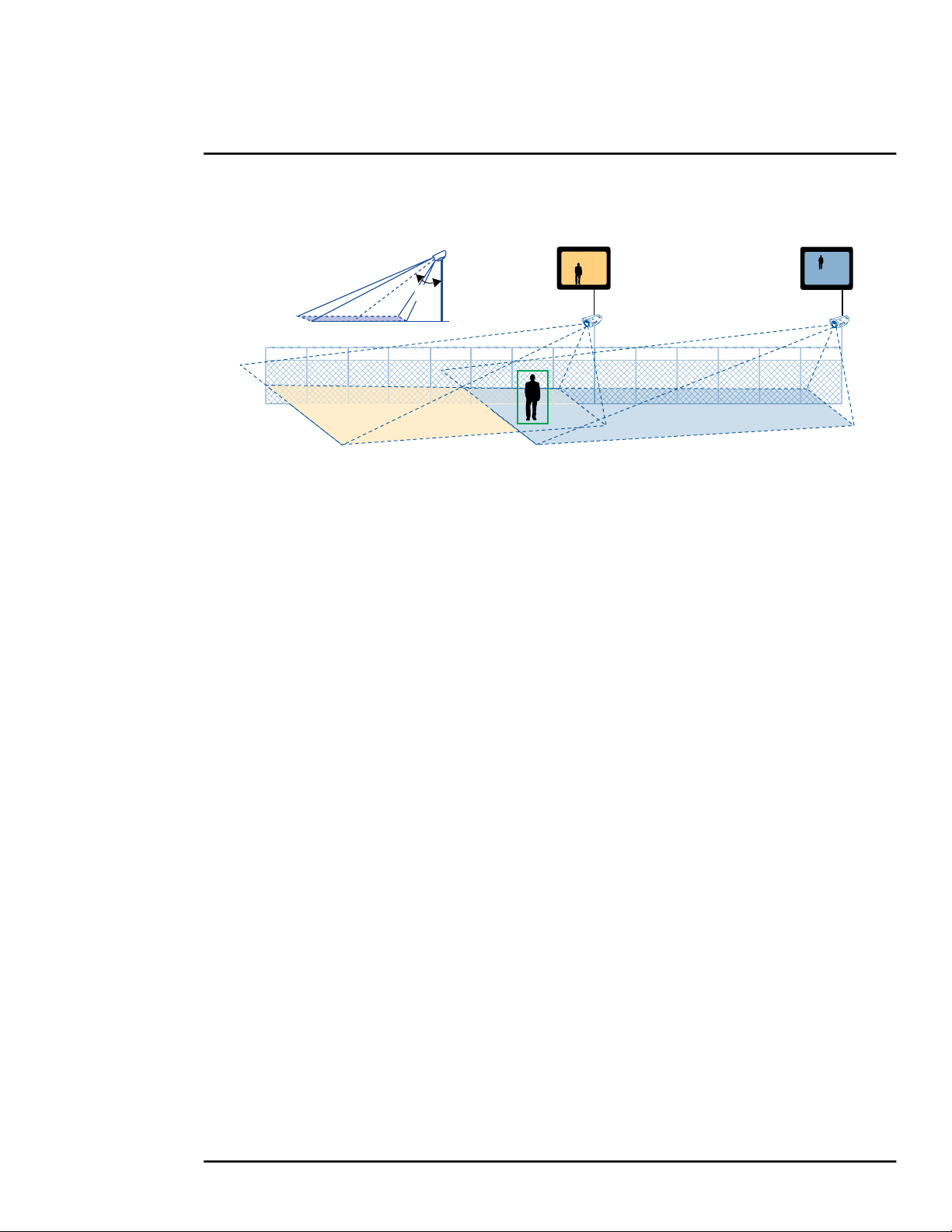

For installations with multiple FC-Series ID cameras with on-board video analytics, the fields of view

of cameras should overlap in order to remove all dead zones in which a camera cannot see a target

“head to toe”. The camera’s on-board analytics must be calibrated to detect targets. Refer to Video

Analytics Setup—FC-Series ID only, pg. 49.

• Install the camera at a height of approximately 4 m (13 ft) or more.

• Typically direct the camera towards the ground with a tilt angle α within a range of 45° to 60°

while ensuring the field of view includes as little of the skyline as possible.

• Ensure that cameras are mounted on stable mounts with minimal vibrations and maximal

resistance to wind.

• The tilt angle (

α) is the angle between vertical and the center of the camera field of view.

Typically direct the camera towards the ground with a tilt angle α of 45° to 60°. Include as little

skyline as possible in the field of view.

1.3.6 Camera Mounting for Rear Cable Access

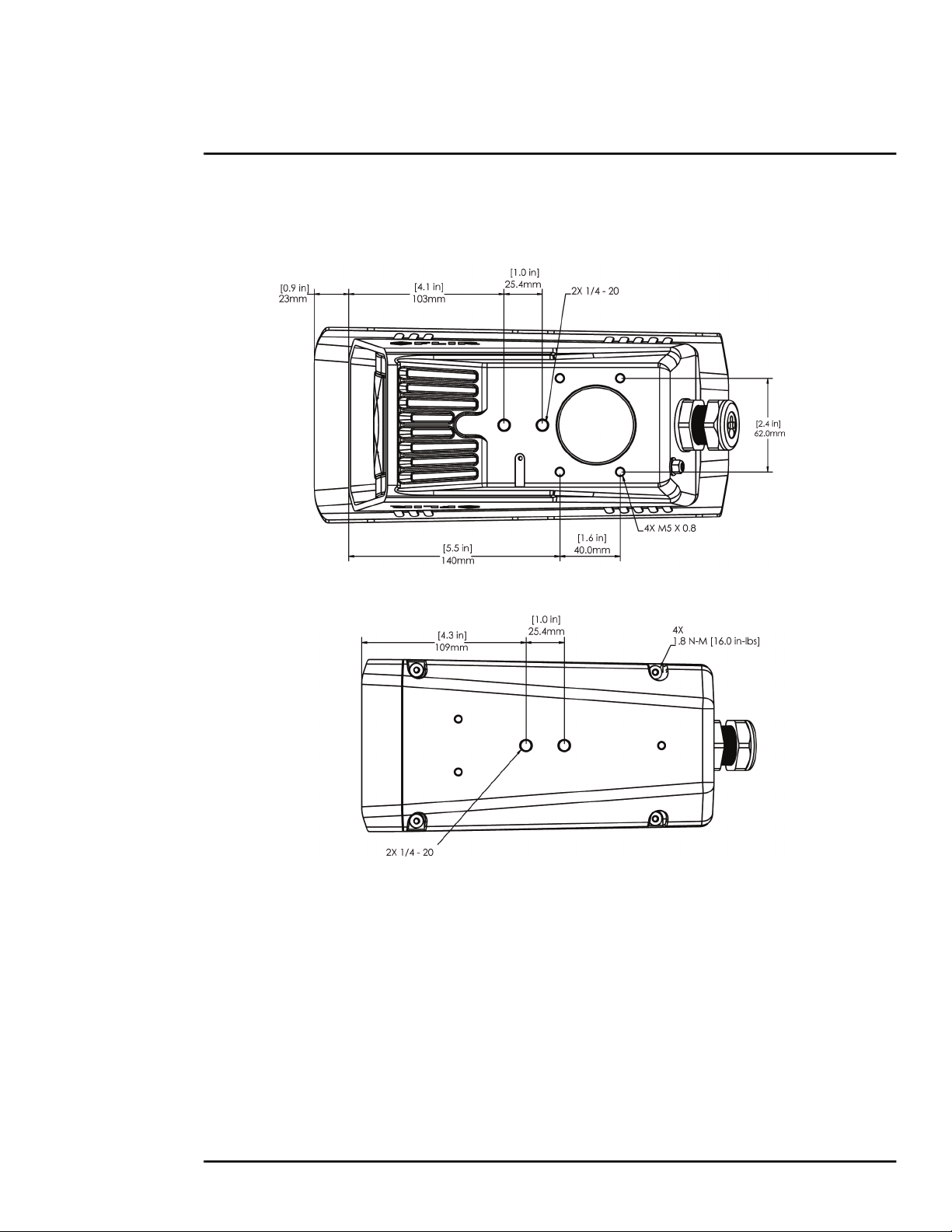

The FC-Series camera can be secured to the mount with two in-line 1/4-20 threaded fasteners on

the top or bottom of the camera. Alternatively the camera can be mounted with four M5 x 0.8

threaded fasteners to the bottom of the camera. Use Loctite 222 low strength threadlocker for the

top mount fasteners (can be used with the bottom mount fasteners also). Refer to the FC-Series ICD

for additional information.

427-0089-00-12 Version 160 March 2019 9

This document does not contain any export-controlled information.

Page 10

Camera Installation

If using two 1/4-20 fasteners in the center of base, the maximum depth of the fastener should not

exceed 12.5 mm (0.5 in). If using four M5 x 0.8 fasteners, the maximum depth of the fastener should

not exceed 10.0 mm (0.4 in).

Figure 1-1: FC-Series Camera Bottom Mounting Holes

Figure 1-2: Top Mounting Holes

If using two 1/4-20 fasteners in the center of top, the maximum depth of the fastener should not

exceed 12.5 mm (0.5 in). If the camera is mounted using the top of the camera, the sunshield must

be removed.

427-0089-00-12 Version 160 March 2019 10

This document does not contain any export-controlled information.

Page 11

Camera Installation

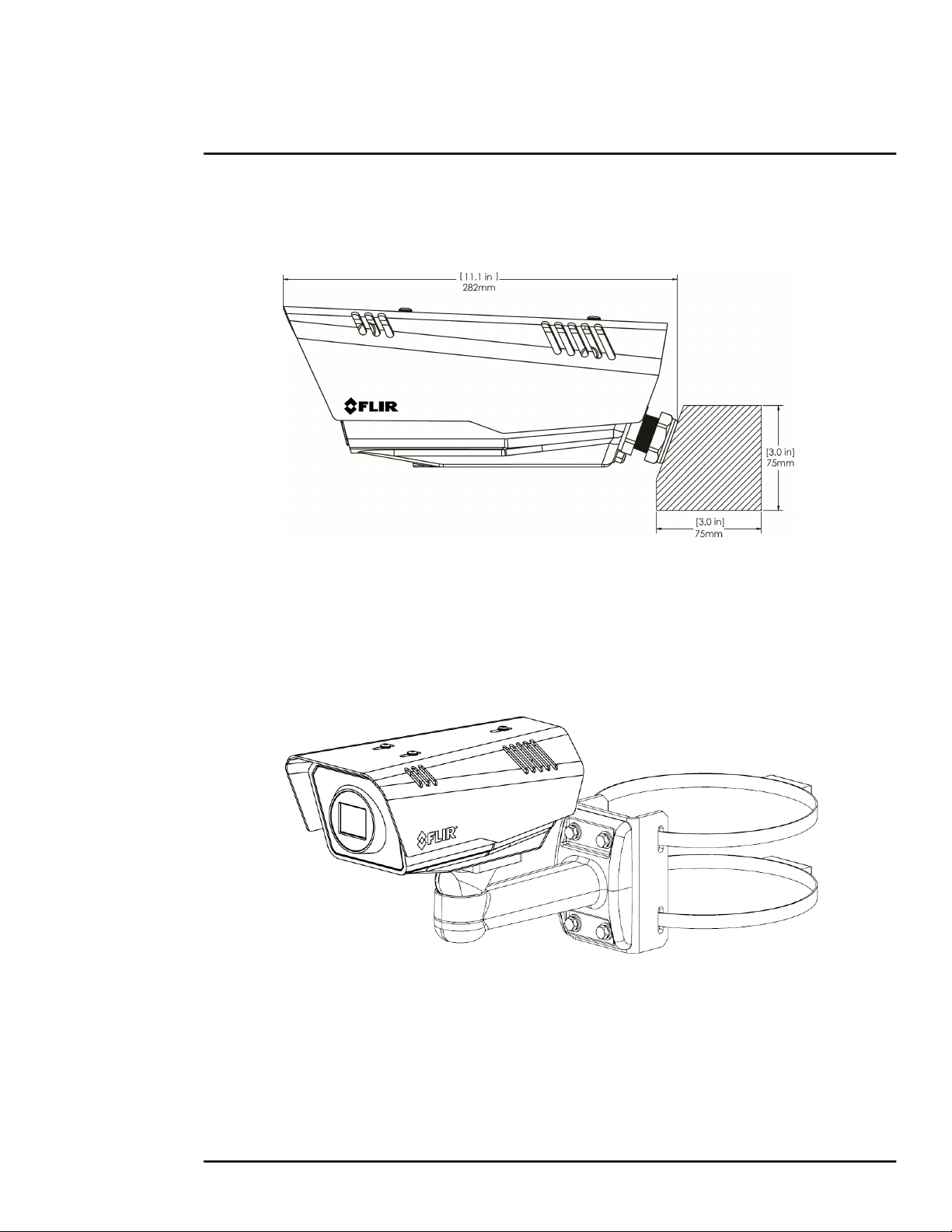

As the diagram below indicates, be sure to allow adequate space for cable egress behind the gland.

This requirement may vary, depending on the installation. Maintain the bend radius per the

recommendation of the cable manufacturer. The typical cable bend radius is 50-75 mm (2-3 in).

Figure 1-3: Rear Cable Bend Radius

1.3.7 Camera Mounting with Concealed Cable Wall Mount

The FC-Series camera can be secured to the optional Concealed Cable Wall Mount with four M5 x

0.8 threaded fasteners to the bottom of the camera. Use Loctite 222 low strength threadlocker for

the mount fasteners. Refer to Concealed Cable Mount Accessory, pg. 18 for additional information.

Figure 1-4: FC-Series Installed with Concealed Cable Wall

Mount and Pole Adapter kit

427-0089-00-12 Version 160 March 2019 11

This document does not contain any export-controlled information.

Page 12

Camera Installation

1.3.8 Sunshield

The camera includes a sunshield which should be used for any installation where the camera is

exposed to direct sunlight or precipitation, If the camera is mounted with the top mounting holes, the

sunshield is not used. Depending on the needs of the installation, the sunshield can be positioned in

the neutral (middle) position, or slightly forward or rearward.To change the position of the sunshield,

temporarily loosen the three 3 mm hex screws on top, slide the sunshield forward or backward, and

re-tighten the screws.

Sunshield mounting screws (x3)

Figure 1-5: Sunshield Mounting

1.3.9 Removing the Cover

In order to access the electrical

connections and install the cables, it is

necessary to temporarily remove the top

cover of the camera housing. The top

cover of the camera is held in place with

four 3 mm hex screws. The screws are

accessible through slots in the

sunshield, so the sunshield does not

need to be removed from the top cover.

Cover mounting screws (x4)

Cover mounting

screws (x4)

Use a 3 mm hex key to loosen the four

captive screws, exposing the

connections inside the camera

enclosure. There is a grounding wire

connected inside the case to the top

cover, as shown. If it (or any of the

grounding wires) is temporarily

disconnected during the installation, it

must be reconnected to ensure proper

grounding of the camera.

Figure 1-6: Cover Removed (Sunshield attached)

When replacing the cover, tighten the four 3 mm hex screws to 1.8 n-m (16.0 in-lbs).

Caution!

When replacing the cover, ensure that the ground wire between the cover and the camera body is

completely inside the o-ring groove. If the wire is pinched between the cover and body the camera

is not sealed against water ingress and can be damaged.

427-0089-00-12 Version 160 March 2019 12

This document does not contain any export-controlled information.

Page 13

Camera Installation

1.4 Camera Connections

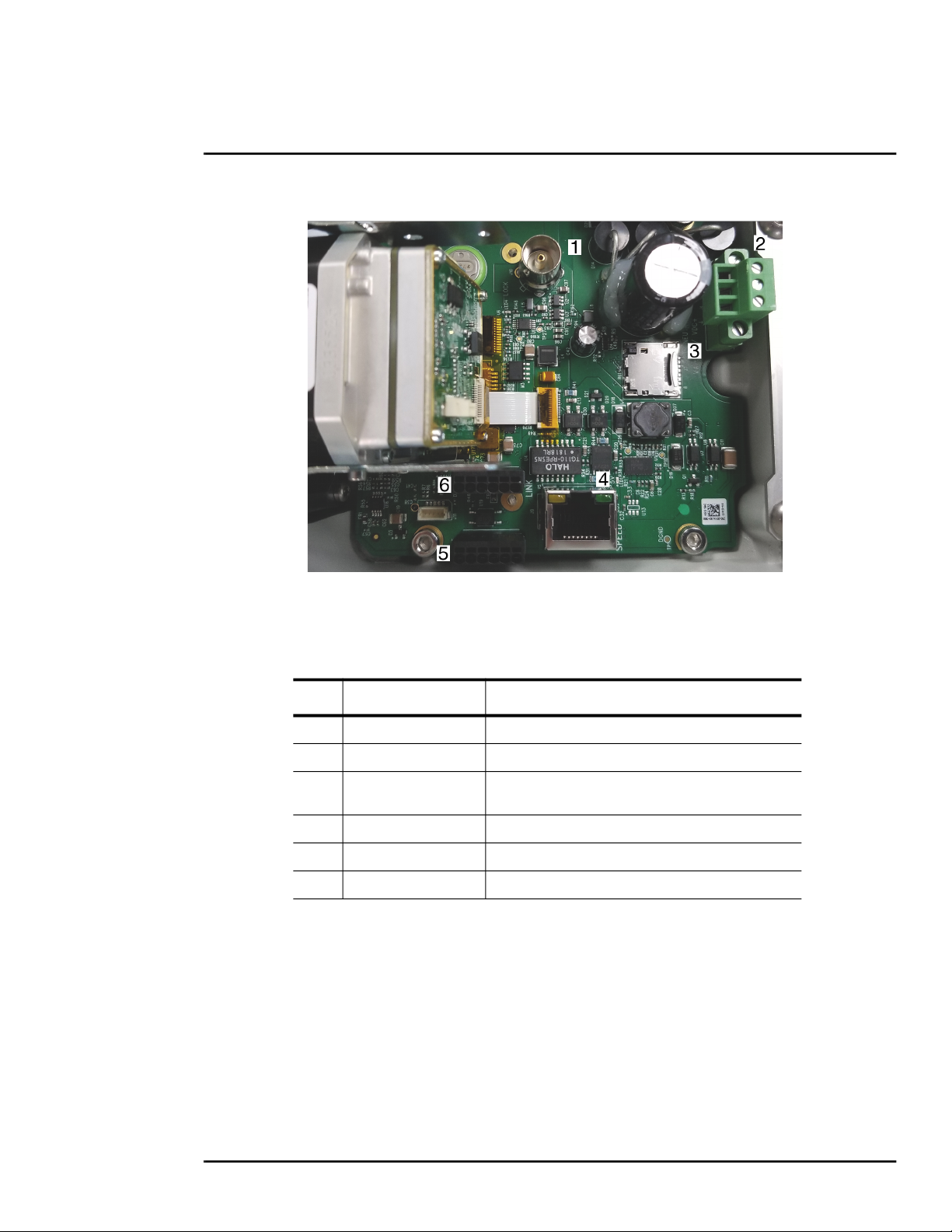

Figure 1-7: Camera Connections

Refer to Table 1-1 for a description of these camera connections.

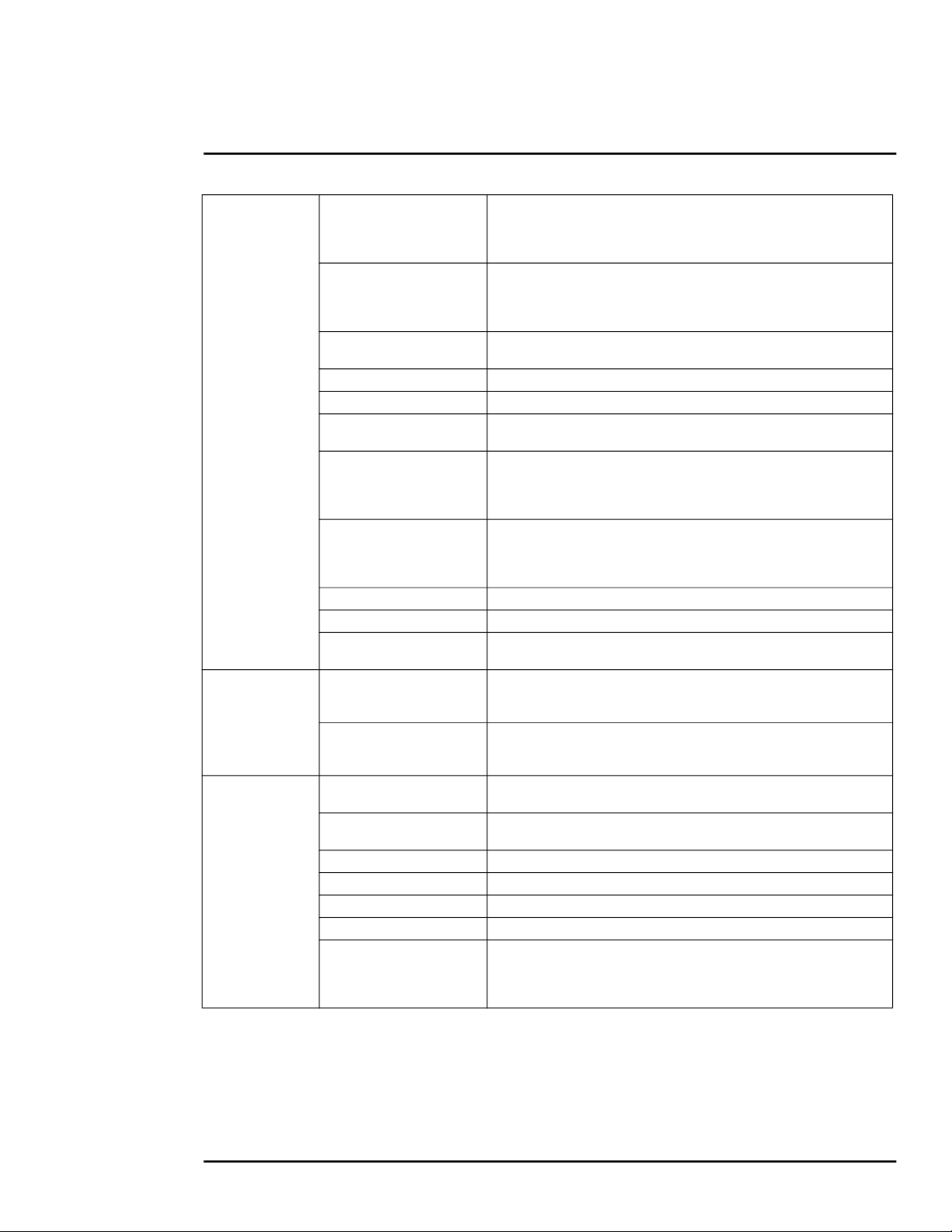

Table 1-1: FC-Series Camera Connections

Connection Purpose

1 BNC Analog video

2 3-pin Terminal Vac or Vdc power

3 microSD card

4 Ethernet PoE+ power, communications, IP video stream

5 6-pin terminal J5 General purpose I/O

6 Accessory inputs Reserved for future use

Local storage of image files up to 64 GB

(supplied by customer)

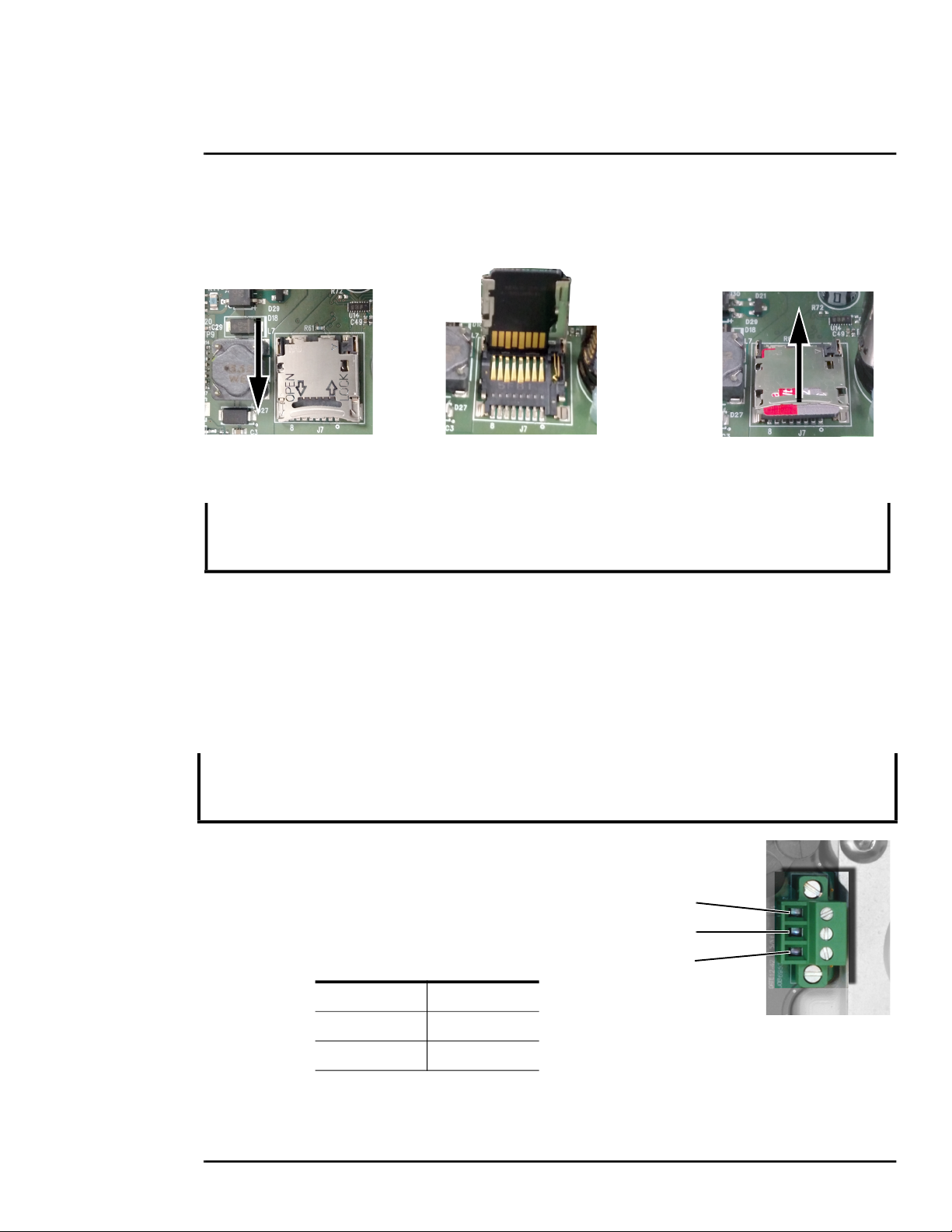

1.4.1 Installing the microSD Card

The FC-Series camera has local storage (on the camera) flash memory to store images captured as

a result of an alarm action. However, these images are lost during a reboot or power cycle. When a

427-0089-00-12 Version 160 March 2019 13

This document does not contain any export-controlled information.

Page 14

Camera Installation

customer supplied microSD card (up to 64 GB) is installed, local storage is persistent through

reboots and power cycles.

Pull back cage to unlock

Lift edge to open

Insert microSD card

Close cage,

press down and

push forward to lock

1.4.2 Bench Testing

Note

If the camera is to be mounted on a pole or tower or other hard-to-reach location, it may be a good

idea to connect and operate the camera as a bench test at ground level prior to mounting the

camera in its final location.

Connect the power, Ethernet, and video, and confirm that the video can be displayed on a monitor

when the power is turned on. For configuration and basic setup information using the onboard web

server, refer to Camera Bench Test, pg. 22 for specific details.

1.4.3 Analog Video Connections

The primary analog video connection of the camera is a BNC connector. The video cable used

should be rated as RG-59/U or better to ensure a quality video signal.

Note

Insert the cables through the cable glands on the enclosure before terminating and connecting them.

In general, terminated connectors will not fit through the cable gland. If a terminated cable is

required, it is possible to make a clean and singular cut in the gland seal to install the cable.

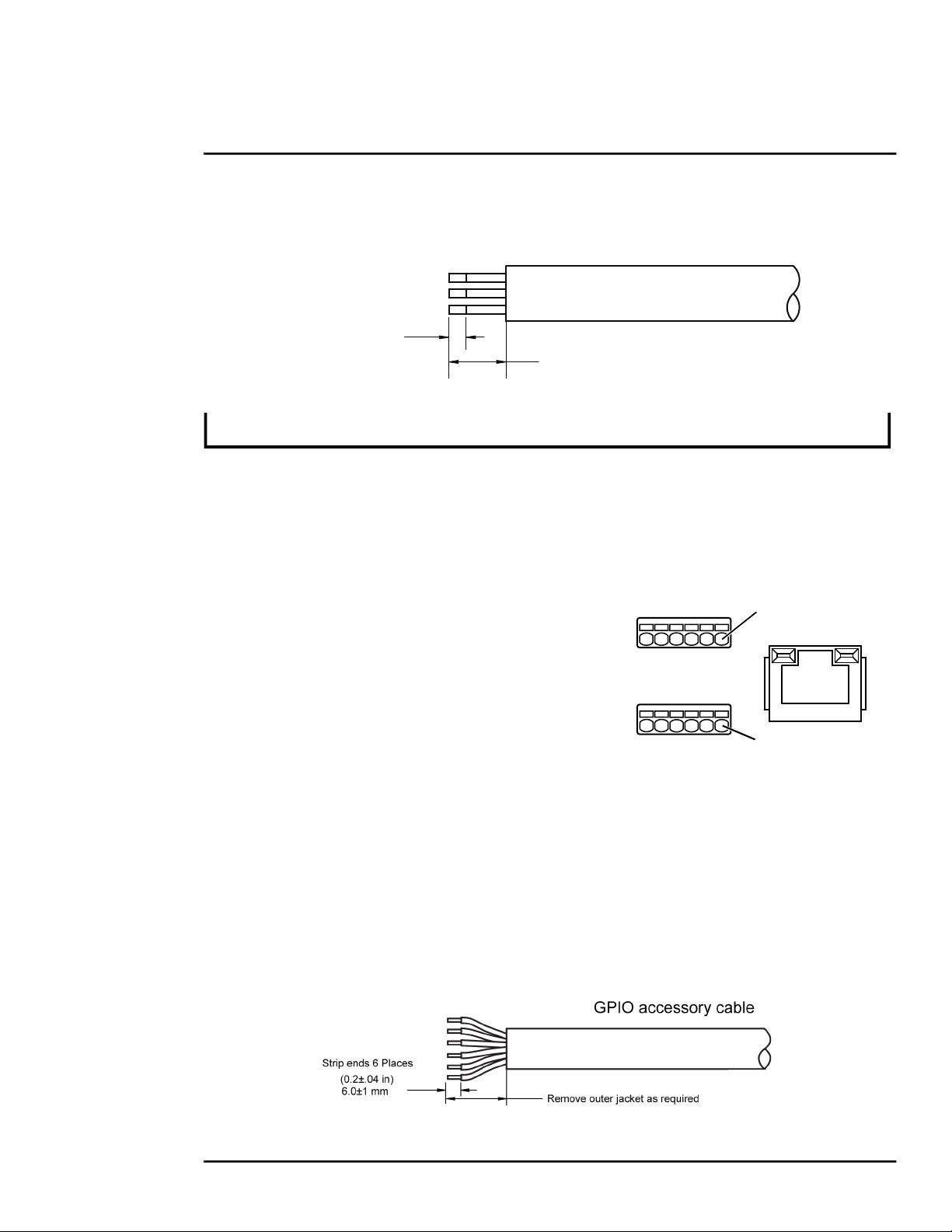

1.4.4 Connecting Power

The camera can be powered with a conventional Vac or Vdc

power supply, rather than PoE+. Prior to making any

connections, ensure the power supply or circuit breaker is

switched off.

Table 1-2: Power Connections

1

2 Vac or Vdc (–)

3

Chassis

Vac or Vdc (+)

1

2

3

Figure 1-8: Power Connector

427-0089-00-12 Version 160 March 2019 14

This document does not contain any export-controlled information.

Page 15

Camera Installation

(0.8±.20 in)

20.0±5 mm

Remove outer

jacket

(0.2±.04 in)

6.0±1 mm

Strip ends

3 Places

Power Cable

The power cable supplied by the installer must use wires that are sufficient size gauge for the supply

voltage and length of the cable run to ensure adequate current carrying capacity (18 AWG

recommended for most installations). Always follow local building/safety codes.

Note

The terminal connector for power connections will accept 16 AWG to 24 AWG wire size.

The power connector plug may be removed for cable installation. After the plug is reattached to the

board, re-tighten the screw terminals.

The camera itself does not have an on/off switch. Generally the FC-Series camera may be

connected to a circuit breaker and the circuit breaker will be used to apply or remove power to the

camera. If power is supplied to it, the camera will be powered on and operating.

1.4.5 GPIO Connections

Input Signal—When the camera senses an external

switch closure which completes the circuit between

J3 pin 1

Ethernet

J5 pins 4 and 5, an input signal is generated by the

GPIO for the Alarm Manager. Refer to Alarm

Manager, pg. 62.

Output Signal—Accessory connector J5 pins 2 and

3 connect to a switch in the camera to complete the

circuit for the receiving device. When open the

resistance between pins 2 and 3 is greater than 100 K

Figure 1-9: GPIO and Ethernet

Connectors

J5 pin 1

ohm. When closed the resistance between pins 2 and

3 is less than 200 ohm. The maximum recommended peak voltage between the pins is 6 volts. The

maximum recommended current allowed between the pins is 30 mA (0.03 A).

By default the GPIO alarm circuits are configured for normally open switches, to configure a GPIO

alarm circuit for a normally closed switch, refer to Devices Menu GPIO, pg. 60.

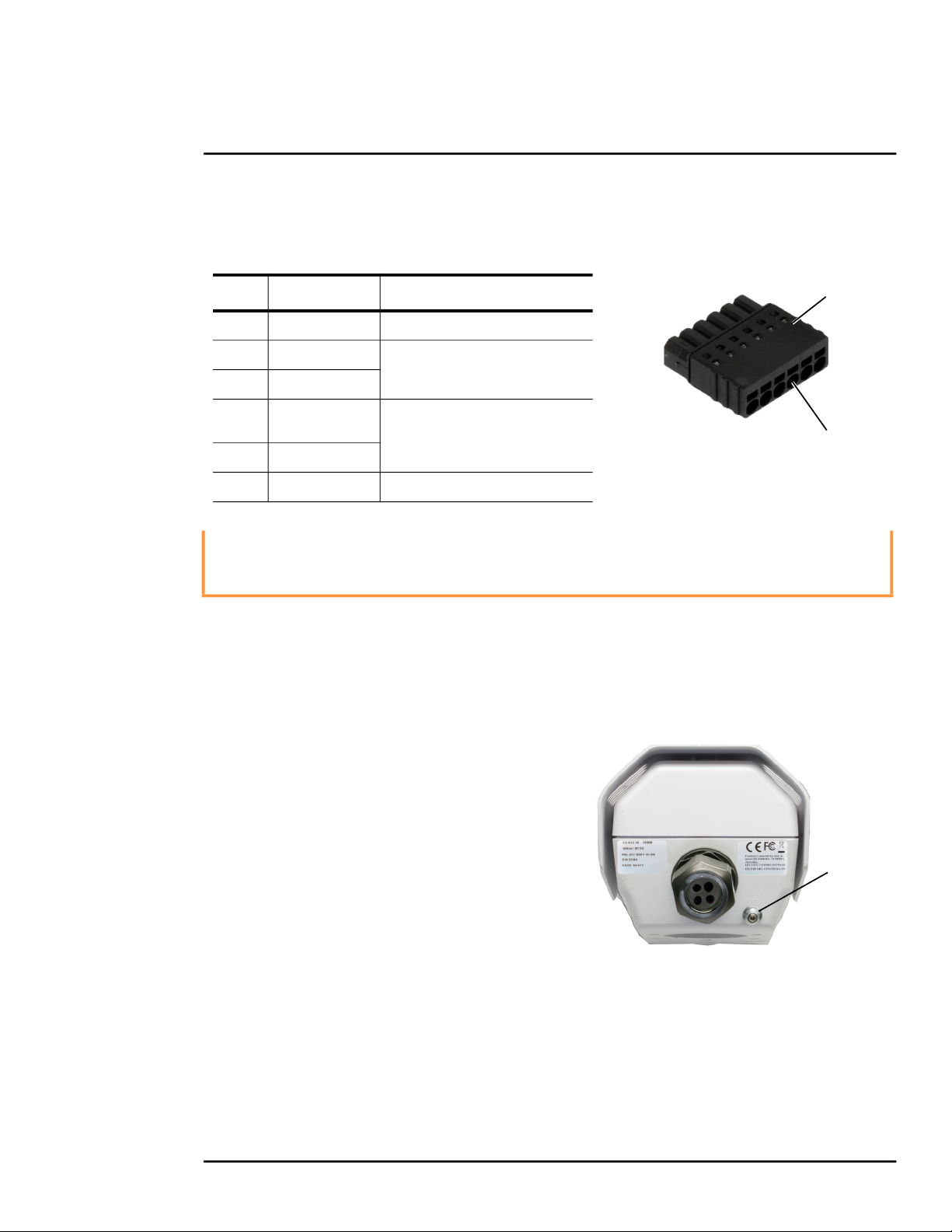

The terminal plug supplied for GPIO connections may be either a fast connect, spring-cage and

pierce contact, or a push-in spring contact.

The push-in spring contact accepts 20 - 24 AWG conductors. Strip conductor ends to 6 mm.

427-0089-00-12 Version 160 March 2019 15

This document does not contain any export-controlled information.

Page 16

Camera Installation

The spring-cage and pierce contact accepts 22 AWG to 24 AWG, stranded conductors with a 1.6 mm

maximum diameter including insulation. Do not strip insulation from conductors.

Table 1-3: GPIO Connections - J5

Pin Connection Notes

Chassis ground

1

2

3

4

5

GPIO Out

GPIO Out

GPIO In2

(Digital ground)

GPIO In1 (+5V)

When the camera sends an output

signal, an external voltage on one

pin is applied to the other pin.

When these pins are connected

externally, the camera reads this as

an input signal.

Pin 1

Insert wires

Figure 1-10: GPIO Terminal Plug

Chassis ground

6

(Push-in spring contact)

Caution!

J5 pins 4 and 5 must not be connected to outside voltages or power sources. Pin 5 must not be

connected to chassis ground. While protection for static discharge has been placed on these pins,

care should be used when making connections to avoid damage to the camera.

1.4.6 Ethernet

Connect a shielded Cat5e or Cat6 Ethernet cable to the RJ-45 jack. If using PoE+ to supply power to

the camera, connect the other end of the cable to a PoE+ switch or PoE+ injector. Otherwise

connect the cable to a network switch.

1.4.7 Camera Grounding

Ensure the camera is properly grounded. Failure to

properly ground the camera can lead to permanent

damage to the camera. Typical to good grounding

practices, the camera chassis ground should be

connected to the lowest resistance path possible. The

camera has an external ground connection on the

outside back of the camera. FLIR requires a

grounding strap anchored to the grounding lug and

Ground

connected to the nearest earth-grounding point.

If, during installation, any ground connections inside

the camera are disconnected, they should be

reconnected prior to closing the camera.

427-0089-00-12 Version 160 March 2019 16

This document does not contain any export-controlled information.

Figure 1-11: Camera Ground

Page 17

Camera Installation

1.4.8 Rear Access Cable Gland Sealing

Proper installation of cable sealing gland and use of appropriate elastomer inserts is critical to long

term reliability. Cables enter the rear of the camera mount enclosure through a liquid-tight

compression gland.

Table 1-3: Rear Exit Cable Min/Max Dimensions

Cable Min Max

Power (3 conductor),

Ethernet, Accessory cables

RG 59 Video cable

4.5 mm

[0.178 in]

5.3 mm

[0.209 in]

5.2 mm

[0.205 in]

6.2 mm

[0.244 in]

Leave the gland nut loosened until all cable installation has been completed, and ensure the

manufacturer’s recommended cable bend radius is observed within the enclosure. Do not forget to

tighten the cable gland seal nut to ensure a watertight seal and provide strain relief for cables.

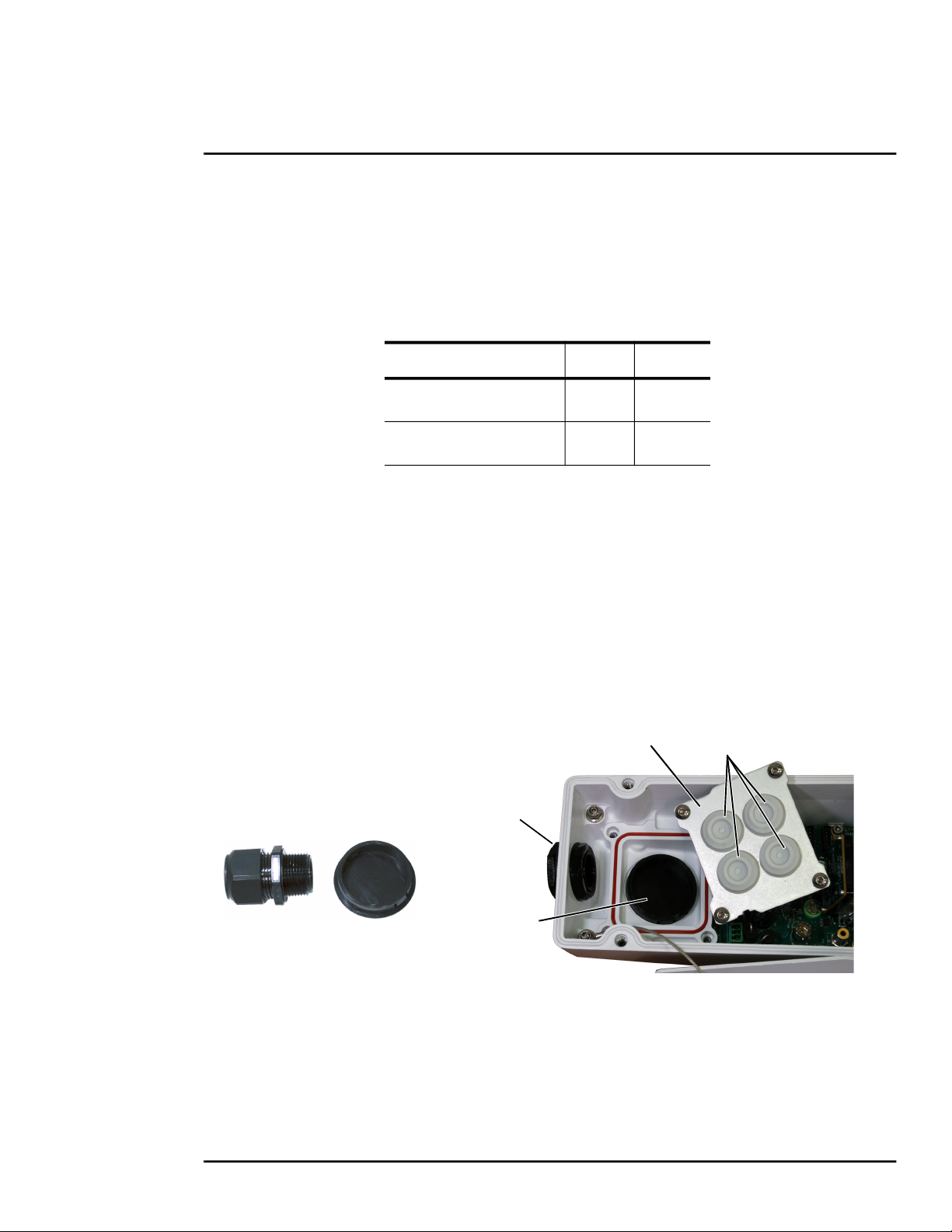

Cable Gland Seal Inserts

The FC-Series camera comes with a single 3/4” NPT cable gland installed in the enclosure, with a

four-hole gland seal insert. The gland includes a sealing washer and is secured to the camera with a

nut on the inside of the enclosure. The gland insert has one hole for the RG-59/U analog video cable

(the larger hole) and three more for a power cable, Ethernet cable, and an accessory cable.

Any of the holes which are not used for cables should be filled with one of

the hole plugs (supplied). Install the cables through the cable gland so that

the cables line up with the connections inside the camera.

Note

Insert the cables through the cable glands on the enclosure before terminating and connecting them.

In general, terminated connectors will not fit through the cable gland. If a terminated cable is

required, make a clean and singular cut in the gland seal to install the cable into the gland seal.

To ensure a water tight seal when using the supplied rear cable gland, cable dimensions must be

within the minimum and maximum as described in Table 1-3.

Video Cable

Accessory cable

Ethernet

RG 59 coaxial

Power Cable

3 Conductor

Figure 1-12: Cable Routing

427-0089-00-12 Version 160 March 2019 17

This document does not contain any export-controlled information.

Page 18

Camera Installation

1.5 Concealed Cable Mount Accessory

Do not route cables through the bottom of the camera unless the concealed cable wall mount (PN

4129742) is used. The wall mount is specifically designed for the camera and allows the opening to

seal properly. When using the concealed cable wall mount, cable dimensions must be within the

minimum and maximum as described in Table 1-4.

Table 1-4: Cable Min/Max Dimensions using Concealed Cable Wall Mount (PN 4129742)

Cable Min Max

Power (3 conductor),

Ethernet, Accessory cables

RG 59 Video cable

4.5 mm

[0.178 in]

5.3 mm

[0.209 in]

10 mm

[0.394 in]

10 mm

[0.394 in]

Proper installation of the seal plate and panel mount gland seals is critical to long term reliability.

Cables enter the bottom of the camera enclosure through the seal plate and panel mount glands. Be

sure to insert each cable through its panel mount gland on the seal plate before terminating them

(connectors will not fit through the gland). Ensure the manufacturer’s recommended cable bend

radius is not exceeded within the enclosure.

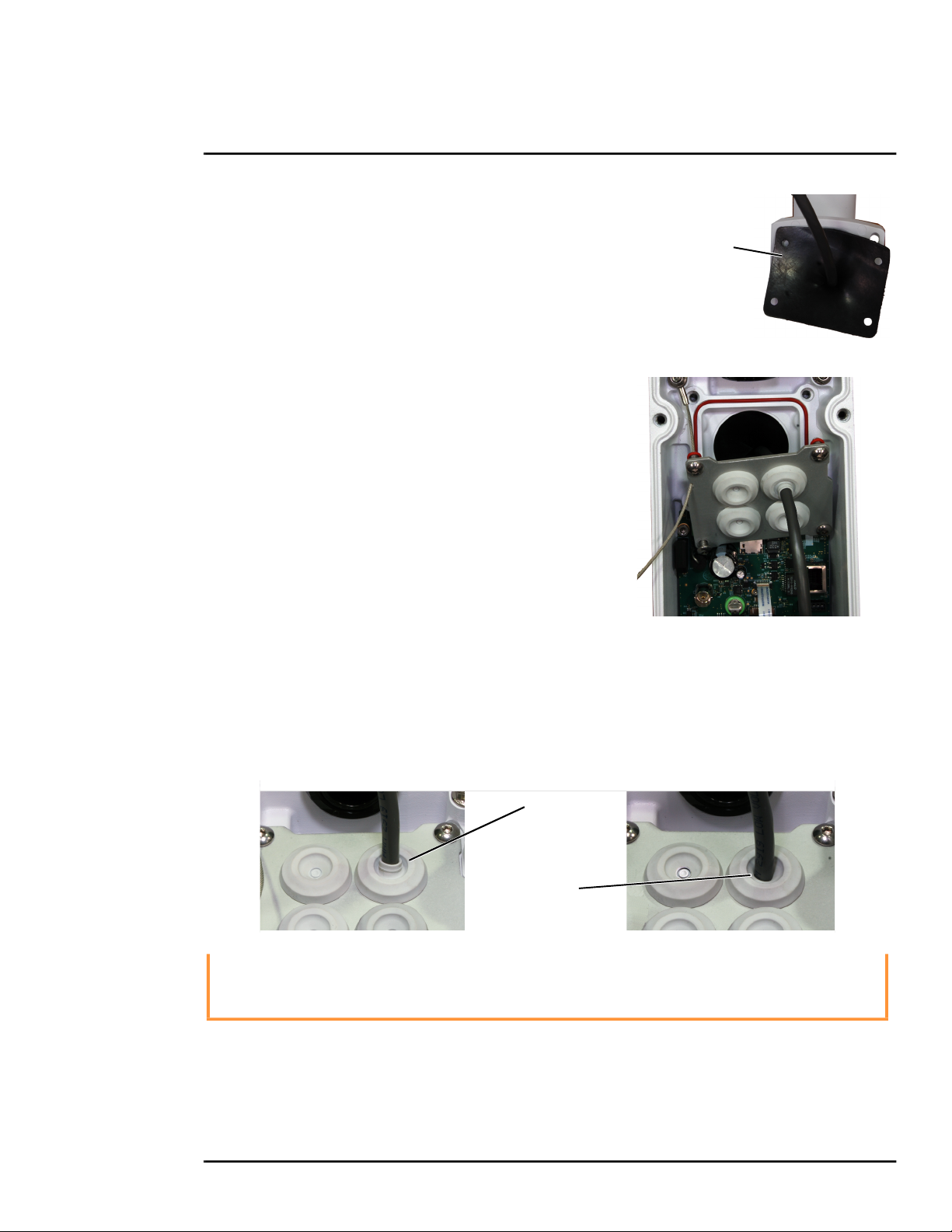

Prepare the Camera

Step 1 Use a 3 mm hex key to loosen the four captive screws and remove the top cover as

described above.

Step 2 Remove the rear cable gland and replace it with the cable gland plug. Use the gasket and

nut that were removed with the cable gland.

Step 3 Use a 3 mm hex key to

Seal plate

Panel mount gland seals (x4)

loosen the four captive

screws and remove the

seal plate, o-ring, and

plug.

Gland plug

installed

Plug

Figure 1-14: Removed Parts

Figure 1-13: Seal Plate Removed

427-0089-00-12 Version 160 March 2019 18

This document does not contain any export-controlled information.

Page 19

Camera Installation

Step 4 Install the wall mount (PN 4129742) to the

wall and pull the cable(s) through the mount.

Cut a small cross-slit in the black mount

gasket and push the cable(s) through the

gasket. Pull the cable(s) through the opening

in the bottom of the camera. A single Ethernet

cable is shown in the images.

Step 5 Secure the camera to the mount using four

M5 x 0.8 threaded fasteners to the bottom of

the camera. Use Loctite 222 low strength

thread locker for the mount fasteners.

Step 6 As needed, clean the o-ring and the o-ring

groove in the bottom of the camera using

isotropy alcohol and press the o-ring into its

groove.

Mount Gasket

Figure 1-15: Camera Mount

Step 7 For each cable, punch a hole in the center of

a gland seal from the top using the 3 mm hex

key. Insert the cable from the bottom though

the hole.

Figure 1-16: Cable through Seal Plate

Step 8 Place the gland plate back into position and

tighten the four 3 mm captive screws using a torque value of 1.8 n-m (16.0 in-lbs).

Step 9 Check the length of each cable to ensure an appropriate bend radius and terminate the

cable. Connect the cables as indicated in Camera Connections, pg. 13.

Step 10 Push the cable back through the gland seal so that the seal is extended down not up, as

shown in the illustration below.

Wrong

Correct

Caution!

When replacing the cover, make sure the ground wire between the cover and the camera body is

completely inside the o-ring groove. If the wire is pinched between the cover and the base, the

camera will not be sealed against water ingress and could be damaged.

Step 11 Ensure that any ground wire that was removed during installation is reconnected. Replace

the cover and tighten the four 3 mm hex screws to 1.8 n-m (16.0 in-lbs).

Step 12 Using the hex key included with the concealed cable mount, loosen the ball joint on the

bottom of the mount, position the camera as required, and then re-tighten the ball joint.

427-0089-00-12 Version 160 March 2019 19

This document does not contain any export-controlled information.

Page 20

Camera Installation

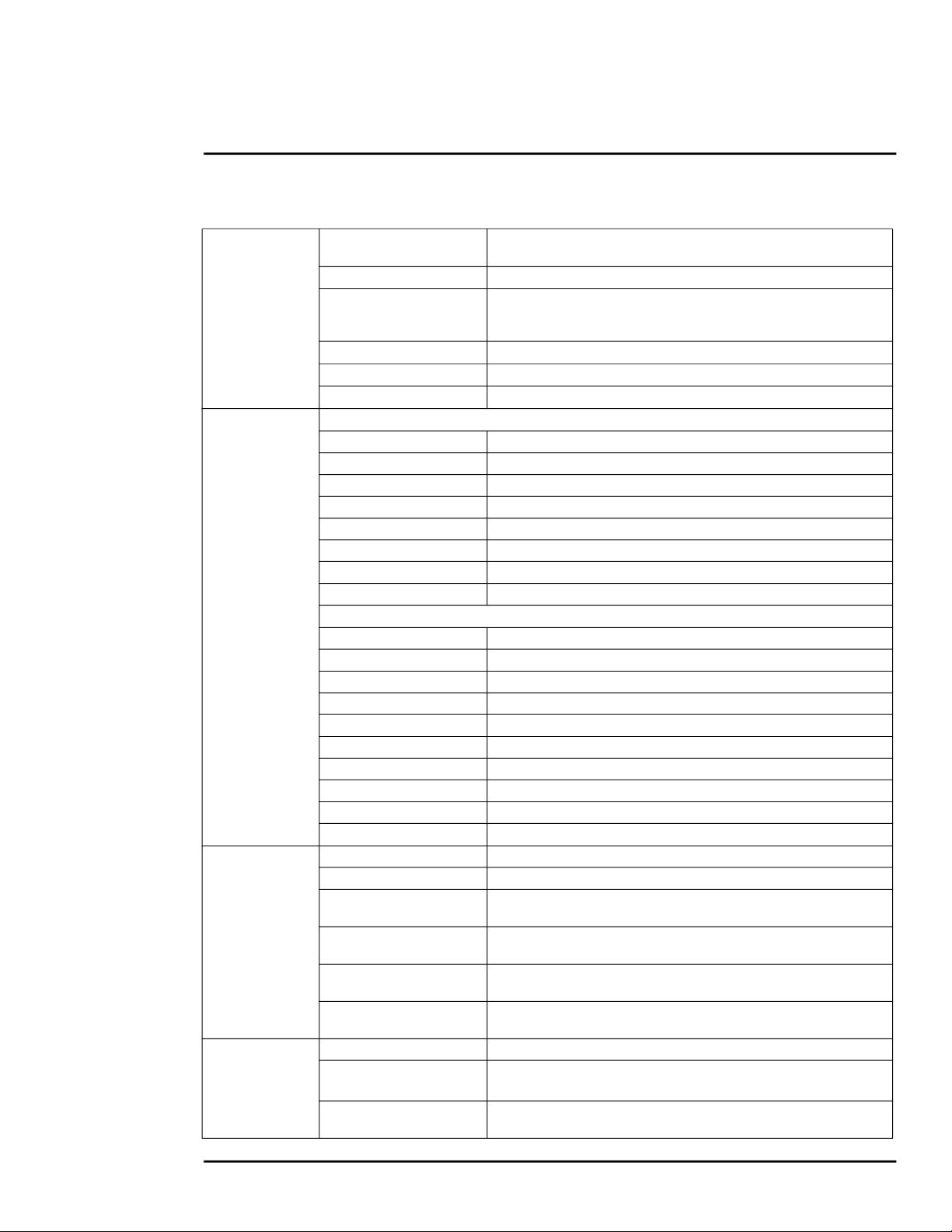

1.6 Camera specifications

Thermal

Camera

Camera Model

Video

System

Integration

Array Format

Detector Type Long-Life, Uncooled VOx Microbolometer

Effective Resolution

Spectral Range 7.5 to 13.5 µm

Lens Athermalized, focus-free

E-zoom Continuous to 4x

Field Of View (Focal Length) for available 640 x 512 camera lens configurations.

FC-690 90° × 69° (7.5 mm)—17 µm pixel pitch

FC-669 69° × 56° (9 mm)—17 µm pixel pitch

FC-644 44° × 36° (13 mm)—17 µm pixel pitch

FC-632 32° × 26° (19 mm)—17 µm pixel pitch

FC-625 25° x 20° (25 mm)—17 µm pixel pitch

FC-617 17° × 14° (35 mm)—17 µm pixel pitch

FC-610 10° × 8.2° (60 mm)—17 µm pixel pitch

FC-608 8.6° × 6.6° (75 mm)—17 µm pixel pitch

Field Of View (Focal Length) for available 320 x 256 and 336 x 256 camera lens configurations.

FC-369 69° x 56° (9 mm)—34 µm pixel pitch

FC-344 44° × 36° (13 mm)—34 µm pixel pitch

FC-332 32° × 26° (19 mm)—34 µm pixel pitch

FC-324 24° × 18° (13 mm)—17 µm pixel pitch

FC-317 17° × 13° (19 mm)—17 µm pixel pitch

FC-313 13° x 10° (25 mm)—17 µm pixel pitch

FC-309 9.2° × 7.0° (35 mm)—17 µm pixel pitch

FC-305 5.4° × 4.1° (60 mm)—17 µm pixel pitch

FC-304 4.3° × 3.3° (75 mm)—17 µm pixel pitch

Camera Platform Type Bullet

Composite Video NTSC or PAL Standard—switchable from Video Setup web page

Video Compression Two independent channels of streaming H.264, MPEG4, or M-JPEG

Streaming Resolution

Thermal AGC Modes

Thermal AGC Region of

Interest (ROI)

Image Uniformity

Optimization

Ethernet 10/100 Mbps

Serial Control Interfaces

External Analytics

Compatible

640 x 512, 336 x 256 (17 µm pixel pitch)

320 x 256 (34 µm pixel pitch)

640 x 512: 327,680

336 x 256: 86,016

320 x 256: 81,920

D1: 720 x 480, 720 × 576; CIF4: 704 x 480, 704 x 576; Native: 640 x 480,

640 × 512; CIF: 352 x 240, 352 x 288; Q-Native: 320 × 256

Preset AGC modes and manual Brightness (ITT Mean), Contrast (Max

Gain), Sharpness (DDE Gain), and AGC Filter controls

Default, Presets and User definable to insure optimal image quality for

subjects of interest

Automatic Flat Field Correction (FFC) - Thermal and Temporal Triggers

Nexus SDK for comprehensive system control and integration; Nexus

CGI for http command interfaces; ONVIF

Yes

®a

Profile S

427-0089-00-12 Version 160 March 2019 20

This document does not contain any export-controlled information.

Page 21

Camera Installation

Weight

Dimensions (L,W,H)

General Purpose Input/

Output (GPIO)

Input Voltage dc 11 Vdc to 32 Vdc

Input Voltage ac 18 Vac to 32 Vac

General

Measurement

and Analysis

Environmental

a. ONVIF is a trademark of Onvif, Inc.

Input Voltage PoE+

Power Consumption

Mounting Provisions

Shipping weight 6.2 lbs (2.8 kg) to 6.9 lbs (3.13 kg)

Shipping Dimensions 14.375”(L) x 7.375”(W) x 7”(H)

microSD card

Analytics Features

Analytics Management

IP rating (dust and water

ingress)

Operating temperature range

Storage Temperature range -55 °C to 85 °C (-67 °F to 185 °F)

Humidity 0-95% relative

Shock MIL-STD-810G Method 514.6

Vibration IEC 60068-2-27, 10g shock, 11 ms half-sine profile

Approvals

4.55 lb (2068 g) with sun shield

(7.5 mm, 9 mm, 13 mm, 19 mm, 25 mm, 35 mm)

5.20 lb (2364 g) with sun shield (60 mm)

5.65 lb (2568 g) with sun shield (75 mm)

9.2" x 4.6" x 4.1" without sun shield,

(234 mm x 117 mm x 104 mm)

11.5" x 5.1" x 4.6" with sun shield,

(292 mm x 130 mm x 117 mm)

One input dry alarm contact;

One output relay contact (rated load 0.025 A max at 5 Vdc)

IEEE 802.3af-2003 standard or higher power,

IEEE 802.3at-2009 standard

5 W nominal at 24 Vdc

Peak at 24 Vdc: 23 W with lens heater

8 VA nominal at 24 Vac

Peak at 24 Vac: 32 VA with lens heater

Two 1/4-20” threaded holes on top and bottom,

1" spacing along center line front to back.

Four M5 threaded holes bottom,

40 mm x 62 mm (1.6 in x 2.4 in) spacing square.

Local storage of image files up to 64 GB

(supplied by customer)

Region Entrance/Intrusion Detection, Crossover/Fence Trespassing;

Auto/Manual Depth Setup, Human and Vehicle Rules, Hand-off target to

autonomous PTZ tracking, Tampering Detection

Web-based configuration and management, Masking of analytic

detection areas, adjustable sensitivity, automatic responses, remote I/O

control

IP66 & IP67

-50 °C to 70 °C (-58 °F to 158 °F) continuous

-40 °C to 70 °C (-40 °F to 158 °F) cold start

FCC Part 15, Subpart B, Class A, EN 55032: 2012 (for IT Equipment),

EN 55024: 2010 (for IT Equipment), EN 50130-4: 2011 (for Alarm

Systems), IEC 62599-2: 2010 (for Alarm Systems), EN 50121-4: 2015 (for

Railway Applications - EMC)

427-0089-00-12 Version 160 March 2019 21

This document does not contain any export-controlled information.

Page 22

2

Basic Operation and Configuration

This chapter provides basic information on how to operate the FC-Series camera. A bench test can be

used to verify camera operation before the camera is configured for the local network. This chapter

also provides general configuration information.

2.1 IP Camera, ONVIF Profile S Compliant

When connected to the network the camera functions as a server; providing services such as camera

control, video streaming, network communications, and geo-referencing capabilities. Network

communication uses an open, standards-based protocol that allows the server to communicate with a

video management client, such as FLIR Latitude or with a third-party VMS client, including systems

that are compatible with ONVIF Profile S. Refer to the individual product web page at https://

www.flir.com/browse/security/thermal-security-cameras/ for a listing of supported VMS clients.

The other process, known as the Nexus Server, listens on the network for connections from clients

such as FLIR Latitude, ONVIF-compliant systems, or other VMS clients. These clients can be used to

control the camera and stream video during day-to-day operations of the camera.

2.2 Camera Bench Test

The camera offers both analog video and IP video, and since the camera can be powered by PoE or by

a conventional power supply, there are several ways to bench test the camera. It is recommended that

the installer test the camera using the same type of connections as in the final installation.

Even if using analog video and conventional power in the final installation, it is a good idea to test the

IP communications when performing the bench test. If any image adjustments are necessary, they can

be done using a web browser over the IP connection, and saved as power-on default settings.

With the camera powered up, analog video can be tested at the BNC connector. Connect the camera

to a video monitor and confirm the live video is displayed on the monitor.

If using a conventional power supply, connect the camera to a network switch with an Ethernet cable,

and connect a PC or laptop to the switch also. Use a web browser to access and test the camera as

described below, and if necessary make configuration changes prior to installation.

Once the camera is connected to a network and powered on, set camera network parameters using

the FLIR Discovery Network Assistant (DNA) software, perform a bench test by using a web browser to

view the video and control the camera, or view video in the local Network Video Management System

(for example, FLIR Latitude

require a license to use and is a free download from the individual product web page at:

https://www.flir.com/browse/security/thermal-security-cameras/.

TM

). The FLIR Discovery Network Assistant (DNA) software does not

2.3 Set IP Address using the FLIR Discovery Network Assistant (DNA)

Assuming the existing network uses IP addresses that are unique and different than the default

address on the camera (192.168.250.116), configuring the camera for IP communications generally

involves the following steps:

Step 1 Connect the Ethernet port of the camera to the existing IP camera network.

Step 2 Connect a PC or laptop to the same network.

427-0089-00-12 Version 160 March 2019 22

This document does not contain any export-controlled information.

Page 23

Basic Operation and Configuration

Step 3 From the PC connected to the camera network, use the DNA utility to discover and display

the camera’s current IP address.

a Download the DNA utility.

b Unzip the utility, then double-click to run the executable file ( DNA.exe). All the units on

the VLAN are discovered.

c For additional instructions on using DNA, refer to the DNA User’s Manual available in the

Help ( ) link while the software is running.

Click to sort

Step 4 Right-click on the camera, select Assign

IP to change the IP address or select

between static IP or DHCP addressing.

Step 5 Double-click the camera in DNA’s

Discovery List to open the camera’s web

server Login page in a web browser, or

point a web browser to the camera’s IP

address.

Step 6 Enter the default user name (admin) and

password (admin) to open the Live Video

page. Refer to Live Video Page, pg. 24.

Online manual

Select a filter

Right-click

Select IP Setup

2.3.1 Log in to the Camera Web Page

With a web browser, log in to the camera using one of three User Names: user, expert, and admin.

By default, the passwords are: user, expert, and admin, respectively.

Important Note

To prevent unauthorized access, change all of the login passwords (admin login required). For

information on how to change the passwords, refer to Basic Camera Configuration, pg. 27.

Open a web browser — Google Chrome, Mozilla Firefox, Microsoft Internet Explorer 11, or Microsoft

Edge — and enter the camera’s IP address. The login screen with a picture of the camera will

427-0089-00-12 Version 160 March 2019 23

This document does not contain any export-controlled information.

Page 24

Basic Operation and Configuration

appear. A pull-down list in the upper right allows the user to select a language option. Enter user for

the User Name and user for the Password, and click Log in.

Figure 2-1: Camera Web Page Login Screen

2.3.2 Live Video Page

The Live Video page displays a live image from the camera on the left part of the screen and at the

top of the screen menu choices: including Live Video (the red text indicates it is selected), Help, and

Log out. The expert and admin logins provide additional menu choices.

Video Source

Snapshot

Toggle Time

Figure 2-2: Live Video Web Page—FC-Series ID

427-0089-00-12 Version 160 March 2019 24

This document does not contain any export-controlled information.

Page 25

Basic Operation and Configuration

In the lower right of the web page there is a frame rate selector. This selector allows the user to

change the rate at which the frames are displayed in the browser from the default 8 fps up to 16 fps.

This rate controls the user’s own web browser only, and does not affect the video streams to other

users or to an NVR. For slow communication links, if there is a problem displaying the video image,

it may help to slow down the frame rate.

Help

The Help menu displays software version information. If it is necessary to contact FLIR Technical

Support for assistance, it will be helpful to have the information from this page on hand. For

information about the camera including hardware part numbers and serial numbers refer to the

Product Info Menu, pg. 70 (requires admin login).

Log out

Use this button to disconnect from the camera and stop the display of the video stream. If a web

session is inactive for 20 minutes, it will be stopped and it will be necessary to log in again.

Toggle PC/Camera time

Use this button to display either the PC time or the camera time.

Camera Control and Status

In the lower left of the screen are two indicator “lights”: Control and Status.

Initially the Control light is off, as in the image above, indicating the user is

not able to control the camera immediately. When multiple users are

connected to a camera, only one user at a time can issue commands to the

camera. If another user has control of the camera, the Control light is yellow.

A user is able to request control of the camera by clicking on the yellow or black “light”, or simply by

sending a command to the camera. The Status light may turn off temporarily while waiting for the

response from the camera. After a short pause, the Control light should turn green.

If a command is sent to the camera when the user does not have control, the command will not be

executed, and it is necessary to send the command again once the light is green.

In addition, when the cursor is moved over the video, a snapshot button also appears in the

upper right of the screen. After clicking the snapshot button, the video image is saved as a

jpeg file and the browser will provide prompts depending on which browser is being used.

Web Control Panel

The control buttons on the right side of the page provide a way to

control the camera in a limited number of ways. When the mouse

cursor is positioned over a button, a tool tip is displayed.

FC-Series O

427-0089-00-12 Version 160 March 2019 25

This document does not contain any export-controlled information.

Page 26

Basic Operation and Configuration

The following buttons appear for the FC-Series cameras:

Digital Zoom—FC-Series O only

These buttons zoom the camera video. The zoom state (and other camera settings)

can be saved in the IR Setup page (refer to Save Settings, pg. 49). This will allow the

camera to retain the desired zoom state (field of view) after the power is cycled.

Note

Changes to the zoom settings require all Analytic detection regions and calibrations to be updated.

Some VMS systems allow zoom setting changes on FC-Series ID cameras which will require a

recalibration of all video detection regions.

Toggle Polarity

This button changes the polarity of the assigned colors to the different temperatures in a

scene. In the black and white palette for example, hot objects are displayed as white and

cold objects as black, or vice versa.

Toggle Palette

This button causes the camera to cycle through six different look up table (LUT) color

palettes. One color palette may be preferable to the others. The Toggle Polarity button

allows access to six more palettes (refer to Misc. (Lookup Table), pg. 49).

Perform IR NUC Calibration

This button causes the camera to perform a Non-Uniformity Correction operation (refer to

Image freezes momentarily, pg. 39).

Function

The FC-Series cameras may have additional features or functions which can be accessed

using an extra numeric function keypad. When the button is selected, the keypad changes

to a numeric keypad providing programmed functions (1 - 9). Select the back arrow to return

to the main keypad. Select the forward arrow to access additional functions (10 - 18).

The available functions are specific to different camera installations. It

is possible to create customized camera functions through a “macro”

interface which can be programmed through XML commands. Contact

FLIR Technical Support for information about the Nexus XML-Based

Control Interfaces.

Test File Transfer

This button causes a request for the camera to transfer a file as determined by the settings

on the Maintenance > Sensor > File Transfer page.

427-0089-00-12 Version 160 March 2019 26

This document does not contain any export-controlled information.

Page 27

Basic Operation and Configuration

Analytics On/Off—FC-Series ID only

The FC-Series ID camera Intrusion Detection Analytics can be enabled or disabled from the

Live Video page. Detection area and tripwire alarms must be setup prior to use.

Refer to Video Analytics Setup—FC-Series ID only, pg. 49.

De-Ice On/Off—Configuration dependent

This button manually turns the lens heater on or off. The heater, when turned on manually,

will run for approximately 2 hours unless turned off either by the user (De-Ice button) or the

thermostat control. Refer to Supplemental Lens Heater, pg. 7.

2.4 Basic Camera Configuration

The following procedures describe how to do the most common bench test camera configuration

steps, such as setting the camera IP address and hostname and changing the user passwords. To

make these changes, it is necessary to login using the admin account. Additional setup and

configuration options required after the camera has been installed in its final location are described

after the basic steps are given, refer to Advanced Configuration, pg. 42.

2.4.1 Setup Menu

The Setup menu is used for GEO Settings (Latitude and Longitude location), Video setup, thermal

(IR) camera setup, and defining Video Analytics motion detection zones. For additional details, refer

to Setup Menu, pg. 42.

Adjustments to the IR settings should only be made by someone who has expertise with thermal

cameras and a thorough understanding of how the various settings affect the image. In most

installations, the only camera settings needed are available from the Web Control panel on the Live

Video page (Scene Presets, Polarity, Palettes, and AGC). Haphazard changes can lead to image

problems including a complete loss of video. Additional information is provided in Thermal Image

Setup, pg. 47.

When a user logs in as admin, a complete Maintenance menu is available (refer to Maintenance

Menu, pg. 54). The Maintenance menu also provides access to other configuration options.

427-0089-00-12 Version 160 March 2019 27

This document does not contain any export-controlled information.

Page 28

Basic Operation and Configuration

2.4.2 Server Menu

When a user logs in as expert or admin, the Maintenance Server menus are

available. When the Server menu is selected, the LAN Settings page

appears.

The basic camera configuration steps are accessed through the Maintenance

Server menu, using the menus on the left side of the page. The LAN

Settings, Services, and Security Options selections are described below.

The expert login has access to these Server pages, but can not change

passwords.

With most configuration changes through the Maintenance menu, it is

necessary to save the changes, then stop and restart the server to make the

changes take effect. When making configuration changes using the Setup

page, most of the changes take effect immediately, and it is not necessary to

start and stop the server. However it is necessary to save the changes (with

the Save Settings button at the bottom of the page) if it is desirable to use the

new settings as a default when the camera is powered on.

LAN Settings: The LAN Settings page can be used to set the hostname, default gateway, and IP address for the camera. Scroll down to see settings for Domain Name System (DNS) server and

802.1x Security.

IP Address

When set to DHCP, if the network does not have a DHCP server, the FC-Series camera will default

to an IP address of 192.168.250.116. To set the IP address using DNA, refer to Set IP Address using

the FLIR Discovery Network Assistant (DNA), pg. 22.

427-0089-00-12 Version 160 March 2019 28

This document does not contain any export-controlled information.

Page 29

Basic Operation and Configuration

When the IP address is changed and the

Save button is clicked, a pop-up message

will appear to indicate the network interface

must be restarted.

Once the IP address of the camera is

changed, the PC may no longer be on the

same network and therefore may not be

able to access the camera until the IP

address on the PC is changed also. For that

reason, it makes sense to change the IP

address after making other configuration

changes.

IEEE 802.1X Security: The 802.1x standard is designed to enhance the security of local area

networks. The standard provides an authentication framework, allowing a user to be authenticated

by a central authority. The FC-Series supports authentication using Transport Layer Security (TLS)

protocol.

Notes

The camera must be connected to a switch or other device on the network that supports

IEEE 802.1x.

The camera also supports TLS for communication with clients outside the LAN, such as

web browsers. For information about enabling and configuring TLS for communication

outside the LAN, see TLS Config, pg. 32.

Configure IEEE 802.1x authentication using TLS

Step 1 On the LAN Settings page, scroll down

to 802.1X Security.

Step 2 Select the Use 802.1x security

checkbox.

Step 3 From the Authentication drop-down

menu, select TLS.

Step 4 In the Identity text box, enter the name

associated with the client certificate.

Step 5 If uploading a PKCS #8 certificate file,

use the Browse and Upload buttons to

upload the associated CA Certificate

from the server provided by the network

administrator.

If uploading a PKCS #12 certificate file,

you do not need to upload a CA

Certificate.

427-0089-00-12 Version 160 March 2019 29

This document does not contain any export-controlled information.

Page 30

Basic Operation and Configuration

Step 6 Use the Browse and Upload buttons to upload the Client Certificate from the server

provided by the network administrator.

Step 7 Using the Browse and Upload buttons, upload the Private Key and Private Key

Password associated with the identity. The Private Key Password field can be left blank

if a password is not required.

If uploading a PKCS #8 file, the private key must be a valid PKCS #8 file.

If uploading a PKCS #12 file, the private key must be a valid PKCS #12 file.

Certificates and keys must be in PEM format. Common file extensions for TLS files in PEM format

are:

• For certificate and public key files: *.crt, *.cer, *.cert, *.pem

• For private key files: *.key

Services Menu

Date and Time: The Date and Time settings page is used to configure the date and time settings.

The date, time, and time zone can be obtained from an NTP server, or can be entered manually. If

NTP mode is selected, the NTP server information can be entered.

Toggle Server

(Stop/Start)

427-0089-00-12 Version 160 March 2019 30

This document does not contain any export-controlled information.

Page 31

Basic Operation and Configuration

If the Custom mode is selected, a pop-up window allows the information to be entered manually.

Note

The Nexus server must be stopped before making changes to the date and time settings.

Set the date and time parameters, then select the Save button at the bottom of the page. After

saving the settings, reboot the system. Refer to Server Status, pg. 35.

Msg Systems: Use the Msg Systems page to setup a connection to a mail server to send outgoing

email notifications.

If the email server is on a different network, ensure the IP default gateway and DNS servers are

configured in the LAN Settings; refer to LAN Settings, pg. 28. Configure the Msg Systems page with

mail server information and then click Save.

427-0089-00-12 Version 160 March 2019 31

This document does not contain any export-controlled information.

Page 32

Basic Operation and Configuration

Notification Lists: Use this page to setup multiple email addresses and other notifications that can

be sent as a result of alarms being processed by the Alarm Manager.

TLS Config: The settings on this page enable secure, encrypted communication between clients

and the camera; for example, when your web browser accesses the camera’s web interface.

Note

The camera also supports TLS authentication over the camera’s LAN. For information

about configuring TLS authentication for LAN communication, see IEEE 802.1X Security,

pg. 29.

By default, TLS is disabled. Before enabling it, you need to generate or upload a valid certificate.

You can:

• Use the camera web interface to generate a self-signed certificate.

• Upload a self-signed certificate and a private key.

• Upload a certificate signed by a third-party, a public key, and a private key.

Certificates and keys must be in PEM format. Common file extensions for TLS files in PEM format

are:

For certificate and public key files: *.crt, *.cer, *.cert, *.pem

For private key files: *.key

From the TLS Config page, you can also download certificates and keys previously uploaded to or generated by the camera. If the certificate saved on the camera is self-signed, you can download the

427-0089-00-12 Version 160 March 2019 32

This document does not contain any export-controlled information.

Page 33

Basic Operation and Configuration

private and public key files. If the certificate was signed by a third-party CA, you can download the

CA Certificate and the private and public key files.

To generate and install a self-signed certificate:

Step 1 Under Generate Certificate, for Method, select Self-Signed.

Step 1 Enter information such as country code, city name, and organization name.

Step 2 Scroll to the bottom of the page and click Generate Certificate.

Step 3 Allow 15 seconds for the camera to generate the certificate, at which point a confirmation

appears.

427-0089-00-12 Version 160 March 2019 33

This document does not contain any export-controlled information.

Page 34

Basic Operation and Configuration

To upload a self-signed or third-party CA signed certificate:

Step 1 For Method, select Upload

Certificates.

Step 2 If you are uploading a self-signed

certificate, under Upload Certificate,

browse for and upload the public key

file. Then, under Private Key, browse

for and upload the private key file.

If you are uploading a third-party CA

signed certificate, under Upload

Certificate, browse for and upload the

public key file. Under CA Certificate,

browse for and upload the CA

certificate file. Under Private Key,

browse for and upload the private key

file.

Step 3 Verify that the camera certificate files are valid. Make sure Certificates are OK appears

under Method.

Certificate information appears at the bottom of the TLS Config page, under Certificate

Information:

To enable and configure TLS:

Step 1 Under TLS Configuration, for Enabled, select

Yes.

Step 2 Select whether to redirect HTTP requests to

HTTPS.

Step 3 Click Save.

Step 4 Click Reboot. The camera reboots. After the camera reboots, TLS is enabled.

427-0089-00-12 Version 160 March 2019 34

This document does not contain any export-controlled information.

Page 35

Basic Operation and Configuration

Server Status: The Server Status page provides an indication of the current server status (either

running or stopped) and buttons for starting or stopping the server or for rebooting the system.

Toggle Server (Stop/Start)

After making configuration changes, it is necessary to save the changes to the server (there is a

Save button at the bottom of each configuration page). The configuration changes do not take effect

immediately. Generally, it is also necessary to stop and restart the server for the changes to become

effective. The server has a configuration that is active and running, and another configuration that is

saved (and possibly different than the running configuration).

The message at the bottom of the page indicates the

saved configuration is different than the active (running)

configuration, and it is necessary to restart the server.

It may take up to 20 seconds or more to stop the server, especially when there are multiple video

streams open. Be patient when stopping the server.

When the server is stopped and the page is refreshed, the status will show Server Stopped and the

Start button will be enabled.

Click on the Start button to restart the server, and when the page refreshes, the status will again

show Server Running. The Start button will be replaced by a Stop button when the startup procedure

has completed.

Note

If the server unexpectedly stops, it automatically and immediately restarts. After manually stopping

the server and not manually restarting it within one hour, the server automatically restarts.

Security Options: Use the Security Options page to enhance the camera’s security by:

• Restricting access through the camera web server to specific IP addresses

• Setting or changing passwords

427-0089-00-12 Version 160 March 2019 35

This document does not contain any export-controlled information.

Page 36

Basic Operation and Configuration

• Enabling the camera’s firewall and enabling or disabling specific services and their ports

• Enabling Nexus CGI digest authentication

Restrict web configuration

Add IP

address

The admin login can limit which computers have access to the web browser interface. Simply add a

computer’s IP address and click Add. After all the allowed IP addresses are entered, select the Save

button to save the changes.

Password management

To maintain security of the system, set new passwords for all of the login accounts.

• anonymous—Used for ONVIF communication.

• expert—The expert account can use the Live Video page, the camera Setup page, and the

Server pages on the Maintenance menu.

• admin—The admin account can use all pages and set passwords.

Select login

Click Edit

Enter new password

Click Save

427-0089-00-12 Version 160 March 2019 36

This document does not contain any export-controlled information.

Page 37

Basic Operation and Configuration

Note

A VMS Remote to the camera, ONVIF, or Nexus CGI, uses the same password as the web interface.

Refer to VMS Remote, pg. 57.

Firewall settings

For enhanced security, a firewall can be

enabled (by scrolling down on the Security

Select Yes

Options page).

With the firewall enabled, you can open the

following services and their default ports by

selecting Enabled:

• RTSP

• SSH

• uPnP Discovery

• Nexus SDK

• TRK Interface

Important Note

Disabling services can affect product

functionality.

Nexus CGI digest authentication

Below the firewall settings, you can enable Nexus CGI digest authentication.

Select

Digest

2.5 Thermal Imaging Overview

The thermal camera makes an image based on temperature differences. In the thermal image, by

default the hottest item in the scene appears as white and the coldest item is black, and all other

items are represented as a gray scale value between white and black.

Both thermal and daylight cameras have detectors (pixels) that detect energy. One difference

between thermal and daylight cameras has to do with where the energy comes from to create an

image. When viewing an image with a daylight camera, there has to be a source of visible light

(something hot, such as the sun or lights) that reflects light off the objects in the scene. The same is

true with human eyesight; the vast majority of what people see is based on reflected light.

427-0089-00-12 Version 160 March 2019 37

This document does not contain any export-controlled information.

Page 38

Basic Operation and Configuration

The thermal camera, on the other hand, detects energy that

is directly radiated from objects in the scene. Most objects

in typical surroundings are not hot enough to radiate visible

light, but they easily radiate energy in the portion of the

infrared spectrum that the camera can detect, the long wave

infrared (LWIR). Even very cold objects, like ice and snow,

radiate this type of energy.

This is why hot objects such as parts on an engines and

exhaust pipes appear white, while the sky, puddles of water

and other cold objects appear dark (or cool)

1

. Scenes with

familiar objects will be easy to interpret with some

experience. The camera automatically optimizes the image to provide the best contrast in most

conditions, and in some cases the Scene Presets mentioned above and other settings can be used

to further improve the image.

The performance of the camera will likely vary throughout the day. After sunset, objects warmed by

the sun will appear warmest. Early in the morning, many of these objects will appear cooler than

their surroundings, so be sure to look for subtle differences in the scene, as opposed to just hot

targets.

2.6 Maintenance and Troubleshooting Tips

If help is needed during the installation process, contact the local FLIR representative, or visit the

FLIR Support Center at: https://www.flir.com/support-center/support-hq/. FLIR Systems, Inc. offers a

comprehensive selection of training courses to help get the best performance and value from the

thermal imaging camera.

Find out more at the FLIR training web page: https://www.flir.com/support-center/training/.

Cleaning

Great care should be used with your camera's optics. They are delicate and can be damaged by

improper cleaning. The FC-Series thermal camera lenses and windows are designed for a harsh

outdoor environment and have a coating for durability and anti-reflection, but may require cleaning

occasionally. FLIR Systems, Inc. suggests that you clean the lens when image quality degradation is

noticed or excessive contaminant build-up is seen on the lens.

Note

Do not disturb or move camera during cleaning. The detection analytics on the FC-Series ID

camera are set and calibrated on the exact position and camera angle. Inadvertent realignment

may require relocation and recalibration of detection regions.

Rinse the camera housing and optics with low pressure fresh water to remove any salt deposits and

to keep it clean. If the front window of the camera gets water spots, wipe it with a clean soft cotton

cloth dampened with fresh water.

Do not use abrasive materials, such as paper or scrub brushes as this will possibly damage the lens

by scratching it. Only wipe the lens clean when you can visually see contamination on the surface.

1. By default, the camera represents hot objects as white and cold objects as black. The camera can

be set to use the Black Hot polarity setting, which displays hot objects as black and cold objects as

white and is effectively the negative of White Hot polarity. Refer to Toggle Polarity, pg. 26.

427-0089-00-12 Version 160 March 2019 38

This document does not contain any export-controlled information.

Page 39

Basic Operation and Configuration