Page 1

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all

4”

4”

safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

1. LOCATION

Indoor Use Only

FW1101

0711

Supersedes

1008

Centrifugal

Constant Pressure

Installation Guide

Insure that a proper utility ground

rod is present and connected.

Mount the Artesian Drive

unit as close as possible

to the service entrance

panel.

Service Entrance

Panel

4”

Min.

Use a dedicated branch circuit for the Artesian

Drive. Wire directly from the service entrance

panel.

Min.

Mount unit to a sturdy

supporting structure (wall or

post)

Min.

4”

Min.

Allow a 4”

clearance around

the Artesian

Drive box for

cooling

DO NOT drill

holes in the

Artesian Drive

box

Use the holes and

guides provided

IL0737

Service

Entrance Panel

DO NOT wire to a sub panel

located in a home.

It is preferable to wire directly to

the service entrance panel.

IN HOME

Sub Panel

GND

GND

Motor

GND

IL0738

2. WIRE ROUTING

Service Entrance

Panel

GND

When possible, DO NOT run

Artesian Drive input power or

motor wires in parallel with

house wiring.

Avoid runing out-building wires

in parallel with motor wires.

Inlet

Motor Pump

GND

Outlet

IL0739

Keep input power and motor

wiring separated by at least 8”.

Input power Motor

GND

Satellite /

Antenna

Wire

Motor

MOTOR

If it is necessary to run wiring in paralell, keep

Artesian Drive input power and motor wires at least

8” from other house wiring.

8” Min.

Telephone

GND

Branch 3

Branch 2

8” Min.

DO NOT run input power and

motor wires together.

Keep separated by at least 8”

GND

GND

Service

Entrance Panel

Branch 1

8” Min.

GND

8” Min.

GND

IL0740

OK

8” Min.

Service Entrance

Panel

90º

Cross over other branch

circuits and house wiring

at 90º

GND

8” Min.

GND GND

IL0741

3. GROUNDING

Insure that a

proper utility

ground rod is

present and

connected.

Service Entrance

Panel

GND.

An input power ground wire from the supply panel

must be connected to the Artesian Drive.

Outlet

Inlet

A dedicated ouput ground

wire from the Artesian

Drive must be connected

to the motor (motor wires

and ground wires must be

bundled together).

Inlet

Motor

GND.

IL0742

Outlet

Pump

Service Entrance

Panel

Use the service

entrance panel

ground ONLY

GND.

ground wire separate.

Motor ground wire MUST be

bundled with motor wires.

GND.

DO NOT run

Inlet

Motor Pump

Outlet

IL0743

Service Entrance

Panel

GND.

GND.

GND.

GND.

Inlet

Motor

Outlet

Pump

Power to

Motor

Power Supply from Circuit

Breaker

Motor

IL0783

GND.

Avoid multiple ground paths

IL0744

022688

Page 2

L1

L2

L3

U

V

W

PEPE

IL0731

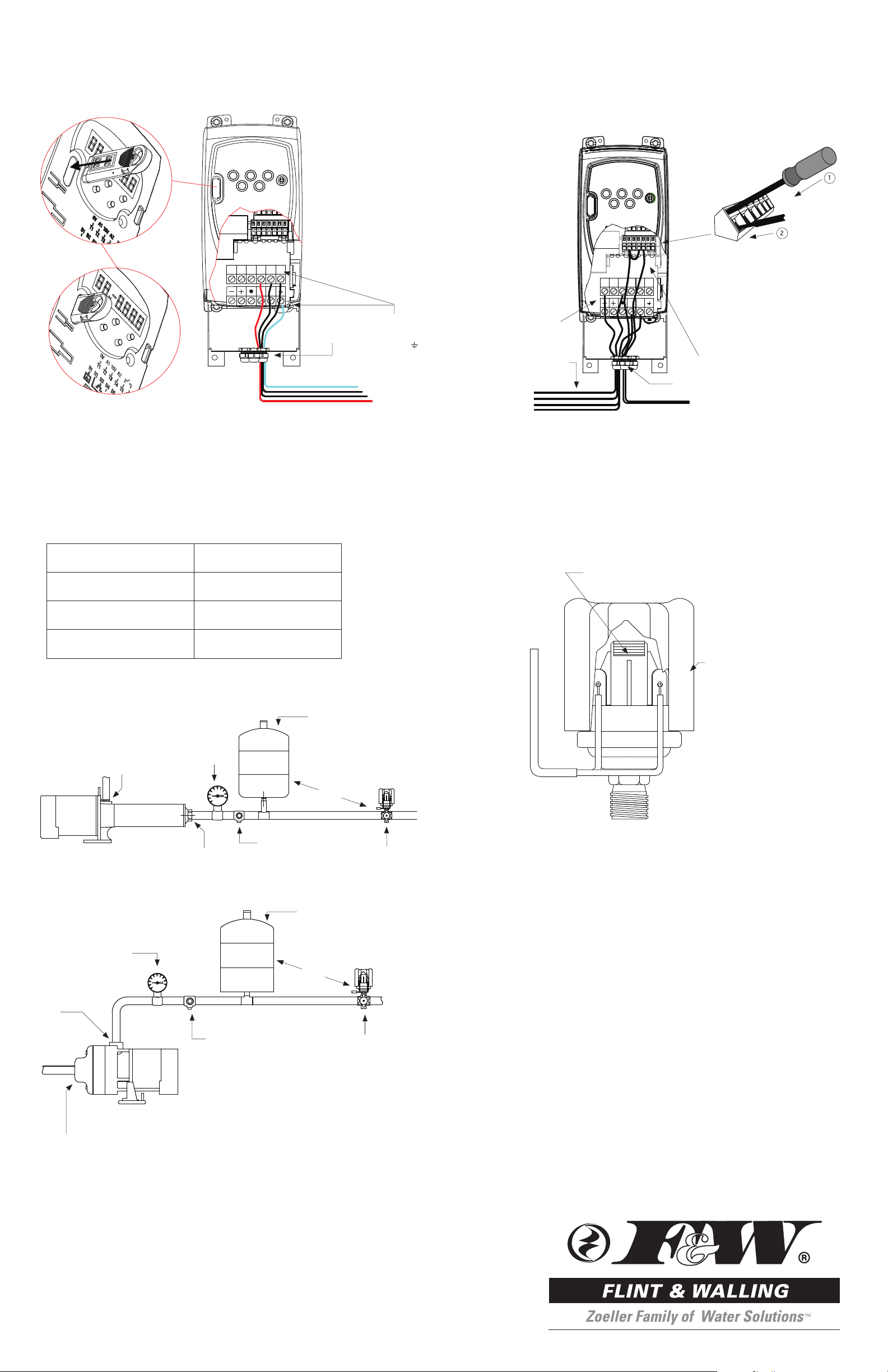

4. WIRING

2

1

MOTOR LEADS

GND

GND

Feed motor leads

through the strain

relief (right side)

Connect

them to the

terminal block

U, V, W &

Output to

Motor

Connect them to the terminal

block marked L1, L3 & PE*.

*PE = Earth Potential (Ground)

Feed the 230V power leads through

the strain relief (left side).

Power Terminal

Connections

POWER AND PRESSURE

SENSOR LEADS

B2

B5

B4

L1 L2 L3 U V W

PE

PE

GND

Feed the pressure sensor wire through the strain

relief (center).

Pressure

Sensor Leads

Connect them to the terminal block “B2”

and “B5”.

IL0732

5. PLUMBING

TABLE 2: MINIMUM PRESSURE TANK

Rated Pump Flow Pressure Tank Size (Total

Volume)

Pump Capacity less than 12

GPM

Pump Capacity greater than

12 but less than 25 GPM

Pump Capacity greater than

25 GPM

The pressure tank pre-charge setting should be 70% of the

system pressure sensor setting.

Inlet

Motor

Pump

Outlet

4 Gallon (AT15)

8 Gallon (AT25)

14 Gallon (AT44)

Pressure

Gauge

Pressure Tank

Pressure

Relief

Required

Tank Precharge 70% of

system pressure

(i.e. 30 PSI for 50 PSI system)

6 ft.

max.

Pressure switch locate

on the house side of

the tank

IL0745

Position sensor with

threaded connection down.

Remove rubber end cap to

adjust pressure with 7/32”

Allen Wrench

Pressure Sensor

Turn clockwise to increase pressure setting.

Turn counterclockwise to decrease pressure

setting.

1/4 turn = 3 PSI

Factory preset to 50 PSI

Pressure Sensor

Boot

IL0730

Outlet

Inlet

Pump

Pressure

Gauge

Motor

Tank Precharge 70% of

system pressure

(i.e. 30 PSI for 50 PSI system)

Pressure Tank

6 ft.

max.

Pressure Relief Valve

Required

Tech Support

Pressure switch locate

on the house side of

the tank

IL1205

®

Toll Free Help Line

1-800-742-5044

Loading...

Loading...