Flight Medical Innovations 60 Series, 60 SL, 60 DL, 60 iO2, FLIGHT 60T Series Service Manual

...

FLIGHT MEDICAL INNOVATIONS Ltd.

FLIGHT 60 VENTILATOR

Service Manual

Models: SL; DL; iO2

LIT-0021 Rev. A12 Aug 2016

TABLE OF CONTENTS

FLIGHT 60 Ventilator II

Legal Notice

ii | FLIGHT 60 Service Manual

Legal Notice

Disclaimer

FLIGHT MEDICAL INNOVATIONS Ltd. (FLIGHT MEDICAL) provides this Service Manual

in its commitment to help reduce patient risk and injury. However, this manual is not

intended to in any way replace or substitute duty of care to a patient, professional

responsibility, or professional judgment, nor is it intended to provide any warranty,

promise, guarantee, assumption of risk or duty, release, or indemnity. Physicians

shall at all times maintain responsibility for patient treatment and outcomes, and

FLIGHT MEDICAL further assumes no liability for patient treatment or outcome or for

physician's negligence, breach of duty of care, or malpractice.

The FLIGHT 60 Ventilator operator is solely responsible for selecting the appropriate

level and method of patient monitoring.

Product modification or misuse can be dangerous. FLIGHT MEDICAL disclaims all

liability for the consequences of product alterations or modifications, as well as for the

consequences which might result from the combination of this ventilator with other

products, whether supplied by FLIGHT MEDICAL or by other manufacturers, unless

such a combination has been specifically endorsed by FLIGHT MEDICAL.

The design of FLIGHT 60 Ventilator, the Operator’s and Service Manuals, and the

labeling on the ventilator, take into consideration that the purchase and use of the

equipment is restricted to trained professionals, and that certain inherent

characteristics of the ventilator are known to the operator. Instructions, warnings,

and caution statements are therefore limited to the specifics of the FLIGHT 60

Ventilator.

Federal law (US) restricts this device to sale by or on the order of a physician.

This Operator’s Manual excludes references to various hazards which are obvious to

medical professionals and operators of this equipment, to the consequences of

product misuse, and to potential adverse effects in patients with abnormal conditions.

When the FLIGHT 60 Ventilator is used in homecare and subacute environments, only

properly trained personnel should operate the ventilator. The FLIGHT 60 Ventilator is

a restricted medical device designed for use by respiratory therapists or other

properly trained and qualified personnel under the direction of a physician and in

accordance with applicable state laws and regulations.

Transport of patients with the FLIGHT 60 Ventilator requires that medical staff have a

good working knowledge of the ventilator’s use and problem resolution. Proper

emergency backup equipment must be immediately available during transport.

FLIGHT 60 Ventilator operators must recognize their responsibility for implementing

safety monitoring mechanisms which supply appropriate information on equipment

performance and patient condition. Patient safety may be achieved through a wide

variety of means, such as electronic surveillance of equipment performance and

Legal Notice

Flight 60 Service Manual | iii

patient condition. However, equipment surveillance should not replace direct

observation of clinical signs.

The liability of FLIGHT MEDICAL is subject to and limited to the exclusive terms and

conditions as set forth herein. Said liability is limited whether arising out of, or related

to, the manufacture and sale of goods, their installation, demonstration, sales

representation, use, performance, or otherwise. Any liability based upon product

warranty is limited regardless of any fault attributable to FLIGHT MEDICAL and the

nature of the action (including breach of warranty, negligence, and strict liability).

The written warranties are in lieu of all other warranties, expressed or implied,

including, without limitation, warranties of merchantability, fitness for any purpose, or

non-infringement.

FLIGHT MEDICAL shall not be liable for any special incidental or consequential

damages incurred by the buyer to a third party. The buyer shall not be entitled to

make liability recoveries from FLIGHT MEDICAL due to such situations.

Warranty

The FLIGHT 60 Ventilator warranty does not apply for/ in case of:

Defects caused by misuse, mishandling, tampering, or by modifications not

authorized by FLIGHT MEDICAL or its representatives.

Rubber and plastic components and materials, which are guaranteed to be free of

defects at time of delivery.

Any product which proves during the warranty period to be defective in workmanship

or material, will be replaced, credited, or repaired. FLIGHT MEDICAL retains the

discretion to select the most suitable of these options. FLIGHT MEDICAL is not

responsible for deterioration, wear, or abuse. In all cases, FLIGHT MEDICAL will not

be liable beyond the original selling price.

Application of this warranty is subject to the following conditions:

FLIGHT MEDICAL or its authorized representatives must be promptly notified

upon detection of the defective material or equipment.

Defective material or equipment must be returned to FLIGHT MEDICAL or its

authorized representative.

Examination by FLIGHT MEDICAL or its authorized representatives must confirm

that the defect is covered by the terms of this warranty.

To ensure complete protection under this warranty, the Warranty Registration Card

must be returned to a FLIGHT MEDICAL authorized representative within ten (10)

days of equipment receipt.

The above is the sole warranty provided by FLIGHT MEDICAL. No other warranty,

expressed or implied, is intended. Representatives of FLIGHT MEDICAL are not

authorized to modify the terms of this warranty.

In no way does this or any of FLIGHT MEDICAL policies, training materials, guidelines,

or instructions create an obligation for FLIGHT MEDICAL to perform any services.

About this Document

iv | FLIGHT 60 Service Manual

About this Document

This document is a service manual for the FLIGHT 60 and F60 Dual Limb Ventilators,

ventilators that provide continuous or intermittent mechanical ventilation support for

the care of individuals who require mechanical ventilation. It is intended for

technicians who are responsible for maintaining, servicing, and providing

troubleshooting assistance for the FLIGHT 60 and F60 Dual Limb Ventilators.

For information on how to use the FLIGHT 60 Ventilator, see the FLIGHT 60

Ventilator Operator's Manual.

Style Conventions

Convention

Used for

Verdana

Regular text.

Arial Bold

Names of labels, buttons, and other elements of the user interface.

Arial Italics

Special terms, the first time they appear.

Notes, which offer an additional explanation or a hint on how to overcome a

common problem.

Warnings, which indicate potentially damaging user operations and explain

how to avoid them.

Table of Contents

Flight 60 Service Manual | v

Table of Contents

1 INTRODUCTION ................................................................................. 1-1

INTENDED USE ................................................................................ 1-1

SYMBOLS ....................................................................................... 1-1

2 SAFETY INSTRUCTIONS ..................................................................... 2-1

GENERAL WARNINGS ......................................................................... 2-1

CAUTIONS ...................................................................................... 2-3

3 FUNCTIONAL DESCRIPTION ............................................................... 3-1

FRONT PANEL .................................................................................. 3-1

3.1.1 Keypad / Control Buttons ..................................................... 3-2

3.1.2 LED Indicators .................................................................... 3-3

LEFT SIDE PANEL .............................................................................. 3-4

RIGHT SIDE PANEL............................................................................ 3-5

BACK PANEL ................................................................................... 3-6

REMOTE ALARM CONNECTION ............................................................... 3-8

VENTILATOR MODULES ....................................................................... 3-9

VENTILATOR MODULES – IO

2

INTERNAL MIXER MODEL .................................. 3-10

PNEUMATIC DIAGRAM ....................................................................... 3-11

PNEUMATIC DIAGRAM – IO

2

INTERNAL MIXER MODEL ................................... 3-12

ELECTRICAL DIAGRAM ....................................................................... 3-13

ELECTRICAL DIAGRAM – IO

2

INTERNAL MIXER MODEL .................................. 3-14

4 REMOVING AND REINSTALLING MODULES ........................................ 4-1

INTRODUCTION ................................................................................ 4-1

REQUIRED EQUIPMENT ....................................................................... 4-1

REPLACING THE DETACHABLE BATTERY .................................................... 4-2

4.3.1 Removing the Detachable Battery ......................................... 4-2

4.3.2 Installing the Detachable Battery .......................................... 4-2

REPLACING THE INTERNAL BATTERY ........................................................ 4-2

4.4.1 Removing the Internal Battery .............................................. 4-2

4.4.2 Installing the Internal Battery ............................................... 4-3

REMOVING THE VENTILATOR COVER ........................................................ 4-3

4.5.1 Removing the Ventilator Cover ............................................. 4-3

4.5.2 Installing the Ventilator Cover .............................................. 4-6

REPLACING THE POWER BOARD ............................................................. 4-6

4.6.1 Removing the Power Board .................................................. 4-6

4.6.2 Installing the Power Board ................................................... 4-9

Table of Contents

vi | FLIGHT 60 Service Manual

REPLACING THE POWER SUPPLY ............................................................ 4-10

4.7.1 Class I Power Supply .......................................................... 4-10

4.7.2 Class II Power Supply ......................................................... 4-13

REPLACING THE FRONT PANEL ASSEMBLY ................................................ 4-14

4.8.1 Removing the Front Panel Assembly ..................................... 4-14

4.8.2 Connecting the Front Panel Assembly ................................... 4-17

REPLACING THE O

2

MIXER NEB BOARD * (IO2 INTERNAL MIXER MODEL ONLY) ...... 4-17

4.9.1 Removing the O2 mixer neb board ........................................ 4-17

4.9.2 Installing the O2 mixer board ............................................... 4-17

REPLACING THE MAIN BOARD .............................................................. 4-18

4.10.1 Removing the Main Board ................................................... 4-18

4.10.2 Installing the Main Board .................................................... 4-21

REPLACING THE TOUCH SCREEN ........................................................... 4-21

REPLACING THE MANIFOLD ASSEMBLY .................................................... 4-22

4.12.1 Removing the Manifold Assembly ......................................... 4-22

4.12.2 Installing the Manifold Assembly .......................................... 4-26

REPLACING THE OXYGEN SENSOR ......................................................... 4-27

4.13.1 Removing the Oxygen Sensor .............................................. 4-27

4.13.2 Installing the Oxygen Sensor ............................................... 4-28

REPLACING THE O

2

LEAK SENSOR * (IO2 INTERNAL MIXER MODEL ONLY) ............ 4-28

4.14.1 Removing the O2 leak sensor ............................................... 4-28

4.14.2 Installing the O2 leak sensor ................................................ 4-28

REPLACING THE OXYGEN MIXER * (IO

2

INTERNAL MIXER MODEL ONLY) .............. 4-29

4.15.1 Removing the Oxygen mixer ............................................... 4-29

4.15.2 Installing the Oxygen mixer ................................................ 4-30

REPLACING THE O

2

MIXER FILTERS * (IO

2

INTERNAL MIXER MODEL ONLY)........... 4-31

REPLACING THE PURGE BOARD ASSEMBLY ............................................... 4-31

4.17.1 Removing the Purge Board Assembly.................................... 4-31

4.17.2 Installing the Purge Board Assembly .................................... 4-32

REPLACING THE SOLENOID BOARD ASSEMBLY ........................................... 4-32

4.18.1 Removing the Solenoid Board Assembly ................................ 4-32

4.18.2 Installing the Solenoid Board Assembly................................. 4-33

REPLACING THE SOLENOID ASSEMBLY .................................................... 4-34

4.19.1 Removing the Solenoid Assembly ......................................... 4-34

4.19.2 Installing the Solenoid Assembly .......................................... 4-36

REPLACING THE LOWER BOARD AND D-TYPE BOARD .................................... 4-36

4.20.1 Removing the Lower Board and D-type Board ........................ 4-36

4.20.2 Installing the Lower Board and D-type Board ......................... 4-38

REPLACING THE FUSE ........................................................................ 4-39

Table of Contents

Flight 60 Service Manual | vii

4.21.1 Removing the Fuse............................................................. 4-39

4.21.2 Installing the Fuse ............................................................. 4-39

REPLACING THE RUBBER BUMPERS ........................................................ 4-40

4.22.1 Removing the Rubber Bumpers ............................................ 4-40

4.22.2 Installing the Rubber Bumpers ............................................. 4-40

5 SERVICE/TECHNICAL MENU............................................................... 5-1

ADVANCED SCREEN ........................................................................... 5-1

SERVICE SCREEN .............................................................................. 5-2

6 SOFTWARE UPGRADE ......................................................................... 6-4

INSTALLING THE SW UPGRADE .............................................................. 6-4

CALIBRATION INTEGRITY CHECK ............................................................. 6-4

7 CALIBRATION AND VERIFICATION TESTS ......................................... 7-6

REQUIRED EQUIPMENT ............................................................................... 7-6

CALIBRATION .................................................................................. 7-6

7.1.1 Pressure Relief Calibration .................................................... 7-6

7.1.2 Pressure Sensors Calibration ................................................ 7-7

7.1.3 Volume Factor Calibration ................................................... 7-10

7.1.4 Oxygen Sensor Calibration .................................................. 7-11

7.1.5 O2 Leak Sensor calibration* (iO2 Internal mixer model only) .... 7-12

OPERATIONAL VERIFICATION PROCEDURE (OVP) ....................................... 7-13

7.2.1 Standard Ventilator Settings (STS) ....................................... 7-13

7.2.2 Front Panel Self Test .......................................................... 7-13

7.2.3 Circuit Test ....................................................................... 7-14

7.2.4 Volume verification ............................................................ 7-15

7.2.5 Pressure Verification ........................................................... 7-15

7.2.6 PEEP ................................................................................ 7-16

7.2.7 Pressure Trigger ................................................................ 7-17

7.2.8 Exhalation Valve Leak ......................................................... 7-18

7.2.9 High Pressure Alarm ........................................................... 7-19

7.2.10 Battery /Charger /Power Supply .......................................... 7-19

7.2.11 Inlet Leak ......................................................................... 7-20

7.2.12 Buzzer Test ....................................................................... 7-21

7.2.13 Oxygen Calibration Test ...................................................... 7-21

7.2.14 Nebulizer compensation test * (iO2 Internal mixer model only) 7-22

7.2.15 OVP Test Results ................................................................ 7-23

TEST TABLE ................................................................................... 7-24

8 MAINTENANCE ................................................................................... 8-1

SCHEDULED MAINTENANCE ................................................................... 8-1

DOWNLOAD LOG FILES ....................................................................... 8-1

9 TROUBLESHOOTING GUIDE ............................................................... 9-3

Table of Contents

viii | FLIGHT 60 Service Manual

INTRODUCTION ................................................................................ 9-3

ERROR MESSAGES ............................................................................ 9-3

10 REPACKAGING AND SHIPPING ........................................................ 10-1

RGA RETURNS ....................................................................................... 10-1

11 SPARE PARTS ................................................................................... 11-2

ELECTRONIC .................................................................................. 11-2

MECHANICAL / ASSEMBLIES ................................................................ 11-5

CABLES ........................................................................................ 11-8

Introduction

Intended Use

Flight 60 Service Manual | 1-1

1 Introduction

This Service Manual (V60-00002-18 Rev. A) provides information for servicing the

FLIGHT 60 Ventilator. It is for use by authorized service personnel while installing,

servicing, and repairing the ventilator.

Intended Use

The FLIGHT 60 Ventilator is intended to provide continuous or intermittent

mechanical ventilation support for the care of individuals who require mechanical

ventilation. Specifically, the FLIGHT 60 Ventilator is applicable for adult and pediatric

patients, greater than or equal to 10 kg (22 lbs).

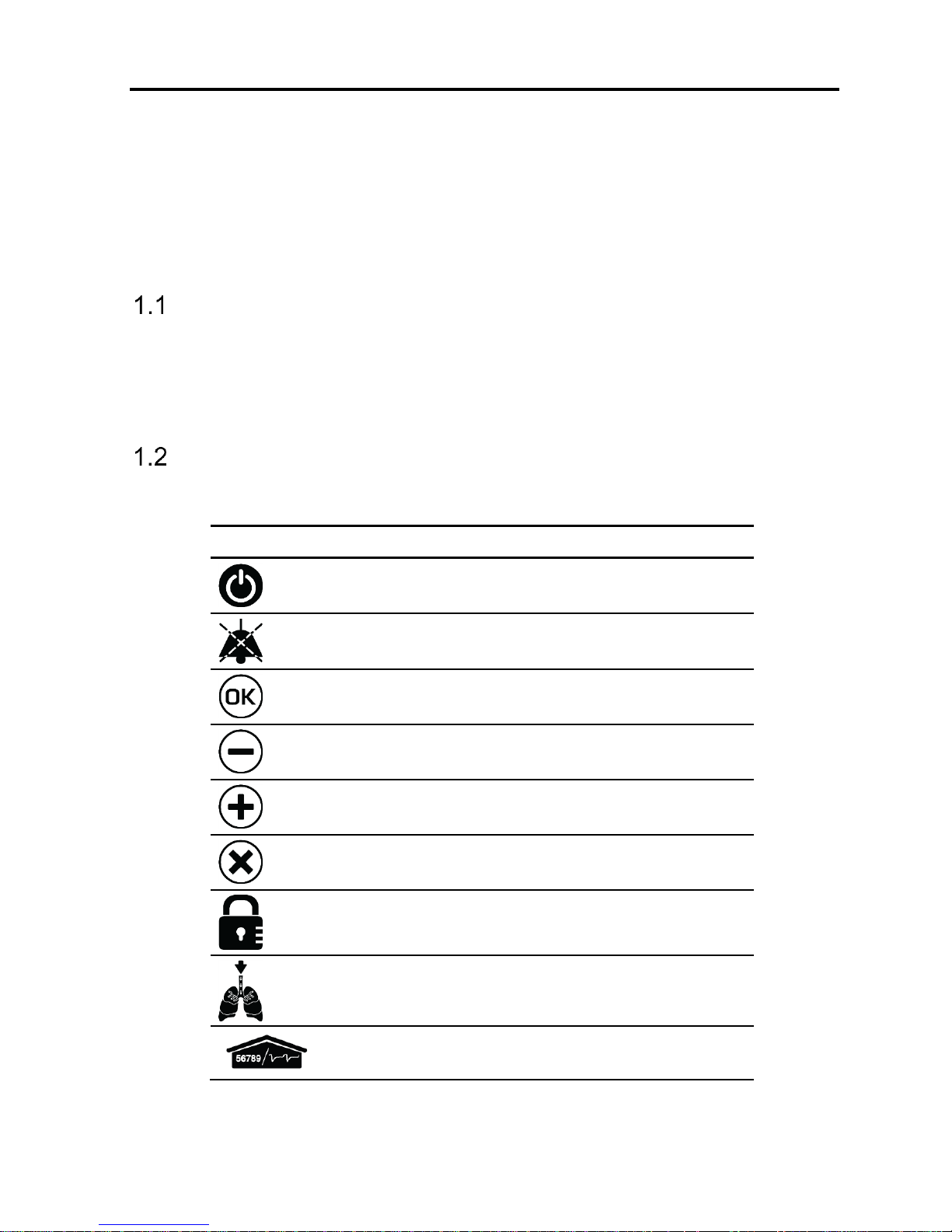

Symbols

Symbol

Description

Front Panel

On/Off

Alarm Reset

OK (Enter)

Decrease Button

Increase Button

Cancel

Panel Lock

Manual Breath

Parameters Screen

Introduction

Symbols

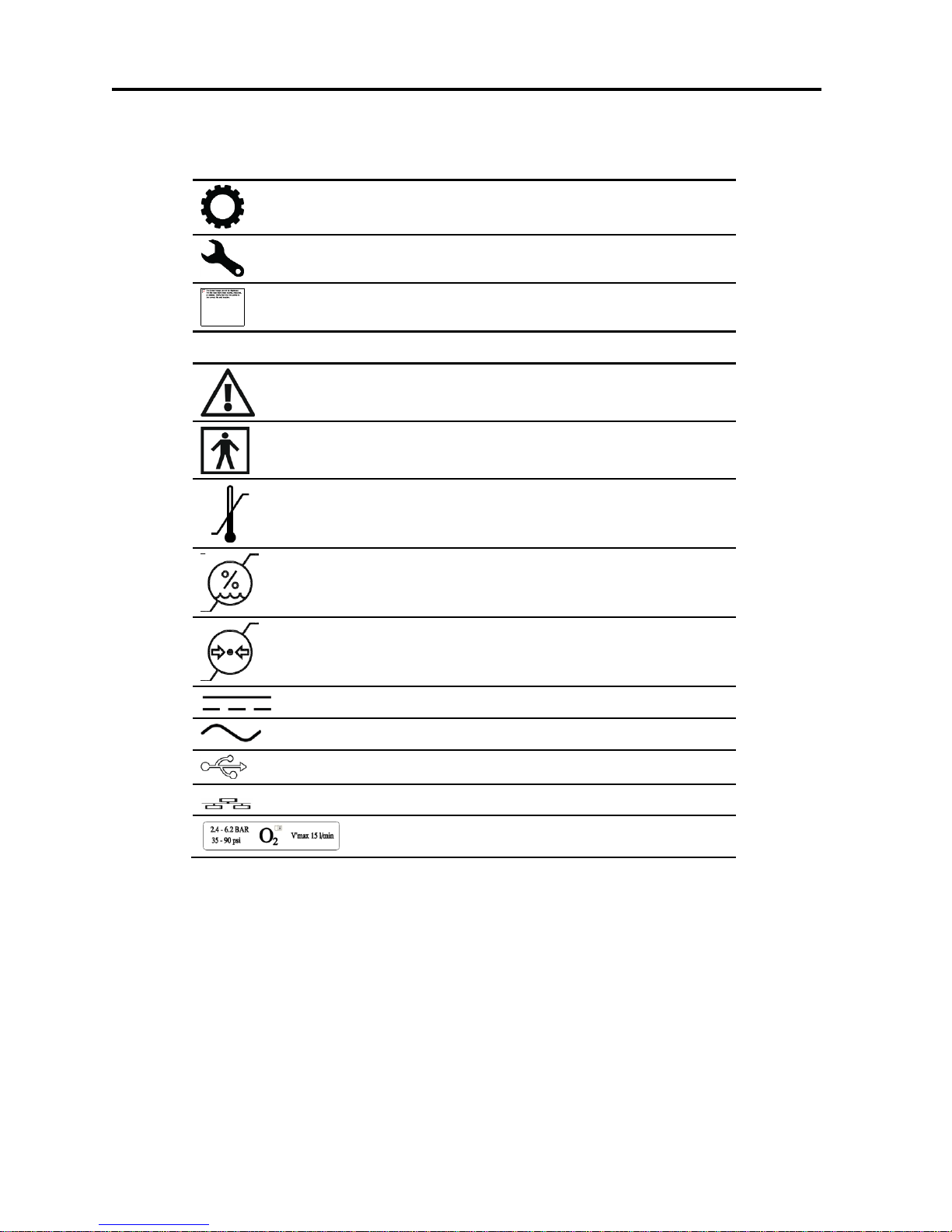

1-2 | FLIGHT 60 Service Manual

Symbol

Description

Extended Screen

Technical Screen

Nebulizer Port

Rear Panel

Caution; consult accompanying documents

Type BF applied part

Temperature limitation

Humidity limitation

Atmospheric pressure limitation

DC – Direct Current

AC – Alternating Current

USB – Universal Serial Bus

LAN – Local Area Network

High Pressure and Low-Flow Oxygen Port

Safety Instructions

General Warnings

Flight 60 Service Manual | 2-1

2 Safety Instructions

At all times, strictly follow this manual. The safe use of the FLIGHT 60 Ventilator

requires full understanding of its operation, and adherence to the manual's

instructions. The equipment is only to be used for the purpose specified in

section 1.1. Observe all of the WARNINGS and CAUTIONS posted in this manual, and

on buttons found on the FLIGHT 60 Ventilator and associated accessories.

General Warnings

External power connection: To maintain grounding integrity when using AC

power, only connect to grounded receptacles. Always disconnect the external

power prior to servicing. There is a risk of explosion if used in the presence of

flammable anesthetics.

All settings and adjustments in the different ventilation modes must be made

in accordance with a physician's prescribed therapy.

Do not use electrically conductive patient circuits.

Always use a clean, disinfected patient circuit.

Always use an outlet filter or equivalent at the Airway Pressure Connector, to

protect the internal sensors from moisture and other contaminants.

The ventilator is ready for operation only when:

1. It is completely assembled.

2. The OVP has been successfully completed.

Failure to identify and correct alarm violations may result in patient injury.

Safety Instructions

General Warnings

2-2 | FLIGHT 60 Service Manual

Ensure that the oxygen source is not empty before and during the use of the

optional Air/Oxygen Entrainment Mixer or Oxygen Blending Bag Kit.

As Li-Ion batteries are charged and discharged over time, their ability to hold a

charge is decreased with use. This can shorten the amount of time the

ventilator can function while on battery power.

The batteries should be replaced when the batteries no longer meet the needs

of the user. This depends on a number of factors including settings and usage

patterns.

Charge the batteries for a minimum of three hours before powering the

ventilator from the batteries. This provides fully charged batteries.

During storage, charge the batteries for a minimum of three hours every 30

days. This provides charged batteries.

Always ensure that the green Ext. Power LED is illuminated after connecting

the FLIGHT 60 Ventilator to an external AC or DC power source. If the LED is

not illuminated, check all power connections and resolve any problems.

Always plug the FLIGHT 60 Ventilator into an AC power supply source when not

in use, to ensure best battery performance.

The flow resistance of the air inlet filter, located on the right side of the

ventilator, is likely to increase with repeated use. Ensure that the filter is

changed regularly.

Only a FLIGHT MEDICAL approved patient circuit can be used with the FLIGHT

60 Ventilator.

Safety Instructions

Cautions

Flight 60 Service Manual | 2-3

Only a FLIGHT MEDICAL approved exhalation valve can be used with the

FLIGHT 60 Ventilator.

Perform a Circuit Test each time a clean circuit/exhalation valve is installed.

This FLIGHT 60 Ventilator has been tested and found to comply with the EMC

limits according to the EN60601-1-1-2 standard class B. These limits are

designed to provide reasonable protection against harmful interference in a

typical medical installation. The equipment generates uses and can radiate

radio frequency energy and, if not installed and used in accordance with these

instructions, may cause harmful interference to other devices in the vicinity.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference with other

devices, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving device.

Increase the distance between the equipment.

Connect the equipment into an outlet on a circuit different from that to which

the device (s) is connected.

Consult the manufacturer for help.

Cautions

Only use medical grade oxygen with the Air/Oxygen Entrainment Mixer or

Oxygen Blending Bag Kit.

Do not place liquid containers in the immediate vicinity or on top of the FLIGHT

60 Ventilator. Liquids that get into the ventilator can cause equipment

malfunction and damage.

After the FLIGHT 60 Ventilator is serviced, it must completely pass an

Operational Verification Procedure (OVP) before being returned to patient use.

Safety Instructions

Cautions

2-4 | FLIGHT 60 Service Manual

An authorized FLIGHT MEDICAL factory-trained technician must do all service

or repairs performed on the FLIGHT 60 Ventilator.

Do not open the ventilator or perform service on an open unit while connected

to external power.

Use standard antistatic techniques while working inside the ventilator or

handling any electronic parts.

Clean all external accessories of the ventilator prior to servicing.

Water in the oxygen supply can cause equipment malfunction and damage.

Batteries contain Li-Ion. Do not discard them in an incinerator or force them

open. Batteries should not be disposed of with normal waste.

Use the tools and equipment specified in this manual to perform specific

procedures.

Functional Description

Front Panel

Flight 60 Service Manual | 3-1

3 Functional Description

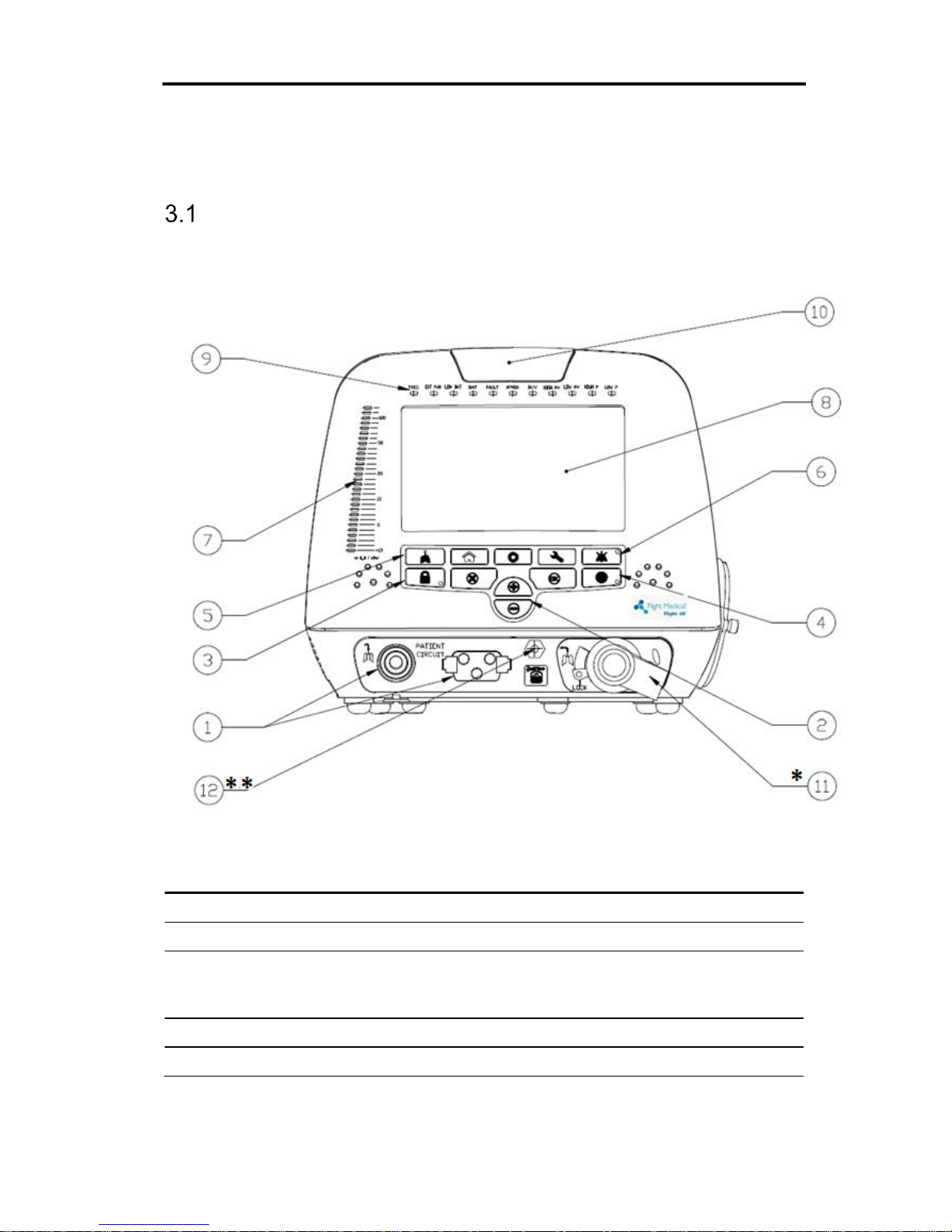

Front Panel

The front panel contains the control buttons, visual indicators, display screen, and

patient circuit connection. There are 2 types of keypad – symbols or print.

Figure 1 – Front Panel

Label

Name

Description

1

Patient Circuit Connector

Composed of a gas outlet and quick connector.

2

+/- button

Enables the user to adjust setting parameters.

3

Panel Lock button

Enables the user to lock the ventilator’s control, preventing

accidental changes. Pressing the button of a locked panel

and then Enter, unlocks the panel.

4

On/Off button

Turns the ventilator on or off, to start or stop ventilation.

5

Manual Breath button

Delivers a user initiated manual inflation.

Functional Description

Front Panel

3-2 | FLIGHT 60 Service Manual

Label

Name

Description

6

Audio Paused / Alarm Reset

button

Toggle button. Pressing Audio Paused temporarily silences

the audible alarm; pressing Alarm Reset clears lit alarm

LEDs.

7

Pressure Gauge

The pressure gauge is a visual indicator of breath activity,

which shows the dynamic movements of the breath

pressures. When a breath is being delivered, the user can

see the relative pressure and phase of the breath

(inspiration or expiration).

The pressure gauge is comprised of 29 LEDs. From -10 to

+20 cmH2O, each notch equals 2 cmH2O; from 20 to

50 cmH2O, each notch equals 5 cmH2O; above 50 cmH2O,

each notch equals 10 cmH2O.

8

Display touch screen

Enables the user to modify the ventilation, alarm, and

technical settings, and to view real time patient data,

alarms, battery status and logs.

9

LED Indicators

Inform the user of various events.

10

Primary Alarm LED

Flashes red to indicate that there is a high priority alarm.

11*

Dual Limb Exhalation Valve

(DL model only)

Connects the patient circuit expiratory limb.

12**

Nebulizer Port (iO2 Internal

mixer model only)

Connects to the pneumatic nebulizer.

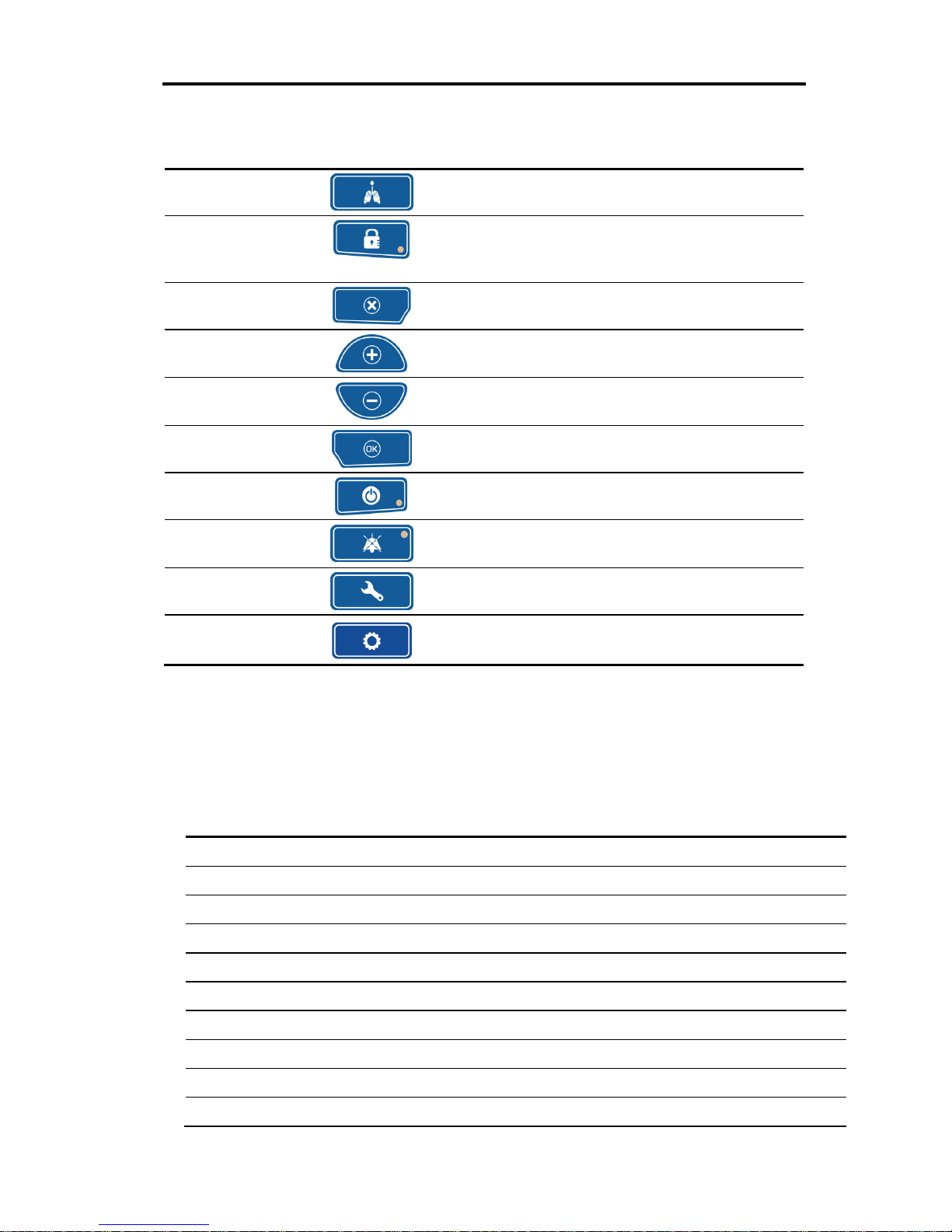

3.1.1 Keypad / Control Buttons

Figure 2 – Keypad / Control buttons

Item

Symbol

Description

1 – Parameters

(home)

The Parameters screen is the Flight 60's default screen.

Display switches automatically to Parameters from the

other screens if not operated for 30 seconds.

Use the Parameters button to toggle between the numeric

and the graphic displays.

Functional Description

Front Panel

Flight 60 Service Manual | 3-3

Item

Symbol

Description

2 - Manual Breath

Delivers a user initiated manual inflation.

3 – Panel Lock

Enables the user to lock the ventilator’s control,

preventing accidental changes. Pressing the button of a

locked panel and then Enter, unlocks the panel.

4 – Cancel

Enable the user to cancel parameters change.

5 – Increase

Button

Enables the user to adjust setting parameters upwards.

6 – Decrease

Button

Enables the user to adjust setting parameters

downwards.

7 – OK (Enter)

Enable the user to confirm parameters or mode change.

8 – On/Off

Turns the ventilator on or off, to start or stop ventilation.

9 – Alarm Reset

The Alarm Reset silences the audible alarm and clears lit

alarm LEDs.

10 – Technical

Technical data and selection options.

11 – Extended

Additional ventilation parameters screen.

3.1.2 LED Indicators

The LED indicators on the front panel inform the user of various events.

The following table describes the available LED indicators.

LED Indicator

Description

TRIG

Green LED indicates a patient’s breathing effort.

EXT PWR

Yellow LED indicates that an external power source is being applied to the ventilator.

LOW BAT

Red LED indicates that total batteries charge level is below 50%.

BAT

Orange LED indicates that the ventilator is powered on batteries.

FAULT

Red LED indicates a ventilator malfunction.

APNEA

Red LED indicates that no breaths have been delivered for the preset APNEA interval.

BUV

Red LED indicates that backup ventilation is active.

HIGH MV

Red LED indicates that the high inspiratory minute volume alarm limit is being violated.

LOW MV

Red LED indicates that the low inspiratory minute volume alarm limit is being violated.

HIGH P

Red LED indicates that the high peak airway pressure alarm limit is being violated.

Functional Description

Left Side Panel

3-4 | FLIGHT 60 Service Manual

LED Indicator

Description

LOW P

Red LED indicates low peak airway pressure.

Left Side Panel

Figure 3 – Left Side Panel

Label

Name

Description

1

Emergency Air Intake

Enables the patient to pull ambient air into the patient circuit in the

event of a complete system failure. The Air Intake opening pressure

is approximately -3 cmH2O (-3 mbar).

Functional Description

Right Side Panel

Flight 60 Service Manual | 3-5

Right Side Panel

Figure 4 - Right Side Panel

Label

Name

Description

1

Fresh Gas Intake and

Filter Cover

Environmental air enters through this 30 mm ID Fresh Gas Intake.

The air inlet particle filter is placed behind the Filter Cover to protect

the patient as well as the ventilator’s piston system from dirt and

particles. The Fresh Gas Intake also serves as the attachment socket

for the optional FLIGHT 60 Ventilator Air/Oxygen Entrainment Mixer

or Oxygen Blending Bag.

Functional Description

Back Panel

3-6 | FLIGHT 60 Service Manual

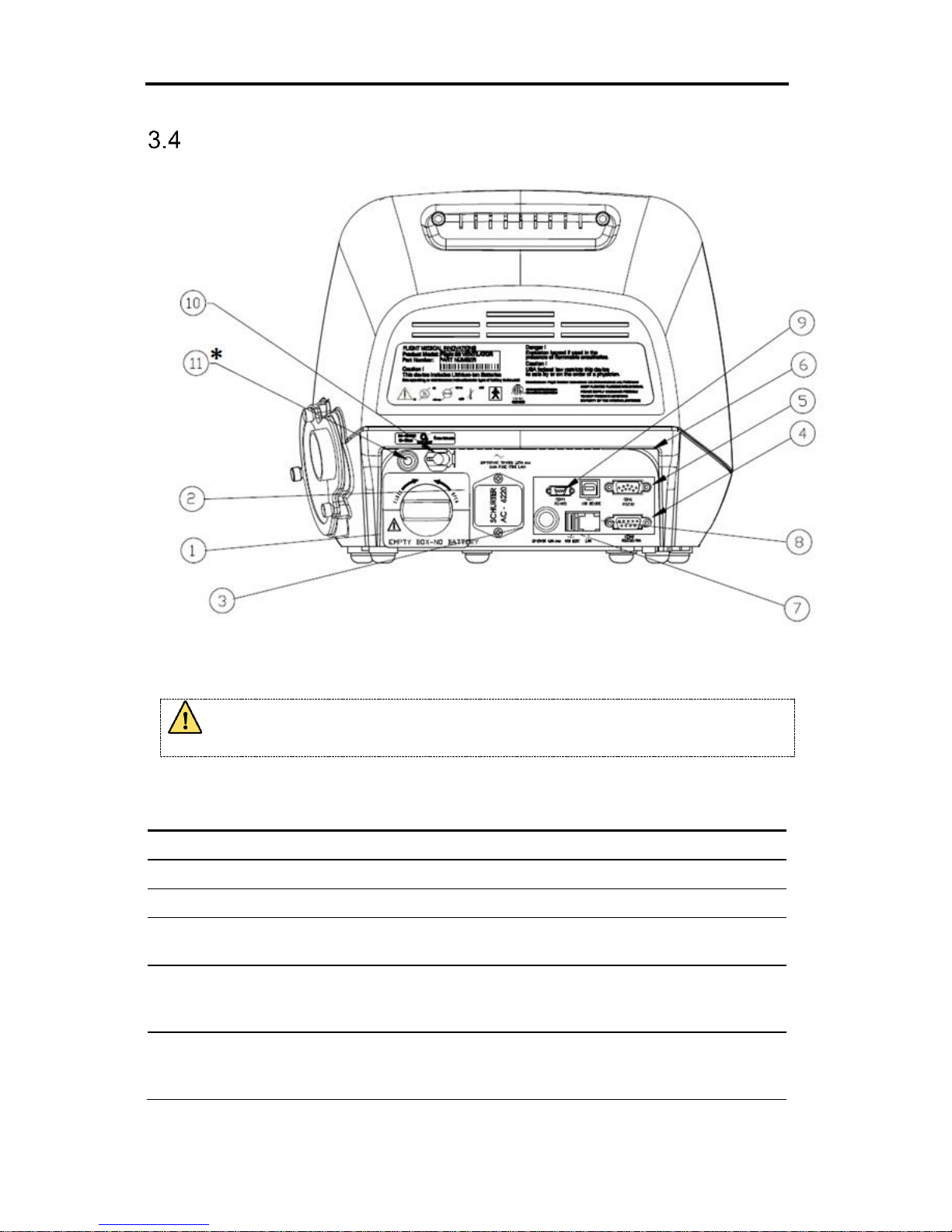

Back Panel

Figure 5 – Back Panel

To ensure proper grounding and prevent possible shock hazards, this device

should only be connected to grounded power receptacles.

Label

Name

Description

1

Detachable Battery

Li-Ion 14.8 VDC

2

AC Connector with Fuses

100 – 240 V AC, 50 – 60 Hz, Fuses 2x8A (time lag)

3

DC Connector

12 – 15 V DC

4

RS-232 Serial Port (COM2)

Remote alarm connector (Normally Open and Normally

Closed options).

5

RS-232 Serial Port (COM1)

Online output of events and error messages to the PC, using

a dedicated PCS2 protocol; for authorized and qualified

service technicians only.

6

USB B type

PC connector: USB port for downloading the main application

from the PC using a dedicated PCS2 protocol; for authorized

and qualified service technicians only.

Functional Description

Flight 60 Service Manual | 3-7

Label

Name

Description

7

USB A type

USB port for uploading LOG files to an external memory

stick; for authorized and qualified service technicians only.

8

LAN (RJ45)

LAN for network logging (currently not available).

9

Mini RS-485 (COM3)

For connecting FLIGHT MEDICAL peripherals. For future use.

10

Low Flow Oxygen Port

Low flow oxygen enrichment source.

11*

High Pressure O2 Port (iO

2

Internal mixer model only)

Connects to high pressure O2.

Functional Description

Remote Alarm Connection

3-8 | FLIGHT 60 Service Manual

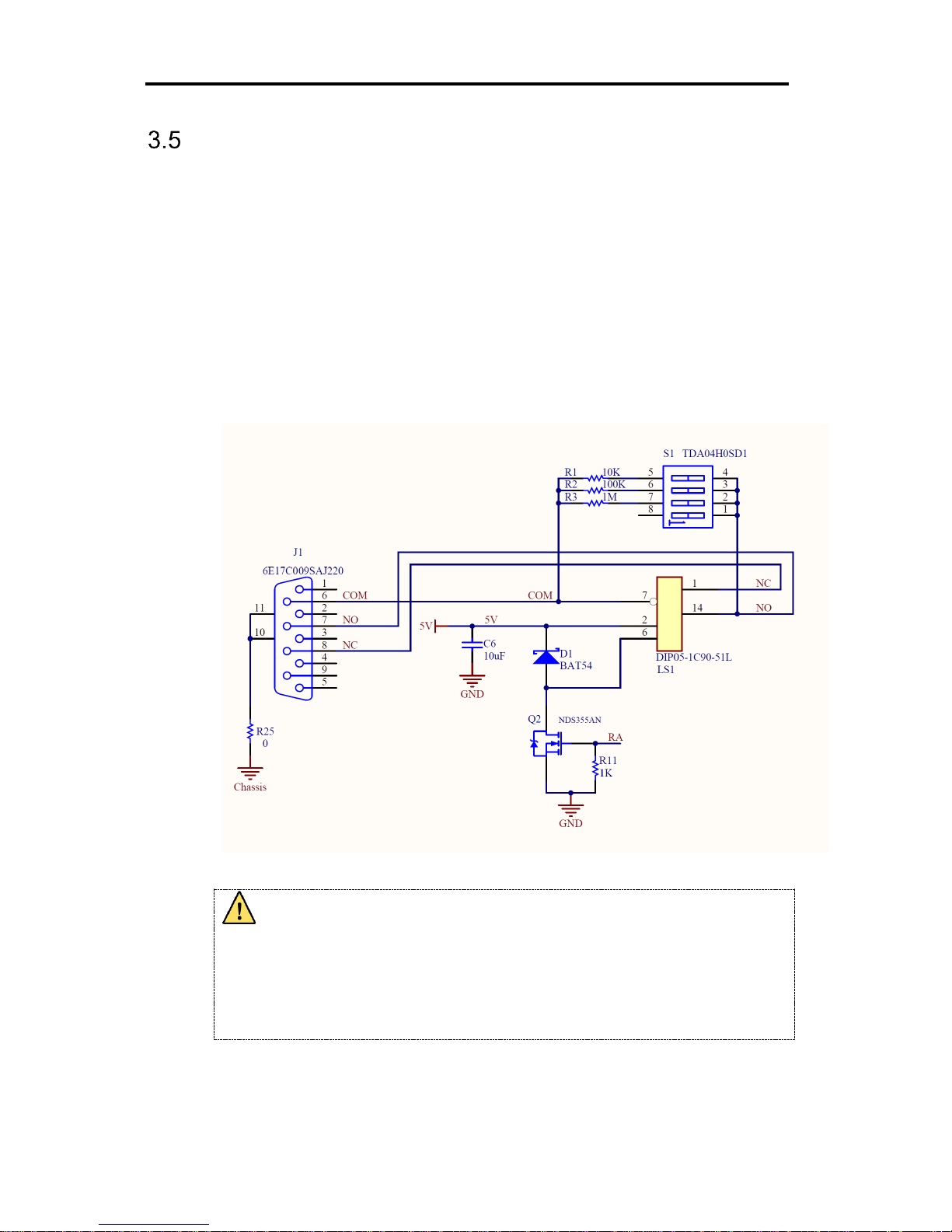

Remote Alarm Connection

The Flight-60 ventilator can be connected to third party remote alarm system.

The remote alarm station displays all visible and audible alarms and alerts if

the ventilator is shutdown.

Remote alarm cable should be connected to the COM2 RS232/RA port (the

lower port) in the back of the ventilator. The COM2 port provides a dry contact

output, both Normally Open (NO) and Normally Closed (NC).

Normally Open – Pin 7 – closing the contacts to transmit an alarm.

Normally Closed – Pin 8 – opening the contacts to transmit an alarm.

The dry contacts current should not exceed 1mA.

The voltage on the contacts must be lower than 12 Volts.

Remote Alarm Electrical schematics

The legal and regulatory responsibility for this integration of the Flight

60 device into any external system lays on the integrator and not the Flight

60 manufacturer. This include but is not limited to responsibilities for the

Design, Implementation, Installation validation verification and safety of

the connection of the Flight-60 to the remote alarm.

Falling to comply with the specification given here may result in damage to

the device and will void its warranty.

Functional Description

Ventilator Modules

Flight 60 Service Manual | 3-9

Ventilator Modules

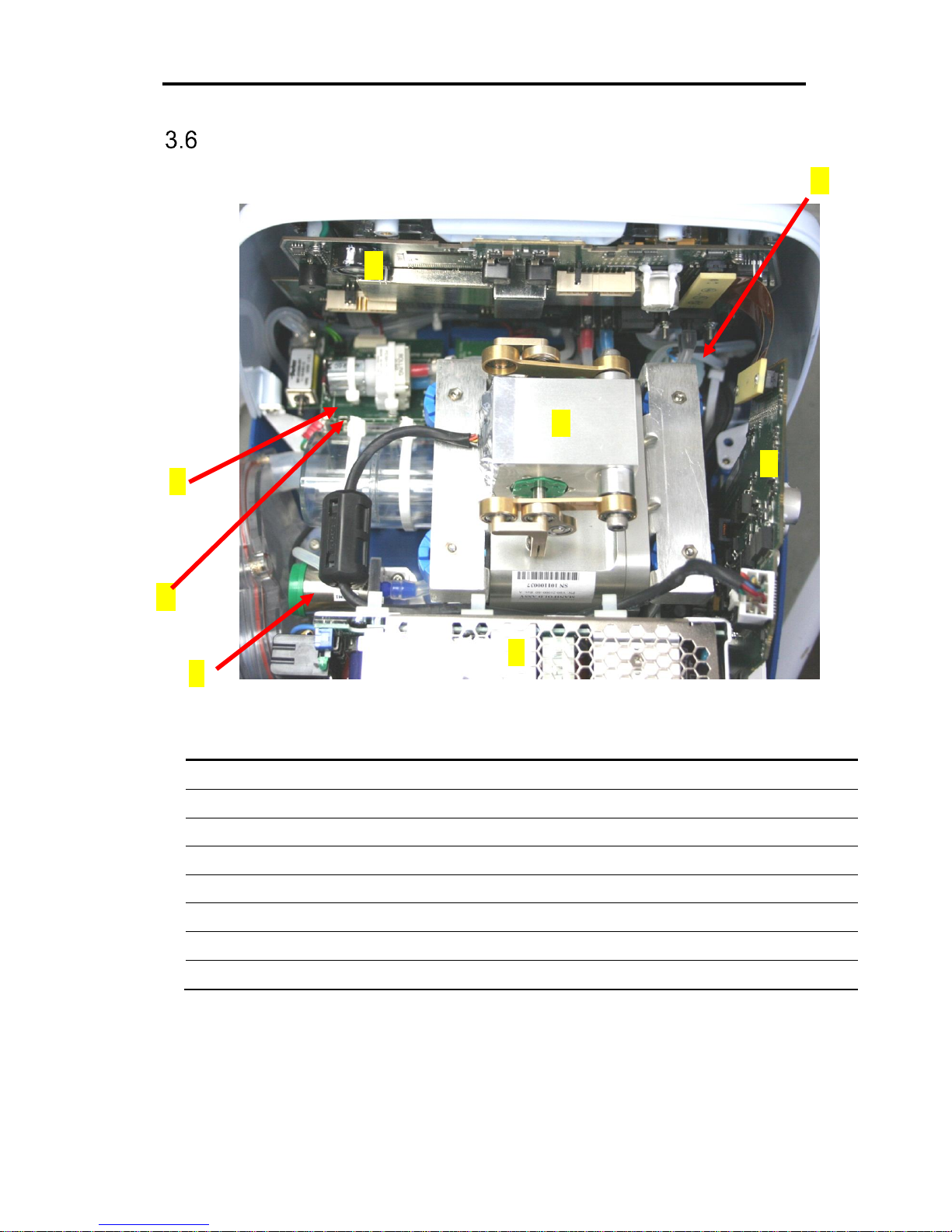

Figure 6 – Ventilator Modules

#

Component

P/N A Main board (MB)

V60-60002-65

B

Power board (PB)

V60-21000-65

C

Power supply (PS)

V60-13000-65

D

Manifold assembly

V60-21000-60

E

Solenoid board assembly

V60-26000-65

F

Solenoid assembly

V60-21400-69

G

Oxygen (O2) Sensor

V60-25000-29

H

Purge board

V60-23000-65

A

B

C D F G E

H

Functional Description

Ventilator Modules – iO2 Internal mixer model

3-10 | FLIGHT 60 Service Manual

Ventilator Modules – iO2 Internal mixer model

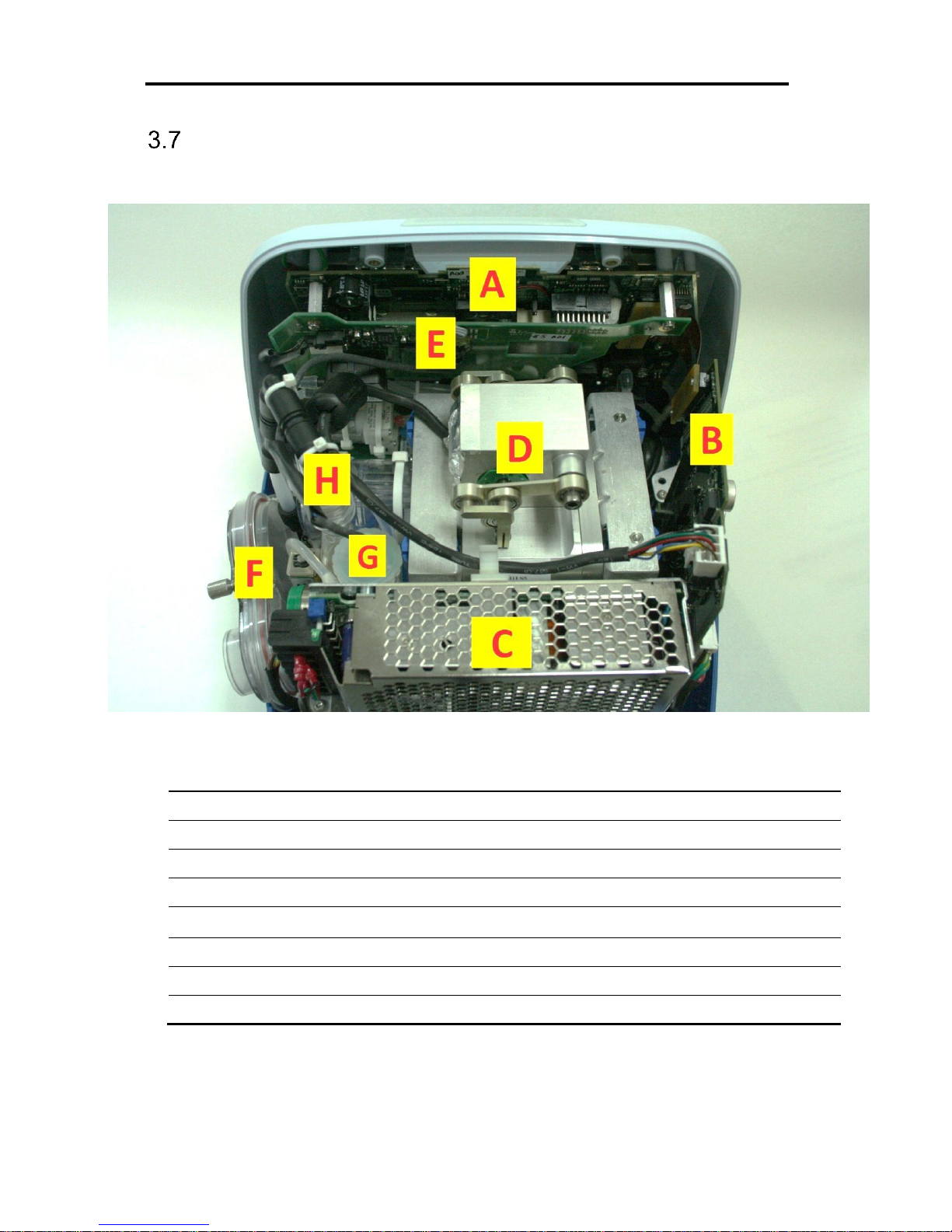

Figure 7 – Ventilator Modules Internal Mixer

#

Component

P/N A Main board (MB)

V60-60002-65

B

Power board (PB)

V60-21000-65

C

Power supply (PS)

V60-13000-65

D

Manifold assembly

V60-21000-60

E

O2 Mixer Neb board

ELE-0001

F

Inlet assembly

V60-21400-69

G

O2 leak sensor

G60-25000-29

H

Internal O2 mixer

SUB-0101

Functional Description

Pneumatic Diagram

Flight 60 Service Manual | 3-11

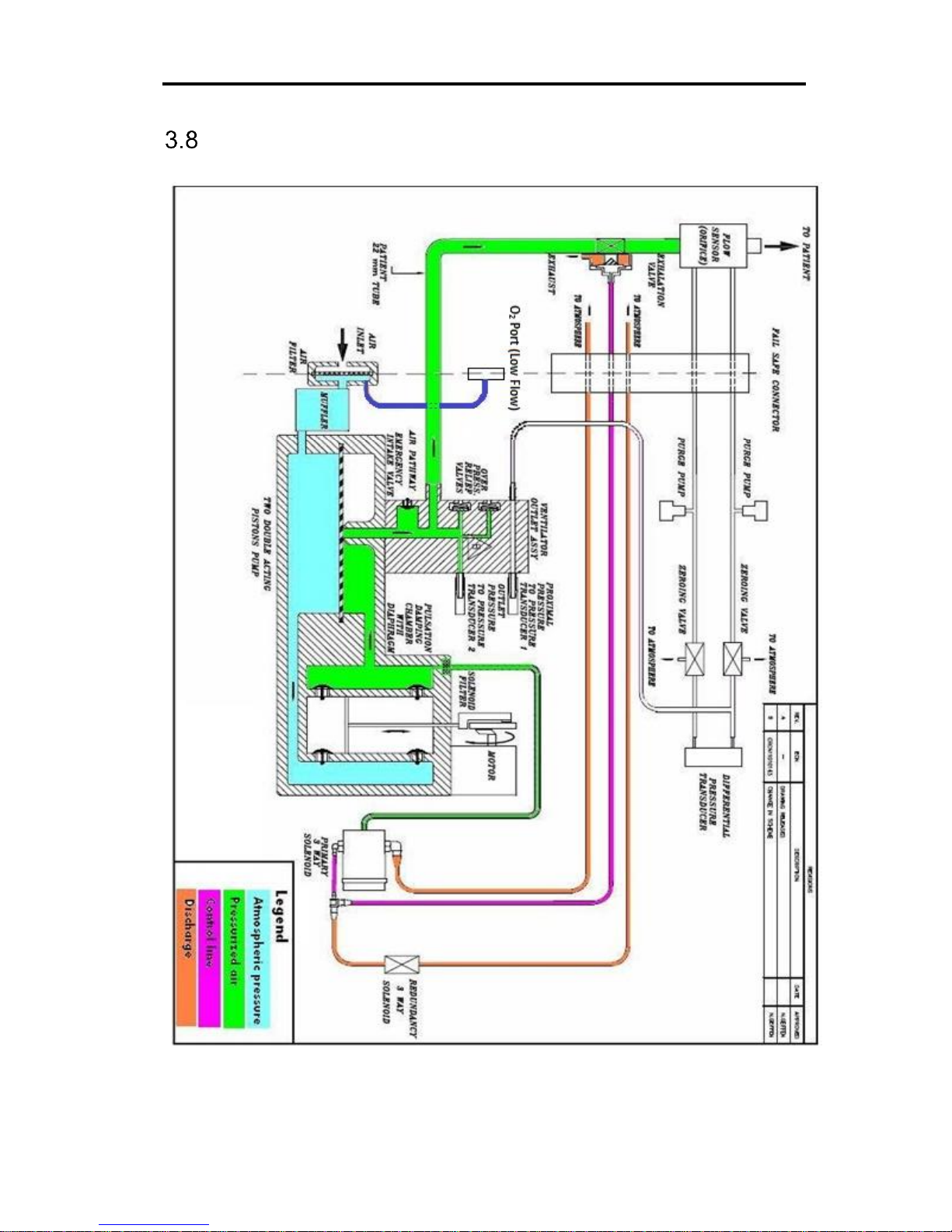

Pneumatic Diagram

Functional Description

Pneumatic Diagram – iO2 Internal mixer model

3-12 | FLIGHT 60 Service Manual

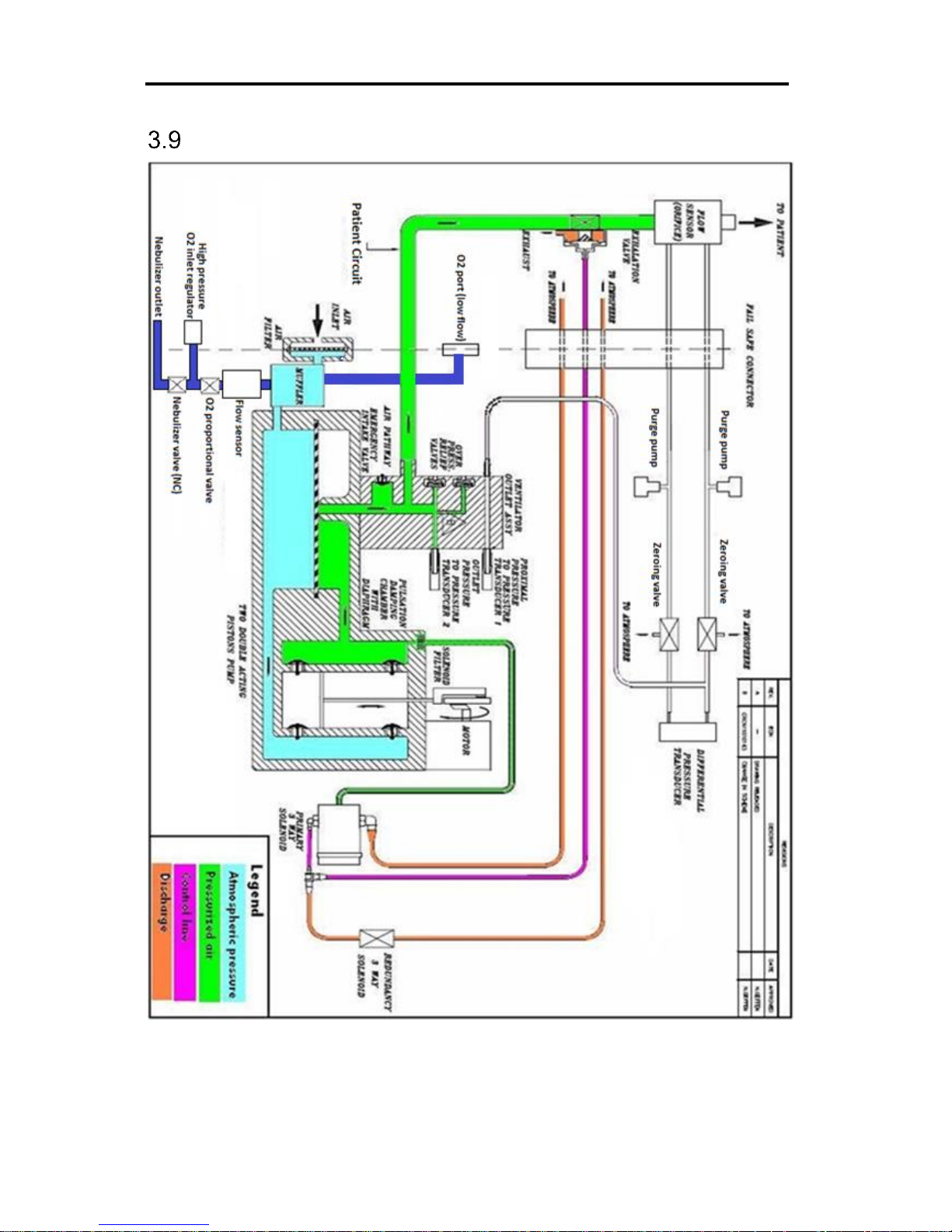

Pneumatic Diagram – iO2 Internal mixer model

Functional Description

Electrical Diagram

Flight 60 Service Manual | 3-13

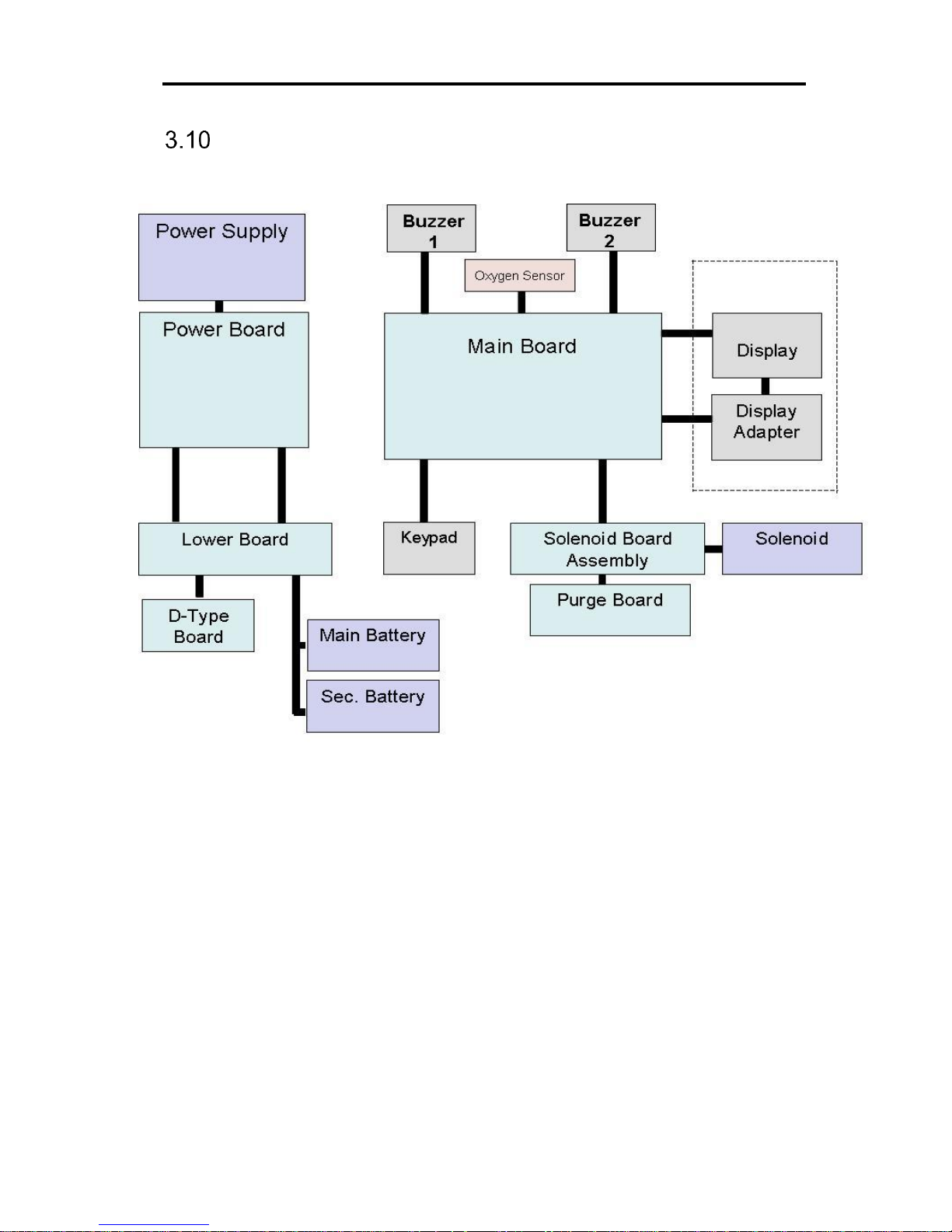

Electrical Diagram

Functional Description

Electrical Diagram – iO2 Internal Mixer model

3-14 | FLIGHT 60 Service Manual

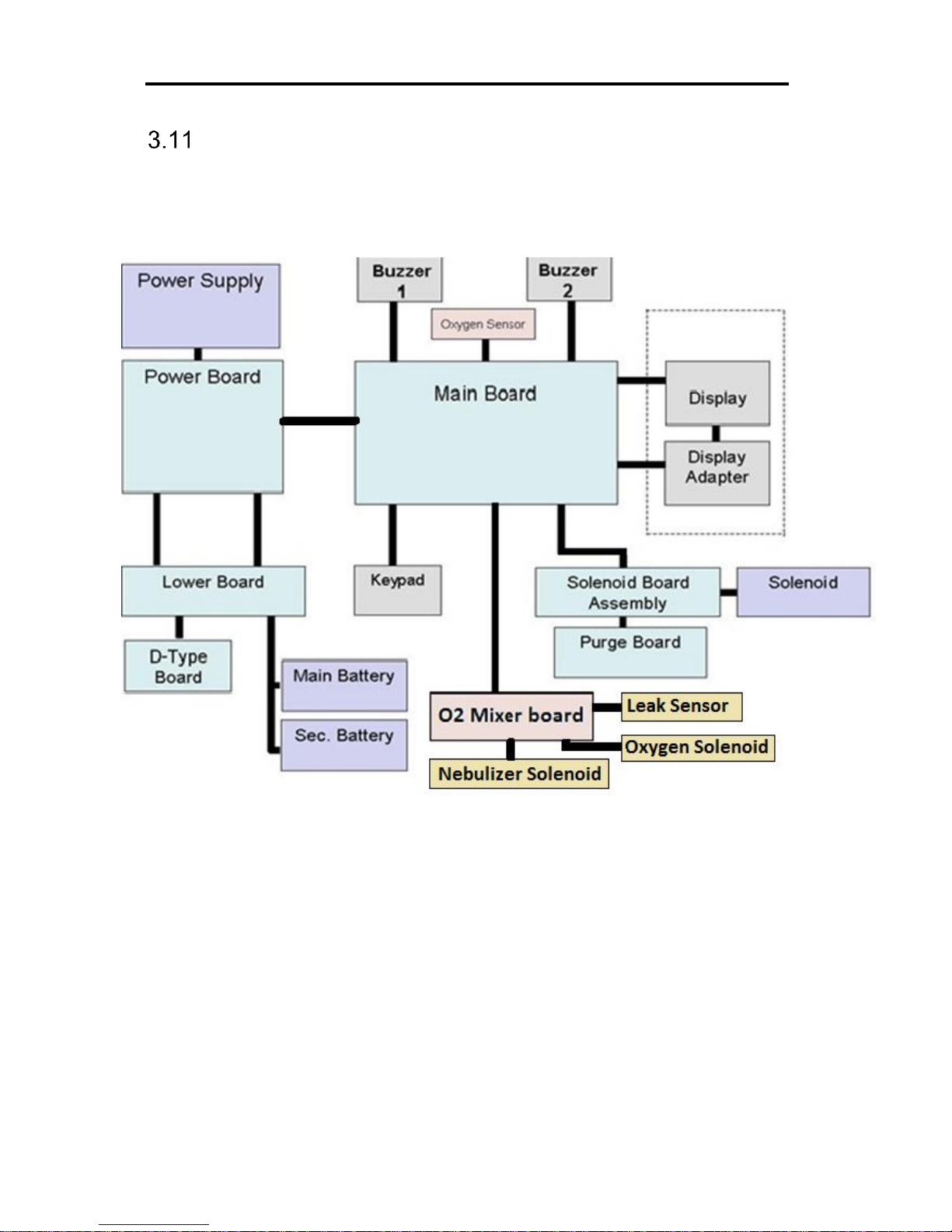

Electrical Diagram – iO2 Internal Mixer model

Loading...

Loading...