Flextool SP118OFT Operation And Parts Manual

OPERATION AND PARTS MANUAL

SP1 SERIES

CONCRETE/ASPHALT STREET

MODEL SP118OFT

HONDA GX390 PETROL ENGINE

SERIAL NO. ____________

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Revision #0 (01/04/10)

PN: 38364

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 3

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

TABLE OF CONTENTS

SP1 StreetPro

Professional Pavement Saw

Proposition 65 Warning ........................................... 2

Silicosis/Respiratory Warnings ................................ 3

Table Of Contents .................................................... 4

Training Checklist ..................................................... 6

Daily Pre-Operation Checklist ................................. 7

Safety Information ..............................................8-14

Dimensions/Specifications (Saw) .......................... 16

Specifications (Engine) .......................................... 17

General Information ............................................... 18

Components .......................................................... 19

Basic Engine .......................................................... 20

Inspection/Setup ............................................... 21-23

Blades ............................................................... 24-26

Raise/Lower And Depth Stop ................................ 27

Operation .......................................................... 28-31

Maintenance (Saw) ................................................ 32

Maintenance (Engine) ........................................... 33

Decommissioning/Water Tank (Optional) ............... 34

Troubleshooting (Saw) ........................................... 35

Troubleshooting (Engine) ....................................... 36

Explanation Of Code In Remarks Column ............ 38

Suggested Spare Parts ......................................... 39

Honda GX390U1QWT2 Engine

Air Cleaner Assembly ....................................... 66-67

Camshaft Assembly .......................................... 68-69

Carburetor Assembly ........................................ 70-71

Control Assembly .............................................72-73

Crankcase Assembly ........................................ 74-75

Crankshaft Assembly ........................................ 76-77

Cylinder Barrell Assembly ................................78-79

Cylinder Head Assembly .................................. 80-81

Fan Cover Assembly ......................................... 82-83

Flywheel Assembly ........................................... 84-85

Fuel Tank Assembly .......................................... 86-87

Ignition Coil Assembly ...................................... 88-89

Muffler Assembly .............................................. 90-91

Piston Assembly ............................................... 92-93

Recoil Starter Assembly ................................... 94-95

Labels Assembly ..............................................96-97

Component Drawings

Nameplate And Decals ..................................... 40-41

Console Frame Assembly ................................. 42-43

Platform Frame/Undercarriage Assembly ......... 44-45

Raise/Lower Assembly ..................................... 46-47

Lifting Bale Assembly ....................................... 48-49

Pointer Assembly .............................................. 50-51

Blade Spindle Assembly ................................... 52-53

Blade Guard Assembly ..................................... 54-55

Engine Assembly .............................................. 56-57

Belts And Tensioning Assembly ........................ 58-59

Belt Guard Assembly ........................................ 60-61

Water System Assembly ................................... 62-63

Optional Water Tank Assembly ......................... 64-65

PAGE 4 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

NOTES

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 5

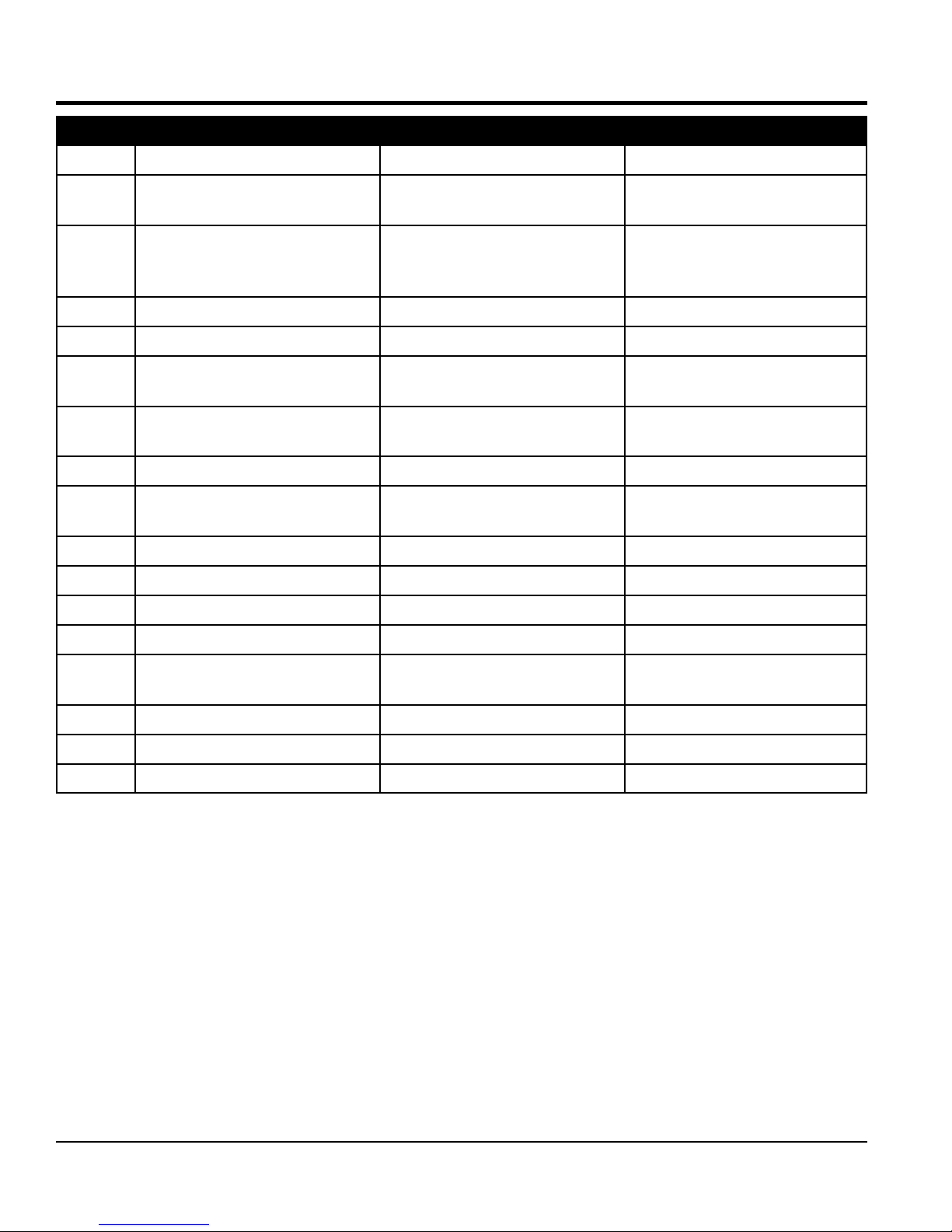

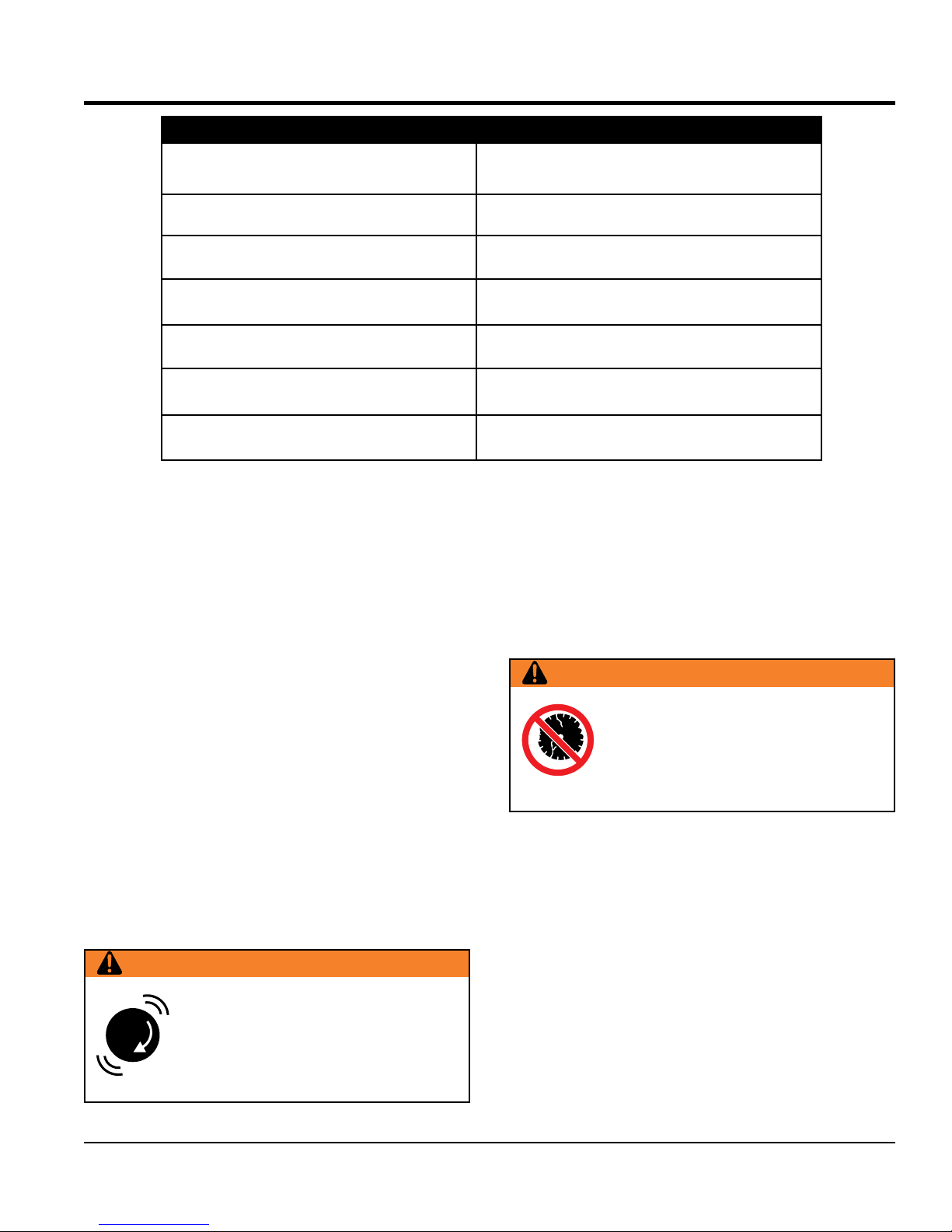

TRAINING CHECKLIST

Training Checklist

No, Description OK? Date

1

2

3 Fuel system, refueling procedure.

4 Operation of spray and lights.

5

6

7 Emergency stop procedures.

8

9 Forward and reverse travel.

10 Starting a cut.

11 Pavement cutting techniques.

12 Stopping a cut.

Read operation manual

completely.

Machine layout, location of

components, checking of engine

and hydraulic oil levels.

Operation of controls (machine

not running).

Safety controls, safety stop switch

operation.

Startup of machine, pre-heat,

engine choke.

13

14 Shutdown of machine.

15 Lifting of machine (lift loops).

16 Machine transport and storage.

Restart after stopping blade within

work surface — explanation

PAGE 6 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

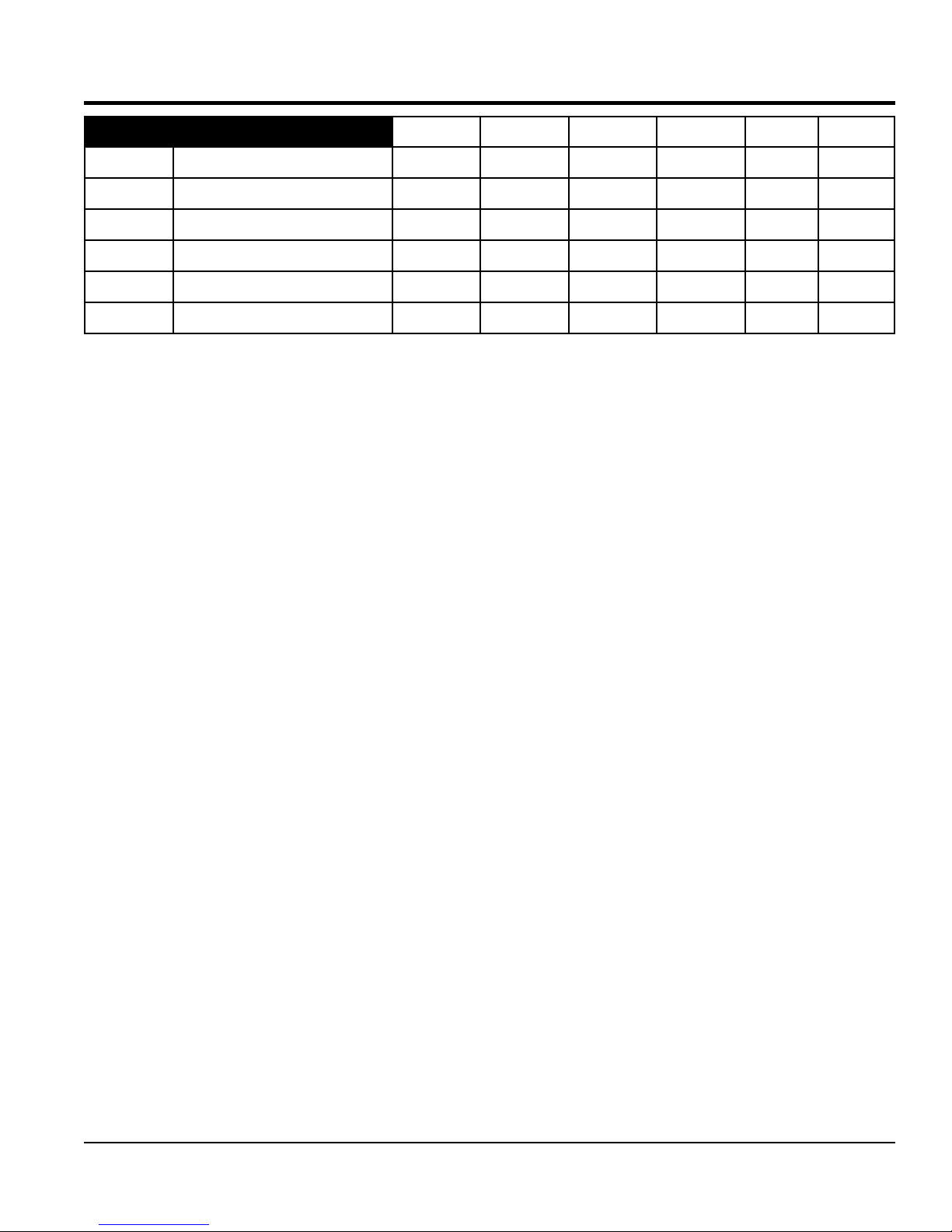

DAILY PRE-OPERATION CHECKLIST

Daily Pre-Operation Checklist

1 Hardware and damage check

2 Engine oil level

3 Hydraulic oil level

4 Condition of blade

5 Safety stop switch operation

6 Braking control operation

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 7

SAFETY INFORMATION

Do not operate or service the equipment before reading

Potential hazards associated with the operation of this

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

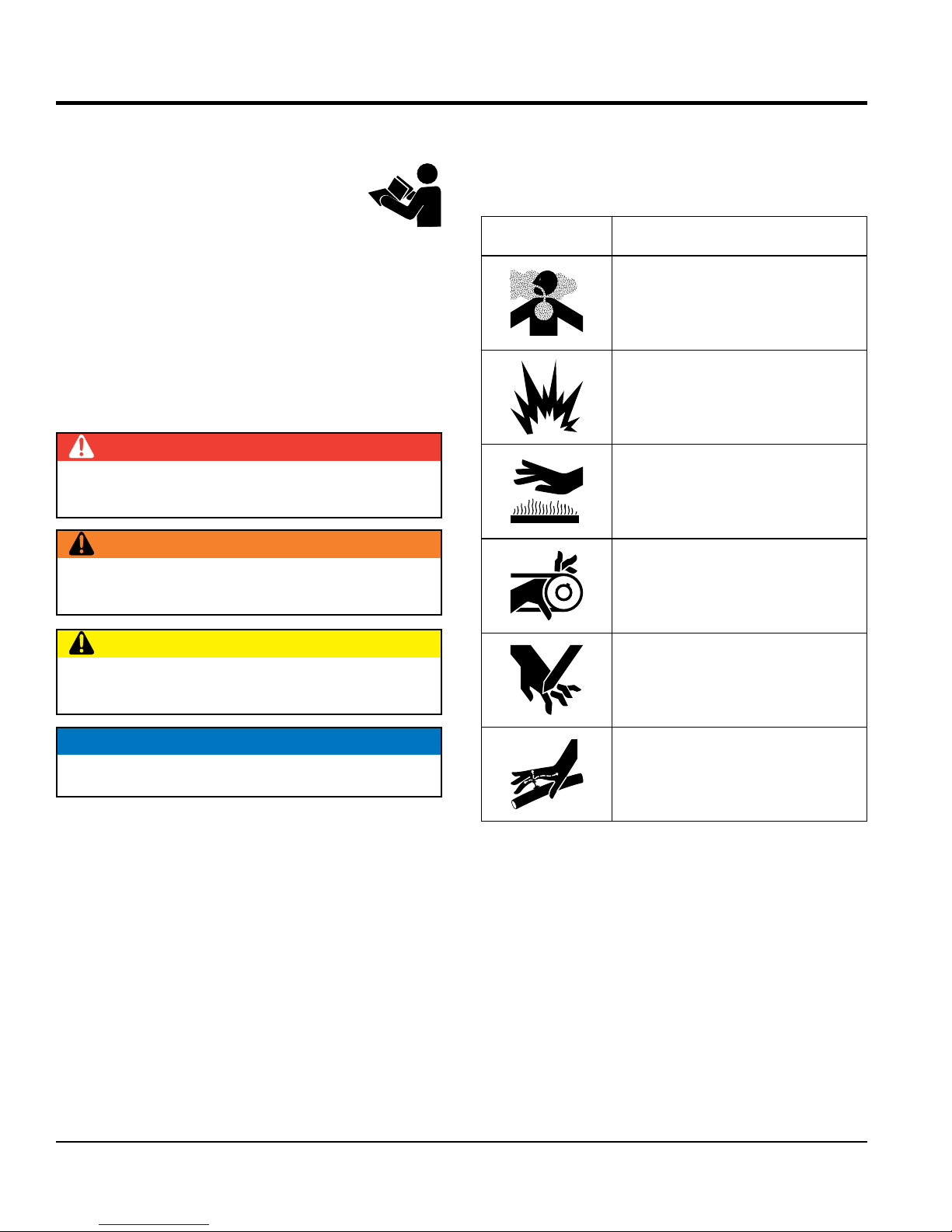

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

Symbol Safety Hazard

Lethal exhaust gas hazards

Explosive fuel hazards

Burn hazards

Rotating parts hazards

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

Cutting and crushing hazards

Hydraulic fluid hazards

PAGE 8 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

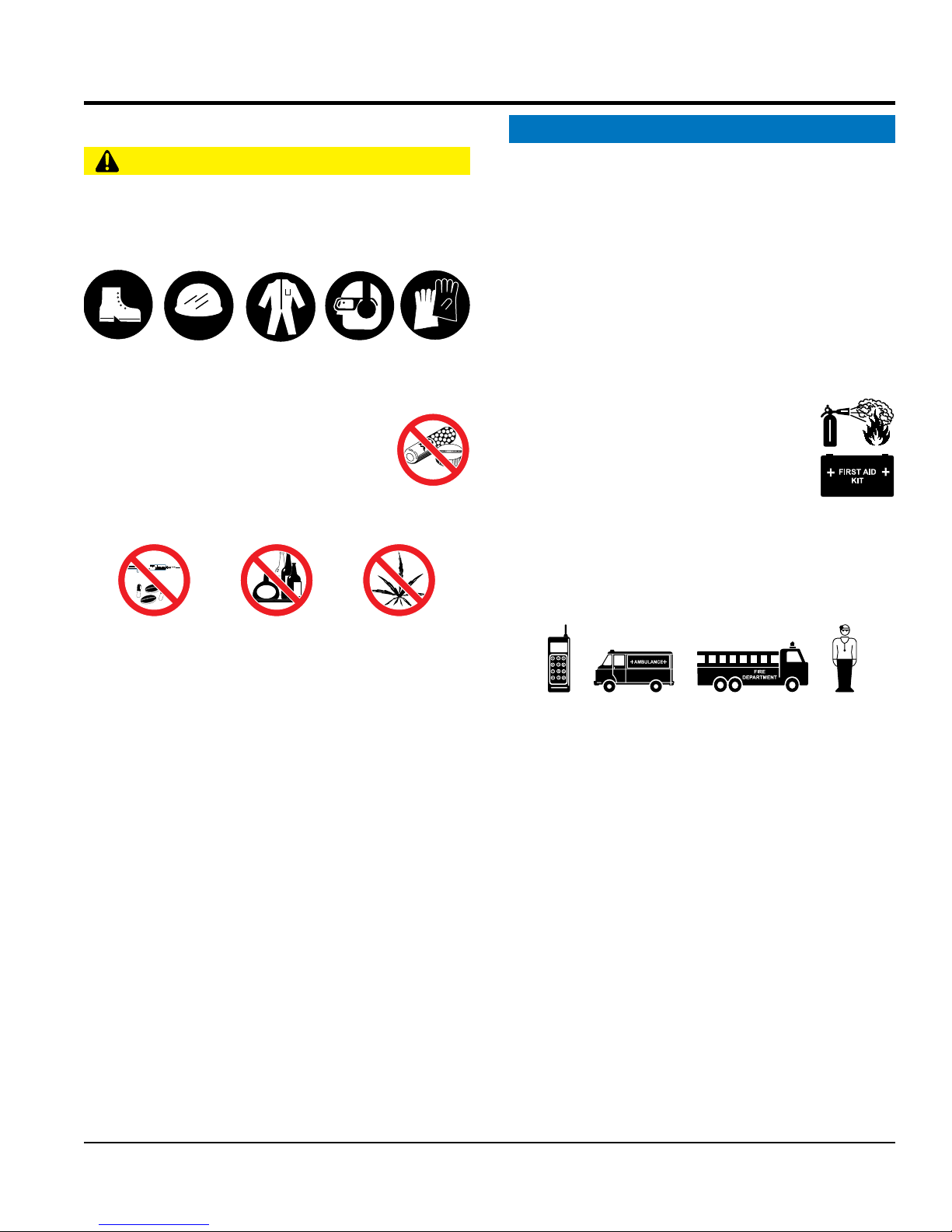

GENERAL SAFETY

NOTICE

This equipment should only be operated by trained and

Whenever necessary, replace nameplate, operation and

accident due to equipment modifi cations. Unauthorized

recommended by Multiquip for this equipment. Damage

keep

Also, know the phone numbers

fi re department.

SAFETY INFORMATION

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

Avoid wearing jewelry or loose fi tting clothes that may

snag on the controls or moving parts as this can cause

serious injury.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the

infl uence of drugs or alcohol.

ALWAYS clear the work area of any debris, tools, etc.

that would constitute a hazard while the equipment is

in operation.

qualifi ed personnel 18 years of age and older.

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

equipment modifi cation will void all warranties.

NEVER use accessories or attachments that are not

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest phone or

a phone on the job site.

of the nearest ambulance, doctor and

This information will be invaluable in the case of an

emergency.

No one other than the operator is to be in the working

area when the equipment is in operation.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 9

SAW SAFETY

NOTICE

placed on appropriate

leaving or when using on a slope. Some saws utilize a

brake system where the brakes are automatically applied

angle of the slope will help prevent accidental downhill

start

use on excessive slopes or on extremely uneven

keep the machine in proper running condition.

Make sure there is no buildup of concrete, grease, oil or

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

SAFETY INFORMATION

DANGER

Engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment requires an adequate free

fl ow of cooling air. NEVER operate this equipment in any

enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury

to people and property and

serio u s dam a ge to t h e

equipment or engine.

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

If applicable, NEVER use your hand to fi nd

hydraulic leaks. Use a piece of wood or

cardboard. Hydraulic fl uid injected into the

skin must be treated by a knowledgeable

physician immediately or severe injury or

death can occur.

Accidental starting can cause severe injury

or death. ALWAYS place the ON/OFF

switch in the OFF position.

NEVER disconnect any emergency or safety devices.

These dev ices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

devices will void all warranties.

CAUTION

Anytime the saw is lifted onto its nose or tilted fully

back, such as for maintenance access, the high end of

the saw MUST be blocked up to prevent the possibility

of crush injury.

DANGEROUS

GAS FUMES

ALWAYS ensure saw is securely

blocks or jackstands when performing maintenance

requires elevation of the saw.

If saw has brakes, ensure brakes are applied when

when the engine is stopped.

If saw has a parking brake, ensure that the parking

brake is engaged and holds the saw safely in place

when parking on a slope.. Turning the saw across the

movement.

ALWAYS block the saw with appropriate blocks when

leaving the saw parked on a slope.

To prevent unexpected loss of control, DO NOT

engine on a sloping surface

DO NOT

surfaces

ALWAYS start engine with the control handle in

NEUTRAL position to prevent unexpected movement.

ALWAYS

Fix damage to machine and replace any broken parts

immediately.

debris on the machine.

ALWAYS

PAGE 10 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

BLADE SAFETY

Rotating blade can cut and crush. ALWAYS

D O NOT drop the diamond blade on ground or

Make certain the operator knows how to and is capable

run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

keep hands and feet clear while operating

the saw.

NEVER operate the saw without blade

guards and covers in place. Exposure of

the diamond blade must not exceed 180

degrees.

Verify the engine start switch is set to the OFF position

before installing a blade.

ALWAY S in spe ct blade before each

use. The blade should exhibit no cracks,

dings, or fl aws in the steel centered core

and/or rim. Center (arbor) hole must be

undamaged and true.

NOTICE

Use proper blades and follow blade manufacturer’s

recommendations. Match the blade RPM (blade shaft

RPM) to the recommended blade surface feet per minute

(SFPM).

Ensure the 5/8" blade-mounting bolt is tightened to 125-

175 foot lbs. of torque.

ALWAYS examine blade flanges for damage and

excessive wear.

Ensure the blade is marked with an operating speed

greater than the spindle speed of the saw.

Only cut the material that is specifi ed for the diamond

blade. Read the specifi cation of the diamond blade to

ensure the proper tool has been matched to the material

being cut.

WARNING

CAUTION

SAFETY INFORMATION

surface.

Ensure that the blade is mounted for proper operating

direction.

Adhere to the blade manufacturer’s recommendations

on handling, storage and safe usage of blades.

ENGINE SAFETY

WARNING

DO NOT place hands or fingers inside

engine compartment when engine is

running.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

ALWAYS shut down the engine before

performing service or maintenance.

DO NOT remove the engine oil drain plug while the

engine is hot. Hot oil will gush out of the oil tank and

severely scald any persons in the general area of the

saw.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

of turning the engine OFF in case of an emergency.

NOTICE

NEVER

frequently to prevent engine malfunction.

If wet cutting, ensure a WET CUTTING blade is being

used and that the water supply system to the blade is

properly functioning and being used.

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 11

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

SAFETY INFORMATION

FUEL SAFETY

BATTERY SAFETY (ELECTRIC START ONLY)

drop the battery. There is a possibility that the

keep the battery charged. If the battery is not

charge battery if frozen. Battery can explode.

environment to avoid the risk of a dangerous concentration

NEGATIVE battery terminal

keep battery cables in good working condition.

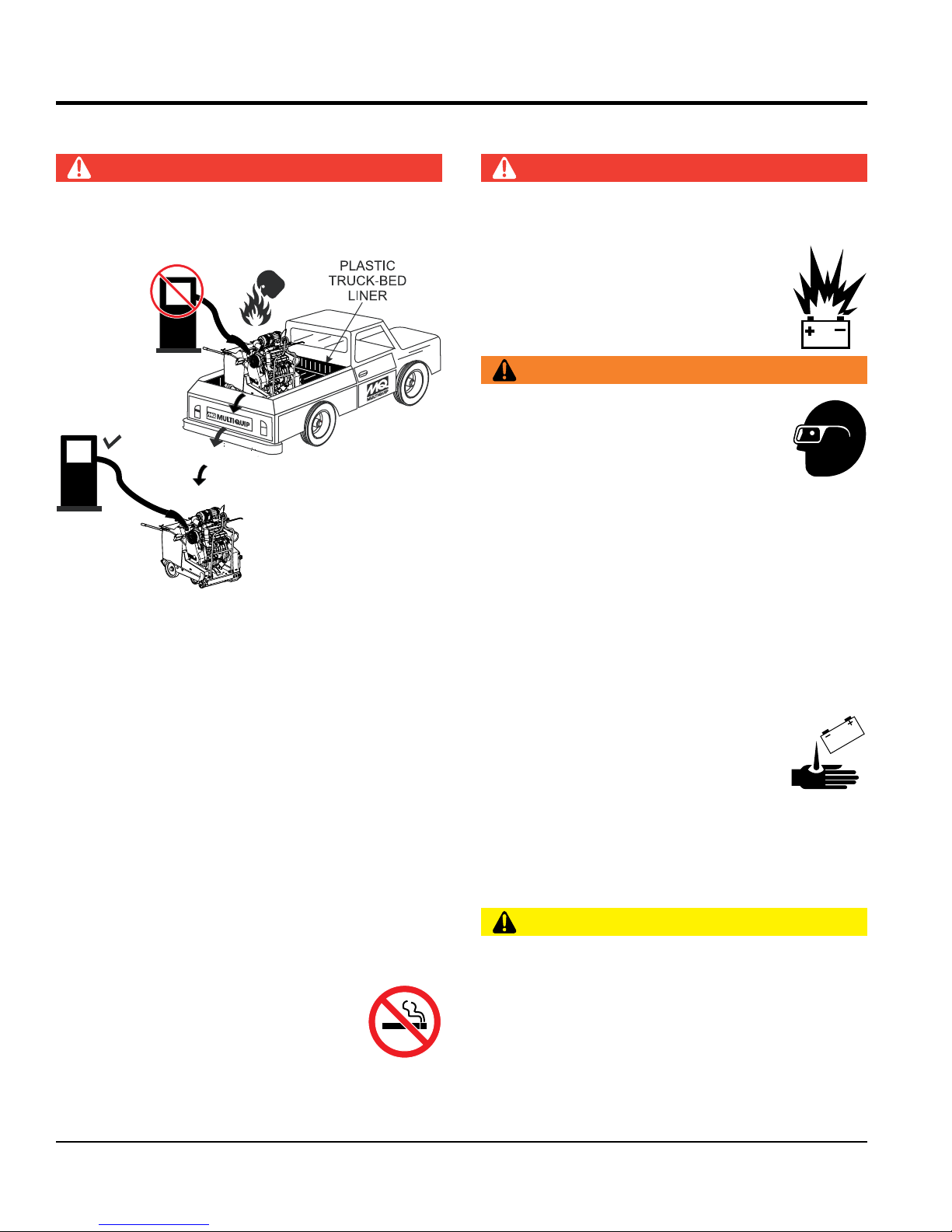

DANGER

DO NOT add fuel to equipment if it is placed inside truck

bed with plastic liner. Possibility exists of explosion or

fi re due to static electricity

FUEL

DO NOT start the engine near spilled fuel or combustible

fl uids. Fuel is extremely fl ammable and its vapors can

cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

D O NOT smoke a round or near th e

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

FUEL

DANGER

DO NOT

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

WARNING

A LWAYS we ar safety g las ses when

handling the battery to avoid eye irritation.

The battery contains acids that can cause

injury to the eyes and skin.

Use well-insulated gloves when picking up

the battery.

ALWAYS

charged, combustible gas will build up.

DO NOT

When frozen, warm the battery to at least 61°F (16°C).

ALWAYS recharge the battery in a well-ventilated

of combustible gases.

If the battery liquid (dilute sulfuric acid)

comes into contact with clothing or skin,

rinse skin or clothing immediately with

plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

ALWAYS disconnect the

before performing service on the equipment.

ALWAYS

Repair or replace all worn cables.

PAGE 12 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

SAFETY INFORMATION

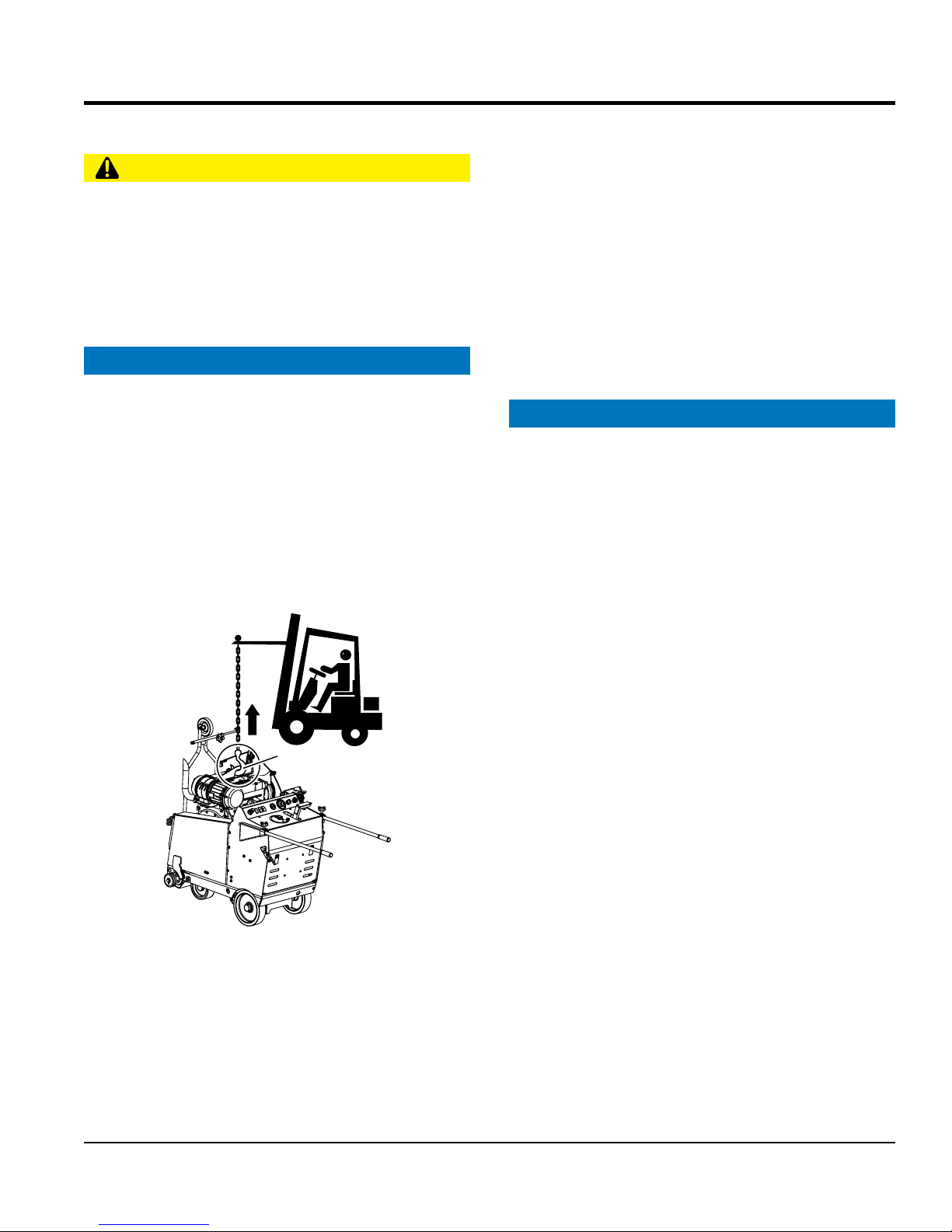

LIFTING SAFETY

NEVER tip the engine to extreme angles during lifting as

it may cause oil to gravitate into the cylinder head, making

use ramps capable of supporting the weight of

Ensure that the diamond blade does not come into contact

transport the saw to or from the job site with the

CAUTION

NEVER allow any person or animal to stand underneath

the equipment while lifting.

Some saws are very heavy and awkward to move around.

Use proper heavy lifting procedures.

DO NOT attempt to lift the saw by the guards, handle

bars or front pointers.

NOTICE

The easiest way to lift the saw is to utilize the lifting bale. A

strap or chain can be attached to the lifting bale, allowing

a forklift or crane to lift the saw up onto and off of a slab

of concrete. The strap or chain should have a minimum

of 2,000 pounds (1,000 kg) lifting capacity and the lifting

gear must be capable of lifting at least this amount.

Before lifting, make sure that the lifting bale is not

damaged.

Use one point suspension hook and lift straight upwards.

the engine start diffi cult.

Always make sure crane or lifting device has been

properly secured to the lifting bale.

DO NOT lift machine to unnecessary heights.

NEVER lift the equipment while the engine is running.

ALWAYS

the saw and the operator to load and unload the saw.

TRANSPORTING SAFETY

NOTICE

ALWAYS shutdown engine before transporting.

Tighten fuel tank cap securely and close fuel cock to

prevent fuel from spilling.

ALWAYS tie down equipment during transport by

securing the equipment with rope.

with the ground or surface during transportation.

LIFTING BALE

NEVER

blade mounted.

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 13

TOWING SAFETY

CAUTION

Avoid sudden stops and starts. This can cause skidding,

Trailer should be adjusted to a level position at all times

underneath wheel to prevent rolling

Place support blocks underneath the trailer’s bumper to

Use the trailer’s swivel jack to adjust the trailer height to

pour waste, oil or fuel directly onto the ground,

SAFETY INFORMATION

or jack-knifi ng. Smooth, gradual starts and stops will

improve towing.

Check with your local county or state safety

towing regulations, in addition to meeting

Department of Transportation (DOT)

Safety Towing Regulations, before towing

your saw.

In order to reduce the possibility of an accident while

transporting the saw on public roads, ALWAYS make

sure the trailer that supports the saw and the towing

vehicle are mechanically sound and in good operating

condition.

NEVER attempt to tow the saw untrailered behind a

vehicle.

ALWAYS shutdown engine before transporting

Make sure the hitch and coupling of the towing vehicle

are rated equal to, or greater than the trailer “gross

vehicle weight rating.”

ALWAYS inspect the hitch and coupling for wear. NEVER

tow a trailer with defective hitches, couplings, chains, etc.

Check the tire air pressure on both towing vehicle and

trailer. Trailer tires should be infl ated to 50 psi cold.

Also check the tire tread wear on both vehicles.

ALWAYS make sure the trailer is equipped with a safety

chain.

Avoid sharp turns to prevent rolling.

when towing.

Raise and lock trailer wheel stand in up position when

towing.

Place chock blocks

while parked.

prevent tipping while parked.

a level position while parked.

ENVIRONMENTAL SAFETY

NOTICE

Dispose of hazardous waste properly.

Examples of potentially hazardous waste

are used motor oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to dispose of

hazardous waste.

DO NOT

down a drain or into any water source.

ALWAYS properly attach trailer’s safety chains to towing

vehicle.

ALWAYS make sure the vehicle and trailer directional,

backup, brake and trailer lights are connected and

working properly.

DOT Requirements include the following:

• Connect and test electric brake operation.

• Secure portable power cables in cable tray with tie

wraps.

The maximum speed for highway towing is 55 MPH unless

posted otherwise. Recommended off-road towing is not to

exceed 15 MPH or less depending on type of terrain.

PAGE 14 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

NOTES

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 15

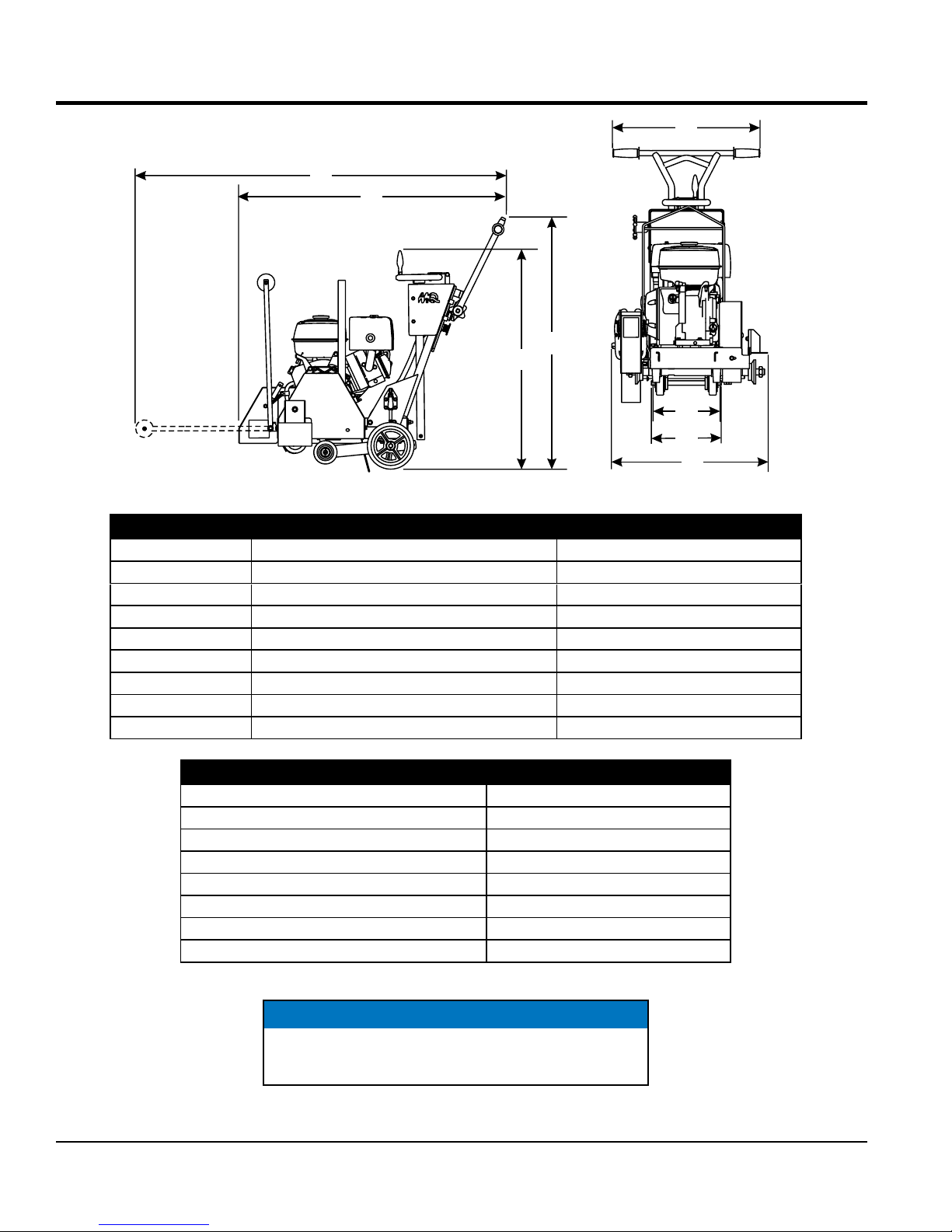

DIMENSIONS/SPECIFICATIONS (SAW)

E

C

B

A

D

F

G

H

Figure 1. SP1 Dimensions

Table 1. Dimensions

REFERENCE LETTER DESCRIPTION DIMENSION

A Height w/handle– in. (cm) 43.00 (109 cm)

B Length w/pointer raised – in. (cm) 46.0" (117 cm)

C Length w/pointer lowered – in. (cm) 67.0" (170 cm)

D Height w/o handle– in. (cm) 37.0" (94 cm)

E Width – in. (cm) 25.0" (64 cm)

F Rear Wheel Base – in. (cm) 17.0" (40 cm)

G Front Wheel Base – in. (cm) 10.0" (25.4 cm)

H Handle Bar Width – in. (cm) 24.5" (40 cm)

Model SP1

Maximum Spindle RPM 2836 RPM

Arbor Size 1.0" (2.54 cm)

Maximum Cutting Depth in. (cm) 7.0" (17.78 cm)

Sound Pressure at Operator's Position 99.8 db

Vibration 4.3 ms

Maximum Operating Mass 274 lbs. (124.3)

Nominal Mass (without blade or fluids) 259 lbs. (117.5)

NOTICE

* Vibration (at handle) results with SP1 Saw AT FULL

THROTTLE.

PAGE 16 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

Table 2. Specifications (Saw)

-2

SPECIFICATIONS (ENGINE)

Table 3. SP1 Engine Specifications

Model HONDA GX390U1QWT2

Engine

Type

Air-cooled 4 stroke, Single cylinder, OHV,

Gasoline Engine

3.5 in. x 2.5 in.

Bore x Stroke

(88 mm x 64 mm)

Displacement 23.7 cu-in. (389 cc)

Net HP Output 11 HP (8.2 kW) @3600 rpm

Approx. 1.72 U.S. Gallons

Fuel Tank Capacity

(6.5 Liters)

Unleaded Automobile Gasoline

Fuel

86 Octane or higher

Lube Oil Capacity 1.16 U.S. qt. (1.1 liter)

Speed Control Method 3.1 in. (78 mm)

Engine Oil Capacity Centrifugal Fly-weight Type

Dry Net Weight 68.3 lbs. (31.0 Kg)

Dimensions (L x W x H)

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 17

16.7 in. x 17.7 in. x 17.4 in

(425 mm x 450 mm x 443 mm).

GENERAL INFORMATION

INTENDED USE

Operate the SP1 Saw, tools and components in accordance

with the manufacturer's instructions. Use of any other tools

for stated operation is considered contrary to designated

use. The risk of such use lies entirely with the user. The

manufacturer cannot be held liable for damages as a result

of misuse.

GENERAL INFORMATION

The SP1 Saws are designed for wet or dry cutting of

concrete or asphalt utilizing Diamond Blades. These saws

have been engineered for general and industrial flat sawing

applications.The reinforced steel box frame design adds

strength necessary to reduce blade vibrations while cutting.

By minimizing blade vibrations the performance of the blade

is enhanced and thus the life of the blade is extended.

Heavy-duty front and rear axles, sturdy oversized wheels,

and industrial undercarriage assembly ensure accurate

tracking and years of reliable use.

Additionally, the general strength-to-weight ratio design

of the frame and chassis assembly provides for optimum

weight distribution to keep the blade running true in the cut.

A rugged spindle bearing assembly ensures minimal flutter

and shaft harmonics providing the most advantageous

condition for a diamond blade at operating speeds.

This saw comes equipped with an 18-inch blade guard and

handles Diamond Blades ranging in size from 12-18-inches

in diameter.

POWER PLANTS

The SP1 saw is generally considered a "low" powered saw

in the industry. This classification is particularly useful when

selecting the proper diamond blade for an application.

This SP1 saw is powered by a HONDA GX390U1QWT2

air cooled, 4-stroke, single cylnder, OHV gasoline engine

rated at 11 HP (8.2 kW) at 3,600 RPM.

Refer to the HONDA Engine Owner's Manual for specific

information regarding engine operation and maintenance

procedures.

BLADE ROTATION

Three premium 3VX belts connecting a properly sized drive

(engine) pulley and an output blade shaft pulley provides

the rotational power of the diamond blade. Specific pulley

diameters have been chosen to support the design of the

SP1 saw.

Ultimate blade shaft RPM speed is very important for the

safe, efficient operation of the diamond blade in the cut.

All SP1 SAW S ar e desig ned, engi neer ed and

manufactured with strict adherence to American

National Standards Institute, Inc. (ANSI) guidelines

B7.1 and B7.5.

FEATURES

Powerful HONDA GX390 Gasoline engine with cyclone

air filtration.

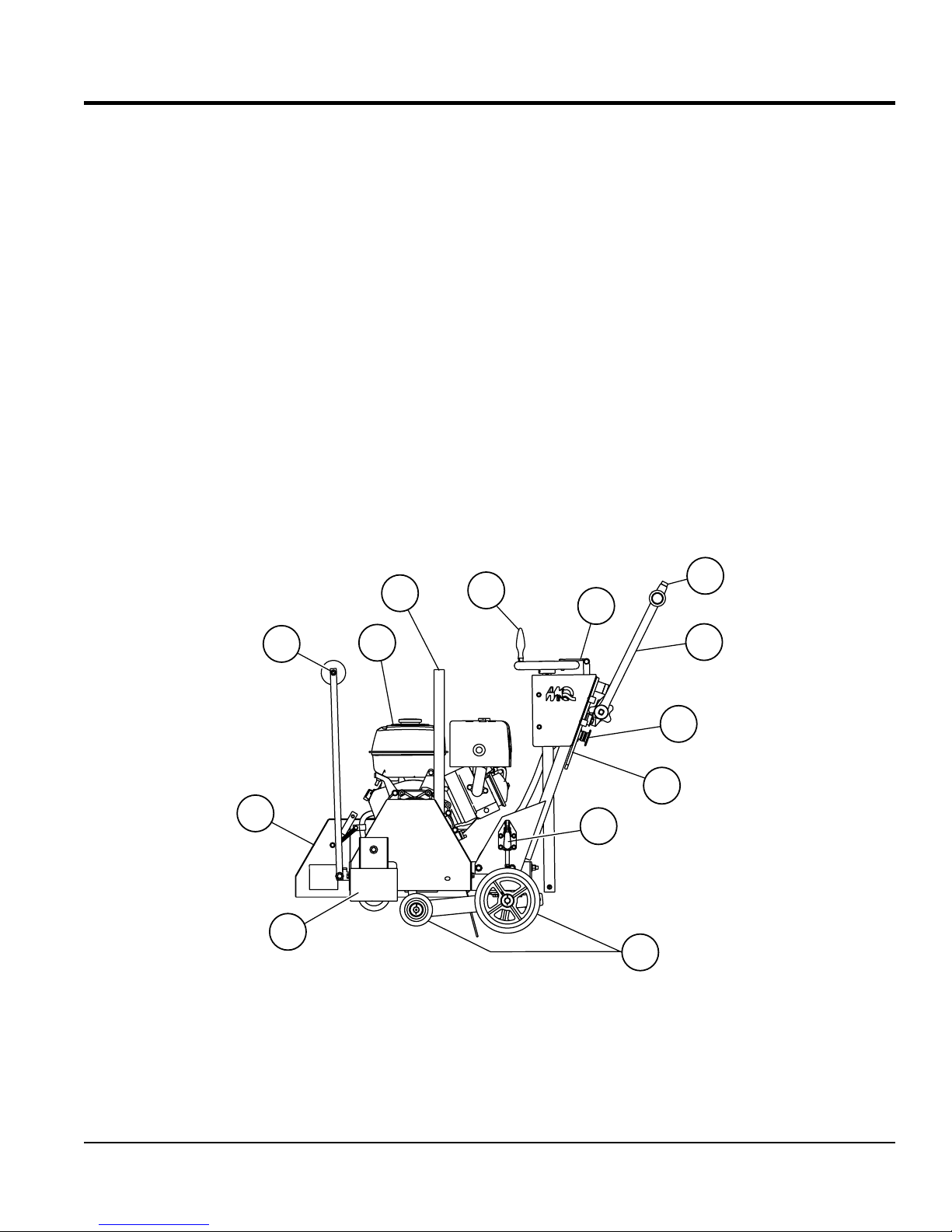

Figure 2. SP1 Saw

PAGE 18 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

Adjustable Anti-Vibration Handle Bar.

Easy adjusting Raise/Lower System with Positive Depth

Lock.

Infinite adjusting Depth Feed Gauge.

Over-center Lifting Bale.

Left OR Right side sawing.

Hinged front Blade Guard.

Rugged Pointer Tracking Arm.

Super-rigid steel box frame.

Manual Wheel Brake.

Water delivery system for Left/Right hand sawing.

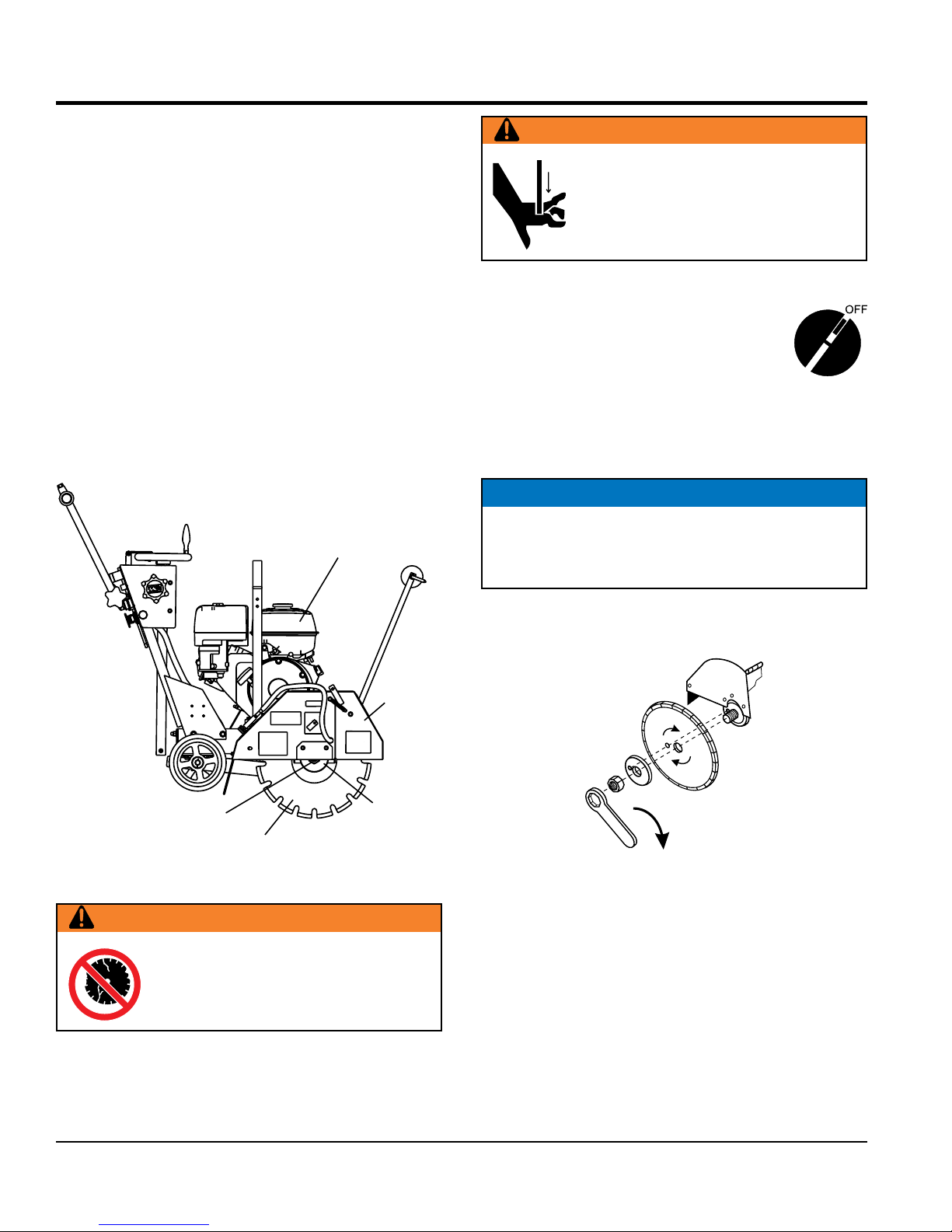

COMPONENTS

For quick reference, Figure 3 highlights basic features of

the SP1 Saw.

1. Engine Stop Switch — Located on the handle bar,

easy toggle to STOP engine.

2. Anti-Vibration Handle Bar — Assists in the harmonic

damping of the saw. Adjustable in height and collapses

flush against the saw frame for efficient storage.

3. Water Connector — Standard garden hose connector

station to deliver cooling water to the blade.

4. Wrench (1.5" Box-end) — Use when removing the

Blade Shaft Nut.

5. Latch — Raise/Lower mechanical STOP.

6. Raise/Lower Hand Wheel —

blade out of cut —

into cut .

Counter-clockwise

Clockwise

to lower blade

to raise

7. Parking Brake — Mechanical clamping stop.

8. Wheels — Heavy-duty roller wheel bearings with

grease fitting.

9. Flange Cover — Guard required for protection as the

flange rotates during operations.

10. Blade Guard — Covers saw blade and flips up to allow

blade changes. Must be kept in place during sawing

operations.

11. Front Pointer — Adjustable device to allow accurate

blade tracking during sawing operations.

12. Engine — HONDA GX390 Gasoline Engine with

Cyclone air filtration and oil alert systems.

13. Lifting Bale — Over-center lifting point for safe

transportation of saw.

10

11

9

13

6

12

Figure 3. Components

1

5

2

3

4

7

8

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 19

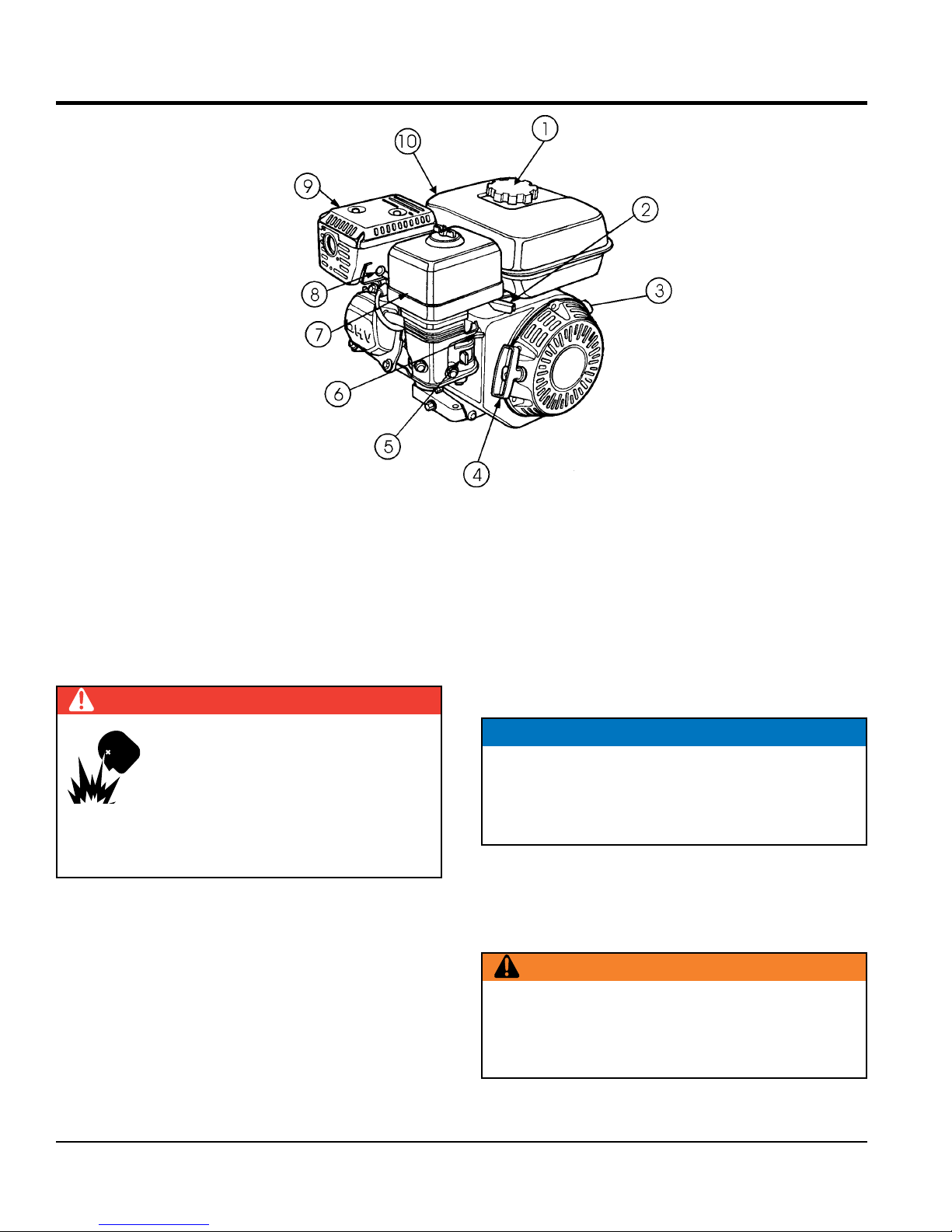

Figure 4. Engine Components

The engine (Figure 4) must be checked for proper

lubrication and filled with fuel prior to operation. Refer to

the manufacturers engine manual for instructions & details

of operation and servicing.

1. Fuel Filler Cap — Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

DANGER

BASIC ENGINE

5. Fuel Valve Lever — OPEN to let fuel flow, CLOSE to

stop the flow of fuel.

6. Choke Lever — Used in the starting of a cold engine,

or in cold weather conditions. The choke enriches the

fuel mixture.

7. Air Cleaner — Prevents dirt and other debris from

entering the fuel system. Remove wing-nut on top of

air filter cannister to gain access to filter element.Spark

Adding fuel to the tank should be done

only when the engine is stopped and has

had an opportunity to cool down. In the

event of a fuel spill, DO NOT attempt to

start the engine until the fuel residue has

been completely wiped up, and the area surrounding

the engine is dry.

2. Throttle Lever — Used to adjust engine RPM speed

(lever advanced forward SLOW, lever back toward

operator FAST).

3. Engine ON/OFF Switch —ON position permits engine

starting, OFF position stops engine operations.

4. Recoil Starter (pull rope) — Manual-starting method.

Pull the starter grip until resistance is felt, then pull

briskly and smoothly.

PAGE 20 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

NOTICE

Operating the engine without an air filter, with a

damaged air filter, or a filter in need of replacement

will allow dirt to enter the engine, causing rapid engine

wear.

Plug — Provides spark to the ignition system. Clean

spark plug once a month.

8. Muffler — Used to reduce noise and emissions.

WARNING

Engine components can generate extreme heat. To

prevent burns, DO NOT touch these areas while the

engine is running or immediately after operating. NEVER

operate the engine with the muffler removed.

9. Fuel Tank — Holds unleaded gasoline. For additional

information refer to engine owner's manual.

INSPECTION/SETUP

INSPECTION/SETUP

1. Read and fully understand this manual, the safety

intructions in particular, and the engine manufacturer's

manual supplied with the saw.

2. Select the correct blade for each application. Refer to

the Blades and Blade Placement sections on pages

20 through 22 for further information.

3. Check blade for wear or damage. Handle all blades

with care and ALWAYS replace a damaged blade.

Clean the saw, removing dirt and dust, particularly the

engine cooling air inlet, carburetor and air cleaner.

4. Check the air filter for dirt and dust. Replace the air

filter if it is found to be dirty.

5. Check carburetor for external dirt and dust. Clean with

dry compressed air.

6. Check fastening nuts and bolts for tightness.

7. Ensure a suitable water supply is available, hooked

up, and used. (connected via garden hose or with an

optional water tank supply system).

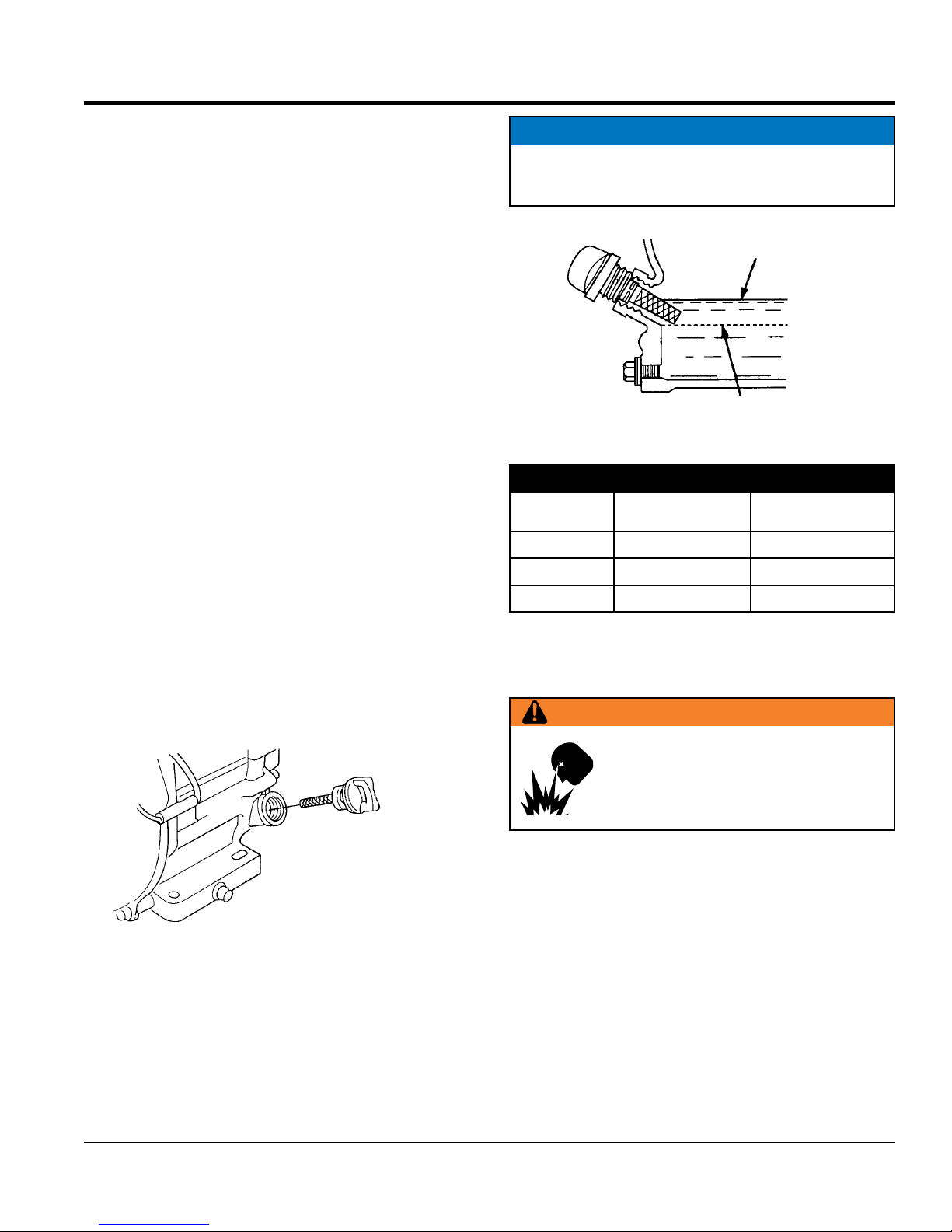

Engine Oil Check

1. To check the engine oil level, place the saw on

secure level ground with the engine stopped. The

frame platform must be

engine oil.

2. Remove the filler dipstick from the engine oil filler hole

(Figure 5) and wipe it clean.

level to

accurately check the

NOTICE

Reference manufacturer engine manual for specific

servicing instructions.

UPPER LIMIT

LOWER LIMIT

Figure 6. Oil Level

Table 4. Oil Type

Season Temperature Oil Type

Summer 25oC or Higher SAE 10W-30

Spring/Fall 25

Winter 25

o

C ~ 10oC SAE 10W-30/20

o

C or Lower SAE 10W-10

Fuel Check

1. Remove the gasoline cap located on top of fuel tank.

WARNING

Motor fuels are highly flammable and can be

dangerous if mishandled. DO NOT smoke

while refueling. DO NOT attempt to refuel

the saw if the engine is hot! or running.

Figure 5. Engine Oil Dipstick (Removal)

3. Insert and remove the dipstick without screwing it

into the filler neck. Check the oil level shown on the

dipstick.

4. If the oil level is low (Figure 6), fill to the edge of the oil

filler hole with the recommended oil type (Table 4).

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 21

2. Visually inspect to see if fuel level is low. If fuel is low,

replenish with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration.

DO NOT top-off fuel. Wipe up any spilled fuel.

INSPECTION/SETUP

Guards And Covers

WARNING

NEVER operate the saw without blade

guards and covers in place. DO NOT

operate with the front of the blade guard

raised. The blade exposure cannot exceed

180 degrees during operation. Adhere to

the safety guidelines or other applicable local regulations.

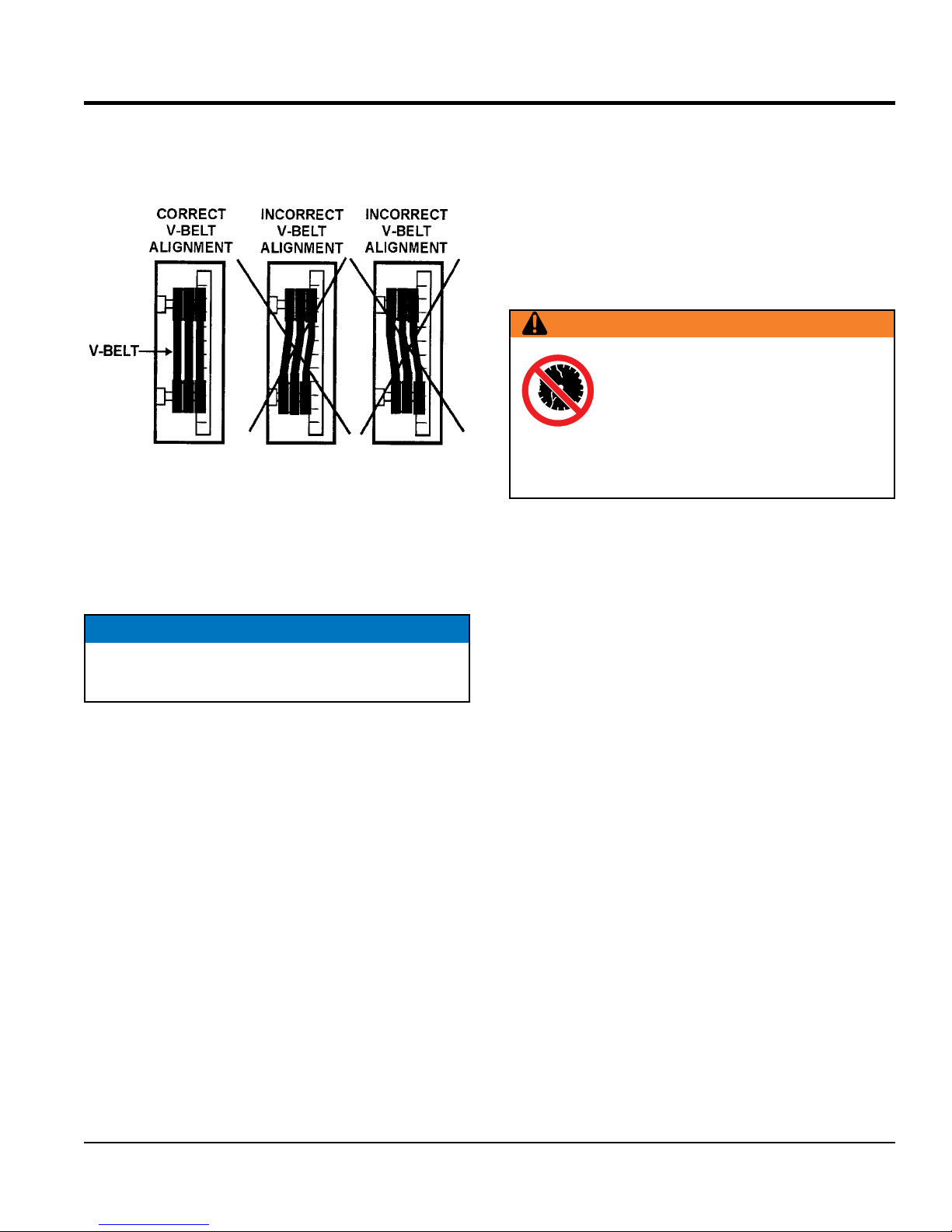

V-Belt Check

A worn or damaged V-belt can adversely affect the

performance of the saw. If a V-belt is defective or worn,

replace ALL the V-belts. V-belts should always be replaced

in sets.

WARNING

NEVER attempt to check the V-belt with

the engine running. Severe injury can

occur. Keep fingers, hands, hair, and

clothing away from all moving parts.

V-Belt Alignment and Tensioning

This saw is equipped with premium V-belts that have been

aligned and tensioned by factory personnel. The V-belt

must be aligned and tensioned for proper operation of the

saw.

Use the following procedure to check the alignment of

V-belt:

Figure 7. Blade Guard (Right-side mounting)

Blade Guard Inspection

CHECK the following on the Blade Guard (Figure 7)

Ensure the water feed tubes are properly positioned to

permit water flow to both sides fo the diamond blade.

Check that the guard is bolted firmly upon the saw frame.

Check that the spring tensioned front cover of the guard

is firmly seated with the rear section of the guard and

there are no gaps. NEVER lift the blade guard while

engine is running.

ENSURE the V-Belt Cover is in place and securely

fastened during operation of the saw (Figure 8).

1. Remove the bolts that secure the V-belt cover (Figure

8) to the saw frame.

Figure 8. V-Belt Cover

2. Check uniform parallelism (Figure 9) of V-belt and

pulley (sheaves). Use a straight-edge or machinist's

square against both pulleys and adjust both pulleys

until equally aligned.

PAGE 22 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

INSPECTION/SETUP

3. Check V-belt tension by using a tension meter (3.0

lbs./1.36Kg) against the inside belt at a mid point

between the two pulleys, or by deflecting the center

belt at a mid point 3/16" (5 mm).

Figure 9. V-Belt Alignment

4. DO NOT over or under tighten the V-belts. Severe

damage can occur to the saw and engine crankshaft

if the belt is over-tensioned. A decrease of power to

the blade and poor performance will result if the belt

is under-tensioned (loose on pulleys).

SPECIFIC TOOLS TO BE USED

This saw is to use tools (blades) as follows:

Steel Core Segmented or Continuous Diamond Rim

Cutting Wheel.

Any other type of tool is not to be used. See Table 5 for

specific blade usage for material.

WARNING

Failure to thoroughly inspect the diamond

blade (Figure 10) for operational safety

could result in damage to the blade or

the saw, and may cause injury to the user

or others in the operating area. Discard

damaged or worn blades and replace with fresh

blade.

NOTICE

V-belt alignment must be rechecked after adjusting

belt tension.

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 23

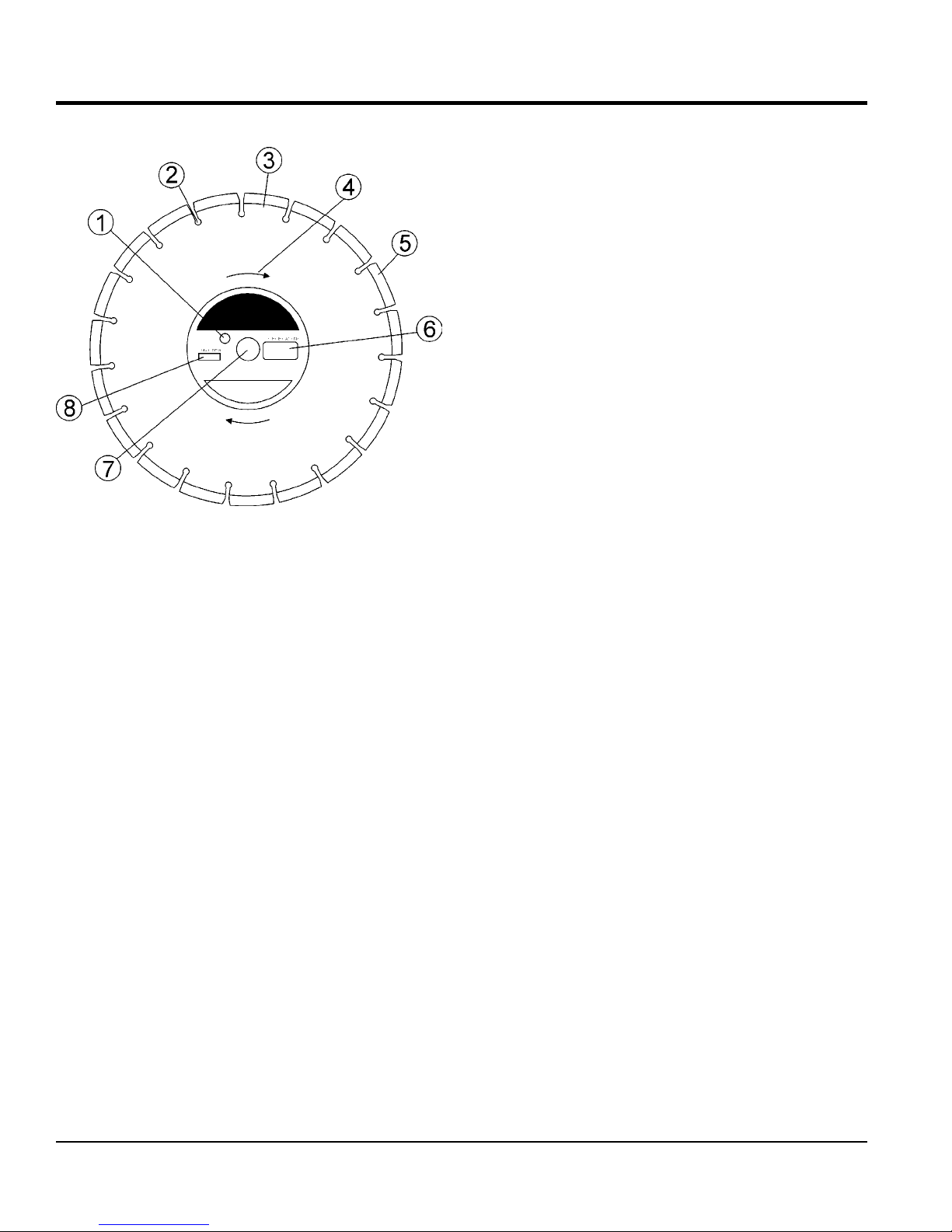

BLADES

Figure 10 highlights the components of a diamond blade.

Figure 10. Diamond Blade

1. Drive Pin Hole – A commonly located hole on the

diamond blade core that prevents operational blade

slippage between the inner & outer blade flanges

(collars). Inspect the diameter of the hole to ensure

there is no distortion, and that a snug fit develops

between the hole and drive pin.

5. Diamond Segment or Rim – Ensure there are no

cracks, dings, or missing portions of the diamond

segment/rim. DO NOT

a segment or a portion of the rim

use a blade that is missing

. Damaged and/

or missing segments/rims may cause damage to your

saw, and injury to the user or others in the operating

area.

6. Specifications – Ensure that the blade specifications,

size, and diameter properly match up to the sawing

operation. Wet blades must have water to act as

a coolant. Utilizing a diamond blade not matched

properly to the task may result in poor performance

and/or blade damage.

7. Arbor Hole – It is essential that the arbor hole diameter

properly matches the shaft arbor, and that it is free

from distortions. Correct blade flanges (collars) must

be used. The inside face of the flanges must be clean

& free of debris. An out of round arbor condition will

cause damage to the blade and the saw.

8. MAX RPM – This RPM reference is the maximum safe

operating speed for the blade selected. NEVER exceed

the max RPM on the diamond blade. Exceeding

the MAX RPM is dangerous, and may cause poor

performance and may damage the blade. All blades

used must be designed for the maximum spindle

RPM.

2. Stress Relief Holes (Gullets) – Check the steel core

for cracks that may have propagated from the slots and/

or gullets. Cracks indicate extreme fatigue failure and if

sawing continues, catastrophic failure will occur.

3. Edge Of The Steel Core – Check the diameter edge for

discoloration (blue oxidation) indicating an overheating

condition caused by insufficient cooling water/air.

Overheating of blades may lead to loss of core tension

and/or increase the possibility for blade failure. Check

to make sure the steel core’s width is uniform about

the rim of the blade, and not succumbing to an “under

cutting” condition brought about by highly abrasive

material or improper under cutting core protection.

4. Directional Arrow – Check to ensure that the blade is

oriented properly on the spindle for sawing. Reference

the directional arrow on the blade and place it so the

direction of rotation “downcuts” with the turn of the

shaft.

PAGE 24 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

Table 5. Material Listing And Blade Selection

Material Blade

Cured Concrete Cured Concrete Blade

Green Concrete Green Concrete Blade

Asphalt Asphalt Blade

Asphalt over Concrete Asphalt/Concrete Blade

Block, Brick, Masonry, Refractories Masonry Blade

Tile, Ceramic, Stone Tile Blade

BLADES

Diamond Blades

Selecting the diamond blade type and grade defines how

the blade will perform both in cutting speed and blade life.

Selection of the proper diamond blade consists of:

Material to be Cut

Type of Saw Being Used

Horsepower of Saw

Hardness Characteristics of the Material

Performance Expectations

Factors for sawing economy:

Type of Blade

Depth of Cut

Sawing Speed

Characteristics of the Material Being Cut

Blade Speed

WARNING

Operating saw blades at rotational speeds

greate r than those speci fied by the

manufacture can cause blade damage,

and may injure the user or others in the

operating area.

A diamond blade’s performance is directly connected to

specific peripheral (rim) speeds.

The following shaft rotational speeds have been factory set

to ensure optimum blade performance:

• SP1 457mm Capacity - 2,836 RPM

BLADE PLACEMENT

WARNING

Failure to thoroughly inspect the diamond

blade for operational safety could result in

damage to the blades or the saw and may

cause injury to the user or others in the

operating area.

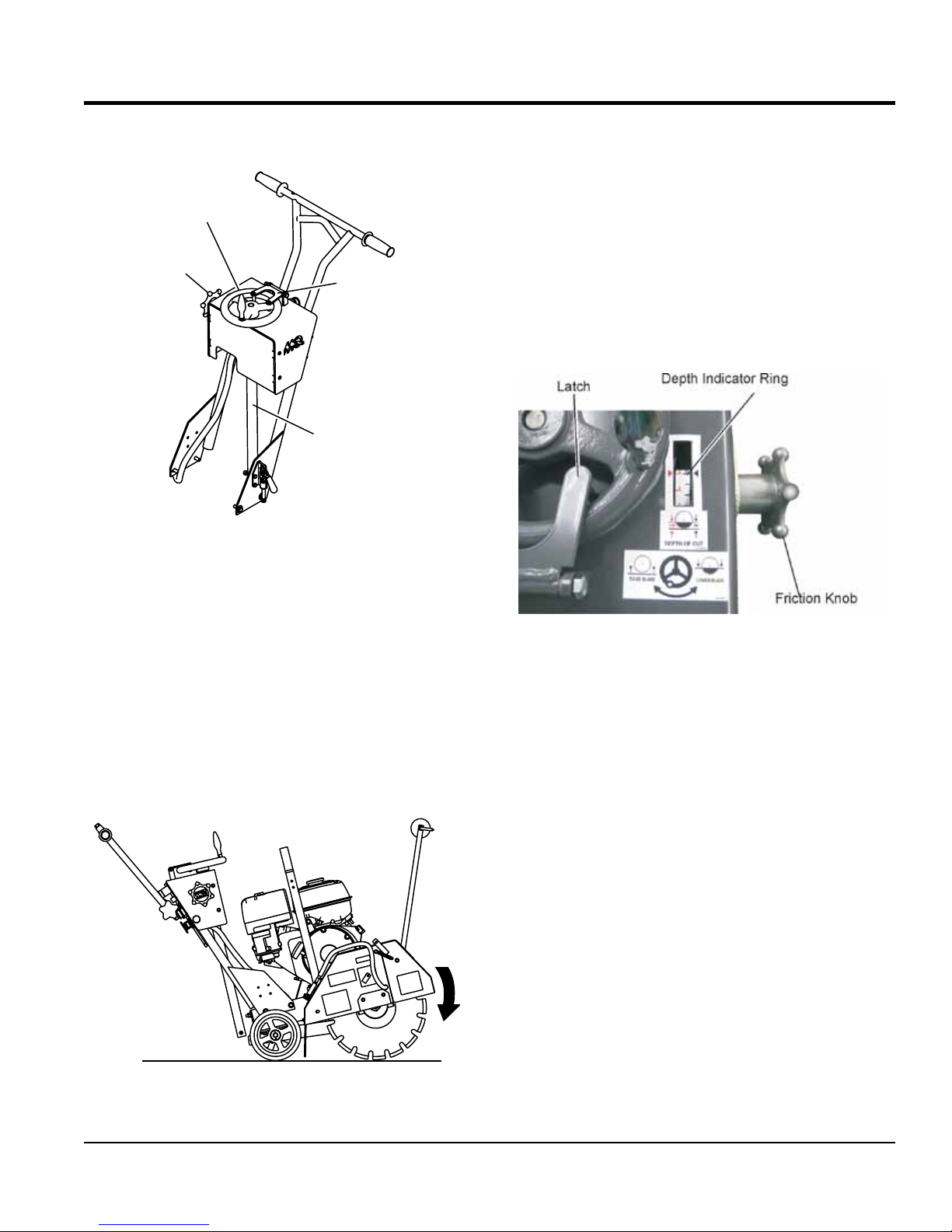

Refer to Figure 11 for the following steps.

1. Engine OFF — Set the ENGINE ON/OFF switches to

the "OFF" position to prevent accidental starting.

2. Blade Guard — Pivot the blade guard front cover all

the way back. The guard tension spring will keep the

front cover in position.

3. Blade Hex Nut — Unscrew the spindle nut (right side

loosens clockwise and tightens counter-clockwise while

the left side loosens counter-clockwise and tightens

clockwise. DO NOT overtighten the nut (approximately

45-50 ft. lb/61-68 N/m) when finalizing the assembly.

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 25

BLADES

4. Outside Blade Flange (Collar) — Ensure that the

outside blade flange is placed flush against the

diamond blade. The inside surface of the flange must

be free of debris and permit a tight closure on the

surface of the blade core.

5. Diamond Blade — Ensure that the proper diamond

blade has been selected for the job. Pay close attention

to the directional arrows on the blade. The blade's

operating directional arrows must point in a "downcutting" direction to perform correctly. When placing

the blade onto the spindle, ensure the arbor hole of the

blade matches the diameter of the shaft.

6. Inner Flange (Collar) — This flange is fixed upon the

spindle. The inside surface of the flange must be free

of debris and permit a tight closure on the surface of

the blade.

ENGINE

WARNING

Dropping or forcing the blade onto the

cutting surface can severely damage the

diamond blade and may cause serious

damage to the saw and bodily harm.

Blade Removal and Replacement

1. Set the ENGINE ON/OFF switches to

the OFF position to prevent accidental

starting.

2. Place the saw on a stable level working surface.

3. Ensure the blade is raised and the raise/lower crank

is locked into position.

NOTICE

When removing or installing a diamond blade, please

note that the blade retaining nuts are left and right-hand

threaded.

BLADE HEX NUT

DIAMOND BLADE

Figure 11. Blade Placement

WARNING

Incorrectly installed blades can cause

damage to the blade or equipment or

cause injury due to breakage.

4. Lift up the blade guard cover to gain access to the

blade.

BLADE

GUARD

BLADE

FLANGE

(COLLAR)

Figure 12. Mounting the Diamond Blade

5. Use the provided blade nut wrench to remove and

install the blade. (Figure 12)

6. Unscrew the spindle nut (right side loosens clockwise

and tightens counter-clockwise while the left side

loosens counter-clockwise and tightens clockwise).

DO NOT overtighten the nut (approximately 45-50 ft.

lb/61-68 N/m) when finalizing the assembly.

PAGE 26 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

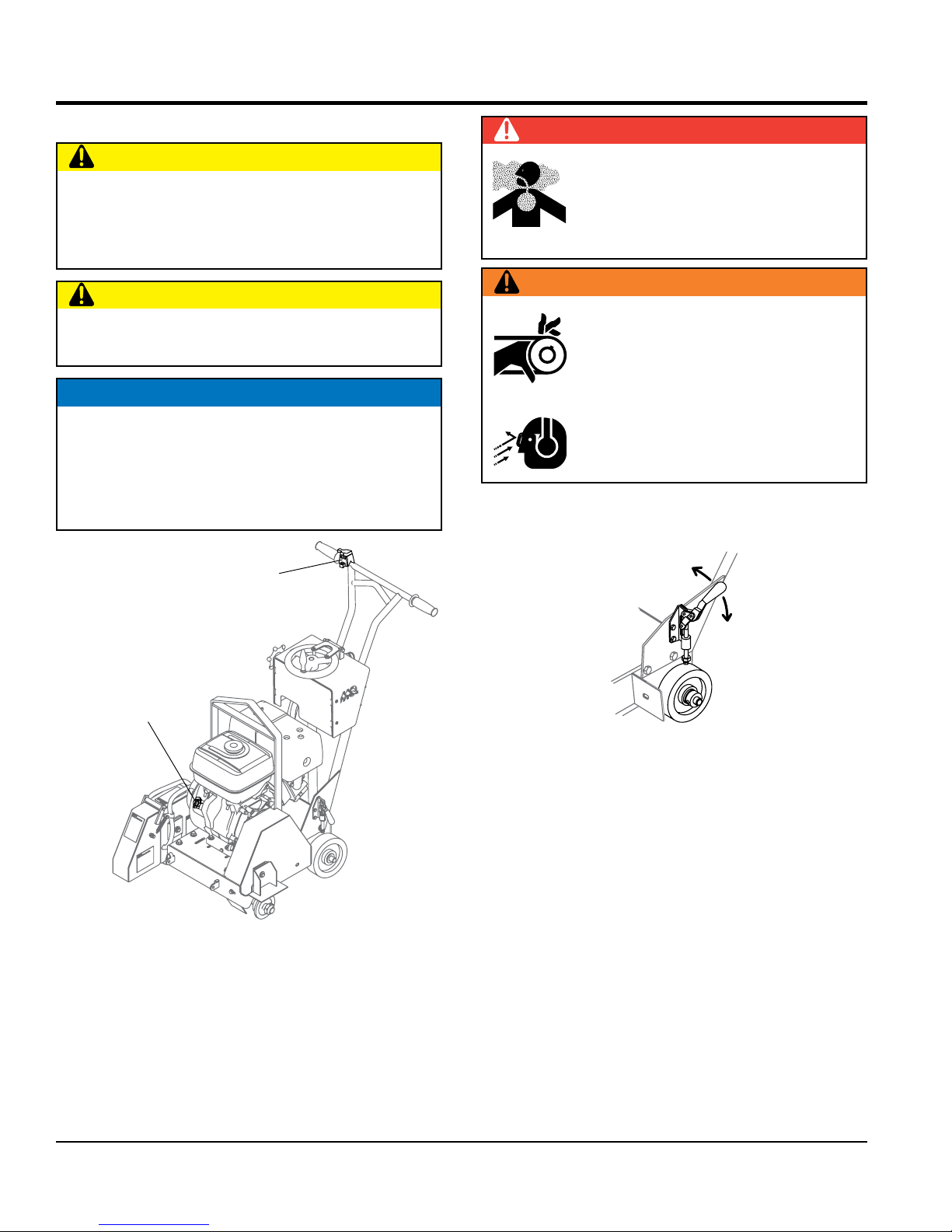

RAISE/LOWER AND DEPTH STOP

Figure 13 highlights the components of the Raise/Lower

Depth Stop Assembly.

Raise/Lower Wheel

Depth Gauge

Friction Knob

ACME Thread Assy.

Figure 13. Raise/Lower Depth Stop

Depth Stop Latch

Raise/Lower

5. Position Depth Indicator Ring to "0".

6. Depth Guage Friction Knob can be adjusted as

necessary using locknut inside of console.

7. The Diamond Blade is now oriented.

8. The Depth Indicator Ring now refernces the depth of

cut.

9. Once the blade is at the desired depth during sawing

operations, position the Depth Stop Latch within the

Raise/Lower Wheel.

Calibrating the Desired Depth of Cut

The SP1 provides for infinite depth adjustment with

Diamond Blades 12" thru 18" in diameter.

1. Turn Engine to off.

2. Place saw on level ground.

3. Select Diamond Blade and mount the blade according

to Figure 12.

4. Lower the blade so it just touches the surface.

Figure 15. Setting Depth Stop

Figure 14. Lowering Blade for Depth of Cut

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 27

OPERATION

START-UP

CAUTION

DO NOT attempt to operate the saw until this manual

has been read and thoroughly understood. Engine

operating steps may vary. See included engine

manufacturer's operating manual.

CAUTION

Ensure the work area is clear of tools, debris, and

unauthorized people.

NOTICE

The Engine Stop Switch located on the handlebar

(Figure 16) serves both as an Emergency Engine

Shut-Off and as the primary ON/OFF switch. This

allows the operator to shutdown the saw safely away

from moving parts.

ENGINE STOP SWITCH

(Emergency Stop

and Primary ON/OFF)

DANGER

NEVER operate the saw in a confined area

or enclosed structure that does not provide

an ample free flow of air.

WARNING

NEVER place hands or feet inside the belt

guard or blade guard while the engine is

running. ALWAYS shut the engine down

before performing any kind of maintenance

service on the saw

ALWAYS wear approved eye and hearing

protection while operating the saw.

1. Keep Wheel Clamp applied (lever DOWN) until

completely ready for cutting operation.

ENGINE STOP

SWITCH

(Secondary ON/OFF)

Figure 16. Engine Stop Switches

Figure 17. Parking Brake

2. Ensure the diamond blade has been mounted correctly

and that it is raised above the surface you are about

to saw.

3. Place the fuel valve lever (Figure 18) to the "ON"

position.

PAGE 28 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

Figure 18. Engine Fuel Valve Lever

4. Place the ENGINE ON/OFF switch located on the

ENGINE (Figure 19) in the "ON" position. Place the

ENGINE ON/OFF switch located on the HANDLEBARS

(Figure 20) in the "ON" (center) position.

OPERATION

NOTICE

The CLOSED position of the choke lever enriches the

fuel mixture for starting a COLD engine. The OPEN

position provides the correct fuel mixture for normal

operation after starting, and for restarting a warm

engine.

Figure 19. Engine ON/OFF Switch (On Engine)

Figure 20. Engine ON/OFF Switch (On

Handlebars)

5. Place the Choke Lever (Figure 21) in the "CLOSED"

position.

Figure 21. Choke Lever

CAUTION

The engine speed has been set at the factory. Changing

the governor speed could damage the blade and/or

the saw.

6. Rotate the throttle lever (Figure 22) halfway between

fast and slow for starting. All sawing is done at full

throttle. The engine governor speed is factory set to

ensure optimum blade operating speeds.

SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10) — PAGE 29

Figure 22. Throttle Lever

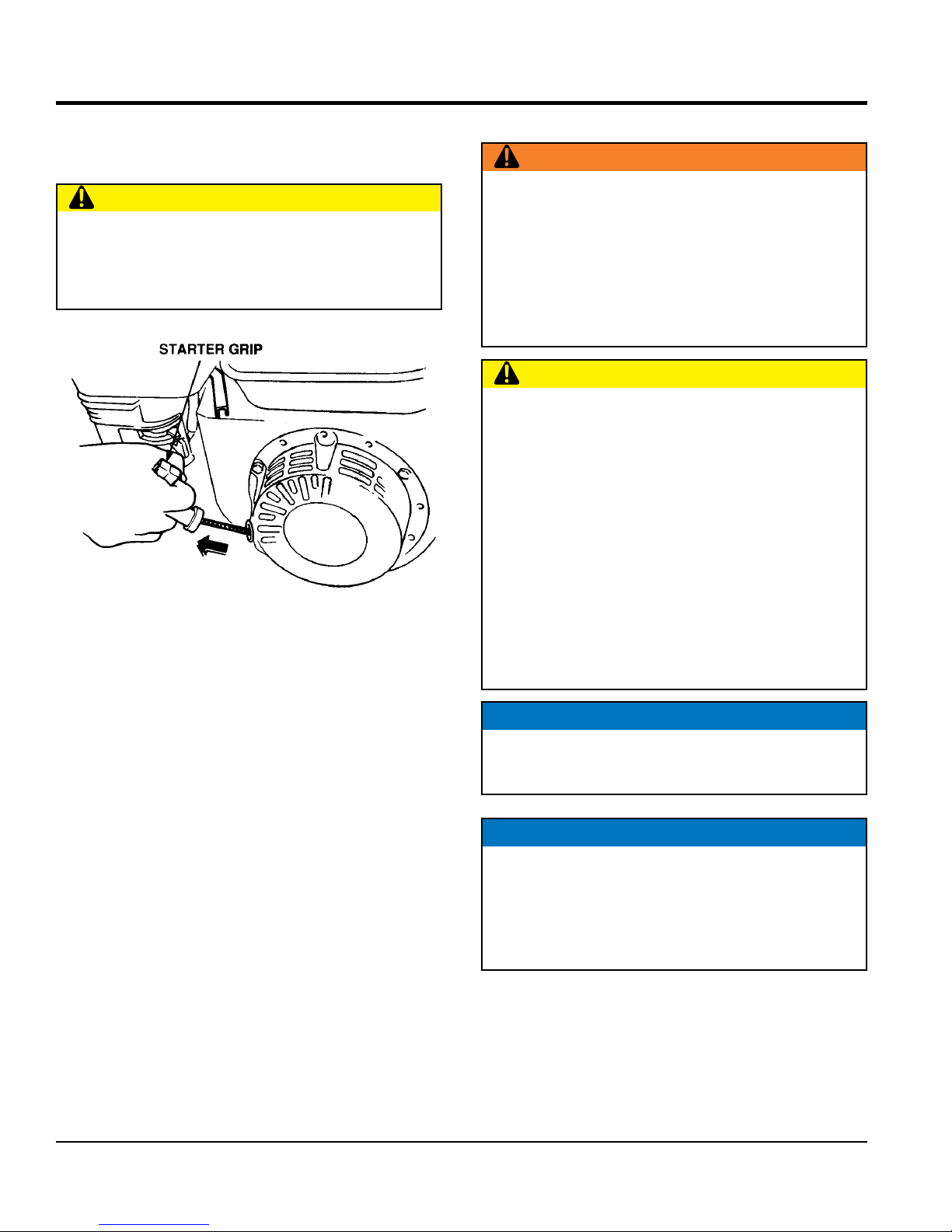

7. Grasp the starter grip (Figure 23) and slowly pull it out.

OPERATION

The resistance becomes the hardest at the compression

point. Pull the starter grip briskly and smoothly for

starting.

CAUTION

DO NOT pull the starter rope all the way to the end.

DO NOT release the starter rope after pulling. Allow it

to rewind as soon as possible.

Figure 23. Starter Grip

8. If the engine has started, slowly return the choke lever

(Figure 21) to the "OPEN" position. If the engine has

not started repeat steps 1 through 7.

OPERATION

WARNING

• ALWAYS cut with the saw at FULL THROTTLE.

Attempting to cut with the saw at less than full throttle

could cause the blade to bind or stop abruptly in the

slab resulting in serious injury to the operator or

others in the area.

• ALWAYS keep clear of rotating or moving parts while

operating this equipment.

CAUTION

• Ensure the cutting area is clear of tools, debris, and

unauthorized people.

• DO NOT try to cut faster than the blade will allow.

Cutting too fast will cause the blade to rise up out of

the cut. Improper cutting rate can decrease the life

of the engine and blades.

• Engin e componen ts and the blade can get

EXTREMELY HOT! during operation. ALWAYS

allow the engine and blade to cool before handling

or servicing.

• Whenever the saw is not in operation or being moved

or transpor ted, apply the wheel clamp brakes to

prevent unwanted displacement.

9. Before the saw is placed into operation, run the engine

for several minutes. Check for fuel leaks, and noises

that could be associated with loose guards and/or

covers.

PAGE 30 — SP1 PAVEMENT SAW • OPERATION AND PARTS MANUAL — REV. #0 (01/04/10)

NOTICE

Mark the cutting line clearly and always saw in a

STRAIGHT LINE ONLY.

NOTICE

The Engine Stop Switch located on the handlebar

(Figure 16) serves both as an Emergency Engine

Shut-Off and as the primary ON/OFF switch. This

allows the operator to shutdown the saw safely away

from moving parts.

Loading...

Loading...