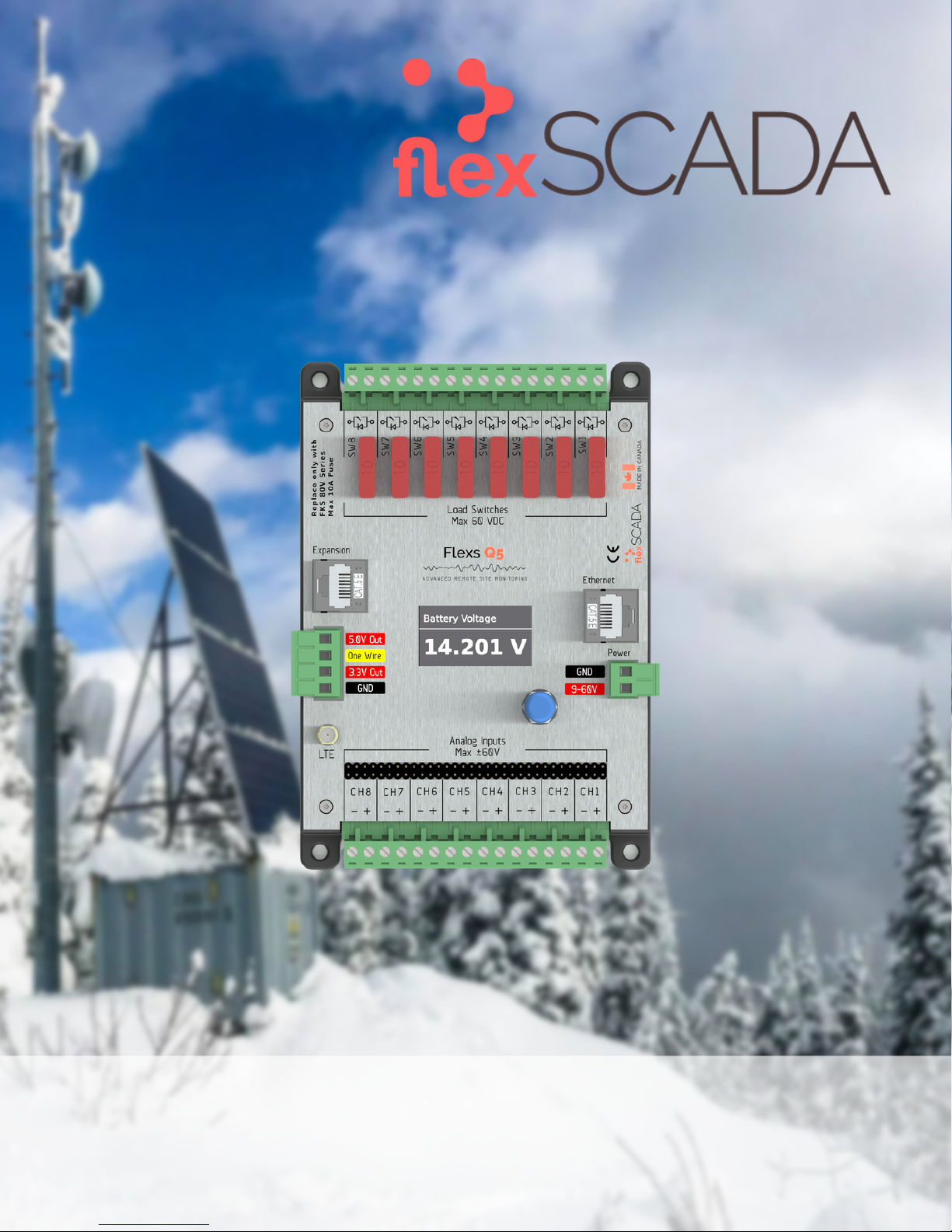

F l e x s Q 5 / Q 5 P r o

A D V A N C E D R E M O T E S I T E M O N I T O R I N G

R e v : 3 . 2 L a s t U p d a t e d : 2 0 1 9 / 0 1 / 2 1

U S E R G U I D E

T A B L E O F C O N T E N T S

G O T Q U E S T I O N S ?

Can't find what you're looking for?

We love hearing from our customers!

Please contact us with any questions.

C O N T A C T

+1 877.352.7398

support@flexscada.com

www.flexscada.com

P.O. Box 277

Lytton, B.C. V0K 1Z0

Canada

C O N T E N T S

Section 1.0: Hardware Specifications

Section 1.1: What's included

Section 1.2: Getting Started

Section 1.3: Web Interface Overview

Section 1.4: Main Menu

Section 1.5: Visualization Menu

Section 1.6: Input Graphing

Section 1.7: Input Oscilloscope

Section 1.8: Device Options Page

Section 1.9: Ping Probes Page

Section 1.10: Network Page

Section 2.0: Analog Inputs

Section 2.1: Voltage Inputs

Section 2.2: Current Inputs

Section 2.3: 1-wire sensors

Section 2.5: AC Power Metrics

Section 3.0: Relay Configuration

Section 4.0: Scripting

Section 5.0: SNMP

Section 6.0: Device Firmware Updater

Section 7.0: Device Interface

Section 8.0: Expansion Interfaces

Section 9.0: Warranty Terms

G L O S S A R Y

1-wire/one-wire - a sensor protocol developed by Dallas Semiconductors

A - Amps (Unit of Current)

AC - Alternating Current

AVG - Average

Bit - The smallest possible amount of data: 0 or 1

Bool or Boolean - true or false, usually represented with a single bit

Byte - 8 bits

CH - Channel

CT - Current Transformer

DC or VDC - Direct Current

DFU - Define Firmware Updater

DHCP - Dynamic Host Configuration Protocol

DNS/NS - Domain Name Service (server that converts names to IPs)

FET - MOSFET (Type of semiconductor switch)

FW - Firmware

Floating Point - Any non-whole number

HTTP - HyperText Transfer Protocol

HTTPS - Secure HyperText Transfer Protocol

HVD - High Voltage Disconnect

HW - Hardware

Hz - Hertz (Cycles per second)

I2C - Communication protocol

INS - Instantaneous Value

IP - Internet Protocol v4

IPv6 - Internet Protocol v6

IoT - Internet of Things

JSON - JavaScript Object Notation

kSPS - Thousand Samples Per Second

LAT/LNG - GPS Latitude/Longitude (Decimal Degrees Format)

LTE - 4G Cellular Service

LVD - Low Voltage Disconnect

MAC - Media Access Control

mA - Milliamps (1000th of an Amp)

mJ - Megajoules

MODBUS - Communication protocol used for Industrial PLC's

Mbps - Megabits Per Second

Ohms - Unit of Impedance

PF - Power Factor

PING or IMCP - Internet Control Message Protocol

PoE - Power Over Ethernet

RMS - Root Mean Square

SLAAC - IPv6 Stateless Address Autoconfiguration

SNMP - Simple Network Management Protocol

SW - Switch

Subnet/Netmask/NM - Refer to Internet Protocol

TCP - Transmission Control Protocol

THD - Total Harmonic Distortion

TX - Transmit

Typ - Typical

UART - TTL Level Serial

UID - Unique Identifier

V - Volts

VDC - Volts DC

VT - Voltage Transformer

W - Watt (Unit of Power)

1 . 0 - H a r d w a r e S p e c i f i c a t i o n s

P H Y S I C A L

Dimensions: 157 mm x 108 mm x 40 mm (Mounting Holes: 96 mm x 144 mm - 4 x 3mm)

Also mount with standard DIN Rail - Recommended DIN Rail space: 120 mm

Temperature Rating: –40 to 85°C (industrial rated components)

Environment: Max 95% relative humidity, non-condensing ( ETSI300-019-1.4 Standard )

Weight: 200g

P O W E R R E Q U I R E M E N T S

Voltage: 9 - 60 VDC (reverse polarity protected)

Power Consumption: 0.6 W @ 12V Typical (varies based on configuration)

A N A L O G I N P U T S

Analog Conversion: 24 bit; 0.05 mV @ ±60 V range; 0.004 mV precision @ ±5 V range

Voltage Range: ±60 V (fully differential, bi-polar) (0.5 MΩ. Imp)

Current Range: 0 - 25 mA (requires hardware jumper change)

L O A D S W I T C H E S

Max Voltage: 60 VDC

Max Current: 8 A Max Cont (100 A Surge <1 ms) (50% derating above 50° C)

Switch Type: Isolated solid state N-Channel FET /w fly-back protection

Fusing: ATO blade style fuse (replace only with fuses rated for correct voltage range)

Software Fuse: 500 mA to 5 A ***PRO ONLY***

Current Sensing: 0 to 5 A ***PRO ONLY***

R E G U L A T E D O U T P U T S

5.0 V output: 500 mA Max

3.3 V output: 500 mA Max (Typ 3.47V)

3.3 V Output /w LTE Module: 150 mA Max (Typ 3.47V)

E T H E R N E T

10/100 Mbps Operation

Long-Range 300 Meter at 10 Mbps

IEEE 802.3az Energy Efficient Ethernet

±15 kV IEC 61000-4-2 Level 4 ESD Protection

IEEE 802.3 Auto-Negotiation

IPv4: DHCP, Static; IPv6: SLAAC, DHCPv6, Static

Passive PoE: Pins 4, 5+; 7, 8- @ 9 to 56V

LTE SPECS ***LTE VERSION ONLY***

LTE CAT–M1/NB–IoT 3GPP release 13 LTE Adv. Pro

SMA Connector: SMA-Female

LTE Bands: 2, 3, 4, 5, 8, 12, 13, 20, 28

Modem: ublox SARA-R410M-02B

Certified by: FCC, ISED, PTCRB, NCC, RCM, RED,

AT&T, Telus, Telstra, Verizon, GITEKI 2

1 . 1 - W h a t ' s I n c l u d e d

1 x Flexs Q5

1 x DIN Rail Mounting Kit

1 x Product Manual

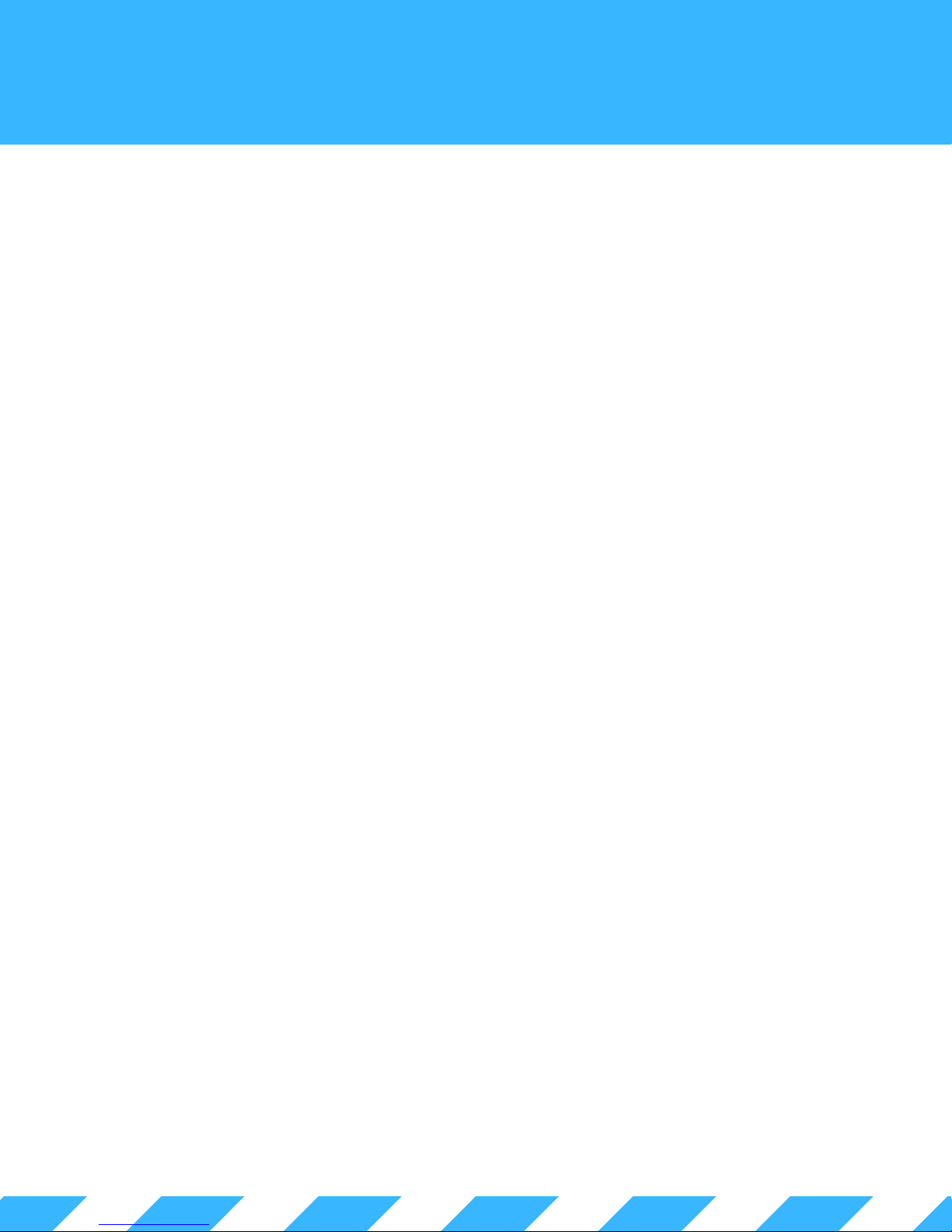

1. 2 - G e t t in g St a r t ed

This section provides a brief overview on how to connect to a FlexsQ5 for the first time.

Attach the Q5 to a power source (9 to 60 VDC) using the two pin power terminal located beside the Ethernet port.

The Q5 can alternatively be powered via POE over the Ethernet port.

DO NOT POWER THIS DEVICE DIRECTLY FROM AN AC POWER SOURCE! DOING SO WILL VOID YOUR WARRANTY!

Powering with a Passive PoEPowering with a DC Power Supply Powering with a Battery

AC Power

Q5 Power Input

Once power is connected, the Q5 display will illuminate indicating that the Q5 has successfully started.

The Q5 will then search for a router on the network to get an IP address. If the Q5 fails to find a router within the first 10s

of bootup, it will fallback to standalone mode. In standalone mode, the Q5 will use the fallback IP (default 192.168.1.20).

Network Connected Mode

DC Power

Supply

Q5 Power Input

9 - 60 V Battery

PC Ethernet Q5 Ethernet

AC Power

Standalone Mode

24 V PoE

Connect using the IP assigned by your network.

This IP can be found on the Q5 display

(highlighted in red above)

Using Chrome, Firefox or Safari enter the device IP in the address bar to load the Q5's web interface.

The default password for the device is "flexscada".

IT IS HIGHLY RECOMMENDED TO CHANGE THIS PASSWORD WITH A SECURE PASSWORD TO AVOID

UNAUTHORIZED ACCESS TO THE DEVICE.

Connect using the following addresses:

http://192.168.1.20 OR with IPv6

http://[fe80::744]

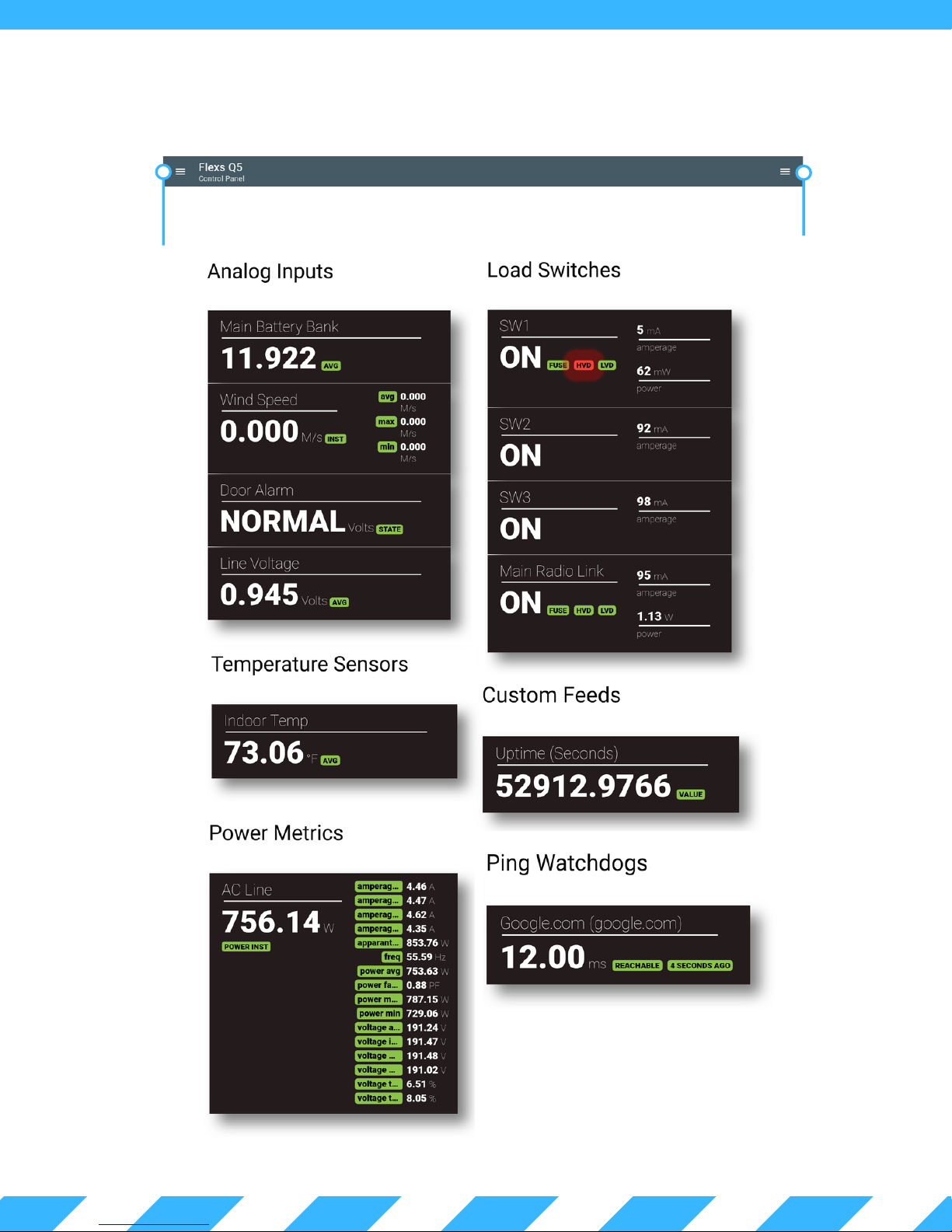

Main Menu

(see sec. 1.4)

Configured

Analog Inputs

(see sec. 2.0)

1 . 3 W e b I n t e r f a c e O v e r v i e w

Visualization Menu

(see sec. 1.5)

Load Control

(see sec. 3.0)

Adopted 1Wire Temp

Sensors

(see sec. 2.1)

Computed

Power Metrics

(see sec. 2.5)

Registers set from

custom scripting

(see sec. 4.0)

Ping Watchdog

Status (see sec. 1.9)

1 . 4 - M a i n M e n u

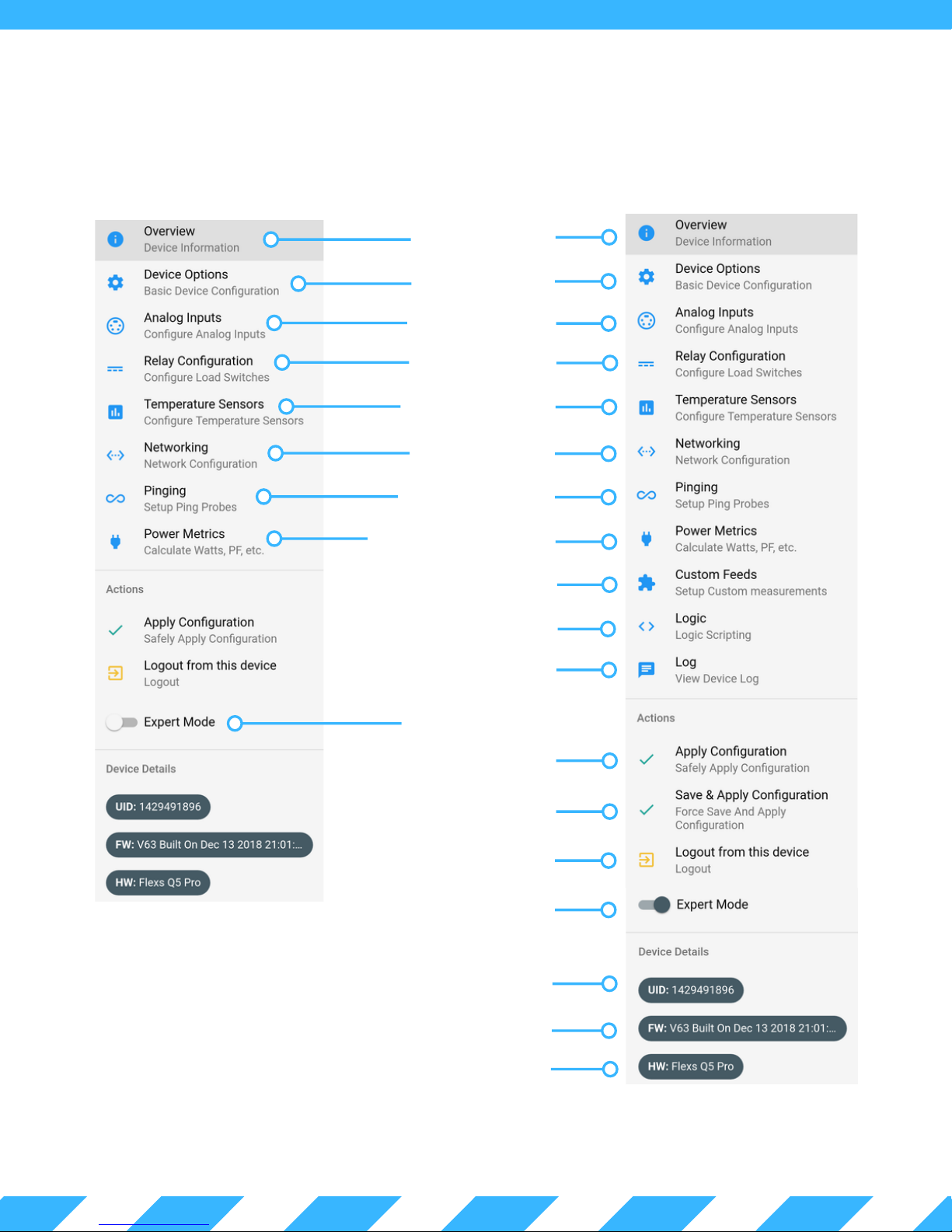

Expert Mode - Disabled Expert Mode - Enabled

Dashboard Page

(see sec. 1.3)

Device Options Page

(see sec. 1.8)

Analog Inputs Page

(see sec. 2.0)

Load Outputs Page

(see sec. 3.0)

1-Wire Sensors Page

(see sec. 2.3)

Networking Page

(see sec. 1.10)

Ping Watchdog Page

(see sec. 1.9)

Calculated Power Metrics

(see sec. 2.5)

Custom Feeds (see sec. 4.0)

Custom Scripts (see sec. 4.0)

System Log Page

Expert Mode (disabled)

Safely Apply Settings

(user must confirm after saving.)

Save and apply settings

(without confirm option)

Logout

Expert Mode (enabled)

Unique Device ID (UID)

Firmware Version

Hardware Type

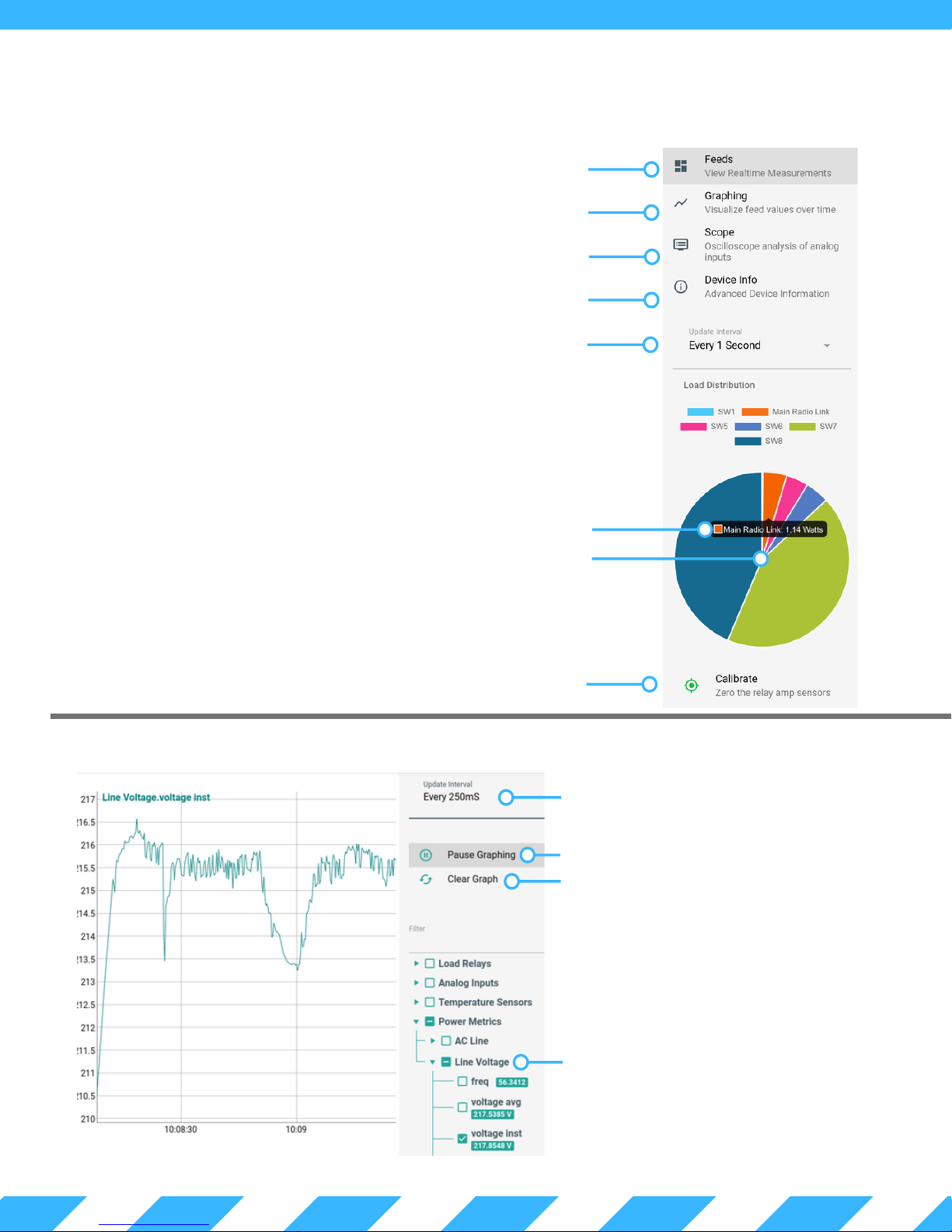

1 . 5 - V i s u a l i s a t i o n M e n u

Dashboard Page (see sec. 1.3)

Input Graphing Page (see sec. 1.6)

Input Oscilloscope Page (see sec. 1.7)

Advanced Device Info

Data Update Interval

View Load Watts (PRO ONLY)

Load Distribution (PRO ONLY)

Manually Zero Load Sensors (PRO ONLY)

1 . 6 - I n p u t G r a p h i n g P a g e

Data Update Interval

Pause/Start Data Collection

Clear Graph Of All Data

The graphing tool is used to view short

term trends, such as current or voltage

readings. The Update Interval range

can be configured from 100ms to 1

minute.

Select Data Metrics to Graph

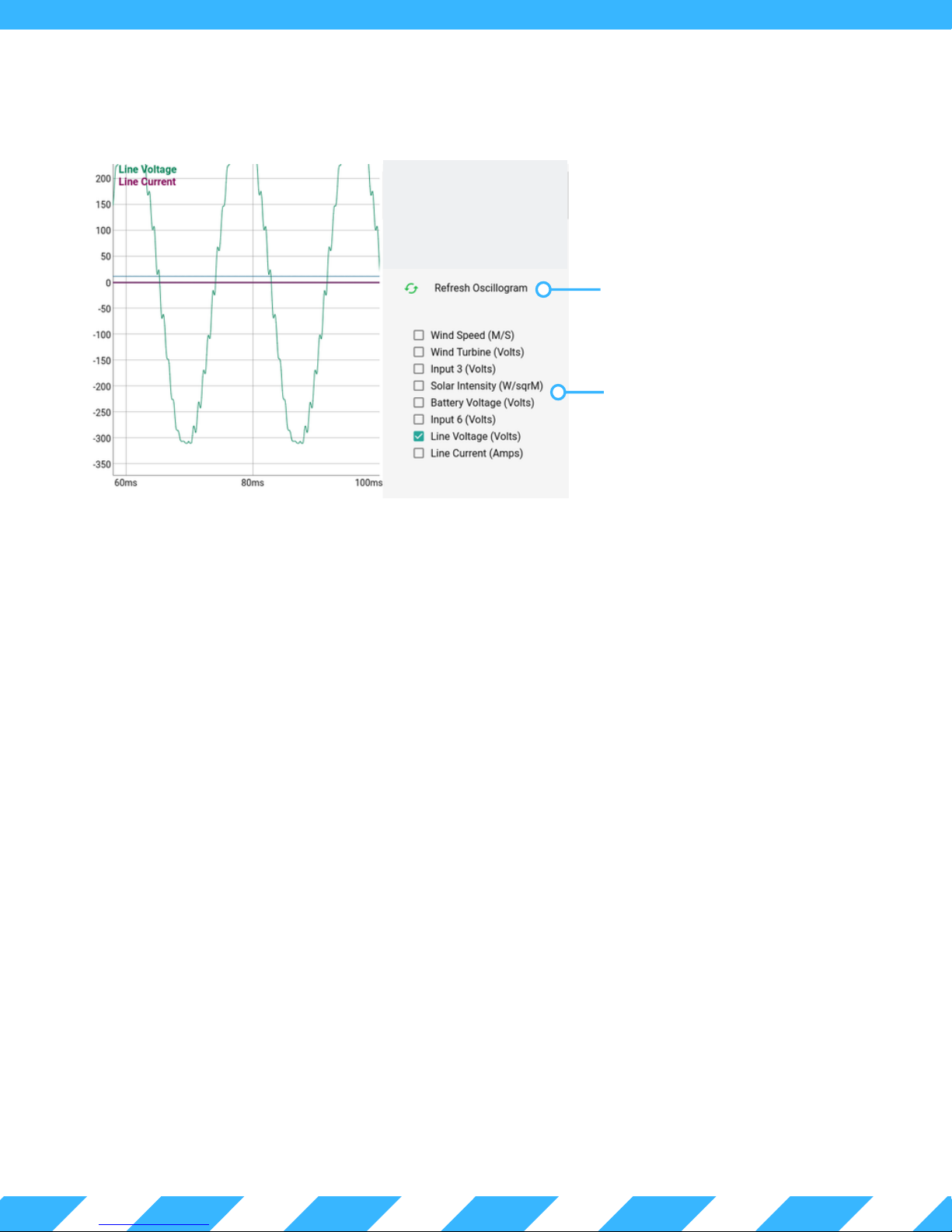

1 . 7 - I n p u t O s c i l l o s c o p e P a g e

Sample Data and

Regenerate Graph

Select Data Channels

to Display

The oscilloscope tool provides a close-up look at how "clean" your power source is.

When the refresh button is clicked, 2,000 simultaneous readings are taken across all 8 channels and then displayed

in the web interface. The sample rate of the Q5 is 8,000 samples/second (i.e. 8 samples taken each millisecond).

Device Name and

Description are displayed

in the cloud platform.

These are useful when

searching for a device.

Tags are used in the

filtering of graph data

in Grafana.

Coordinates will autofill

when a GPS module is

attached.

Event logging level.

Transmit measurements

to cloud at this interval.

Also used for avg, min

and max values on the

dashboard.

Sync configuration

data with cloud at this

interval.

1 . 8 - De v i c e O p ti o n s P a g e

Default address change this only when

running customer

hosted cloud software.

If enabled Q5 will check

cloud for available

updates at boot. See

Section 6.0.

UPDATE FIRMWARE allows you to

manually enter the Device Firmware

Updater (DFU) to manually update the

device firmware. More on this in

section 6.0.

EDIT CONFIG FILE allows the advanced

feature of editing the actual JSON

config file. This is only recommended

for expert users.

1 . 9 - Pi n g P r o b es P a g e

Ping Probe Label.

Status of a probe as found on the

dashboard.

Ping this Host

Ping Timeout

1 . 1 0 - N e t w o r k Pa g e

Select a relay to run

action on (optional).

Perform an action if

destination is

unreachable

If the network mode is set to DHCP, the device will

request an IP from a DHCP server on the network.

Should the Q5 fail to get an IP it will fall back to the

IP configuration entered here. The same applies to

IPv6. The FlexesQ5 supports both IPv4 and IPv6 at

the same time.

Additionally, this page includes options for enabling

and disabling SNMP, Modbus TCP and modifying

the SSL Certificate.

See Section 5.0 SNMP

2 . 0 - An a l o g I n pu t s

There are several types of inputs, each of which can be roughly categorized as

Analog, Frequency, Pulse Counter and Alarm Contacts. This section provides

greater detail on how to use and configure each of these input types.

Enable/Disable this input.

Channel Name (displayed on dashboard).

Channel Description (optional).

Used for most applications with DC or AC.

Eg. wind speed, RPMs, pulse inputs.

Always up counting. Eg. total gallons.

Eg. Door open, or water detected.

See section 2.4 for more details on

measurement types.

These expert

options should

not be changed

unless directed

by FlexSCADA.

Units shown on dashboard.

The Q5 hardware has been designed to accept a wide range of inputs.

To insure proper operation, it is important to select the correct Channel

Mode and corresponding hardware configuration.

Voltage Mode accepts a wide voltage range (±60V AC/DC) and can be

used for a number of functions (alarm contacts, battery voltages, 0-5V

sensors, AC Power Metrics, etc). See sec 2.1 for examples

Current Mode is used for current based sensors, such as 4-20mA sensors

and current transformers. See sec 2.2 for examples.

Extra low Voltage Mode is used where high accuracy in a very low voltage

range is required. The max voltage range for this mode is ±2.4V AC/DC.

When changing between input Channel Modes, you will be alerted

about a required hardware change to the jumpers on the Q5. When

making this change the Q5 must be powered down.

FAILURE TO MAKE THIS HARDWARE CONFIGURATION CHANGE BEFORE CONNECTING YOUR INPUT MAY

DAMAGE YOUR DEVICE AND VOID YOUR WARRANTY!

In the Logging / Dashboard section, you must enable the

metrics you wish to be visible on the dashboard or sent to

the cloud for graphing. Some items may be grayed out,

depending on the input configuration chosen. For

example, the State metric is only valid when the

Measurement Type is set to Alarm Contact.

For min, max and average time period see Section 1.8 Measurement Interval.

2 . 1 - Vo l t a g e I np u t

Below is an example of a typical 0-10V sensor attached and configured for use with the Q5. When installing, first confirm

that the Q5 is configured in Voltage Mode (see section 2.0 for details on voltage mode). Next, attach the analog output

from your sensor to the + terminal on the Q5 channel (shown in the diagram below).

Navigate to the Analog Inputs menu, select the channel, then select Voltage Mode under Channel Mode. Next select

Analog Value under the Measurement Type drop down (Channel Mode and Measurement Type are highlighted in the

blue box).

Set the sensor range using the specs found on the side of the sensor or in the provided data sheet. In the above

example, 0V corresponds to 0 PSI and 10V corresponds to 100 PSI. Enter the voltage output range of the sensor's

analog output in the green box. If the sensor output was a 0-5V signal level, the values in the green box would be 0

and 5 instead of 0 and 10.

The Multiplier, Offset and Gain are automatically set when using the Input Scaling section.

For higher voltages (up to 300V) the Q5 Voltage Reducer hardware module may be used with the following

configuration. For more details on AC power, refer to section 2.5.

Q5 Voltage Reducer

Module (for voltages

up to 300V RMS).

Input Scaling for Q5 Voltage Reducer Module

Q5 Voltage Reducer

Module (installed).

Current Sensors

Current sensors (not to be confused with current transformers) take a current signal and convert it to an analog voltage

output. FlexSCADA and its resellers can provide a 100 A non-invasive current sensor which can be configured as shown

below.

Scale Ratio

Load wire

shown in

blue.

To double the accuracy and halve

the range the load wire can be

looped through the sensor a

second time. In the above example,

the new max range is ±50 A.

Input Scaling with two loops.

The load wire can be looped

through the sensor as many times

as needed to get the desired scale.

Only the Full Scale field is modified

to reflect this ratio change.

Load wire

shown in

blue.

Sensor Power Requirements: 5 V DC

Max Current: ±100 A

Part No. ACC-AMP-100NI

1:1 ratio

Example channel configuration.

The exact values to be entered can be found on

the calibration document included with the

current sensor.

Example calibration report included with each current sensor.

2 . 2 - Cu r r e n t I np u t s

The 4 - 20 mA sensor is the de facto industry standard. This section details how to configure the Q5 to accept

this type of input. As the Q5 does not power current loops, external power will need to be provided in order for

your current loop to function.

To utilize this feature the hardware jumpers must be configured in Current Mode (see section 2.0). Next,

configure the input from the Analog Inputs menu. The Channel Mode and Measurement Type must be configured

as shown below. The configuration example below shows a 4 - 20 mA sensor with a range of 0 - 150 PSI. The

sensor range for the specific sensor must be entered as shown in the red boxes.

WARNING! EXCEEDING THE CURRENT RATINGS OF THE Q5 WILL DAMAGE YOUR DEVICE AND VOID THE WARRANTY!

Hardware configuration example for a 4 - 20 mA sensor.

Current transformers can also be used

with the Q5 without the need for

additional conditioning. Current

transformers are connected as shown

above.

Note: Current transformers are not to

be confused with the 100A noninvasive current sensors sold by

FlexSCADA. The non-invasive current

sensor converts current readings into a

0-5V voltage style reading. See sec 2.1

2 . 3 - 1- W i r e S e ns o r s

The Q5 supports 1-wire sensors. The below diagram shows how to connect and provide a 1-wire sensor with power

and data communication. The Q5 supports up to 64 sensors, each sharing the same 3 wires.

To attach additional one-wire sensors a standard wiring

bus will be required, as the terminals are not physically

capable of holding more than a few sensors.

Each one-wire sensors has a unique digital ID that makes

it possible to view its value without interfering with the

other sensors.

Once the sensors have been connected, they must be configured. In the web interface, navigate to the Temperature

Sensors menu. Located at the bottom of the page you will see "1 unconfigured sensors found on this device" followed by

the unconfigured sensor showing an ADD button (any one-wire sensor can be used in this way).

Alternately, it is possible to pre-add the sensors using the ID found on the sensors sold by FlexSCADA and its resellers. All one-wire sensors will have a unique ID. FlexSCADA one-wire sensors have been labeled with this preexisting ID for ease of use.

Adopt unconfigured

temp sensor.

The below example shows a newly added temp sensor, along with the options to name the sensor and choose which

metrics to log or add to the dashboard.

Manually add temp sensor.

(Sensor ID found on sensor

wire shown right.)

Show/Hide sensor options.

ID of the sensor, this can be updated

if a sensor needs to be replaced.

Sensor Label - this label is used on the

dashboard and in the graphing.

Detailed sensor description. (optional)

Select what metrics you wish to graph or

display on the dashboard. For min, max

and average time period see Section 1.8 Measurement Interval.

The display units can be modified in the

Device Options menu.

New temp sensor displayed

on the dashboard.

Tags help in selecting datasets when graphing. An example might be "greenhouse 1"

allowing an easy way to select sensors belonging to that greenhouse.

Delete this sensor.

2 . 4 - Un d e r s t a n di n g M e a s u r e m e n t T y p e s

Not all measurements utilize an analog value. This section details the various Measurement Types supported by the

Q5.

Each channel provides the following Measurement Type's option:

For additional information on

the Analog Value option

and Input Scaling calculator

refer to sections 2.1 and 2.2.

Both Frequency and Pulse Counter require a threshold to recognize when a valid

signal has been detected. This is known as the Pulse Detection Threshold. To

avoid counting the same rising edge twice, the signal must exceed 20% of the

Pulse Detection Threshold in order to be considered a valid pulse (see graphic

below).

20% Over Threshold

Pulse Detection Threshold

Frequency is the number of valid pulses per second or hertz (Hz).

Alternately, Power Metrics can be used to find the frequency of an input (see

section 2.5 for more information).

Pulse Counter is a total count of all pulses since the Q5 has booted.

Pulse Multiplier is used to adjust sensor readouts. For example, the spec sheet

for an anemometer reads as follows: Output Frequency: 1,1 HZ / m/s. But we

want the sensor to read out the exact m/s on our graphs. The multiplier could

be set to 1 / 1.1 = 0.909 multiplier.

In another example a flow sensor reads 450 output pulses/liter. The multiplier

could adjust the output to read in liters/minute. We are looking at Hz (pulses

per second) so we need to divide by 60 seconds. 450 / 60 = 1 liter per 7.5

pules/s = 1 (liter) / 7.5 (pulses) = 0.133333 multiplier.

Alarm under threshold.

Send update to cloud

when alarm is triggered.

Threshold over or under

which to trigger alarm.

2 . 5 - Po w e r M e t ri c s

The Power Metrics menu provides the ability to calculate a number of power related metrics for both DC and AC

power. With AC power it is possible to calculate watts, amps, volts, power factor, apparent power, frequency and

Total Harmonic Distortion (THD). With DC the main use for power metrics is for calculating wattage.

Metric Label

Detailed sensor description (optional).

See sec 2.0 for

more details on

source channels.

Select AC or DC mode

Expert options for AC metrics.

Power Metrics as displayed

on the dashboard.

Instantaneous, Average, Minimum

and Maximum can be selected for

Calculated Real Power

Calculated as Volts x Amps

Ratio of Real Power to Apparent Power

Calculated Voltage

Total Harmonic Distortion

Calculated Amperage

graphing or logging of each available

metric. For min, max and average

time period see Section 1.8 Measurement Interval.

Calculated AC Frequency

3 . 0 - Re l a y C o n fi g u r a t i o n

Both the Q5 and Q5 Pro include 8 solid state load relays capable of switching up to 10A DC (Max

100W). The pro version includes internal current sensing on all 8 relays capable of accurately measuring loads up to

5 Amps DC.

Toggle State

ATO Style Fuse

(PRO ONLY)

Polarity must

be correct, or

load will not

turn off.

Load switch only,

circuit must be

powered.

Load Name

Default state after Q5 is rebooted

Toggle State for

10 seconds

Load Relay as found on the dashboard

Digital Fusing

(PRO ONLY)

Eg Battery voltage powering this device,

required for Low/High Voltage Disconnect.

Reset Low/High Voltage

Disconnect or Digital

Fusing (PRO ONLY)

Load Current

(PRO ONLY)

Load Voltage is

required to calculate

wattage (PRO ONLY).

Low and High Voltage Disconnect serve

the same purpose; protecting the load

from damage in the event of extreme

power fluctuations.

Choose the metrics to be logged or

displayed on the dashboard. LVD, HVD and

Load Power require Load Voltage to be

provided. Load Amperage, Load Power and

Digital Fusing are available with the Q5 Pro

only.

Switched Load

Power Distributor Bus

No. ACC-Q5-DIST15A

Power Source

For systems using a single voltage we offer a distribution bus to cut down on

the required wiring. When using the distributor each channel acts as a power

source rather than an isolated switch. The max combined load across all

channels must not exceed 15 A. No software configuration is required for this

hardware accessory.

3 . 1 - Re l a y S p e ci f i c a t i o n s

The Q5 Relays are subject to environmental de-rating as detailed below.

8 Amps

6 Amps

4 Amps

2 Amps

0 Amps

41 to 55° C

-45 to 40° C

Red - under 30 Volts.

Blue - 30 to 60 Volts.

55 to 100° C

50 Amps

40 Amps

30 Amps

20 Amps

10 Amps

0 Amps

10 S

30 S

100 mS

Max on time in 1 minutes period.

Technical Specifications

Switch Impedance: 8 mOhms (Not including fuse)

Max Open Voltage: 70 VDC

Power Consumption: 2 mW in closed state

Isolation Level: +/- 125 V (Channel to Channel or

Channel to Q5 Ground)

Max Surge Rating: 250 A transient pulsed; tp ≤ 10 µs

Max Current Sensing: 5 A (PRO ONLY)

Contains fly-back suppression for switching inductive

loads such as relays, motors, etc.(up to 140 mJ (Max

250 A Peak Current)

4 . 0 - Sc r i p t i n g

The FlexsQ5 has an on-board scripting language that utilizes JavaScript syntax. This scripting provides access to

all on-board analog inputs, temperature sensors, load outputs, custom feeds and Modbus TCP.

Custom feeds are a location where you can store data generated by your scripts. This data is uploaded to the cloud

server and can also be viewed on the dashboard. Additionally you can access custom feeds from SNMP. See

section 5.0.

Custom feeds can be configured as either a bool (true or false) or as a floating point number (a number with

decimal places). See the on board "Custom Feeds" example for more info on how to write to the custom feeds.

Custom Feed Label

Status of custom feed as

Delete this custom feed.

Warning: Deleting a feed

will increment all other

feeds requiring change to

the scripting.

displayed on the dashboard.

Add a new custom feed.

Logic menu is where all the action with scripting takes place. Included on this page are a number of helpful

examples (highlighted in blue). Below you will find the syntax highlighted code editor (highlighted in red).

All scripting is managed as a secondary priority to the

main functions of the Q5 (to avoid interruptions to

system tasks). For a more in-depth look at scripting,

please see the on board examples.

Any errors in the scripting will prevent all of the script

from functioning. Details on where the error is located

can be seen at the top of the page upon saving the

settings.

The line in your

script causing the

error.

Error shown at top of page,

indicating the line causing the

problem.

4 . 1 - HT T P A P I

The FlexsQ5 has a HTTP/HTTPS API that allows for a number of

parameters to be accessed or modified. Below are some

examples of how to use this API.

All requests must be authenticated using the BASIC AUTH

headers with the password hashed using SHA256.

This PHP example requests all the metrics from the FlexsQ5. The

response shown left includes all enabled channels and relays. The

/crypto endpoint displays IP Address info and other system

parameters.

The above example code can be downloaded here:

https://pastebin.com/y66r1niS

This PHP example shows how to

set a relay state on the flexsQ5.

The Q5 will respond with the

above reply indicating that the

state change was successful.

Using this same API endpoint it

is also possible to reset the soft

fuse, toggle the relay and toggle

the relay for a timed 10

seconds.

The example shown left can be

downloaded here:

https://pastebin.com/fsvaPpP4

In this manual we have only

shown examples written in PHP,

however the Q5 API can be

accessed from any code

language using the correct HTTP

requests.

5 . 0 - SN M P

Simple Network Management Protocol (SNMP) has been used by networks for over 30 years, making it one of

the most widely supported protocols.

The Q5 supports SNMP version 1 and 2c, with the default community of "public". At this time, the community

can not be changed to encourage better security methods such as a VPN.

Enable SNMP in the Networking menu as shown.

1.3.6.1.4.1.412.A.B.C.D

Base OID

Type

0: Analog Input

2: Load Relay

4: Custom Feeds

8: Temp Sensors

10: Power Metrics

Power Metrics

0: Real Power (W)

1: Voltage (V or Vrms)

2: Min Voltage (V or Vrms)

3: Max Voltage (V or Vrms)

4: Amperage (A)

5: Min Amperage (A)

6: Max Amperage (A)

7: Real Power (W)

8: Min Real Power (W)

9: Max Real Power (W)

10: Power Factor

11: Apparant Power (W)

12: Freqency (Hz)

13: THD Voltage (%)

Metric

SNMP Return Format

0: Text String

1: Numerical - SNMP does not support floating

numbers. All numbers are rounded to the third

decimal place and then multiplied by 1,000. For

example, 24.123 would be sent over SNMP as

24,123.

Analog Input

0: Avg Value / Alarm State

1: Instantaneous Value

2: Minimum Value

3: Max Value

4: Alarm State

5: Ripple

Load Relay

0: Switch State

1: Load Current Avg (Pro Only)

2: Load Power (W) (Pro Only)

3: HVD Trip Alarm

4: LVD Trip Alarm

5: Fuse Trip Alarm (Pro Only)

Custom Feed

0: Value / Sate

Temp Sensor

0: Instantaneous Value

Channel ID

Under the Analog

Inputs or Relay

Configuration menu

Under Temperature

Sensor Menu

Under Custom Feed

Menu

Example: Poll the Average

Value of analog channel 1

OID:1.3.6.1.4.1.412.0.1.0.1

Example: Poll the Frequency of

Power Metric ID:0

OID: 1.3.6.1.4.1.412.10.0.12.1

Example: Poll the Current

Average of Load Relay Channel 2

OID: 1.3.6.1.4.1.412.2.2.1.1

Example: Poll the average value of channel 1 using the NetSNMP command line tool.

# snmpget -v2c -c public <IP Address> 1.3.6.1.4.1.412.0.1.0.1

6 . 0 - De v i c e F i rm w a r e U p d a t e r

FlexSCADA will occasional release new firmware to add additional functionality to the Q5. This section explains how

the Device Firmware Updater (DFU) mode works to upgrade your Q5's firmware.

Select Device Options from the main menu. On the Device Options Page, you will find two options relating to firmware

updates.

When enabled, the Q5 will check for available updates on the FlexSCADA server when the Q5 is rebooted. If using

scripting this option is discouraged, as future updates may affect script operation.

The UPDATE FIRMWARE button allows you to manually update the firmware of the Q5

using the DFU mode.

After selecting and starting the upload do not

unplug or refresh the page for 30 seconds.

After refreshing the page, you should be in

DFU mode (shown at right).

You have 5 minutes to find and upload your

firmware before the Q5 will revert back to the

main operating system. You can also exit the

DFU mode by clicking the link marked "Exit

DFU".

The UID, MAC and current IP configuration

are also visible from the DFU mode.

It is also possible to manually force the device into DFU mode by holding the control knob down while power is applied to

the device. This is also mentioned in Section 7.0.

7 . 0 - De v i c e I n te r f a c e

Using the multi-function knob on the Q5, it is possible to view a number of

parameters without using the web interface. The knob can be rotated and pressed to

Rotating goes between

pages, clicking accesses

additional views.

Pressing the knob while the power is applied will put the device in DFU mode - See

Section 6.0. Continuing to hold the knob for an additional 60 seconds will reset the

configuration to factory default.

Ethernet Page - Shows current

IP, Gateway, Netmask, Name

Server and MAC Address.

navigate between pages or access additional views. In the case of relays, clicking the

knob allows you to change the state of the relay. The naming and scaling of each

view found below corresponds to what has been configured in the web interface.

Q5 Homes Page - showing

current IP, device UID,

available buffer for readings

and Bytes of readings taken.

Analog Input Page - See

Section 2.0. There will

be one page for each

enabled analog input.

Press the knob to

switch between views.

Load Relay Page - Press the knob to

switch relay ON/OFF. See Section 3.0

for more info on naming relay channels.

Custom Feed Page - See

Section 4.0 for more details.

One Wire Sensors Page - See

Section 2.3 for more details.

Ping Page - See Section 1.9

for more details.

Power Metrics Page - See

Section 2.5 for more details.

8 . 0 - Ex p a n s i o n I n t e r f a c e s

This section details how some of the expansion interfaces on the Q5 can be used.

RJ45 Expansion Connector

Expansion Pinout

1 . . . . . I2C-SCL / UART-TX (I/O)

2 . . . . . I2C-SDA / UART-RX (I/O)

1 . . . . . . 8

Expansion

3 . . . . . 3.3V DC OUT (500 mA Max)

4 . . . . . GND

5 . . . . . 5V DC OUT (500 mA Max)

6 . . . . . IO Push/Pull 1.8 V / 5 V Open Drain Out

7 . . . . . GND

8 . . . . . One-Wire (I/O)

Memory Expansion

WARNING! CONNECTING A POE TO THIS PLUG WILL

DAMAGE YOUR Q5 AND VOID YOUR WARRANTY!

Note: The I2C, UART and IO

pins are not accessible via

the Q5 software at this time.

Customers that need access

to one of these interfaces

should contact FlexSCADA.

The Q5's internal memory allows for roughly 1 month* of readings

to be stored before older data is erased. In applications where

extensive long term data-logging is required the Q5 may be

outfitted with an external memory card for additional capacity.

For more info on how to use this feature please contact

FlexSCADA.

*Actual duration depends on measurement interval and number of

metrics being logged.

9 . 0 - Wa r r a n t y Te r m s

The FlexsQ5 comes with a 3 yearLimited Manufacturer'swarranty. The FlexsQ5 Pro comes with a 5

yearlimitedManufacturer'swarranty.

For warranty coverage the following terms and conditions apply:

The product must have failed while operating within the specifications outlined in this document.

Water or moisture damage is not covered.

Physical damage to the product as a result of improper use will not be covered.

Buyer must submit an RMA via our website showing proof of purchase.

Buyer must ship the product to our RMA department for review.

Please contact us with any additional warranty questions.

Loading...

Loading...