Page 1

CERTIFIED FINAL DOCUMENT

FLEX-PRO

Peristaltic Metering Pump

R

Exclusive:

2

TWO-YEAR

WARRANTY

system

TFD

Tube Failure Detection

Patent No. 7,001,153 & 7,284,964

ProSeries

SERIES A2

Operating Manual

Protected by Patents: 7,001,153;

7,284,964; 4,496,295

and other patents pending

Page 2

Page 2

Flex-Pro

TABLE OF CONTENTS

Section Heading Page

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Available Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Materials of Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Agency Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.0 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Installing the Discharge Injection Fitting and Suction Strainer . . . . . . 7

5.0 Input Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.0 How to Operate Flex-Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.0 Pump Output Speed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8.0 Contact Closure Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9.0 Set FVS (flow verification system) . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10.0 Pump Tube Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

11.0 TFD (tube failure detection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12.0 Alarm relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

13.0 Reverse Rotor Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

14.0 How To Maintain the Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

15.0 Tube Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

16.0 A2 Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.0 Introduction

Congratulations on purchasing the Flex-Pro variable speed Peristaltic Metering Pump. A peristaltic pump is a type

of positive displacement pump used for pumping a variety of fluids.

Your Flex-Pro pump is pre-configured for the tubing that shipped with your metering pump. The tubing assembly

has an Identification number printed for easy re-order.

Please Note: Your new pump has been pressure tested at the factory with clean water before shipping. You may

notice trace amounts of clean water in the pre-installed tube assembly. This is part of our stringent quality assurance program at Blue-White Industries.

Page 3

Flex-Pro

1.1 Available Models

Feed Rate

Norprene A2V Tube Pumps

Meets FDA criteria for food | Excellent chemical resistance | CIP | SIP

GPH

.01 - 1.4

.11 - 11.1

Norprene Chemical A2V Tube Pumps

Meets FDA criteria for food | Excellent chemical resistance | Extra long life at low pressures

GPH

.10 - 10.8

Gore Style 400, A2V Tube Pumps

Meets FDA criteria for food | Superior chemical resistance

GPH

.15 - 15

®

LPH

.05 - 5.4

.42 - 42

®

LPH

.41 - 126

®

LPH

.56 - 56.4

ML/Min

.

09 - 90

7 - 700

ML/Min

6.8 - 680

ML/Min

9.4 - 940

Max

Speed

RPM

125

125

RPM

125

RPM

125

Max

Pressure

PSI (bar)

125 (8.6)

125 (8.6)

PSI (bar)

50 (3.4)

PSI (bar)

65 (4.5)

Max

Temperature

F (C)

185 (85)

185 (85)

F (C)

130 (54)

F (C)

130 (54)

A3 Model Numbers

115V AC

A2V24-ND

A2V24-NH

115V AC

A3V24-TH

115V AC

A3V24-VH

230V AC

A2V25-ND

A2V25-NH

230V AC

A3V25-TH

230V AC

A3V25-VH

Page 3

220V AC

A3V26-ND

A2V26-NH

220V AC

A3V26-TH

220V AC

A3V26-VH

Tygothane A2 Tube Pumps

®

Meets FDA criteria for food | Resistant to oils, greases and fuels

GPH

.04 - 3.5

.07 - 7.29

.17 - 17.44

* Inlet/outlet connection type

S = 3/8” OD x 1/4” ID tubing compressions type connections

M = ½” male NPT

C-= 3/4” tri-clamp connections

The Flex-Pro Pump’s motor speed is linear over the entire 1% to 100% adjustment range.

!

!

Output versus pressure is nearly linear in all models. Larger tubes exhibit greater losses.

For optimum tube life, specify the pump to operate at the lowest possible RPM and pressure.

!

LPH

.13 - 13.2

.27 - 27.6

.66 - 66

ML/Min

2.2 - 220

4.6 - 460

11 - 1100

RPM

125

125

125

PSI (bar)

65 ( )

4.5

65 ( )

4.5

65 ( )

4.5

F (C)

130 (54)

130 (54)

130 (54)

115V AC

A2V24-GE

A2V24-GG

A2V24-GH

230V AC

A2V25-GE

A2V25-GG

A2V25-GH

220V AC

A2V26-GE

A2V26-GG

A2V26-GH

Page 4

Flex-Pro

2.0 Specifications

Maximum working pressure (excluding pump tubes):

125 psig (8.6 bar)

Note: see individual pump tube assembly maximum pressure ratings.

Maximum Fluid temperature (excluding pump tubes):

3/8” OD x 1/4” ID tubing connections: 130 F (54 C)

M/NPT connections: 185 F (85 C)

Note: see individual pump tube assembly maximum temperature ratings.

Ambient Operating Temperature

OOOO

14 F to 115 F (-10 C to 46 C)

Ambient Storage Temperature

OOOO

-40 F to 158 F (-40 C to 70 C)

oo

Operating Voltage:

115VAC/60Hz, 1ph (1.5 Amp Maximum)

230VAC/60Hz, 1ph (0.7 Amp Maximum)

220VAC/50Hz, 1ph (1.0 Amp Maximum)

240VAC/50Hz, 1ph (1.0 Amp Maximum)

Power Cord Options:

115V60Hz = NEMA 5/15 (USA)

230V60Hz = NEMA 6/15 (USA)

220V50Hz = CEE 7/VII (EU)

240V50Hz = AS 3112 (Australia/New Zealand)

oo

Motor speed adjustment range 100:1:

1.0% - 100% motor speed

Motor speed adjustment resolution:

0.1% increments

Maximum viscosity:

12,000 Centipoise

Maximum suction lift:

30 ft. Water, 0 psig (4.5 m, 0 bar)

Display

Backlit LCD, UV resistant.

Keypad

Eight button positive action tactile switch keypad.

Enclosure:

NEMA 4X (IP66), Polyester powder coated aluminum.

Maximum Overall Dimensions:

7-1/2” W x 10-1/4” H x 14” D (19 W x 26 H x 35.6 D cm)

Approximate shipping wt:

25 lb. (12.0 Kg)

Page 4

Duty cycle:

Continuous

2.1 Materials of construction

Wetted components:

Pump Tube Assembly (Model Specific - 2 provided):

Tubing: .....Norprene or Norprene Chemical or Tygothane

Adapter fittings: .PVDF

Injection / Back-flow Check valve:

Body & insert: . . . . . . PVDF

Check Ball: . . . . . . . . Ceramic

Spring: ..... .....Hastelloy C-276

Ball Seat O-ring: . . . . . Viton (optional EPDM)

Static Seal O-ring: ....Viton (optional EPDM)

Duckbill anti-scale valve: Santoprene

Ancillary Items provided

With “S” tubing type connections only:

Suction Tubing: . . . . . 3/8” OD x 1/4” ID x 10’ Clear PVC

Discharge Tubing: . . . . 3/8” OD x 1/4” ID x 10’ Polyethylene (LLDPE)

Suction Strainer: . . . . . Polypropylene

With “B” tubing and “M” M/NPT connections only:

Suction Strainer:

Body: .................PVDF

Check Ball: ............Ceramic

Ball Seat O-ring: ........Viton (optional EPDM)

With “C” Tri-clamp connections only:

none

q q q

q

q

q

q

Non-Wetted components:

Enclosure:

413 Aluminum (Polyester powder coated)

Pump Head:

q

Valox (PBT) thermoplastic

Pump Head Cover:

Clear Acrylic - Annealed for added strength and chemical resistance.

Permanently lubricated sealed motor shaft support ball bearing.

Brass shaft support bearing retainer.

Cover Screws:

Stainless Steel

Roller Assembly:

Rotor:..................................Valox (PBT)

Rollers: ...............................Nylon

Roller Bearings: .................SS Ball Bearings

q

Motor Shaft:

Chrome plated steel

TFD System Sensor pins:

Hastelloy C-276

Power Cord:

3 conductor, SJTW-A Water-resistant

Tube Installation Tool:

GF Nylon

Mounting Brackets and Hardware:

316 Stainless Steel

TDS #85000-114 rev. 100611

E

Page 5

Page 5

3.0 Features

!

Peristaltic pump design does not have valves that can clog requiring maintenance.

!

Self priming - even against maximum line pressure. By-pass valves are not required.

Cannot vapor lock or lose prime.

!

Output rates to: 17 GPH (64 LPH) and pressures to 125 PSI (8.6 Bar).

!

Variable speed DC motor.

!

Specially engineered tubing for long life at high pressures. Meets FDA 21 CFR

requirements for food contact applications.

!

Patented Tube Failure Detection (TFD) system. Senses tube failure by detecting

chemical in the pump head. No false triggering.

!

100:1 turndown ratio.

!

Operator friendly digital touch pad.

!

Backlit LCD displays motor speed, input signal values, service and alarm status.

!

Outputs include: one 250V/1A relay to monitor TFD (Tube Failure System) and FVS

(Flow Verification System)

!

Two CNC precision machined squeeze rollers and two alignment rollers for optimum

squeeze, unparalleled accuracy, and tube life.

!

Heavy duty rotor - single piece plastic rotor means no flexing and increased accuracy

with no metal springs or hinges to corrode.

!

Inject at maximum pressure in either direction (clockwise and counter clockwise).

!

Compatible with Blue-White’s output Flow Verification Sensor (FVS) system.

Flex-Pro

Enclosure Rating:

NEMA 4X: Constructed for either indoor or outdoor use to provide a degree of protection to personnel against

incidental contact with enclosed equipment; to provide a degree of protection against falling dirt, rain, sleet, snow,

windblown dust, splashing water, and hose-directed water; and that will be undamaged by external formation of ice

on enclosure.

IP66: No ingress of dust; complete protection against contact. Water projected in powerful jets against enclosure from

any direction shall have no harmful effects.

Page 6

Page 6

4.0 Installation

CAUTION

!

Flex-Pro

Risk of chemical overdose. Be certain pump does not overdose chemical during

backwash and periods of no flow in circulation system.

CAUTION

!

CAUTION

!

Always wear protective clothing, face shield, safety glasses and gloves when working on

or near your metering pump. Additional precautions should be taken depending on

solution being pumped. Refer to MSDS precautions from your solution supplier.

All diagrams are strictly for guideline purposes only. Always consult an expert before

installing metering pump on specialized systems. Metering pump should be serviced by

qualified persons only.

4.1 Mounting Location

Choose an area located near chemical supply tank, chemical injection point, and electrical supply. Install pump

where it can be easily serviced.

!

316SS Mounting brackets are included. Mount pump to a secure surface using enclosed mounting hardware.

!

Mount pump close to injection point. Keep inlet (suction) and outlet (discharge) tubing as short as possible.

Longer discharge tubing increases back pressure at pump head.

!

A back flow prevention check valve is recommended at the discharge of the pump to prevent system fluid from

flowing back through the pump during tube replacement or if the tube should rupture.

!

A pressure relief valve is recommended at the discharge of the pump to prevent premature wear and damage to

the pump tube in the event the discharge line becomes blocked.

!

The Flex-Pro does not require back pressure. Keep the discharge pressure as low as possible to maximize tube

life.

4.2 Dimensions

Dim

A

B

C

D

E

F

A2 Series

Inches

10-1/4”

7-1/2”

14”

9-1/2”

11”

3-3/8”

cm

26

19

35.6

24.1

27.9

8.6

B

A

F

OptionalExtended Brackets

Model Number 72000-380

Stainless Steel extended brackets allow pump to be securely mounted to most any surface;

floor, shelf, or skid. Brackets lift pump up 4-1/2 inches (11.43 cm), for easy pump access in

hard to reach areas.

Raise metering pump 4-1/2 inches (11.43 cm) off ground or a surface.

n

Made out of tough Stainless Steel.

n

n

Provides a stable mounting surface.

C

D

E

Model #

72000-380

Extended Mounting Bracket, 1 Pair, SS, 4 SS Screws

Description

Page 7

Flex-Pro

CLICK HERE TO RETURN TO WEBSITE

4.3 Installing Discharge Injection Fitting and Suction Strainer

Page 7

CAUTION

!

CAUTION

!

Proper eye and skin protection must be worn when installing and servicing pump.

This Pump Has Been Evaluated for Use with Water Only.

1/2” Male NPT Connection and 1/2”Hose Barb Models

Discharge Injection / Check Valve

Pipe

Tee

½” Male NPT

½” Male NPT

or ½” Hose Barb

Discharge

Pipe or

½” Tubing

(not included)

Install

upward

for best

results

PVDF

Viton (optional EP)

Hastelloy C-276

Ceramic

T/FEP (optional EP)

PVDF

½” Male NPT

or ½” Hose Barb

Suction

Strainer

Removable

275 Micron

Filter

Suction Strainer

PVDF

Viton (optional EP)

PVDF

Polypropylene

3/8”OD x 1/4” ID Tubing and Tri-Clamp connection Models

Discharge Injection / Check Valve

Pipe tee

1/4” male NPT

½” male NPT

Injection

Check valve

Tube retaining

nut

Discharge

Tubing

PVDF

Viton (optional EP)

Santoprene

PVDF

Hastelloy C-276

Ceramic

T/FEP (optional EP)

PVDF

Duckbill is used to help reduce

calcium buildup when injecting

chemicals that calcify (such as

sodium hypochlorite). Duckbill

may add additional back

pressure to pump (up to 7 psi).

Suction Tubing and Strainer

PVC Suction Tubing

3/8" OD x 1/4” ID

Ceramic

Weight

Polypropylene

Strainer

Page 8

Flex-Pro

Page 8

5.0 Input Power Connections

WARNING

WARNING

Risk of electric shock – cord connected models are supplied with a grounding

conductor and groundingcertain that it is connected only to a pro

Electrical connections and grounding (earthing) must conform to local wiring codes.

Be certain that a

type attachment plug. To reduce risk of electric shock, be

perly grounded, grounding-type receptacle.

grounding conductor is connected to terminal T11-1 located in the

wiring compartment.

WARNING

Risk of electric shock - Disconnect electricity before removing the wiring

compartment cover.

Be certain to connect pump to proper supply voltage. Using incorrect voltage will damage pump and may result in

!

injury. Voltage requirement is printed on pump serial label.

Input power range is 96VAC to 264VAC 50/60 Hz.

!

Voltage Selection is automatically detected and adjusted by power supply. No mechanical switch necessary.

!

Use voltage your power cord is rated for.

!

!

Cord connected models are supplied with a ground wire conductor and a grounding type attachment plug (power

cord). To reduce risk of electric shock, be certain that power cord is connected only to a properly grounded,

grounding type receptacle.

!

Permanently connected models must be properly grounded. Be certain that a grounding conductor is connected

to terminal T11-1 located in the wiring compartment.

!

Never strap control (input / output) cables and power cables together.

!

Power Interruption: This pump has an auto-restart feature which will restore pump to operating state it was in

when power was lost.

Note: When in doubt regarding your electrical installation, contact a licensed electrician.

WIRING COMPARTMENT COVER POWER CORD OPTIONS

Three power cord plug types available.

Power cord length is 6 feet (3.83 meters)

230V 60Hz

NEMA 6/15 (USA)

max: 250V AC

Ø

.50

(12.7 mm)

2-PLCS.

5.99 in.

(152.1 mm)

.84 in.

Ø

(21.3 mm)

3-PLCS.

115V 60Hz

NEMA 5/15 (USA)

max: 125V AC

Cable and conduit connectors included

DESCRIPTION

QTY.

.50 INCH (12.7 mm) LIQ-TIGHT HOLE PLUGS (MAT’L = NEOPRENE), PRE-INSTALLED

2

.875 INCH (22.2 mm) LIQ-TIGHT HOLE PLUGS (MAT’L = NEOPRENE), 2 PRE-INSTALLED

3

.50 INCH (12.7 mm) LIQ-TIGHT CONNECTORS FOR PASS THRU CORDS (MAT’L = NYLON)

2

ACCEPTABLE CABLE DIAMETER .118 TO .255 INCH (3.0 TO 6.5 MM), NOT INSTALLED

.875 INCH (22.2 mm) METALLIC LIQ-TIGHT CONNECTORS FOR PASS THRU CORDS (MAT’L = NYLON)

3

ACCEPTABLE CABLE DIAMETER .200 TO .395 INCH (5.1 TO =10.0 MM), 1 PRE-INSTALLED WITH POWER CORD MODELS

2

METALLIC LIQ-TIGHT CONNECTORS FOR .50 INCH FLEXIBLE CONDUIT (MAT’L = DIE CAST ZINC), NOT INSTALLED

240V 50Hz

CEE 7/VII (EU)

max: 250V AC

Page 9

Page 9

6.0 How To Operate Flex-Pro

Flex-Pro

Flex-Pro

To STOP pump at any time

To START pump

Control Panel - Button Operation

Pump can be stopped at any time by pressing STOP button.

overrides all other controls and stops pump. Display will read OFF if pump has

been stopped in this manner. Pump will not respond to incoming input signals

while in OFF state. When START button is pressed, pump will start according to

it’s previous operating state.

Press START button to start pump. If a remote start/stop input signal is used, the pump will begin

“listening” for the input signal.

Pressing the START button repeatedly will toggle the display to indicate the %SPEED, RPM, and Tube

Timer Hours.

STOP button

UP Arrow

Press UP arrow to increase pump output.

Press UP arrow to navigate through menu items.

DOWN Arrow

Press DOWN arrow to increase pump output.

Press DOWN arrow to navigate through menu items.

To PRIME pump

Press PRIME button to start 60 second prime feature. Pump will run at full speed for 60 seconds or

until STOP or START button is pressed. STOP button will stop pump and display will read OFF. START

button will stop prime feature and jump back into previous operating state.

To REVERSE ROTATION of rotor

Press REVERSE ROTATION button to reverse flow.

CAUTION: Motor will reverse its rotation immediately after the REVERSE ROTATION button is pressed.

Page 10

Page 10

7.0 Pump Output Speed Adjustment

Press UP arrow to increase pump output. Press DOWN arrow to increase

pump output.

8.0 Contact Closure Input (Remote Start/Stop)

Used to remotely start and stop the pump using a close=run or open=stop signal. If the pump must

start when the loop is open, then select “Close: Stop Pump” option. Can be used with an external

foot pedal, a PLC, contact closure, or other similar external devices.

Default settings: Disable

CC Input Range: 6 - 30 VDC

or

Dry Contact Closure (no voltage required)

[See section 5.1 for wire connections]

Navigate to Contact Input menu by holding the START button for 5 second. While motor is off.

Press UP or DOWN arrow to scroll through your options.

Flex-Pro

Press START to make a selection. The radio button (square box) is now filled in next to your

selection.

Press DOWN arrow to scroll down to Done selection. Then press START.

IMPORTANT: To begin operation, press the START button to place pump in STANDBY. The display

background will turn blue indicating the pump has been stopped remotely. When the pump is

started by the remote contact, the display background will turn green.

IMPORTANT: If the Contact Closure Input is enabled, the pump will display STANDBY if the pump

has been stopped by the Remote Contact Closure. Please use caution in this mode as the pump

may Start at anytime. If you must perform maintenance to the pump, Press STOP button.

When Contact Closure Input is enabled, the word Remote will always be displayed on the lower left

side of the display screen.

Page 11

Flex-Pro

9.0 Set FVS (Flow Verification System)

Used to monitor pump output. If pump does not dispense fluid when pump head rotor is turning,

pump will go into an alarm mode and stop pump. Blue-White offers a flow verification sensor that

can easily attach to fitting on pump.

Default settings: 000 (off)

Navigate to Set FVS menu by pressing UP and DOWN arrows at the same time while pump is off,

then select Input Setup, then Set FVS.

Press UP or DOWN arrow to set the FVS delay time in seconds.

Press START to save changes and exit FVS screen.

Flow Verification System (sensor sold separately)

Flex-Pro is equipped with a Flow Verification System which is designed to stop pump and energize

a 6 amp relay in event sensor does not detect chemical during pump operation. This could indicate

a clogged injection fitting, empty chemical solution tank, worn pump tube, loose tubing connection,

etc.

To allow pump to clear any gasses that may have accumulated during stopper operation (such as

with chlorine), an alarm delay time value from 1-255 seconds must be programmed (An alarm

delay value of 000 seconds disables FVS system).

Page 11

If FVS alarm occurs, pump will stop, send an external signal (if setup), and screen will flash FVS

with an alarm icon.

To clear FVS alarm, you must press START button or re-cycle power (unplug power to pump, then

plug back in).

Install FVS Flow Sensor - Flow Verification Sensor (FVS) should be installed on the inlet (suction)

side of the pump tube. Sensor includes a PVC tubing insert, located inside sensors female thread

connection, that is designed to seal sensor onto pump tube inlet adapter. Thread sensor onto

pump tube until tubing insert is snug against pump tube inlet fitting - do not over-tighten.

Confirm the FVS flow range - Flow

Verification Sensor (FVS) will only function

within its operating range. See chart for

available ranges.

NOTE: For low viscosity (water-like) fluids

only. Consult the factory if attempting to

use with viscous fluids.

SENSOR MODEL NUMBER

3/8”OD tube

connections

FV-100-6V

FV-200-6V

FV-300-6V

FV-400-6V

FV-500-6V

FV-600-6V

1/2” F/NPT

connections

FV-100-3V

FV-200-3V

FV-300-3V

FV-400-3V

FV-500-3V

FV-600-3V

OPERATING

FLOW RANGE

(ml/min)

30-300

100-1000

200-2000

300-3000

500-5000

700-7000

Page 12

Page 12

10.0 Pump Tube Timer

Flex-Pro has a built in Pump Tube Timer. Timer starts when rotor is rotating and stops

when rotor is idle. To view current Pump Tube Timer value, press the START and

DOWN buttons and the Tube Timer screen will appear. Screen will display current

Pump Tube Time in run-time hours. The Tube Timer screen will display for 4 seconds

and then switch back to the previous operating display screen.

While displayed, press DOWN arrow button twice to reset Pump Tube Timer to zero.

When replacing pump tube, pump will ask you if you’d like to reset Pump Tube Timer.

If you choose YES, screen will display current Pump Tube Time for 5 seconds before

timer is reset to zero.

11.0 TFD (Tube Failure Detection)

Flex-Pro is equipped with a Tube Failure Detection System which is designed to

stop the pump and provide an output alarm (see Output menu) in the event pump

the tube should rupture and chemical enters the pump head. The pump will

detect a chemical with a conductivity reading greater than 500 microsiemens.

Chemicals with a conductivity of less than 500 microsiemens will not be

detected.

Flex-Pro

This patented system is capable of detecting the presence of a large number of

chemicals including Sodium Hypochlorite (Chlorine), Hydrochloric (muriatic)

Acid, Sodium Hydroxide, and many others. The system will not be triggered by

water (rain, condensation, etc.) or silicone oil (roller and tubing lubricant).

If system has detected chemical, pump tube must be replaced and pump head

and roller assembly must be thoroughly cleaned. Failure to clean the roller

assembly will void warranty.

If TFD alarm occurs, pump will stop, close an alarm output, and screen will flash

TFD with an alarm icon.

Confirm Chemical Detection - To determine if your chemical will be detected by

the system, remove the pump head cover and the pump tube and roller assembly. Place a small amount of chemical in the bottom of the pump head - just

enough to cover the sensors. Replace the pump head cover only. When asked if

the tube was replaced, select “no” and press enter. Turn on the pump (press

start). If the TFD system detects the chemical, the pump will stop after a two

second confirmation period and the TFD Alarm screen will display. If the TFD

system does not detect the chemical, the pump will continue to run after the

confirmation period. Carefully clean the chemical out of the pump head being

sure to remove all traces of the chemical from sensor probes. Replace the roller

assembly and tubing. Replace the pump head cover. Press the START button to

clear the alarm condition and restart the pump.

Chemical from tube failure

12.0 Alarm Relay

Pump has a built in 6 amp alarm output relay. Relay is pre-configured to

energize on tube failure detection (TFD) and on Flow Verification Sensor (FVS).

A Flow Verification Sensor must be installed and configured for relay to trigger

on no-flow conditions.

E

Page 13

Flex-Pro

13.0 Reverse Rotor Rotation

Increase tube life with this feature!

Page 13

CAUTION

!

CAUTION

!

Prior to service, pump clean water through the pump and suction / discharge line to

remove chemical.

Always wear protective clothing, face shield, safety glasses and gloves when working on

or near your metering pump. Additional precautions should be taken depending on

solution being pumped. Refer to MSDS precautions from your solution supplier.

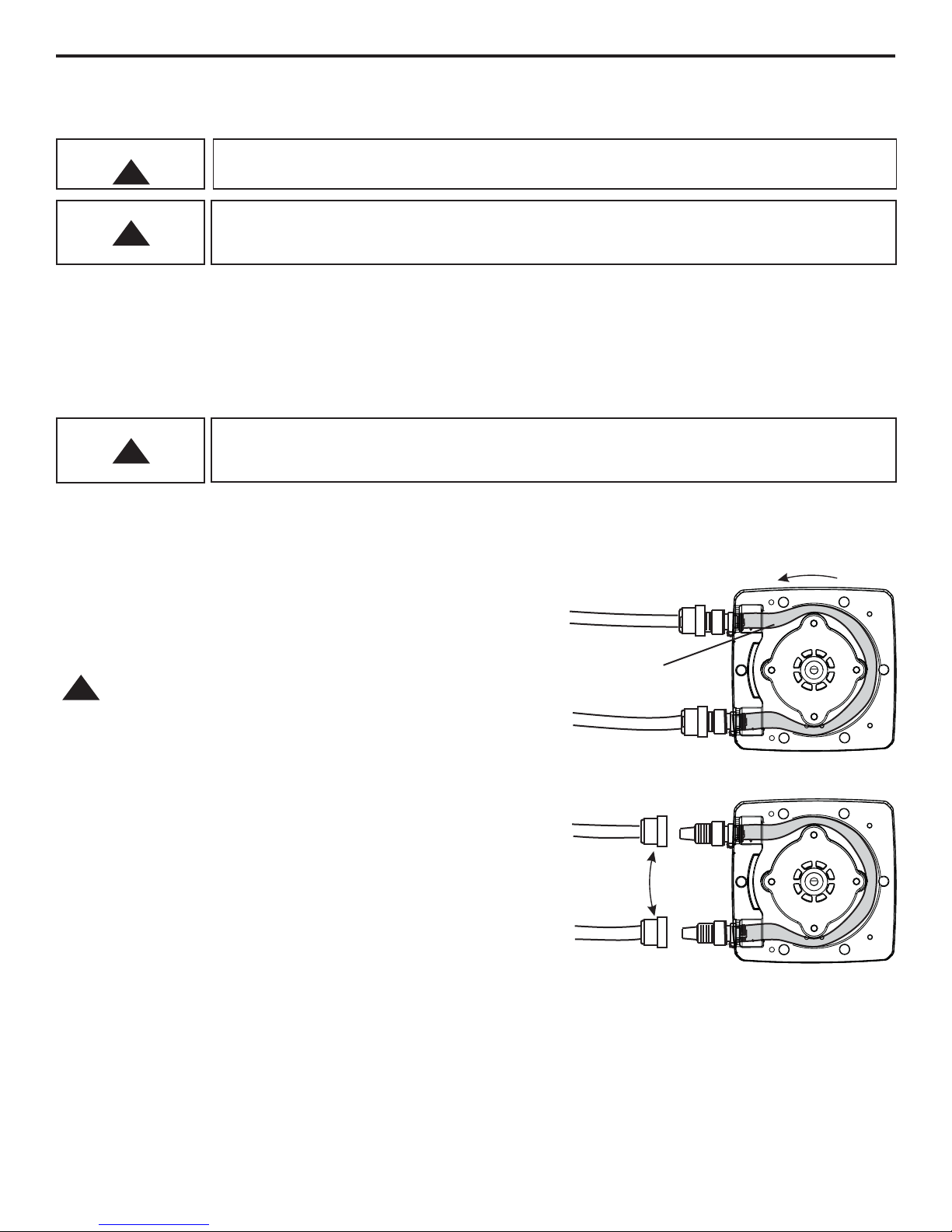

Pump rotor can reverse rotation by pressing REVERSE ROTATION button. This process can be used for many

reasons throughout various industries.

Two reasons for reversing current rotor rotation; to purge chemical from tubing and to extend tube life.

Plan ahead before reversing rotor rotation. If checkvalves are installed, make necessary arrangements to allow

back flow.

CAUTION

!

Failure to install checkvalves in their proper flow direction can cause excess pressure

(PSIg) build up in system and can result in tube rupture.

Always use extreme caution and ensure proper connections when using this feature.

If your desire is to simply extend tube life:

Typically tubing fails on outlet side (pressure side) of tube assembly in pump head.

D

n

o

i

t

a

t

o

R

Reversing rotation, moves outlet side (pressure side) to

opposite side of tube assembly, greatly increasing tube life.

Outlet

i

r

e

c

t

i

o

n

Stop pump before tube failure occurs.

Disconnect power from pump. Carefully purge any pressure

in discharge line of pump. Disconnect suction end tubing and

!

discharge end tubing from pump head tubing.

IMPORTANT! Swap sides of suction (inlet) and discharge

(outlet) tubing. No need to remove Pump Head Cover.

Double check all connections before starting pump.

Typical Failure Point

(pressure side)

Inlet

Swap Inlet

and Outlet

O

N

R

T

F

O

N

R

T

F

Page 14

Flex-Pro

15.0 Tube Replacement

Page 14

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

Tube Installation Tool

90002-278

Prior to service, pump clean water through the pump and suction / discharge line to remove

chemical.

Always wear protective clothing, face shield, safety glasses and gloves when working on

or near your metering pump. Additional precautions should be taken depending on

solution being pumped. Refer to MSDS precautions from your solution supplier.

Use provided Tube Installation Tool to leverage tubing into pump head, NOT YOUR

FINGERS.

Use extreme caution when replacing pump tube. Be careful of your fingers and DO NOT

place fingers near rollers.

E

Pump Head

Spacer, Rear

Rotor

Spacer, Front

Tubing Assembly

Pump Head Cover

Thumb

Screws

Tube Nut

Remove Pump Head Cover by unscrewing four Thumb Screws. Pull out Pump

Head Cover.

Pump will detect Pump Head Cover is removed and enter MAINTENANCE MODE.

Rotor will rotate at a maximum of 6 RPM for your safety.

Pull out suction side of Tubing Assembly.

Press START button. While rotor is rotating, pull out old Tube Assembly.

TIP! Let pump do the work for you. Just guide tubing out between two rollers

located on Rotor.

Press STOP button at any time to stop the pump.

Pull out suction line adapter from Pump Head. Pull out Tubing Assembly as the

Rotor rotates around.

Stop pump by pressing STOP button.

Thoroughly clean Pump Head and Rotor. Rotor can be removed by pulling straight

out. After cleaning process, push Rotor back on shaft. See drawing above for

proper assembly. IMPORTANT! Rotor direction; the word “FRONT” on Rotor must

face front of pump.

Locate your new tubing and Tube Installation Tool. Please see next page on how to

install new Tube Assembly into Pump Head.

Page 15

Page 15

14.0 How to Maintain Pump

Flex-Pro

CAUTION

!

Routine Inspection and Maintenance

Pump requires very little maintenance. However, pump and all accessories should be checked weekly. This is

especially important when pumping chemicals. Inspect all components for signs of leaking, swelling, cracking,

discoloration or corrosion. Replace worn or damaged components immediately.

Cracking, crazing, discoloration and the like during first week of operation are signs of severe chemical attack. If this

occurs, immediately remove chemical from pump. Determine which parts are being attacked and replace them with

parts that have been manufactured using more suitable materials. Manufacturer does not assume responsibility for

damage to pump that has been caused by chemical attack.

How to Clean and Lubricate Pump

Pump will require occasional cleaning. The amount will depend on severity of service.

]

When changing pump tube assembly, pump head chamber, roller assembly and pump head cover should be wiped

free of any dirt and debris.

]

Pump head cover bearing may require grease periodically. Apply a small amount of grease (Aeroshell aviation

grease #5 or equivalent) when necessary.

]

Although not necessary, 100% silicon lubrication may be used on the roller assembly and tube assembly.

Always wear protective clothing, face shield, safety glasses and gloves when working on

or near your metering pump. Additional precautions should be taken depending on

solution being pumped. Refer to MSDS precautions from your solution supplier.

]

Periodically clean injection/check valve assembly, especially when injecting fluids that calcify such as sodium

hypochlorite. These lime deposits and other build ups can clog fitting, increase the back pressure and interfere with

check valve operation.

]

Periodically clean suction strainer.

Page 16

Page 16

Flex-Pro

1

Insert suction fitting into pump head. Remove your

fingers from pump head. Start pump by pressing

START button. Grab hold of Tube Installation Tool

and use it to leverage tubing into pump head.

3

2

Introduce tubing into pump head while the rotor is

rotating. Avoid using fingers to guide the tubing.

Stop pump at anytime by pressing STOP button.

Start pump by pressing START button.

4

PULL

Continue to follow rotation of rotor while directing

tube into pump head. At this point, you may need to

pull Tube Installation Tool to stretch tubing into

position. Let rotor spin a few rotations while pulling

Installation tool so fitting can be properly installed.

Continue to pull Tube Installation Tool to allow

enough room to slide discharge fitting into pump

head tongue and groove. Once discharge fitting is

secured in pump head, stop pump by pressing STOP

button. Replace pump head cover. Pump will ask you

if you’d like to reset tube timer. If you choose yes,

current tube time will display for 5 seconds before

resetting to zero. Make note of your displayed tube

life. Select Yes again to reset tube life timer.

Re-attach Pump Head Cover using the four Thumb Screws.

Page 17

Flex-Pro

16.0 Blue-White Industries pump replacement parts list

Page 17

Tubing in this group are

®

interchangeable with

single roller assembly

(rotor).

Norprene

Tubing in this group are

interchangeable with

single roller assembly

®

(rotor).

Norprene

Tubing in this group are

interchangeable with

single roller assembly

®

(rotor).

Tygothane

Description

Pump Head

1

Spacer, Back (replaces 90011-184)

2

Roller Assembly Complete (Rotor), For ND, NF Tubes

3

Tube Assembly, 3/8” tube connect, Norprene ND (.075 ID)

4

4

Tube Assembly, 1/2” Male NPT connect, Norprene ND (.075 ID)

Tube Assembly, 3/8” tube connect, Norprene NF (.155 ID)

4

Tube Assembly, 1/2” Male NPT connect, Norprene NF (.155 ID)

4

3

Roller Assembly Complete (Rotor), For NH, NJ, NK, NKL Tubes

Tube Assembly, 3/8” tube connect, Norprene NH (.250 ID)

4

Tube Assembly, 1/2” Male NPT connect, Norprene NH (.250 ID)

4

Tube Assy, 3/8” tube cont, Norprene NKL (.375 ID)

4

Tube Assy, 1/2” Male NPT, Norprene NKL (.375 ID)

4

Roller Assembly Complete (Rotor), For GE, GG, GH, GK Tubes

3

Tube Assembly, 3/8” tube connect, Tygothane GE (.125 ID)

4

Tube Assembly, 1/2” Male NPT connect, Tygothane GE (.125 ID)

4

Tube Assembly, 3/8” tube connect, Tygothane GG (.187 ID)

4

Tube Assembly, 1/2” Male NPT connect, Tygothane GG (.187 ID)

4

Tube Assembly, 3/8” tube connect, Tygothane GH (.250 ID)

4

Tube Assembly, 1/2” Male NPT connect, Tygothane GH (.250 ID)

4

Low Pressure (30 psi max)

Low Pressure (30 psi max)

Part NumberItem

A2-SXX-H

76001-503

A2-SND-R

A2-SND-T

A2-MND-T

A2-SNF-T

A2-MNF-T

A2-SNH-R

A2-SNH-T

A2-MNH-T

A2-SNKL-T

A2-MNKL-T

A2-SGE-R

A2-SGE-T

A2-MGE-T

A2-SGG-T

A2-MGG-T

A2-SGH-T

A2-MGH-T

QTY

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Tubing in this group are

interchangeable with single

roller assembly (rotor).

®

Norprene Chemical

3

Roller Assembly Complete (Rotor), For TH, TK Tubes

4

Tube Assembly, 3/8” tube connect, Norprene Chemical TH (.250 ID)

4

Tube Assembly, 1/2” Male NPT, Norprene Chemical TH (.250 ID)

5

Spacer, Front

6

Pump Head Cover, Annealed Acrylic

Thumb Screw

7

Tube Nut, Compression, For 3/8” Tubing

8

Not

Stainless Steel mounting bracket kit (pair)

Shown

Not

Stainless Steel extended mounting bracket kit (pair)

Shown

Not

Rubber feet

Shown

5

4

6

A2-STH-R

A2-STH-T

A2-MTH-T

90011-014

A3-SXX-C

90011-183

C-330-6

72000-379

72000-380

90003-561

1

1

1

1

1

4

2

1

1

4

7

1

2

3

8

Page 18

LIMITED WARRANTY

Your new Flex-Pro pump is a quality product and is warranted for 24 months from date of purchase (proof of purchase is required). The

pump will be repaired or replaced at our discretion. Pump Head and roller assembly is warrantied against damage from chemical

attack when proper TFD (Tube Failure Detection) system instructions and maintenance procedures are followed.

WHAT IS NOT COVERED

• Pump Tube Assemblies and rubber components – They are perishable and require periodic replacement.

• Pump removal, or re-installation, and any related labor charge.

• Freight to the factory, or ProSeries service center.

• Pumps that have been tampered with, or in pieces.

• Damage to the pump that results from misuse, carelessness such as chemical spills on the enclosure, abuse, lack of

maintenance, or alteration which is out of our control.

• Pumps damaged by faulty wiring, power surges or acts of nature.

Blue-White Industries does not assume responsibility for any loss, damage, or expense directly or indirectly related to or arising out of

the use of its products. Failure must have occurred due to defect in material or workmanship and not as a result of operation of the

product other than in normal operation as defined in the pump manual.

Warranty status is determined by the pump's serial label and the sales invoice or receipt. The serial label must be on the pump and

legible. The warranty status of the pump will be verified by Blue-White Industries or a factory authorized service center.

OTHER IMPORTANT WARRANTY INFORMATION

Please be advised; injection and metering devices are not intended as a means of treating water to render it suitable for human

consumption. When used as hypochlorinators, they are meant to destroy bacteria and algae contamination, before its removal by

filtration. Acid and soda injectors are used for PH control (balance). Blue-White Industries injectors are factory tested with water only

for pressure and performance. Installers and operators of these devices must be well informed and aware of the precautions to be

taken when injecting various chemicals -especially those considered hazardous or dangerous, eye protection must be worn when

working around this product or any other metering type of pump.

Should it become necessary to return the pump for repair or service, you must attach information regarding the chemical used as some

residue may be present within the unit which could be a hazard to service personnel.

Blue-White Industries will not be liable for any damage that may result by the use of chemicals with their injectors and its components.

Thank you.

PROCEDURE FOR IN WARRANTY REPAIR

Contact the factory to obtain a RMA (Return Material Authorization) number. Carefully pack the pump to be repaired. It is recommended

to include foot strainer and injection/check valve fitting since these devices may be clogged and part of the problem. Please enclose a

brief description of the problem as well as the original invoice or sales receipt, or copy showing the date of purchase. Prepay all

shipping costs. COD shipments will not be accepted. Warranty service must be performed by the factory or an authorized ProSeries

service center. Damage caused by improper packaging is the responsibility of the sender. When In-Warranty repair or replacement is

completed, the factory pays for return shipping to the dealer or customer.

Users of electrical and electronic equipment (EEE) with the WEEE marking per Annex IV of the WEEE Directive must not

dispose of end of life EEE as unsorted municipal waste, but use the collection framework available to them for the return,

recycle, recovery of WEEE and minimize any potential effects of EEE on the environment and human health due to the

presence of hazardous substances. The WEEE marking applies only to countries within the European Union (EU) and Norway.

Appliances are labeled in accordance with European Directive 2002/96/EC.

Contact your local waste recovery agency for a Designated Collection Facility in your area.

Loading...

Loading...