FLEXPOWER FLEXC II-12PX, FLEXC II-6PX, FLEXC II-9PX, FLEXC II-3PX Instruction Manual

INSTRUCTIO N MA NUA L

MODEL NO.: FLEXC II-12PX

FLEXC II-9PX

FLEXC II-6PX

FLEXC II-3PX

18V Brushless Cordless Torque Screwdrivers

Rev 1. 5/18/2012

www.mountztorque.com

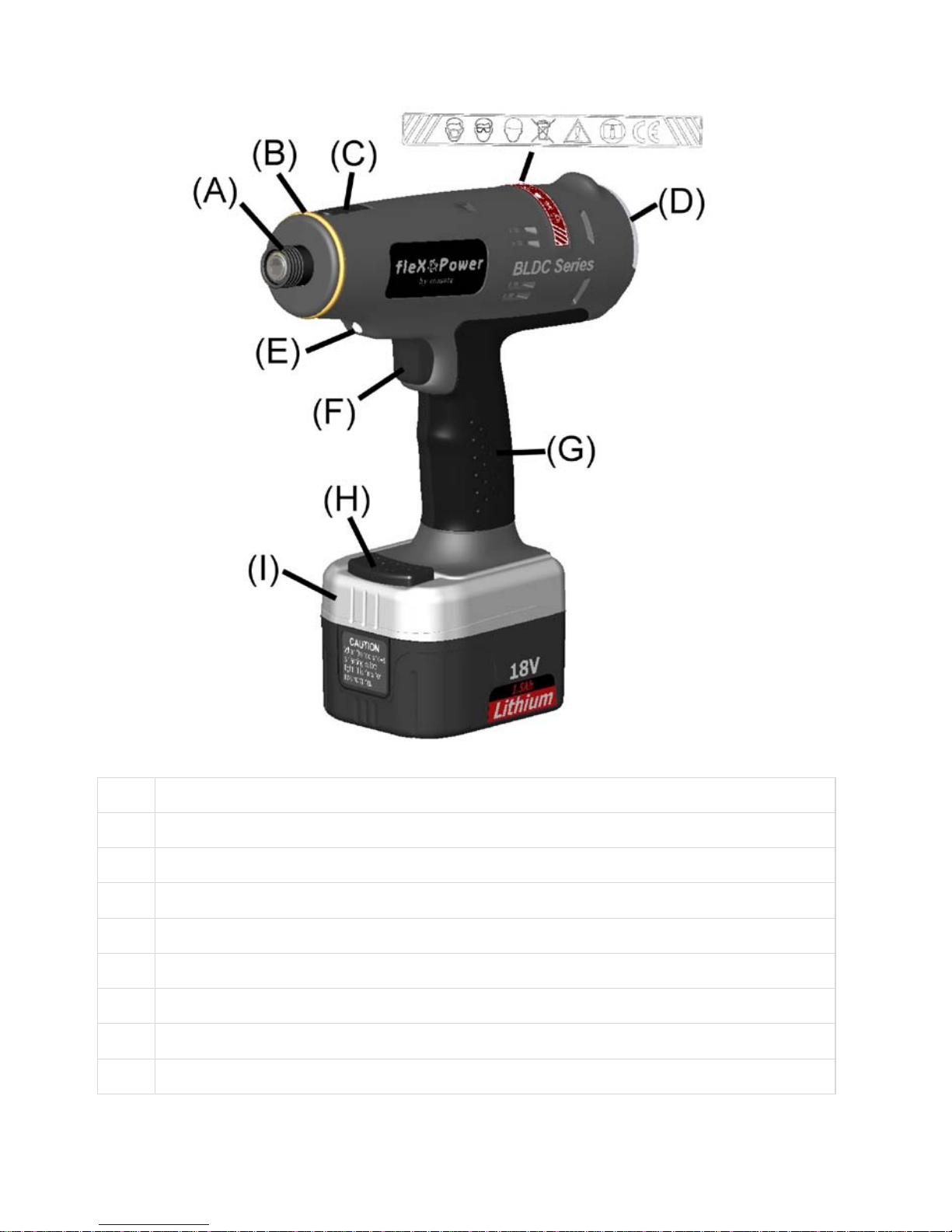

FUNCTIONAL GUIDES

(A) 1/4" F/Hex with quick change chuck

(B) Color Ring - color code specific torque values in production areas.

(C) Torque adjustment cover

(D) LED indicator provides simple process information to the operator

(E) LED light for working in dark area

(F) Trigger repeat protection. Avoid double hits on already seated screw

(G) Soft texture ergonomic grip.

(H) Quick release button. Easily slide and change battery.

( I ) High capacity Li-ion battery pack delivers longer run-time

- 2 -

WARNING! "READ ALL INSTRUCTIONS" Always observe the safety

regulations appl icable in your country to reduc e the risk of fire, electric shock and

personal injur y. Understand th e following saf ety instructions bef ore attempting to

operate this pr oduct. Always wear e ye protectio n when working w ith power t ools.

Keep these instructions in a safe place.

SAVE THESE INSTRUCTIONS

Work Area Safety

General Safety Rules

Personal Safety

- 3 -

Keep your work area clean and

well lit. Cluttered benc h es and

dark areas invite accidents.

Do not operate power tools in

explosive atmospheres, such as

in the presence of flammable

liquids, gases, or dust. Power

tools create sparks which may

ignite the dust or fumes.

Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can

cause you to lose control.

Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use tool while tired or under

the influence of drugs, alcohol,

or medication. A moment of

inattention while operati ng po wer

tools may result in serious personal

injury.

Dress properly. Do not wear

loose clothing or jewelry.

Contain long hair. Keep your

hair, clothing, and gloves away

from moving parts. Loose

clothes, jewelry, or long hair can be

caught in moving parts.

Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance

enables better control on the tool in

unexpected situations.

Use safety equipment. Always

wear eye protection. Dust mask,

non-skid safet y shoes, hard hat , or

hearing protection must be used

for appropriate conditions.

Tool Use and Care

Use clamps or other practical

ways to secure and support the

work piece to a stable platform.

Holding the work piece by hand or

against your body is unstable and

may lead to loss of control.

Do not force tools. Use the

correct tool for your application.

The correct tool will do the job

better and safer at the rate for

which it is designed.

Do not use tool if switch does

not turn it on or off. Any tool that

cannot be controlled with the switch

is dangerous and must be repaired.

Store idle tools o u t o f re ach o f

children and other untrained

persons. Tools are dangerous in

the hands of untrained users.

Check for misalignment or

binding of moving parts,

breakage of parts, and any other

condition that may affect the tool

operation. If damaged, have the

tool serviced before using. Many

accidents are caused by poorly

maintained tools.

- 4 -

Use only accessories that are

recommended by the manufacture

for your model. Accessories that

may be suitable for one tool, may

become hazardous when used on

another tool.

Service

Tool service must be performed

only by qualified repai r

personnel. Service or maintenance

performed by unqualified personnel

could result in a risk of injury.

When servicing a tool, u se o n ly

identical replacement parts.

Follow instructions in the

Maintenance section of this

manual. Use of unauthorized parts

or failure to follow maintenance

instructions may create a risk of

electric shock or injury.

Additional Safety Rules

for Shut Off Screwdriver

Battery Charger

Caution: To reduce risk of injury,

charge only the authorized

batteries. Other types of battery

may burst, causing personal injury

and damage.

Before using battery charger, read

all instructions and cautionary

markings on batteries, chargers and

products using batteries.

Do not allow anything to cover or

clog the charger vents.

Do not expose charger to rain,

snow or wet conditions.

To reduce the risk of damage to

electric plug and cord, pull by plug

rather than cord when

disconnecting charger.

Use of an attachment not

recommended or sold by the

manufacturer may result in a risk of

fire, electric shock, or injury to

persons.

Make sure cord for charger is located

so that it will not be stepped on,

tripped on, tripped over, or otherwise

subjected to damage or stress.

Do not abuse the power cord. Never

use the cord to carry the charger.

Keep cord away from heat, oil, water,

sharp edges, or moving parts.

Replace damaged cords

immediately.

Do not operate charger if it has been

damaged in any way, take it to a

qualified service center for repair.

To reduce risk of electric shock,

unplug charger from outlet before

attempting any maintenance or

cleaning. Turning off contr ols will not

reduce this risk.

Do not disassemble charger or

battery cartridge, take it to a qualified

service center when repair is

required. Incorrect reassembly may

result in a risk of electric shock or

fire.

Battery Pack

Do not charge battery pack when

temperature is below 0

o

C (32oF) or

above 40

o

C (104oF).

Do not attempt to use a step-down

transformer, an engine generator or

DC power receptacle.

Do not short the battery pack: Do not

touch the terminals with any

conductive mater ial. Avoi d stor ing

battery cartridge in a container with

other metal objects such as nails,

coins, paper clips, etc.

Do not expose battery cartridge to

water or rain. A battery short can

cause large current flow, overheating,

possibly burns and even a break-

down.

- 5 -

Do not store the machine and

battery pack in locations where the

temperature may reach or exceed

50

o

C (122oF).

Do not incinerate the battery pack

even if it is severely damaged or

completely worn out. The battery

pack can explode in a fire.

Be careful not to drop, shake, or

strike the battery.

Do not charge inside a box or

container of any kind. The battery

must be placed in a well ventilated

are during charging.

Do not dispose of battery packs into

household waste, fire or water.

Battery packs should be collected,

recycled or disposed of in an

environmentally-friendly manner.

Call the authorized warranty centers

for places to dispose of damaged or

inoperable batteries.

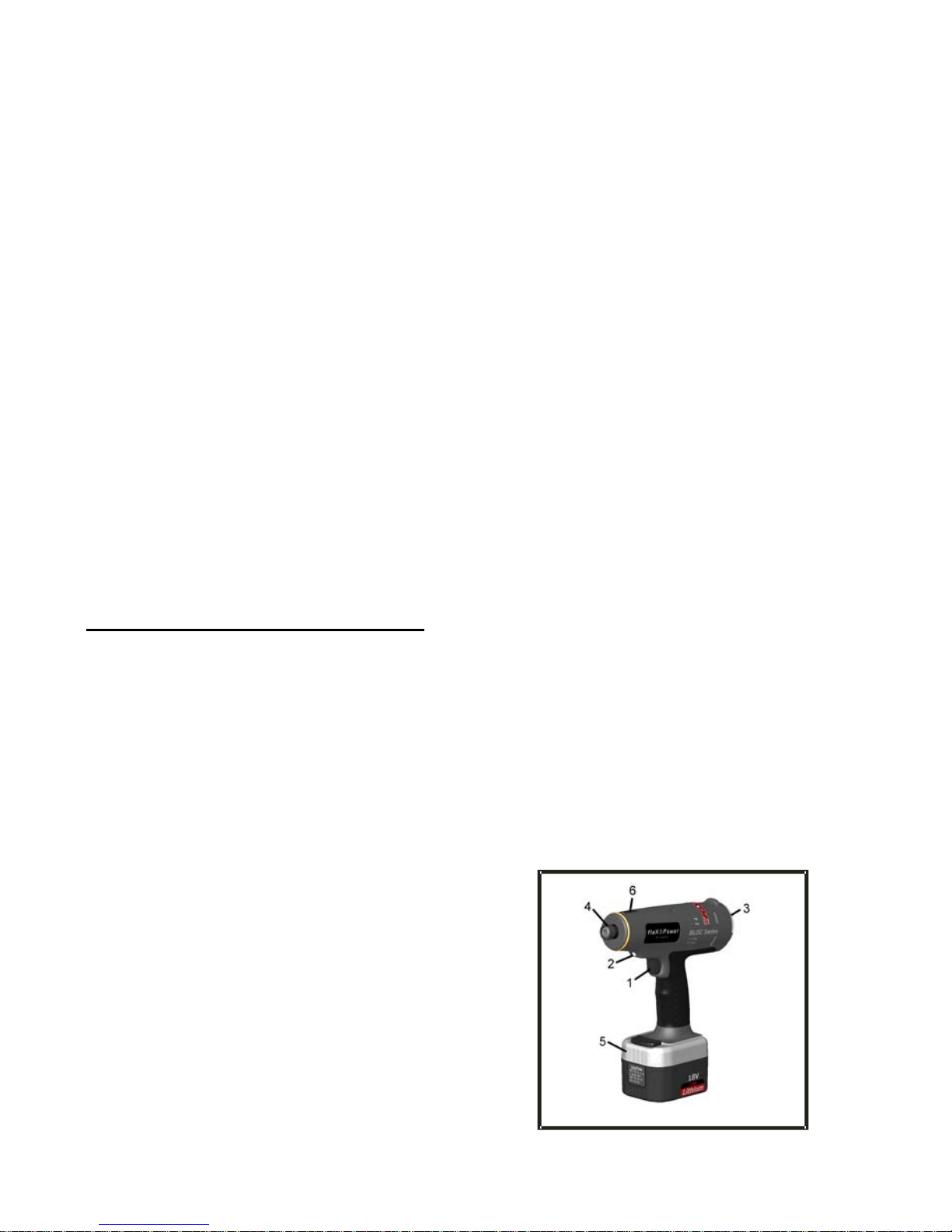

FUNCTIONAL DESCRIPTION

This industrial shut off screwdriver is

designed for nut tightening/loosening

and screw driving/loosening. It is not

appropriate to use for wood/mild steel

drilling. Please refer to the figure on the

page to familiarize yourself with the

major components of this tool before

use.

1. Power Sw it ch

Pressing the power switch wil l energi ze

the LED light (2) in front and the tool

starts to rotate. When released, power

to the motor will cease and the tool

stops to work immediately. But the LED

light will remain for 10 seconds then off.

2. Lamps

It turns on every time that the trigger

is pressed, and helps to illuminate

the darks areas.

3. Forward/Reverse Button

The tool is always in forward

operation unless the

Forward/Reverse butt on is press ed.

When the button is pressed, the blue

LED shows and the tool will be in

reverse operation. To get the tool

back in forward operation, just

simply press the button again and

the blue LED would disappear and

the tool is back in forward operation.

4. Quick Change Holder

This driver accepts only 1/4”

(6.35mm) hexagonal bits. Be sure

the bit is fully engaged b y the chuck

before operating tool. Otherwise, the

bit may fly off and cause property

damage or personal injury.

5. Li-ion Battery

This battery provides electrical

power to the motor. Please charge

it according to the charging

instruction listed in this manual.

6. Torque Adjustment Cover

Open the torque adjustment cap.

Use the torque adjustment tool to

either tighten or loosen the spring

until the desired torque is reached.

Use a torque tester to view and

verify torque setting.

Figure

Loading...

Loading...