Flexit UNI 2 User Manual

111537EN-11

2019-10

UNI 2

User Manual

Air Handling Unit & Automatic Control

Contents

1 Functional description of balanced ventilation

1.1 Fans (M1, M2)

1.2 Filters (FI1, FI2)

1.3 Rotor (HR-R)

1.4 Heating element (EB1) (for UNI 2 E)

1.5 Temperature sensors (B1, B4)

2 Operating the door

2.1 Wall-mounted unit

2.2 Floor-mounted unit

2.3 Ceiling-mounted unit

3 Overview of CI60 control panel

4 CI60 in use

.............................................................................................................................................. 9

4.1 General

4.2 Increasing/reducing air supply

4.3 Adjusting the air supply

4.4 Temperature adjustment

4.5 Filter replacement

4.6 Alarm

4.7 Reset

............................................................................................................................................... 9

.............................................................................................................................................. 10

5 Overview of CI600 control panel

6 CI600 in use

6.1 General

6.2 Idle mode

6.3 Menu navigation

6.4 Startup

6.5 Operating status

7 CI600 main menu

7.1 Fan speeds

7.2 Max timer

7.3 Settings

7.4 Temperature

7.5 Timer

...............................................................................................................................................13

7.6 Daily/weekly timer

7.7 Time and date

7.8 Language

7.9 Filters

7.10 Alarm

..............................................................................................................................................14

..............................................................................................................................................14

7.11 Operating information

8 CI600 advanced user menu

8.1 PIN

...................................................................................................................................................15

8.2 Advanced user

8.3 Temperature regulation

8.4 Fan control

8.5 Configuration

8.6 Operating time

8.7 Service

8.8 Menu tree

9 Cleaning and maintenance

9.1 Changing the filters

9.2 Cleaning the fans

9.3 Changing the brush strips

9.4 Tightening of rotor belt

9.5 Cleaning the rotor

9.6 External cleaning

10 Maintenance table

11 Troubleshooting

12 CE Declaration of Conformity

................................................................................................................................. 4

............................................................................................................................... 4

................................................................................................................................. 4

.......................................................................................... 4

.................................................................................................... 4

............................................................................................................................... 5

........................................................................................................................ 5

...................................................................................................................... 6

................................................................................................................... 7

.......................................................................................................... 8

............................................................................................................................................ 9

................................................................................................... 9

............................................................................................................... 9

............................................................................................................. 9

......................................................................................................................... 9

..................................................................................................... 10

.......................................................................................................................................... 11

........................................................................................................................................... 11

...................................................................................................................................... 11

........................................................................................................................... 11

........................................................................................................................................... 11

.......................................................................................................................... 11

.................................................................................................................................12

.....................................................................................................................................12

.......................................................................................................................................12

..........................................................................................................................................12

..................................................................................................................................12

.......................................................................................................................13

............................................................................................................................... 14

.......................................................................................................................................14

................................................................................................................14

...............................................................................................................15

..............................................................................................................................15

..............................................................................................................15

.................................................................................................................................... 16

................................................................................................................................17

............................................................................................................................. 18

.......................................................................................................................................... 18

...................................................................................................................................... 19

............................................................................................................. 20

................................................................................................................... 20

.........................................................................................................................21

..........................................................................................................24

..............................................................................................................25

.......................................................................................................................25

.........................................................................................................................25

..............................................................................................................................26

..................................................................................................................................26

........................................................................................................... 27

.............................................................................. 4

2

Important Safety Instructions:

!

!

It is the installer's responsibility to carry out a full safety and function assessment of the appliance.

To reduce the risk of fire, electric shock or injury, read all the safety instructions and warning texts before using the unit.

• This unit is only designed for ventilation air in homes and commercial buildings.

• It must not be used to extract combustible or flammable gases.

• Remove the power plug before commencing any service and maintenance work.

• Before opening the door: switch off the heat, let the fans continue for 3 minutes to remove hot air, unplug the unit and wait 2

minutes before opening the doors.

• If the power lead is damaged, it must be replaced by the manufacturer, the manufacturer's service agent or a similarly

qualified person.

• The unit contains heating elements that must not be touched when they are hot.

• The unit must not be operated without the filters being in place.

• Do not cook any combustible substances under the kitchen hood if one is installed.

• Do not leave a saucepan or frying pan containing oil or grease unsupervised when using a kitchen hood.

• The instructions in the user manual must be followed for complaints to be accepted.

To maintain a good indoor climate, comply with regulations and avoid condensation damage, the unit must never be

stopped apart from during service/maintenance or in connection with an accident.

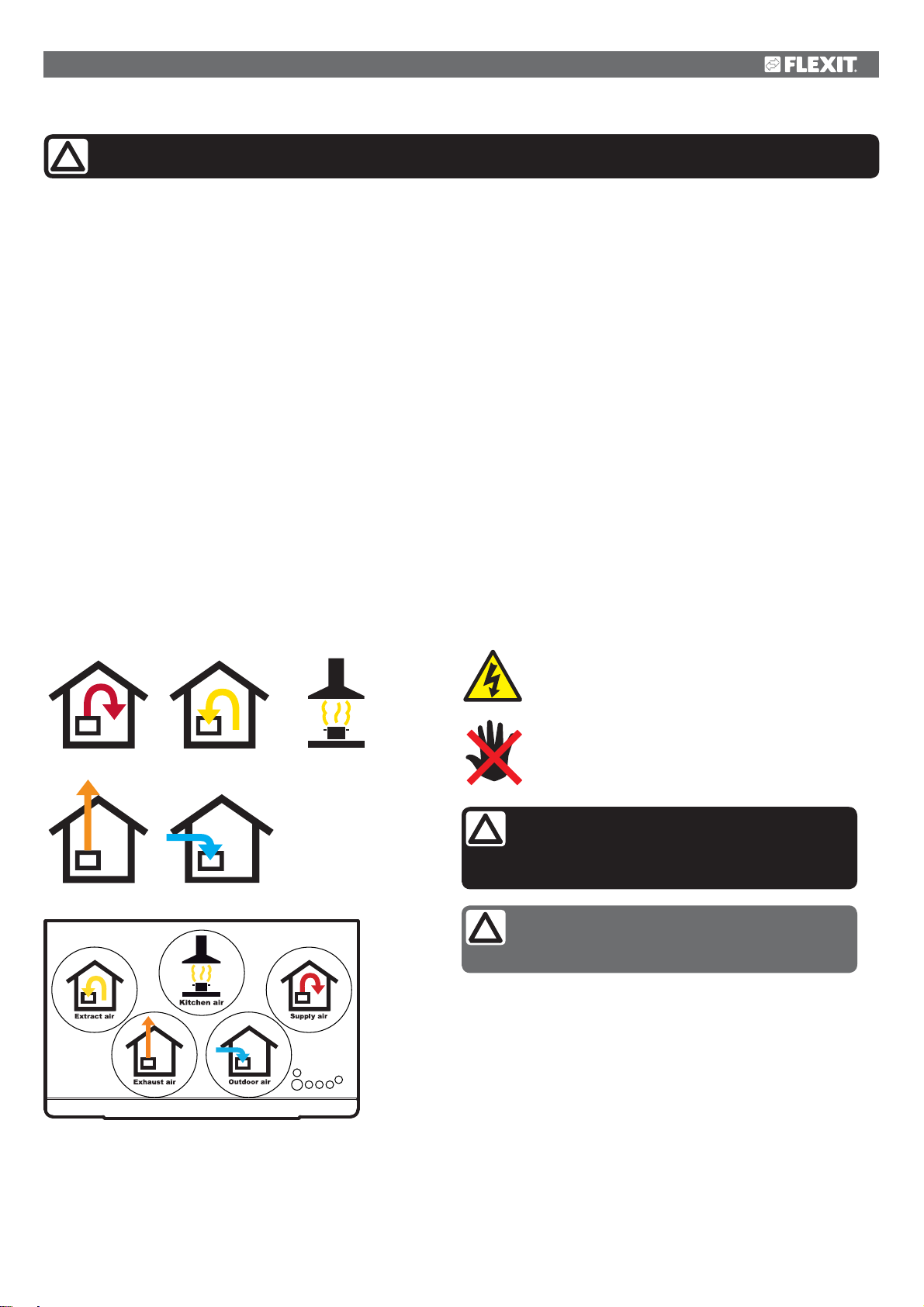

Symbols used

These products have a number of symbols that are used to label the product itself and in the installation and user documentation.

Supply air

Exhaust air

Extract air Kitchen air

Outdoor air

EXAMPLE OF NIPPLE LOCATION

(shown as a right-hand model)

DANGER! ELECTRICITY

DANGER! DO NOT

TOUCH

CAUTION! When a text bears this symbol, it

means that personal injury or serious damage to

the equipment may result if the instructions are

not followed.

NB! When a text bears this symbol, damage to

equipment or poor efficiency may be the consequence of not following the instructions.

This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and understand the hazards involved.

use by children.

Children shall not play with the appliance. Cleaning and user maintenanc

shall not be made by children without supervision.

Our products are subject to continuous development and we therefore

reserve the right to make changes.

We also disclaim liability for any printing errors that may occur.

Note that the product is not intended for

e

Our products are subject to continuous development and we therefore reserve the right to make changes.

We also disclaim liability for any printing errors that may occur.

3

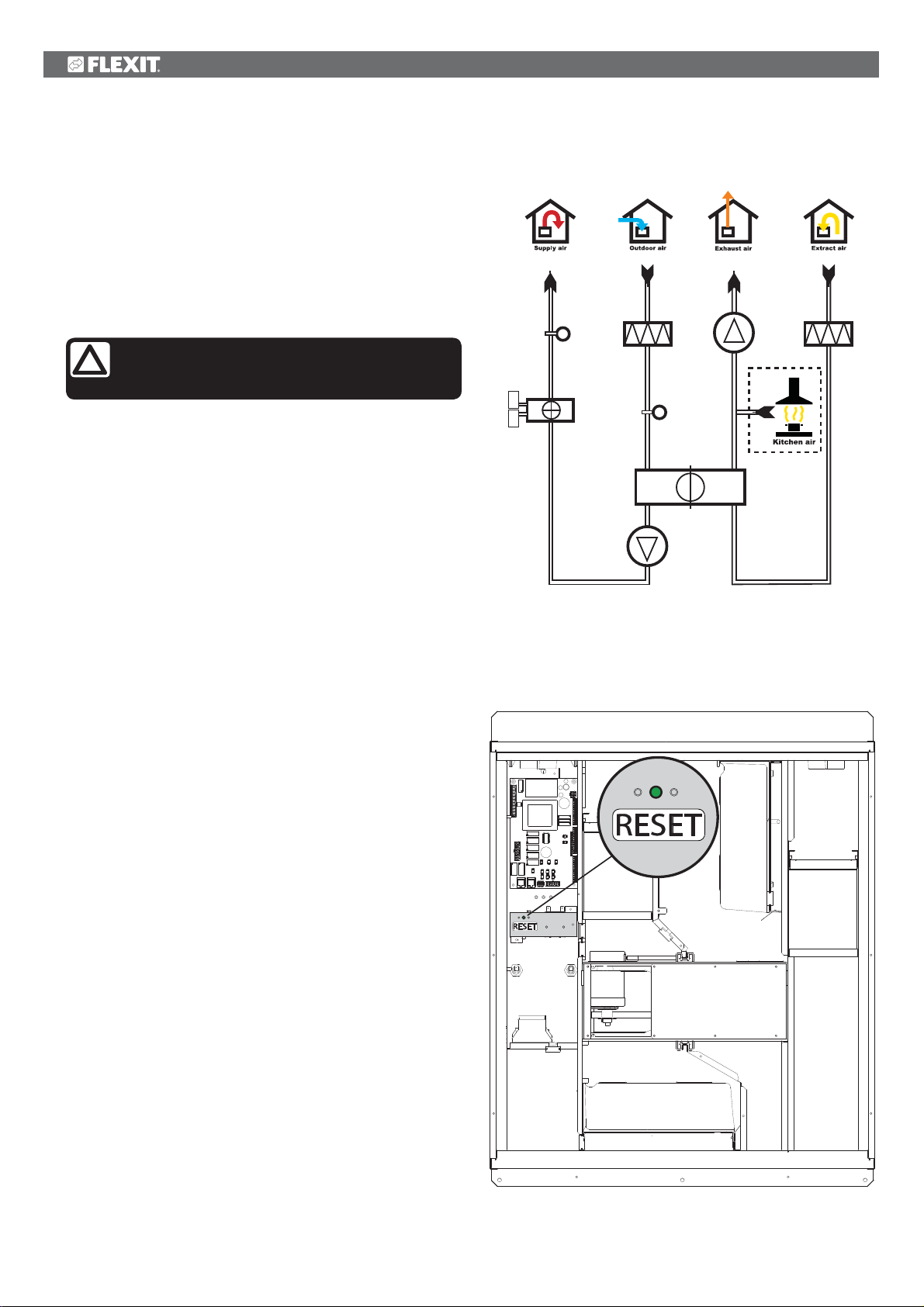

1 Functional description of balanced

!

ventilation

1.1 Fans (M1, M2)

The fans ensure that air enters and leaves the building.

They can be individually adjusted for optimal operation.

The unit can be regulated at three different speeds via the

control panel: Min, Normal and Max. See chapter 5.1 for more

information.

Adjustment must always be carried out by

qualified staff before the installation is used for

the first time.

1.2 Filters (FI1, FI2)

Filters with a high filter grade (ePM1 55% F7) are used as

standard for both supply air and extract air so that the air

which enters the building is clean. The filters also ensure that

the unit stays clean and can maintain thermal efficiency and

air flow.

Fig. 1

F10

F20

EB1

M4

M2

FI2

K

FI1

B1

B4

HR-R

M1

1.3 Rotor (

HR-R)

The air passes through the rotary wheel-type heat

exchanger (recovery). The rotor functions as a heat

magazine. The heat from the extract air heats up one part of

the rotor. When the heated part comes over to the supply

air side, the heat is transferred to the supply air.

1.4 Heating element (EB1) (for UNI 2 E)

If the energy recovered from the extract air is insufficient to

maintain the set supply air temperature, an electric heating

element will help raise the temperature. The heating element

is protected against overheating by the thermostat (F20)

which cuts out at high temperature. For extra safety, the

thermostat (F10) cuts out at critical temperatures. If the

thermostat (F10) is tripped, it has to be reset manually by

pressing the reset button (see Fig. 2). If the alarm is tripped

repeatedly, contact the service company or distributor. See

chapters 4.7 and 7.10 for more information.

1.5 Temperature sensors (B1, B4)

The unit has two temperature sensors as standard. The

supply air sensor (B1) registers the temperature after the

heating battery. The outdoor air sensor (B4) registers the

temperature of the outdoor air.

Fig. 2

4

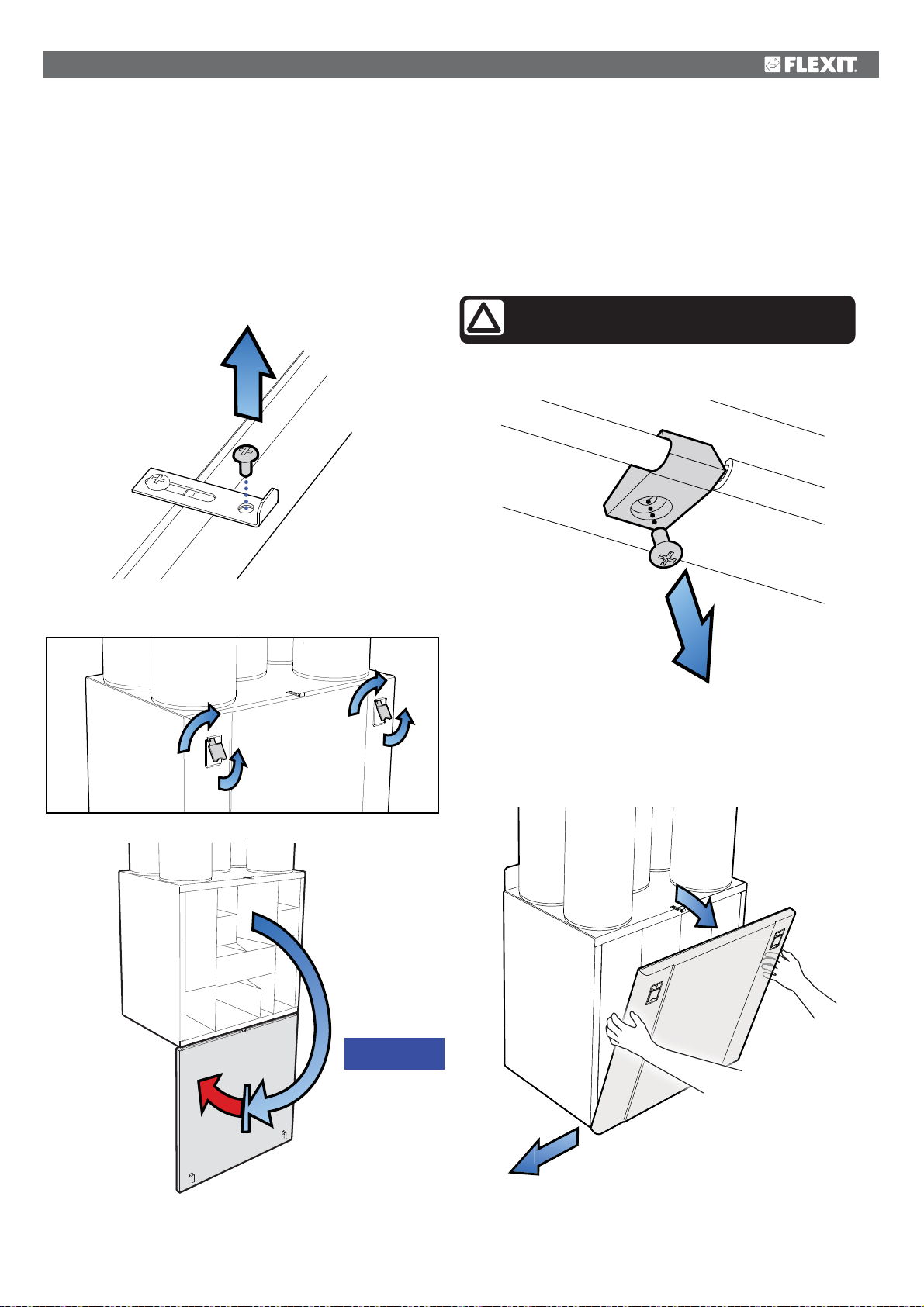

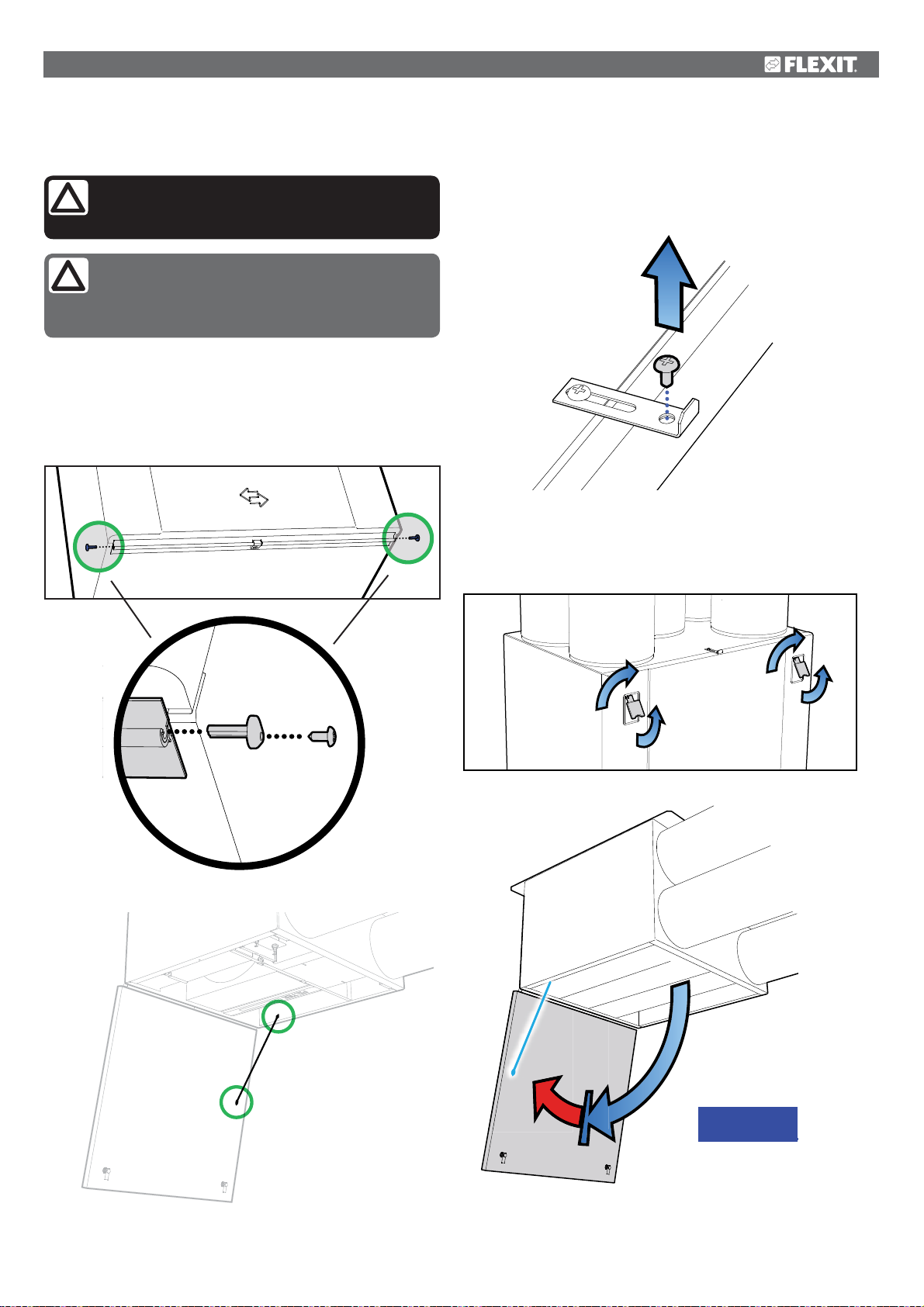

2 Operating the door

!

2.1 Wall-mounted unit

1. First undo the screw in the top of the door (see Fig. 3).

2. Pull the handles out and rotate to the side (see Fig. 4).

3. The door can now be opened to hang open at 180º

(see Fig. 5) or unhooked (see point 2.4).

Fig. 3

Fig. 4

If the door needs to be removed

The door can be removed when it is open between 40º

and 105º. If there is limited space in front of the unit, the

lock screw on the underside of the unit can be unscrewed

temporarily (see Fig. 6). Then the door can be pushed out

sideways (see Fig. 7).

The door is heavy, so take care when

removing it.

Fig. 6

Fig. 5

Fig. 7

MAX 180°

5

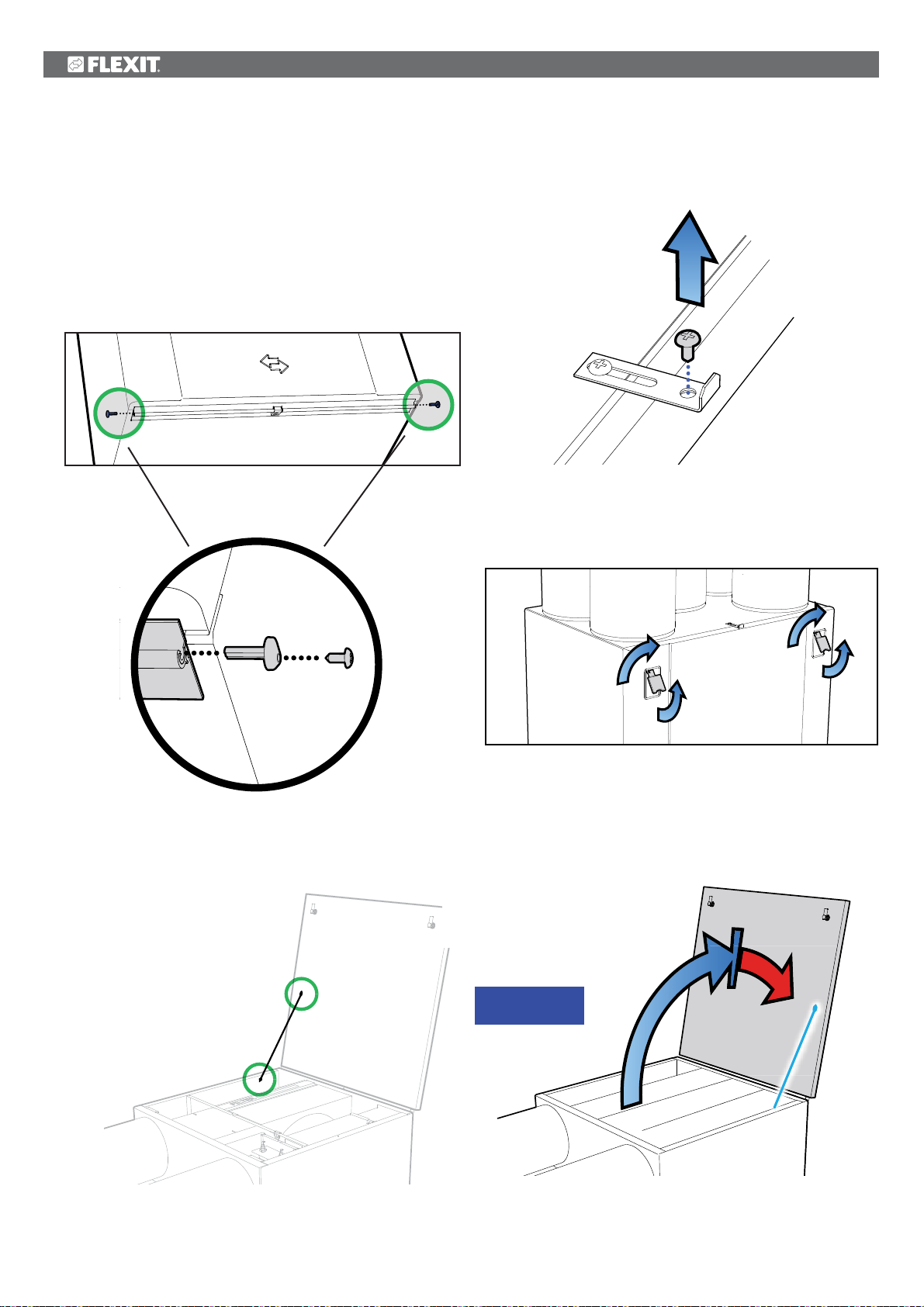

2.2 Floor-mounted unit

1. Make sure that hinge stops and a door strap are fitted

(see Fig. 8, 9 and 10).

2. Undo the screw in the top (see Fig. 11).

3. Pull the handles out and rotate to the side (see Fig. 4).

4. The door can now be opened to a maximum of 105º

(se Fig. 8).

Fig. 8

Fig. 9

Fig. 11

Fig. 12

Fig. 10

Fig. 13

AX 105°

MAX. 105°

6

X

2.3 Ceiling-mounted unit

!

Check first that hinge stops are fitted (see Fig.

14 and 15). If not, the door could fall off when

opened! Be careful!

Note that a door strap also needs to be fitted if

the unit is mounted on the ceiling. This protects

the hinge stops against damage and prevents

the door from opening more than 105° (see Fig. 16).

1. First undo the screw in the top of the door (see Fig. 17).

2. Pull the handles out and rotate to the side (see Fig. 18).

3. The door can now be opened to a maximum of 105º (see

Fig. 19).

Fig. 14

Fig. 17

Fig. 18

Fig. 15

Fig. 16

Fig. 19

MAX. 105°

105°

7

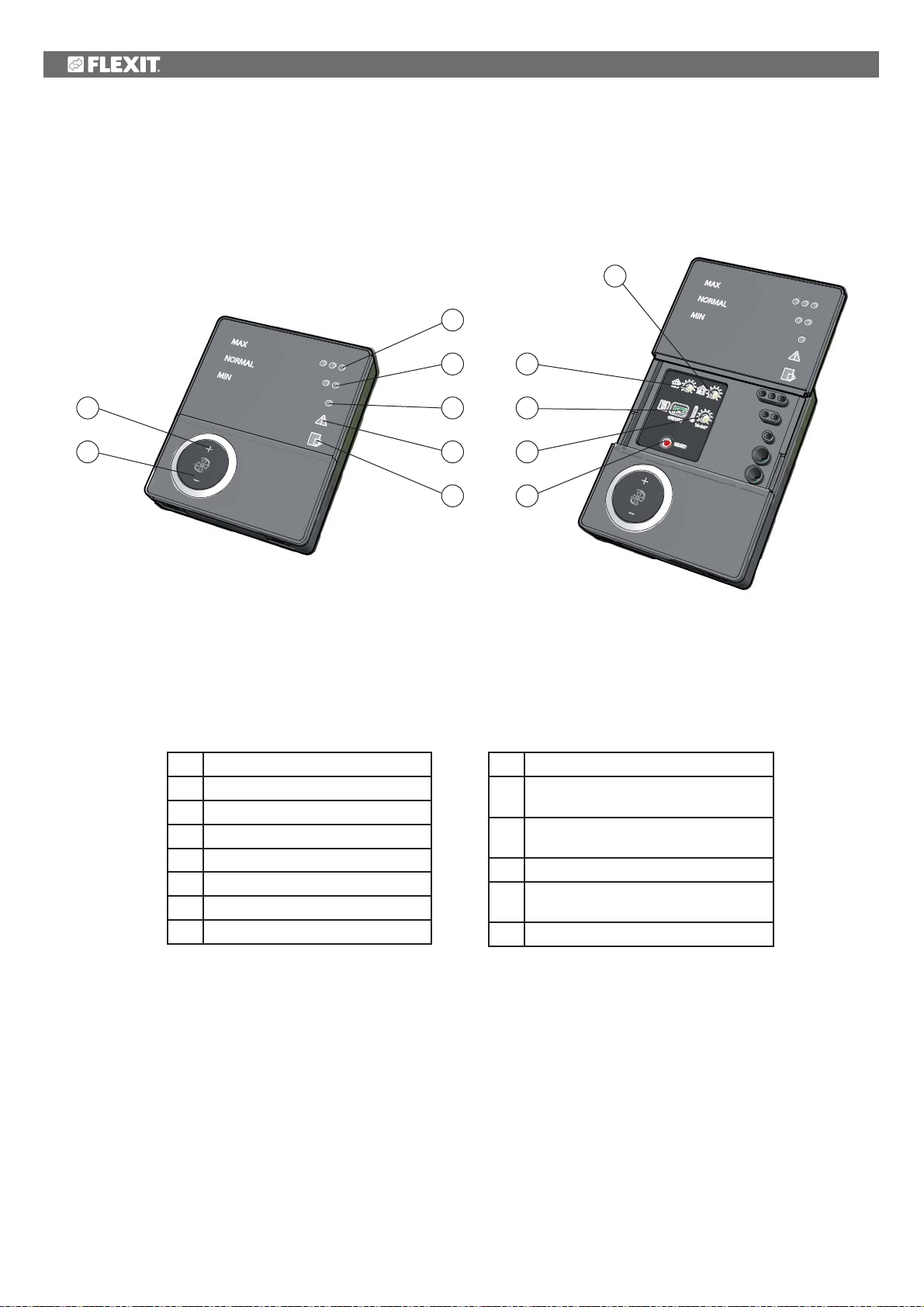

3 Overview of CI60 control panel

Fig. 20

8

3

4

*

1

2

5

6

7

No. Description

*

1

Switch for increased ventilation

2 Switch for decreased ventilation

3

Indication of MAX speed

4

Indication of NORMAL speed

5

Indication of MIN speed

6

Indication of ALARM

7

Indication of FILTER CHANGE

9

10

11

12

No. Description

8 Potentiometer for adjusting extract air

at NORMAL speed

9 Potentiometer for adjusting supply air at

NORMAL speed

10

Switch for additional heating ON/OFF

11 Potentiometer for adjusting supply air

temperature

12 Switch to reset alarm

Nos. 8, 9 and 10 are used to adjust the unit before it

is used for the first time.

*The numbers are used as references in subsequent descriptions

8

4 CI60 in use

4.1 General

The control unit consists of a touch panel with pushbuttons,

LEDs for indication and adjustment potentiometers and

switches for adjusting the ventilation unit. The control unit

communicates with the ventilation unit via a low-voltage

cable.

4.2 Increasing/reducing air supply

Use switches 1 and 2 to increase and reduce the fan speed

and thus the air flow. Different speeds depending on the

operating situation.

MIN

NORMAL

MAX

Do not use during first year of operation, or

when the building is in use.

Used under normal conditions. In this

setting, the air supply must be adjusted

according to current regulations.

Used if there is a need for increased air

supply on account of increased occupancy

or a higher humidity level, for example

during showering or when clothes are being

dried. This setting is usually used for limited

periods of time.

4.4 Temperature adjustment

The temperature required in the supply air can be set with

potentiometer 11. The adjustment range is 10 - 30 °C. Using

the factory settings is recommended.

If necessary, the ventilation unit’s heating can also be

switched ON/OFF with switch 10. In this case only the rotating

heat exchanger is used as a source of heat. It is best to leave

it in ON position, as the unit will then respond automatically

when there is a need for additional heating.

ON

ITEM 10

OFF

4.5 Filter replacement

Every six months, LED 7 lights up to remind you that it is time

to replace the air filters in the unit. See section 2 for more

information on filter r

After the activity has been carried out, the

indicator must be reset. See more under the

Reset section.

eplacement.

The different speeds are indicated with LEDs 3, 4 and 5.

4.3 Adjusting the air supply

At NORMAL speed level, the air flow must be adjusted

according to project data. Potentiometer 9 is used for the

supply air level and potentiometer 8 for the extract air level.

The adjustment range is 20-100% of the maximum level

according to the scale of the potentiometer.

Factory settings:

MIN

NORMAL

MAX

Fig. 21

50% (fixed)

75% (variable)

100% (fixed)

9

10 11

8

4.6 Alarm

If anything unforeseen occurs with the

ventilation unit, indicator 6 lights up.

The signal given by the indicator depends on the

reason for the indication.

A permanent light indicates:

• Fault return water detector (B5)

• Heat recovery fault (B)

A permanent light with indicator 5 (MIN speed) flashing

indicates:

• Fault supply air detector (B1)

• Fault extract air detector (B3)

• Fault outdoor air detector (B4)

A flashing light indicates:

• Overheating thermostat fault (applies only to electric hea-

ting)

• Fault in external fire/smoke detector (accessory)

• Heat recovery fault (A)

• Additional heating fault (applies only if the unit has a water

battery)

!

9

Loading...

Loading...