FLEXIT S3 R

SL4 R

S4 R/S7 R

Operating Instructions

Air Handling Unit - Rotor

94273E-07

2011-01

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

2

Contents

1 Dimensioned Drawings/Measures 4

1.1 Dimensioned Drawing S3 R 4

1.2 Dimensioned Drawing SL4 R 4

1.3 Dimensioned Drawing S4 R/ S7 R 4

2 Mounting - Preparatory Work 5

2.1 Inspection/Maintenance 5

2.2 Required Space 5

2.3 Mounting requirements 5

2.4 Recommended sound isolation - Horizontal mounting 5

2.5 Recommended sound insulation - Wall mounting 5

3 Installing S3 R 6

3.1 Location 6

4 Installing SL4 R 7

4.1 Wall Mounting 7

4.2 Horizontal Mounting 8

5 Montering av S4 R/S7 R 9

5.1 Wall Mounting 9

5.2 Horizontal Mounting 9

6 Connections/ Electrical Connection 10

6.1 Automatics 10

6.2 Supply Air Temperature Sencor (B1) 10

6.3 Temperature sensor for water battery (B5) 10

6.4 External Components 10

7 Plumbing Works 11

7.1 Technical Spesifications Water Battery 11

7.2 Possible Valve Types 12

7.4 Possible Vent Motors 12

7.5 Placement of Duct Battery 12

7.6 Connections 12

8 General Pictures/System Drawings 13

8.1 S3 R 13

8.2 SL4 R 14

8.3 S4 R/S7 R 15

9 Capasity and sound data 16

9.1 Capacity Diagram, Sound Data, Specifications - S3 R 16

9.2 Capacity Diagram, Sound Data, Specifications - SL4 RE/SL4 RW 17

9.3 Capacity Diagram, Sound Data, Specifications - SL4 RE EC/SL4 RW EC 18

9.4 Capacity Diagram, Sound Data, Specifications - S4 RE/S4 RW 19

9.5 Capacity Diagram, Sound Data, Specifications - S4 RE EC/S4 RW EC 20

9.6 Capacity Diagram, Sound Data, Specifications - S7 RE/S7 RW 21

9.7 Capacity Diagram, Sound Data, Specifications - S7 RE/S7 RW EC 22

10 Installation of External Kitchen Hood 23

10.1 Technical Data 23

10.2 Installation of External Kitchen Hood 23

11 Adjusting the Kitchen Hood 24

11.1 Basic Ventilation 24

11.2 Forced Ventilation 24

11.3 Pressure Drop Measurement 24

12 Adjustment Curves External Kitchen Hood 25

12.1 Basic Ventilation S3 R/S3 RK 25

12.2 Forced Ventilation S3 R 25

12.3 Basic Ventilation SL4 R/SL4 R EC 26

12.4 Forced Ventilation SL4 R/SL4 R EC 26

13 Technical Spesifications 27

13.1 Technical Spesifictions S3 R 27

13.2 Technical Spesifictions SL4 R 27

13.3 Technical Data S4 R 28

13.4 Technical Data S7 R 28

14 Final Check 29

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

3

15 Important Safety Instructions 30

16 Functional Description 30

16.1 Heating Elements 30

16.2 Operation via Kitchen Hood (S3 R/SL4 R) 30

17 Cleaning - Maintenance, S3 R 31

18 Cleaning - Maintenance SL4 R 32

19 Cleaning - Maintenance S4 R/S7 R 33

20 Fault Location 34

21 CE Declaration of Conformity 35

22 Product/Environmental Declaration 36

!

CAUTION: When a text bears this symbol, it means that personal injury

or serious damage to the equipment may follow if the instructions are

not followed.

NB: When a text bears this symbol, damage to equipment or a poor utilisation ratio may be the consequence of not following the instructions.

Symbols used

This product has a number of symbols that are used to label the product itself and in the installation and user documentation. Here is an explanation of some of the commonest symbols.

Our products are subject to continuous development and we therefore reserve the right to make changes.

We also disclaim liability for any printing errors that may occur.

EXTRACT AIR

OUTDOOR AIR

SUPPLY AIR

EXHAUST AIR

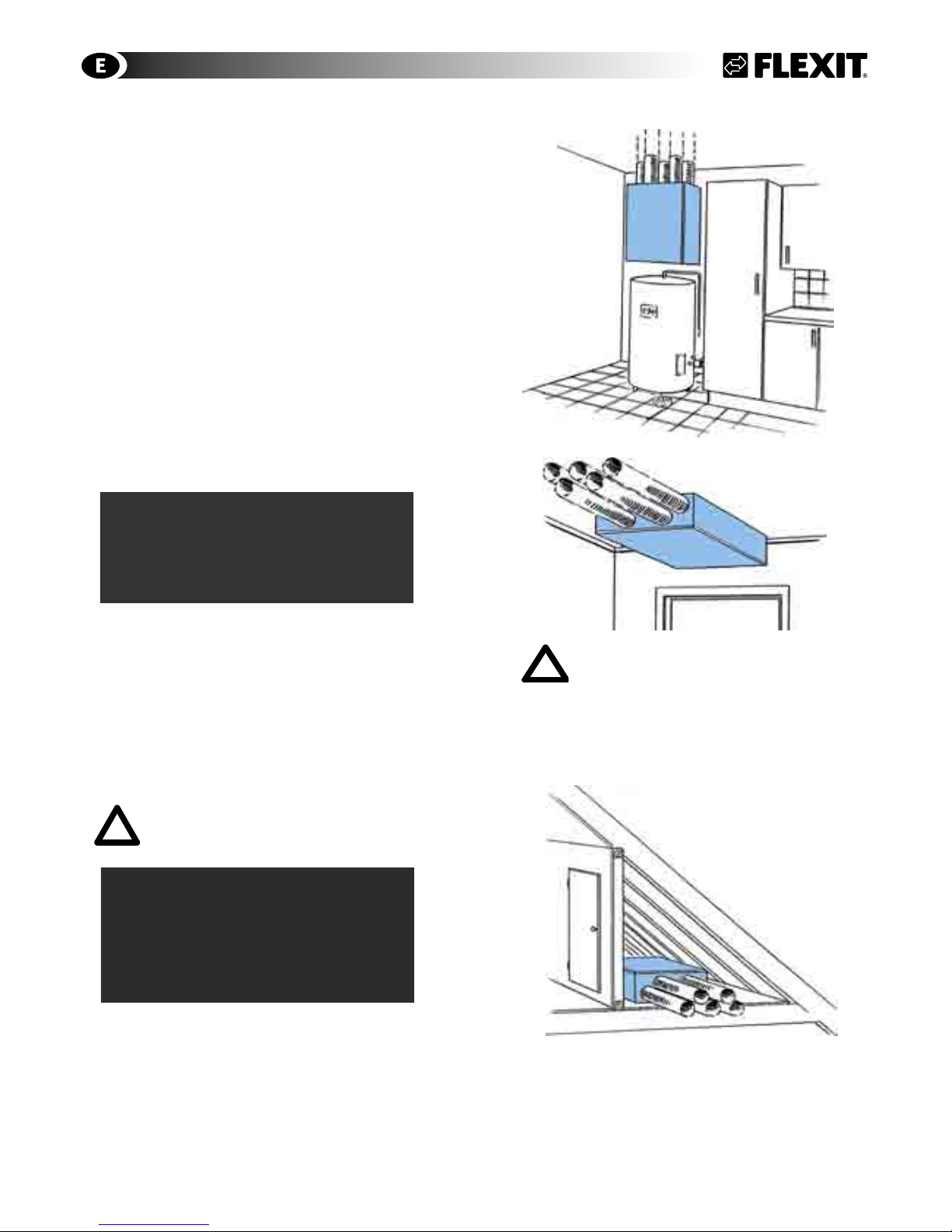

EXAMPLES OF DUCT LOCATIONS

DANGER! ELECTRICITY

DANGER! DO NOT TOUCH

TOP

BOTTOM

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

4

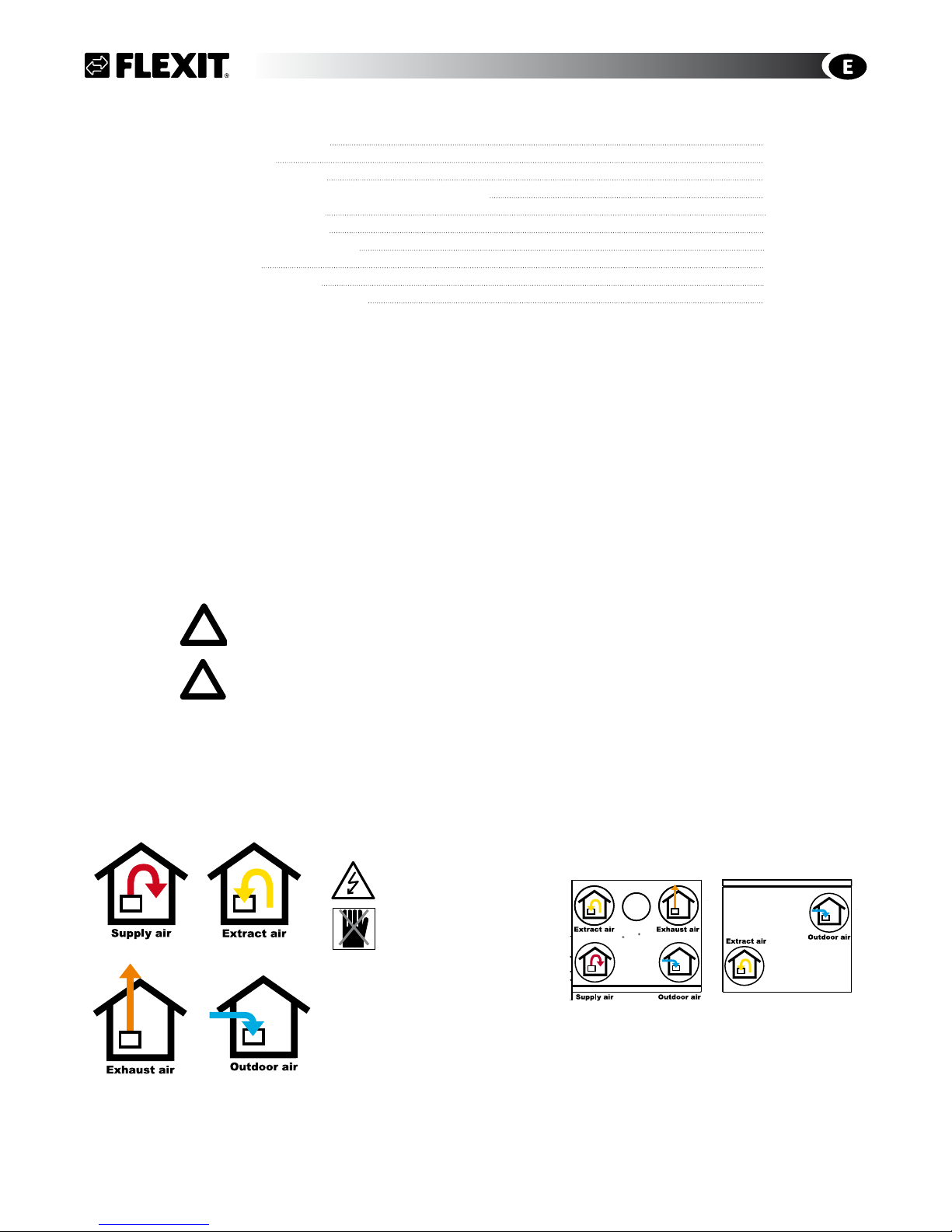

1 Dimensioned Drawings/Measures

1.1 Dimensioned Drawing S3 R

Kitchen hood

1.2 Dimensioned Drawing SL4 R

Unit bottom - Air stream direction

Unit top - Air stream direction

1

2

3

4

5

6

Date

Status

Description

Drawn

Approved

Projection

Scale

Replaces:

Replaced by:

07.02.2007

jan

7

0

0

,

0

600,0

320,0

7

3

0

,

0

84,0

232,0

517,0

95,0

385,0

8

2

,

0

2

3

0

,

0

9

8

,

5

9

8

,

0

3

2

0

,

0

1.3 Dimensioned Drawing S4 R/ S7 R

Right hand model

The left model is inverted

All measures in mm

All measures in mm

Right hand model

The left model is inverted

All measures in mm

Right hand model

The left model is inverted

S3 R

598

455

700

320

128

107

107

106

106

106

320

299299

320

106

Ø160 Ø160

Ø160

Ø160

Ø125

Kitchen Hood

Unit top - Air stream direction

Unit top - Air stream direction

Ø125 (5x) Muffemål

Ø200 (4x)

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

5

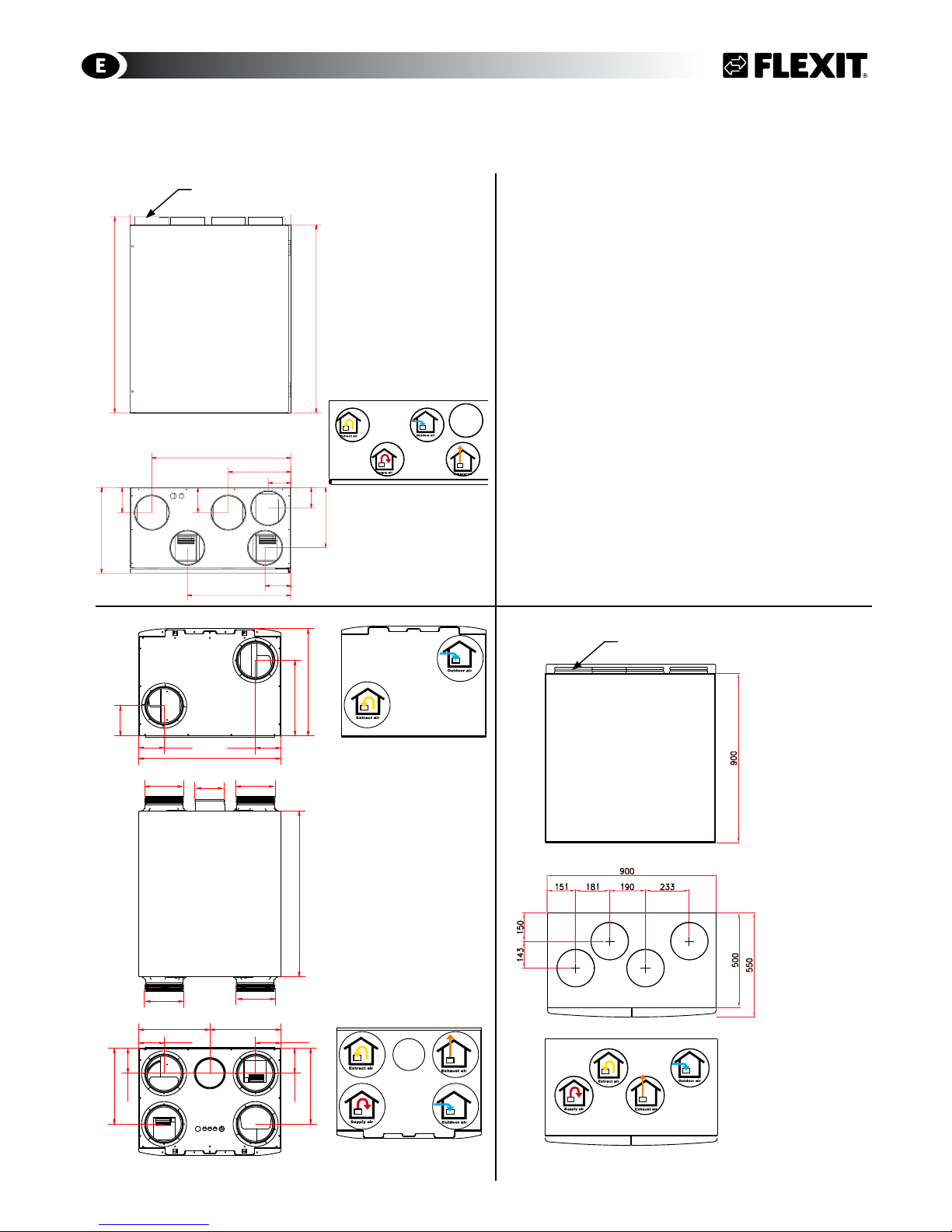

2 Mounting - Preparatory Work

Aggregatet er beregnet for innendørs

montering.

2.1 Inspection/Maintenance

The unit must be installed with space for service

and maintenance such as filter replacement and

cleaning the fans and recovery system. It is also

important for the unit to be located so that the

connectioncabinet is easily accessible for electrical

connection, troubleshooting and future component

replacement.

2.2 Required Space

Type A B

S3 R 1000 mm 0 mm

SL4 R 1000 mm 0 mm

S4/S7 R 1000 mm 60 mm

A: In front/over the unit

B: Distance to wall

These are minimum requirements that only take

service needs into account. National statutory

requirements for electrical safety may deviate from

this. Check which rules apply in your country.

2.3 Mounting requirements

The unit is intended for use in washing rooms, baths,

attics or other suitable locations.

The unit is available in left and right versions

(exhaust air nipple to the left or right), depending

on what is the most favourable duct location. In wet

rooms the unit must be located in zone 3 (minimum

0.6 m from the edge of the bath and 1.2 m from the

shower head).

2.4 Recommended sound isolation - Horizontal

mounting

When mounted horizontally the unit should be on a firm

base, for example gypsum or chipboard, which must be

level.

If the room below is sensitive to noise, the panel can be

placed on a very firm panel of mineral wool for maximum

sound absorption (Fig. 2).

The unit should not be placed directly above a bedroom.

2.5 Recommended sound insulation -

Wall mounting

For wall mounting, the (included) wall bracket fixed to the

unit is used.

The unit must not be placed on a wall with rooms on the

other side which are sensitive to noise. The wall must be

sound-insulated. If necessary, use double plasterboards

on the wall.

Interrupted studs must be used.

Ekstra gulvplate

Ekstra isolasjon

Gulv

Isolasjon

Recommended surface

Fig. 2

Fig. 1

COMMON

B

B

A

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

6

3 Installing S3 R

3.1 Location

Mounting brackets and suspension have several

mounting holes to enable securing the unit to two

pillars. If this is not possible, consider using additional

studs (transoms).

Wall Mounted (3A)

The enclosed wall bracket is used for wall mounting

(Fig. 3B). (The wall must be sound insulated to prevent

sound penetration).

• The wall bracket (Fig. 3B) is screwed to the wall with

the enclosed screws.

• The unit is suspended from the rail.

• Fix the unit at the bottom with the enclosed

mounting bracket

The wall must be sound insulated to prevent noise

transfer. The unit shuld be palced against a wall which

does not have a sound sencitive adjoining room.

Ceiling Mounted (4A)

The enclosed ceiling brackets are used for ceiling

mounting (Fig. 6B).

• Attach the 4 small brackets to the unit in the

prefitted blind nuts with the 8 enclosed screws with

countersunk heads.

• Fit the suspension rails to the ceiling with the

enclosed screws.

• Lift the unit into place. The brackets on the unit

must lock into the ceiling-mounted rails.

The mounting hole furthest out (2 on each

side) must be fixed to joists or a concrete

ceiling. Use at least 8 screws

Fig. 3A

Fig. 6 A

Fig. 5

Fig. 4B

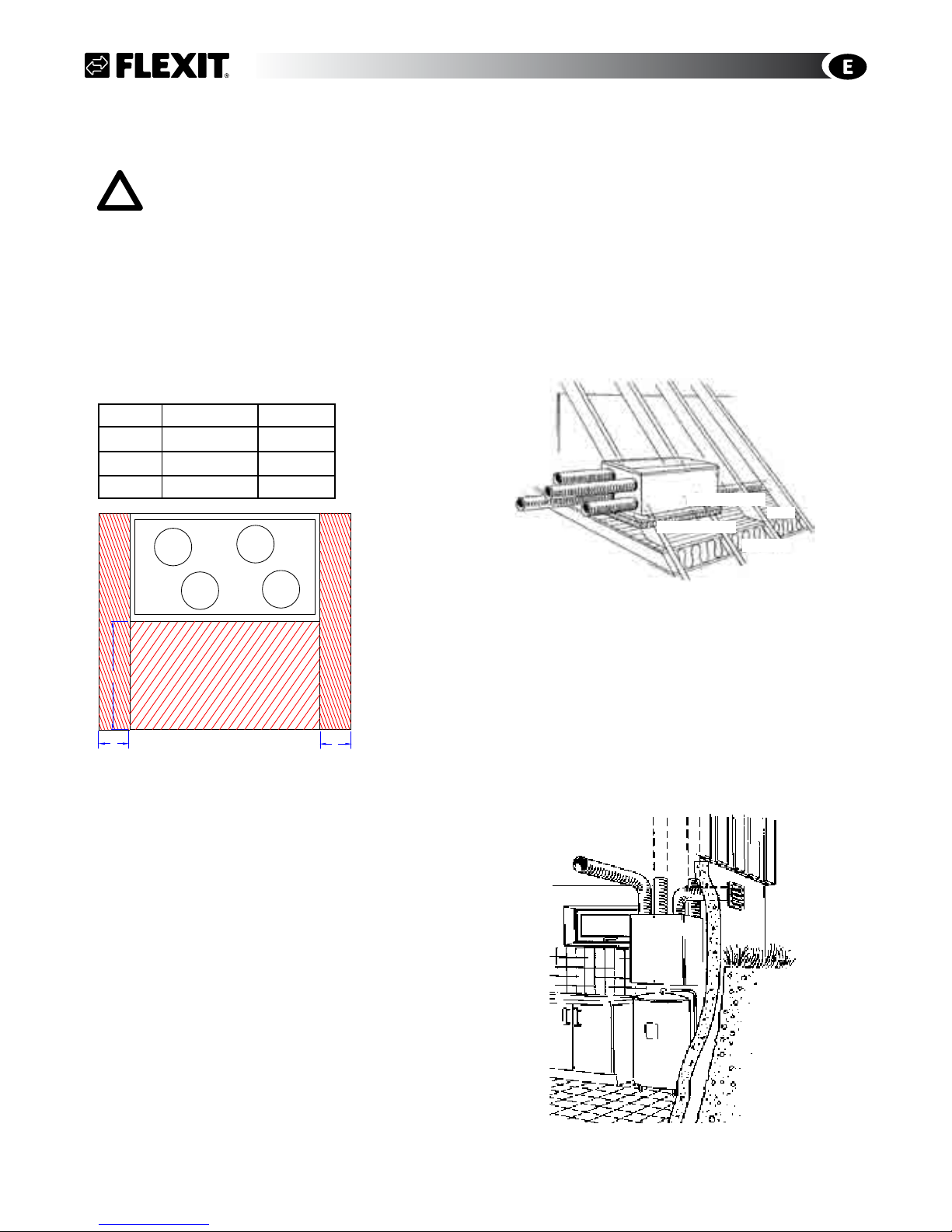

Horizontal mounting (Fig. 3) in the loft requires no

brackets. The unit should not be placed directly above

bedrooms on account of noise. Install it on a firm base

(gypsum/chipboard) that is level. Place the panel on

a very firm panel of mineral wool if additional sound

absorption is required (Fig2/Section. 2).

Fig. 3B

FOR CEILING-MOUNTED UNITS:

Be careful with the doors when opening the unit. They open suddenly when

the last screw is removed. Take care as

well when removing components. Hold

them when you remove the last screw

to avoid objects falling down. The rotor

requires extra care on account of its

weight.

!

Fig. 4A

S3 R

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

7

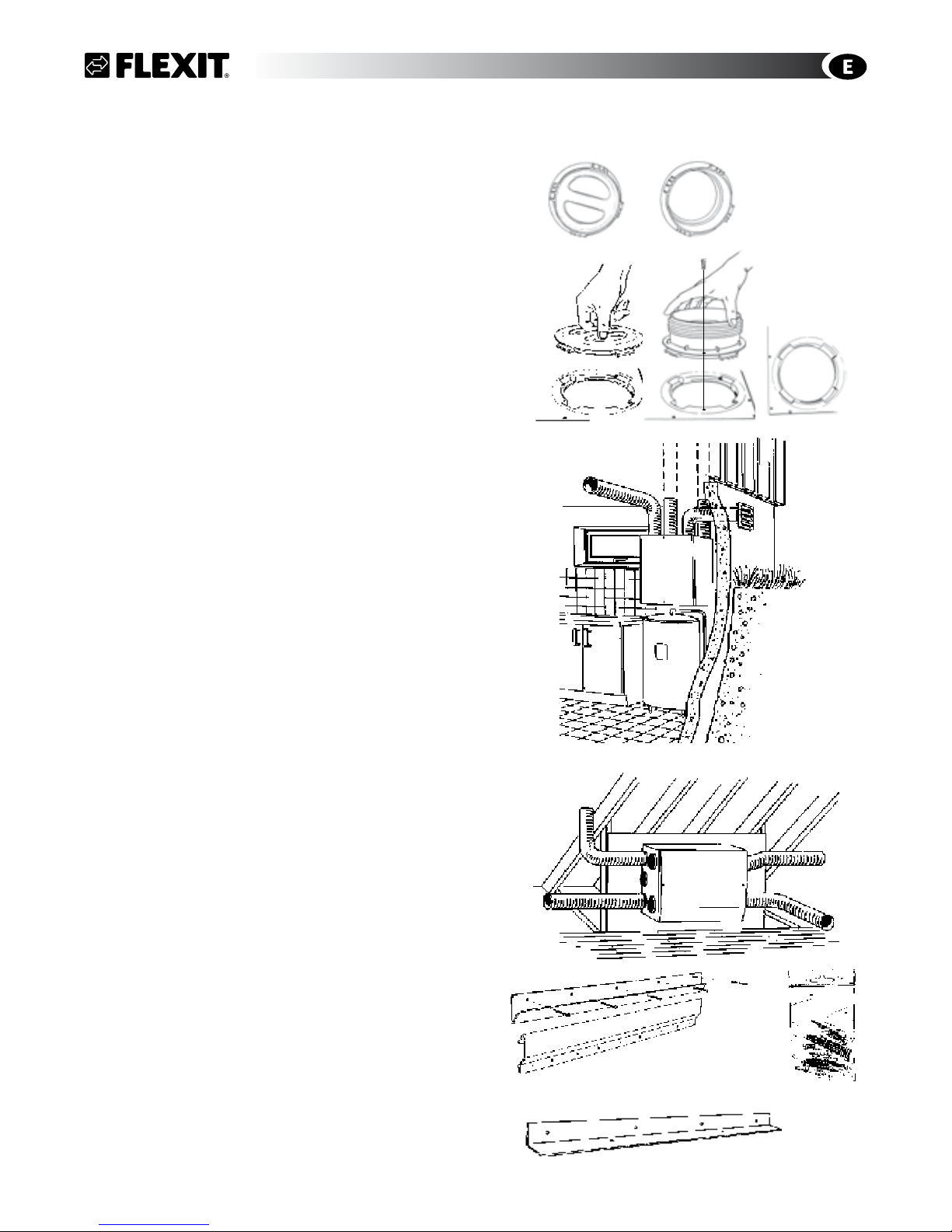

4 Installing SL4 R

The duct connections on the top and bottom of the unit

can be moved by turning the nipples/covers a quarter

turn and lifting them up (Fig. 8).

Fix the movable ducts at the top and bottom of the unit

(extract air and exhaust air) with self-tapping screws

from the installation kit. The location of the screws is

indicated on the ducts.

4.1 Wall Mounting

The enclosed wall bracket is used for wall mounting

(Fig. 8B/8C), which is fixed to the unit. Wall must be

sound insulated (Fig. 2/Chapt. 2).

The wall must be sound insulated to prevent noise

transfer. The unit should be placed against a wall which

does not have a sound sencitive adjoining room.

Duct connection top (Fig. 9)

• The wall bracket (Fig. 10B) is screwed to the wall with

the enclosed screws (Fig. 10D).

• The unit is suspended from the rail. As standard, the

unit has the mounting bracket mounted on the top

for 90o installation.

• Fix the unit at the bottom with the enclosed

mounting bracket (Fig. 10E).

Duct connection to the side (Fig. 10)

• For 180o/sideways installation, the mounting bracket

(Fig. 10C) must be unscrewed and installed on the

long side which faces up.

• The suspension rail (Fig. 10B) is screwed to the wall

with the enclosed screws (Fig. 10D).

• The unit is suspended from the rail.

• Fix the unit at the bottom with the enclosed

mounting bracket (Fig. 10E).

Fig. 9

Fig. 10A

Fig. 10B

Fig. 10D

Fig. 10C

Fig. 8

Fig. 10E

SL4 R

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

8

Fig. 11

Fig. 12

Fig. 13

Fig. 14

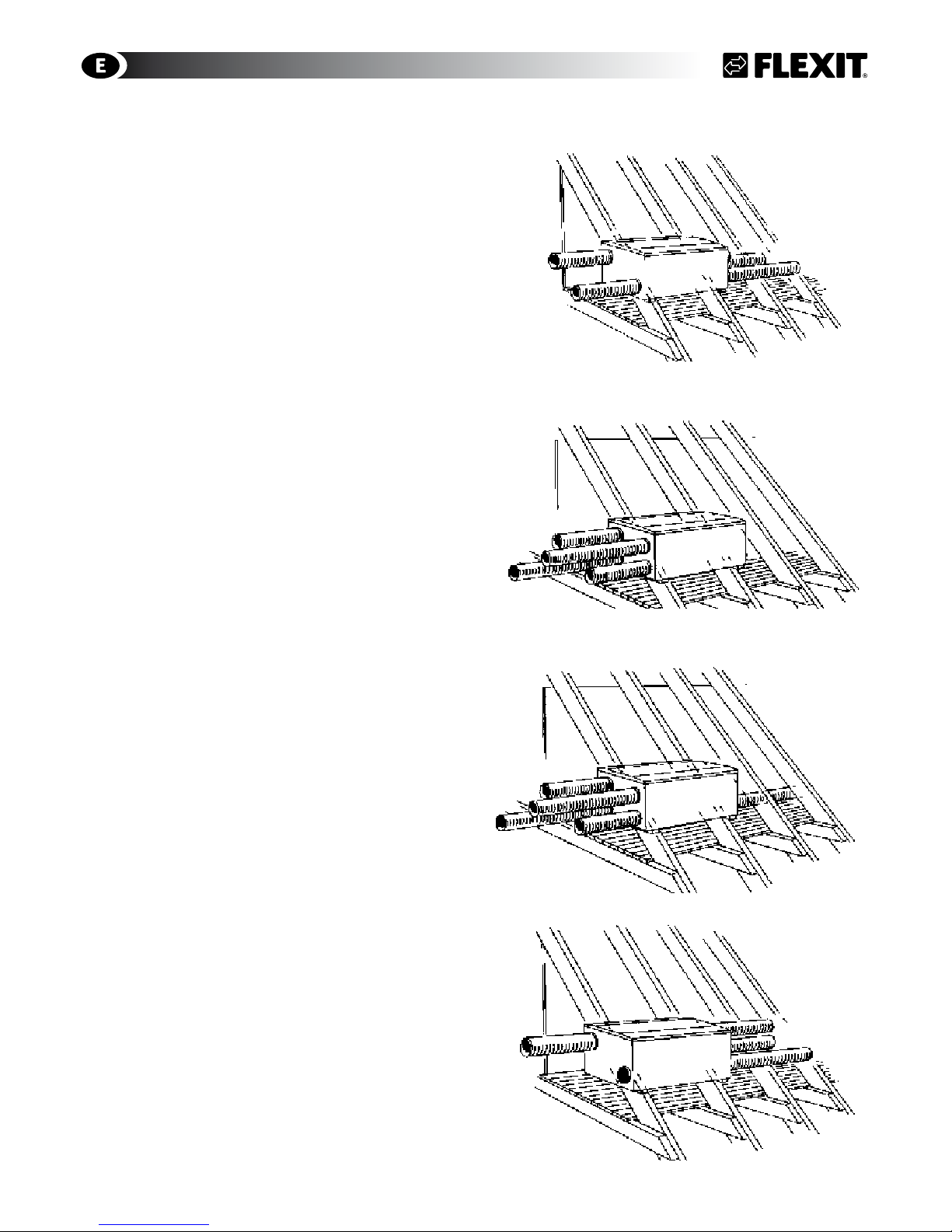

4.2 Horizontal Mounting

The ventilation unit should be installed on a firm base

(e.g. gypsum/chipboard) that is level.

If the room is noise sensitive, place the panel on a

very firm panel of mineral wool for additional sound

reduction (Fig. 2/Kap. 2). The unit should not be

installed above a bedroom. The figures 11-14 describe

the various duct connections available.

SL4 R

Right hand model

The left model is inverted

Right hand model

The left model is inverted

Left hand model

The right model is inverted

Left hand model

The right model is inverted

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

9

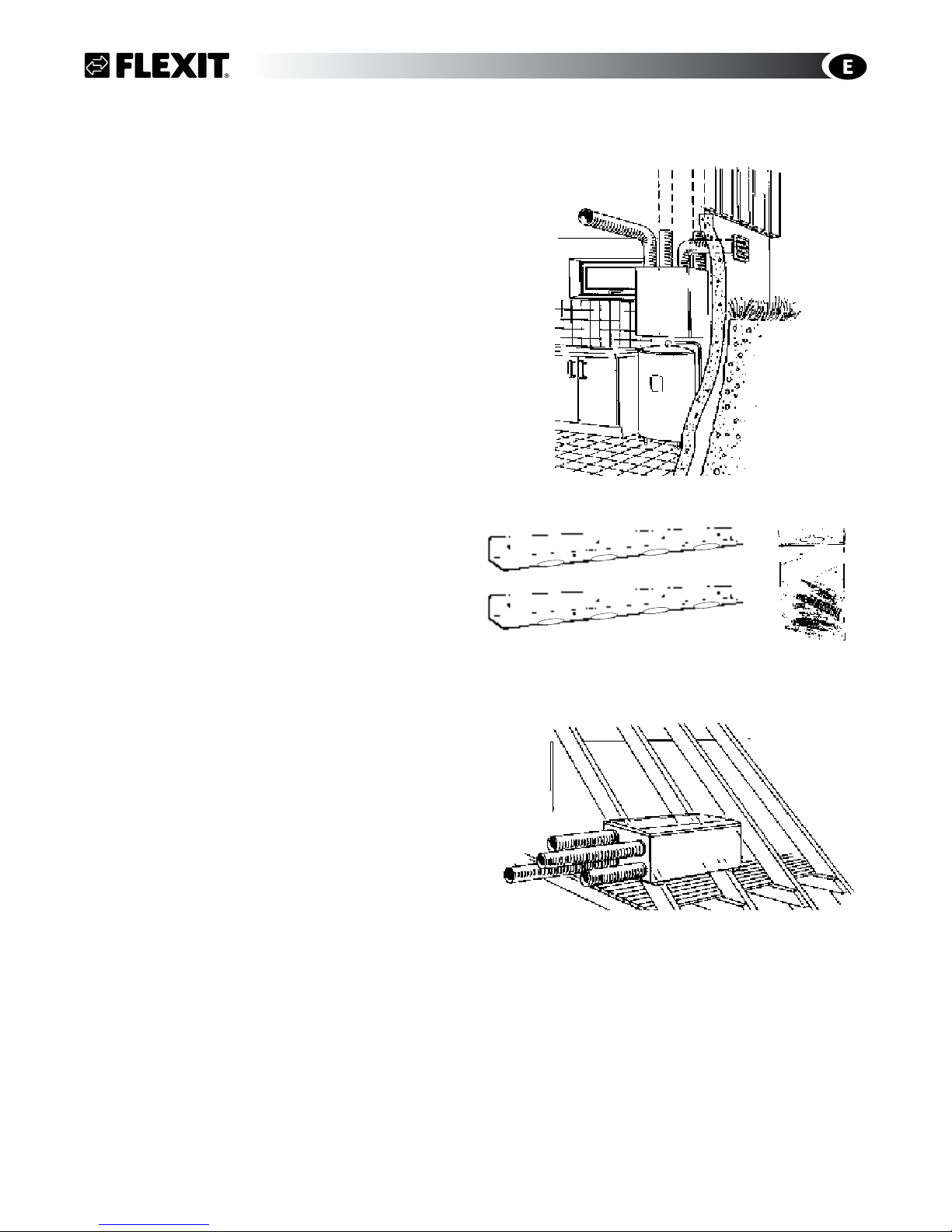

5 Mounting of S4 R/S7 R

These units are heavy and therfore it is necessary

to use additional studs (transcoms) between the

pillars on 48 x 98 mm, or 48 x 148 mm for suspension

above and support bracket below (c/c distance 900

mm) If using existing wall framework, mount an 18

mm plywood wallboard first to distribute the weight,

minimum the seize of the unit.

The wallboard must be secured to the framework in at

least 3 places with countersunk screws (6 attachment

screws 4.5 x 50 are included).

Mounting alternatives for the unit:

• Wall mounting (Fig. 15)

• Horizontal mounting (17)

5.1 Wall Mounting

The enclosed wall brackets are used for wall mounting

(Fig. 14A/14B). The wall must be sound insulated to

prevent noise transfer. The unit should be placed

against a wall which does not have a sound sencitive

adjoining room.

Duct connection top (Fig. 16)

• Attach one of the 2 mounting brackets (Fig. 16A) to

the ventilation unit with the enclosed screws (Fig.

16B).

• Lift the unit onto the wall and fasten with screws.

• Fix the unit at the bottom with the second enclosed

mounting bracket (Fig. 16A).

5.2 Horizontal Mounting

The ventilation unit should be installed on a firm base

(e.g. gypsum/chipboard) that is level.

If the room is noise sensitive, place the panel on a

very firm panel of mineral wool for additional sound

reduction (Fig. 2/Kap. 2). The unit should not be

installed above a bedroom.

Fig. 15

Fig. 16B

Fig. 16A

S4 R/S7 R

Fig. 17

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

10

COMMON

6 Connections of ducts and electrical

connection

• The ducts usually come from joists and are

connected to the nipples on the top of the unit.

• Ensure that the ducts are connected to the right

nipple. See the labelling on the unit (top/bottom

and behind door). The symbols are explained on

page 3 and the placing is shown on measurement

drawing in Chap. 1.

• Pull the duct insulation well up to the unit.

• To avoid condensation, it is very important for the

outdoor air duct to have insulation and a plastic

sleeve pulled right down to the unit. Seal the plastic sleeve to the unit with tape.

The outdoor air duct is normally designed with 25

mm insulation.

• Lay the outdoor air duct with a slight incline towards the outdoor air cap so that any water that

enters drains out again.

• With a short distance between the unit and the

exhaust point, sound insulation must be installed

to meet the requirements for the outdoor sound

level.

• Ducts must have good sound insulation, particularly above the unit.

• All electrical connections must be made by qualified personell only.

The unit must be equipped with a separate

earth-leakage circuit-breaker.

Power Cord

The unit is supplied with a 1.8 m cable and plug (which

also functions as the service switch). The cable emerges on the top of the unit (front) on the left side of a right

model and the right side of a left model. This is connected to a 230 V 50 Hz single-phase earthed power

point that is located in an easily accessible position

close by. For fuse types, see chapt. 14.

6.1 Automatics

The control package is supplied with the unit. The lowvoltage cable must be laid between the unit and the

switch unit. See separate automatics documentation.

The low-voltage cable must be laid at least

30 cm away from the 230 V cable. For flush installation, lay the cable in 20 mm conduit pipe.

6.2 Supply Air Temperature Sencor (B1)

Temperature sensor B1 must be placed after

the water battery.

This should be placed in the supply air duct (red on Flexit

Drawing/

Symbold Used

page 3) approx. 1 m from the unit.

Roll out the marked wire coil on the unit located close to

the supply air intake. Drill a Ø 7 mm hole in the duct where

the sencor can be placed. Seal the hole with a sealant and

tape the wire on the outside of the duct to keep in place.

6.3 Temperature sensor for water battery (B5)

In order to avoid that the water battery is destroyed by

frost a temperature sensor (B5) must be installed on the

return water pipe where the cold water leaves the battery.

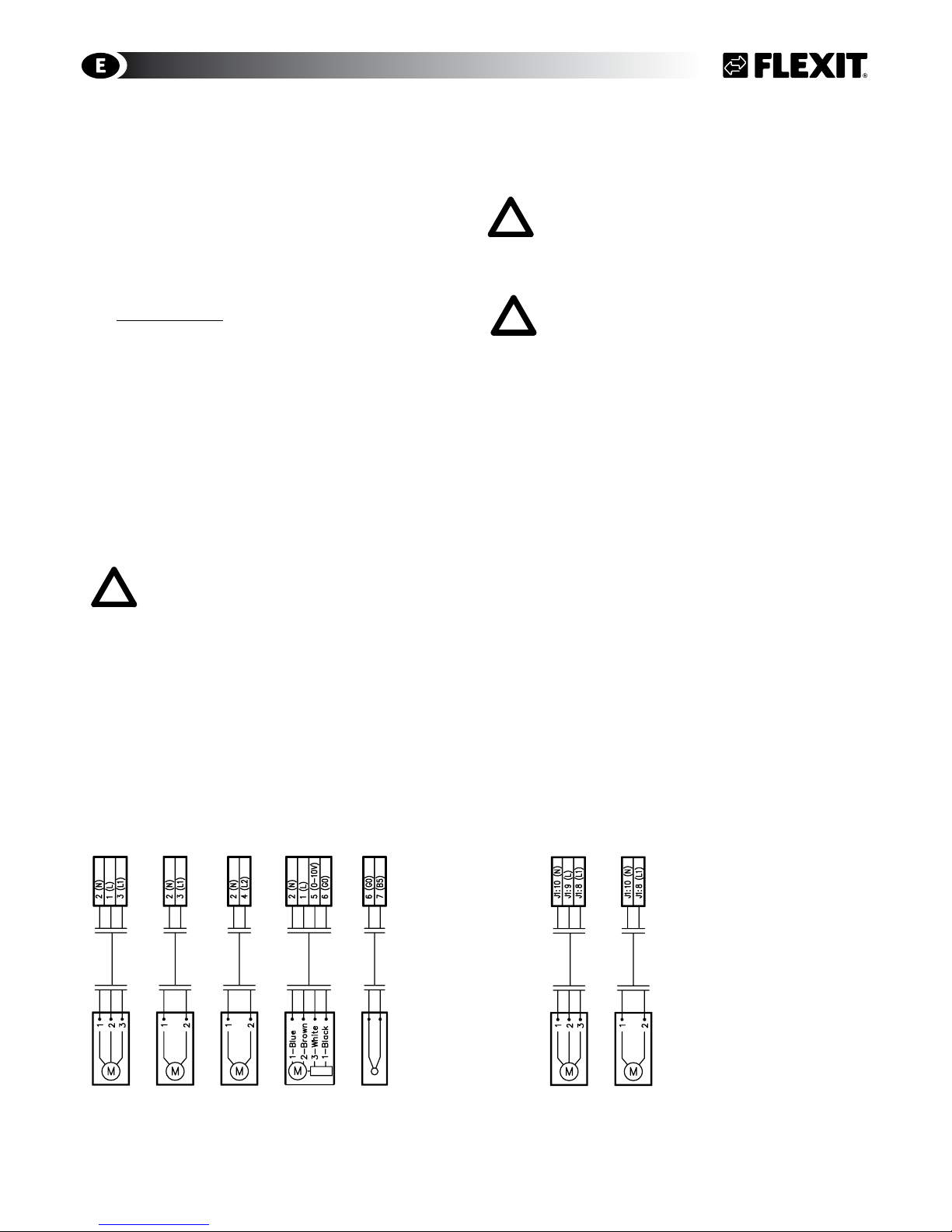

6.4 External Components

Refer to separate electrical circut drawing enclosed

with the individual ventilation unit and Fig. 18 below.

Water models Electrical models

Connected to external box Connected directely on the mainvboard

Damper motor 230V

3-wires

Damper motor 230V

2-wires

Pump motor 230V

Vent motor 230V

3-way vent

B5 Temperature sensor

Water battery

Damper motor 230V

3-wires

Damper motor 230V

2-wires

Fig. 18

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

11

WATER BATTERY

7 Plumbing Works

All plumbing must be performed by a qualified plumber.

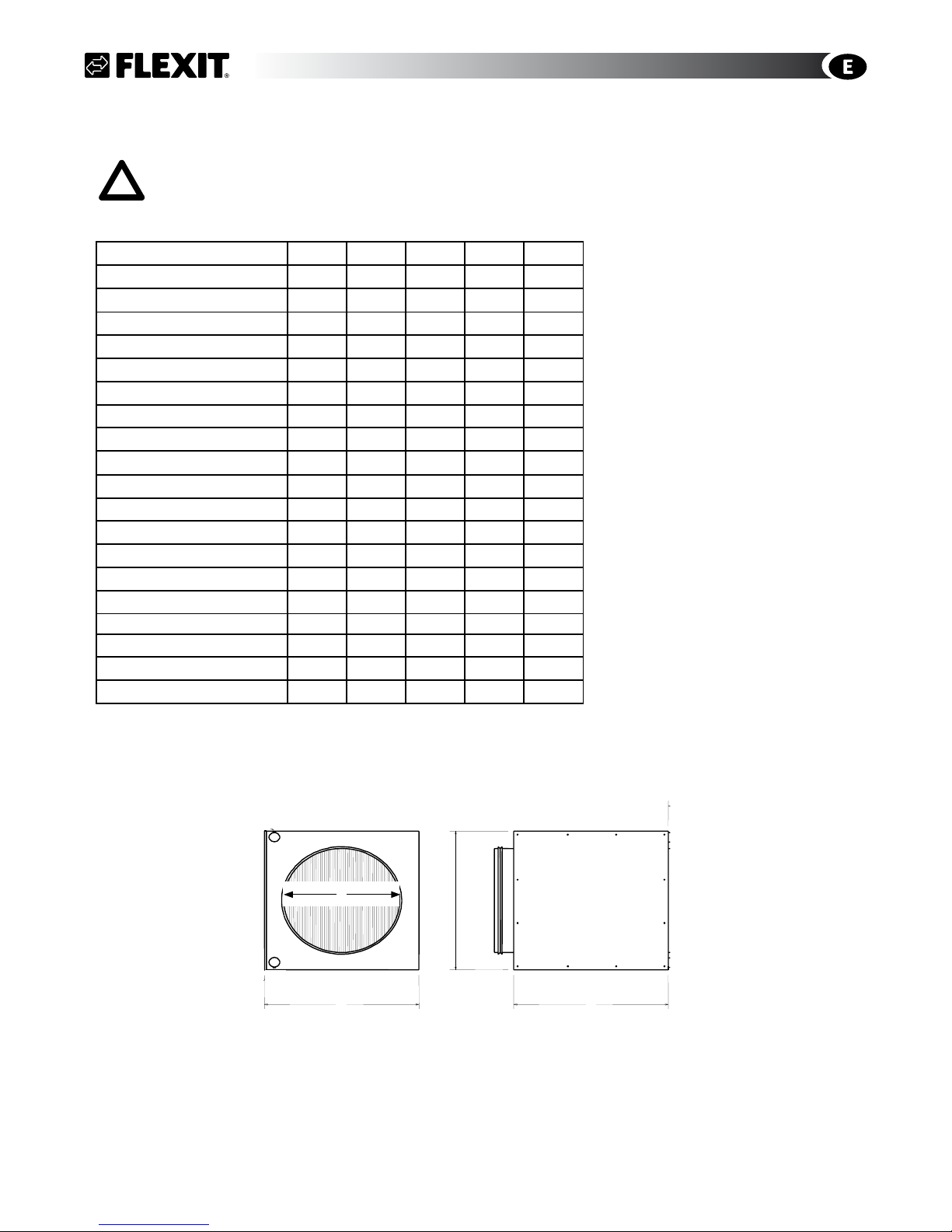

7.1 Technical Spesifications Water Battery

Water temp. In °C 80 70 60 50 40

Water temp. Out °C 60 50 40 30 30

S4R/SL4R

Water pressure l/s 0,03 0,03 0,02 0,02 0,02

Pressure drop waterside kPa 2,99 1,98 1,1 1,24 1,8

Max battery capasity kW 2,86 2,23 1,56 1,25 1

Max temp. increase °C 23,4 18,2 12,8 10,2 8,2

Pipe connection Ø mm 10 10 10 10 10

Recommended kvs-value 1,0 1,0 1,0 1,0 1,0

S7R

Water pressure l/s 0,08 0,06 0,05 0,03 0,06

Pressure drop waterside kPa 17,85 12,58 8,04 4,25 12,97

Max battery capasity kW 6,19 5,01 3,82 2,6 2,42

Max temp. increase °C 29,5 23,9 18,25 12,4 11,5

Pipe connection Ø mm 1/2” 1/2” 1/2” 1/2” 1/2”

Recommended kvs-value 1,6 1,6 1,6 1,0 1,0

PHYSICAL DIMENSIONS

A B C D

S4R/SL4R mm 205 205 350 160

S7R mm 351 255 350 200

Fig. 20 Duct battery

D

B

C

A

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

12

7.2 Possible Valve Types

3-way valve, type Belimo DN15:

Article no. 56597 Kvs 1,6

Article no. 56604 Kvs. 1,0

7.3 Possible Vent Motors

Vent motor type Belimo L230A-SR, 0-10V.

Article no. 56596.

24V motor can not be used

7.4 Placement of Duct Battery

The duct battery must be placed horizontally (Fig. 20/

Chapter 8.1). When placed in an non-insulated room

the battery itself must be insulated.

S4 R/SL4 R 14466

S7 R 14467

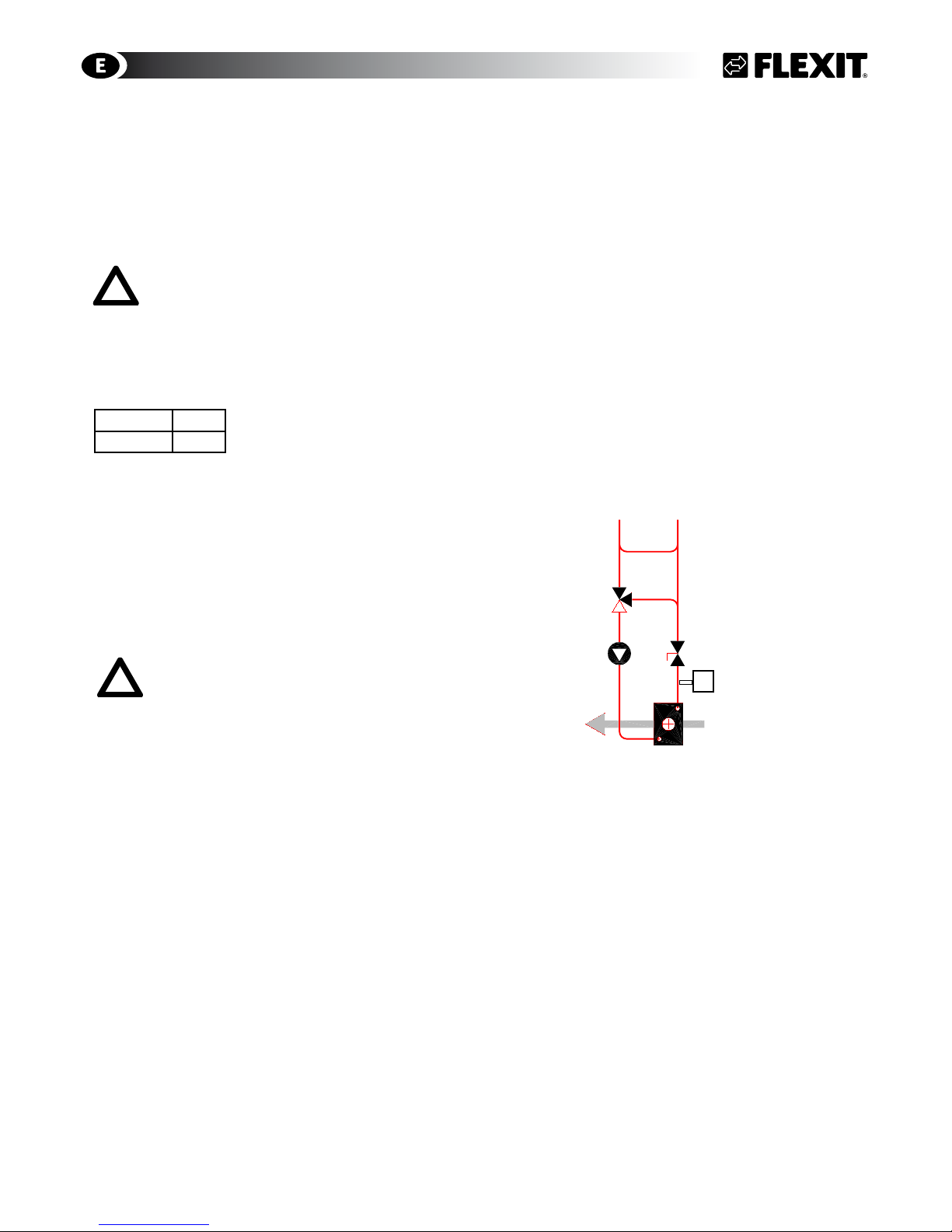

7.5 Connections

Use the recommended connection (see Fig. 20) unless

specified otherwise. The water supply must be at the

bottom of the water battery - the return must be on

the top.

Place the adjustment valve as close to the unit as

possible. (Please note that many valve motors can go

in both directions and this can be set on the motor.

Set it so that the valve opens on an increasing 0-10 V

signal.)

Before connecting the water battery, it

is necessary to check that the inspection

doors are accessible and there is space

enough to change the water battery.

If you use a water battery that has not had glycol

(or another antifreeze) added, the unit should be in

a heated room on account of the risk of frost in the

battery. Install air dampers with spring-loaded return

for outdoor air. Place the unit close to a gully to avoid

damage caused by any water leaks.

Fig. 21 Recommended connection

Pump

Throttle valve

3-way valve

Hot water from

boiler system

Water battery in the

supply air system

WATER BATTERY

B5

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

13

FI2

M1

M2

EB1

F10

F20

M4

HR-R

FI1

B1

8 General Pictures/System Drawings

8.1 S3 R

General Picture - Rotor Heat Exchanger

1 (FI2) Extract air filter F 7

2 (FI1) Supply air filter F 7

3 (EB1) Heating battery, electrical

4 (F10-20) Overheating thermostat (manual reset)

5 (M1) Supply air fan

6 (M2) Extract air fan

7 (HR-R) Rotor heat exchanger

8 (M4) Rotor motor

9 Control box

10 Adjustment switch

System Drawing - Electrical Battery

B1 Temperature sensor, supply air

EB1 Heating battery, electrical

F10 Overheating thermostat (manual reset)

F20 Overheating thermostat (automatic reset)

FI1 Supply air filter

FI2 Extract air filter

M1 Supply air fan

M2 Extract air fan

HR-R Rotor heat exchanger

M4 Rotor motor

Extract air Supply Outdoor Exhaust

S3 R/S3 RK

Right model

(left model inverted)

Extract air Supply air Outdoor air Exhaust

6

2

5

1

3

4

9

10

8

7

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

14

8.2 SL4 R

General Picture - Rotor Heat Exchanger

1 (FI2) Extract air filter F 7

2 (FI1) Supply air filter F 7

3 (EB1) Heating battery, electrical

4 (F10-20) Overheating thermostat (manual reset)

5 (M1) Supply air fan

6 (M2) Extract air fan

7 (HR-R) Rotor heat exchanger

8 Control box

9 Adjustment switch

10 Connection: Control panel/kitchen hood

System Drawing - Electrical Battery

B1 Temperature sensor, supply air

B5 Temperature sensor, water battery * (- EB1/F10/F20)

EB1 Heating battery, electrical

F10 Overheating thermostat (manual reset)

F20 Overheating thermostat (automatic reset)

FI1 Supply air filter

FI2 Extract air filter

M1 Supply air fan

M2 Extract air fan

HR-R Rotor heat exchanger

M4 Rotor motor

MODELS WITH KITCHEN HOOD ONLY:

K Kitchen hood (SL4 RK)

System Drawing - Water Battery *

FI2

M1

M2

EB1

VF10

F20

M4

HR-R

FI1

B1

K

Extract Supply Outdoor Exhaust

SL4 R

Supply air Extract air Kitchen hood Outdoor air Exhaust

Right model

(left model inverted)

System Drawing - Electrical Battery

8

6

10

3

2

7

1

4

5

9

FI2

M1

M2

M4

HR-R

FI1

K

B1

B5

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

15

8.3 S4 R/S7 R

General Picture - Rotor Heat Exchanger

1 (FI2) Extract air filter F 7

2 (FI1) Supply air filter F 7

3 (EB1) Heating battery, electrical

4 (F10-20) Overheating thermostat (manual reset)

5 (M1) Supply air fan

6 (M2) Extract air fan

7 (HR-R) Rotor heat exchanger

8 (M4) Rotor motor

9 Control box

10 Adjustment switch (AC)

11 Connection control panel

System Drawing - Electrical Battery

B1 Temperature sensor, supply air

B5 Temperature sensor, water battery

* (- EB1/F10/F20)

EB1 Heating battery, electrical

F10 Overheating thermostat (manual reset)

F20 Overheating thermostat (automatic reset)

FI1 Supply air filter

FI2 Extract air filter

M1 Supply air fan

M2 Extract air fan

HR-R Rotor heat exchanger

M4 Rotor motor

System Drawing - Water Battery *

S4 R/S7 R

Supply air Extract air Exhaust Outdoor air

Supply Extract Exhaust Outdoor

B1

FI2

M1

M2

EB1

F10

F20

FI1

M4

HR-R

Right model

(left model inverted)

1

11

4

5

3

8

6

2

7

10

9

System Drawing - Electrical Battery

B1

FI2

M1

M2

FI1

M4

HR-R

B5

B1

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

16

9 Capasity and sound data

9.1 Capacity Diagram, Sound Data, Specifications - S3 R

0

100

200

300

Pa

m3/h

0

200

0

300

100

0

40 80

W

0

40

80

120

160

l/s

100

60

20

40dB(A)

55dB(A)

45dB(A)

230V

190V

50dB(A)

120V

170V

150V

105V

85V

60V

60V

85V

105V

120V

150V

170V

190V

230V

F5-filter

Pa

24

45

65

0

0

100

200

300

Pa

m3/h

0

200

0

300

100

0

40 80

W

0

40

80

120

160

l/s

100

60

20

Pa

24

45

65

0

83dB(A)

80dB(A)

70dB(A)

230V

150V

190V

105V

75dB(A)

230V

150V

120V

85V

190V

170V

105V

60V

60V

85V

120V

170V

65dB(A)

-11

-28

-53

Water Battery

F5 Filter

S3 R

Supply air side (with F7 filter)

Sound data is given at sound power level LwA in the capacity

diagrams and is corrected with the table below for the various

octave bands. Radiated noise produces Lw in the various octave

bands and total LwA. Radiated noise is estimated by finding the

noise level from the supply air table and deduct the total value

found in the correction factor table below.

Correction factor for Lw

Hz 63 125 250 500 1000 2000 4000 8000 LwA

Supply air 3 2 -2 -5 -5 -6 -13 -29

Extract air 18 14 1 -12 -14 -28 -37 -43

Radiated 47 -42 -40 -43 -44 -45 -49 -57 -38,7

Extract air side (with F7 filter)

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Data for supply air is measured in accordance with ISO 5136,

"In-duct method".

Radiated noise is measured in accordance with ISO 9614-2.

Bruel & Kjær measuring equipment, type 2260.

Air capacity at various capacity settings in Volt.

Supply air fan power consumption at various capacity settings.

Sound power level Lw

A, cf. correction table.

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

17

9.2 Capacity Diagram, Sound Data, Specifications - SL4 RE/SL4 RW

0

100

200

300

Pa

400

m3/h

0

400

200

0

300

100

0

40 80

W

0

50

100

150

200

l/s

100

60

20

Pa

15 25 35

45

0

65dB(A)

60dB(A)

50dB(A)

230V

150V

120V

85V

190V

170V

105V

60V

55dB(A)

230V

150V

120V

85V

190V

170V

105V

60V

45dB(A)

F5 Filter

0

100

200

300

Pa

400

m3/h

0

400

200

0

300

100

0

40 80

W

0

50

100

150

200

l/s

100

60

20

80dB(A)

75dB(A)

65dB(A)

150V

120V

190V

170V

105V

70dB(A)

150V

85V

190V

170V

105V

60V

60dB(A)

230V

85V

60V

83dB(A)

230V

120V

Pa

15 25 35

45

0

-10 -25

-55

-90

Water Battery

F5 Filter

SL4 R

Supply air side (with F7 filter)

Sound data is given at sound power level LwA in the capacity

diagrams and is corrected with the table below for the various

octave bands. Radiated noise produces Lw in the various octave

bands and total LwA. Radiated noise is estimated by finding the

noise level from the supply air table and deduct the total value

found in the correction factor table below.

Correction factor for Lw

Hz 63 125 250 500 1000 2000 4000 8000 LwA

Supply air

3 1 2 -1 -7 -11 -18 -31

Extract air

10 8 5 -2 -11 -19 -30 -48

Radiated

-50 -40 -34 -42 -46 -47 -56 -63 -38,5

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Extract air side (with F7 filter)

Data for supply air is measured in accordance with ISO 5136,

"In-duct method".

Radiated noise is measured in accordance with ISO 9614-2.

Bruel & Kjær measuring equipment, type 2260.

Air capacity at various capacity settings in Volt.

Supply air fan power consumption at various capacity settings.

Sound power level Lw

A, cf. correction table.

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

18

9.3 Capacity Diagram, Sound Data, Specifications - SL4 RE EC/SL4 RW EC

77dB(A)

70dB(A)

80%

60%

40%

75dB(A)

65dB(A)

60dB(A)

100%

40%

100%

60%

80%

0

100

200

300

Pa

400

m3/h

0

400

200

0

300

100

0

40 80

W

0

25

50

75

100

l/s

100

60

20

Pa

15 25 35

45

0

-10 -25

-55

-90

Water Battery

F5 Filter

60dB(A)

50dB(A)

80%

60%

40%

55dB(A)

80%

60%

40%

45dB(A)

40dB(A)

100%

100%

0

100

200

300

Pa

400

m3/h

0

400

200

0

300

100

0

40 80

W

0

25

50

75

100

l/s

100

60

20

Pa

F5-filter

15 25 35

45

0

SL4 R

Supply air side (with F7 filter)

Sound data is given at sound power level LwA in the capacity

diagrams and is corrected with the table below for the various

octave bands. Radiated noise produces Lw in the various octave

bands and total LwA. Radiated noise is estimated by finding the

noise level from the supply air table and deduct the total value

found in the correction factor table below.

Correction factor for Lw

Hz 63 125 250 500 1000 2000 4000 8000 LwA

Supply air

9 3 -1 -2 -4 -10 -18 -31

Extract air

13 9 3 -2 -10 -19 -31 -48

Radiated

-43 -35 -32 -40 -43 -45 -55 -63 -36,9

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Extract air side (with F7 filter)

Data for supply air is measured in accordance with ISO 5136,

"In-duct method".

Radiated noise is measured in accordance with ISO 9614-2.

Bruel & Kjær measuring equipment, type 2260.

Air capacity at various capacity settings in Volt.

Supply air fan power consumption at various capacity settings.

Sound power level Lw

A, cf. correction table.

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

19

9.4 Capacity Diagram, Sound Data, Specifications - S4 RE/S4 RW

0

100

200

300

Pa

400

m3/h

0

400

500

200

0

300

100

0

40 80

120

W

0

50

100

150

200

l/s

100

60

20

Pa

9 17 25

32

0

F5 Filter

62dB(A)

60dB(A)

50dB(A)

55dB(A)

45dB(A)

230V

190V

170V

150V

120V

105V

85V

60V

230V

60V

85V

120V

150V

170V

190V

105V

0

100

200

300

Pa

400

m3/h

0

400

500

200

0

300

100

0

40 80

120

W

0

50

100

150

200

l/s

100

60

20

Pa

9

0

-11 -28

-53

-90

Water Battery

F5 Filter

17

25

32

75dB(A)

70dB(A)

60dB(A)

65dB(A)

55dB(A)

190V

230V

170V

150V

120V

105V

85V

60V

230V

60V

85V

105V

120V

150V

170V

190V

S4 R

Supply air side (with F7 filter)

Sound data is given at sound power level LwA in the capacity

diagrams and is corrected with the table below for the various

octave bands. Radiated noise produces Lw in the various octave

bands and total LwA. Radiated noise is estimated by finding the

noise level from the supply air table and deduct the total value

found in the correction factor table below.

Correction factor for Lw

Hz 63 125 250 500 1000 2000 4000 8000 LwA

Supply air

7 3 -1 -3 -6 -7 -17 -30

Extract air

8 9 5 -2 -11 -21 -29 -48

Radiated

-43 -31 -33 -34 -38 -38 -39 -44 -30,6

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Extract air side (with F7 filter)

Data for supply air is measured in accordance with ISO 5136,

"In-duct method".

Radiated noise is measured in accordance with ISO 9614-2.

Bruel & Kjær measuring equipment, type 2260.

Air capacity at various capacity settings in Volt.

Supply air fan power consumption at various capacity settings.

Sound power level Lw

A, cf. correction table.

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

20

9.5 Capacity Diagram, Sound Data, Specifications - S4 RE EC/S4 RW EC

S4 R

60dB(A)

50dB(A)

80%

60%

40%

55dB(A)

80%

60%

40%

45dB(A)

40dB(A)

100%

100%

0

100

200

300

Pa

400

m3/h

0

400

200

0

300

100

0

40 80

W

0

25

50

75

100

l/s

100

60

20

Pa

F5-filter

10 15 25

30

0

73dB(A)

70dB(A)

80%

60%

40%

55dB(A)

65dB(A)

60dB(A)

100%

100%

80%

40%

60%

0

100

200

300

Pa

400

m3/h

0

400

200

0

300

100

0

40 80

W

0

25

50

75

100

l/s

100

60

20

Pa

10 15 25

30

0

-10 -25

-55

-90

Water Battery

F5 Filter

Sound data is given at sound power level LwA in the capacity

diagrams and is corrected with the table below for the various

octave bands. Radiated noise produces Lw in the various octave

bands and total LwA. Radiated noise is estimated by finding the

noise level from the supply air table and deduct the total value

found in the correction factor table below.

Correction factor for Lw

Hz 63 125 250 500 1000 2000 4000 8000 LwA

Supply air

10 4 -3 -4 -3 -10 -20 -34

Extract air

11 11 4 -4 -8 -23 -32 -48

Radiated

-43 -43 -31 -33 -34 -38 -39 -44 -30,6

Supply air side (with F7 filter)

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Extract air side (with F7 filter)

Data for supply air is measured in accordance with ISO 5136,

"In-duct method".

Radiated noise is measured in accordance with ISO 9614-2.

Bruel & Kjær measuring equipment, type 2260.

Air capacity at various capacity settings in Volt.

Supply air fan power consumption at various capacity settings.

Sound power level Lw

A, cf. correction table.

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

21

9.6 Capacity Diagram, Sound Data, Specifications - S7 RE/S7 RW

0

200

400

Pa

l/s

0

40 80

120

160

Pa

0 800

m3/h

600

32

42

0

600

W

0

50

100

150

250

200

200

350

300

-39

Water Battery

F5 Filter

-4

-30

-52

38

9

47

400

200

-22

-14

-8

25

17

80dB(A)

75dB(A)

70dB(A)

65dB(A)

230V

150V

120V

85V

190V

170V

105V

60dB(A)

83dB(A)

230V

60V

85V

120V

150V

170V

105V

190V

60V

S7 R

Supply air side (with F7 filter)

Sound data is given at sound power level LwA in the capacity

diagrams and is corrected with the table below for the various

octave bands. Radiated noise produces Lw in the various octave

bands and total LwA. Radiated noise is estimated by finding the

noise level from the supply air table and deduct the total value

found in the correction factor table below.

Correction factor for Lw

Hz 63 125 250 500 1000 2000 4000 8000 LwA

Supply air

3 1 -4 -4 -5 -7 -14 -24

Extract air

10 10 11 -4 -9 -15 -26 -41

Radiated

-43 -31 -33 -34 -38 -38 -39 -44 -30,6

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Extract air side (with F7 filter)

Data for supply air is measured in accordance with ISO 5136,

"In-duct method".

Radiated noise is measured in accordance with ISO 9614-2.

Bruel & Kjær measuring equipment, type 2260.

Air capacity at various capacity settings in Volt.

Supply air fan power consumption at various capacity settings.

Sound power level Lw

A, cf. correction table.

0

200

400

l/s

0

40 80

120

160

0 400 800

m3/h

200 600

600

W

0

50

100

150

250

200

200

350

300

Pa

17 32

42

0

25

38

9

47

F5 Filter

68dB(A)

60dB(A)

55dB(A)

230V

150V

120V

85V

190V

170V

105V

60V

50dB(A)

230V

150V

120V

85V

190V

170V

105V

60V

65dB(A)

45dB(A)

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

22

9.7 Capacity Diagram, Sound Data, Specifications - S7 RE/S7 RW EC

0

200

400

Pa

l/s

0

40 80

120

160

0 400

m3/h

200 600

600

W

0

25

75

100

175

150

200

Pa

15 30

40

0

25

35

9

F5 Filter

125

50

80%

60%

100%

40%

40%

60%

80%

100%

45dB(A)

50dB(A)

55dB(A)

60dB(A)

64dB(A)

0

200

400

Pa

l/s

0

40 80

120

160

0 400

m3/h

200 600

600

W

0

25

75

100

175

150

200

Pa

15 30

40

0

25

35

9

125

50

60dB(A)

65dB(A)

70dB(A)

75dB(A)

80dB(A)

60%

80%

100%

40%

100%

80%

60%

40%

-5 -10

-15

-45

Water Battery

F5 Filter

-25

-35

Supply air side (with F7 filter)

Sound data is given at sound power level LwA in the capacity

diagrams and is corrected with the table below for the various

octave bands. Radiated noise produces Lw in the various octave

bands and total LwA. Radiated noise is estimated by finding the

noise level from the supply air table and deduct the total value

found in the correction factor table below.

Correction factor for Lw

Hz 63 125 250 500 1000 2000 4000 8000 LwA

Supply air

3 1 -4 -4 -5 -7 -14 -24

Extract air

10 11 3 -4 -9 -15 -26 -41

Radiated

-43 -31 -33 -34 -38 -38 -39 -44 -30,6

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Power consumption in Watt

Contact resistance (Pa)

Air flow rate, m3/h - Pressure correction factor

Extract air side (with F7 filter)

S7 R

Data for supply air is measured in accordance with ISO 5136,

"In-duct method".

Radiated noise is measured in accordance with ISO 9614-2.

Bruel & Kjær measuring equipment, type 2260.

Air capacity at various capacity settings in Volt.

Supply air fan power consumption at various capacity settings.

Sound power level Lw

A, cf. correction table.

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

23

10 Installation of External Kitchen

Hood

10.1 Technical Data

Width: 60 cm

El. connection: 230 V earthed

Light: Fluorescent tube, base G23, 11 W

10.2 Installation of External Kitchen Hood

Installing the sleeve and damper

The sleeve is inside the volume hood on delivery.

Place the damper shaft A in the hoop under the

damper lid, see Fig. 21. Ensure that the grips B are

under the edge of the plate. The sleeve snaps into

place.

Installing the kitchen hood

The kitchen hood must be placed under or recessed

in the row of cabinets, see Fig. 22. The distance

between the cooker and the kitchen hood must be at

least 40 cm. For a gas cooker, the distance must be

65 cm. The kitchen hood can also be installed using

wall mountings that can be purchased as accessories,

Fig. 13. Instructions for installing the accessories are

enclosed with them.

Electrical installation

The kitchen hood is supplied with a cable and earthed

plug for connection to an earthed socket. The control

cable (12 V) is connected between marked 2-core

cables from the kitchen hood and the unit. The colour

of the cables connected to the terminals is of no

significance. The control cable between the kitchen

hood and the unit must at least be of type 2 x 0.75

mm2. The voltage between the units is 12 V DC.

The installation must be carried out by an

authorised expert.

Adjustment

For adjustment of the kitchen hood, see Chap. 12, and

for the unit see Chap. 13 Adjustment Curves.

Fig. 21

Fig. 23

Fig. 22

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

24

11 Adjusting the Kitchen Hood

11.1 Basic Ventilation

The basic ventilation is adjusted by setting the sliding damper A to the desired position as shown in detail B in Fig. 24

(see diagram 13.1).

11.2 Forced Ventilation

Open the damper and remove the throttle piece C, Fig. 25. Adjust the forced ventilation by cutting out a suitable

number of rings in the throttle piece, Fig. 26 (see diagram 13.2). Ensure that the guide slot D is in position when the

piece is in place.

11.3 Pressure Drop Measurement

The pressure drop is measured by the hose being fitted to the measuring outlet at the front of the damper, Fig. 27.

The pressure drop corresponds to the axis in the adjustment diagram (left side), see Chap. 13.

If basic ventilation is not required, the enclosed piece can be installed, see Fig. 28 for the procedure.

Fig. 25

Fig. 27

Fig. 24

Fig. 26

Fig. 28

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

25

12 Adjustment Curves External Kitchen Hood

12.1 Basic Ventilation S3 R

12.2 Forced Ventilation S3 R

S3 R

0 - Open = Number of rings removed

100/150/200 Pa = Total duct resistance for the extract air and exhaust

air side

Lw (A) measured 1 m from the kitchen hood varies between 46 and 48

dB(A) throughout the measuring area

S3 R/S3 RK

S3 R

Min. - Max. = Damper position

dB = Lp(A) measured 1 m from the kitchen hood in the kitchen landscape.

0

50 Pa

100

150

200

250

300

350

0 20 40 60 80 100 m³/h

Min

Max

6

54

3

2

7

8

9

10

11

35 dB(A)

32 dB(A)

30 dB(A)

25 dB(A)

Pa 125

175

225

275

325

125

175 225

275 m³/h

0

Open

5

4

3

2

1

200 Pa

150 Pa

100 Pa

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

26

12.3 Basic Ventilation SL4 R/SL4 R EC

12.4 Forced Ventilation SL4 R/SL4 R EC

0

50 Pa

100

150

200

250

300

0 20 40 60 80 100 m³/h

Min

Max

6

5

4

3

2

7

8

9

10

11

35 dB(A)

32 dB(A)

30 dB(A)

26 dB(A)

SL4 R

Min. - Max. = Damper position

dB = Lp(A) measured 1 m from the kitchen hood in the kitchen landscape.

SL4 R

0 - Open = Number of rings removed

100/150/200 Pa = Total duct resistance for the extract air and exhaust

air side

Lw (A) measured 1 m from the kitchen hood varies between 45 and 49

dB(A) throughout the measuring area

0

5

4

3

2

1

200 Pa

150 Pa

100 Pa

Open

Pa 75

125

175

225

275

125

175 225

275

m³/h

325

0

50 Pa

100

150

200

250

300

0 20 40 60 80 100 m³/h

Min

2

30 dB(A)

28 dB(A)

32 dB(A)

35 dB(A)

3

Max

4

5

6

7

8

9

10 11

0

5

4

3

2

1

200 Pa

150 Pa

100 Pa

Open

Pa 50

100

150

200

250

100

150 200

250

m³/h

300

SL4 R EC

Min. - Max. = Damper position

dB = Lp(A) measured 1 m from the kitchen hood in the kitchen landscape.

SL4 R EC

0 - Open = Number of rings removed

100/150/200 Pa = Total duct resistance for the extract air and exhaust

air side

Lw (A) measured 1 m from the kitchen hood varies between 45 and 49

dB(A) throughout the measuring area

SL4 R

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

27

13 Technical Spesifications

13.1 Technical Spesifictions S3 R

S3 R

Rated voltage 230 V/50 Hz

Fuse 10 A

Rated current, total 5,5 A

Rated power, total 1271 W

Rated power, electric batteries 900 W

Rated power, fans 2 x 165 W

Fan type F-wheel

Fan motor control Transformer

Max. fan speed 2230 o/min

Automatic control standard CS 50

Filter type (SUP/EXTR) F7/F7

SUP filter dimensions (WxHxD) 285x130x50 mm

EXTR filter dimensions (WxHxD) 285x130x50 mm

Weight 38,5 kg

Duct connection

Ø 125 mm

(127 mm muffe)

Height 700 mm

Width 598 mm

Depth 320 mm

13.2 Technical Spesifictions SL4 R

SL4 RE SL4 RE EC SL4 RW SL4 RW EC

Rated voltage 230 V/50 Hz 230 V/50 Hz 230 V/50 Hz 230 V/50 Hz

Fuse 10 A 10 A 10 A 10 A

Rated current, total 5,5 A 4,8 A 1,6 A 0,9 A

Rated power, total 1271 W 1107 W 371 W 207 W

Rated power, electric batteries 900 W 900 W - -

Rated power, fans 2 x 165 W 2 x 83 W 2 x 165 W 2 x 83 W

Fan type F-wheel F-wheel F-wheel F-wheel

Fan motor control Transformer EC-stepless Transformer EC-stepless

Max. fan speed 2230 o/min 1970 o/min 2230 o/min 1970 o/min

Automatic control standard CS 50 CS 50 CS 50 CS 50

Filter type (SUP/EXTR) F7/F7 F7/F7 F7/F7 F7/F7

SUP filter dimensions (WxHxD) 350x185x50 mm 350x185x50 mm 350x185x50 mm 350x185x50 mm

EXTR filter dimensions (WxHxD) 350x185x50 mm 350x185x50 mm 350x185x50 mm 350x185x50 mm

Weight 48 kg 48 kg 48 kg 48 kg

Duct connection Ø 160 mm Ø 160 mm Ø 160 mm Ø 160 mm

Duct connection, kitchen hood Ø 125 mm Ø 125 mm Ø 125 mm Ø 125 mm

Height 700 mm 700 mm 700 mm 700 mm

Width 598 mm 598 mm 598 mm 598 mm

Depth 455 mm 455 mm 455 mm 455 mm

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

28

13.3 Technical Data S4 R

S4 RE S4 RE EC S4 RW S4 RW EC

Rated voltage 230 V/50 Hz 230 V/50 Hz 230 V/50 Hz 230 V/50 Hz

Fuse 10 A 10 A 10 A 10 A

Rated current, total 6,8 A 6,1 A 1,6 A 0,9 A

Rated power, total 1581 W 1417 W 381 W 217 W

Rated power, electric batteries 1200 W 1200 W - -

Rated power, fans 2 x 165 W 2 x 83 W 2 x 165 W 2 x 83 W

Rated power, pre-heating

- - - -

Fan type F-wheel F-wheel F-wheel F-wheel

Fan motor control Transformer EC-stepless Transformer EC-stepless

Max. fan speed 2230 o/min 1970 o/min 2230 o/min 1970 o/min

Automatic control standard CS 50 CS 50 CS 50 CS 50

Filter type (SUP/EXTR) F7/F7 F7/F7 F7/F7 F7/F7

SUP filter dimensions (WxHxD) 468x200x70mm 468x200x70mm 468x200x70mm 468x200x70mm

EXTR filter dimensions (WxHxD) 468x200x70 mm 468x200x70mm 468x200x70mm 468x200x70mm

Weight 85 kg 85 kg 85 kg 85 kg

Duct connection Ø 200 mm Ø 200 mm Ø 200 mm Ø 200 mm

Height 900 mm 900 mm 900 mm 900 mm

Width 900 mm 900 mm 900 mm 900 mm

Depth 550 mm 550 mm 550 mm 550 mm

13.4 Technical Data S7 R

S7 RE S7 RE EC S7 RW S7 RW EC

Rated voltage 230 V/50 Hz 230 V/50 Hz 230 V/50 Hz 230 V/50 Hz

Fuse 13 A 13 A 10 A 10 A

Rated current, total 10,7 A 8,9 A 3,3 A 1,5 A

Rated power, total 2464 W 2045 W 765 W 345 W

Rated power, electric batteries 1700 W 1700 W - -

Rated power, fans 2 x 375 W 2 x 175 W 2 x 375 W 2 x 175 W

Rated power, pre-heating

- - - -

Fan type F-wheel F-wheel F-wheel F-wheel

Fan motor control Transformer EC-stepless Transformer EC-stepless

Max. fan speed 2000 o/min 2000 o/min 2000 o/min 2000 o/min

Automatic control standard CI 50/CU 500* CI 50/CU 500* CI 50/CU 500* CI 50/CU 500*

Filter type (SUP/EXTR) F7/F7 F7/F7 F7/F7 F7/F7

SUP filter dimensions (WxHxD) 468x200x70 mm 468x200x70 mm 468x200x70 mm 468x200x70 mm

EXTR filter dimensions (WxHxD) 468x200x70 mm 468x200x70 mm 468x200x70 mm 468x200x70 mm

Weight 92 kg 92 kg 92 kg 92 kg

Duct connection Ø 200 mm Ø 200 mm Ø 200 mm Ø 200 mm

Height 900 mm 900 mm 900 mm 900 mm

Width 900 mm 900 mm 900 mm 900 mm

Depth 550 mm 550 mm 550 mm 550 mm

* CI 50: Control Panel, CU 500: Circuit Board

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

29

S3 R Right model

S3 R Left model

S4 R/S7 Right model S4 R/S7 R Left model

SL4 R Right model

SL4 R Left model

Unit top - air flow direction

Kitchen Hood

Unit bottom - air flow direction

Kitchen Hood

COMMON

Kitchen Hood

14 Final Check

Control that:

• The duct insulation is in accordance with the manual and the technical documents

• Ducts are connected to the right nipples – check against the unit drawings below

• Adjustment has been carried out in accordance with the manual and ventilation data documentation

• The unit operates normally at all stages

• Heating switches on

The installer may be held liable for any incorrect or defective installation.

Kitchen Hood

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

30

15 Important Safety Instructions

To reduce the risk of fire, electric shock or

injury, read all the safety instructions and

warning texts before using the unit.

• This unit is only designed for ventilation air in

buildings.

• It must not be used to extract combustible or

flammable gases.

• Remove the power plug before commencing any

service and maintenance work.

• Before you open the door, the unit must be dead

and the fans must have been given time to stop

(min. 3 minutes).

• The unit contains heating elements that must not be

touched when they are hot.

• The unit must not be operated without the filters

being in place.

• Do not cook any combustible substances or flame

anything under the fan (only when a kitchen hood is

connected).

• Do not leave a saucepan or frying pan containing oil

or grease unsupervised (only when a kitchen hood is

connected).

• Follow the instructions in the user manual.

To maintain a good indoor climate, comply

with regulations and, to avoid condensation damage, the unit must never be

stopped apart from during service/maintenance or in connection with an accident.

16 Functional Description

In the (HR-R) rotor, the cold outdoor air and the warm

extract air pass each other without being mixed. With

this principle, a large part of the heat in the extract

air will be transferred to the supply air (see drawings

in Chap. 8). If the outdoor temperature is extremely

low, a thermostat-controlled (EB1) heating element

will also ensure that the supply air has the desired

temperature. This supply air is passed via ducts and

valves to living rooms and bedrooms. The extract air is

extracted either from the same room or via door gaps/

overflow gratings to toilets and wet rooms. The used

air is passed via a duct system back to the unit, emits

heat and is blown out of the building via a roof hat or

wall grating.

The temperature of the supply air is controlled by the

rotor. Only when the rotor is not able to maintain the

set temperature, will the heating element start up.

When there is no need for heating (for example in the

summer), the rotor will stop.

16.1 Heating Elements

The heating elements are protected against

overheating by the (F20) overheating thermostat,

which switches off at 60 °C. As an additional safety

measure, the (F10) overheating thermostat switches

off at 85 °C. The F10 overheating thermostat can be

reset manually by pressing the reset button.

You will find the thermostat by opening the unit doors

(located right above the heating element).

16.2 Operation via Kitchen Hood (SL4 R)

A - Knob for damper/timer

B - Pushbutton for light

Open the damper when preparing food. The damper

closes automatically after a maximum of 60 minutes

or if you turn the damper knob to

as shown in Fig.

29. When the timer is activated, the air handling unit is

forced in addition to the damper function.

This is purely a ventilation system and

not a heating system. The home must

be heated in the normal manner. The

heat gained from heat recovery must

be seen in relation to a situation in

which the extract air is blown right out

of the home without recovery.

!

Fig. 29

USER GUIDE

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

31

S3 R

17 Cleaning - Maintenance, S3 R

Before opening the door of the heat recovery system or carrying out maintenance on the

kitchen hood: switch off the heat, let the fans continue for three minutes to remove hot air,

remove the power from the unit and wait 2 minutes before opening the doors.

Fans: Item nos. 6 and 7/Chap. 9 General Drawing. The fans must be cleaned once pr. year. The fans are

cleaned with a small brush and compressed air, if available. NB! Do not use water. Dismantle the

fan as follows: Open the doors as instructed. Pull out the electric quick-release contact for the

motor. Unscrew 2 screws at the front of the motor’s mounting plate. The fan can then be pulled

carefully down and out of the unit.

Filters: To preserve a healthy indoor environment, it is important to change filters when they are dirty.

Dirty filters lead to:

Increased air resistance in the filter – less air in the home – the risk of bacterial growth in

the filter – in the worst case scenario, the system can be damaged.

How often the filters need to be changed depends on the degree of contamination of the air where

they are installed. In general, the filters need to be changed once a year, preferably in the autumn

(after the pollen season). In areas with a lot of dust and contamination, the filters should be

changed in the spring and autumn. The supply air filter and extract air filter (2 and 1) consist of a

compact filter (F7). These are pushed into place.

It is recommended that you order a filter subscription to ensure full benefit from the system and the

cheapest prices.

Order no. for a complete set of filters: 12328

When changing filter, please perform an overall check of the ventilation unit.

Rotor: As the system has filters installed with a high tightness class, it is not normally necessary to clean

the rotor. If, for various reasons, it should still be necessary, dust can be removed with a soft

brush. Further cleaning is possible if you remove the rotor, spray it with fat-soluble detergent and

then blow it clean from the opposite side. Distance approximately 60mm and max. pressure 80

bar. Ensure that the motor is not exposed to water during cleaning. Ensure that all seals around

the rotor are intact and tight.

Do not use detergent that is harmful to aluminium or the environment.

Valves and

duct system: Clean the valves at least once a year. The duct system must be cleaned at least every 10 years.

Outdoor air

intake: Check once a year that the grille is not clogged.

Roof hat: Check once a year that the drainage gap at the bottom is not clogged with leaves. This applies

only if the system has a roof hat.

Filter location

(the drawing shows the left model/the right model is inverted)

Supply air filter:

Compact filter

Rotor

Extract air filter:

Compact filter

!

!

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

32

SL4 R

!

!

18 Cleaning - Maintenance SL4 R

Before opening the door of the heat recovery system or carrying out maintenance on the kitchen

hood: Switch off the heat, let the fans continue for three minutes to remove hot air, remove the

power from the unit and wait 2 minutes before opening the doors.

Fans: Item pos. 5 and 6/Chap. 9 General Drawing, SL4 R. The fans must be cleaned once pr. year. The

fans are cleaned with a small brush and compressed air, if available. Remove the fans as follows:

(Fan item no. 6) Remove the cover in front of the fan by pressing the snap locks at the bottom

of the cover. For both fans: pull the fan out of the track and disconnect the contact. The motor

and fan blades are removed by unscrewing the 4 screws in the round motor plate and carefully

pulling the motor out of the motor housing. Mounting takes place in the reverse order.

Filters: To preserve a healthy indoor environment, it is important to change filters when they are

clogged/dirty. Clogged filters lead to:

Increased air resistance in the filter – less air in the home – the risk of bacterial growth in

the filter – in the worst case scenario, the system can be damaged.

How often the filters need to be changed depends on the degree of contamination of the air

where they are installed. In general, the filters need to be changed once a year, preferably in

the autumn (after the pollen season). In areas with a lot of dust and contamination, the filters

should be changed in the spring and autumn.

The supply air filter, which cleans the outdoor air (item no. 2) is a compact filter (filter class F7).

The filter is pushed in place in the fixing rails. The extract air filter (item no. 1) is a compact filter

(filter class F7) and is located in its own drawer which can be pulled right out after the finger

screws have been removed. We recommended that you order a filter subscription for full benefit

from the system and the cheapest prices.

Order no. for a complete set of filters: 12336

When changing filter, please perform an overall check of the ventilation unit.

Rotor: As the system has filters installed with a high tightness class, it is not normally necessary to

clean the rotor. If, for various reasons, it should still be necessary, dust can be removed with

a soft brush. Further cleaning is possible if you remove the rotor, spray it with fat-soluble

detergent and then blow it clean from the opposite side. Distance approximately 60mm and max.

pressure 80 bar. Ensure that the motor is not exposed to water during cleaning. Ensure that all

seals around the rotor are intact and tight.

Do not use detergent that is harmful to aluminium or the environment.

Valves and

duct system: Clean the valves at least once a year. The duct system must be cleaned at least every 10 years.

Outdoor air

intake: Check once a year that the grille is not clogged.

Roof hat: Check once a year that the drainage gap at the bottom is not clogged with leaves. This applies

only if the system has a roof hat.

Filter location

(the drawing shows the right

model/the left model is inverted)

Rotary wheel-type heat exchanger

Supply air filter

Extract air filter

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

33

S4 R/S7 R

19 Cleaning - Maintenance S4 R/S7 R

Before opening the door of the heat recovery system or carrying out maintenance on the kitchen

hood: switch off the heat, let the fans continue for three minutes to remove hot air, remove the

power from the unit and wait 2 minutes before opening the doors.

Doors: Opened by unscrewing the two screws in one door.

Fans: Item nos. 5 and 6/Chap. 9 General Drawings. The fans must be cleaned once pr. year. The fans are

cleaned with a small brush and compressed air, if available. NB! Do not use water. Disassemble as

follows: Open the doors as directed. Pull out the electric quick-release contact for the motor. Unscrew

2 screws under the front edge of the motor’s mounting plate. The fan can then be carefully pulled down

and out of the unit.

Filters: To preserve a healthy indoor environment, it is important to change filters when they are dirty. Dirty

filters lead to:

Increased air resistance in the filter – less air in the home – the risk of bacterial growth in the

filter – in the worst case scenario, the system can be damaged.

How often the filters need to be changed depends on the degree of contamination of the air where they

are installed. In general, the filters need to be changed once a year, preferably in the autumn (after the

pollen season). In areas with a lot of dust and contamination, the filters should be changed in the spring

and autumn. The supply air filter and extract air filter (2 and 1) consist of an EU 3 prefilter on top (coarse

filter) and a compact filter (EU7). They are pushed into place and fastened with filter tighteners.

It is recommended that you order a filter subscription to ensure full benefit from the system and the

cheapest prices.

Order no. for a complete set of filters: 12327

When changing filter, please perform an overall check of the ventilation unit.

Rotor: As the system has filters installed with a high tightness class, it is not normally necessary to clean

the rotor. If, for various reasons, it should still be necessary, dust can be removed with a soft brush.

Further cleaning is possible if you remove the rotor, spray it with fat-soluble detergent and then blow

it clean from the opposite side. Distance approximately 60mm and max. pressure 80 bar. Ensure that

the motor is not exposed to water during cleaning. Ensure that all seals around the rotor are intact

and tight.

Do not use detergent that is harmful to aluminium or the environment.

Valves and

duct system: Clean the valves at least once a year. The duct system must be cleaned at least every 10 years.

Outdoor air

intake: Check once a year that the grille is not clogged.

Roof hat: Check once a year that the drainage gap at the bottom is not clogged with leaves. This applies only if

the system has a roof hat.

!

!

Rotary wheel-type exchanger

Supply air filter:

Prefilter and

compact filter

Extract air filter:

Prefilter and

compact filter

Rotor model filter location

(the drawing shows the right

model/the left model is inverted)

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

34

20 Fault Location

If a power failure occurs the ventilation unit will return to the factory settings when restarting.

For other types of errors which are indicated on the control panel/hand terminal, please refer to

separate automatics manuals.

If non of these measures solves the trouble, contact your supplier for service.

Please report the model type and serial number (found on the sign inside the ventilation unit/

open door).

Error:

The fans do not function and/

or:

Do the following:

Control panel (Chap.

18) is turned off

- Check that the power cord is correctly inserted in the outlet

- Check that the fuses in the fuse box are active

- Check the cable between control panel and ventilation unit

Cannot be adjusted - Deactivate forced ventilation from kitchen hood if connected to unit

The air quantity is considerably

reduced

Do the following:

- Filter (Pos.no. 1, 2/Kap. 9) my be clogged with dirt.

Clean or change, see Cleaning - maintenance

- Fan wheel must be cleaned, see Cleaning - maintenance

COMMON

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

35

21 CE Declaration of Conformity

This declaration confirms that the products meet the requirements in the following Council Directives and

standards:

2004/108/EC Electromagnetic Compatibility (EMC)

2006/95/EC Low-voltage Directive (LVD)

2006/42/EC Machinery Directive (Sikkerhet)ikkerhet)

Producer: FLEXIT AS, Televeien 15, N-1870 Ørje

Type: S3 R 2005 Ventilation Units

SL4 R 2006 Ventilation Units

S4 R 2002 Ventilation Units

S7 R 2002 Ventilation Units

Complies with the

following standards:

The product is CE-marked: Shown in the list above

FLEXIT AS 2010-02-12

Frank Petersen

General Manager

The right to give notice of lack of conformity applies to this product in accordance with the existing terms of sale,

provided that the product is used

correctly and maintained.

Filters are consumables.

The symbol on the product shows that this product must not be treated as household waste. It must be taken to a reception station for

recirculation of electric and electronic equipment.

By ensuring the correct disposal of the equipment, you will contribute to preventing the negative consequences for the environment and

health that incorrect handling may entail. For further information on recirculation of this product, please contact your local authority, your

refuse collection company or the company from which you purchased it.

Notice of lack of conformity as a result of incorrect or defective installation must be submitted to the installation company responsible. The right to

give notice of lack of conformity may lapse if the system is used incorrectly or maintenance is grossly neglected.

Safety Standard EN 60335-1:2002

EMF Standard: EN 50366:2003

EMC Standard: EN 55014-1.2000

EN 61000-3-2:2000

EN 61000-3-3:1995

EN 55014-2:2:1997

COMMON

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

36

22 Product/Environmental Declaration

The declaration applies to the Flexit S3 R, SL4 R, S4 R and S7 R ventilation units

Materials:

Materials with which the user or treated air come into contact:

• The unit’s outer walls are made of galvanised steel DX51D+Z275 (NS-EN 10142)

• The rotary wheel-type heat exchanger, made of aluminium

• Miscellaneous electric cables with PVC insulation

• Electric motors consisting of galvanised steel, aluminium and copper

• Heating elements made of steel

• Air filters of glass fibre, cardboard and EVA melting glue

Materials in the unit with which service personnel may come into contact:

• Plastic-insulated electric cables

• Miscellaneous other electrical components

• Insulation of type EPS/Dacron

Other materials that may occur in small quantities:

• Silicon sealant

• Polyethylene foamed plastic

• EPDM rubber gaskets

• Miscellaneous steel screws, nuts and pop rivets, plus small quantities of copper and brass.

Safety:

Materials: The materials are considered to be completely harmless to users.

Use: The unit is an electrical appliance which must be made dead for service and inspection. The unit also

contains rotating motors that must have time to stop before the inspection door is opened, plus heating

elements with a high operating temperature.

COMMON

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

37

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

38

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

39

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

Flexit AS, Televeien 15, N-1870 Ørje www.flexit.com

gpd.sunwayinfo.com.cngpd.sunwayinfo.com.cn

Loading...

Loading...