116026EN-03

2019-10

Eq 2

Assembly and Operation Instructions

Heat recovery single-room reversible ventilation unit

ART. NO.:

116001

EQ 2

2

Contents

2. Purpose ....................................................................................................................................................................................................................... 6

3. Delivery set

1. Technical data

4. Product description

5. Mounting and set-up

5.1. Wall-mounted control panel installation and connection

5.2. Unit mounting

6. Connection to power mains and control

7. Technical maintance

8. Troubleshooting

9. Storage and transportation regulations

10. CE Declaration of conformity

.......................................................................................................................................................................................................... 6

................................................................................................................................................................................................ 6

............................................................................................................................................................................. 8

......................................................................................................................................................................10

..............................10

........................................................................................................................................................................... 12

.................................................................................................... 16

....................................................................................................................................................................... 19

....................................................................................................................................................................................... 21

.................................................................................................... 21

.........................................................................................................................................22

EQ 2

3

!

SAFETY REQUIRE-

!

MENTS

EQ 2

• Read the user’s manual carefully prior to

installing and operating the unit.

• Fulfil the user’s manual requirements as well

as the provisions of all the applicable local

and national construction, electrical and

technical norms and standards.

• The warnings contained in the user’s

manual must be considered most seriously

since they contain vital personal safety

information.

The user’s manual consisting of the technical details,

operating instructions and technical specification applies

to the installation and mounting of the single-room energy

CAUTION! When a text bears this

symbol, it means that personal injury

or serious damage to the equipment

may result if the instructions are not

followed.

• Failure to follow the rules and safety

precautions noted in this user’s manual may

result in an injury or unit damage.

• After a careful reading of the manual, keep it

for the entire service life of the unit.

• While transferring the unit the User’s manual

must be turned over to the receiving

operator.

recovery reversible ventilator Eq 2 (hereinafter referred to

as «the unit»).

NB! When a text bears this symbol,

damage to equipment or poor

efficiency may be the consequence

of not following the instructions.

The right to give notice of lack of conformity

applies to this product in accordance with the

existing terms of sale, provided that the product is

used correctly and maintained.

Filters are consumables.

The symbol on the product shows that this product must not

be treated as household waste. It must be taken to a collection point for recycling electrical and electronic equipment.

By ensuring correct disposal of the equipment, you will

contribute to preventing negative consequences for the

environment and health that incorrect handling may entail.

For further information on recycling of this product, please

contact your local authority, your refuse collection company

or the company from which you purchased it.

Notice of lack of conformity as a result of incorrect or

defective installation must be submitted to the installation

company responsible. The right to give notice of lack of

conformity may lapse if the system is used incorrectly or

maintenance is grossly neglected.

This appliance may be used by children of 8 years or above or

by persons with reduced sensory capacity or reduced physical

or mental capacity, or by persons with lacking experience or

knowledge, provided they have received instructions in the safe

use of the appliance or are supervised to ensure safe use and

providing they are aware of the risks.

The product is not suitable for use by children. Children must not

be allowed to play with the appliance. Children must not carry

out cleaning or maintenance without supervision.

Our products are subject to continuous development and we

therefore reserve the right to make changes.

We also disclaim liability for any printing errors that may occur.

4

Unit mounting and operation safety precautions

• Disconnect the unit from power mains

prior to any installation operations.

• Do not lay the power cable of the unit in

close proximity to heating equipment.

• Unpack the unit with care.

• While installing the unit follow the safety

regulations specific to the use of electric

tools.

• Do not use damaged equipment or

cables when connecting the unit to

power mains.

• Do not touch the unit controls with wet

hands.

• Do not carry out the installation and

maintenance operations with wet hands.

• Do not operate the unit outside the

temperature range stated in the user’s

manual.

• Do not operate the unit in aggressive or

explosive environments.

• Protect the electric parts of the unit

against ingress of water.

• Do not open the unit during operation.

• Do not block the air duct when the unit is

switched on.

• Disconnect the unit from power mains

prior to any technical maintenance.

• If the unit generates unusual sounds,

odour or emits smoke disconnect it from

power supply and contact the Seller.

• In case of continuous operation of the

unit periodically check the security of

mounting.

• Use the unit only for its intended

purpose.

EQ 2

5

EQ 2

!

!

2. Purpose

The unit is designed to ensure continuous mechanical air

exchange in houses, apartments, commercial buildings and

other utility and public spaces.

The unit is equipped with a ceramic regenerator that enables

supply of fresh filtered air heated by means of extract air

heat energy regeneration.

The unit is designed for through-the-wall mounting.

The choice of unit installation location

must prevent unauthorized access by

unattended children.

The unit is rated for continuous operation.

Transported air must not contain any flammable or explosive mixtures, evaporation of chemicals, sticky substances,

fibrous materials, coarse dust, soot and oil particles or

environments favourable for the formation of hazardous

substances (toxic substances, dust, pathogenic germs).

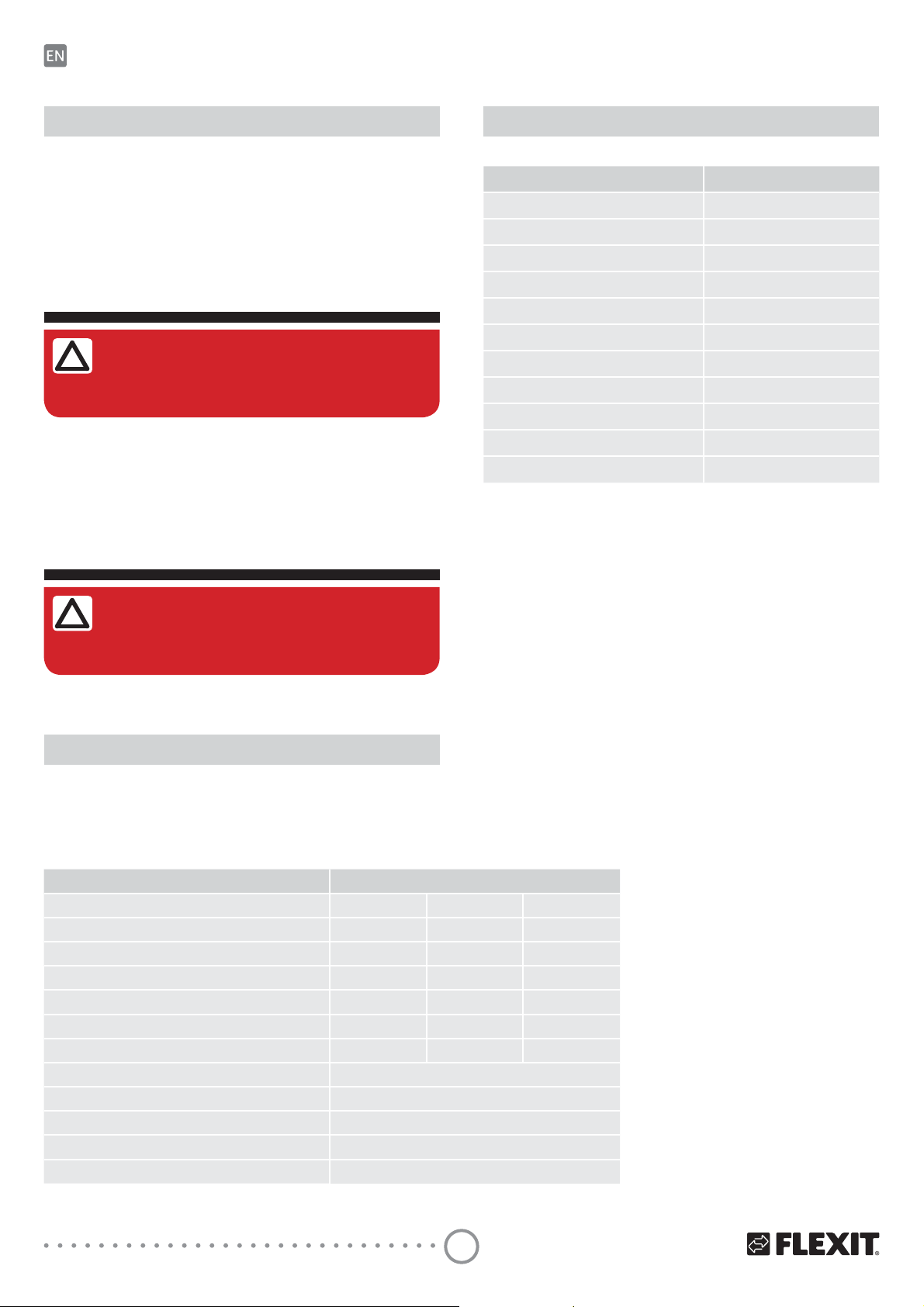

3. Delivery set

Name

Air duct 2 item

Sound-absorbing layer 2 item

Assembled cartridge 2 item

Internal square ventilation grille 2 item

External grille, aluminium 2 item

External grille, plastic* 2 item

Control panel 1 item

Fastening set 1 pack

Mounting box 2 item

User's manual 1 item

Packing box 1 item

*available

Number

Turn off the unit if the air temperature

is outside the temperature range

stated in the technical data.

1. Technical data

The unit is designed for indoor use. The units is constantly

being improved, so some models can slightly differ from

those ones described in this manual.

Eq 2 (2 units)

Speed I II III

Airflow (m

Sound pressure* Lp(A) 3m dB 19 28 37

Sound power* Lw(A) dB

Power consumption* (W) 1,6 3 5,6

Current* (A) 0,018 0,032 0,06

Fan speed (rpm) 1030 1760 2690

Voltage (V/50-60Hz) 100-240V

Filter class

Ingress protection IP 24

Operating temperature

Wall thickness 350-500 mm

3

/h) 15 30 50

36 45 54

G3 (F8 accessories)

** -25°C to 50°C

**Minimum operating temperature is

measured at an indoor humidity of 35% RH.

Variations in temperature and humidity may

lead to freezing at higher temperatures

than specified.

In the event of possible freezing, take the

cassette out with the heat recovery system

and fan. Let it thaw at room temperature.

Wait to start the room fan if the

temperature and humidity conditions are

unchanged. Minimum speed reduces the

risk of frost.

* Per unit

6

241 mm

Air duct length, 500 mm

180/ 200

160

241 mm

External grille

Decorative panel

Ø160 mm

The duct can be cut at 350 mm. Not shorter due to the outer

grille and the heat exchanger.

Hoods for thinner walls are available as accessories. Min. wall

thickness can with theese be reduced by 100 mm.

86 mm

42,5 mm

13,5 mm

82 mm

350-500

42.5

240

*aluminium grille/plastic grille

R 2 mm

68 mm

4 mm

Control panel

The sensor panel contains touch buttons for unit control and

an emergency indicator.

Boxes for both flush and on wall mount are included in the

package.

Unit voltage [V /50-60 Hz] 110-230

Temperature range [˚C] from +10 up to +45

Humidity range [%] 10 - 80 (no condensation)

Service life, switching operations 100 000

Ingress protection IP30

Weight [g] 190

EQ 2

7

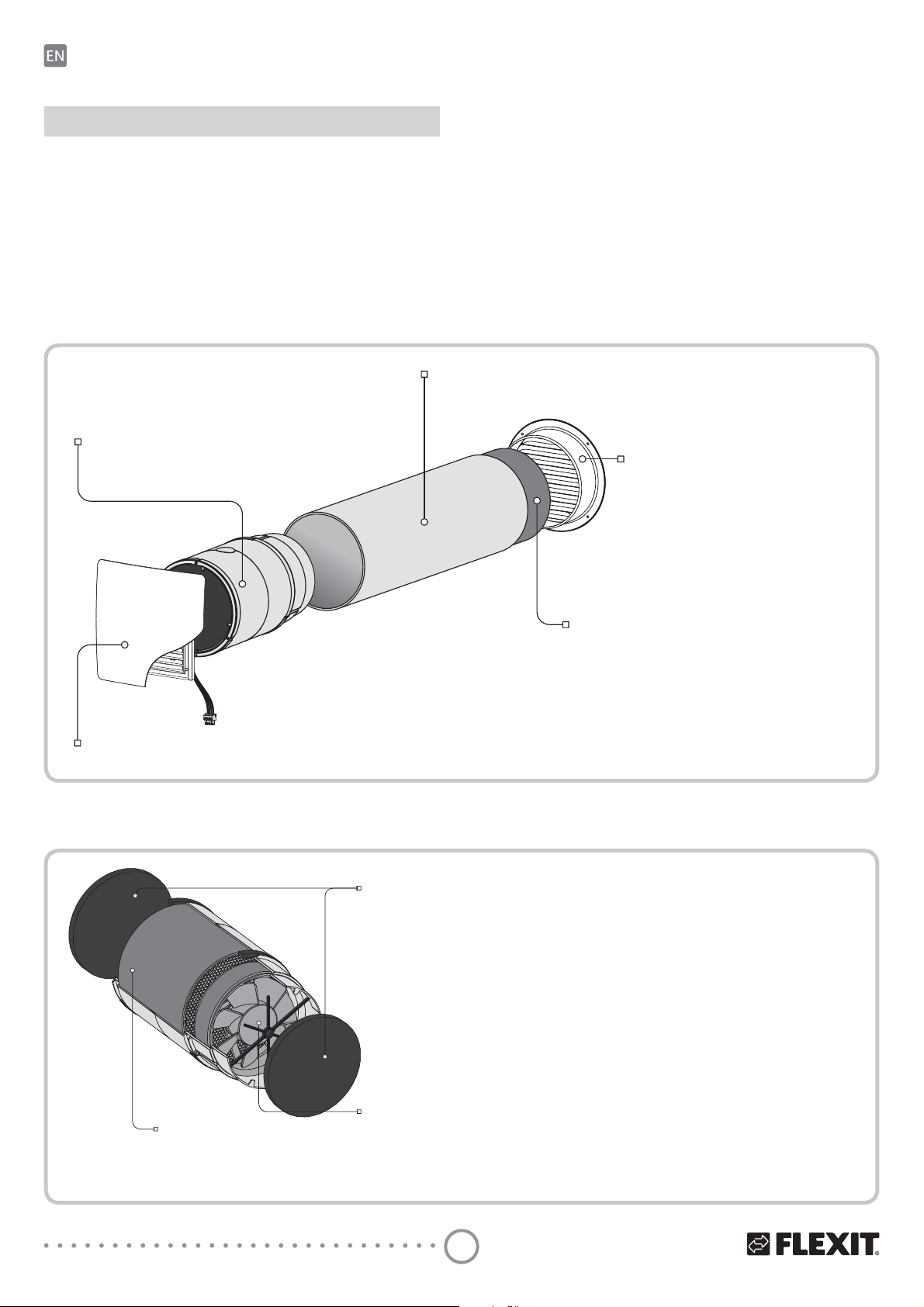

4. Product description

EQ 2

The unit consists of a protecting internal grille with a decorative panel, a cartridge, an air duct and a protecting external

ventilation grille or a hood.

The cartridge is the basic functioning part of the unit.

The cartridge consists of a fan, a regenerator and two filters

that ensure rough air filtration and prevent ingress of dust

Unit design

Cartridge

Generates air flow, provides

energy recovery and air cleaning.

and foreign objects into the regenerator and the fan.

The internal grille is equipped with manually actuated shutters which can close the air duct during the unit standstill.

The external protective grille on the outer wall prevents

ingress of water and foreign objects into the unit.

Air duct

Plastic air duct

External grille

Protects the unit from ingress of water

and foreign objects.

Internal ventilation grille with a decorative panel

Equipped with manually actuated louvre shutters.

Cartridge design

Filter

Cleans the air flowing through

the ventilator of dust and foreign

objects.

Prevents contamination of the

regenerator.

Sound-absorbing material

Serves for sound attenuation of outdoor noise.

Cartridge is a block consisting

of removable filters and a solid

fan-regenerator unit.

The filters are easy removable

for maintenance.

Regenerator

Provides extract air energy

regeneration for warming

up of supply air flow.

Fan

Generates air flow

8

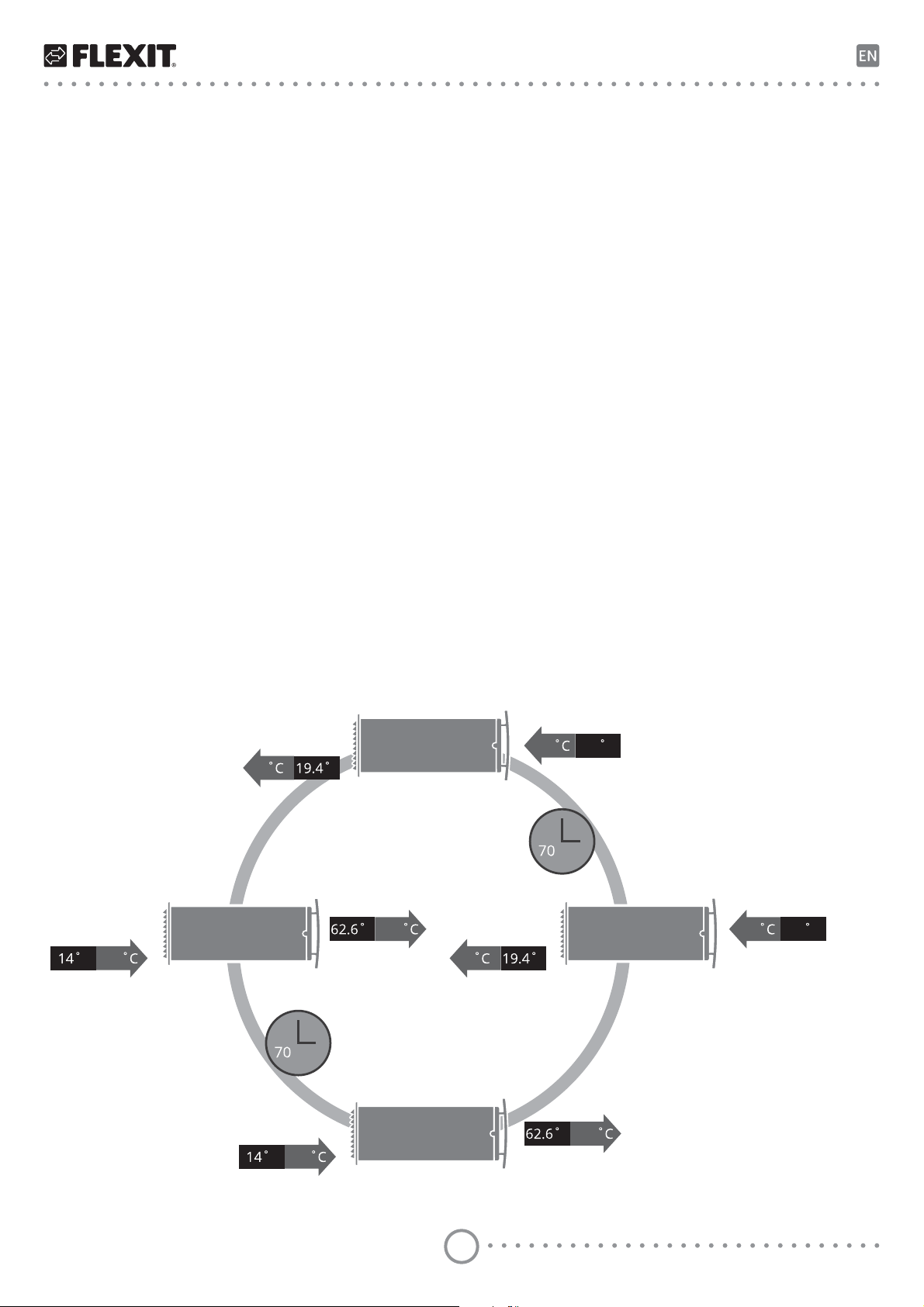

Unit operation modes

The unit has two ventilation modes:

Regeneration. The unit operates in reversible mode with

heat and humidity regeneration in two cycles, 70 seconds

each.

Ventilation. The unit operates in permanent supply or

extract mode at set speed. In case of two units operating in

this mode one unit operates in supply and the other one in

extract mode.

Cycle I.

As warm stale extract air flows through the ceramic regenerator, it heats up and moisturizes the regenerator and

transfers up to 97 % of heat energy.

In 70 seconds as the ceramic regenerator gets warmed the

unit is switched to supply mode.

Cycle II.

Fresh intake air from outside flows through the ceramic

regenerator, absorbs accumulated moisture and is heated

up to the room temperature.

In 70 seconds as the ceramic regenerator gets cooled down,

the unit is switched to air extract mode and the cycle is

renewed.

In this operation mode, in case if two units are installed each

of them operates two cycles in opposite phases.

While one unit operates in air supply mode the other one

operates in air extract mode.

Example:

+20

F-7

+17F

-7 F-10F

s

AIR SUPPLY

-10F

68 F

AIR EXTRACT

s

F

+17

+20 68 F

EQ 2

9

5. Mounting and set-up

!

!

5.1. WALL-MOUNTED CONTROL PANEL

INSTALLATION AND CONNECTION

EQ 2

Installation and connection of control

panel shall only be performed by

professional electrician.

Make sure that the control panel is not

damaged. Do not use a damaged

control panel!

1. a) Flush mount

Prepare a hole in the wall and route all the wires to the

installation place. Insert the supplied mounting box for

flush wall mounting. The mounting box is included in

delivery.

Do not install the control panel on an

uneven surface!

While tightening the screws, do not

apply excessive force to prevent the

control panel casing deformation.

74

mm

34

4

mm

mm

1. b) On-wall mount

Fix the supplied mounting box for on-wall mount onto

the wall. The mounting box is included in the delivery.

88

mm

32

mm

10

2. Use a screwdriver to carefully undo the clips on the

backside of the control panel and remove the back

cover.

3. Screw the backside of the casing to the mounting

box through the fastening holes. Fastening screws for

mounting of the control panel are included in the control

panel delivery set. Then connect the cable to the control

panel in compliance with the wiring diagram, page 16.

4. Install the control panel display and press it to fix.

EQ 2

11

5.2. UNIT MOUNTING

!

min 3 °C

Read the user’s manual prior to mounting the unit.

Do not block the air duct of the installed unit with dust accumulating materials, such as curtains, cloth shutters,

etc. As it prevents air circulation in the

room.

EQ 2

1. Prepare holes for the air ducts.

Prepare a round core hole in the outer wall, depending

on the unit equipment.

For efficient operation of the ventilation system it is

recommended to install the units as far apart from one

another as possible.

2. Prepare air ducts of required length.

Measure the wall thickness.

Cut the air duct so it fits flush on both sides of the wall.

Min. length is 350 mm.

Cut the air duct on the outher side which don´t have

cable grooves.

Insert the air duct into a prepared hole in the wall.

The cable grooves must be located on inner wall side.

When making holes, we recommend ensuring that the

power cables and control cables are in order.

Recommended hole dimension;

When using an external metal grille: Ø170 mm

When using an external plastic grille: Ø180 mm

Polystyrene wedge

Fill the gap between the air duct

and the wall with mounting foam

or similar.

12

3. Install the sound-absorbing layer in the air duct.

Prior to installation adjust its length with respect to the

dimensions of the cartridge, external grille or the outer

ventilation hood as well as the internal square or round

grille.

This example shows adjustment of the soundabsorbing layer length calculated from the flange

width of the square inner grille.

Insert the cartridge during adjustment in the air duct.

L = 40 mm

During adjustment of the insulation layer length cover

the air duct and the cartridge with the internal grille.

Roll the sound-absorbing layer to match the air duct

diameter with the protecting paper layer outside and

insert the roll in the air duct against stop.

Do not remove the paper layer!

The adjustment of the sound-absorbing layer length

for the unit with an external grille

Mark the sound-absorbing layer at the end of the air

duct (1).

From the mark (1) measure 55 mm and make a new

mark (2). Cut the excessive part of the soundabsorbing layer.

Insert the adjusted and ready sound-absorbing layer

into the air duct.

No glue is required for fixation!

The adjustment of the sound-absorbing layer length

for the unit with an outer hood (accessories)

Mark the sound-absorbing layer at the end of the air

duct (1). Cut the excessive part of the sound-absorbing

layer.

Insert the adjusted and ready sound-absorbing layer

into the air duct.

No glue is required for fixation!

50 mm (2”)

1

1

2

1

EQ 2

13

4. Insert the air duct in the wall.

Install the air duct with the sound-absorbing layer with

minimum slope 3° downwards using polystyrene wedges.

Fill the gaps between the wall and the opening with a

mounting foam.

Make sure that moisture cannot permeate into the

opening in the external wall. Use a suitable sealant.

To enable easy installation of the cartridge in the air duct

cut out a recess in the mounting foam layer on the side

of the cable installation parallel to the groove in the air

duct.

For freedom of placement of the cable in the groove

without any damage to the cable insulating material, cut

off the excess of the mounting foam.

EQ 2

Fill the gaps between the wall

and the opening with a mounting

foam or similar

min 3 °C

Polystyrene wedge

5. Install the cartridge in the air duct.

14

6. Connect the socket connector from

the control panel in compliance with

the external wiring diagram. Connect

the socket connectors of the cartridge

and the control panel.

7. Install the internal grille and fix the external grille.

External grille

For mounting of the outer ventilation hood, please refer to a

respective hood installation instruction.

Internal grille with a decorative panel

EQ 2

15

6. Connection to power mains and control

!

!

!

Disconnect the unit from power supply

prior to any electric installation operations.

The following installation shall only be

performed by a professional electrician according the instruction in the

user manual.

The rated electrical parameters are

stated on the rating plate. Any tampering with the enternal connections is

prohibited and will void the warranty.

EQ 2

Wiring diagram

Unit 2

(supply*)

YELLOW

BLUE

RED

T P +

+

T2

P2

+

T2

P2

BLACK

-

-

-

Unit 1

(extract*)

YELLOW

BLUE

T P +

T1

P1

T1

P1

The unit is rated for connection to single-phase AC 100-240

V/ 50-60 Hz power mains.

The units shall be installed according to current laws and

regulations.

Signal cables shall be shielded and with a minimum cross

2

section of 0.25 mm

RED

BLACK

.

Connect the units to power mains in compliance with the

wiring diagram.

-

100230 V

-

+

+

5060 HZ

-

L

N

*in ventilation mode only

16

Unit control

!

The unit is operated with the control panel.

The control panel must be installed in

the included mounting box during

operations.

Press the buttons precisely on the

control panel. Pressing the buttons

quickly and shortly may result in

malfunction of the unit!

The following parameters are set with the control panel:

• unit operation speed: I, II, III;

• unit operation mode: REGENERATION or VENTILATION;

• timer-based operation of the unit: 4 hours at speed III or 8

hours at speed I.

The control panel displays the following parameters:

• current unit speed

• current operation mode of the unit

• timer operation status (on/off)

• filter replacement/cleaning need according to indications

of the filter timer (factory setting 90 days)

• emergency shutdown of the unit in case of a motor failure

In case of power cut-off the set parameters are saved in the

non-volatile memory of the control panel.

EQ 2

17

Timer

Speed III

4 hours

Speed III

Speed II

Speed I

Timer

Speed I

8 hours

EQ 2

Unit control with a sensor control panel

After expiry of the period set for the filter timer

(factory setting 90 days) the FILTER

contamination indicator starts glowing. In this

case clean or replace the filters and reset the

filter timer.

Resetting the filter timer and the operating

hours: press and hold the FILTER indicator.

REGENERATION

VENTILATION

The ALARM indicator glows in case of

emergency stop of the motor, as a result of

which the unit stops.

Resetting alarm indication: press and hold

the ALARM indicator until the indicators start

blinking rapidly.

Turning the unit on

Turning the unit off

Unit speed selection

Unit operation mode selection

Turning the timer on

Timer selection

Turning the timer off

Press any of speed selection buttons

Press the active speed button

Press the inactive speed button

Press the inactive REGENERATION

, , or the timer buttons , .

, , or the active timer button , , if no speed button is active.

, , .

or VENTILATION button.

The direction of air flow in the unit (supply and extract mode) is set when connecting the unit according to

the external connections wiring diagram.

Press the timer

Press the inactive timer

Press the active timer

button or .

button or .

button or .

If the timer period expires:

The unit continues operation at a set speed. The speed can be selected before switching on the timer as

well as during the timer-based operation.

The unit turns off if the speed was not selected.

18

To close the air duct pull a small handle between the

!

grille shutters to the left against stop.

To open the air duct pull this handle to the right.

7. Technical maintance

Air duct closing

Open

Close

Disconnect the unit from power supply

before any maintenance operations!

Maintenance of the unit means regular cleaning of the unit

surfaces of dust and cleaning and replacement of the filters.

To access the basic assembly units follow the steps:

Disconnect the socket connectors. Push the cable from

the control panel aside to the wall and pull the cord from

the cartridge to remove it from the air duct. Remove the

filters from the cartridge.

EQ 2

19

Clean the filters as they get contaminated, but not

less than once in three months.

• After expiry of the period set for the filter timer

(factory setting 90 days) the filter replacement

EQ 2

indicator

• Wash the filters and let those dry out completely.

Then install the dry filters in the air duct.

• Vacuum cleaning is allowed.

• The filter rated service life is 3 years.

• For new filters contact the Seller.

Even regular technical maintenance may not completely

prevent dirt accumulation on the regenerator and the

fan.

• Clean the regenerator regularly to ensure its high

regeneration efficiency.

• Clean the regenerator with a vacuum cleaner at

least once a year.

appears on the control panel display.

20

8. Troubleshooting

Problem Possible reasons Troubleshooting

The fan does not start up

during the unit start-up.

The control panel displays

no information and does

not respond to the button

pressing.

The control panel displays an

alarm indicator

Automatic switch tripping

following the unit turning on.

Low air flow.

Noise, vibration. The impeller is clogged. Clean the impeller.

No power supply.

Motor is jammed, the impeller blades are clogged.

Communication loss in connecting cable between the

.

fan motor and the control panel.

Overcurrent as a result of short circuit in the electric

line.

Low set fan speed. Set higher speed.

The filters, the fan or the regenerator are clogged.

Make sure the power supply line is connected correctly, otherwise troubleshoot the connection error.

Turn the unit off. Clean the impeller to troubleshoot

the motor jam. Restart the unit.

Turn the unit off. Contact the Seller for further

information.

Turn the unit off.

Contact the Seller for further information.

Clean or replace the filter. Clean the fan and the heat

exchanger.

9. Storage and transportation regulations

Store the unit in the manufacturer’s original packing box in a

dry ventilated premise at ambient temperatures from +5 °C

up to +40 °C.

Storage environment must not contain aggressive vapours

and chemical mixtures provoking corrosion, insulation and

sealing deformation.

Use suitable hoist machinery for handling and storage operations to prevent possible damage to the unit.

Follow the handling requirements applicable for the particular type of cargo.

The unit can be carried in the original packing by any mode

of transport provided proper protection against precipitation

and mechanical damage.

Avoid sharp blows, scratches or rough handling during

loading and unloading.

Do not expose the unit to sudden changes in temperature.

Such changes can lead to condensation of moisture inside

the unit and performance disturbance when the unit is

switched on.

Prior to the initial power-up after

transportation at subzero

temperatures allow the unit to warm

up at room temperature for at least 2

hours.

EQ 2

21

10. CE Declaration of conformity

EQ 2

This declaration confirms that the products meet the

requirements in the following Council Directives and standards:

2014/30/EC Electromagnetic compatibility (EMC)

2014/35/EC Low-voltage Directive (LVD)

93/68/EEC CE-marking Directive on the

approximation of the laws of the

Member States relating to

electromagnetic compatibility.

Producer: VENTILATION SYSTEMS PrJSC

1, Mikhaila Kotzubinskogo St., Kiev, 01030,

Ukraine

Type: Single-room ventilators;

Roomie One Wifi

Roomie Dual

Roomie Dual Wifi

Eq 2

Art.no.: 115996, 115999, 116000, 116001

Compliance with valid versions of the following standards on

the date on which the declaration of conformity was signed:

Safety standard: EN 60335-1

EN 60335-2-80

EMF standard: EN 62233

EMC standard: EN 55014-1

EN 55014-2

EN 61000-3-2

EN 61000-3-3

Flexit AS 30.11.2016

Frank Petersen

CED

22

EQ 2

23

Flexit AS, Televeien 15, N-1870 Ørje www.flexit.no

Loading...

Loading...