Flexit CS2000 User Manual

112140E-06

2019-09

CS2000 Automatic control V3

User Guide

Contents

This user guide only applies to software version V3.x

To view current software version:

Start page > Main menu > System Overview > Versions > Flexit.ahu = V3.x

!

1. Introduction

1.1. Document description ................................................................................................................................4

1.2. Highlighted boxes ........................................................................................................................................4

1.3. System overview ..........................................................................................................................................5

1.3.1. System structure ....................................................................................................................................5

1.3.2. Ventilation unit's switching space ......................................................................................................6

1.3.3. Ventilation unit's control cabinet .......................................................................................................7

2. Getting started

2.1. HMI ..................................................................................................................................................................9

2.2. Settings ..........................................................................................................................................................9

2.2.1. Introduction ............................................................................................................................................9

2.2.2. Select language......................................................................................................................................9

2.2.3. Login .........................................................................................................................................................9

2.2.4. Set time/time channels .......................................................................................................................10

2.3. Adjust the setpoints for speeds and temperatures ............................................................................12

2.4. Service switch ............................................................................................................................................. 12

2.5. Extract air regulation ................................................................................................................................ 12

2.6. Change the unit for the flow display ......................................................................................................12

2.7. Alarm handling .......................................................................................................................................... 12

3. Menu tree ...................................................................................................................................................13

4. Backup and program updates

4.1. Save a configuration ................................................................................................................................ 25

4.2. Load a configuration ................................................................................................................................ 25

4.3. Loan an application or software ............................................................................................................ 25

4.4. Error diagnosis - Snapshot ..................................................................................................................... 26

5. General functions ...................................................................................................................................26

6. Configuration

6.1. Configuration 1 .......................................................................................................................................... 27

6.2. Configuration 2 .........................................................................................................................................32

6.3. Configuration of inputs and outputs ..................................................................................................... 36

7. Cooling

7.1. Installation ..................................................................................................................................................37

7.2. Configuration - Cooling control ..............................................................................................................37

7.3. For activation of circulation pump (only applies to liquid cooling) ................................................37

7.4. Blocking in connection with outdoor temperature .............................................................................37

7.5. Operating times (only applies to DX cooling) ......................................................................................37

7.6. Cooling restriction depending on fan speed (only applies to DX cooling) ................................... 38

7.7. Setting of temperature setpoint ............................................................................................................ 38

2

8. Temperature regulation

8.1. Extract air regulation ............................................................................................................................... 38

8.2. To adjust supply air temperature limits with extract air regulation................................................ 38

9. Summer/winter compensation

9.1. Adjustment of fan setpoint in connection with high/low outdoor temperature .......................... 39

9.2. Parameter settings for fan compensation .......................................................................................... 39

9.3. Adjustment of temperature setpoint in connection with high/low outdoor temperature ......... 39

9.4. Parameter settings for temperature compensation ......................................................................... 39

9.5. Settings for switching between summer and winter operation ....................................................... 40

9.6. Switch between summer and winter via signal ................................................................................... 40

9.7. Switch between summer and winter via date/outdoor temperature .............................................. 41

9.8. Temperature test for nighttime operation ........................................................................................... 41

9.9. Nighttime cooling ..................................................................................................................................... 42

9.10. Support operation .................................................................................................................................... 42

9.10.1. To activate the function..................................................................................................................... 42

9.10.2. To configure the function .................................................................................................................. 42

10. Fan regulation

10.1. Select method of regulation ....................................................................................................................43

10.1.1. Selection fan regulation method ......................................................................................................43

10.2. Pressure control .........................................................................................................................................43

10.2.1. Configuration of the pressure sensors’ measuring ranges .........................................................43

10.2.2. Pressure setpoint adjustment. ........................................................................................................ 44

10.3. External fan setpoint ............................................................................................................................... 44

10.3.1. Parameter settings for Comp. .......................................................................................................... 45

10.3.2. Parameter settings for Main ............................................................................................................. 45

10.4. External fan control via digital inputs ................................................................................................... 46

10.5. Fire fan ........................................................................................................................................................ 46

11. Connection of external equipment

11.1. Fire damper ................................................................................................................................................ 47

11.2. Fire/smoke detector ................................................................................................................................. 50

11.3. Air quality .................................................................................................................................................... 51

11.4. AUX Damper .............................................................................................................................................. 52

12. Web ..............................................................................................................................................................53

13. ModBus TCP/IP ........................................................................................................................................ 54

14. DX heating/cooling ...............................................................................................................................55

14.1 Configuration of control system ...........................................................................................................55

14.2 Installation ................................................................................................................................................56

3

1. Introduction

!

!

1.1. Document description

This document describes the main functions of the CS2000 automatic control and is divided into different sections for

different parts of the system. If you only want to make basic settings to start the ventilation unit, there is a special section

describing the startup procedure. If you require more detailed information, select the relevant section in the document.

All electrical connections must be made

by an expert.

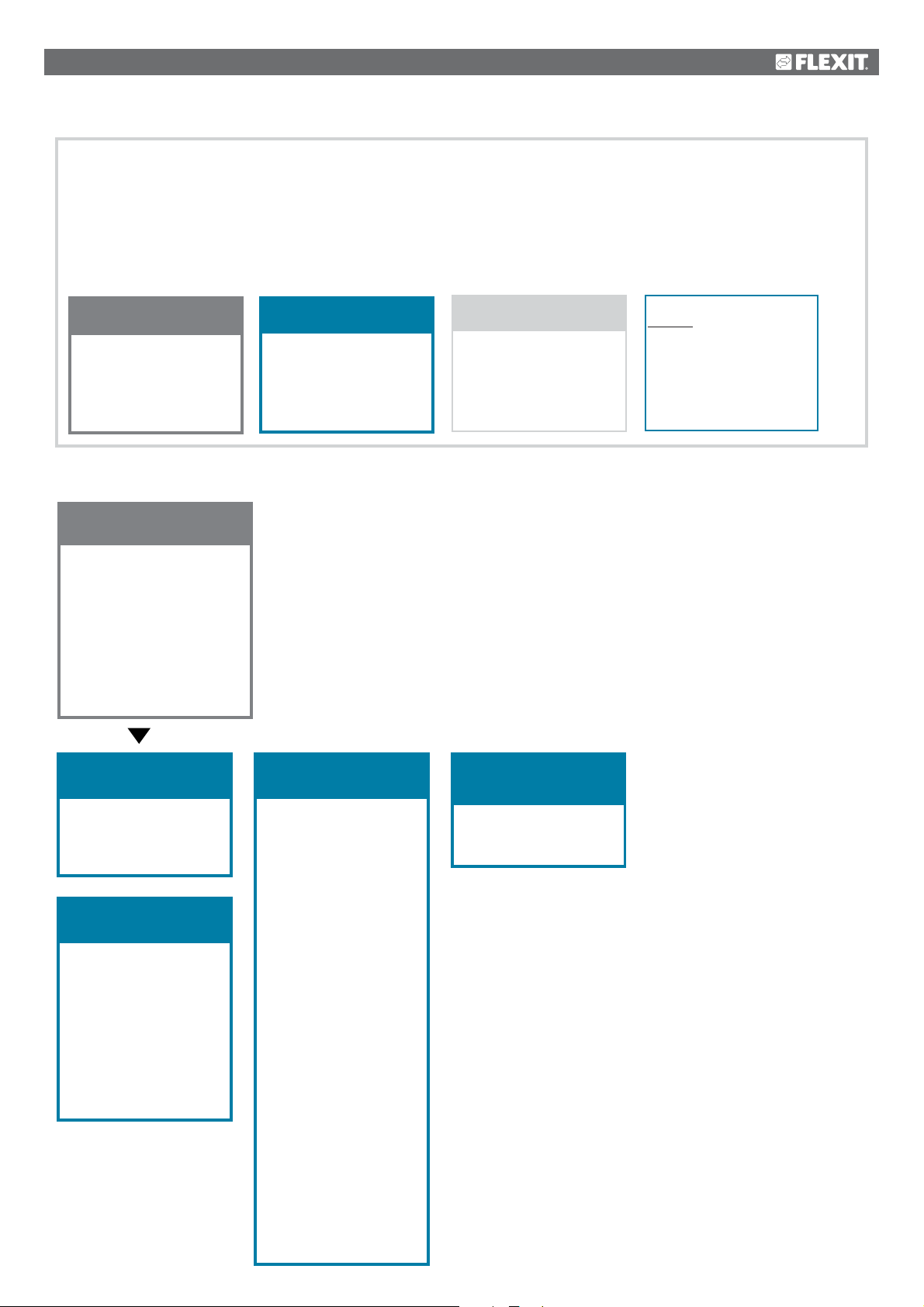

1.2. Highlighted boxes

A number of different text boxes are used in the document to draw the user's attention to various things. This may be anything

from pure information text to particularly important details to ensure that the system is not used incorrectly. Here is a brief

description of the various boxes:

WARNING! When a text is highlighted like

this, it means that personal injury or serious

damage to the equipment may result if the

instructions are not followed.

NB! When a text is highlighted like

this, it means that the equipment may

be damaged or function poorly if the

instructions are not followed.

RESTART

> EXAMPLE

Italicised text boxes show examples

A table looks like this

with various values with various values

with various values with various values

4

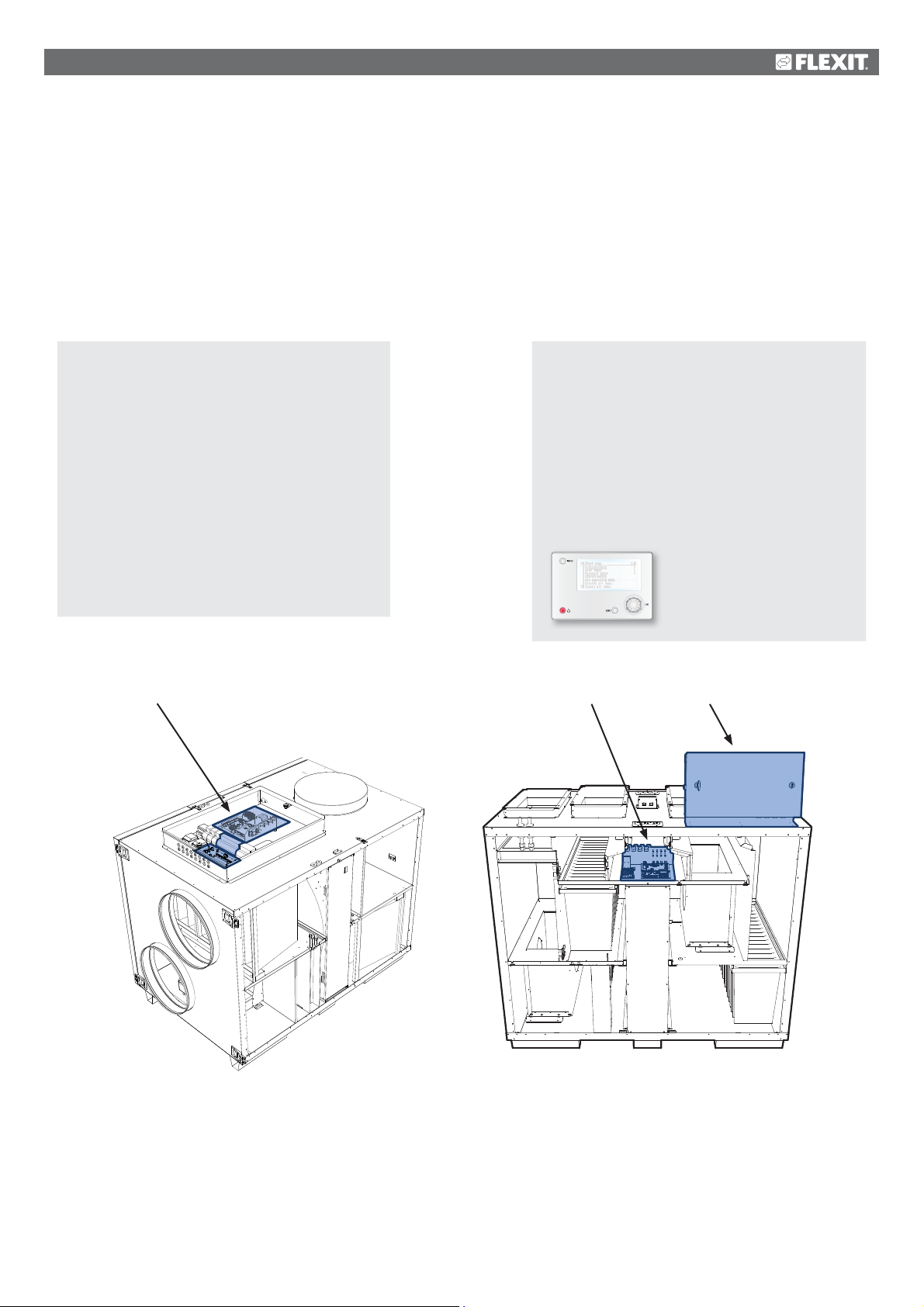

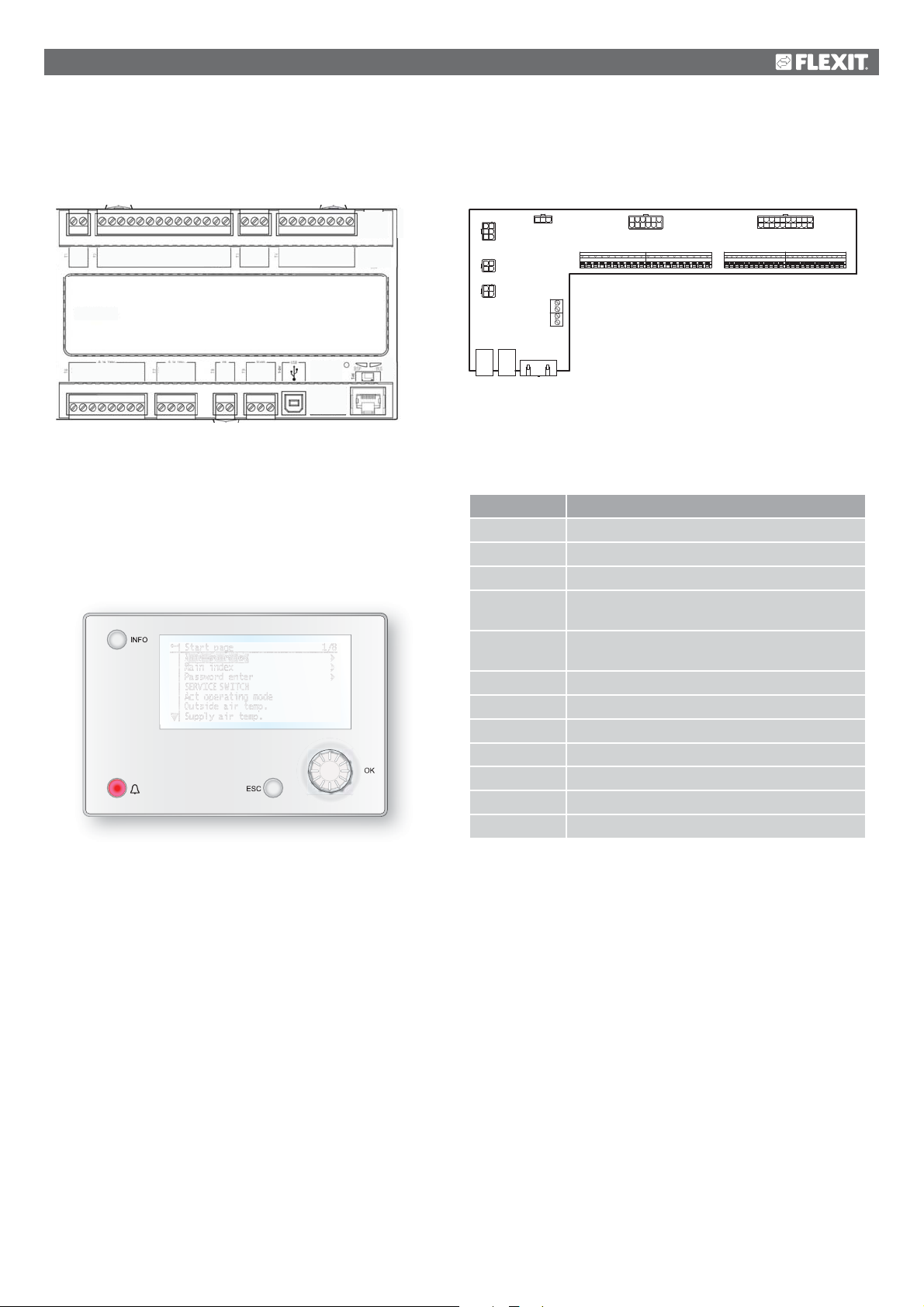

1.3. System overview

1.3.1.

The control system is divided into two subgroups:

1. One part that is located in the ventilation unit's switching space

2. One part that is located in a separate control cabinet on the outside of the ventilation unit

System structure

1.

Terminal blocks for incoming feed

Fuse for automatic control and fans (not electric

heating coil)

Modbus extender - a communication card that

connects the ventilation unit's components to

the regulator via data communication

Power supply board - a circuit board that

distributes the power supply to the ventilation

unit's components and makes it possible to

connect components to a water heating coil

1, 2

2.

Regulator - the overall control system of the

ventilation unit

Terminal board - a circuit board with terminal

blocks for connection of additional components

and accessories

HMI - the control panel used to communicate

with the regulator

1 2

L model S model

5

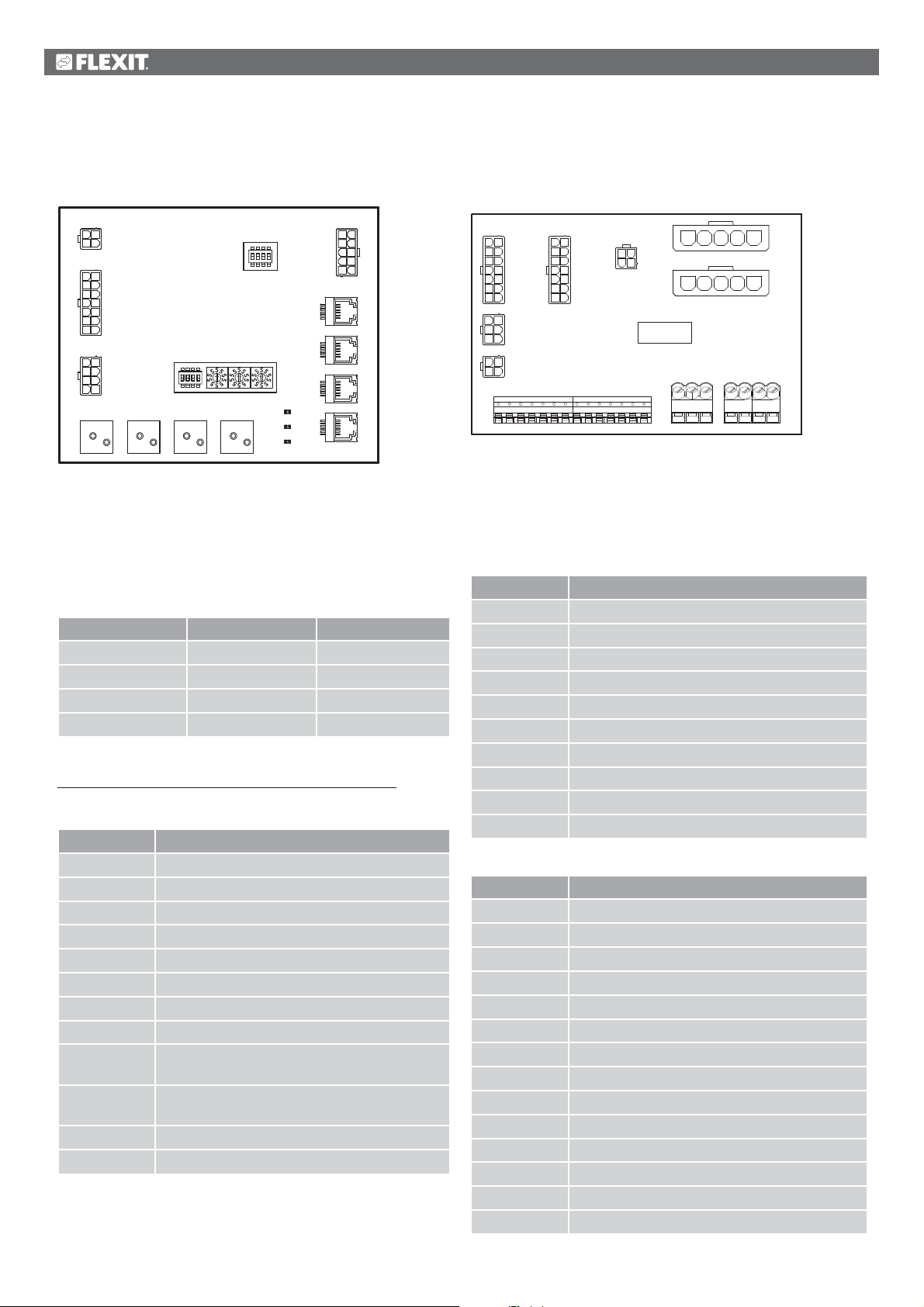

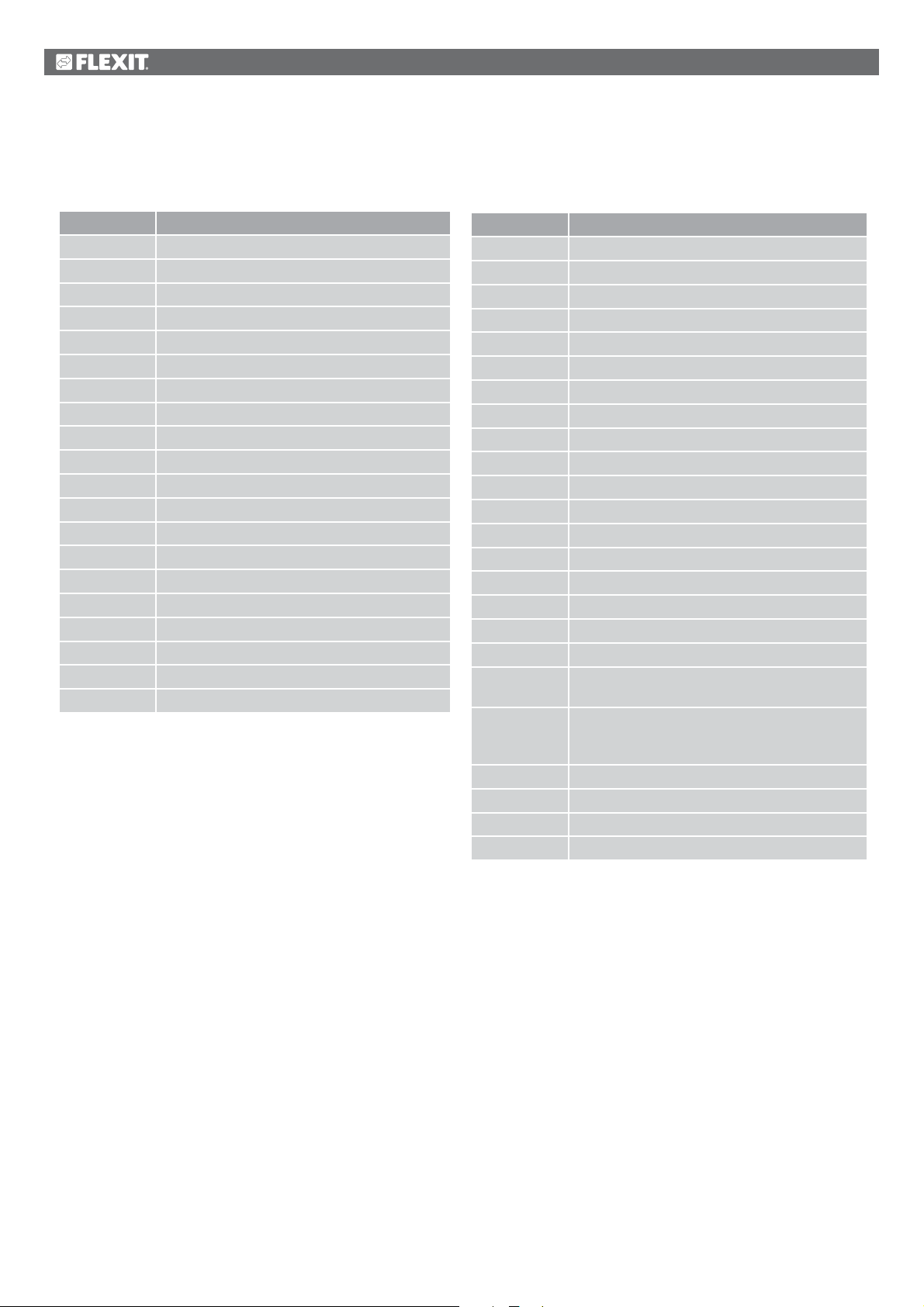

1.3.2.

Ventilation unit's switching space

Modbus extender

A3

123

P1

4

128

9

3410

11

P2

5612

13

714

125

6

P3

347

8

Q1 Q2

USER

FACTORY

FP1 FP2

1095

4

873

P8

2

61

P7

P6

P5

P4

It is a communication card that connects the ventilation

unit's components to the regulator.

The card has four dipswitches called 'USER' that are used

to configure the unit, depending on the type of heating coil

installed.

Dipswitch no. ON OFF

1 Heating coil No heating coil

2 Electric heating coil Water heating coil

3 - Must be OFF

4 - Must be OFF

The other four dipswitches and the rotary switches marked

'FACTORY' are factory-set and must not be changed.

The board's components have the following functions.

Component Function

P1 Power supply

P2 Control signals to heating coil

P3 Control signals to rotor and temperature sensor

P4 Communication connection

P5 Communication connection

P6 Communication connection

P7 Communication connection

P8 Control signals to fans

Q1 Differential pressure monitor for flow

measurement on supply air fan

Q2 Differential pressure monitor for flow

measurement on extract air fan

FP1 Differential pressure monitor for supply air filter

FP2 Differential pressure monitor for extract air filter

Power supply board

A4

18

29

310

411

P6 P7

512

613

714

14

25

P5

36

13

P4

24

1 2 3 4 5 6 7 8 9

18

29

310

411

512

613

714

P3

34

12

P8

10 11 12 13 14

1 2345

P9

1 2345

P10

PE PE PE

P1P2

L1 L2 L3 N

It is a circuit board that distributes the power supply to the

components of the ventilation unit (not the electric heating

coil) and control cabinet.

There is also a terminal block for the components required to

regulate a water heating coil.

The board's components have the following functions.

Component Function

P1 Terminal block for power supply

P2 Terminal block for protective earth (PE)

P3 Terminal block for water heating coil

P4 Power supply to modbus extender

P5 Power supply to control cabinet

P6 Control signals to heating coil

P7 Control signals to heating coil

P8 Power supply to rotor control

P9 Power supply to supply air fan

P10 Power supply to extract air fan

Terminal block P3 has the following signals:

Block no. Function

1 Valve motor - G0

2 Valve motor - 24 V+

3 Valve motor - G0

4 Valve motor - control signal 0-10 V

5 G0 (for F10 or B5)

6 Overheating thermostat F10

7 Return water sensor B5

8 No connection

9N

10 Pump motor - relay contact

11 Pump motor - relay contact

12 L

13 N

14 L

6

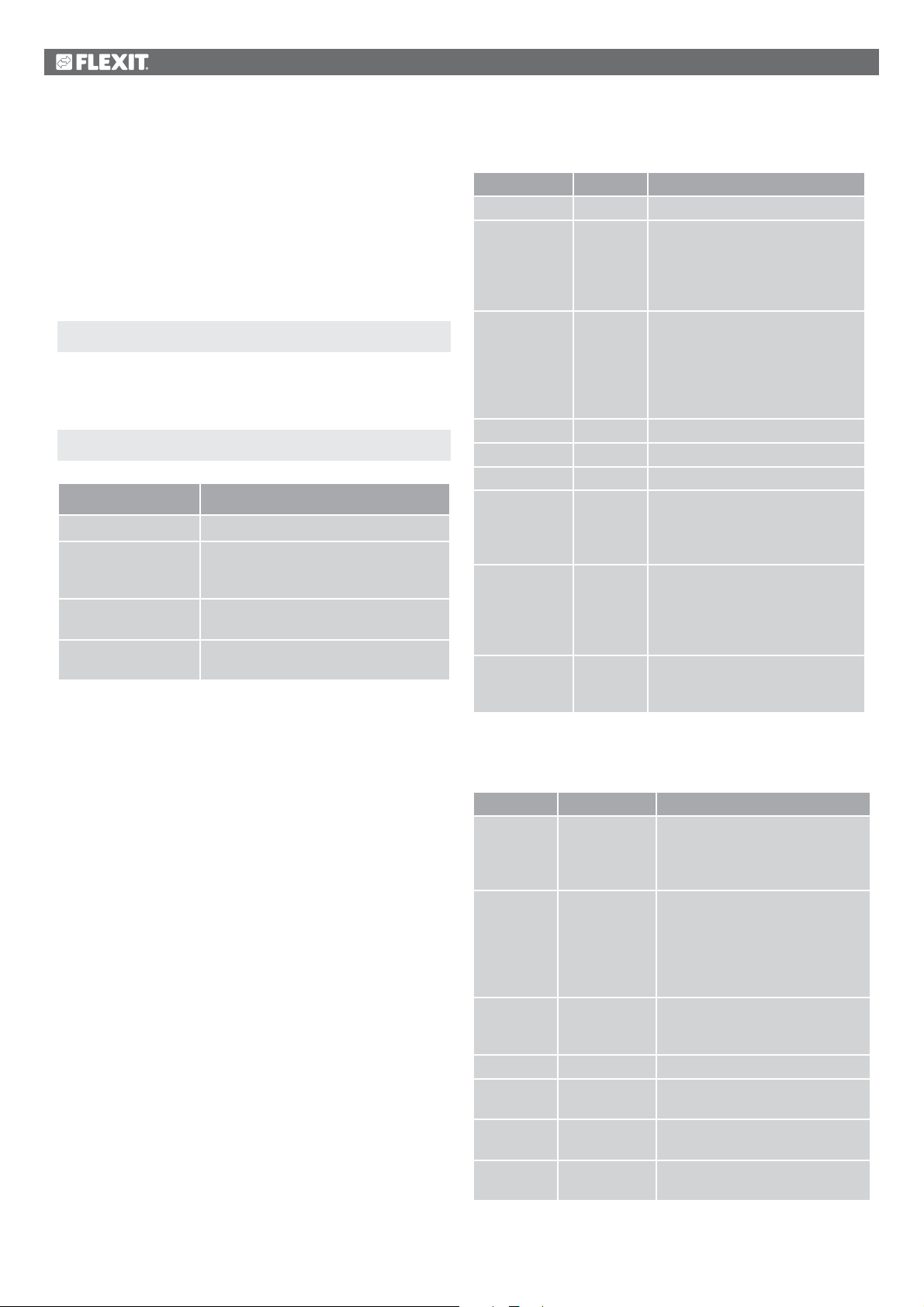

1.3.3.

Ventilation unit's control cabinet

Regulator

A1

X1MX2X3MX4X5MX6X7MX3+24V

0V

24V=

T1 T2 T3 T4

T6 T7 T8 T9

Q13

Q14

Q23

Q24

Q33

Q34

Q43

Q44

Q53

Q54

Q63

Q64

+24VY1M

CE -

CE+

Y2

REF

B -

A +

D1MD2D3MD4D5

M

The ventilation unit's control system. This is where the

control panel (HMI) and sensors and other components

of the ventilation unit are connected. It is also possible

to connect an SD memory card to back up or reload

configuration settings and parameters for the regulator.

HMI

The control panel on which all settings and readings take place.

It has an 8-line graphic display and you navigate the menu

tree using a dial that is turned. Selections are confirmed by

pressing the same button.

Terminal board

A2

12 7

4

2

5

P6

3

6

123

P5

4

123

P4

4

1312

P7

1 2 3 4 5 6 7 8 9

P14

P1P3 P2

1 2 3 4 5

829310411

16

5 623144155978

P8

10 11 12 13 14 15 16 17 18 19 20

20 11

12131819 1617

110

P9

P12P10

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44

It is a circuit board that connects the components to

the regulator. External components such as dampers are

connected to this board via the terminal blocks on the board.

The board's components have the following functions.

Component Function

P1 Connection for power supply

P2 Data communication

P3 Data communication

P4 Connection for external pressure sensor

(accessory)

P5 Connection for external pressure sensor

(accessory)

P6 Connection for 24 V transformer

P7 Data communication

P8 Connection for digital outputs

P9 Connection for control signals

P10 Terminal block for 230 V signals

P12 Terminal block for control signals

P14 Terminal block for protective earth (PE)

7

Terminal board

Terminal block P10 has the following signals:

Block no. Function

1L

2N

3 L (Outdoor air damper)

4 L1 (Outdoor air damper ON/OFF)

5 N (Outdoor air damper)

6 L (Exhaust air damper)

7 L1 (Exhaust air damper ON/OFF)

8 N (Exhaust air damper)

9 L (Fire damper)

10 L1 (Fire damper ON/OFF)

11 N (Fire damper)

12 Buzzer alarm IN

13 Buzzer alarm OUT

14 DX cooling/cooling pump IN

15 DX cooling/cooling pump OUT

16 L

17 Heating IN

18 Heating OUT

19 N

20 Not used

Terminal block P12 has the following signals:

Block no. Function

21 Cooling - 0-10 V [AO]

22 Cooling - G0

23 External control 1 [DI]

24 External control 1 - G0

25 External control 2 [DI]

26 External control 2 - G0

27 Fire/smoke [DI]

28 Fire/smoke - G0

29 Air quality - 0-10 [AI]

30 Air quality - G0

31 Heating - 0-10 V [AO]

32 Heating - 24 V+

33 Heating - G0

34 Fire damper open [DI]

35 Fire damper closed [DI]

36 Fire damper - G0

37 AUX damper - 0-10 V [AO]

38 AUX damper - G0

39 Return water sensor B5 [AI]/Overheating

thermostat F20 [DI]

40 Return water sensor B5 [AI] - G0 /

Overheating thermostat F20 [DI] - G0

External setpoint, supply air fan 0-10 V [AI] - G0

41 CE- [Data bus]

42 CE+ [Data bus]

43 External setpoint, supply air fan 0-10 V [AI]

44 External setpoint, extract air fan 0-10 V [AI]

8

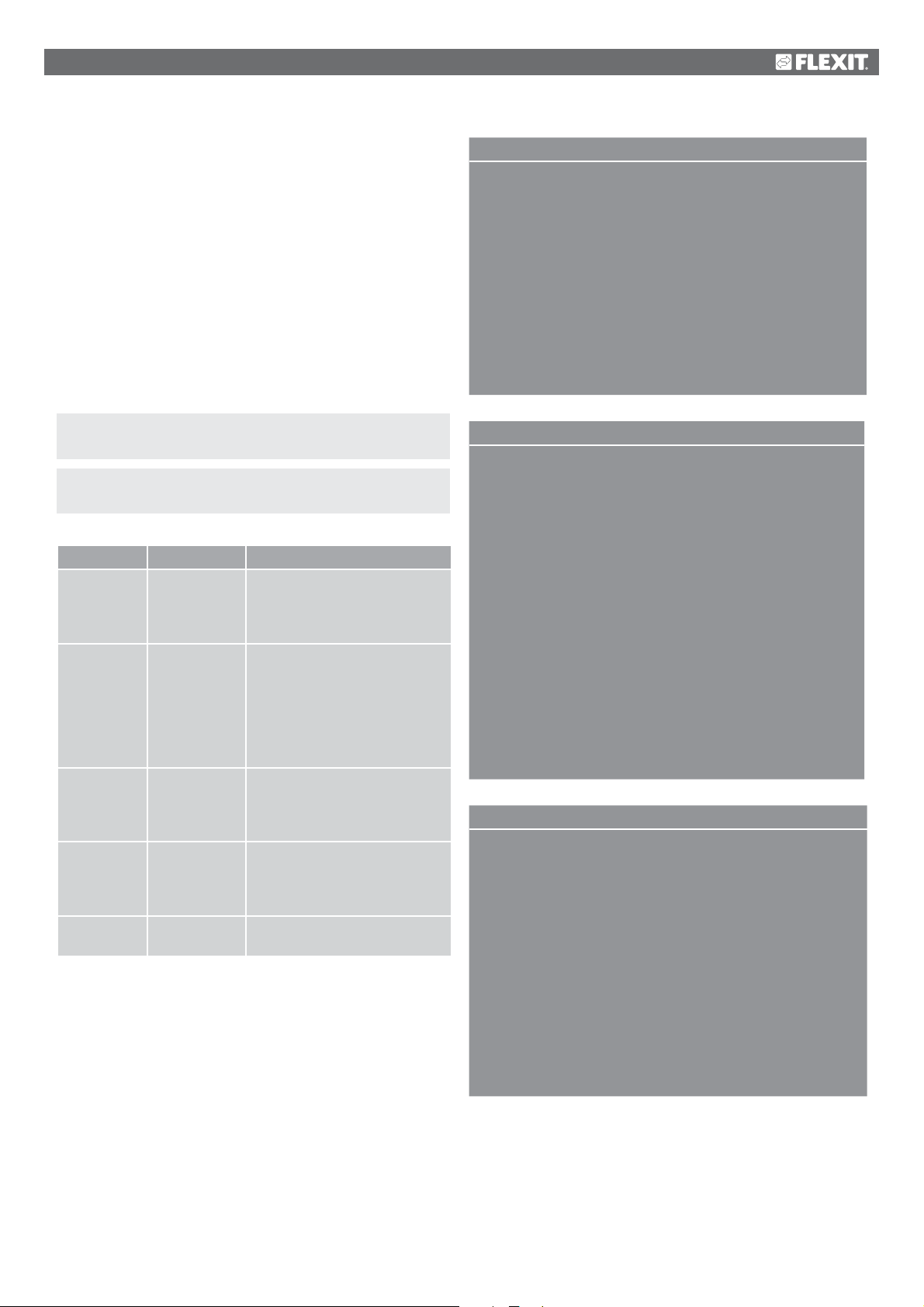

2. Getting started

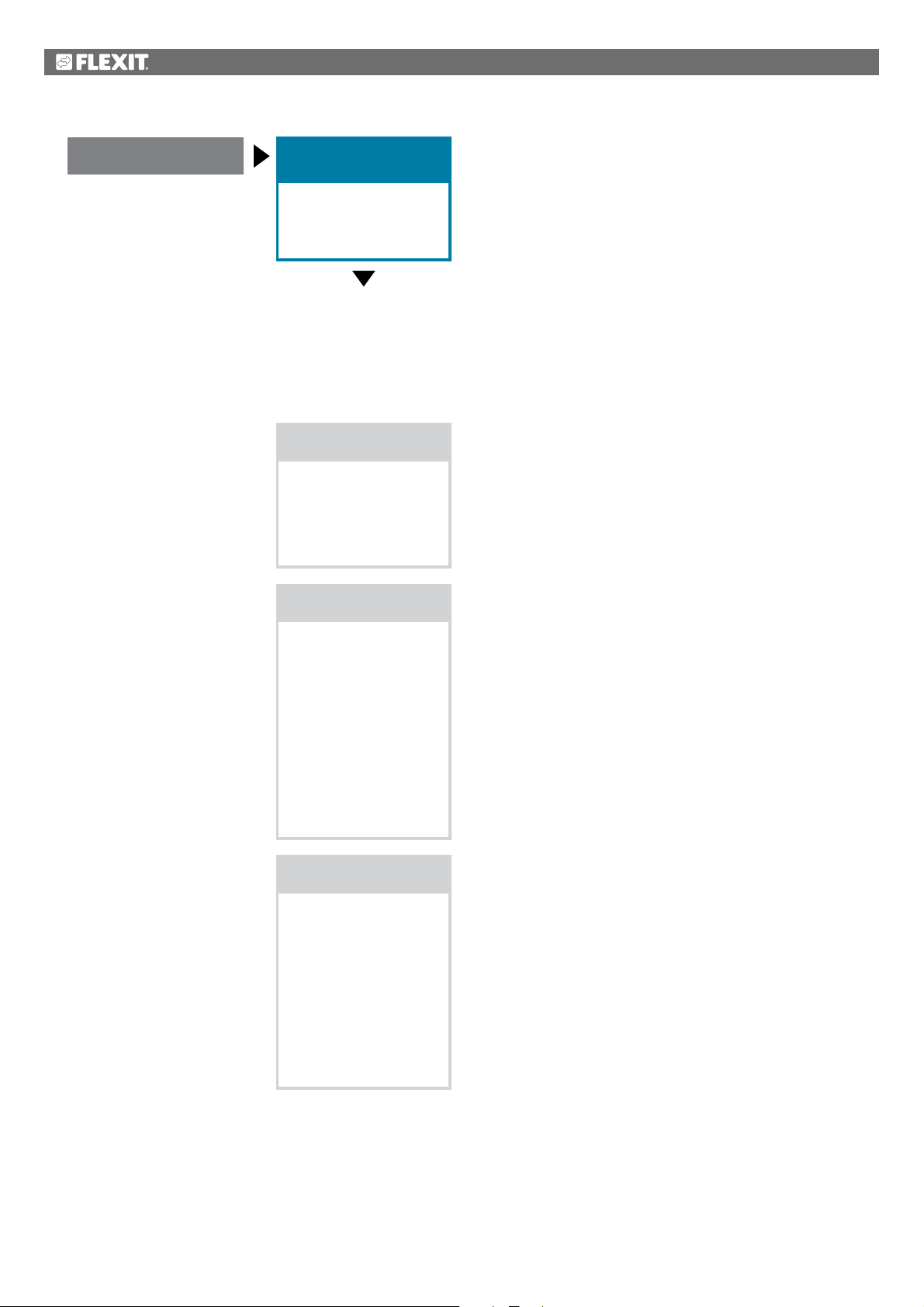

2.1. HMI

A central element in the system is the HMI (control panel), where you can adjust settings and take readings. The control panel

consists of an 8-line graphic display, indicator lamps and controls for the settings.

Here is a short introduction to the control panel showing how to enter the initial settings in the system.

Info button

Press to go to

Main Menu

• Off = Stop, cool down

• Green lamp, steady =

Normal operation

• Flashing green =

Starting, Night

operation test, Night

cooling or Night

heating/night cooling.

• Orange lamp, steady =

Emergency stop and

alarm with stop

• Flashing orange = Fire

damper in motion

• Alternating green/

orange = Manual

control

Alarm button

• Flashing red = alarm

• Red lamp, steady =

alarm acknowledged

but remaining

ESC button

• Returns to the

previous menu page

• Cancels current

editing

Display

Shows information

Dial

• Turn

counterclockwise/

clockwise to go up/

down in menus or to

change values

• Press the button

to enter a menu or

change a value

• Hold the button

down to go directly

to the login menu if

the value you want

to change

• requires login

2.2. Settings

2.2.1.

The first time the system is started, you need to go through

some simple steps to ensure that the system will function.

If a heating coil has been installed in the ventilation unit and

the associated settings have been made with dipswitches

in the switching space in the unit, the automatic control

system will be restarted automatically once to complete the

operation. No extra action needs to be taken. It is simply

necessary to wait until the system has restarted.

There is a quick menu to access the most commonly used

functions in the control panel, Language, Timing Program

and Setpoint Settings.

2.2.2.

To change the language on delivery:

Start page > Quick menu > Language selection >

HMI Language > English

Changes the menu language to English.

Introduction

Select language

2.2.3.

Login

In order to make changes to the system, it is normally necessary

to log in. There are four authority levels in the system, and three

of them are password protected. The level at which the user is

currently logged in is shown by the number of keys in the top

left hand corner of the display. The menus show more options or

fewer, depending on the level at which you are logged in.

The following actions are possible at the different levels:

Level 1: No restrictions, no password required.

• Read rights to all menus except system parameters,

configuration and detail menus.

• Read rights to alarm lists and alarm history.

Level 2: End user, password 1000.

• All rights as for level 1, plus:

• Read rights to all menus except configuration menus.

• Write rights to the most important setpoints (Setpoints/

Settings > Setpoints).

• Alarms and alarm history can be acknowledged and reset.

9

Level 3: System administrator, password 2000.

• All rights as for level 2, plus:

• Rights to all menus except I/O configuration and system

settings.

Level 4: OEM, password given only in consultation with the

Flexit service organisation.

• All rights as for level 3, plus:

• Rights to all menus and system settings.

Start page > Main menu > Log in

2.2.4.

Set time/time channels

Start page > Quick menu > Timing program

Parameter Function

Date and Time This is where you set the time and date

Continuous operation This is where you can override the

timing programs and switch the unit to

continuous operation

Current value Displays the current timing

(temperature and speed)

Monday to Sunday See explanation of week schedule

(2.2.4.2)

2.2.4.1.

Set the calendar and timing program

General

This section describes functions and settings for the timing

program and calendars.

When no object with higher priority (for example Manual

control <> Auto) is activated, the system can be switched off

or the steps changed via the timing program. A maximum of

six switch-over times can be specified per day.

The calendar stop overrides the calendar exception, which in

turn overrides the normal timing program (only in operating

mode). Up to 10 periods or exception days can be specified

for each calendar.

NB! Both setpoints for fan steps and temperature setpoints

(comfort /economy) are controlled by the timing program.

2.2.4.2.

Parameter Value Function

Current value --- Switching according to schedule

Monday Shows current command when the

Copy schedule

Tuesday Same function as for Monday

... ...

Sunday Same function as for Monday

Exception Shows current command when the

Period: Start

Period: Start

Period: End

Period: Start

Week schedule

–Mon to

–Tu– Fr

–Tu– Su

current day is Monday. The latest

time that can be entered for a day

is 23:59. Go to the day switching

schedule for Mondays

Copies times for the timing

program from Monday to

Tuesday–Friday/Tuesday–Sunday.

– Passive (no copying).

– Copying starts. Return to the

display screen

current day is an exception day.

Go to the day switching schedule

for exception days

(Only Authority level 3.)

Start date for week schedule.

*,* *.00 means that the week

schedule is always activated. --->

Activate week schedule

(Only Authority level 3.)

Start date and start time for

deactivating week schedule

2.2.4.3.

Parameter Value Function

Current

value

Day

schedule

Time-1 Special case: This time must not

Value-1 Switching command for Time-1

Time-2 Switching time 2

Value-2 ...

Value-6

Time-3 ...

Time-6

Dayschedule

--- Switching according to the

schedule when the current

weekday is the same as the

switching day

Status for current week or

exception day:

– Passive

– Active

– Current weekday (system day) is

not the same as the switching day.

– Current weekday (system day) is

the same as the switching day

be changed, and must always be

00:00

*: * ---> Time deactivated

Analogue value 1

Analogue time 2

10

2.2.4.4.

Kalender (undantag och stopp)

Exception days can be defined in the calendar. These can

include specific days, periods or weekdays. Exception days

override the weekly schedule.

EXAMPLE: Val-x = Date

Only the time for (start) is relevant.

• -(Start)Date = *,01.01.16

Calendar exceptions

Switching follows the weekly schedule and the exceptions

specified in the day schedule when a switching time is

activated in the calendar exception.

Calendar stop

The system is turned off when the calendar stop is activated.

Parameters:

Start page > Main Menu > Unit > Operating

information > Timing program > Calendar exceptions

Start page > Main Menu > Unit > Operating

information > Timing program > Calendar stops

Parameter Value Function

Current

value

– Passive

– Active

Val-x

– Date

– Interval

– Weekday

– Passive

-(Start)Date – Val-x = interval: Enter the start

-End date Val-x = interval:

-Weekday Val-x = only weekdays: Enter

Shows whether a calendar time

is activated:

– No calendar time activated

– Calendar time activated

Specification of exception type:

– A certain day (e.g. Friday)

– A period (e.g. holiday)

– A certain weekday

– Times are deactivated

This value must always be placed

last, after the date

date for the period

– (Val-x = date: Enter specific

date)

Enter the end date for the period

The end date must be later than

the start date

a weekday

Result: 1 January 2016 is an exception date.

• -(Start)Date = Mo,*.*.00

Every Monday is an exception day

• -(Start)Date = *,*.Even.00

All days in even months (February, April, June, August, etc.)

are exception days.

EXAMPLE: Val-1 = Interval

The times for (Start)Date and End date are adjusted.

• -(Start)Date = *,23.06.16 / -End date = *,12.07.16.

23 June 2016 until end of 12 July 2016 are exception days

(for example holidays).

• -(Start)Date = *,23.12.16 / -End date = *,31.12.16

23–31 December are exception days every year. Time End

date = *,01.01.16 will not work because 1 January comes

before 23 December.

• -(Start)Date = *,23.12.16 / -End date = *,01.01.17.

23 December 2016 up to and including 1 January 2017 are

exception days.

• -(Start)Date = *,*.*.17 / -End date = *,*.*.17

Warning! This means that the exception is always active!

The system is constantly in exception mode or turned off.

EXAMPLE: Val-1 = Weekday

Val-1 = Weekday

The times for weekdays are adjusted.

• Weekday = *,Fr,*

Every Friday is an exception day.

• Weekday = *,Fr,Even

Every Friday in even months (February, April, June, August,

etc.) is an exception day.

• Weekday = *,*,*

Warning! This means that the exception is always active!

The system is constantly in exception mode or turned off.

11

2.3. Adjust the setpoints for speeds and

temperatures

Start page > Quick menu > Setpoints/Settings

Parameter Function

All settings >

Timing program >

Setp.comf.heat Indicates the temperature setpoint

Setp.econ.heat Indicates the temperature setpoint

Setp.TF step 1 Indicates the supply air flow

Setp.TF step 2 Indicates the supply air flow

Setp.TF step 3 Indicates the supply air flow

Setp.FF step 1 Indicates the extract air flow

Setp.FF step 2 Indicates the extract air flow

To adjust supply air temperature limits with extract air regulation.

Start page > Quick menu > Setpoints/Settings

Parameter Function

Setpoint, min. supply

air temp.

Setpoint, max. supply

air temp.

Indicates the lowest permitted supply air

temperature

Indicates the highest permitted supply

air temperature

2.6. Change the unit for the flow display

Toggles between m3/h and l/s in the air flow rate display.

Start page > Main menu > Configuration >

Configuration 2 > Flow display

Setp.FF step 3 Indicates the extract air flow

2.4. Service switch

The service switch is used to stop the unit for service.

Start page > SERVICE SWITCH

Parameter Function

Auto The unit is controlled via time channel

Off Service mode, unit stopped

2.5. Extract air regulation

The unit is configured by default to regulate temperature via

the supply air. However, it can be reconfigured to regulate

via the extract air. To do this, go to the following menu:

Start page > Main menu > Configuration >

Configuration 1 > Temperature regulation type

Parameter Function

Supply air Temperature regulation is controlled by

the supply air temperature

Extract air Temperature regulation is controlled by

the extract air temperature

After making a change in a configuration menu, a restart is

required.

Parameter Function

No Not used.

l/s Displays flow in l/s

3

/h Displays flow in m3/h

m

After making a change in a configuration menu, a restart is

required.

Start page > Main menu > Configuration >

Configuration 2 > Restart > Execute

RESTART

2.7. Alarm handling

If an alarm has been triggered, it will be shown by the flashing

alarm symbol. You can get more information by pressing the

alarm button. To reset the alarm, press the alarm button twice

and select Confirm/Reset and then Execute in the menu.

Alternatively, the alarm can be reset with the menu option:

Start page > Main menu > Alarm management >

Alarm reset > Execute

Start page > Main menu > Configuration >

Configuration 1 > Restart > Execute

RESTART

12

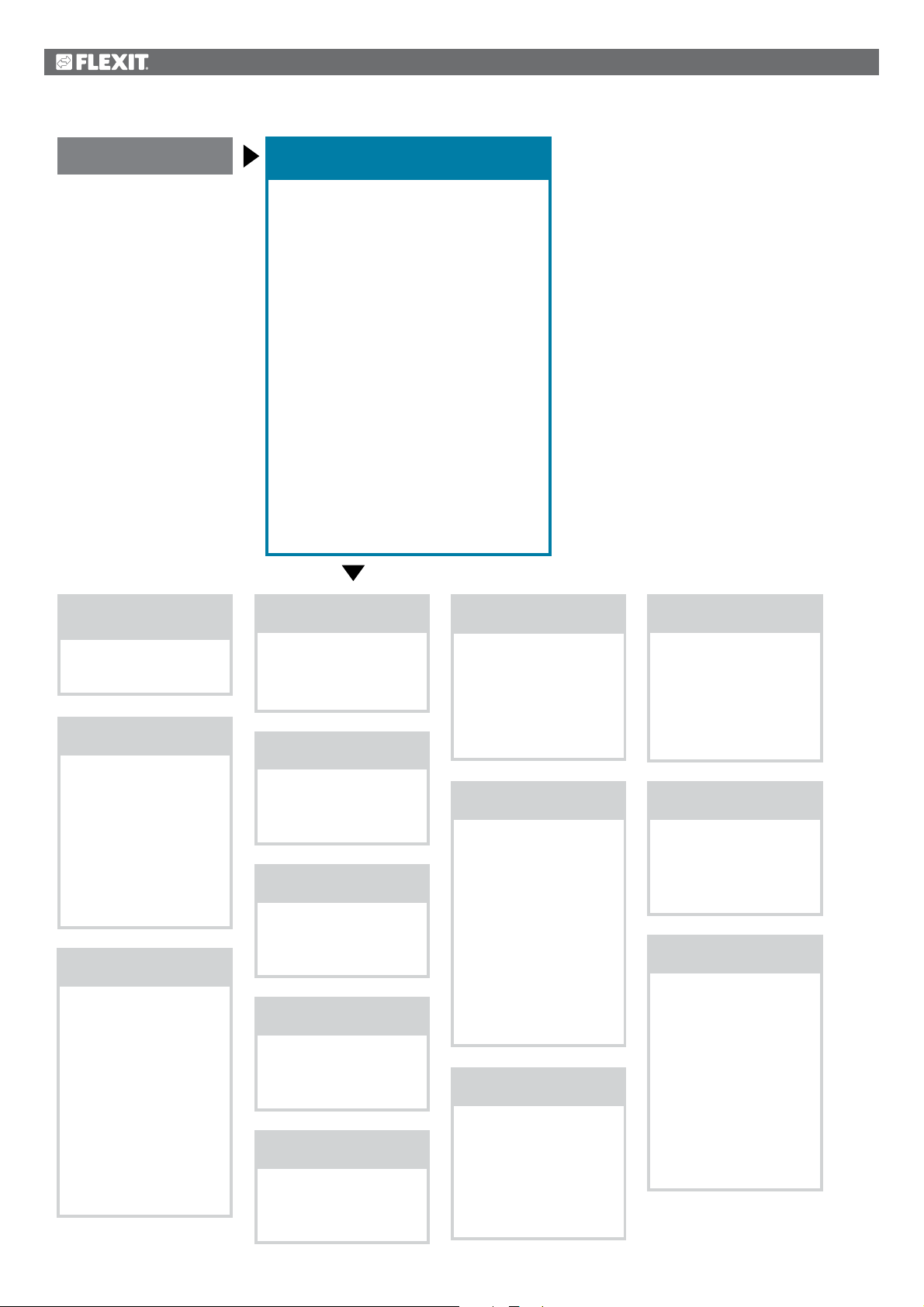

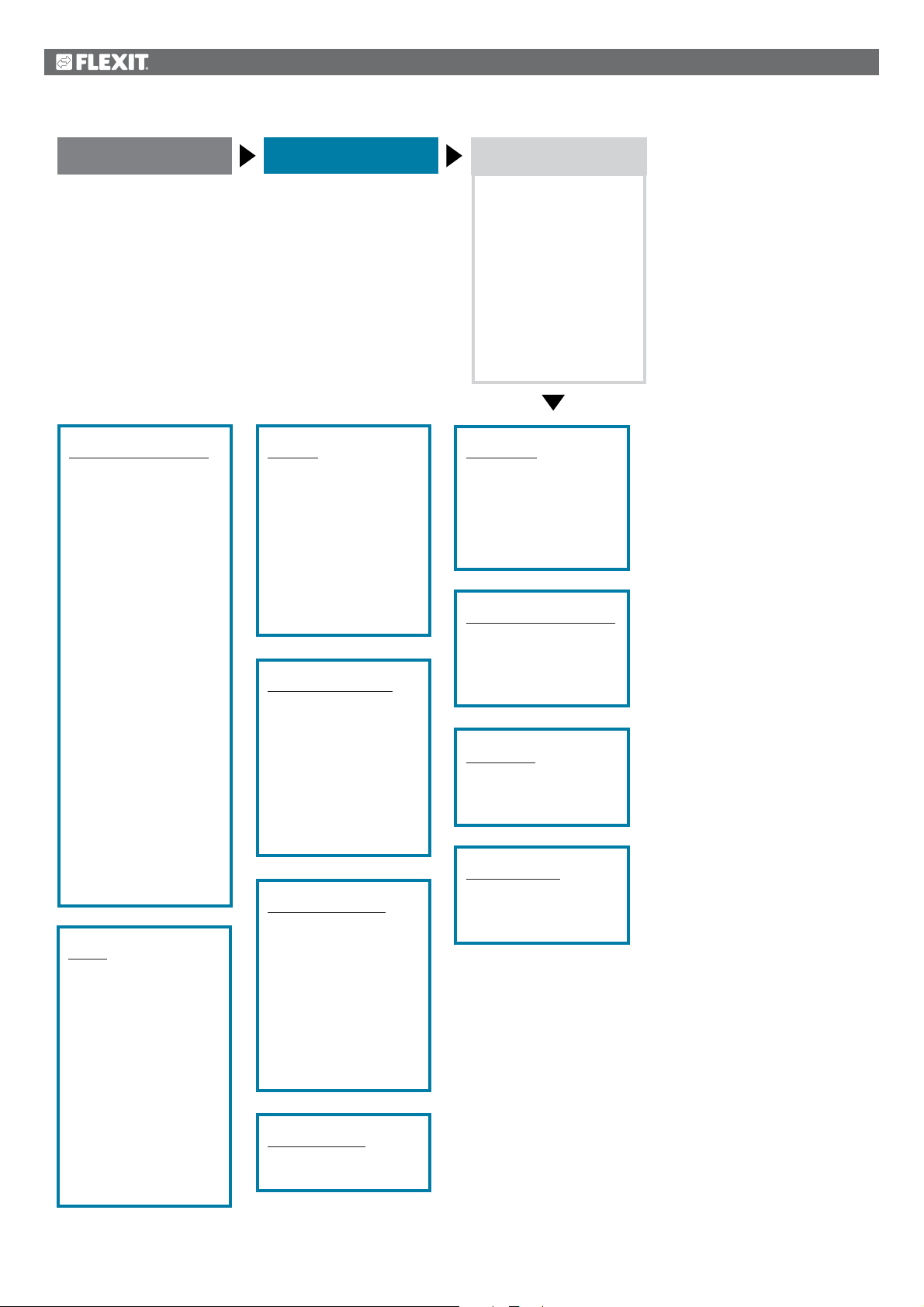

3. Menu tree

Logging in gives you access to several menu options.

The menu tree reflects the default configuration.

It may be different in other configurations.

Level 1

•

Start page

• Quick menu

• Main menu

• Operating information

• SERVICE

SWITCH

Operating mode

Outdoor temperature

Supply air temp.

Extract air temp.

Level 2

•

Level 3

•

Level 4

•

Quick menu

• Language selection

• Timing program

• Setpoints/Settings

Main menu

• Log in

• Unit

• Communication

• General func.

• Alarm handling

• System overview

• Overview of IO config./

raw values

• Configuration

Operating information

• Current operating

mode

• - Alarm

• Timing program

• Outdoor temp.

• Extract air temp.

• Supply air temp.

• Outdoor air damper

• Exhaust air damper

• Current fan step

• Current setpoint SF

• Current actual

value SF

• Supply air fan

• Supply air flow

• Current setpoint FF

• Current actual

value EF

• Extract air fan

• Extract air flow

Current actual

value temperature

• Supply air

• Current setpoint

heating

• Recovery

SERVICE SWITCH

• Auto/Off

Save/Cancel

13

Start page

Quick menu

• Language selection

• Timing program

• Setpoints/Settings

Language selection

• HMI language

+ Alarm snapshot

• Save -> SD

+ Modem

• SMS language

Timing program

Date Time

• Continuous operation

Current value

• Monday

• Copy schedule

• Tuesday

• Wednesday

• Thursday

• Friday

• Saturday

• Sunday

Setpoints/Settings

• All settings

• Timing program

• Setp.comf.heat

• Setp.econ.heat

• Setp.TF step 1

• Setp.TF step 2

• Setp.TF step 3

• Setp.FF step 1

• Setp.FF step 2

• Setp.FF step 3

14

Start page

Main menu

• Log in

• Unit

• Communication

• General func.

• Alarm handling

• System overview

• Overview of IO config./

raw values

• Configuration

Log in

• Password

Unit

• Operating information

• Inputs

• Outputs

• Operating functions

• Setpoints/Settings

• Damper control

• Fan control

• Temperature regulation

• Regulators

• Operating time

Communication

• Comm. modules

• Process bus

• TCP/IP

• Climatix IC

• Modbus

• Modem

• SMS

• Restart

General func.

• Summer/winter mode

• Manual operation

• Activate manual alarm

• Activate comm. test

• Communication test

• Set IO to

• Alarm Snapshot

• Snapshot memory full

• Trend archiving

• Trend archive export

• Trend archive full

Alarm handling

• Alarm reset

Danger (A)

High (A)

Low (B)

Warning (C)

• Alarm output selection

• Alarm output 1

• Modbus alarm

• Process bus comm.

• IO exp. bus

• Comm. module 1

- Communication error

- Status

• Comm. module 2

- Communication error

- Status

• Comm. module 3

- Communication error

- Status

System overview

• Date Time

• Communication

• Application info.

• Versions

• Save/Reset

• Diagnosis

• Trend archiving

• Alarm Snapshot

• Password

administration

• HMI

• Language selection

Overview of IO

config./raw values

• Temperatures

• Pressure/Flows

• Digital inputs

• Digital alarm

• Damper outputs

• Fan outputs

• Temp. control outputs

• Alarm outputs

Configuration

• Configuration 1

• Configuration 2

• Config. lnputs/Outputs

• IO config. control

Duplicated

Not configured

• Set IO to

• Overview, Outputs

• Inputs

• Integrations

15

Start page

Operating information

• Current operating mode

• - Alarm

• Timing program

• Outdoor temp.

• Extract air temp.

• Supply air temp.

• Outdoor air damper

• Exhaust air damper

• Current fan step

• Current setpoint SF

• Current actual value SF

• Supply air fan

• Supply air flow

• Current setpoint EF

• Current actual value EF

• Extract air fan

• Extract air flow

Current actual value, temperature

• Supply air

• Current setpoint, heating

• Recovery

Current operating

mode

• Auto/Off

Save/Cancel

- Alarm

• Current

• Operating status

• SERVICE SWITCH

• Continuous operation

• Timing program

• From BMS

• External control

• Power up delay

Timing program

Current value

• Monday

• Copy schedule

• Tuesday

• Wednesday

• Thursday

• Friday

• Saturday

• Sunday

• Calendar exception

• Exception

• Calendar stop

Outdoor temp.

• Supply air

• Outside

• Extract air

Extract air temp.

• Supply air

• Outside

• Extract air

Supply air temp.

• Supply air

• Outside

• Extract air

Outdoor air damper

• Outdoor air damper

• Exhaust air damper

• Open time

Exhaust air damper

• Outdoor air damper

• Exhaust air damper

• Open time

Current fan step

• Supply air fan

• Extract air fan

Current fan step

• Block high speed

• Setting, operating

time

Current setpoint SF

Current fan step

Current setpoint

supply air

• Step 1

• Step 2

• Step 3

• Max. forced ventilation

• Min. operating time

• Power up delay

• Deviation alarm

• Ext. setpoint

function SF

Current actual value SF

Current value

• Regulator

• Output signal

• Operation

• Alarm

• Setpoints/Settings

Supply air fan

Current value

• Regulator

• Output signal

• Operation

• Alarm

• Setpoints/Settings

Supply air flow

• Supply air flow

• Extract air flow

• Supply air filter

• Extract air filter

Current setpoint EF

Current fan step

Current setpoint

extract air

• Step 1

• Step 2

• Step 3

• Max. forced ventilation

• Min. operating time

• Deviation alarm

• Ext. setpoint

function EF

16

Start page

Operating information, cont.

Current actual value EF

Current value

• Regulator

• Output signal

• Operation

• Alarm

• Setpoints/Settings

Extract air fan

Current value

• Regulator

• Outdoor signal

• Operation

• Alarm

• Setpoints/Settings

Extract air flow

• Supply air flow

• Extract air flow

• Supply air filter

• Extract air filter

Current setpoint,

heating

Current actual value

temperature

Supply air

Current setpoint

heating

• Comfort heating

• Economy heating

Recovery

• Regulator

• Output signal

• Alarm

• Start time

• Start temp.

17

Start page

Main menu

Unit

• Operating information

• Inputs

• Outputs

• Operating functions

• Setpoints/Settings

• Damper control

• Fan control

• Temperature

regulation

• Regulators

• Operating time

Operating information

• Current operating

mode

• - Alarm

• Timing program

• Outdoor temp.

• Extract air temp.

• Supply air temp.

• Outdoor air damper

• Exhaust air damper

• Current fan step

• Current setpoint SF

• Current actual

value SF

• Supply air fan

• Supply air flow

• Current setpoint EF

• Current actual

value EF

• Extract air fan

• Extract air flow

Current actual

value temperature

Supply air

• Current setpoint

heating

• Recovery

Inputs

+Temperatures

• Extract air

• Supply air

• Outside

+Pressure/Flows

• Supply air flow

• Extract air flow

• Supply air filter

• Extract air filter

+Digital alarm

• Supply air fan

• Extract air fan

• Recovery alarm

• Digital inputs

Outputs

+Digital outputs

• Supply air fan

• Extract air fan

• Outdoor air damper

• Exhaust air damper

• Alarm output 1

+Analogue outputs

• Supply air fan

• Extract air fan

• Recovery

Operating functions

Current

Operating status

• SERVICE SWITCH

• Continuous

Operation

• Timing program

• From BMS

• External control

• Power up delay

Setpoints/Settings

• All settings

• Timing program

• Setp.comf.heat

• Setp.econ.heat

• Setpoint, SF step 1

• Setpoint, SF step 2

• Setpoint, SF step 3

• Setpoint, EF step 1

• Setpoint, EF step 2

• Setpoint, EF step 3

Damper control

• Power down delay

• Damper

Fan control

• Supply air fan

• Extract air fan

Current fan step

• Block high speed

• Setting, operating

time

Temperature regulation

Current actual

temperature value

• Temp. setpoints

• Heat recovery

Regulators

• Supply air fan

• Extract air fan

• Heat recovery

Operating time

• Supply air fan

• Extract air fan

• Settings.fan

18

Loading...

Loading...