Flexiheat FHSPN 35, FHSPN 70 Instruction Manual

1. General information

The Original Instruction Manual constitutes an

integral and material part of the product, and is to be

transferred to the user with the transfer of

ownership. It needs to be studied thoroughly and

retained for future reference, as all remarks included

in it provide important hints on safety during

installation, use and maintenance of the appliance.

The heating unit needs to be assembled and

installed with adherence to the standards in force in

the country of operation, according to indications of

the manufacturer, and operated by trained

professionals. Improper device installation might be

the cause of injury to people and animals and of

material damage, for which the manufacturer is not

liable.

The air heating unit may be used exclusively for the

purpose for which it was clearly designed. Any other

use shall be considered improper, and,

consequentially, hazardous.

In case of errors during installation, use or

maintenance that were caused by negligence in

terms of the law in force, of provisions in force or the

Original Instruction Manual (or any different manual

supplied by the manufacturer), the manufacturer is

not liable for any contract or other responsibility for

the arising damages, and the equipment warranty

becomes void.

The choice of heating units for heating buildings is

conducted based on a building thermal heat balance

sheet, with particular consideration of losses

stemming from the transfer of heat to buildings.

2. Foreseen use of the heating unit

The NPS series heating units are foreseen for

heating air in small to medium-sized rooms, in

buildings without a water-based central heating

system.

Thermal heat is generated as a result of combustion,

and the thermal energy is transferred through the

combustion chamber walls and the heat exchanger.

The air heaters are devices ideally suited for:

industrial halls, workshops

warehouses, shops, megastores,

additional burner - pellets) directly from the heat

exchanger tube to the outside environment,

without any intermediate liquid. During

combustion, smoke and other gases are

generated, which are ventilated by the chimney

line.

NOTE!

Due to the specifics of operation of the solid

fuel-fired air heater, operation supervision in

the form of operation parameter control is

necessary.

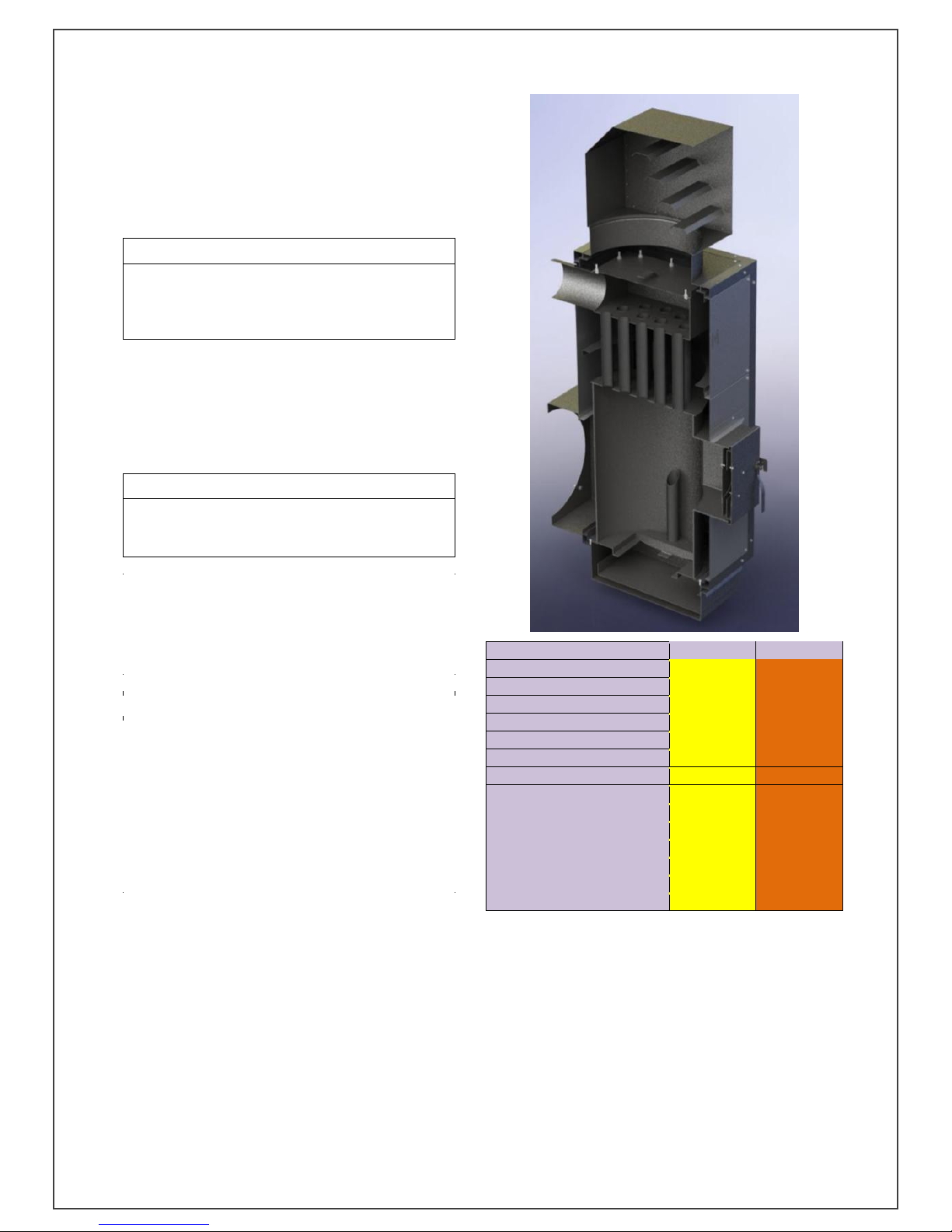

combustion chamber with thermal heat

exchanger (body)

covers

ash tray

cast iron grid

ventilator system

electric switch box with thermostat

air blower.

Thermal heat is generated as a result of combustion

in the combustion chamber, which is equipped with a

cast iron grid. The thermal energy is transferred from

the combustion gases to the ambient fresh air by

means of natural and forced convection.

The air and combustion gases are passed through

different ducts, which are welded and properly

insulated. The emerging combustion gases, after

cooling, are led out through a duct that must be

connected to a chimney or gas duct. The chimney or

gas duct diameter must be sufficiently large to

guarantee effective combustion gas removal. The air

used in the combustion process is taken directly

from the room or building being heated. For this

reason, it is of paramount importance to provide

appropriate ventilation for the heated room or

building that will guarantee the provision of an

appropriate volume of fresh air. The ash emerging in

the combustion process falls to the ash tray, from

which it can be removed without difficulty. The

heated air is distributed around the room through a

rotating blower, which is mounted in the top area of

the air heater.

The electric switch box with thermostat is

responsible for the assurance of electric energy to

the heater fan. When the heater outer casing

reaches the set temperature (35 °C), the fan is

switched on and warm air is distributed around the

room, in which the heater was installed.

3. Heater description

The FHSPN series air heaters are composed

of the following parts:

wholesalers

swimming pools, tennis courts, sports halls

exhibition tents, trade fair stands

religious sites.

The FHSPN series heater is a device generating

thermal heat through combustion of solid fuel

(wood, coal, following the installation of an

The ventilator is automatically shut down if the

heater casing cools down to less than 35 °C.

4. Fuel parameters

HINT!

The wood should be seasoned for at least a

year. Wood humidity exceeding 25% can

cause energy losses and damage to the

heater body.

It is permitted to use replacement fuels with different

quality parameters and of a different granularity as

additions to the basic fuel (up to 10% with respect to

the wood chunk volume), such as waste wood.

When burning small pieces of fire wood note that

they should be separated by large fuel wood chunks.

NOTE!

The NPS series heater is not a furnace for

burning waste, and fuel that is forbidden may

not be burned in it.

NOTE!

Permanent use of certain wet fuel types, with

simultaneous maintenance of low combustion

gas temperature (less than 160 °C) will cause

faster

wear of the heater body, corrosion of the

convection ducts, the flue and tar deposits in the

combustion chamber. This is caused by

condensation of the combustion products: water,

nitrogen oxides and sulphur oxides, which

together form a very aggressive environment

facilitating faster corrosion.

As replacement fuel there may also be used a mix of

nut coal of class 24/12 at 70% with coal dust of class

21/15 at 30% according to the standards indicated

above.

5. Heater technical data

Rated power

35 kW

70 kW

Power supply

230 V 50 Hz

400 V 50 Hz

Energy consumption

1.2 A

1.6 A

Fan air flow

5500 m3/h

12500 m3/h

Width

600 mm

780 mm

Length

1000 mm

1250 mm

Height with head

1400+500 mm

1720+550 mm

Combustion rack chamber dia.

450 mm

620-mm

Combustion rack chamber height

680 mm

860 mm

Smoke stack diameter

150 mm

180 mm

Weight

200 kg

280 kg

Ventilation head rotation

Yes

Yes

Fuel

Wood/coal

Wood/coal

Burner installation option

Yes

Yes

6. Heater transport and assembly

6.1. Transport and storage

The heater units are delivered assembled on pallets,

packed in film.

Use appropriate lifting equipment to raise and lower

the heater. Before transporting the heater, it should

be protected against shifting and tilting on the

vehicle platform by means of belts, chocks or

wooden blocks

The basic fuel for FHSPN heaters is fuel wood in

chunks. It should be seasoned under a roof for a

period of at least two years at a humidity level of 1520%.

Air heater FHSPN 35 FHSPN

70

As replacement fuel for FHSPN type air heaters,

energy coal may be used, nut type, classes 24/12,

type 31-2, according to standard PN-91/G-04510.

The indicated designation of 24/12 concerning fuel

characteristics determines the calorific value to be

approx. 24000 kJ/kg with an ash content of 12%.

This type of fuel guarantees the maintenance of the

declared power values.

Loading...

Loading...