Flexiheat Compact ePlus6, Compact ePlus24, Compact ePlus9, Compact ePlus12, Compact ePlus18 Instructions For Installation, Handling Operation And Maintenance

Instructions for installation, handling operation and maintenance – ENG

Compact ePlus

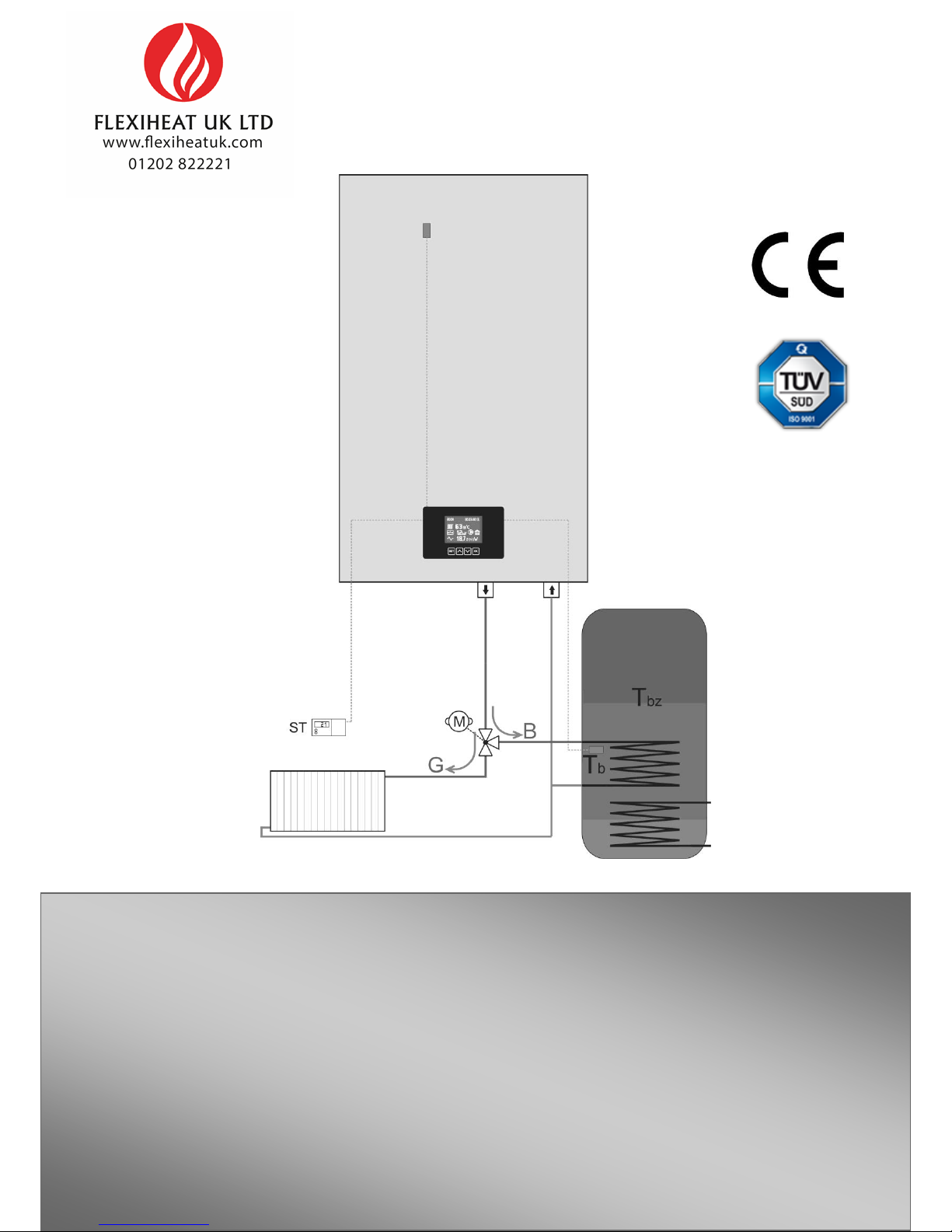

Electric boiler for heating and preparation of sanitary water with processor handling control

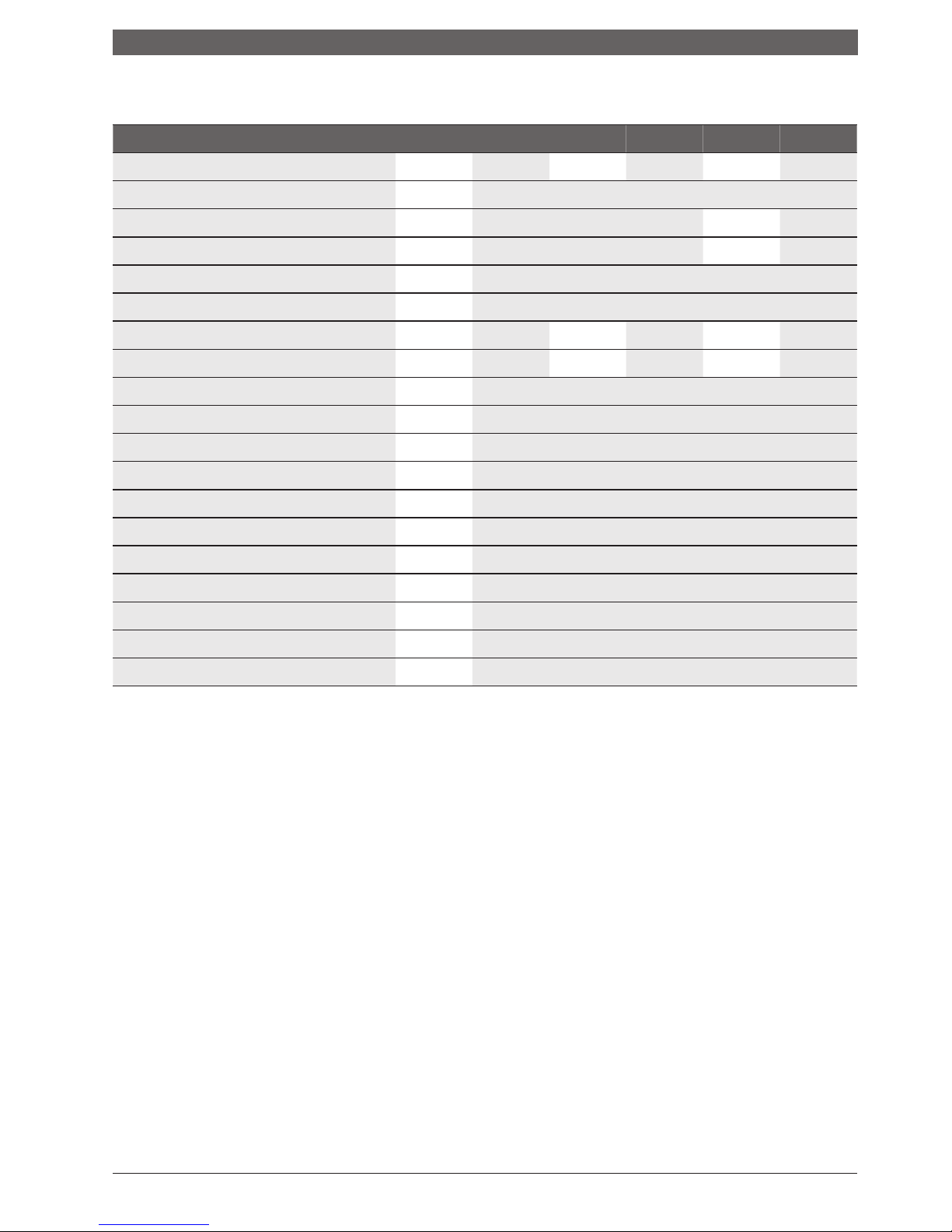

CONTENT

Content

1. Explanation of symbols

2. Device data

2.1. Overview of types

2.2.1 Declaration of Conformity

2.2.2 Proper use

2.3 Installation instructions

2.4 Instructions for operation

2.5 Use of chemicals

2.6 Norms, regulations and standards

2.7 Tools, materials and auxiliary means

2.8 Minimum spacing and hazardous means

2.9 Product description

2.11 Scope of delivery

2.12 Type panel

2.13 Dimensions and technical data

3. Transport

4. Installing

4.1 Caution when installing

4.2 Distance

4.3 Disassembly of the front cover

4.4 Installation of the boiler

4.5 Introduction of hydraulic connectors

4.6 Filling and checking the installation

4.6.1 Filling the boiler with water and testing

4.6.2 Air discharging of the pump and unblocking

4.6.3 Discharge air from the boiler and installation

5. Electrical connector

5.1 Position of the entry for the introduction of the cable

5.2 Connecting the cable

5.3 Connection scheme

5.4 Power cable connection scheme

5.5 External control of the boiler (room thermostat)

6. Putting into operation

6.1 Before putting into operation

6.2 First putting into operation

6.3 Record on putting into operation

7. Handling operation of the heating regime and the preparation of sanitary water of heating

7.1 Instructions for operation

7.2 Overview of the setting elements

7.2.1 Functions of device

7.2.2 Basic settings

7.2.3 Heating regime

7.2.4 Symbols on the display

7.2.5 Symbols and warning codes

7.2.6 Symbols and error codes

7.3 Heating regulation

7.3.1 Regulator of room temperature

7.3.2 Cease of heating

7.4 Putting the boiler out of operation

7.5 Sanitary water preparation regime

7.6 Regime of heating and preparation of sanitary water

8. Cleaning and maintenance

9. Environmental protection and disposal into waste

10. Faults and their remedy

11. Instructions for designing

Explanation of symbols and instructions for safe work

1.

Explanation of symbols and instructions for safe work

1.1 Explanation of symbols

1.2 Instructions for safe work

Instructions and warnings

Warnings are marked with a gray triangle in

the text, and are framed.

The risk of electric shock is indicated by the symbol

of lightning in the triangle, and framed.

Signal words at the beginning of the safety note indicate the

manner and severity of the consequences that threaten

unless there are applied measures to prevent danger.

•

NOTE means that minor material damages may

occur.

•

CAUTION

means that minor or medium-sized injuries

may occur.

•

WARNING

means that serious injuries can occur.

•

DANGER

means that serious injuries can occur.

Important information

Important information, which does not pose a

danger to people or things, is indicated by the

symbol shown in the text below.

They are limited by lines, above and below the text.

Other symbols

Table 1

General safety instructions

Failure to follow the safety instructions can result in serious

injuries - as well as to deadly consequences, material

damages and damage to the environment.

Provide a professional examination of the electrical

installation before installing the device.

All electrical operations must be carried out by a person

authorized to carry out electrical operations, according to

the relevant regulations.

Ensure that putting into operation, as well as

maintenance and repairs are carried out by an

authorized service centre.

Provide technical reception of the installation in

accordance with the relevant regulations.

Danger due to not respecting one's own safety in case of

an emergency, eg. in the event of fire.

Never expose yourself to life threatening situations.

Your

own safety is always a priority

.

Damage caused by wrong handling

Handling errors can lead to injury of persons and/or damage

to the installation.

Make sure that only people who know how to handle

properly the device have access to it.

Installation and putting into operation, as well as

maintenance and repair, must only be carried out

by an authorized service centre with appropriate

authorization for electrical works.

Installation and putting into operation

Leave the installation of the device only to an

authorized service centre.

Always start the boiler only if the installation is at an

appropriate pressure and the operating pressure is correct.

Do

not close the safety valves in any case in order to avoid

damage caused by too high pressure.

During heating,

the water can leak on the safety valve of the hot water

circuit and hot water pipe.

Install the device only in a room where freezing cannot

occur.

Do not store flammable materials or liquids near the

device.

Keep a safe distance according to applicable regulations.

Symbol

Meaning

Step of the action

Guidance to other places in the document or to other

documents.

•

Listing/Entry from the list

–

Listing/Entry from the list (2.)

Explanation of symbols and instructions for safe work

Life-threathening danger from electric shock

Leave the introduction of electrical connection to an

authorized service technician. Follow the connection

scheme.

Before all works: disconnect the electric power supply.

Secure youself from accidental turning on.

Do not install this device in wet rooms.

Inspection / maintenance

Recommendation for the user: Make a maintenance

contract with an authorized service centre, that will

perform annual maintenance and control checks.

The user is responsible for the safety and

environmental acceptability of the installation.

Follow the safety instructions for safe work which are to b

found in the chapter

‘Cleaning and maintenance’

.

Original spare parts

No liability can be claimed for damages arising because of

the spare parts which are not supplied by the manufacturer.

Use only original spare parts.

Material damages from freezing

In the event of a risk of freezing, drain the water from the

boiler, tank and pipes of the heating system.

The risk of

freezing does not exist only when the entire installation

is dry.

Instructions for service technicians/centres

Inform the users about the operating mode of the device and

maintenance.

Inform the users that they must not make any changes

or repairs on their own.

Warn the users that children without adult supervision

should not be kept near the heating installation.

Fill in and submit the “Putting into operation” and

“Take-over Minutes” contained in this document.

Hand over the technical documentation to the user.

Disposal into waste

Dispose of packaging in an environmentally acceptable

manner.

Dispose of the device in an environmentally acceptable

manner at an authorized place.

Cleaning

Clean the device with a damp cloth from the outside.

Device data

2.

Device data

These instructions contain important information on safe and

professional installation, putting into operation and

maintenance of the boiler.

These instructions are intended for installers who, on the

basis of their expertise and experience, have knowledge in

working with heating installations.

2.4 Instructions for operation

When working with the heating installation, observe the

following instructions:

The boiler should work in the working area up to a maximum

temperature of 80 °C, a minimum pressure of 0.8 bar and a

maximum pressure of 2.2 bar, and should be monitored regularly.

2.1 Overview of types

These instructions apply to the following types:

Compact ePlus

6-24k

W

2.2.1 Declaration of Conformity

We declare that the devices have been tested in

accordance with Directives 2006/95/EC (Low Voltage

Directive, LVD) and 2004/108/EC (Electromagnetic

Compatibility Directive, EMC).

2.2.2 Proper use

The boiler can only be used for heating the heating water and

for the indirect preparation of hot water. In order to ensure

proper use, it is necessary to comply with operating

instructions, data on the factory tile and technical data.

The boiler should only be handled by adults who are familiar

with the instructions and the work of the boiler.

Do not close the safety valve.

Inflammable objects must not be placed on or near

the boiler (within the safety distance).

Clean the surface of the boiler only with non-combustible

materials and agents.

Do not keep inflammable things in the room intended for

installation of the boiler (eg. petroleum, oil).

No cover must be opened during operation.

Keep a safe distance according to the local valid

regulations.

2.3 Installation instructions

2.5

Anti-freezing agents and inhibitors

Use only original spare parts of the manufacturer or

spare parts approved by the manufacturer.

No

liability is assumed for damages arising because

of the spare parts that are not supplied by the

manufacturer.

When installing a heating installation, follow the

following instructions:

•

valid construction regulations

• regulations and norms on the safety and technical

equipment of the heating installation

It is not allowed to use anti-freezing agents or inhibitors.

If

the use of the anti-freezing agent cannot be avoided, there

should be used anti-freezing products that are permitted for

heating installations.

Use of anti-freezing agents

:

shortens the lifetime of the boiler and

its parts

reduces the transfer of heat

• changes at the place of installation in accordance

with applicable regulations

Device data

2.6 Norms,

regulations and standards

2.7 Tools, materi

als and auxiliary means

The product is in compliance with the following norms and

regulations:

Fo

r installation and maintenance of the boiler, standard tools

•

EN

50110-1:2003

–

handling and operation with

electrical installations

•

EN

55014:2001

– electromagnetic compatibility

conditions for household devices, electrical devices and

similar devices

•

EN 60

335-1+ed.2:2003

- electrical household

devices

•

EN 60

335-1+ed.2 zm.A

1:2005

- electrical household

devices

•

EN

61000-3-2 ed

.3:2006

- electromagnetic compatibility

(EMC)

– the limit for the harmonic current emission

•

EN

61000-3-3:1997

- electromagnetic compatibility (EMC

)

–

Law on the limitation of voltage fluctuations and

flickering of the low-voltage partition network

Certificates provided by accredited laboratory no.:

LVD standards : 08131402 i.no: I-005 10.01.2014

EMC standards : 071375680 i.no: I-005 10.01.2014

from the field of heating, plumbing and electrical installations

are required.

Device data

2.8 Minimum spacing and

flammability of construction

materials

2.9 Product description

The basic components of the boiler are

:

Depending on the applicable regulations, other minimum

distances, other than those mentioned below, may be valued.

Follow the regulations on electrical installations and the

minimum distances in force in the countries concerned.

The minimum distance for heavily flammable and

self-extinguishing materials is 200 mm.

Flammability of component elements

A

non-flammable

A

1:

non-flammable

Asbestos, stone, ceramic wall tiles,

baked clay, mortar, (without organic

additives)

A

2:

with a small

amount of

inflammable

additional

elements (organic

components)

Panels made of plasterboard,

panels made of basac felt,

glass fibres,

panels made of

ACUMIN,

ISOMIN; RAJOIT,

LOGNOS, VELOX

and

HERACLI

T

B

flammable

B

1:

hardly

inflammable

Beech,

oak, veneered wood,

felt,

panels made of HOBREX,

VERZALIT i

UMAKART

B

2:

normally

flammable

Pine, larch and spruce, veneered

wood

B3:flammable

Asphalt, cardboard, cellulosic

materials, waterproofing tape, panels

of chipboard, cork, polyurethane,

polystyrene, polyethylene, floor

fibrous materials

Table 3 Flammability of component elements according to DIN

4102

•

Container of the boiler

with associated components

•

Frame of the device and the shell of the boiler

•

Control unit

•

Pum

p

•

Expansion container (according to capacity)

• Processor board and electronics of the

boiler

•

Water pressure sensor

•

Safety valve

The boiler can be installed as an integral part of the central

heating system, floor heating, and hybrid or accumulation

systems.

The boiler consists of a welded housing made of steel sheet with

thermal insulation. The boiler is fixed to the wall by using a frame and

the delivered installation kit.

Built-in thermal insulation in the shell

of the boiler reduces loss of heat.

At the same time, the

insulation also protects against noise.

The safety elements (valve for discharging of air, fuse of the

control surface, safety temperature limiter) are located at the

top of the boiler.

Depending on the type of boiler, electric heaters of different

power are used. The power of the boiler can be precisely

adjusted. The setting of different levels of power of the

boiler is done by using the buttons on the dashboard. The

number of levels of power is given in the table

(chapter

2.13.2

)

Device data

1 UL

return

line of the boiler

2 IZ

starting line of the

boiler

3

Exchanger of the boiler

4

Electric heaters

5

Exspansion container

6

Pump

7

Valve for discharging of air (on the

pump)

8

Power line for the pump

9

Drainage tap

10

Automatic air discharger

11

Automatic fuses

12

Clamp for thermostat

13

Network board

14

Relays of electric heaters

15

Clamps of electric heaters

16

Strain relief connector for electric cable

17

Control panel with display

Device data

2.10 Waste disposal

Dispose of packaging in an environmentally acceptable manner.

Take care that the components are replaced in an

environmentally acceptable manner.

2.11 Content of packaging

When delivering the boiler, comply with the following:

Make sure that the packaging is undamaged on

delivery.

Check whether the delivery is complete.

Part

number of pieces

Boiler

Compact ePlus

1

Installation kit

1

Manual

1

2.12 Factory tile

The factory tile is located on the outside of the boiler and contains the following technical data:

•

type of boiler

•

serial number/catalog

number

•

power

•

input power

•

maximum temperature

•

work pressure

•

volume of boiler’s container

•

mas

s

•

electric power supply

•

level of

protection

• manufacturer

Device data

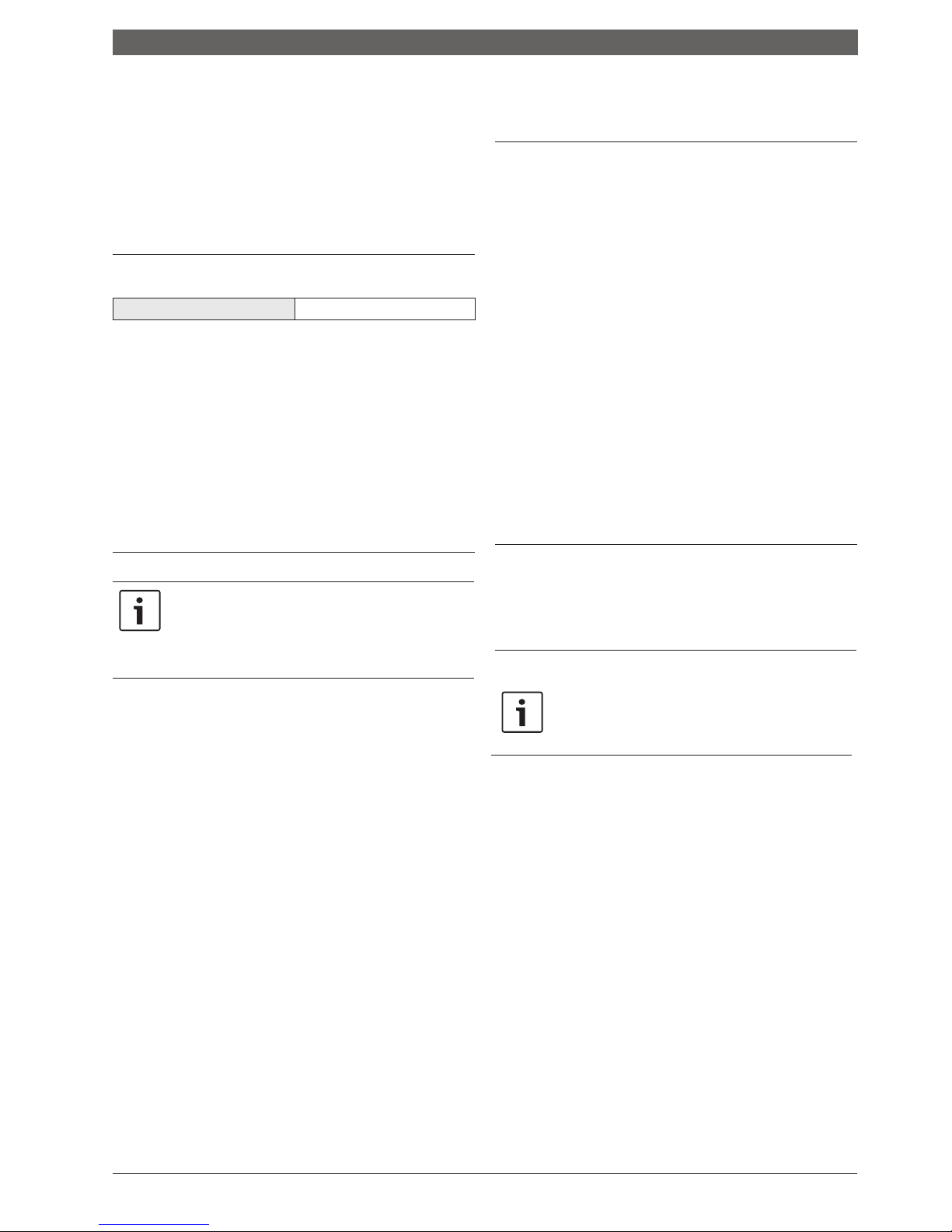

2.13 Dimensions and technical data

2.13.1 Dimensions and technical data for boiler Compact ePlus

DS – Bottom side; FS – Front side; LS – Left side; TS – Upper side; BS – Back side

Image number 2 Dimensions and connectors

Device data

2.13.2 Technical data

Power

Degree of utilization

Number of degrees of power

Division of degrees of power

unit

ePlus

6

k

W

6

%

3

3x2

ePlus

9

ePlus

12

ePlus

18

ePlus

24

9 12 18 24

99

6 6 9 9

6x1,5 6x2 9x2 9x2,7

Network voltage

Protection level

Required fuses

V AC

3x400/230 50Hz

IP40

A

16 20 25 32 40

Minimum intersection of

introductory cable

Safety valve

Max. permissible operating pressure

Min. permissible operating pressure

Max. temperature

of the boiler

Volume of water in the boiler

Volume of expansion container

Connector of starting line

Connector of return line

Mass of device (without water)

mm 5x2,5

bar

bar

bar

˚C

l

l

col

co

l

k

g

5x2,5 5x4 5x4 5x6

3

2,2

0,8

80

12,5

7

G3/

4

”

G3/

4

”

25

Dimen

sions

mm

Processor umit

Table: Technical data of the device Compact ePlus

700x430x230 (HxWxL)

YES

Transport

3.

Transpor

t

NOTE:

Transport damage

Pay attention to the transport instructions

that are written on the packaging.

Use a suitable transport vehicle, e.g. trolley for

bags with clamp tape.

The product should be in

the lying position during the transport.

Avoid impacts or crashes.

Put the packed boiler on the trolley for bags, if necessary,

secure it with the clamp strip and transport it to the place

where it will be set.

Remove packaging accessories.

Remove boiler’s packaging material and dispose of

it in an environmentally acceptable manner.

Installation of the device

4.

Installation of the device

CAUTION:

Human or material damages

caused by improper installation!

Never install the boiler without an expansion

container (AG) and a safety valve

.

The boiler must not be installed in the protective

zone of the wet area and the area where a bathtub

is located.

NOTE:

Material damages from freezing!

The boiler may only be installed in rooms where

freezing cannot occur.

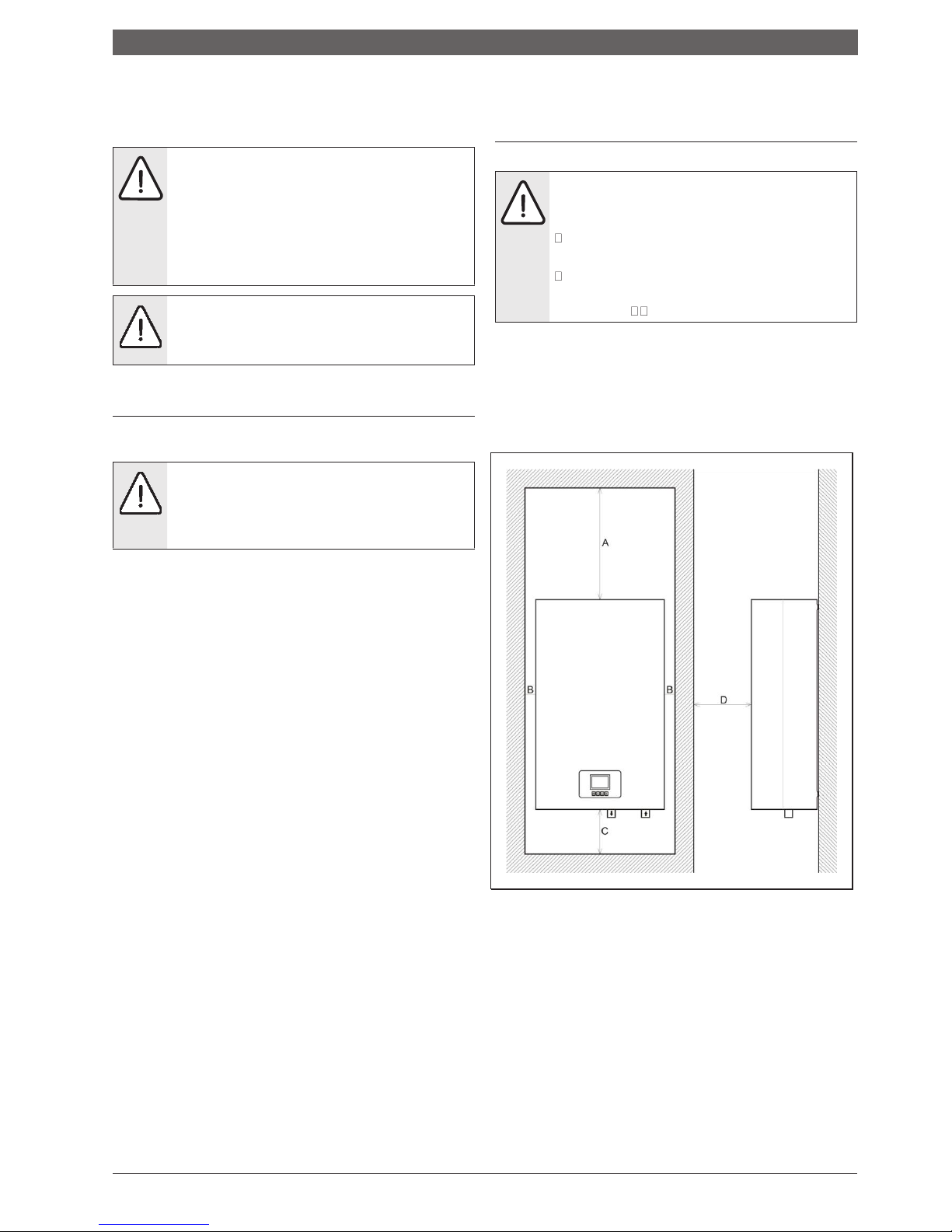

4.2 Distance

DANGER: Fire hazard due to flammable

materials or liquids!

Do not dispose of flammable materials or

liquids near the boiler.

Inform the user about applicable regulations

of minimum distances from highly flammable

materials ( chapter 2.8, page 7).

4.1 Be careful about the following

before installation

NOTE:

Material damages caused by non-

compliance with further instructions!

Follow the instructions for the boiler and all

installed components.

•

follow the regulations on electrical installations

and the minimum distances which are in force in

the countries concerned.

•

set the boiler on the wall in such a way that there remains the

minimum free space as shown in Image no.3

Before installing, keep an eye on the following

:

•

all electrical connections, protection measures and

fuses should be carried out by an authorized person,

complying with all applicable norms and regulations

as well as local regulations.

•

the electrical connection must be carried out according to

connection schemes.

•

after proper installation of the device, carry

out the grounding.

•

switch off the electric power before opening and

all operations.

•

unprofessional and unauthorized attempts of

connection can cause material damages to the device

and lead to dangerous electric shocks.

A = 500

mm / B = 50mm / C =

200

mm / D =

500

mm

Image number 3 Minimum distances during installation

Installation of the device

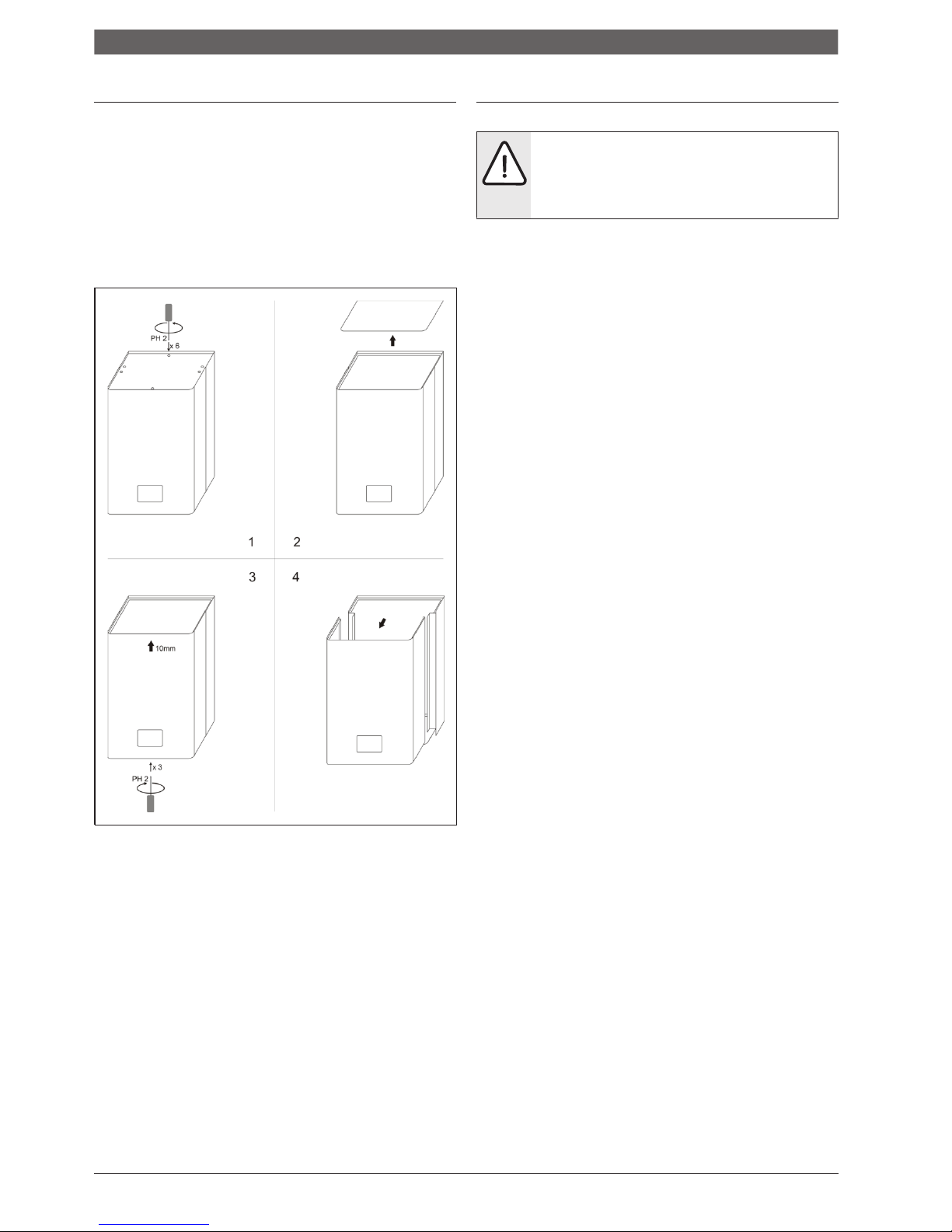

4.3 Disassemble the front cover of the boiler 4.4 Installation of the boiler

The shell of the boiler can be removed for easy handling and

installation.

Unscrew the screws on the top

cover.

Unscrew the screws on the bottom

cover.

With a slight pulling towards you, disassemble the front

shell of the boiler.

NOTE:

Material damages caused by

improper installation onto wall!

Suitable material for fixing should be used

This chapter describes installation of the boiler on the wall.

Draw the positions of openings for drilling for the installation kit

according to the dimensions shown in Image 2.

Take care when marking the openings for the installation

in order to allow the boiler to stand vertically.

Drill the holes in the wall with an adequate drill.

In the drilled holes, place the plastic anchors that are part

of the package of the device (or the anchors that are

adequate for some non-standard type of wall).

Then screw in the bolts that are supplied together with the

anchors (or some other) so that they stick out of the wall

min 5mm and maximum 10mm.

Carefully attach the device to the wall, make sure that the

boiler is installed vertically.

Fix the boiler from the inside with the nuts from the

installation kit.

Image number 4 Opening of the boiler (disassembling of the front shell)

Installation of the device

4.5

Introduction of hydraulic connectors

NOTE:

Material damages caused by

throughput connectors!

Install the connection lines without connecting to

the connectors of the boiler.

NOTE:

Damages to the installation due to poor

water quality! Depending on the properties of the

water, the heating installation may be damaged

by corrosion or by the formation of limescale.

Follow the requirements for water for filling

according to VDI 2035, i.e. project documentation

and the catalog.

Connect the heating lines as follows:

Connect the return line to the IN connector.

Connect the starting line to the OU

T

connector

.

Check the pre-pressure of the expansion container.

Open the charging and discharging tap.

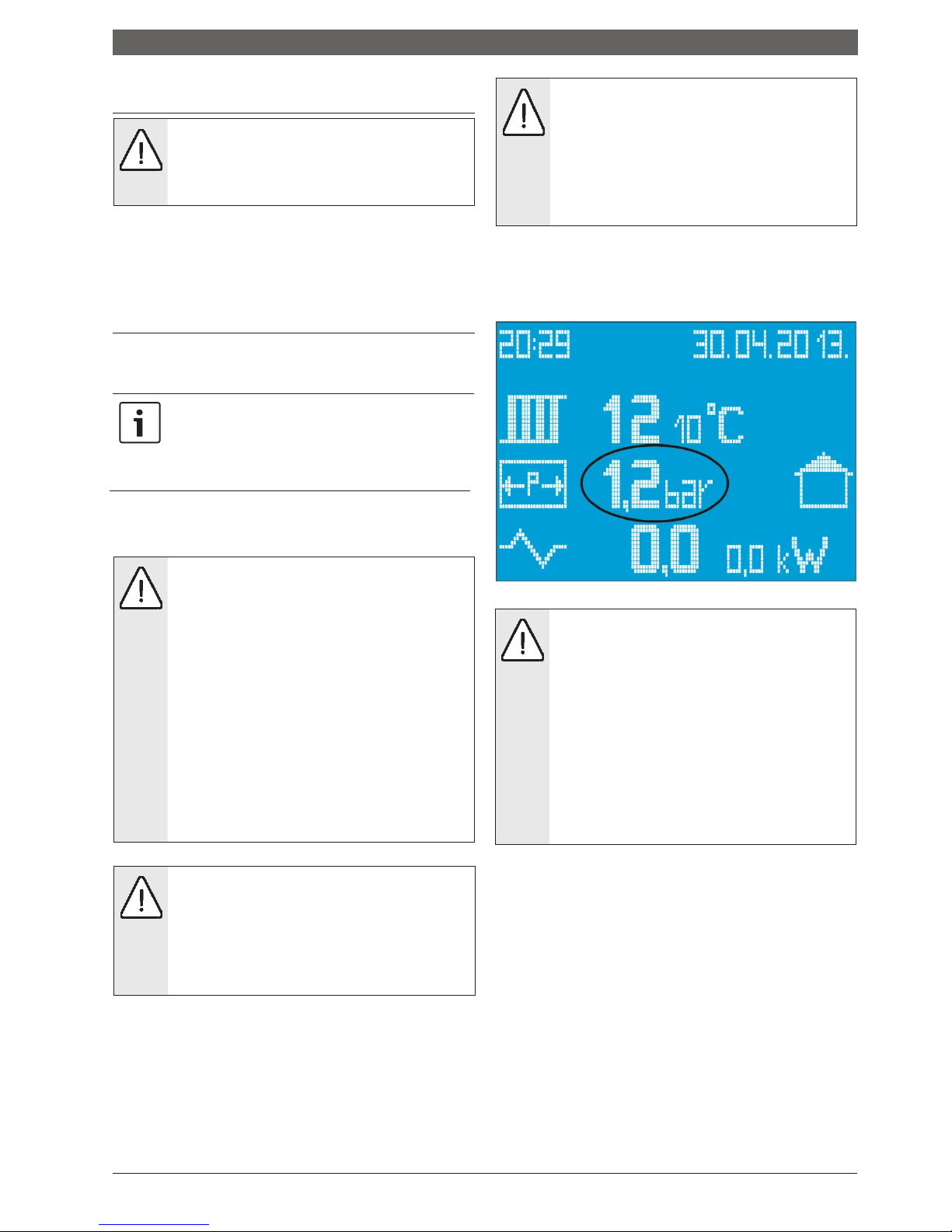

Fill the boiler slowly. Follow the pressure on the display.

4.6 Fill the installation and check the

impermeability.

Before filling the system, the boiler must be connected

to the electrical installation and switched on via the

ON/OFF switch on the bootom side of the boiler to the

STAND BY mode in order to monitor the value of

pressure in the installation.

4.6.1 Fill the boiler with water (demineralized water is

recommended) and test the welds and seals

The impermeability must be tested before putting the boiler into

operation.

DANGER: Injuries and/or material damages

can occur by exceeding the pressure during

the testing of impermeability!

High pressure can damage the control and safety

devices as well as the tank itself.

Fill the boiler with pressure that corresponds to

the pressure of the opening of the safety valve.

Observe the maximum pressure of the built-in

components.

After checking the impermeability, re-open the

valves.

Ensure that all control and safety parts

for pressure control work properly.

DANGER: Danger to health due to mixing

drinking water!

Be sure to follow national regulations

and norms to avoid mixing drinking water

(eg. with water from heating installations).

please follow EN

1717.

Image number 5 Display with highlighted pressure

NOTE:

Material damages caused by

temperature stress.

If you fill the boiler in a warm/hot condition, the

temperature stresses can cause cracks due to

straining. The boiler will start to leak water.

Fill the boiler only in cold condition (the

temperature of starting line may be maximally

40°C).

Fill the boiler only through the quick valve on the

boiler's pipe installation (return line).

Close the tap when the operating pressure is reached.

Discharge the air from the boiler through the valve for air

discharging

(image 5

and image 6).

Discharge the air from the installation via the valve on

the radiator.

When the operating pressure is lowered by discharging of

air, the water must be refilled.

Test the impermeability according to local regulations.

After checking the impermeability, open all the items

that you closed because of the filling.

Make sure all the security elements work correctly

If the boiler is tested for impermeability and no leakage has

been detected, set the correct operating pressure

Loading...

Loading...