Page 1

Hydraulic Flexco® XP™ Staple Fastener

Installation System

Safety, Operation, and Maintenance Manual

h I Mb

WARNING

Improper use of this tool can result in serious bodily injury! is manual contains important information about

product function and safety. Please read and understand this manual BEFORE operating the tool. Please keep this

manual available for other users and owners before they use the tool. is manual should be stored in a safe place.

www.flexco.com

www.flexco.com

Page 2

Hydraulic Flexco® XP™ Staple Fastener System

Table of Contents

Introduction .................................................................................................................................... 3

Tool Specications ..........................................................................................................................3

System Components .................................................................................................................. 4-6

General Safety Rules ................................................................................................................... 7-9

Operational Instructions .............................................................................................................10

Belt Preparation ............................................................................................................................11

Installation Instructions ........................................................................................................11-17

Troubleshooting Guide ................................................................................................................ 18

Power Diagram .............................................................................................................................19

CE Declaration ..............................................................................................................................20

Limited Warranty

Flexco warrants to the original purchaser that this product is free from defects in material and workmanship, and

agrees to repair or replace, at Flexco’s option, any defective product within 1 year from the date of purchase. is

warranty is not transferable. It only covers damage resulting from defects in material or workmanship, and it does not

cover conditions or malfunctions resulting from normal wear, neglect, abuse, accident or repairs attempted or made by

other than our regional repair center or authorized warranty service center.

To obtain warranty service, return the product at your expense together with proof of purchase to Flexco or a Flexco

authorized distributor.

ww w.flexco.com

—2—

Page 3

Hydraulic Flexco® XP™ Staple Fastener System

Introduction

Role of Applicator

e Hydraulic Staple Applicator is designed to be used with Flexco® XP Staple Fasteners.

Precision Built

Flexco tools are precision-built tools designed for precise, high volume installation. ese tools will deliver ecient, dependable

service when used correctly and with care. As with any ne power tool, for best performance, the manufacturer’s instructions must

be followed. Please study this manual before operating the tool and understand the safety warnings and cautions. e instructions

on installation, operation, and maintenance should be read carefully, and the manual kept for reference.

Flexco® XP™ Hydraulic Staple Applicator

Specifications

Overall weight 26 kg

Overall dimensions 559 mm x 482 mm

Operating pressure 110 bar, 11 Mpa, 1600 psi

Min. pressure 103 bar, 10.3 Mpa, 1500 psi

Max. pressure 117 bar, 11.7 Mpa, 1700 psi

Flow rate 7-9 L/m, 1.5-2 GPM

Hydraulic fluid MSHA approved fire resistant hydraulic fluid, MA approved #46 or equivalent (not included)

Coupling ISO 16028 compliant couplings, flat face quick release coupling

High pressure in: Female 3⁄8” body size

Low pressure return: Male ½” body size

Max. hose length

(hoses included with

Flexco power source

purchase)

10 meters, 32.8 feet

High pressure hose (smaller hose OD), each end has factory installed male and female 3/8” body size

couplings

Low pressure return hose (larger hose OD), each end has factory installed male and female 1/2” body size

couplings

—3—

Page 4

Hydraulic Flexco® XP™ Staple Fastener System

System Components

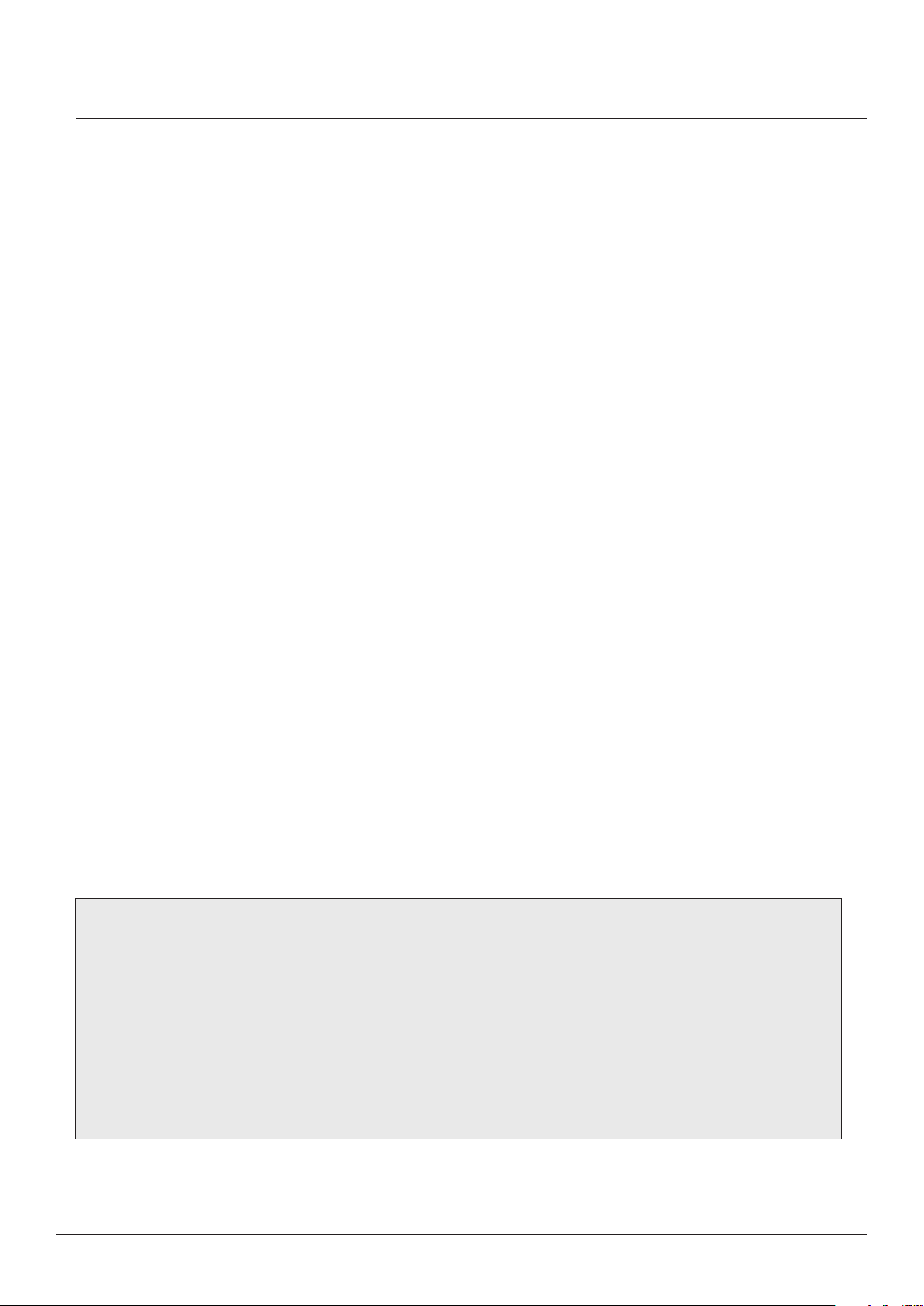

Flexco® XP™ Hydraulic Staple Applicator

1. Advance/actuation handle 6. Advance mechanism lever

2. Carrying handle 7. Hydraulic cylinder

3. Fastener compression adjustment knob and lock 8. High pressure in: 3/8” Female quick release coupling

4. Integrated belt thickness gauge 9. Low pressure return: 1/2” Male quick release coupling

5. Mounting bracket 10. Standalone belt thickness gauge

1

3

2

7

9

4

5

6

8

10

ww w.flexco.com

—4—

Page 5

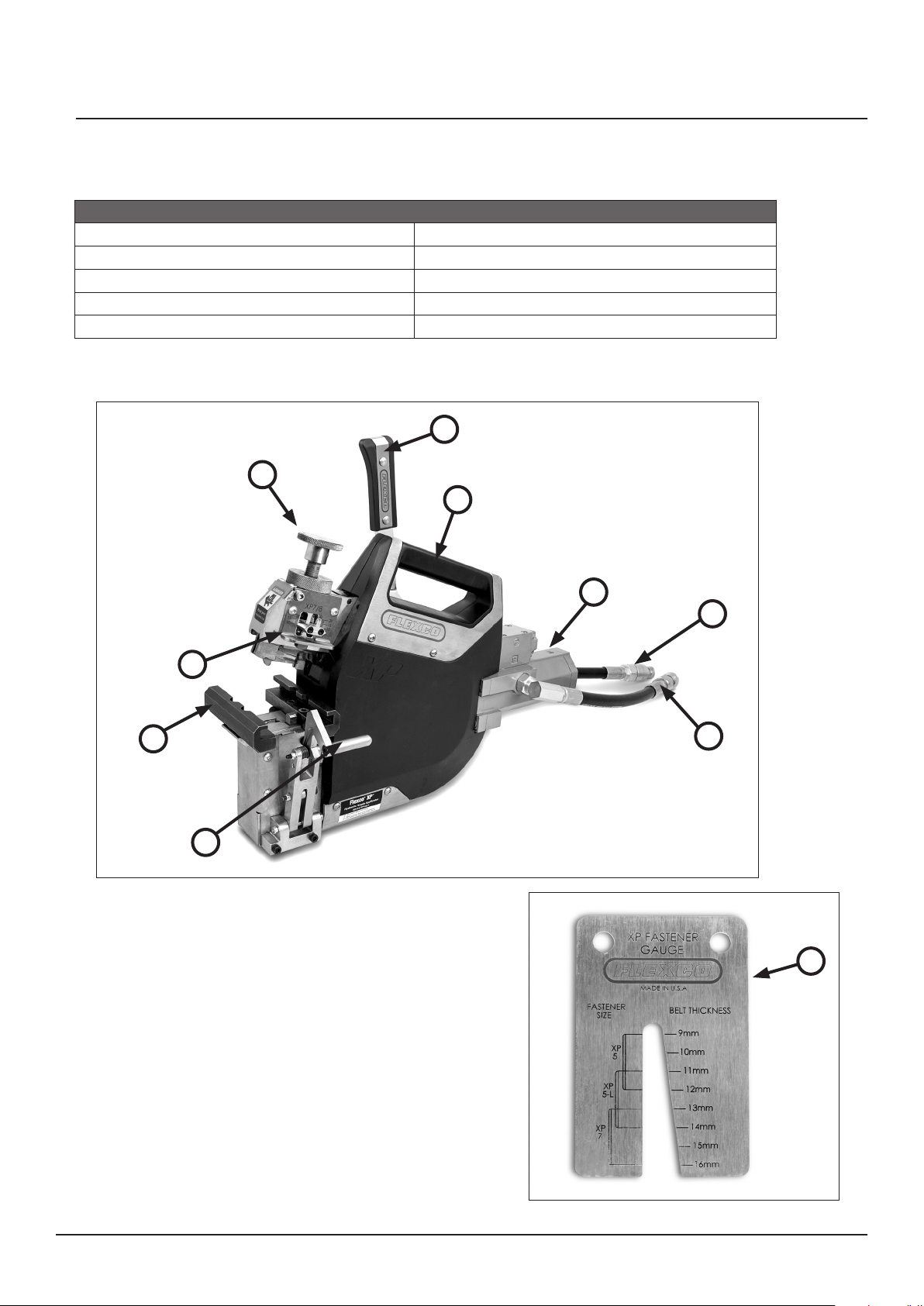

Hydraulic Flexco® XP™ Staple Fastener System

System Components

Flexco® XP™ Staple Tool Frame

1. Frame 4. Clamp bar

2. Belt guide plate 5. Bed

3. Clamp bar handle 6. Hydraulic staple applicator

6

4

3

5

2

1

—5—

Page 6

Hydraulic Flexco® XP™ Staple Fastener System

System Components

Flexco® XP™ Staple Fasteners

1. Fastener Strips

2. Hinge Pin

2

1

Protective Equipment

1. Safety Glasses

2. Gloves

3. Hearing Protection

4. Safety Shoes

Power Source

Immediate Need Power Pack

– For mobility throughout the mine

– OR –

1 2

3 4

Power Take-off Unit (PTO)

– For diverting hydraulic power from your conveyor at the mine

ww w.flexco.com

—6—

Page 7

Hydraulic Flexco® XP™ Staple Fastener System

General Safety Rules – Save These Instructions

Signal words

“DANGER” indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury. e signal word is

limited to the most extreme situations.

“WARNING” indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used to

alert against unsafe practices.

International Safety Symbol

!

is international safety symbol is used

to identify and call attention to specic

safetymatters.

Safety Information

To Avoid Severe Personal Injury or Property

Damage, read carefully and understand the

following Safety Precautions.

2. PERSONAL PROTECTIVE EQUIPMENT

!

WARNING

EYE PROTECTION which conforms to ANSI specications and provides protection against ying particles

both from the FRONT and SIDE should ALWAYS be

worn by the operator and others in the work area. Eye

protection is required to guard against ying debris,

which could cause severe eye injury.

e employer and/or user must ensure that proper

eye protection is worn. Eye protection equipment

must conform to the requirements of the Ameri- can

National Standards Institute, ANSI Z87.1 and provide

both frontal and side protection. NOTE: Non-side

shielded spectacles and face shields alone do not provide

adequate protection.

!

CAUTION

HEARING PROTECTION will be required in some

environments. For example, the working area may

include exposure to noise level which can lead to

hearing damage. e employer and user must ensure

that any necessary hearing protection is provided and

used by the operator and others in the work area.

!

CAUTION

HEAD PROTECTION – Some environments will

require the use of head protection equipment. When

required, the employer and user must ensure that

head protection conforming to ANSI Z89.1 is issued.

FOOT PROTECTION – Safety footwear should

always be worn. Operators must be protected against

falling tools and slippery conditions.

HAND PROTECTION – Safety gloves should always

be worn against hot surfaces and other sharp objects.

—7—

Page 8

Hydraulic Flexco® XP™ Staple Fastener System

General Safety Rules

3. PERSONAL SAFETY

!

WARNING

Do not use in explosive environments as this may result in serious personal injury.

Always handle the tool with care: 1.) Never engage in horseplay; 2.) Never pull the advance/actuation handle unless the

applicator is loaded onto the bed/frame base; 3.) Keep others a safe distance from the tool while tool is in operation as

accidental actuation may occur, possibly causing injury; 4.) Never place a hand or any part of body in the downward path of

the head applicator.

Potential Pinch Points

1. Adjustment Knob & Tool Cover

2. Tool Head & Clamp Bar

Potential Hot Surfaces

Do not operate the equipment if you are:

1.) Taking medication, feeling drowsy, feeling unwell or feeling tired; 2.) Under the inuence of drugs or alcohol; 3.) Experiencing

pain in hands, feet, lower back, or other parts of your body hurt or are injured. Failure to observe this precaution can result

serious injury or even death.

3. Tool Head & Bed (Fastener)

4. Hydraulic Tool & Frame

1

2

3

4

5

5. Clamp Bar & Bed (Belting)

6. Tool Advance & Cover Plate

6

!

CAUTION

Do not touch the machine with your bare hands: 1.) e oil tank may become hot under continuous running; 2.) Tools may

become hot under continuous use, make sure to wear safety gloves before any contact with the tools. Failure to observe this

precaution can result in burn injuries.

When lending someone the equipment, make sure the safety instructions have been thoroughly read and fully understood by

the person who is going to use the equipment.

ww w.flexco.com

—8—

Page 9

Hydraulic Flexco® XP™ Staple Fastener System

General Safety Rules

4. HYDRAULIC SAFETY

!

DANGER

is hydraulic tool is only designed to be used to

install Flexco XP staple fasteners. DO NOT operate

this hydraulic tool when: 1.) Part of the tool or whole

tool has been drenched in water or seawater; 2.) e

power source exceeds the oil ow and pressure range

prescribed; 3.) Operating with oil temperature below

10°C or over 100°C.

Do not operate hydraulic applicator unless it is

loaded onto the bed/frame base.

!

WARNING

At the beginning of each shi, conduct a TOOL

OPERATION CHECK: 1) Remove all fasteners from

tool before performing tool operation check; 2.) Do

not use if there is any oil leakage from hoses or tool

itself; 3) Do not use if there is damage to the tool.

Spilled hydraulic oil can cause burns, accidents

due to slippery conditions, and will also harm the

environment: 1) Take care of all spilled oil and

handle it according to your safety and environmental

regulations; 2) Avoid getting hydraulic oil on your

hands; 3) Always use protective gloves when working

with hydraulic oil; 4) Wash hands aer contact with

hydraulic oil.

At the end of operation, secure the tool to prevent

unauthorized use. Never assume you will nd the

equipment in the same condition in which you le it.

Never leave a tool unattended with the hoses

attached.

!

CAUTION

Always carry the tool by a handle.

Do not alter or modify this tool from the original

design or function without approval from FLEXCO.

Always be aware that misuse and improper handling

of this tool can cause injury to yourself and others.

5. MAINTENANCE SAFETY

!

DANGER

Always disconnect hydraulic hoses at tool and

electric supply at power pack when servicing the tool

or before making adjustments.

!

CAUTION

REPLACEMENT PARTS:

FLEXCO replacement parts are recommended. Do

not use modied parts or parts which will not give

equivalent performance to the originalequipment.

When using the machine to perform work-related

activities, you may experience discomfort in the hands,

arms, shoulders, neck, or other parts of the body: 1)

Adopt a comfortable posture while maintaining secure

footing and avoid awkward o-balanced postures; 2)

Changing posture during extended tasks may help

avoid discomfort and fatigue; 3) In case of persistent

or recurring symptoms, consult a qualied health

professional.

Do not store tool in a cold weather environment to

prevent frost or ice formation on the tool's operating

valves and mechanisms that could cause tool failure.

—9—

Page 10

Hydraulic Flexco® XP™ Staple Fastener System

Operational Instructions

Guidelines

1. When using hydraulic power units not manufactured by Flexco, make sure the operating pressure of the power unit is

110bar, 11 Mpa, 1600 psi and ow rate is in the range of 7-9 L/m (1.5-2 gpm).

2. When connecting and disconnecting couplings, make sure dirt, dust, and other foreign substances do not enter or attach to

coupling and hoses.

3. Make sure the power unit is OFF when connecting the hydraulic tool to the power unit.

!

4. If the oil temperature is below 10°C, warm up the hydraulic tool before operating.

!

5. Do not trip over the hydraulic hoses.

6. Make sure there are no jobsite obstacles.

!

7. Be cautious not to injure your back while liing the hydraulic tool.

!

8. In case of sudden hydraulic hose breakage STOP the power unit IMMEDIATELY.

!

9. Replace with new hoses when they are worn or when oil exudes from them.

10. When couplers detach, a small amount of oil may leak out. Make sure that surrounding area does not get drenched in oil.

11. To prevent dirt from entering the quick release couplings, be sure to clip couplings together aer disconnecting driver.

Couplings should be wiped down before clipping them together.

12. When detached from power source, attach two hoses to each other. Couplings should be wiped down before clipping

them together.

13. When frequently attached and detached to the power unit, hydraulic oil will decrease accordingly. Always check the

hydraulic oil level before operating and rell if necessary.

Tool Inspection

Examine the tool before applying fasteners.

• Clean any dirt build-up from the bed rails.

• Check the hydraulic applicator to make sure the mounting brackets are free from dirt build-up.

• Check for any nicks in the bed that may interfere with the movement of the head. Should any nicks be found, they should

be led o before using the tool.

• Ensure applicator moves freely on bed. If not spray SLP5 GLIDE silicone lubricant on bed rails and

mounting brackets for smoother operation.

• Inspect swipe arms, pusher tip and front/rear locator prongs for damage, chips or cracking. Replace

damaged parts by authorized distributor.

ww w.flexco.com

—10—

Page 11

Hydraulic Flexco® XP™ Staple Fastener System

R9

BR14 R6/R8

R5½

BR10 R5/190

BR6 140

Belt Preparation

1. Square belt using centerline method.

2. Cut belt at least 4" (100 mm) behind old splice

using Flexco belt cutting tool.

Installation Instructions

1. Select the Proper Fastener and Hinge Pin

a. Measure the belt thickness from cut edge

using belt gauge or tape measure.

b. determine the diameter of the smallest pulley

in the system which the belt will wrap at least 90º

(including the belt take up and storage unit) and

the mechanical fastener rating of the belt.

3. Skive belt when top cover permits. Adjust

fence on FSK2 skiver to the R5 setting for XP5/

XP5-L, half way between R5 and R5 1/2 for XP7,

and to the R5 1/2 setting for XP8.

Flexco® XP Staple Belt Fastener Selection Chart

A B C D

Fastener

Size

XP5 2000 1150 9-12 350 8.1

XP5-L 2000 1150 11-14 350 8.1

XP7 3500 2000 13-15 500 10.3

XP8 3500 2000 15-18 500 11.0

XP8-L 3500 2000 17-20 500 11.0

c. Refer to the table above to select the proper size fastener.

Belt

Strength

kN/m P.I.W. mm mm mm

Tension

Rating

Belt Thickness

Range

Recommended

Min. Pulley Diameter

—11—

Max. Hinge Pin

Diameter

Page 12

Hydraulic Flexco® XP™ Staple Fastener System

Installation Instructions (continued)

2. Load the Fasteners

1-1/2 inches

(38 mm)

a. Determine the exact number of fasteners needed for the belt by

laying strips of fasteners across the belt end. Center fasteners so that

approximately 1-1/2 inches (38 mm) of belt extends beyond the

fasteners on each edge.

b. If a shorter fastener strip is needed, hold strip in one hand and

carefully twist the strip with the other hand. Prior to placing in tool

bed, trim any welded wire that remains at the end of the shortened

strip so wire is ush with end fastener.

c. Center fastener strips within the bed.

• Insert the fasteners, with the open end of the fasteners toward the

clamp bar. e heads (crowns) of the staple will t into the slots

in the bed.

• Use rocking motion to guide staple pairs (two staples per fastener

plate) into each individual bed opening.

• Make sure there are no empty slots between fastener strips.

3. Load the Belt

BEST PRACTICE: Run crown side of staples on the carry side of the belt for optimal belt cleaner interface. Place carry side of

belt facing down in frame for installation.

a. Place belt on belt guide plate and slide the belt end under the

clamp bar and into the fastener.

ww w.flexco.com

b. Push the belt end into the fasteners until it is tight against the belt

stops which are built into the fasteners. If belt end rises above the

belt stop push the belt back so it is properly aligned.

—12—

Page 13

Hydraulic Flexco® XP™ Staple Fastener System

Installation Instructions (continued)

3. Load the Belt (Continued)

c. Center the belt so that approximately 1-1/2 inches (38 mm) of

belt extends beyond the fasteners on each edge.

d. Secure the belt in this position by evenly tensioning the clamp

bar handle on both ends of the clamp bar until the belt is securely

clamped.

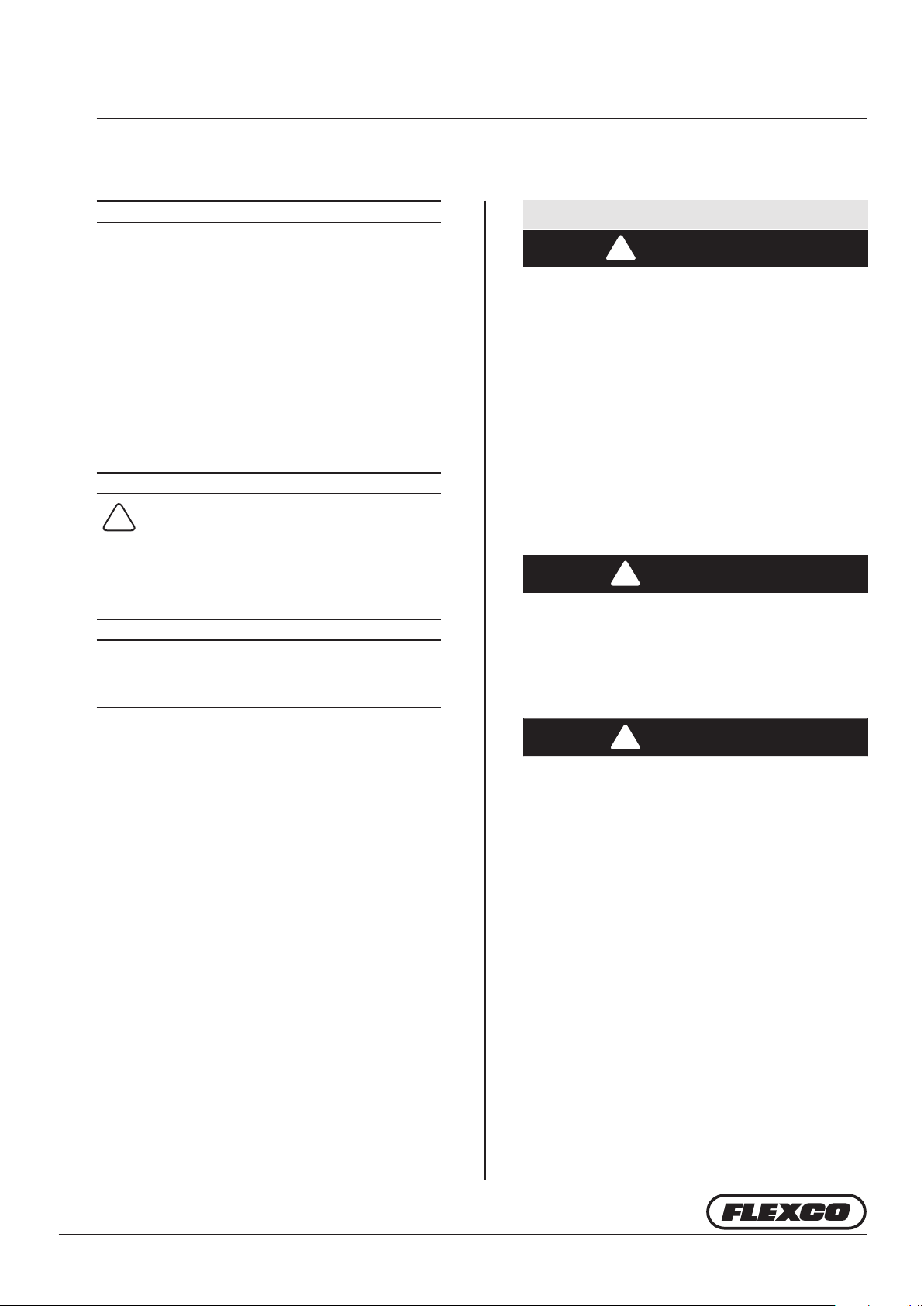

4. Load the Applicator

NOTE: Make sure to read the power source (Power pack or PTO) manual prior to operating the equipment.

a. Attach the hydraulic applicator to the bed by sliding the

mounting brackets located on the applicator onto the le end of the

bed rail. Ensure the advance/actuation handle is in the forward

position “0”.

b. Push the applicator rmly to the right until the tool is solidly on

the bed. Verify hydraulic hoses are not connected.

c. e applicator can be moved to the right either by continuing to

push it across the bed or by using the handle to rapidly advance the

head along the tool bed. e applicator can be moved to the le by

disengaging the advance mechanism lever and pushing the head to

the le.

—13—

2

d. To use the rapid advance feature move the advance/actuation

handle from start position “0” to positon “1” and repeat to quickly

advance the tool. Position the applicator over the rst two fasteners

in the fastener strip.

01

Page 14

Hydraulic Flexco® XP™ Staple Fastener System

Installation Instructions (continued)

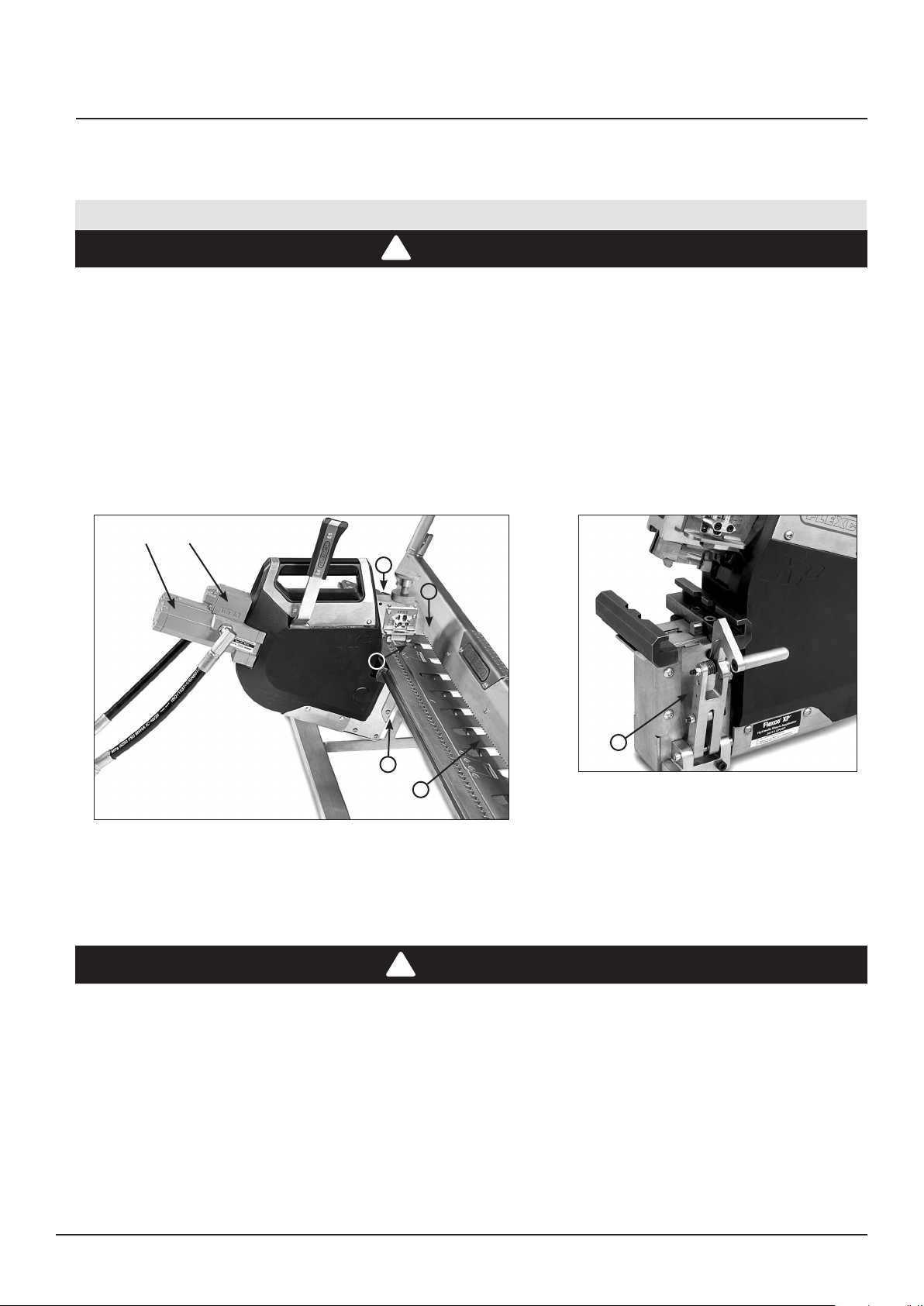

5. Set the Belt Thickness Gauge

a. Insert sample belt end into the belt thickness gauge located on

the sides of the head. e side used is determined by the fastener

size that will be applied. For an XP7 fastener use the le side belt

gauge marked “XP7/XP8”. For an XP5 or XP5-L fastener use the

right side belt gauge marked “XP3/XP5”.

NOTE: If the belt doesn’t t into the gauge, the gauge is probably set from a previous use.

• Loosen the locking knob and open the gauge by turning the compression knob counter-clockwise several turns.

• Lock gauge in place by tightening the locking knob and remove belt from gauge. This setting is approximate.

b. Adjust the fastener compression knob until the belt just slides

in the gauge opening. Turn clockwise to tighten. Turn counterclockwise to loosen.

BEST PRACTICE: Use XPLT XP-LOK™ Tensioner

and XPLW-120 XP-LOK™ Belt Wire to prevent belt

wave and ripple on rubber plied belting.

Always perform a test sample to verify proper belt

thickness setting before completing nal installation.

A nal adjustment may be necessary aer the rst few

fasteners have been installed.

c. Use the stand alone belt thickness gauge as an

alternative when a belt sample is not available.

Correlate the belt thickness reference number marked

on the gauge and adjust fastener compression knob

accordingly.

ww w.flexco.com

—14—

Page 15

Hydraulic Flexco® XP™ Staple Fastener System

Installation Instructions (continued)

6. Connect Hydraulic Power

a. Make sure the hydraulic power source is in "OFF" position.

1. Connect the low pressure return hose (1⁄2" ID):

• Connect the male nipple (hose) to the female coupler at the power pack.

• Connect the female coupler (hose) to the male nipple at the hydraulic tool.

2. en connect the high pressure hose (3/8" ID):

• Connect the female coupler (hose) to the male nipple at the power pack.

• Connect the male nipple (hose) to the female coupler at the hydraulic tool.

NOTE: If quick release couplings are dicult to join, excess pressure has built up in the line. To relieve the pressure either turn the power pack o and on again

or move the advance/actuation handle one full cycle.

3. When making connections, do not over stretch the hoses or bend them at a sharp angle.

4. To disconnect the hose, pull the locking collar to release the connection at the hydraulic tool. Do not disconnect hose at power pack unless necessary. Fluid

spillage will result.

b. Connect hydraulic power pack to appropriate

electric source. WARNING: Make sure the power

source is not energized and follow proper LockOut/Tag-Out protocols.

Electrical examples (reference only):

Canada: 480VAC/575VAC, 3 phase, 60Hz

China: 380VAC/660VAC, 3 phase, 50Hz

Europe: 380VAC, 3 phase, 50Hz

US: 480VAC, 3 phase, 60Hz

PSI

c. Turn on the power source. d. Inspect gauges when tool is in idle mode. e

pressure gauge should read 110 bar, 11 Mpa,

1600psi. If the pressure gauge shows no pressure,

turn o the power source immediately. Examine

the power source connect with correct wiring.

—15—

Page 16

Hydraulic Flexco® XP™ Staple Fastener System

Installation Instructions (continued)

7. Fastener Installation

a. Move the advance/actuation handle from position “0’ to end of

travel (positon “2”). is action will result in the following sequence

of events: advance applicator to the next fastener, compress top

plate, drive staples, fold and swipe staple legs. Hold handle in

position “2” until feedback in handle is felt.

c. Examine the rst fasteners to ensure that the staple legs are

properly set. e leading edge of the fastener must be set tight on

the belt to reduce the fastener’s exposure to cleaner blades, skirt

rubbers, and return idlers.

NOTE: To prevent belt ripple, do not over compress fasteners on

the belt.

b. Push the advance/actuation handle forward (position “0”). is

action completes the drive cycle. Completed cycle time is about two

seconds.

1

2

d. Because belt thicknesses may vary across the width of the belt, it is

important to examine the fasteners as they are applied. If the top plate of

the fasteners is not tight on the belt, adjust the compression by turning

the adjustment knob (1) 1/4 turn to the right (clockwise), check and

repeat as necessary. If the applied fasteners appear to create a “ripple” in

the belt, the fasteners are over compressed. Adjust the compression by

turning the adjustment knob (1) 1/4 turn to the left (counter-clockwise),

check and repeat as necessary. Hold the compression position by

tightening the adjustment knob’s locking knob. (2).

e. Loosen clamp bar, remove belt, and repeat the fastener

installation procedure on the mating belt end.

ww w.flexco.com

f. When nished, turn o the power source. Pull back on lock collar

to disconnect hydraulic hoses.

—16—

Page 17

Hydraulic Flexco® XP™ Staple Fastener System

Installation Instructions (continued)

8. Complete the Splice

a. Insert the hinge pin. For ease of hinge pin insertion, overlap both

belt ends. Tent both ends and start to join loops from one side.

Insert hinge pin and continue to join the rest of loops.

d. Mark the splice date on the belt using the Flexco Belt

Identication Tool or other comparable method and record it in

your belt maintenance record.

Leading

edge

2

Direction of belt travel

c. Notch the trailing belt edge (1) and attach Flexco Hinge Pin

Retaining Collars (2) to maintain proper hinge pin position.

Trailing

edge

1

9. Tool Transport

NOTE: When transporting the tool over any distance, it is recommended that the hydraulic applicator be removed and carried separately. If you need to

move the tool a short distance or reposition it, it can be carried. Take care to keep the tool level and use two people to move it as the weight may not be

evenly distributed.

—17—

Page 18

Hydraulic Flexco® XP™ Staple Fastener System

Troubleshooting

Problem Cause Correction

Pull advance/actuation handle but

applicator does not advance

Pull advance/actuation handle down

but applicator does not actuate

Functioning but weak or low speed

Oil leakage from cylinder, hydraulic

hose, coupling

Power pack motor runs but there is no

pressure at the outlet

Staple legs are pushed up but staples

are only partially bent over

Staple legs are pushed up but staples

are not completely set

Belt has too much ripple or wave 1. Fastener compression was incorrectly

Staple legs are pushed up but staples

are not bent over

Cannot load applicator onto frame 1. Pilot punch is in up position

1. Advance mechanism lever was in disengage

position

2. Advance/setting handle was not pulled down to

position “1” to complete advance cycle

3. Advance/setting handle was not fully pushed

forward (position ”0”) to engage advance mechanism

4. Bed rails are dirty

5. Advance mechanism lever spring was not in position

or damaged (Rare)

1. Power pack unit is not turned ON

2. Hoses are not connected

3. Couplings are not connected properly

4. Power source relief valve pressure is set too low

5. No hydraulic pressure due to incorrect electric

cable connection at motor

1. Low fluid flow rate from power source unit

2. Relief valve pressure set too low

3. Back pressure is too high

4. Over-heated hydraulic fluid

1. Damage, wear or hardened O-ring

2. Damaged hose

3. Damaged connection at coupling

1. Motor turns in wrong direction due to incorrect

electric cable connection

2. Relief valve pressure is set too low

3. Relief valve stuck/malfunction

4. Low hydraulic fluid level

1. Operator did not wait for handle feedback at end

of the pull (position “2”) before returning handle to

start position “0”

1. Fastener compression was incorrectly

set (under-compress)

set (over-compress)

2. Using rubber plied belting

1. Damaged swipe arms

2. Damaged swipe linkages

2. Mounting brackets are not aligned properly

1. Engage advance mechanism lever

2. Pull handle down to position “1”

3. Push handle forward all the way to complete cycle

4. Clean surfaces and spray SLP5 GLIDE silicone

lubricant on bed rails and mounting brackets

5. Adjust or replace spring

1. Turn ON power pack unit

2. Connect hoses

3. Check if couplings have been connected properly

4. Adjust pressure to 110 bar, 11 Mpa, 1600 psi

5. Check proper electric cable connection, voltage,

and phases

1. Check electric cable connection, voltage, and

phases

2. Adjust pressure to 110 bar, 11 Mpa, 1600 psi

3. Use bigger diameter hose for return hose

4. Turn OFF power pack approximately one hour to

allow hydraulic fluid to cool

1. Replace O-ring by authorized distributor

2. Replace hose assembly

3. Replace hose assembly

1. Check proper electric cable connection, voltage,

and phases

2. Adjust pressure to 110 bar, 11 Mpa, 1600 psi

3. Replace relief valve by authorized distributor

4. Add hydraulic fluid accordingly

1. Pull advance/actuation handle down to position “2”

and wait for handle feedback prior to releasing

1. Adjust fastener compression by turning the

adjustment knob ¼ turn to right (clockwise) and

repeat as necessary

1. Adjust fastener compression by turning the

adjustment knob ¼ turn to left (counter-clockwise)

and repeat as necessary

2. Use XPLT XP-LOK™ Tensioner and XPLW-120

XPLOK™ Belt Wire to prevent belt wave and ripple

1. Replace swipe arms by authorized distributor

2. Replace swipe linkages by authorized distributor

1. Push advance/actuation handle to position “0” prior

to loading onto frame

2. Inspect and verify mounting bracket are properly

installed

ww w.flexco.com

—18—

Page 19

Hydraulic Flexco® XP™ Staple Fastener System

REV

REV DESC

DATE

100

RELEASE FOR PRODUCTION

PER ECR DG170368

4/28/17

2

4

35

6

Power Diagram

—19—

Page 20

Hydraulic Flexco® XP™ Staple Fastener System

CE Declaration

ww w.flexco.com

—20—

Page 21

Hydraulic Flexco® XP™ Staple Fastener System

—21—

Page 22

Hydraulic Flexco® XP™ Staple Fastener System

ww w.flexco.com

—22—

Page 23

Hydraulic Flexco® XP™ Staple Fastener System

—23—

Page 24

Flexco Europe GmbH • Leidringer Strasse 40-42 • D-72348 Rosenfeld • Germany

Tel: +49-7428-9406-0 • Fax: +49-7428-9406-260 • E-mail: europe@flexco.com

Visit www.flexco.com for other Flexco locations and products.

©2018 Flexible Steel Lacing Company. 05-17-19. For reorder: X4571

Loading...

Loading...