Flexco

®

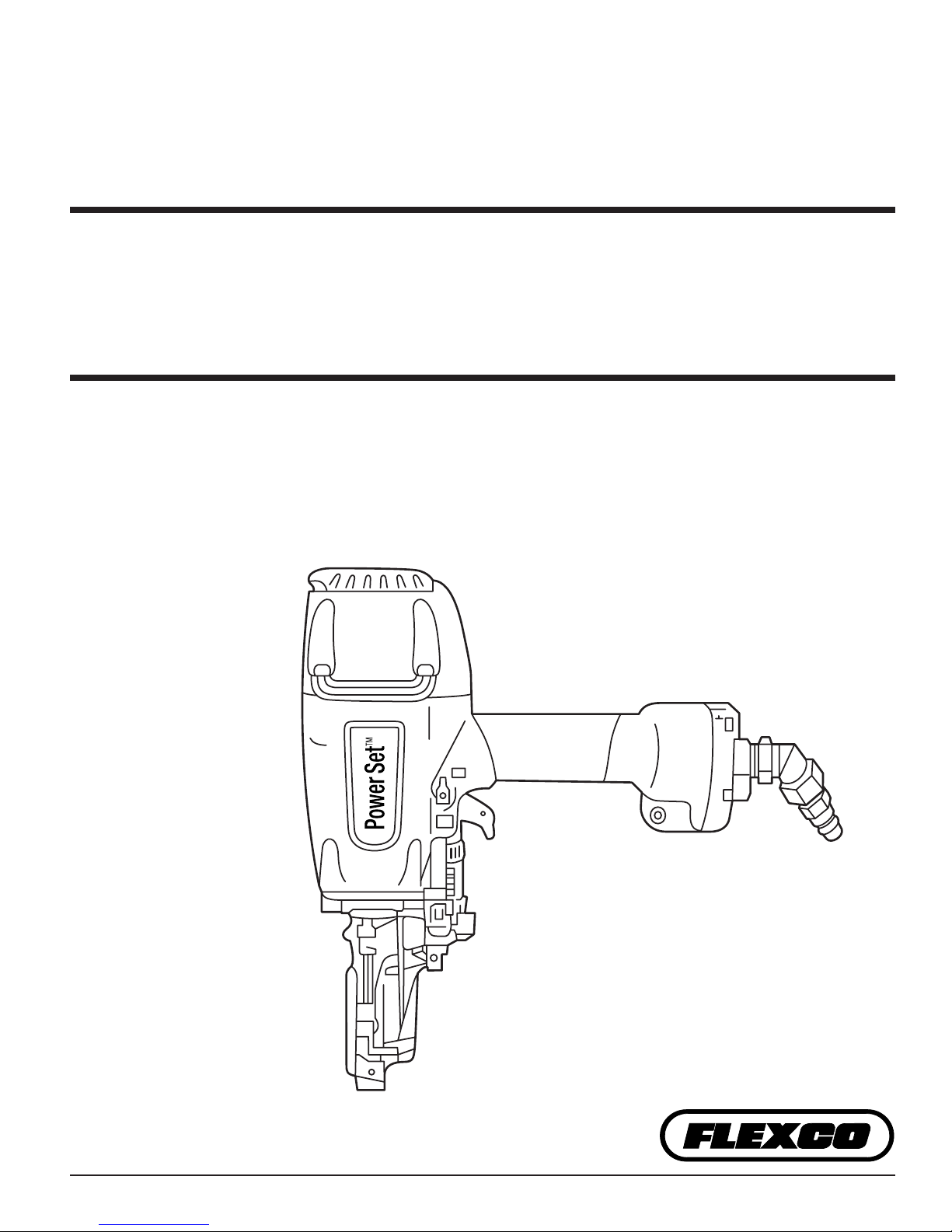

Power Set

™

Rivet Driver

Power Set Model No. PSRD-1

OPERATING MANUAL

and

USERS GUIDE

Pneumatic Rivet Driver

FOR USE WITH THE

Flexco®SR™Rivet Hinged Fastener System

RH336

Patents Pending.

2

Table of Contents Page

Safety Instructions..............................................................................................3-4

Power Set

™

Rivet Driver Product Specifications and Tool Features ........................5

Pneumatic Specifications and Pneumatic Parts Specifications.............................6-8

Power Set Rapid Loader

™

Rivet Strips with Washers and Rivet Selection Guide ....9

Installing Flexco

®SR™

Fasteners Using The Power Set Driver........................10-11

Power Set Rivet Driver Tool Maintenance and Troubleshooting.....................12-13

Power Set Accessories and Replacement Parts......................................................14

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

3

PRECAUTIONS ON USING THE TOOL

1. WEAR SAFETY GLASSES OR GOGGLES

Danger to the eyes always exists resulting from tool impact and air discharge.

The employer and/or user must ensure that proper eye protection is worn. Follow the most current

guidelines published by MSHA/OSHA for eye protection.

The employer is responsible to enforce the use of eye protection equipment by the tool operator and all

other personnel in the work area.

Note: Non-side shielded safety glasses and face shields alone do not provide adequate protection.

2.

HEARING PROTECTION MAY BE REQUIRED IN SOME ENVIRONMENTS

If you are using the Power Set™Rivet Driver intermittently or for an extended period of time, you may

need to wear hearing protection. The decibel rating on the Power Set Driver is 92 dBA (weighted single

event emission sound pressure level at workstation).

The employer should check guidelines to assure compliance to MSHA or OSHA requirements on

required hearing protection.

3.

DO NOT USE ANY POWER SOURCE EXCEPT AN AIR COMPRESSOR

The tool is designed to operate on compressed air. Do not operate the tool on any other high-pressure gas

or combustible gases (e.g., oxygen, acetylene, etc.) since there is the danger of an explosion.

4.

OPERATE WITHIN THE PROPER AIR PRESSURE RANGE

The Power Set Rivet Driver is designed to operate within an air pressure range of 60 to 120 PSI (4-8 bar).

WARNING: Never operate the Power Set Model PSRD-1 air control assembly over 120 PSI (8 bar). The

Power Set regulator pressure relief safety value will activate. Always use the Power Set Rivet Driver with the

air control assembly (regulator, filter, oiler) supplied in your Power Set Kit.

The Power Set

™

Rivet Driver, Power Set Rapid Loader™collated rivets strips with washers, and the SR™ Family of Rivet

Hinged Fasteners have been designed to work together as a system.

Note: To insure proper Power Set Rivet Driver usage and prevent tool damage, use this tool only with Flexco SR

Fasteners and use only the Power Set Rapid Loader

™

collated rivet strips with washers.

The Power Set Rapid Loader collated rivet strips with washers have been developed to maintain alignment of the

rivet during installation. Using any other types of rivet, including those manufactured by Flexco will not yield

satisfactory results. Damage to your Power Set Rivet Driver resulting from the use of products other than Flexco

SR Belt Fasteners and Power Set Rapid Loader collated rivet strips with washers will void your tool warranty.

More importantly, using non Flexco products with your Power Set Rivet Driver could result in unsafe tool

operation resulting in either belt damage, or possible injury to the tool operator and others in the vicinity.

Safety Instructions

WARNING

: TO AVOID SEVERE PERSONAL INJURY OR PROPERTY DAMAGE BEFORE USING THIS TOOL READ

CAREFULLY AND UNDERSTAND THE FOLLOWING

“SAFETY INSTRUCTIONS.” FAILURE TO FOLLOW WARNINGS

COULD RESULT IN DEATH OR SERIOUS INJURY

.

4

5.

IMPROPER USE OF TEFLON TAPE ON ANY OF THE PNEUMATIC FITTINGS ON THE POWER SET RIVET DRIVER

SYSTEM CAN DAMAGE THE TOOL

When Teflon tape is applied improperly to the pneumatic fittings, it can break off and migrate into your

Power Set

™

Rivet Driver. This could result in a blockage and the need to send the tool in for repair.

6.

DO NOT OPERATE THE POWER SET RIVET DRIVER NEAR FLAMMABLE SUBSTANCES

Never operate the Power Set Rivet Driver near a flammable substance (e.g., thinner, gasoline, methane,

acetylene etc.). Volatile fumes from these substances could be drawn into the compressor and when

compressed together with the air could cause an explosion.

7.

NEVER PULL THE CONTACT ARM BACK AND ACTUATE THE TOOL UNLESS THE NOSE IS FULLY INSERTED IN

THE METAL GUIDE BLOCK

Actuating the tool when it is not fully inserted in the metal guide block may damage the tool and could

result in injury to the operator or others in the vicinity.

8.

KEEP HANDS AND BODY PARTS AWAY FROM THE DISCHARGE OUTLET

When using the Power Set Rivet Driver, never place a hand or any part of the body near the discharge area

of the tool. Serious injury may occur.

9.

DO NOT OPERATE THE POWER SET RIVET DRIVER IF THE CONTACT ARM IS NOT WORKING FREELY

This could result in the unplanned firing of the drive rod resulting in damage to the tool and injury to the

tool user. Send the tool in for repair.

10.

DO NOT CARRY THE POWER SET RIVET DRIVER BY THE AIR HOSE

This can result in loosening the pneumatic hose fittings resulting in air leaks or a failed hose fitting.

11.

MAKE SURE METAL GUIDE BLOCK HOLES ARE FREE OF DEBRIS AND FOREIGN OBJECTS

Before using the Power Set Rivet Driver, check the metal guide block to assure that no dirt, misfired rivets,

or other foreign objects have lodged in the guide block holes. Objects lodged in the guide block holes,

could result in a broken drive rod or could deflect a driven rivet into the operator. CAUTION: Be Careful

Not To Place Power Set Rapid Loader

™

Collated Rivets with Washers Into a Guide Block Hole

Where an Existing Rivet Has Already Been Driven. Accidentally driving over the top of an already

installed rivet can result in possible damage to the Power Set Rivet Driver, the guide block or belt, and

could result in injury to the operator or anyone in the vicinity.

12.

ONLY USE SPECIFIED POWER SET RAPID LOADER™COLLATED RIVETS WITH WASHERS (see page 9)

The Power Set Rivet Driver can only be used with specially designed Power Set Rapid Loader

™

collated

rivet strips with washers, intended to work with the Power Set Rivet Driver. They have a flute (washer) at

the end of each rivet pilot nail, which helps keep the rivet aligned in the guide block hole. Do not use

rivets without washers. Without washers, misfires will occur. Using any rivets, other than Power Set

Rapid Loader

™

collated rivets with washers, may result in permanent damage to the tool, guide block, belt,

or Power Set operator.

13.

ONLY USE FLEXCO®SR™FASTENERS, POWER SET METAL GUIDE BLOCKS AND TOOLS WITH THE POWER

SET RIVET DRIVER

The Power Set Rivet Driver and Power Set Metal guide blocks were designed to specifically work with the

Flexco line of SR

™

tools. Using an alternative tool base may result in rivet misfires, belt damage, damage to

the Power Set Rivet Driver, or may result in a deflected rivet that could injure the Power Set Operator or

others in the vicinity.

14.

DO NOT MODIFY THIS TOOL FROM ITS EXISTING DESIGN

Modifying the tool could result in injury to the operator or others in the vicinity and will void the warranty.

15. DO NOT ATTEMPT TO REPAIR OR REPLACE BROKEN PARTS

Send the tool in for service. Failure to do so will void the warranty.

5

1 Frame

2 Cylinder Cap*

3 Exhaust Cover

4 Trigger Lock Dial

5 Trigger

6 Grip

7 Pneumatic Fitting H2E 3/8”

Male Nipple

8 Contact Arm Spring Housing

9 Nose

10 Contact Arm Mechanism

11 Adjustment Dial**

* Rotate to desired direction

** Pre-set at factory –

No adjustment possible.

Specifications and Technical Data – Flexco®Power Set™Rivet Driver

1

2

3

4

5

6

7

8

9

10

11

TOOL SPECIFICATIONS

HEIGHT................................................14-7/16” (367mm)

WIDTH..................................................5-1/6” (129mm)

LENGTH ...............................................15” (380mm)

WEIGHT ...............................................7.5 lbs. (3.4kg)

RECOMMENDED

OPERATING PRESSURE.....................85 TO 90 PSI (approximately 6 bar)

AIR CONSUMPTION..........................9 SCFM 85-90 PSI (6 bar) for Optimal Operating Performance

TECHNICAL DATA – Noise

A-Weighted single-event

LWA, 1s, d sound power level ..................100.77 dB

A-Weighted single-event

LpA, 1s, d emission sound pressure

level at work station .................................92.22 dB

Note: Refer to MSHA or OSHA requirements on sound protection equipment regulations

to assure you are in compliance.

6

Specifications and Technical Data –

Pneumatic Accessories and Connections

WARNING: Read Section titled “Safety Instructions”

The Flexco

®

Power Set™Air Control Assembly consists of an Oiler, Filter Unit and Pressure Gauge. This regulator system was

configured to work specifically with the Power Set System.

AIR CONTROL ASSEMBLY SPECIFICATIONS

Regulator/Filter............Parker No. PS901P Filter or equivalent

Oiler.............................Parker No. F442 Oil or equivalent: Petroleum based non-detergent I.S.O. Grade #32

WARNING: The Air Control Assembly regulator is designed to operate up to 120 PSI. Do not connect this

regulator to an air source over 120 PSI. The Power Set regulator pressure relief safety value will activate.

Note: Oiler is shipped empty. Prior to operating tool, fill oiler with oil as indicated above. Using lubricants other than those

specified will damage the tool and void the warranty.

Note: Change regulator filter if you are experiencing reduced airflow to the Power Set Driver. When replacing filter, clean out

filter bowl to prevent restrictions to airflow.

COMPRESSOR REQUIREMENTS

A compressor that will generate at least 9 SCFM at 85-90 PSI will satisfy the requirements for running one Power Set driver at a

firing rate of twice/second. For two Power Set drivers coming off the tee-fitting 18 SCFM is required. Note: Follow all MSHA

regulations and requirements for using a compressor in an underground mining environment.

USING A COMPRESSOR WITH A SURGE TANK

Power Set users can use a smaller compressor by using a surge tank. Surge tank size requirements will vary based on HP of the

compressor.

HOSE SPECIFICATIONS

Parker Pneumatic “Push-Lok” Hose ......Parker No. 831-6

Length...................................................25 feet

I.D. / O.D.............................................3/8” (10mm) / .63” (16 mm)

Minimum Bend Radius.........................3” (75mm)

Working Pressure ..................................300 PSI

Burst Pressure........................................1400 PSI

Material Construction...........................Synthetic Rubber (Note: MSHA Accepted)

Chemical Resistance..............................

Petroleum hydraulic and lubricating oils, antifreeze solutions, water /oil emulsions

FITTING SPECIFICATIONS

Regulator/Filter Assembly .....................Parker No. H2E 3/8” Male Nipple 20 Series Industrial Interchange

Tee Fitting ............................................Parker No. 24 Quick Coupler, Male 20 Series Industrial Interchange

Hose Fitting to Tee Fitting.....................Parker No. H5EP Nipple 3/8” Push-Lok Hose 20 Series Industrial

Interchange

Hose Fitting to Driver ...........................

Parker No. 24-5BP Coupler 3/8” Push-Lok Hose 20 Series Industrial Interchange

Power Set Rivet Driver...........................Parker No. H2E 3/8” Male Nipple 20 Series Industrial Interchange

7

1. Remove contents of the Power Set™Rivet Driver

toolbox. The toolbox includes one Power Set Rivet

Driver; one specially designed metal guide block, air

control assembly, tee-fitting, 25 feet of air hose and

two belt gauges (not shown).

2. Mount Air Control Assembly in upright position.

The air control assembly kit must remain level

during tool operation. Fill oiler with Parker

Hannifin F442 oil or equivalent.

OILER

FILTER

Parker No. H2E

3/8" Male Nipple

Flexco®Power Set™Rivet Driver Set-Up

8

5. To adjust air pressure pull cap “

1” up and turn

clockwise. After desired air pressure is set, snap cap

down into locked position. For optimal results operate

the driver at 85-90 PSI (approximately 6 bar). Do not

exceed 120 PSI (8 bar).

6. To adjust oil flow turn cap “

2” clockwise, until tight,

then turn cap counterclockwise 1 turn for proper

adjustment.

1

2

3. Connect your air compressor to the Parker

No. H2E 3/8” Male Nipple on the regulator kit.

Use compressed air directly from an air compressor.

WARNING: Do not use any bottled gasses,

including oxygen, to operate this tool.

An explosion can occur.

4. Continue connecting your pneumatic fittings as

shown.

1

2

3

4

5

1 Parker No. H2E 3/8” Male Nipple

2 Parker No. 24 Quick Coupler, Male

3 Parker No. H5EP Nipple 3/8” Push-Lok Hose

4 Parker No. 24-5BP Coupler 3/8”Push-Lok Hose

5 Parker No. H2E 3/8” Male Nipple

®

9

NOTE: The Power Set

™

Rivet Driver can only be

used with Power Set

Rapid Loader

™

collated

rivet strips with washers.

SR™RIVET SELECTION CHART

For use with Flexco®Rivet Hinged Fasteners and Rapid Loader™Collated Rivets

Belt Thickness For Fastener Size

in. mm R5

7/32 6

A9/32 7

5/16 8

11/32 9

3/8 10

13/32 10.5

7/16 11

15/32 12

1/2 13

17/32 13.5

9/16 14

19/32 15

5/8 16

21/32 16.5

11/16 17

23/32 18

3/4 19

25/32 20

13/16 21

27/32 21

7/8 22

15/16 24

C

B

C/D

R5-1/2

RAR6LP

C

D

F*

B

C/D

E

G*

R6/R8 R9

C/D

D

E E

F F

G G

H

H

J**

K**

I

* Applies to RAR6LP only

**Use with 3/4" (19mm) diameter hinge pin

NOTE: • When installing Flexco Rivet Hinged fasteners with the Flexco Power Set™Rivet Driver, you must use Rapid Loader

Collated Rivets with washers.

• In areas of overlap, to select the proper rivet choose the shorter rivet for softer, compressible belts and the longer

rivet for hard belts.

Skiving Recommended:

Whenever possible, Flexco recommends skiving the belt in order to countersink mechanical fasteners. Skiving reduces the

fastener profile on the belt, resulting in improved fastener/cleaner compatibility and increased fastener service life. To determine

proper rivet selection, always measure the belt thickness after a portion of the belt cover has been removed. This may allow

for the selection of a one to two size shorter rivet for increased material savings while maintaining maximum holding ability.

In some cases, where belt-operating tension allows for it, a smaller fastener can be applied.

™

10

Instructions

Installing Flexco

®

SR™Fasteners with the Flexco® Power Set™Rivet Driver

1. Square belt using centerline

method. Cut belt 2-3” (50-75 mm)

behind old splice using Flexco

®

840

Series Belt Cutter. Skive belt when

top cover permits.

2. Measure belt thickness from cut

edge using gauge or tape measure.

Select correct size Power Set Rapid

Loader

™

collated rivets with washers

for your belt thickness. When skiving,

measure the belt thickness after a

portion of the belt cover has been

removed.

3. Place tool on wooden board the

width of the conveyor framework for

support when using the MSRT or

MSRT8 tool. Adjust gauge pin guide

to the correct fastener size.

4. Center fastener strip on tool,

Flexco stamp facing up. The holes in

the fasteners and anvil plate must line

up. Insert gauge pin through guides

and fastener loops.

5. Center belt in fastener strip. Look

through viewports; belt ends should

be tight against belt stops. Tighten

hold down bar to secure belt.

6. Set all fastener top plates with

hammer blows. Place metal guide

block(s) at either end of the fastener

strip. Use the metal guide blocks

designed for use with the Power Set

™

Rivet Driver. Reduce installation time

by adding guide blocks across the

tool.

11

7. Load guide blocks with Power

Set

™

Rapid Loader™collated rivets

with washers. Note: Do not use

rivets without washers. Without

washers, misfires will occur. If a

shorter strip is needed, break off extra

rivets by bending strip at checkpoint.

8. Using a hammer, hit collated rivets

to release all rivets from plastic.

Remove plastic from guide blocks and

discard.

Note: For optimal results operate the

driver at 85-90 PSI (approximately 6

bar). Do not exceed 120 PSI (8 bar).

9.

Insert the Power Set driver nose

directly into the counter bore of the

guide block. Make sure Trigger Lock

Dial is in the unlocked position. The

driver nose must be completely

inserted so that the contact arm is

retracted. Pull the trigger to fire the

driver. Wait approximately 1 second

between shots to allow the driver to

fill with air.

10. Drive Rivets into center hole of

both end plates. This will anchor

fastener strip in position. Continue

driving rivets into all center holes.

Complete driving the other two rows

of rivets in the sequence shown above.

While hitting rivets keep the guide

blocks as level as possible to avoid

misfires. Hit each rivet two to four

times.

11. Remove guide block(s) and make

sure rivets are set completely. If some

rivets are not completely set, replace

guide block(s) and hit the rivets that

need to be set. Remove guide blocks

and check the rivets again. Use the

total number of hits on each rivet in

subsequent blocks. Complete belt end

by moving the block across the width

of the belt and continue driving

rivets.

12. Repeat steps 1-11 on other belt

end. Bring belt ends together and

insert hinge pin. Notch trailing edge

of belt only. Splice is complete.

12

POSSIBLE SOLUTIONS:

• Make sure the nose of the Power Set Rivet Driver is

vertical with the guide block, and the contact arm

mechanism is fully engaged, and properly seated into the

drive block hole. If the contact arm mechanism is not fully

engaged, the Power Set Rivet Driver will not fire.

• Is your trigger lock dial broken? If your trigger lock is

broken, it can prevent the trigger from activating and

prevent the driver from firing.

• Check the contact arm mechanism and components for

dirt or debris. Use an air hose to blow out if needed.

• Do you have the right amount of air pressure?The Power

Set Rivet Driver requires 60-120 PSI (4-8 Bar) to operate

effectively.

• Do you have the right fitting(s) on your hose? We

recommend a 3/8” fitting. If you have modified your fittings

and downsized the opening below 3/8”, the Power Set Rivet

Driver may not get enough air pressure to operate properly.

• Is your air source sized properly? The Power Set Rivet

Driver requires 9 SCFM to fire two shots per second. Two

Power Set Rivet Drivers coming off the Tee-fitting requires

18 SCFM to fire two shots per second.

• Is your air line blocked? Check your hose(s) and fitting(s)

to see that you have air flow. If you do not have good airflow

to your Power Set Rivet Driver, you may have a blockage in

your Power Set Rivet Driver pneumatic fitting on the grip, or

you may have blockage in the internal part of the driver.

Send your Power Set Rivet Driver in for repair.

• Does your regulator filter need to be changed? Check

your regulator filter. The filter and filter bowl may be dirty

resulting in air restriction. Clean your filter and filter bowl.

Also check to make sure lubrication oil has not leaked into

the filter housing. This can result in significant air restriction.

This regulator uses a Parker No. PS901 filter or equivalent.

• Do you have an old air hose? Check your air hose. As air

hoses age, they soften and expand when pressurized resulting

in a drop in air hose line pressure. Also check for hose breaks

and cracks around hose fitting(s).

• Are you connected (from your air assembly unit) by an

air hose that is over 25 feet in length?The longer the air

hose is from the Power Set Rivet Driver to the air assembly

unit, the greater the drop in SCFM. For maximum driver

performance, do not use a hose from the driver to the air

assembly unit that is over 25 feet in length, and use a hose

that meets the hose specifications on page 6.

• Do you have oil in the air regulator oiler? Before using

your Power Set Rivet Driver, always check the oil level gauge.

Operating the Power Set Rivet Driver without the proper

lubrication or level of lubrication in your oiler for an

extended period of time can result in damage to the Power

Set Rivet Driver o-ring seals, and can result in damage to the

air piston walls. This can cause your Power Set drive rod to

return slowly because the air piston walls have become

scoured.

Note: Operating the Power Set Tool without lubricant or

with lubricants other than those specified here will void the

warranty.

• Do you have the right lubricant (oil) in your air regulator

oiler? Using the wrong lubricant in your regulator oiler can

gum up the small air orifices in the Power Set Rivet Driver

restricting air flow, and could possibly cause chemical

deterioration of the o-ring seals, resulting in air leaks and loss

of Power Set Rivet Driver force. Use Parker Hannifin F442

oil or equivalent. Never use oils with additives, graphite or

solvents. Using these oils will damage your Power Set Driver

o-ring seals.

Flexco®Power Set Rivet Driver Tool Troubleshooting and Maintenance

If your Flexco®Power Set™Rivet Driver is not working properly, use this checklist to pinpoint possible operating

problems.

IMPORTANT: Always disconnect the Power Set Rivet Driver from your air source before inspecting or

cleaning it.

SYMPTOM:

My Power Set Rivet Driver is not firing continuously or not at all when I pull the trigger.

13

POSSIBLE SOLUTIONS:

• Is your drive rod damaged? If your Power Set Rivet Driver

is not driving rivets all the way through the belt, your drive

rod may be bent, chipped, cracked, or has been broken off.

– Remove your guide block(s), hold them up to the

light and inspect each hole to make sure the drive rod

is not broken off in any of the holes.

– Check your work area for a broken piece of the drive

rod. If you cannot find anything you will need to

extend your Power Set drive rod for inspection. Follow

these procedures:

1. Make sure trigger locking dial (see page 5 #4) is in

the unlocked position.

2. Place the guide block on SR tool base and insert

the Power Set driver nose directly into one of the

holes of the guide block.

3. The driver nose must be completely inserted so

that the contact arm is retracted. Pull the trigger

to fire the driver and hold the trigger to extend

your drive rod.

4. While holding the trigger, remove the drive rod

from the guide block and inspect the drive rod for

chipping, cracks, bending, or to see if it has

broken off.

5. Point the Power Set Rivet Driver toward the

ground and release the trigger.

Note: If your drive rod is broken, you should then contact your

Flexco distributor to take the driver in for repairs. Any attempt

to repair the tool yourself will void the warranty.

• Are you using Power Set

™

Rapid Loader™collated rivet

strips with washers? The Power Set Rivet Driver can only be

used with specially designed Power Set Rapid Loader

™

collated rivet strips with washers intended to work with the

Power Set Rivet Driver. They have a patented flute (washer)

at the end of the rivet pilot nail, which help keep the rivet

aligned in the guide block hole. Do not use rivets without

washers. Without washers, misfires will occur.

• Are you using the correct size rivet? Make sure you are

using the correct length (size) rivet for your belt thickness. If

your rivet is too short, this may prevent the rivet from

properly curling into the anvil plate of your SR

™

tool.

• Is your metal guide block properly positioned on your

SR tool base? If not, this can result in a misfire causing the

rivet to hook into the belt. Check to make sure the holes on

your guide block and SR tool base line up, and that your

guide block is locked down properly.

PROPER TOOL MAINTENANCE AND CARE

• Never leave your Flexco®Power Set Rivet Driver on a pressurized air line for an extended period of time when

the driver is not being used. This will hold pressure inside the driver and can weaken o-ring seals over time.

• Keep the Power Set Rivet Driver and regulator away from strong solvents. Certain solvents will chemically

attack driver elastomers and plastic components.

• When storing the Power Set Rivet Driver for an extended period of time, place four (4) drops of Parker

Hannifin F442 oil into the pneumatic fitting on the Power Set grip.

SYMPTOM:

My Flexco

®

Power Set™Rivet Driver is not driving rivets all the way through the belt.

14

Power Set™Accessories and Replacement Parts

POWER SET KITS

DESCRIPTION ORDERING ITEM WT.

NUMBER CODE LBS

Flexco®Power Set™Rivet Driver PSRD-1 43003 7.5

Metal Guide Block for R5, R51⁄2, R6 PSRD-GB5 43016 17.0

Metal Guide Block for R8, R9 PSRD-GB8 43017 21.0

Air Control Assembly PSRD-RF 42521 4.0

Air Hose Assembly 25 Ft. with Fittings PSRD-AH 42522 3.0

Tee Fitting PSRD-TF 41011 1.0

DESCRIPTION ORDERING ITEM WT.

NUMBER CODE LBS

Power Set Kit for

R5, R51⁄2, R6 MPSK5 43018 34.0

Power Set Kit for R8 & R9 MPSK8 43019 37.0

Flexco®Power Set™Rivet

Driver Kits Include:

One Power Set Rivet Driver

One specially designed metal

guide block

Air control assembly

Tee fitting

25 feet of air hose and two

belt gauges.

Plastic carrying case.

POWER SET COMPONENTS

15

Corporate Headquarters:

FLEXIBLE STEEL LACING COMPANY

2525 Wisconsin Avenue

Downers Grove, IL 60515-4200 U.S.A.

1-630-971-0150 Telephone

1-630-971-1180 Fax

info@flexco.com

www.flexco.com

Global Locations:

Australia: 61-2-9680-3322

England: 44-1457-891-000

Germany: 49-7428-9406-0

Mexico: 52-55-56-74-53-26

South Africa: 27-11-974-2771

© Flexible Steel Lacing Company 4/05-1 Part# X2023

Flexco®is a registered trademark, and Power Set™and Rapid Loader™are trademarks of Flexible Steel Lacing Company.

Loading...

Loading...