Page 1

Ply Separator

PLY 130 WB + Optional Workshop Cart

Safety and Operation Manual

Separate between the plies of a conveyor belt.

IMPROPER OR UNSAFE use of this tool can result in serious bodily injury! is manual contains important information

about product function and safety. Please read and understand this manual BEFORE operating the tool. Please keep this

manual available for other users and owners before they use the tool. is manual should be stored in a safe place.

www.flexco.com

www.flexco.com

WARNING

Page 2

www.flexco.com

—2—

Page 3

Table of Contents

Main Components Ply 130™ ........................................................................ 4

Main Components Ply Cart™ ......................................................................5

Description .....................................................................................................6

Tool Specications .........................................................................................6

General Safety Rules ......................................................................................7

Retrot Tray .................................................................................................11

Workbench Installation ..............................................................................13

Cart Installation ...........................................................................................15

Separating for Finger over Finger Joints ..................................................19

Maintenance: Ply Separation Blade Replacement ................................... 23

Adjustment of clearance between rollers and blade ...............................29

Disclaimer e Ply 130 ply separator has been tested successfully with dierent

belt types. However this is no guarantee for good results. Fabricating belts does

require the operator to master skills and have a certain level of crasmanship.

Results also depend on good practice, material composition and sharpness of

blade. If results are not as expected, please contact Flexco.

—3—

Page 4

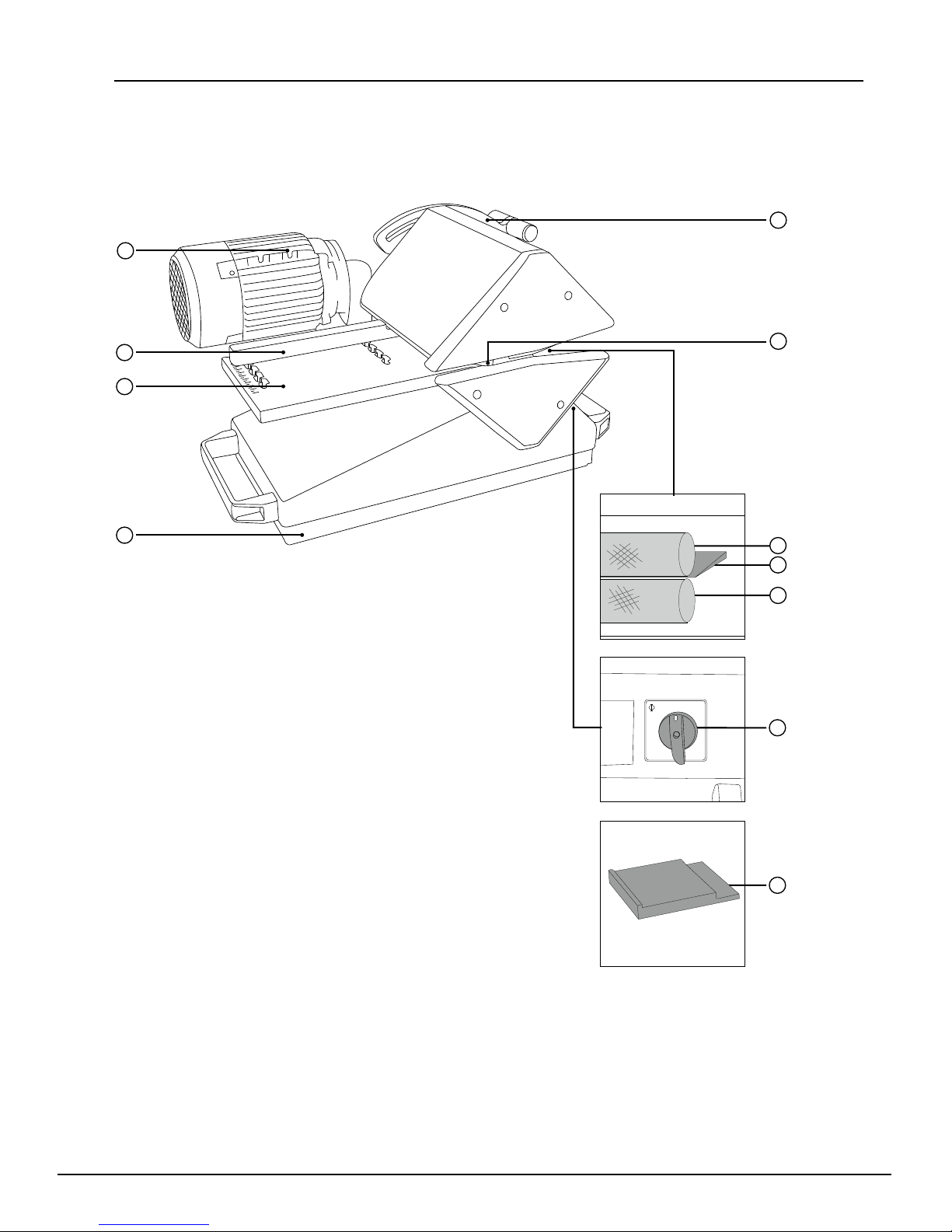

Main Components Ply 130

6

™

1

7

8

11

1. Adjuster handle

2. Finger catcher

3. Upper traction roll

4. Ply Separation Blade

FORWARD

2

3

4

5

OFF

REVERSE

9

5. Lower traction roll

6. Electric motor

7. Adjustable guide

8. Input table

9. Operating switch

10. Calibration jig

11. Ply tray

www.flexco.com

10

—4—

Page 5

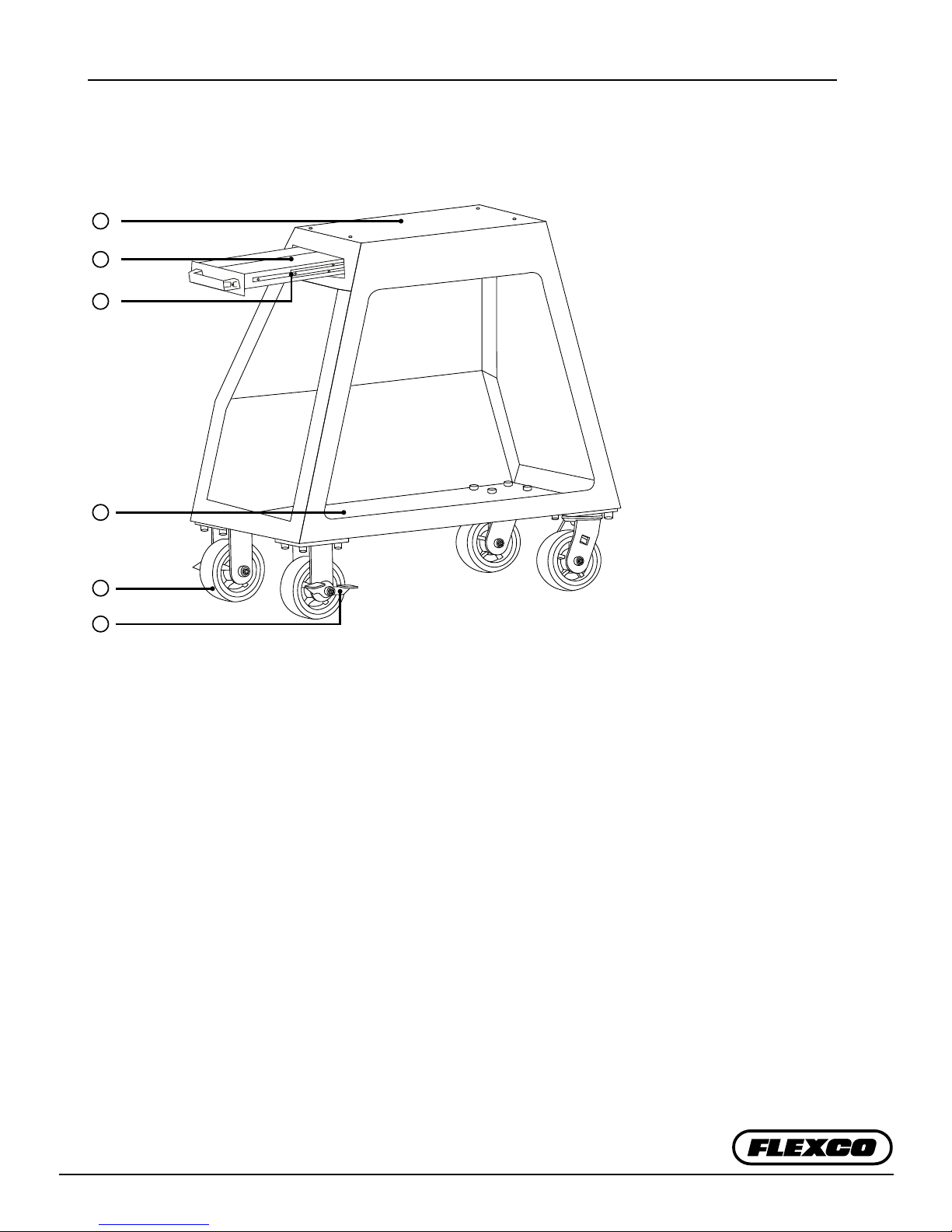

Main Components Ply Cart

1

2

3

4

™

5

6

1. Support Deck

2. Drawer

3. Drawer Slides

4. Housing

5. Casters

6. Locking Brake

—5—

Page 6

Description

e Ply 130™ is used to separate between the plies of a

conveyor belt. is cutting action is oen required in

preparation before splicing a belt with a splice press.

A great advantage of this ply separator is that it can

split as deep as 5” (130 mm) in one action. is is

especially helpful when splitting very thin belts which

are dicult to cut, such as thin polyurethane belts.

Tool Specifications

Ply 130™ Tool Specifications

Specifications

Splitting Depth 1.5” (40 mm) 5.1” (130 mm)

Belt thickness above cut .014” (0.35 mm) .3” (8 mm)

Belt thickness below cut .014” (0.35 mm) .2” (5 mm)

Maximum belt thickness N/A .4” (10 mm)

Tool dimensions

Tool weight 121 lbs (55kgs)

Minimum Maximum

22” x 17” x 17”

(550 x 420 x 420 mm)

e robust construction of the Ply 130™ allows for precise

splitting of thermoplastic belts - both thin and thick. As little

as 0.014” (0.35 mm) can be separated - allowing for users to

create lm from the belt used in the splicing process.

e Ply 130™ can be used to prepare nger over nger

splices and stepped splices. With only one handle you

determine the depth you want to split the belt. It may be

possible to split between every layer of the belt and in this

way generate two or three separations within one belt.

Ply 130™ Ordering Information

Ordering

Number

Work Bench Model

PLY130-WB-460V3PH60HZ 08013 no plug

PLY130-WB-460V3PH60HZ-L16-20 08053 L16-20

PLY130-WB-460V3PH60HZ-L16-30 08054 L16-30

PLY130-WB-400V50HZ 08102 no plug

PLY130-WB-230V3PH50HZ 08046 no plug

PLY130-WB-230V3PH50HZ-L15-20 08055 L15-20

PLY130-WB-230V3PH50HZ-L15-30 08056 L15-30

PLY130-WB-230V50HZ 08246 no plug

Cart Model

Ply-130-CART-ONLY 08100 no plug

Replacement Parts

PLY-BL Blade & Jig 08014 N/A

PLY-JG Jig Only 08015 N/A

Item

Code

NEMA

Plug

www.flexco.com

—6—

Page 7

General Safety Rules

Signal words:

“DANGER” indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury. e signal word is

limited to the most extreme situations.

–Save These Instructions–

1. WORK AREA

!

CAUTION

Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

“WARNING” indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

Safety Symbol

!

is international safety symbol is used to

identify and call attention to specic

safety matters.

Safety Information

To Avoid Severe Personal Injury or Property

Damage, read carefully and understand the

following Safety Precautions.

!

DANGER

Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

!

CAUTION

Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

!

WARNING

Never leave tool until it comes to a complete stop.

!

WARNING

Store idle tools out of reach of children and other

untrained persons. Tools are dangerous in the

hands of untrained users.

—7—

2. ELECTRICAL SAFETY

!

DANGER

e Ply Separator is a single insulated tool and

needs a multiple wire grounded power cord

and grounded power supply system. Contact

a qualied electrical installation company to

connect the right plug.

!

WARNING

Avoid body contact with grounded surfaces such

as pipes, radiators, ranges, and refrigerators.

ere is an increased risk of electric shock.

Page 8

General Safety Rules -Save These Instructions-

!

WARNING

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock and will

damage the tool.

!

DANGER

Do not abuse the cord. Never use the cord to

carry the tool or pull the plug from a receptacle.

Keep cord away from heat, oil, sharp edges,

or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of

electric shock.

!

WARNING

Do not use outdoors. is power tool is

designed for indoor use only.

!

WARNING

Avoid accidental starting. Be sure switch is o

before plugging in. Carrying tools with your

nger on the switch or plugging in tools that

have the switch on invites accidents.

!

WARNING

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

!

CAUTION

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

!

WARNING

Do not use tool if switch does not turn it on or

o. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

3. PERSONAL SAFETY

!

WARNING

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the inuence

of drugs, alcohol, or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

!

WARNING

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be

caught in moving parts.

!

WARNING

Never alter or remove safety devices.

!

WARNING

Keep your hands and ngers away from all

moving and sharp parts, e.g. rolls and blade, at

all times.

!

WARNING

Engage caster locks on cart when not

transporting

4. TOOL USE AND CARE

!

WARNING

Always use the ply separator on a level, rm

surface. Splitting should be performed operating

the machine with two hands on the material.

www.flexco.com

—8—

Page 9

General Safety Rules -Save These Instructions-

!

CAUTION

Do not force tool when the belt material blocks

or jams and do not continue feeding the material

through tool. When jamed put the operating

direction in reverse to remove the material.

!

WARNING

Do not use tool if switch does not turn it on or

o. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

!

WARNING

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing or transporting the tool.

Such preventive safety measures reduce the risk

of starting the tool accidentally.

!

WARNING

Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

!

CAUTION

e Ply Separator should not be used to split

other materials than thermoplastic belting

materials. e thickness of the belting material

should never exceed 10 mm.

5. SERVICE AND MAINTENANCE

!

WARNING

Tool service must be performed only by

qualied repair personnel. Service or

maintenance performed by unqualied

personnel could result in a risk of injury.

!

CAUTION

When servicing a tool, use only identical

replacement parts. Use of unauthorized parts or

failure to follow Maintenance Instruction may

create a risk of electric shock or injury.

!

DANGER

Do not use power tools if the housing is

damaged or not closed. Damaged or (partially)

open housing can lead to electric shock. Such

tools should not be used until repaired or closed.

!

CAUTION

Do not wipe plastic parts with solvent.

Solvents such as gasoline, thinner, benzene,

carbon tetrachloride, and alcohol may damage

and crack plastic parts. Do not wipe them with

such solvents. Wipe plastic parts with a so

cloth lightly dampened with soapy water and

dry throughly.

!

WARNING

!

CAUTION

Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may aect the tool’s operation. If damaged,

have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

!

WARNING

Stow foot pedal when not in use.

!

WARNING

Disconnect and stow cables before moving.

—9—

NEVER use a tool which is defective or

operating abnormally. If the tool appears to be

operating unusually, making strange noises,

or otherwise appears defective, stop using it

immediately and arrange for repairs.

!

CAUTION

Maintain tools with care. Keep blades sharp

and clean. Properly serviced tools and knifes

with sharp edges are less likely to bind or clutter

material and are easier to control.

Page 10

General Safety Rules -Save These Instructions-

6. PLY CUTTER SAFETY

!

WARNING

Make sure that the power cable is not near the

material entrance opening.

!

WARNING

Keep your body positioned perpedicular to the

material feeding direction on the oposite side of

the electric motor.

!

WARNING

Keep your hands away from the feeding rolls

and splitting area. Always guide the material in a

way that your hands have a minimum distance of

3.94” (10 cm) from this area.

!

CAUTION

Do not use dull or damaged blades/ knives.

!

WARNING

Avoid inclines, declines and oor obstructions

when pushing cart. Only push cart in directions

permitted by xed casters, never pull or attempt

to slide sideways.

!

WARNING

Ensure Ply 130 WB plug is disconnected and

cables are stored before transporting cart.

!

WARNING

Ply cart is for Ply 130 WB installation only.

8. REPLACING THE BLADE

!

CAUTION

Do not attempt to resharpen blades. is will

aect splitting completely through belt.

7. PLY CART SAFETY

!

WARNING

Install casters onto Ply Cart before installing

Ply 130 WB.

!

WARNING

Casters must be locked, and cart blocked from

moving during Ply 130 WB installation.

!

WARNING

Installing Ply 130 WB onto Ply Cart requires

two persons. Ensure Ply 130WB is tightly secured

to Ply Cart using mounting bolts provided.

!

WARNING

Do not push or tow the Ply Cart with a driven

machine.

!

WARNING

Always wear cut-proof safety gloves and safety

glasses when replacing blade. Blade is razor

sharp, treat it accordingly.

!

WARNING

Before performing a blade replacement, follow

all procedures stated in manual.

!

WARNING

Only authorized and trained technicians should

work on the ply separator.

!

WARNING

Test the splitter aer blade / knife replacements

to make sure that it can be used safely.

!

WARNING

www.flexco.com

www.flexco.com

Stow spare blades safely.

—10—

Page 11

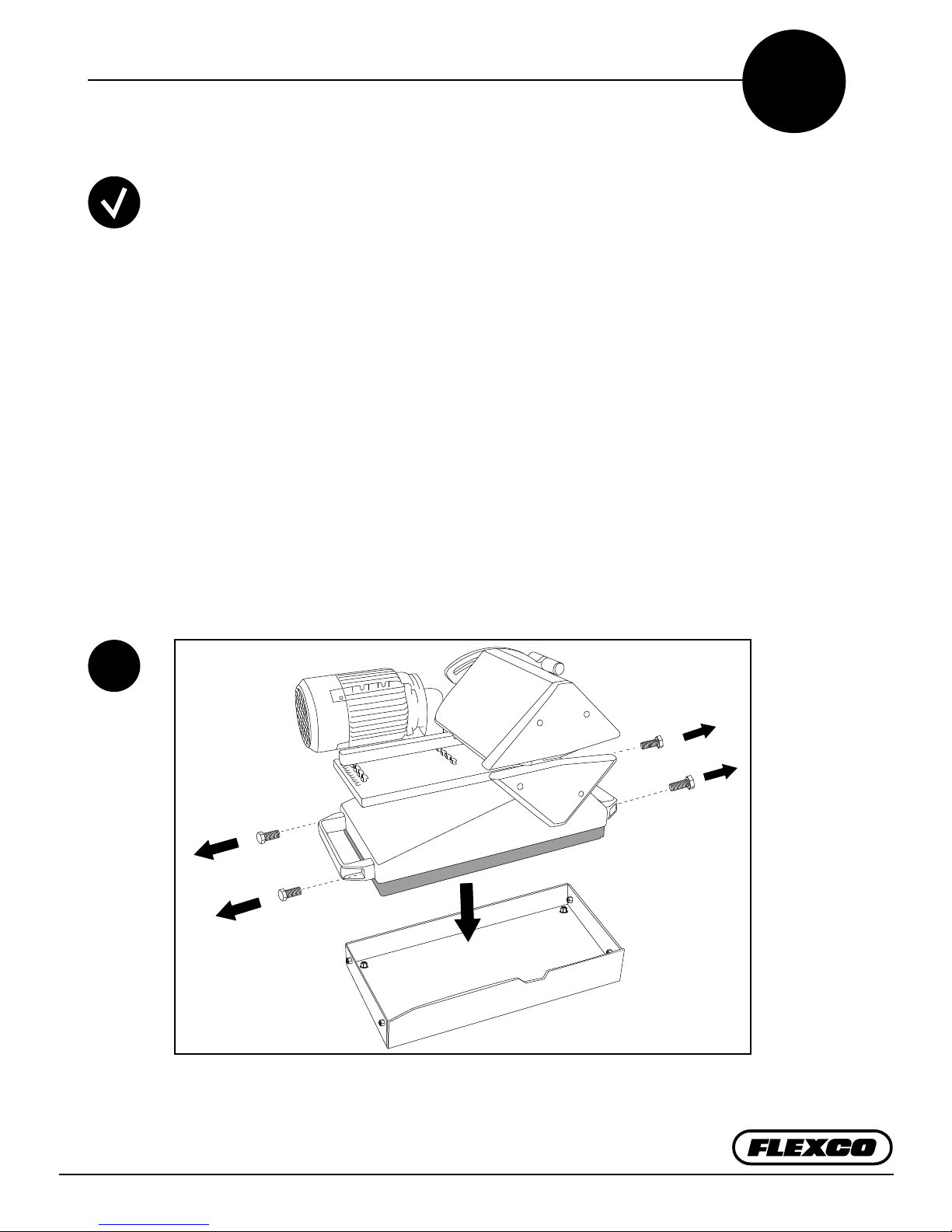

Retrofit Tray

To mount an earlier model Ply 130 WB on a new model Ply 130 Cart (item

code 08100) the Ply tray on the earlier ply 130 WB, must be replaced with

retrot Ply 130 Tray (item 08233).

A

A1

To remove existing tray from the Ply 130, remove fasteners from handles and

remove handles. The tray can now be removed. Then install new tray (item

code 08233) oriented as shown in above illustration and reinstall handles.

—11—

Page 12

www.flexco.com

—12—

Page 13

Workbench Installation

e Workbench version should for safety reasons be mounted on a rm and

level workbench (A1).

B

B1

Tighten 4 bolts in holes on bottom of machine.

—13—

Page 14

www.flexco.com

—14—

Page 15

Cart Installation

A

C

C

B

Bottom View

A

B

C

2x Fixed casters with brake

1x

1x

16x

Swiver caster with brake

Swiver caster

Bolt M10x25

Bolt M8x204x

16x

M10 Nylok anged

—15—

Page 16

Cart Installation

C1

A

A

C

C

B

B

C2

Mount wheels. For position and materials refer to drawing on page 15.

A

For access to Ply 130WB mounting bolt hole positions (A), remove drawer by

pushing the drawer latch on two sides.

www.flexco.com

—16—

Page 17

Cart Installation

C3

C4

Lock casters and block cart before installing Ply 130.

A

B

Center Ply 130 onto cart with motor (A) toward the logo side (B). Mount Ply 130

on cart. Ensure keyed patterns of cart and Ply tray t properly. Tighten M8x20

bolts (included with Ply 130 Cart) rmly.

—17—

Page 18

Cart Installation

C5

C6

Reinstall drawer by pushing it fully into the cart.

2

1

For moving cart; 1. Put foot pedal in cart. 2. Hang power cord on cart.

www.flexco.com

—18—

Page 19

Separating for Finger over Finger Joints

Prior to splitting ensure:

• e Ply 130 is mounted properly (B-C).

• When using the Ply 130 in combination with the Ply Cart; always lock three

casters before starting to work with the Ply 130.

To prepare for a nger over nger splice the

i

material is separated between the plys . e

point of separation should be determined by the

operator since it will depend on belt material,

number of plys and desired splice.

e stepped pattern and ngers are created with

a nger punching tool aer the separation.

D

D1

Release side guide and move to set to desired splitting depth. Setting is

performed in steps of 5 mm. Lock guide.

—19—

Page 20

Separating for Finger over Finger Joints

D2

0

5

D3

Set the belt thickness point of separation using the adjuster handle to position

the lower traction roller.

NOTE: Scale is for reference only and not a linear dimension.

OFF

REVERSE

FORWARD

Set switch to forward.

CAUTION: When engaging in “REVERSE”, traction rollers are

immediately powered.

www.flexco.com

—20—

Page 21

Separating for Finger over Finger Joints

D4

D5

Operate traction rolls in the forward direction by pressing footpedal.

Use sample piece to verify the thick point of separation, adjusting position (D2)

as needed. When required, separate trailing corner (as illustrated) to prepare

sample for full width ply separation.

—21—

Page 22

Separating for Finger over Finger Joints

D6

Feed belt material through machine.

TIP! make your own logbook of belting material and settings for

future reference. Set operating switch to o when separation is complete.

www.flexco.com

—22—

Page 23

E

Maintenance Ply Separation Blade Replacement

Prior to the replacement ensure:

• Acquire ocial Flexco replacement set PLY BL Blade & Jig

(item code 08014).

• When replacing Ply Separation Blade always wear cut-proof safety gloves

and safety glasses as mentioned in chapter General Safety Rules.

E1

!

Before replacing Ply Separation Blade, check for burs, straightness

and atness. WARNING: DO NOT TOUCH EDGE OF BLADE

—23—

Page 24

Maintenance Ply Separation Blade Replacement

E2

! !

E3

Put handle in position 3 and guide at 125 mm.

FORWARD

OFF

REVERSE

Put calibration jig on feed table with thin edge toward rollers and turn switch

to forward.

www.flexco.com

—24—

Page 25

Maintenance Ply Separation Blade Replacement

E4

E5

Push block into machine and simultaneously turn on machine with foot pedal.

When jig stops, stop machine.

NOTE: calibration jig must be parallel to frame!

Release blade by unscrewing two bolts at bottom of blade with an allen key.

Carefully remove blade nuts.

DISCONNECT POWER CABLE FROM ELECTRICAL POWER SOURCE.

—25—

Page 26

Maintenance Ply Separation Blade Replacement

E6

E7

Remove blade carefully.

WARNING: DO NOT TOUCH EDGE OF BLADE

Install new Ply Separation Blade with bevel side down. Mount bolts and blade nuts.

WARNING: DO NOT TOUCH EDGE OF BLADE

www.flexco.com

—26—

Page 27

Maintenance Ply Separation Blade Replacement

E8

E9

Tighten bolts suciently to allow blade to slide but not li.

1

2

1. Push Ply Separation Blade by hand so it presses against calibration block.

2. Tighten bolts rmly.

—27—

Page 28

Maintenance Ply Separation Blade Replacement

E10

FORWARD

OFF

REVERSE

Reconnect power cable to electrical power supply. Rotate switch to reverse

to release calibration block from machine.

www.flexco.com

—28—

Page 29

F

Adjustment of clearance between rollers and blade

Aer replacing the Ply Separation Blade, it may be necessary to adjust the

traction rolls.

e recommended traction roller clearance is 0.2mm (0.008”).

F1

F1

To evaluate clearance, begin by positioning the adjustment handle to 0. Insert the white

clearance shim between the ply separation blade and the traction rolls. e shim should

move freely. e black clearance shim should not t between the ply separation blade

and the traction rolls.

—29—

Page 30

Ply 130™ ply separator

F2

F3

If adjustment is needed, unscrew electric motor to gain sucient access for

adjustment of traction rolls.

Put handle in position 3.

www.flexco.com

—30—

Page 31

Ply 130™ ply separator

F4

A

F5

Unscrew (A) and take out tting bolt of the air spring.

Loosen xation screw of air spring.

—31—

Page 32

Ply 130™ ply separator

F6

B

F7

Pull air spring down slightly to rolate the black arm (B).

B

C

D

For increasing the clearance: Loosen the screw (D) a small amount and tighten screw (C).

is rotates the sha counterclockwise, related to lever (B). A short 5 mm Hex

wrench is required to reach the screws.

www.fl exco.com

—32—

Page 33

Ply 130™ ply separator

F8

F9

B

For decreasing the clearance: Loosen screw (C) a small amount and tighten screw (D).

is rotates the sha clockwise, relative to lever (B).

C

D

A

Put air spring in its original position and reinstall bolt (A). See item F3.

—33—

Page 34

Ply 130™ ply separator

F10

F11

Check for the clearance between the top roller and the blade by inserting the

clearance shims. ere should be no/little pressure on the white shim, but the

black shim should not pass through.

Lock the air spring.

www.flexco.com

—34—

Page 35

Ply 130™ ply separator

F12

E

F

F13

Repeat operation for bottom roll with screws (E) and (F) but move handle to

position 0. Use clearance shims to achieve a clearance of 0.2 mm (0.008”).

Reinstall motor aer adjustments are complete.

—35—

Page 36

Ply 130™ ply separator

ank you for choosing the Novitool® Ply 130™ ply separator.

Your feedback is appreciated and may be directed to Flexco Customer Service at 1-800-541-8028

2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 U.S.A.

Telephone: (630)-971-0150 • Fax: (630)-971-1180 • E-mail: info@exco.com • Web: www.flexco.com

Australia: 61-2-9680-3322 • China: 86-21-33528388 • England: 44-1274-600-942

Germany: 49-7428-9406-0 • Mexico: 52 -55- 5674-5326 • South Africa: 27-11-608-4180

©2010 Flexible Steel Lacing Company. 04-10. For reorder: X2660 01/08-5. For Reorder: X0000

Loading...

Loading...