Flexco Novitool PUN M 300, Novitool PUN M 600, Novitool PUN M 900 Safety And Operation Manual

Page 1

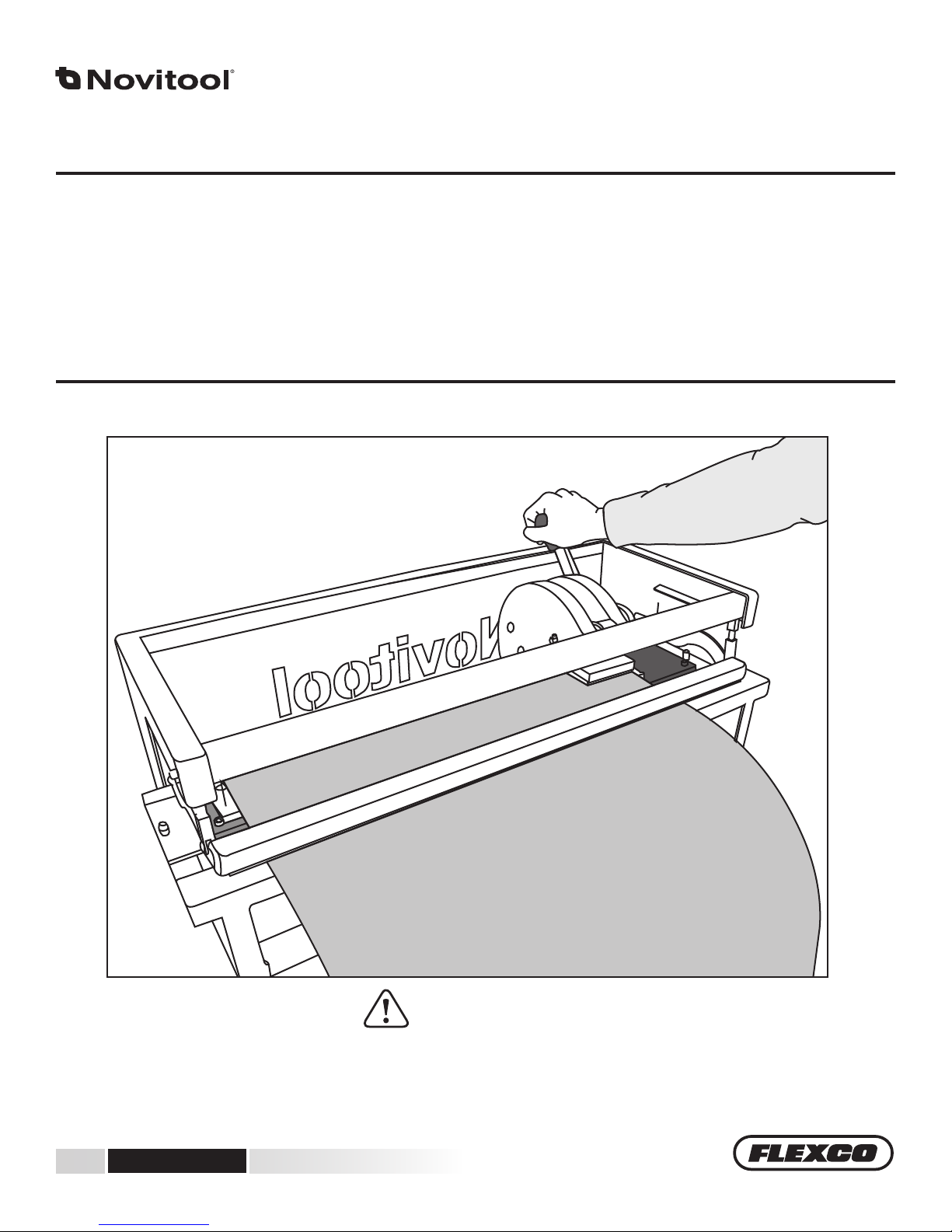

PUN M™ Manual Finger Punch

300 - 600 - 900

Safety and Operation Manual

For punching thermoplastic belting materials only.

IMPROPER OR UNSAFE use of this tool can result in serious bodily injury! is manual contains important information

about product function and safety. Please read and understand this manual BEFORE operating the tool. Please keep this

manual available for other users and owners before they use the tool. is manual should be stored in a safe place.

www.flexco.com

www.flexco.com

WARNING

Page 2

Table of Contents

Main Components .........................................................................................3

Description ..................................................................................................... 3

Tool Specications .........................................................................................4

General Safety Rules ......................................................................................5

Work Preparation and Replacing Punchboards ........................................ 7

Punching Single Fingers .............................................................................12

Punching Finger over Finger .....................................................................19

Bias Finger Punching ..................................................................................27

Bias Finger Over Finger Punching ............................................................ 32

Replacement Parts ....................................................................................... 41

Transportation Security .............................................................................. 42

ww w.flexco.com

—2—

Page 3

+

-

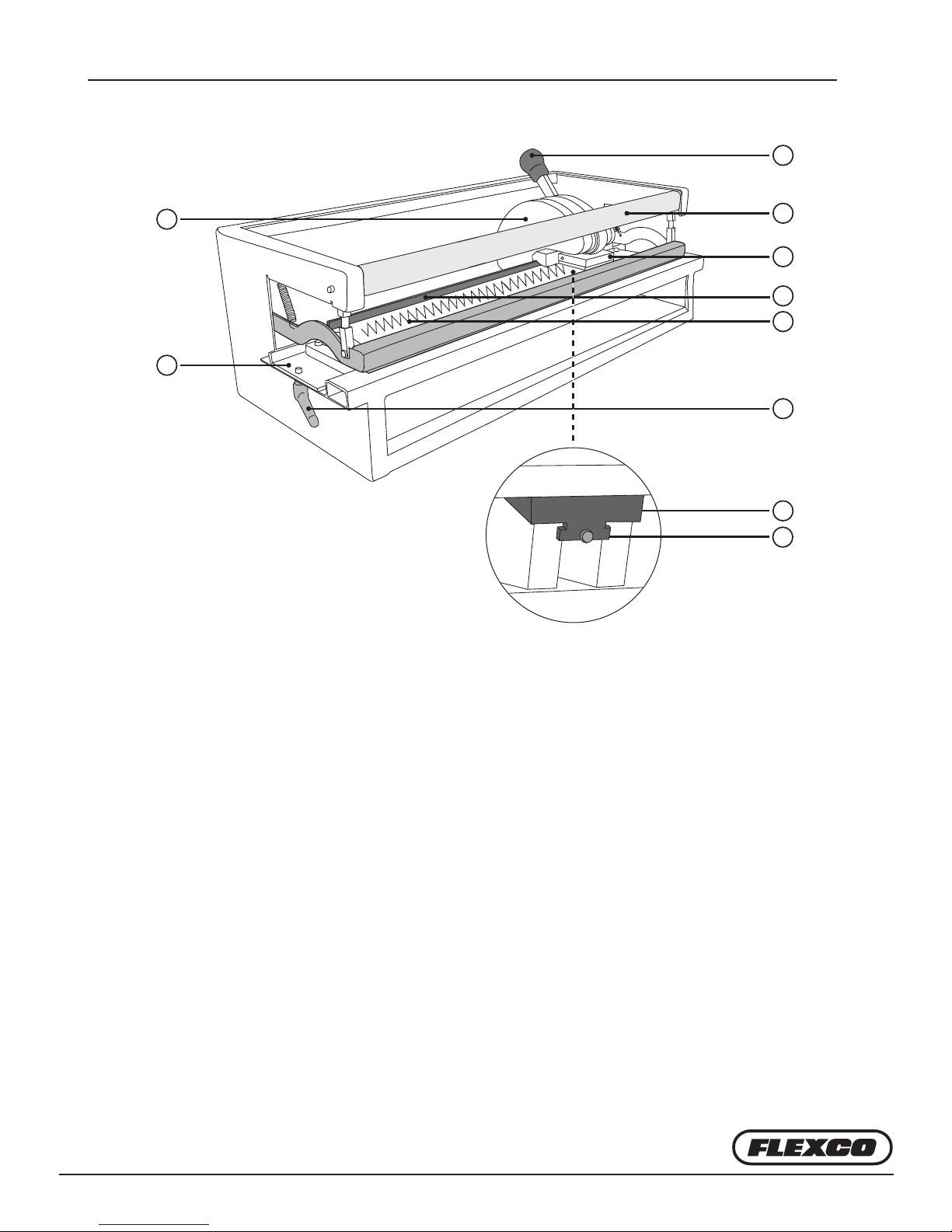

Main Components

1

7

8

1. C-Frame Handle

2. Belt Clamp Bar

3. Punchblock

4. Belt Stop

5. Punchboard with Finger Knives

2

3

4

5

6

9

10

6. Lock Handle

7. C-frame

8. Punchboard Tray

9. C-frame Wedge

10. Fixation Screw and Punching Force Adjustment

Description

e PUN M™ is designed to punch ngers on the ends of

lightweight thermoplastic conveyor belts as a preparation for

making nger- or nger-over-nger splices.

e Pun M is manually operated and does not need electricity

or air pressure for its operation. e punching force of

11,000lbs. (50 kN) is created by pulling the lever and is easily

done with one hand by an average person. Because of its easy

set-up and manual operation, the PunM is an ideal tool for

working on location, as well as in a workshop.

Although all punchboards of the Pun M have a specied net

width, the open construction of the frame allows belts of

larger widths to be punched with these machines.

With one lever pull, a nger punch of 90 mm wide can be

made (based on 50 × 20 ngers for nger-overlap-nger

splicing) or 60 mm wide (based on 80 × 20 or 70 × 15 ngers

for single nger splicing). e maximum thickness is up to

5mm for light weight belting.

—3—

Page 4

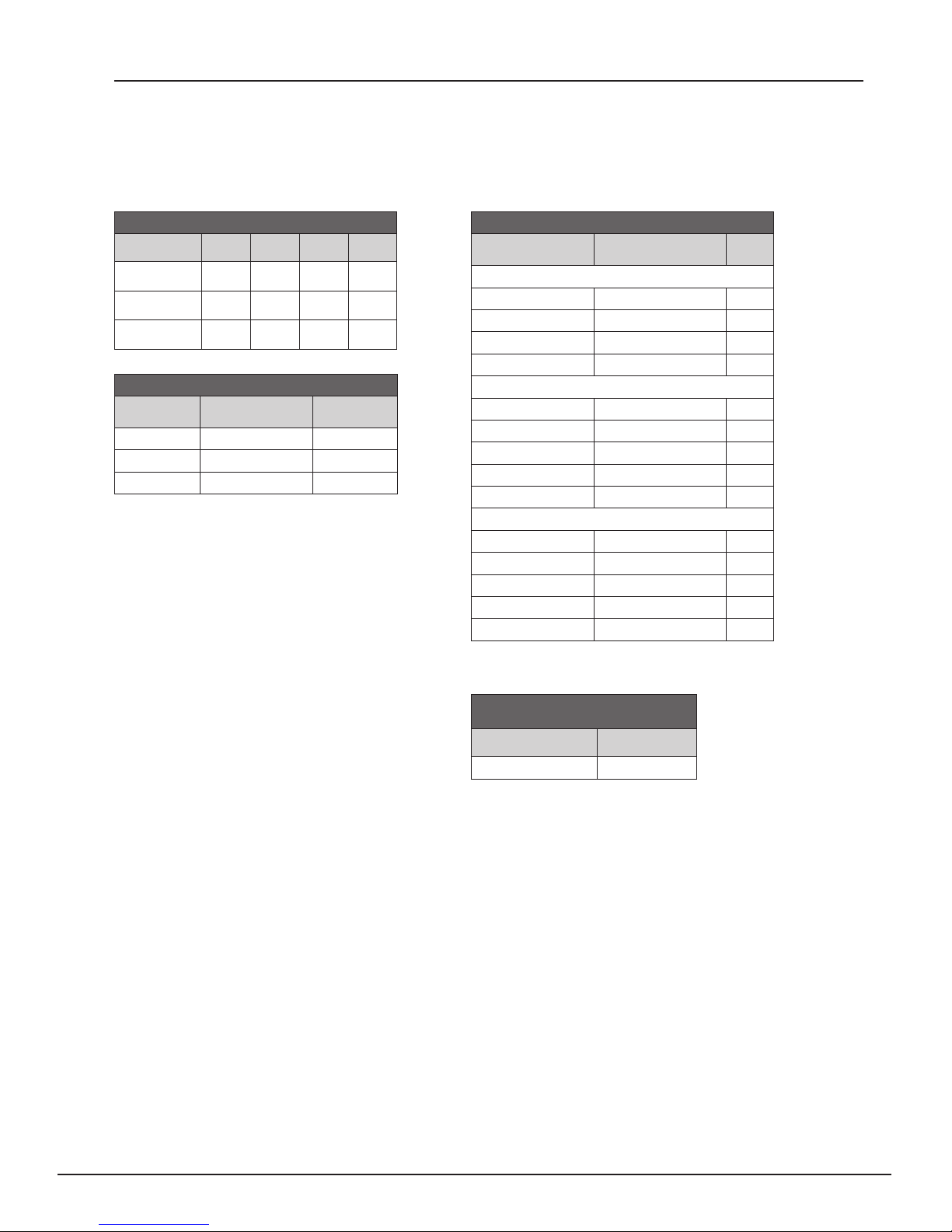

Tool Specifications

Pun M™ Dimensions

L H W Weight

Pun M 300

Pun M 600

Pun M 900

23"

570 mm

34"

870 mm

46"

1170 mm

15"

370 mm

15"

370 mm

15"

370 mm

14"

360 mm

14"

360 mm

14"

360 mm

Pun M™ Ordering Information

Ordering

Number

PUN-M-300 300 08016

PUN-M-600 600 08017

PUN-M-900 900 08018

Effective

Punching Length

Item Code

31 lbs

14 kg

37 lbs

17 kg

44 lbs

20 kg

Pun M™ Punchboard Specifications

Ordering Number

Pun M 300 Punchboards

1.97" × 0.79" (50 × 20 mm)* PUN-B-50x20-300 08019

2.76" × 0.59" (70 × 15 mm) PUN-B-70x15-300 08022

3.15" × 0.79" (80 × 20 mm) PUN-B-80x20-300 08025

1.97” x 0.71” (50 x 18 mm) PUN-B-50x18x31BIAS-300 08539

Pun M 600 Punchboards

1.97" × 0.79" (50 × 20 mm)* PUN-B-50x20-600 08020

2.76" × 0.59" (70 × 15 mm) PUN-B-70x15-600 08023

3.15" × 0.79" (80 × 20 mm) PUN-B-80x20-600 08026

1.97” x 0.71” (50 x 18 mm) PUN-B-50x18x31BIAS-600 08540

3.15” × 0.79” (80 × 20 mm) PUN-B-80x20x113BIAS-600 08439

Pun M 900 Punchboards

1.97" × 0.79" (50 × 20 mm)* PUN-B-50x20-900 08021

2.76" × 0.59" (70 × 15 mm) PUN-B-70x15-900 08024

3.15" × 0.79" (80 × 20 mm) PUN-B-80x20-900 08027

1.97” x 0.71” (50 x 18 mm) PUN-B-50x18x31BIAS-900 08526

3.15” × 0.79” (80 × 20 mm) PUN-B-80x20x113BIAS-900 08440

* Also suitable for Finger-Over-Finger splices.

** Custom Punch Boards Available Upon Request.

Item

Code

Pun M™ Punching Block

Nylon Inlay

Ordering Number Item Code

PUN-M-NYLONPAD-KIT 08279

ww w.flexco.com

—4—

Page 5

General Safety Rules

–Save These Instructions–

Signal words:

“DANGER” indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury. e signal word is

limited to the most extreme situations.

“WARNING” indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used to

alert against unsafe practices.

Safety Symbol

!

is international safety symbol is used to

identify and call attention to specic

safety matters.

Safety Information

2. PERSONAL SAFETY

!

WARNING

Stay alert, watch what you are doing and use

common sense when operating a tool. Do not

use tool while tired or under the inuence of

drugs, alcohol, or medication. A moment of

inattention while operating tools may result in

serious personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be

caught in moving parts.

Do not overreach. Keep proper footing and

balance at all times to enable better control of

the tool in unexpected situations.

Never alter or remove safety devices.

Keep your hands and ngers away from the

knives in the punchboard, at all times.

To Avoid Severe Personal Injury or Property

Damage, read carefully and understand the

following Safety Precautions.

1. WORK AREA

!

CAUTION

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

!

CAUTION

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

—5—

Page 6

General Safety Rules

3. TOOL USE AND CARE

!

WARNING

Always use the punching machine on a level,

rm surface. Punching should be performed

operating the machine with one hand on the

handle and the other on the top part of the

frame or C-frame.

Tool service must be performed only by

qualied repair personnel. Service or

maintenance performed by unqualied

personnel could result in a risk of injury.

!

CAUTION

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools,

with sharp cutting edges, are less likely to

require unnecessary high forces and are easier

to control. If damaged, have the tool serviced

before using. Many accidents are caused by

poorly maintained tools.

4. PUNCHBOARD SAFETY

AND REPLACEMENT

!

CAUTION

Always use original Flexco punchboards in

combination with the Pun M

Do not use dull or damaged punchboards.

Always protect yourself against the knives of

unused punchboards by shielding them with

cardboard packaging material or wood. is

material should also protect the knives from

getting damaged.

™

.

e Punching machine should not be used

to punch materials other than thermoplastic

belting materials. e thickness of the belting

material should never exceed 0.24 inch (6 mm).

When servicing a tool, use only original Flexco

replacement parts.

Do not wipe plastic parts with solvent. Solvents

such as gasoline, thinner, benzene, carbon

tetrachloride, and alcohol may damage and

crack plastic parts. Do not wipe them with such

solvents. Wipe plastic parts with a so cloth

lightly dampened with soapy water and

dry thoroughly.

www.flexco.com

—6—

Page 7

1

2

A

Work Preparation and Replacing Punchboards

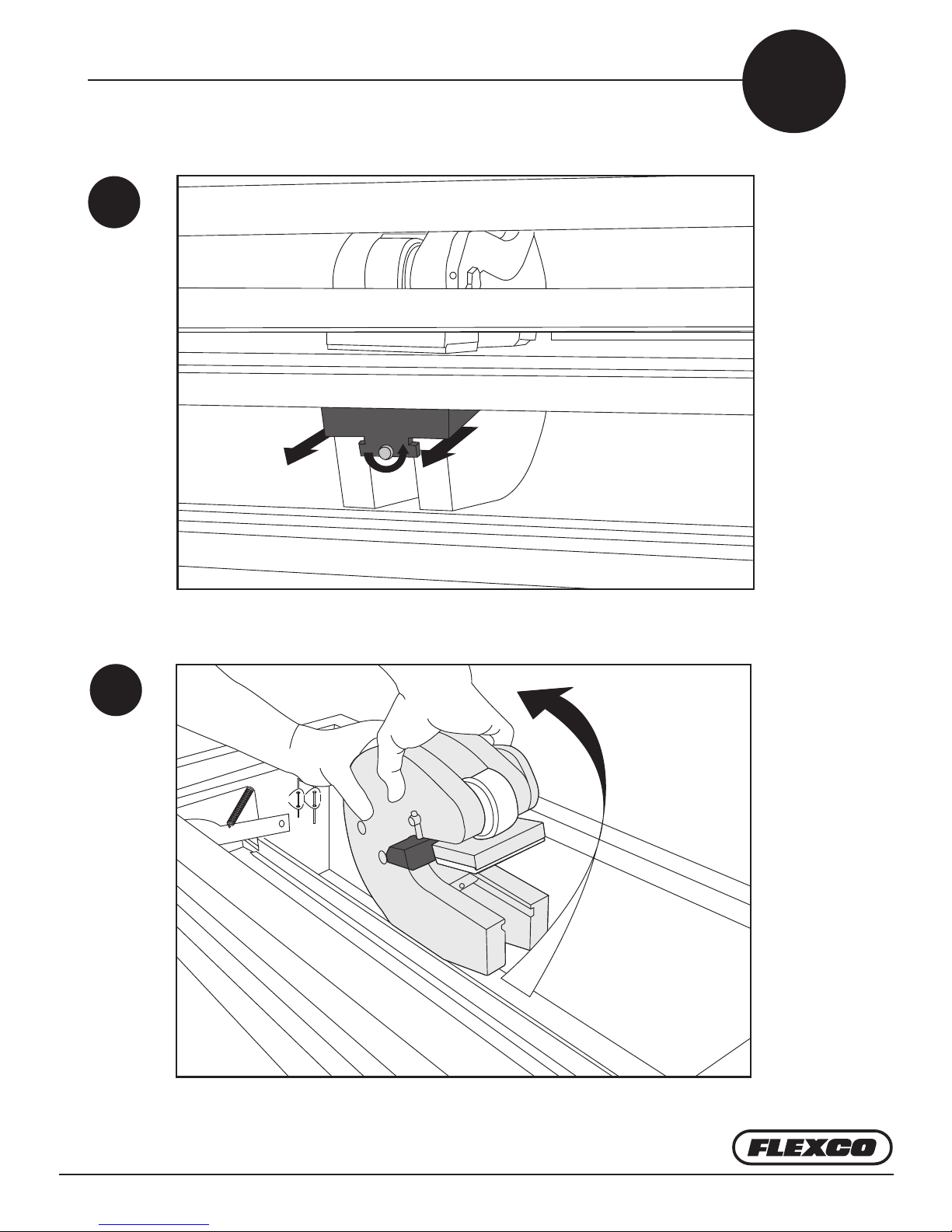

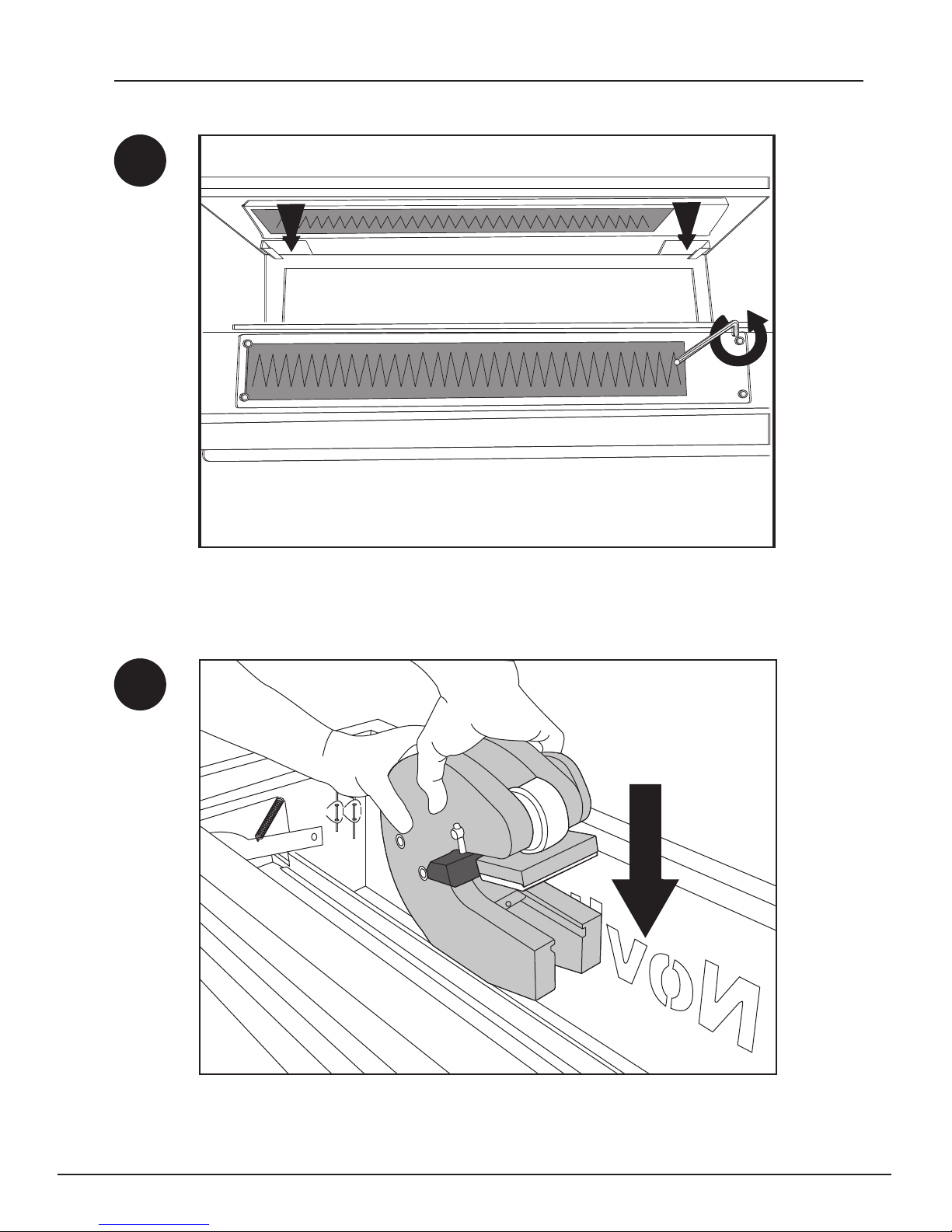

A1

A2

1. Loosen and remove xation screw. 2. Take out the black C-frame wedge.

Ensure tray is in forward position. Twist C-frame to remove.

—7—

Page 8

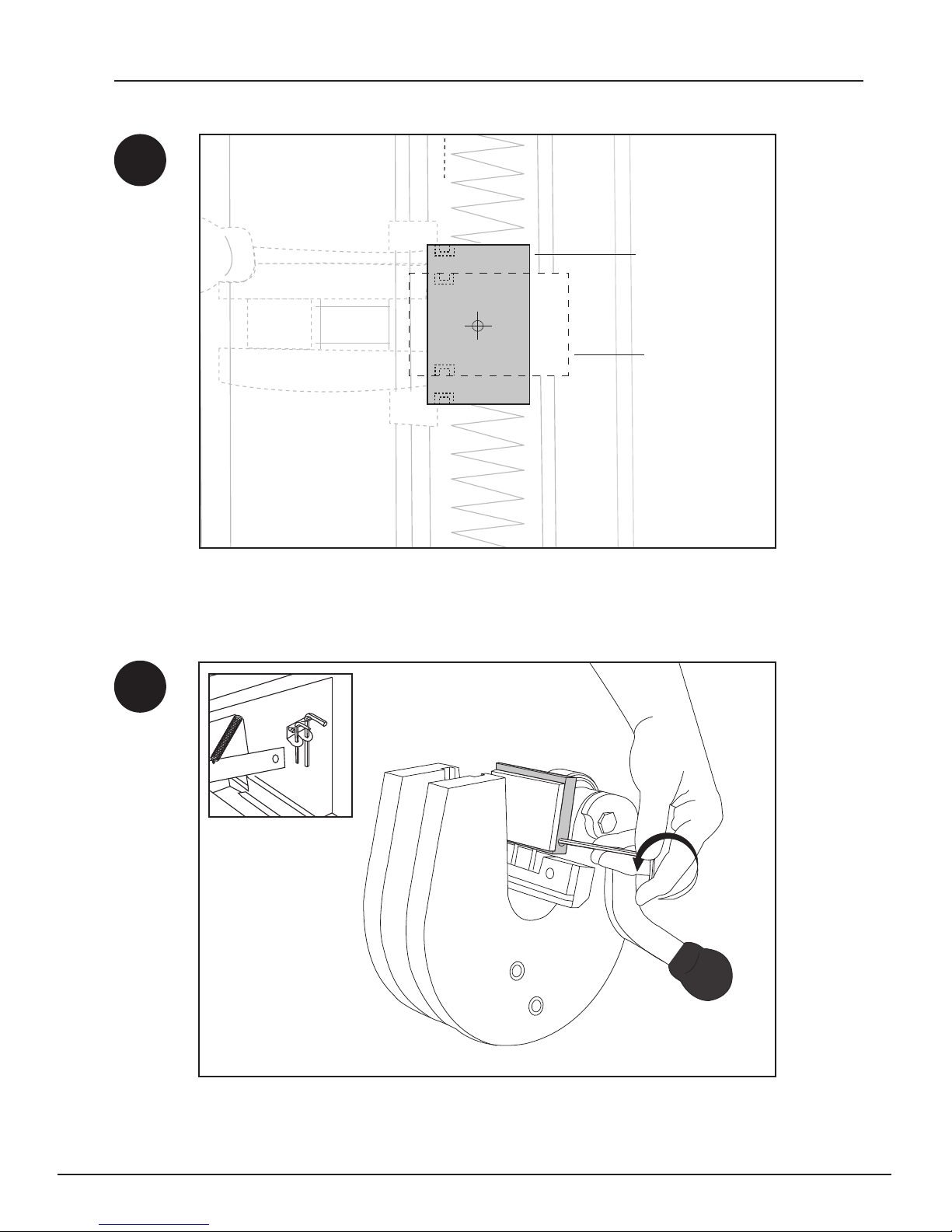

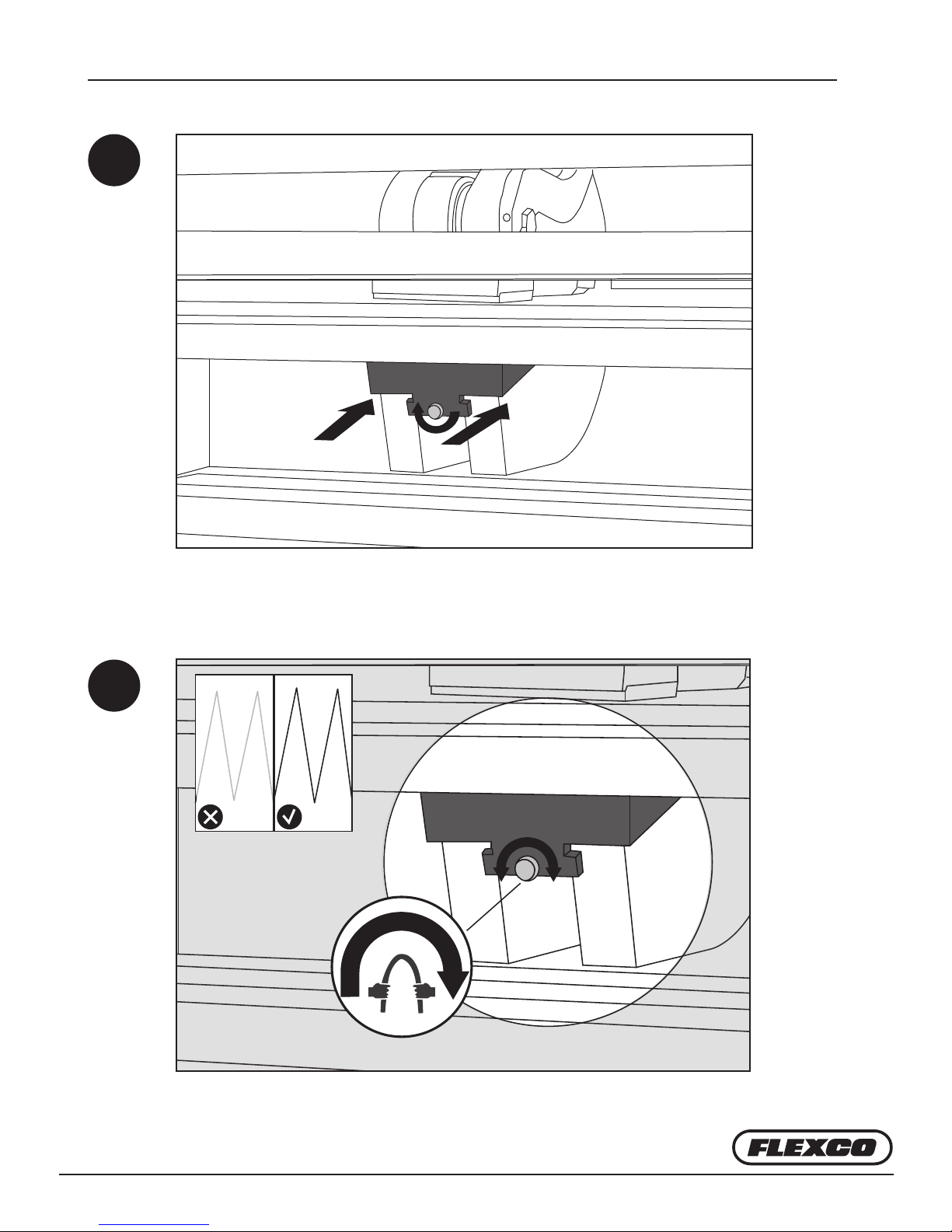

Work Preparation and Replacing Punchboards

A3

Pun-B-50×20

Pun-B-50×18×31 Bias

Pun-B-70×15

Pun-B-80×20

Pun-B-80×20×113 Bias

A4

Determine required punchblock position.

Loosen set screw that holds punchblock in place when repositioning

isrequired.

ww w.flexco.com

—8—

Page 9

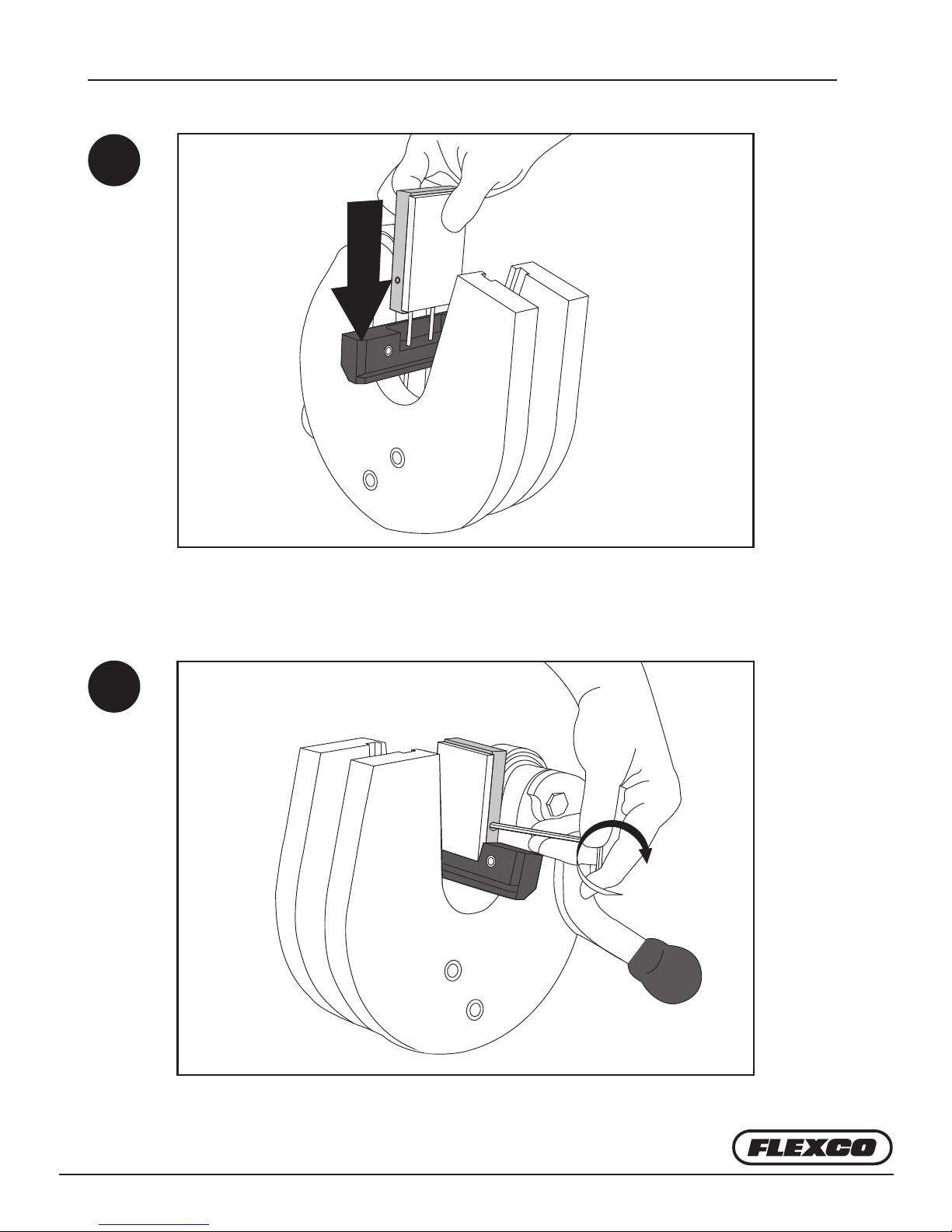

Work Preparation and Replacing Punchboards

A5

A6

Slide punchblock over pins.

Secure punchblock with set screw.

—9—

Page 10

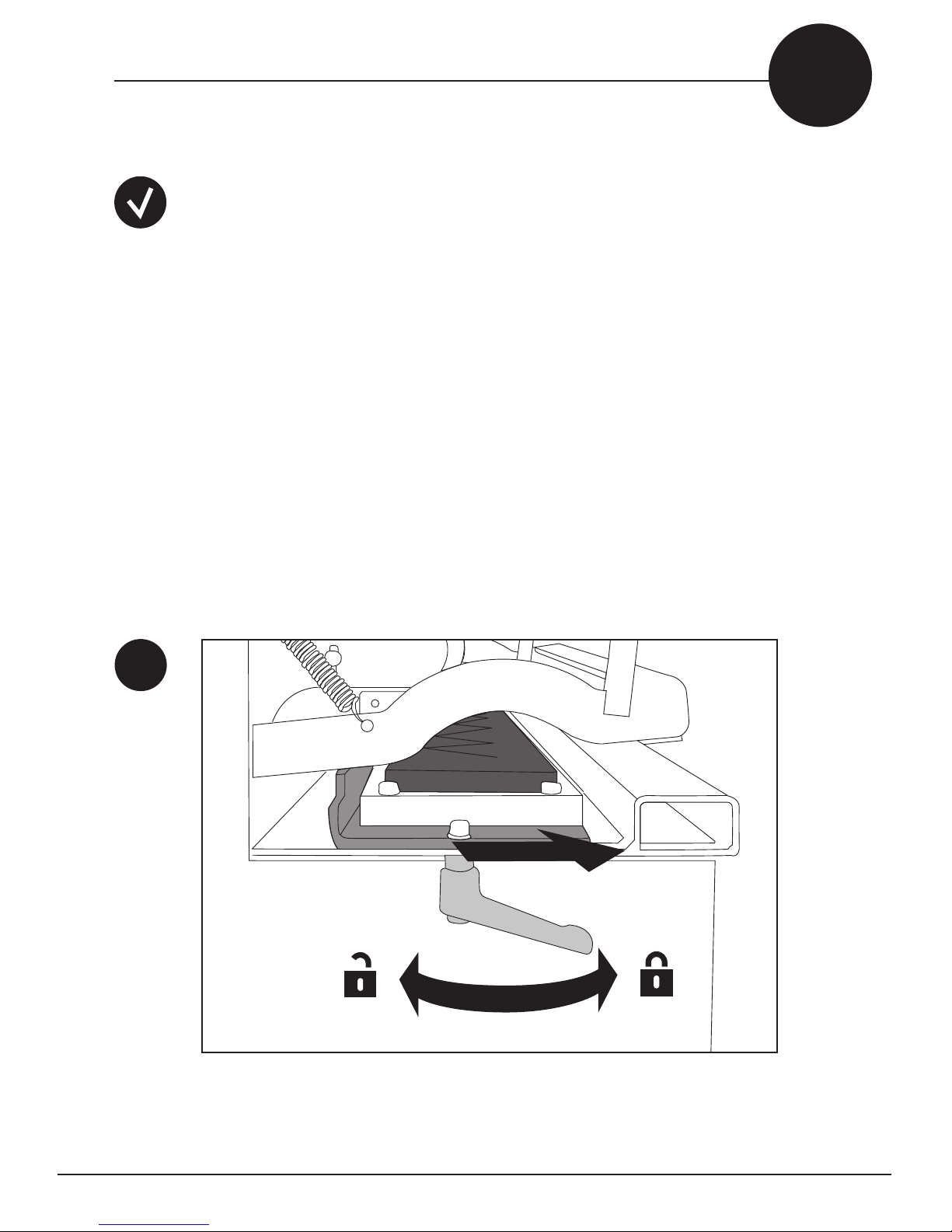

Work Preparation and Replacing Punchboards

A7

A8

Replace punchboard by unscrewing the four hex bolts. Stow unused

punchboard in holder on the back.

Reinstall C-frame.

ww w.flexco.com

—10—

Page 11

Work Preparation and Replacing Punchboards

A9

A10

2

Secure C-frame. 1. Reinstall C-frame wedge. 2. Turn the xation screw to the

right. Attention: e screw is also used to adjust punching force.

1

Turn xation screw clockwise to increase punch cutting force.

-

+

—11—

Page 12

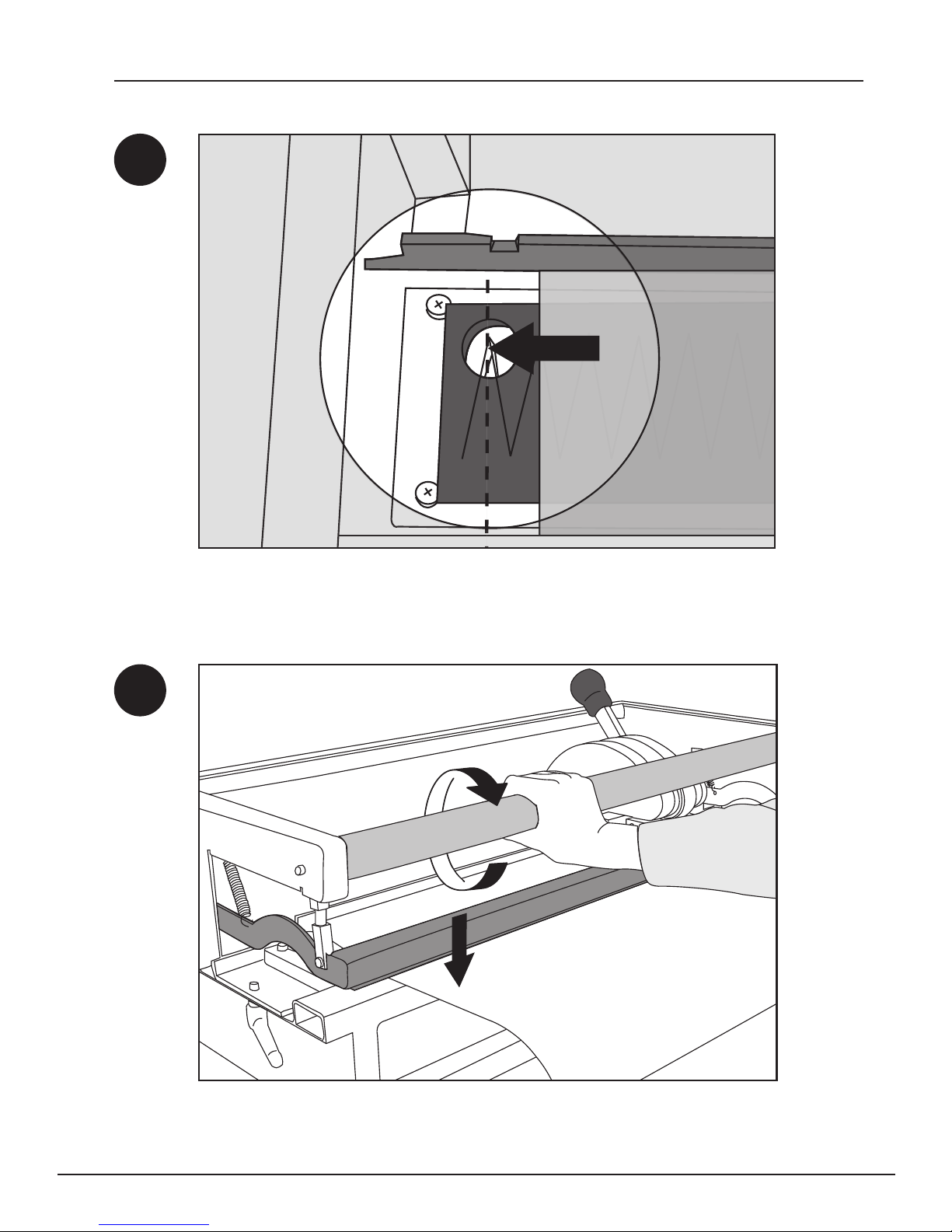

Punching Single Fingers

Prior to punching ensure:

• e punchblock is in the right position (A3)

• e correct punchboard is installed (A7)

• e punch force has been adjusted for material (A10)

B

B1

2

1

1. Unlock punchboard tray at both ends. 2. Move punchboard tray to front most

position. 3. Lock punchboard tray at both ends.

Attention: When required, reposition lock handle (A11).

3

ww w.flexco.com

—12—

Page 13

Punching Single Fingers

B2

B3

Pull lock handle down if repositioning is required to rmly lock tray.

Insert belt until ush against belt stop.

—13—

Page 14

Punching Single Fingers

B4

B5

Le align belting material with top of V-Pattern in knife set.

Turn belt clamp bar to clamp belt.

ww w.flexco.com

—14—

Page 15

Punching Single Fingers

B6

B7

Place le hand on rear frame for support. Use other hand to operate lever to

punch belt. Punch in center, at both ends, and then across remainder of material.

Remove excess punched material.

Turn belt clamp bar. Remove belt.

—15—

Page 16

Punching Single Fingers

B8

2

IN

OUT

1

B9

Remove punched belt end. Install opposite belt end with cover side down into

the machine.

Insert belt end until ush with belt stop. Le align belt with the bottom of

V-Pattern in knife set.

ww w.flexco.com

—16—

Page 17

Punching Single Fingers

B10

B11

Turn belt clamp bar to clamp belt.

Repeat punching process as shown in B6.

—17—

Page 18

Punching Single Fingers

B12

Turn belt clamp bar. Remove belt.

ww w.flexco.com

—18—

Page 19

Punching Finger over Finger

Prior to punching ensure:

• e punchblock is in the right position (A3)

• e correct punchboard is installed (A7)

• e punch force has been adjusted for material (A10)

• Make sure belt ends are ply separated

C

C1

2

1

1. Unlock punchboard tray at both ends. 2. Move punchboard tray to front most

position. 3. Lock punchboard tray at both ends.

Attention: When required, reposition lock handle (B2).

3

—19—

Page 20

Punching Finger over Finger

C2

C3

Insert belt until ush against belt stop.

Align belt with top of V-Pattern in knife set.

ww w.flexco.com

—20—

Page 21

Punching Finger over Finger

C4

C5

Turn belt clamp bar to clamp belt.

Fold top layer of belt towards you.

—21—

Page 22

Punching Finger over Finger

C6

C7

Place le hand on rear frame for support. Use other hand to operate lever to

punch belt. Punch in center, at both ends, and then across remainder of material.

Remove excess punched material and loosen ngers from punch board prior to

sliding back the tray.

35 mm

2

Keep belt clamped. 1. Unlock punchboard tray at both ends. 2. Slide it to the

nal back position. 3. Lock punchboard tray at both ends.

ww w.flexco.com

1 3

—22—

Page 23

Punching Finger over Finger

C8

C9

Repeat punching process for second array of ngers. Again remove punched

excess material.

Turn belt clamp bar. Remove belt.

—23—

Page 24

Punching Finger over Finger

C10

2

C11

1

1. Unlock punchboard tray at both ends. 2. Move punchboard tray to front most

position. 3. Lock punchboard tray at both ends.

3

2

IN

OUT

1

Install opposite belt end with cover side down into the machine.

ww w.flexco.com

—24—

Page 25

Punching Finger over Finger

C12

C13

Insert belt end until ush with belt end stop. Le align belting material with

bottom of V-Pattern in knife set.

Repeat punching process as shown in C5-C6 for rst layer.

Repeat C7-C9 second layer.

—25—

Page 26

Punching Finger over Finger

C14

Turn belt clamp bar. Remove belt.

ww w.flexco.com

—26—

Page 27

Bias Finger Punching

Prior to punching ensure:

• e punchblock is in the right position (A3)

• e correct punchboard is installed (A7)

• e punch force has been adjusted for material (A10)

D

D1

4.8” (120 mm)

5:1 Ratio

24” : 4.8”

600 mm : 120 mm

4.8” (120 mm)

Prepare the belt ends for bias nger punching by cutting opposing (5:1 ratio) angles

on each belt end. NOTE: Both belt ends will be punched with the conveying side

upwards in the PUN M.

24” (600 mm)

Conveying Side

—27—

Page 28

Bias Finger Punching

D2

D3

Insert the initial belt end cover side up and ush against belt stop. Align the le

edge of belting with top of V-pattern in knife set.

Clamp the belt in place by rotating the belt clamp bar.

ww w.flexco.com

—28—

Page 29

Bias Finger Punching

D4

D5

Place le hand on rear frame for support. Use other hand to operate lever to

punch belt. Punch in center, at both ends, and then across remainder of material.

Remove excess punched material.

Turn belt clamp bar. Remove belt.

—29—

Page 30

Bias Finger Punching

D6

D7

Insert the opposite belt end cover side up into the Punch. Flush against belt.

Align right belt edge with bottom of V-pattern in knife set.

Turn belt clamp bar to clamp belt.

ww w.flexco.com

—30—

Page 31

Bias Finger Punching

D8

D9

Clamp the belt in place by rotating the belt clamp bar. Punch in center, at both

ends, and then across remainder of material.

Turn belt clamp bar. Remove belt.

—31—

Page 32

Bias Finger Over Finger Punching

Prior to punching ensure:

• e punchblock is in the right position (A3)

• e correct punchboard is installed (A7)

• e punch force has been adjusted for material (A10)

• Make sure belt ends are ply separated.

E

E1

E1

14.2” : (360 MM)

5:3 Ratio

24” : 14.2”

600 mm : 360 mm

14.2” : (360 MM)

Prepare the belt ends for bias nger over nger punching by cutting opposing

(5:3ratio) angles on each belt end. Use the Ply 130™ to separate each belt end to

4.3” (110 mm) depth.

24” (600 mm)

Conveying Side

ww w.flexco.com

—32—

Page 33

Bias Finger Over Finger Punching

E2

2

E3

1

1. Unlock punchboard tray at both ends. 2. Move punchboard tray to front most

position. 3. Lock punchboard tray at both ends.

Attention: When required, reposition lock handle (B2).

3

Insert initial belt end cover side up and ush against belt stop. Align the le

edge of the belting with the top of V-pattern in knife set.

—33—

Page 34

Bias Finger Over Finger Punching

E4

E5

Clamp belt in place by rotating belt clamp bar.

Place le hand on rear frame for support. Use other hand to operate lever to

punch belt. Li top layer of belt up. In this step you will only punch the bottom

layer. Punch in center, at both ends, and then across remainder of material.

ww w.flexco.com

—34—

Page 35

Bias Finger Over Finger Punching

E6

35 mm

2

E7

1 3

Keep belt clamped. 1. Unlock punchboard tray at both ends. 2. Slide it to nal

back position. 3. Lock punchboard tray at both ends.

Lay top cover down and repeat punching process for second array of ngers.

Remove excess punched material.

—35—

Page 36

Bias Finger Over Finger Punching

E8

E9

Turn belt clamp bar. Remove belt.

2

1. Unlock punchboard tray at both ends. 2. Move punchboard tray to front most

position. 3. Lock punchboard tray at both ends.

Attention: When required, reposition lock handle (B2).

ww w.flexco.com

1

3

—36—

Page 37

Bias Finger Over Finger Punching

E10

E11

Insert opposite belt end cover side up and ush against belt stop. Align right

belt edge with bottom of V pattern in knife set.

Turn belt clamp bar. Remove belt.

—37—

Page 38

Bias Finger Over Finger Punching

E12

E13

Li top layer of belt up and then tuck the bottom layer under the

punchboardtray.

Once bottom layer is out of the way, lay top layer down and punch belt. Place le

hand on rear frame for support. Use other hand to operate lever to punch belt.

Punch in center, at both ends, and then across remainder of material. Remove

excess punched material.

ww w.flexco.com

—38—

Page 39

Bias Finger Over Finger Punching

E14

E15

Keep belt clamped. 1. Unlock punchboard tray at both ends. 2. Slide it to nal back

position. 3. Lock punchboard tray at both ends (=1.38”/35mm displacement).

Li top layer up of belt up and reposition bottom layer over punchboard. In

this step you will only punch the bottom layer. Punch in center, at both ends,

and then across remainder of material. Remove excess punched material.

—39—

Page 40

Bias Finger Over Finger Punching

E16

Turn belt clamp bar. Remove belt.

ww w.flexco.com

—40—

Page 41

+

-

Replacement Parts

F

1

7

8

Replacement Parts

POSITION DESCRIPTION

C-frame Handle Grip PUN-M-CFRAMEHNDLGRIP 08197

1

Belt Clamp Bar for

PunM 300

Belt Clamp Bar for

2

PunM 600

Belt Clamp Bar for

PunM 900

3 Complete Punchblock PUN-M-PUNCH-PLATE 08128

Component

of 3

Replacement Nylon

Punchpad and Tape

5 Torsion Bushing FGTBSG 56521

ORDERING

NUMBER

PUN-M-ACTUATORBAR-300 08182

PUN-M-ACTUATORBAR-600

PUN-M-ACTUATORBAR-900 08184

PUN-M-NYLONPAD 08279

ITEM

CODE POSITION DESCRIPTION

Lock Handle for

6

Punchboard Tray

Punchboard Support

08183 Punchboard Support

10

Table for PunM 300

8

Table for PunM 600

Punchboard Support

Table for PunM 900

C-frame Wedge

Wedge Hardware Kit

(plastic cap, locking

collar, adjusting bar)

2

3

4

5

6

9

10

ORDERING

NUMBER

PUN-M-TABLELEVER 08191

PUN-M-TABLE-300 08188

PUN-M-TABLE-600 08189

PUN-M-TABLE-900 08190

PUN-MADJUSTERWEDGE

PUN-MADJUSTINGWEDGEHARDWARE

ITEM

CODE

08194

08713

PUN M™ Manual Punch

ORDERING

NUMBER

PUN M* PUN M 600 PUNCHBOARDS PUN M 900 PUNCHBOARDS

PUN-M-300 08016 PUN-B-50×20-600 08020 PUN-B-50×20-900 08021

PUN-M-600 08017 PUN-B-70×15-600 08023 PUN-B-70×15-900 08024

PUN M 300 PUNCHBOARDS PUN-B-50×18×31BIAS-600 08540 PUN-B-50×18×31BIAS-900 08526

*Punchboards not included with Pun M; purchase separately.

Note: Custom punchboards are available for other finger dimensions. Contact Customer Service for information.

PUN-M-900 08018 PUN-B-80×20-600 08026 PUN-B-80×20-900 08027

PUN-B-50×20-300 08019 PUN-B-80×20×113BIAS-600 08439 PUN-B-80×20×113BIAS-900 08440

PUN-B-70×15-300 08022 REPLACEMENT PARTS

PUN-B-80×20-300 08025 PUN-M-NYLONPAD-KIT 08279

PUN-B-50X18X31BIAS-300 08539

ITEM

CODE

ORDERING

NUMBER

—41—

ITEM

CODE

ORDERING

NUMBER

ITEM

CODE

Page 42

Transportation Security

F1

G

Position C-frame to middle of punchboard tray and slide locking pin into hole.

ww w.flexco.com

—42—

Page 43

Page 44

2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 • USA

Tel: (630) 971-0150 • Fax: (630) 971-1180 • E-mail: info@flexco.com

Visit www.flexco.com for other Flexco locations and products.

©2018 Flexible Steel Lacing Company. 11/15/18. For reorder: X2347

Loading...

Loading...