Flexco Flex-Lag Rubber, Flex-Lag Ceramic, Flex-Lag Weld-On Installation, Operation And Maintenance Manual

Page 1

Flex-Lag® Cold Bond Pulley Lagging

Installation, Operation

and Maintenance Manual

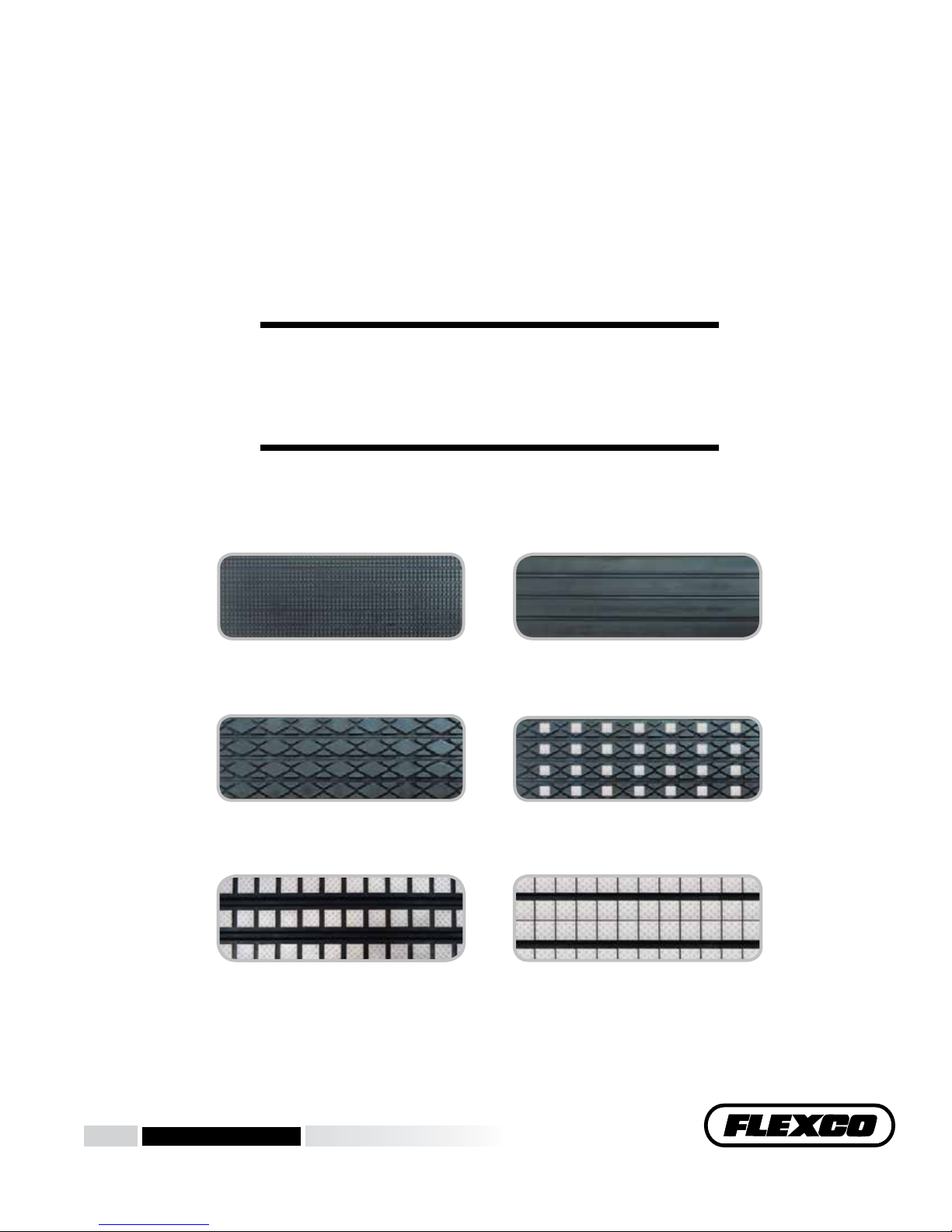

Light-Duty Plain-Pattern

Diamond-Pattern Rubber

Medium Ceramic (39%)

www.flexco.com

www.flexco.com

Diamond-Pattern Ceramic (13%)

Full Ceramic (80%)

Page 2

Flex-Lag® Cold Bond Pulley Lagging

Purchase Date: ______________________________________________________________

Purchased From: ____________________________________________________________

Installation Date: ____________________________________________________________

This information will be helpful for any future inquiries or questions

about replacement parts, specifications or troubleshooting.

2 Flex-Lag® Cold Bond Pulley Lagging

Page 3

Table of Contents

Section 1 – Important Information ....................................................................... 2

1.1 General Introduction .......................................................................................... 2

1.2 User Benets ........................................................................................................ 2

1.3 Service Option ..................................................................................................... 2

Section 2 – Safety Considerations and Precautions .............................................. 3

2.1 Stationary Conveyors .......................................................................................... 3

2.2 Operating Conveyors .......................................................................................... 3

Section 3 – Pre-Installation Checks and Options .................................................. 4

3.1 Checklist ............................................................................................................... 4

Section 4 – Installation Instructions...................................................................5-8

Section 5 – Pre-Operation Checklist and Testing.................................................. 9

5.1 Pre-Op Checklist ................................................................................................. 9

5.2 Test Run the Conveyor .......................................................................................9

Section 6 – Maintenance .................................................................................10-12

6.1 New Installation Inspection ............................................................................. 10

6.2 Routine Visual Inspection ................................................................................ 10

6.3 Routine Physical Inspection .............................................................................10

6.4 Maintenance Log ............................................................................................... 11

6.5 Lagging Maintenance Checklist ......................................................................12

Section 7 – Troubleshooting ................................................................................ 13

Section 8 – Specs and CAD Drawings............................................................. 13-21

8.1 Specications ......................................................................................................13

8.2 CAD drawing - Light Duty .............................................................................. 14

8.3 CAD drawing - Plain Rubber...........................................................................15

8.4 CAD drawing - Diamond-Pattern Rubber.....................................................16

8.5 CAD drawing - Diamond Ceramic .................................................................17

8.6 Medium Ceramic, Dimpled Tiles ....................................................................18

8.7 Medium Ceramic, Smooth Tiles ......................................................................19

8.8 Full Ceramic, Dimpled Tiles .......................................................................... 20

8.9 Full Ceramic, Smooth Tiles .............................................................................. 21

Section 9 – Lagging Adhesives/Toolbox .............................................................. 22

Section 10 – Other Flexco Conveyor Products .................................................... 25

1

Page 4

Section 1 – Important Information

1.1 General Introduction

We at Flexco are very pleased that you have selected Flex-Lag® Pulley Lagging for your conveyor system.

is manual will help you to understand the operation of this product and assist you in making it work up to

its maximum eciency over its lifetime of service.

It is essential for safe and ecient operation that the information and guidelines presented be properly

understood and implemented. is manual will provide safety precautions, installation instructions,

maintenance procedures and troubleshooting tips.

If, however, you have any questions or problems that are not covered, please contact your eld representative

or our Customer Service Department:

Customer Service: 1-800-541-8028

Visit www.exco.com for other Flexco locations and products.

Please read this manual thoroughly and pass it on to any others who will be directly responsible for

installation, operation and maintenance of this pulley lagging. While we have tried to make the installation

and service tasks as easy and simple as possible, it does however require correct installation and regular

inspections to maintain top working condition.

1.2 User Benets

Correct installation and regular maintenance will provide the following benets for your operation:

• Eliminate belt slippage

• Reduced conveyor downtime

• Reduced man-hour labor

• Lower maintenance budget costs

• Increased service life for the lagging and pulley

1.3 Service Option

Flex-Lag® Pulley Lagging is designed to be easily installed and serviced by your on-site personnel. However, if

you would prefer complete turn-key factory service, please contact your local Flexco Field Representative.

2 Flex-Lag® Cold Bond Pulley Lagging

Page 5

Section 2 – Safety Considerations and Precautions

Before installing and operating Flex-Lag® Pulley Lagging, it is important to review and understand the following safety

information.

There are set-up, maintenance and operational activities involving both stationary and operating conveyors. Each case

has a safety protocol.

2.1 Stationary Conveyors

The following activities are performed on stationary conveyors:

• Installation

• Cleaning

!

DANGER

It is imperative that OSHA/MSHA Lockout/Tagout

(LOTO) regulations, 29 CFR 1910.147, be followed before

undertaking the preceding activities. Failure to use LOTO

exposes workers to uncontrolled behavior of the products

caused by movement of the conveyor belt. Severe injury or

death can result.

Before working:

• Lockout/Tagout the conveyor power source

• Disengage any takeups

• Clear the conveyor belt or clamp securely in place

!

WARNING

Use Personal Protective Equipment (PPE):

• Safety eyewear (splash goggles optional)

• NIOSH-approved air respirator with organic

vapor cartridge (if ventilation is not available as

recommended in enclosed Safety Data Sheets)

• Hardhat • Long-sleeve shirt

• Safety footwear • Apron (optional)

• Nitrile gloves

Close quarters and heavy components create a worksite

that compromises a worker’s eyes, feet and skull.

PPE must be worn to control the foreseeable hazards

associated with conveyor lagging. Serious injuries can

be avoided.

2.2 Operating Conveyors

There are two routine tasks that must be performed while the conveyor is running:

• Inspection of performance

• Dynamic troubleshooting

!

DANGER

Every belt pulley is an in-running nip hazard. Never

touch or prod an operating pulley. Pulley hazards cause

instantaneous amputation and entrapment.

!

WARNING

Pulleys can become projectile hazards. Stay as far from the

pulley as practical and use safety eyewear and headgear.

Missiles can inflict serious injury.

!

WARNING

Never adjust anything on an operating pulley.

Unforseeable belt projections and tears can cause

violent movements. Flailing hardware can cause

serious injury or death.

3

Page 6

Section 3 – Pre-installation Checks and Options

3.1 Checklist

• Check that the lagging size is correct for the pulley width

• Check that the correct amount of lagging strips are available to lag the

pulley (see Page 6).

• Check that the correct amount of primer, adhesive and activator are

available to lag the pulley (see Page 6).

• Check the carton and make sure all the parts are included

• Review the “Tools Needed” list on the top of the installation instructions

• Check the conveyor site:

· Will the lagging be installed in a chute

· Is the install on an open head pulley

Flex-Lag Primer, Adhesive and Activator ONLY for use with

cold-bond rubber-to-rubber or rubber-to-metal adhesion.

4 Flex-Lag® Cold Bond Pulley Lagging

Page 7

Section 4 – Installation Instructions

If using non-Flexco adhesives, please follow that company’s instructions for usage, mixing, application and safety

procedures.

Flex-Lag® Pulley Lagging can be used with Flex-Lag Adhesives. Flex-Lag Adhesives consist of a Primer, Adhesive

and Activator. Before using, the Primer should be thoroughly mixed. Before using, one Adhesive and one Activator

should be thoroughly mixed and used within three hours. Reference the Adhesive Usage Charts on Page 6 for

quantity of each material required based on Pulley Diameter and Face Width.

ese materials are meant for use at room temperature. e ambient temperature and temperature of the lagging

and pulley must be between 41˚F113˚F (5˚C 45˚C), and the relative humidity should not exceed 80% during the

lagging procedure. ese should be checked prior to starting and occasionally during the lagging process to ensure

proper bonding.

Proper protective equipment should be used during the lagging process. Wear safety glasses with side shields.

Wear chemical splash goggles if the possibility exists for eye contact with splashing liquid. Avoid skin contact by

wearing chemically-resistant gloves (nitrile) and long sleeved shirt. An apron may be appropriate if splashing can

occur. Respiratory protection may be required to avoid overexposure when handling this product. If general room

ventilation is not available or sucient use a NIOSH-approved air purifying respirator with organic vapor cartridge.

Please reference the Safety Data Sheets for Adhesive, Activator and Primer to see detailed requirements. Also, please

follow any local or state guidelines for use of this product.

Fig. 1

Fig. 2

Physically lock out and tag the conveyor at the power source

before you begin pulley lagging installation.

Tools Needed:

• Grinder (low RPM recommended)

• 24 Grit Flap Disc

• Bench Brush

• Coarse Dish Wheel

• Paint Brushes

1. Prepare the pulley by removing the old lagging, paint and primer.

Sand blast the entire pulley or use a grinder with 24 grit flap disc or

paper disc. Use bench brush and non-oil-based metal solvent to clean

remaining particles from the pulley surface. Paint the pulley surface,

including the edges, with Flex-Lag Primer. Allow to dry completely –

a minimum of 30 minutes.

2. Use a grinder with coarse dish wheel to buff the edges and bottom

of the lagging. Be careful not to smoke the rubber. Wipe with non-

oil-based solvent to clean surface of any particles.

• Heavy Duty Knife

• Chalk Line

• Dead Blow Rubber Hammer

• Lagging Stitchers/Rollers

• Oscillating Tool (for cutting rubber)

5

Page 8

Section 4 – Installation Instructions (cont.)

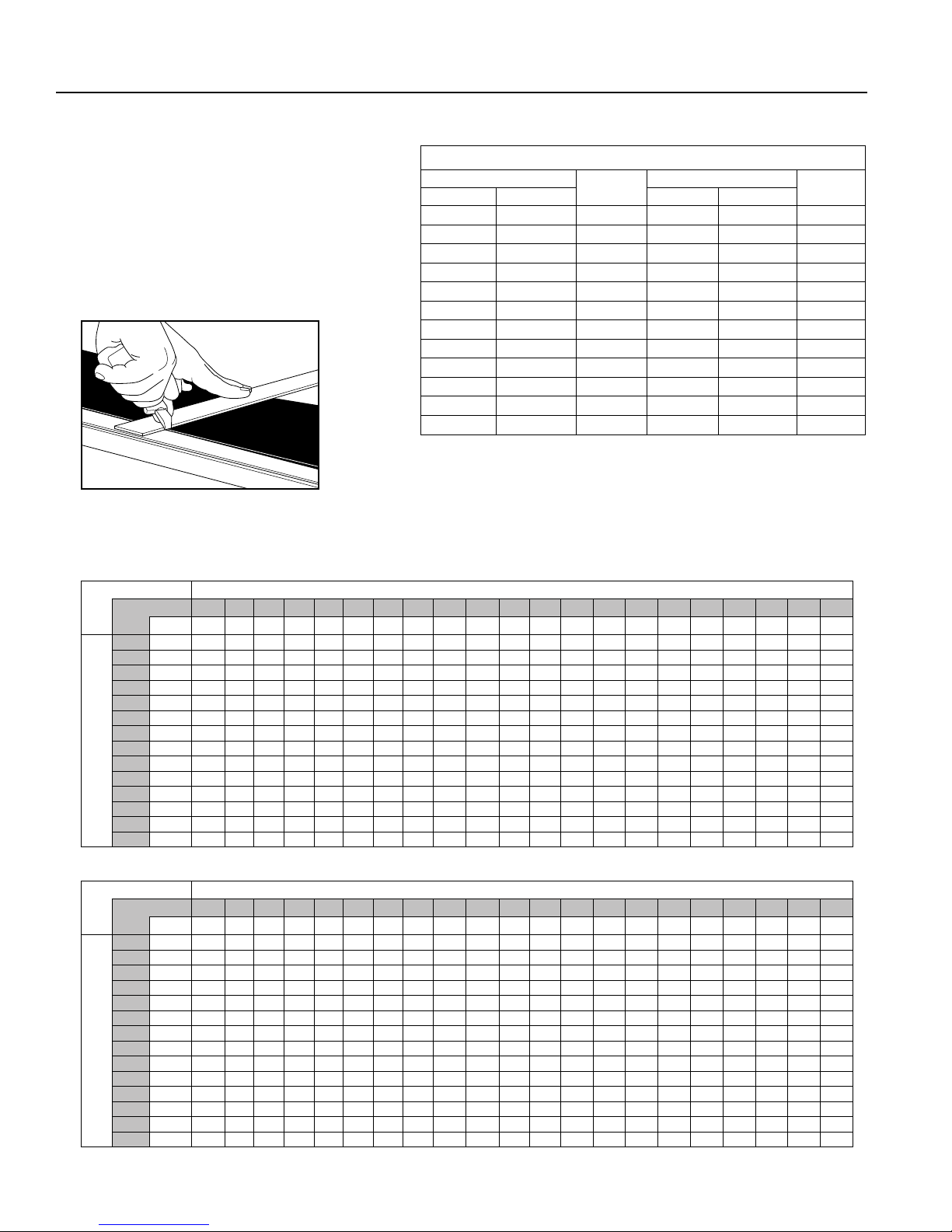

3. Use the Strip Selection Chart at right to

calculate the number of strips required for

your pulley diameter. Using a heavy duty

knife, cut lagging strips 4" (100mm) longer

than the pulley face width. Medium and Full

Ceramic lagging come in pre-specified strip

lengths. Note: Do not allow ceramic tiles to

sit at, or over, the edge of the pulley face.

PULLEY DIAMETER

in. mm in. mm

12.6-15.0 320-381 6 42.6-45.0 1083-1145 18

15.1-17.5 382-445 7 45.1-47.5 1146-1210 19

17.6-20.0 446-510 8 47.6-50.1 1211-1273 20

20.1-22.5 511-573 9 50.2-52.6 1274-1336 21

22.6-25.0 574-636 10 52.7-55.1 1337-1400 22

25.1-27.5 637-700 11 55.2-57.6 1403-1463 23

27.6-30.0 701-764 12 57.7-60.1 1466-1527 24

30.1-32.5 765-827 13 60.2-62.6 1529-1590 25

32.6-35.0 828-891 14 62.7-65.1 1593-1654 26

35.1-37.5 892-955 15 65.2-67.6 1656-1717 27

37.6-40.0 956-1018 16 67.7-70.1 1720-1781 28

40.1-42.5 1019-1082 17 70.2-72.6 1783-1844 29

Fig. 3

Adhesive, Activator and Primer Usage Charts

FLEX-LAG® ADHESIVE 0.8L / ACTIVATOR 40g (1:1 mix ratio)

Face Width

In. 10 14 18 22 26 30 34 38 42 46 50 54 58 62 66 70 74 78 82 86 90

Pulley Diameter

FLEX-LAG

Face Width

Pulley Diameter

mm 254 356 457 559 660 762 864 965 1067 1168 1270 1372 1473 1575 1676 1778 1880 1981 2083 2184 2286

8 203 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 3 3 3

12 305 1 1 1 1 1 2 2 2 2 2 2 3 3 3 3 3 3 3 4 4 4

16 406 1 1 1 2 2 2 2 2 3 3 3 3 3 4 4 4 4 4 5 5 5

20 508 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 6 6 6

24 610 1 2 2 2 2 3 3 3 4 4 4 5 5 5 5 6 6 6 7 7 7

28 711 1 2 2 2 3 3 3 4 4 5 5 5 6 6 6 7 7 7 8 8 8

32 813 2 2 2 3 3 4 4 4 5 5 6 6 6 7 7 8 8 8 9 9 10

36 914 2 2 3 3 3 4 4 5 5 6 6 7 7 8 8 8 9 9 10 10 11

40 1016 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 11 11 12

44 1118 2 2 3 4 4 5 5 6 6 7 7 8 9 9 10 10 11 11 12 12 13

48 1219 2 3 3 4 4 5 6 6 7 7 8 9 9 10 10 11 12 12 13 13 14

52 1321 2 3 3 4 5 5 6 7 7 8 9 9 10 11 11 12 13 13 14 15 15

56 1422 2 3 4 4 5 6 6 7 8 9 9 10 11 11 12 13 14 14 15 16 16

60 1524 2 3 4 5 5 6 7 8 8 9 10 11 11 12 13 14 14 15 16 17 17

®

PRIMER .75L

In. 10 14 18 22 26 30 34 38 42 46 50 54 58 62 66 70 74 78 82 86 90

mm 254 356 457 559 660 762 864 965 1067 1168 1270 1372 1473 1575 1676 1778 1880 1981 2083 2184 2286

8 203 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

12 305 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

16 406 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

20 508 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

24 610 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

28 711 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

32 813 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

36 914 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2

40 1016 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2

44 1118 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2

48 1219 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2

52 1321 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2

56 1422 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2

60 1524 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2

Strip Selection

STRIPS

REQUIRED

PULLEY DIAMETER

STRIPS

REQUIRED

6 Flex-Lag® Cold Bond Pulley Lagging

Page 9

Section 4 – Installation Instructions (cont.)

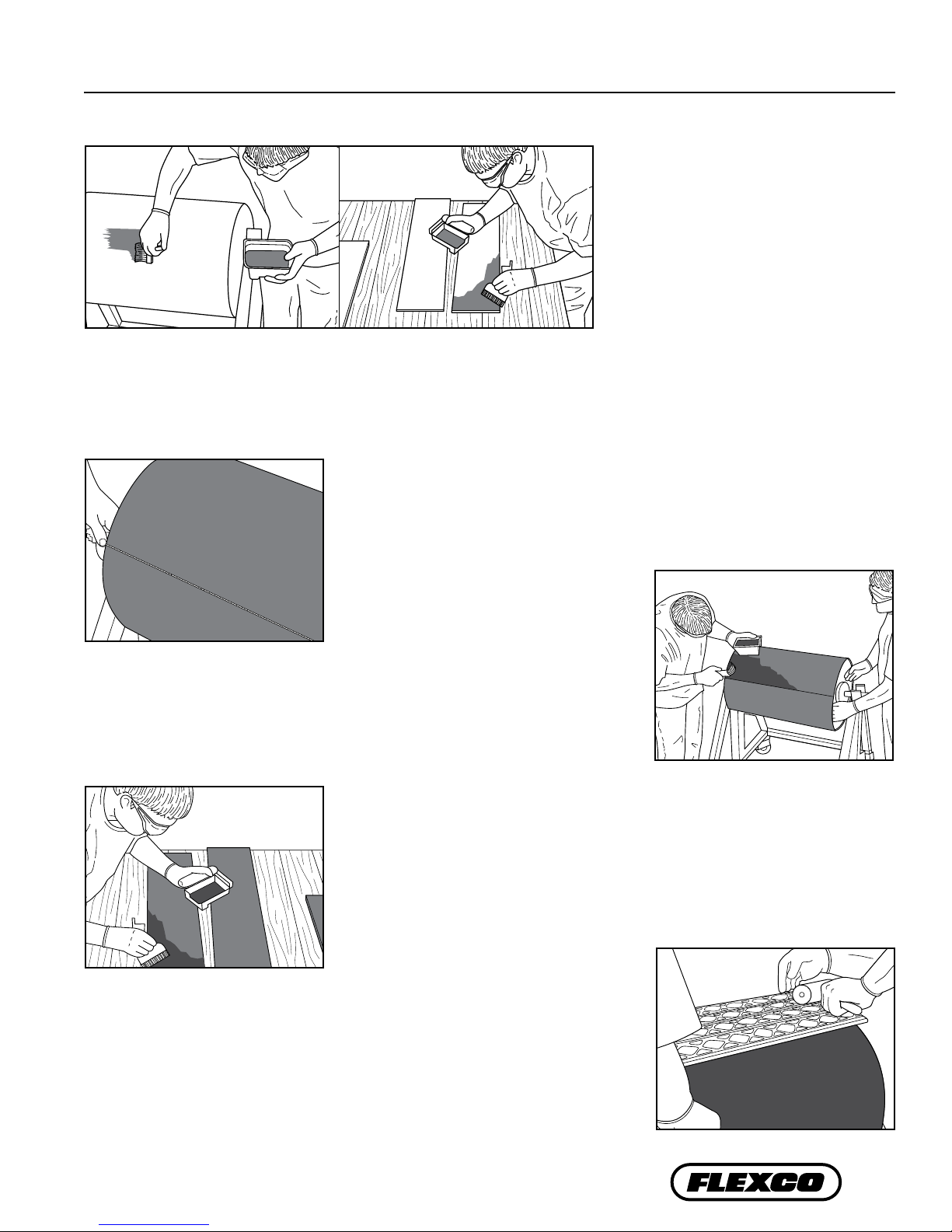

Fig. 4a Fig. 4b

4. Apply first coat of adhesive. Thoroughly mix one can of adhesive and one activator at a time, immediately applying it

to the pulley and strips of lagging. Be sure to apply adhesive to the edges of the lagging as well. This process should use

half of the adhesive/activator required in the chart on Page 6. Note: Allow 4 hours for the first coat to properly cure.

Temperature and humidity will affect dry time.

Fig. 5

6. Apply second coat of adhesive to the pulley. Thoroughly mix one can of

adhesive and activator at a time. From the perpendicular line, apply the

second coat of adhesive to an area slightly greater than one strip of lagging.

Fig. 7

5. After the first coat of adhesive has dried completely, mark a line across the

pulley face using a chalk line or scriber, ensuring the line is parallel to the

shaft’s centerline and square to the edge of the pulley.

7. Apply a second coat of adhesive to one strip of lagging. Be sure to apply

adhesive to the edges of the lagging as well.

Fig. 6

8. After the second coat has reached the appropriate tackiness (approximately

2-5 minutes, touch with back of hand – feels tacky and leaves no adhesive on

hand) install one strip of lagging, using the perpendicular line to assure the

strip is square to the pulley. Working out from the center of the strip, use a

dead blow rubber hammer for tamping to remove the air gaps, ensuring all

surface area receives one hammer blow. Repeat this process with Lagging

Stitchers/Rollers to remove air gaps from drainage grooves. Be sure to check

edges to verify seal.

Fig. 8

7

Page 10

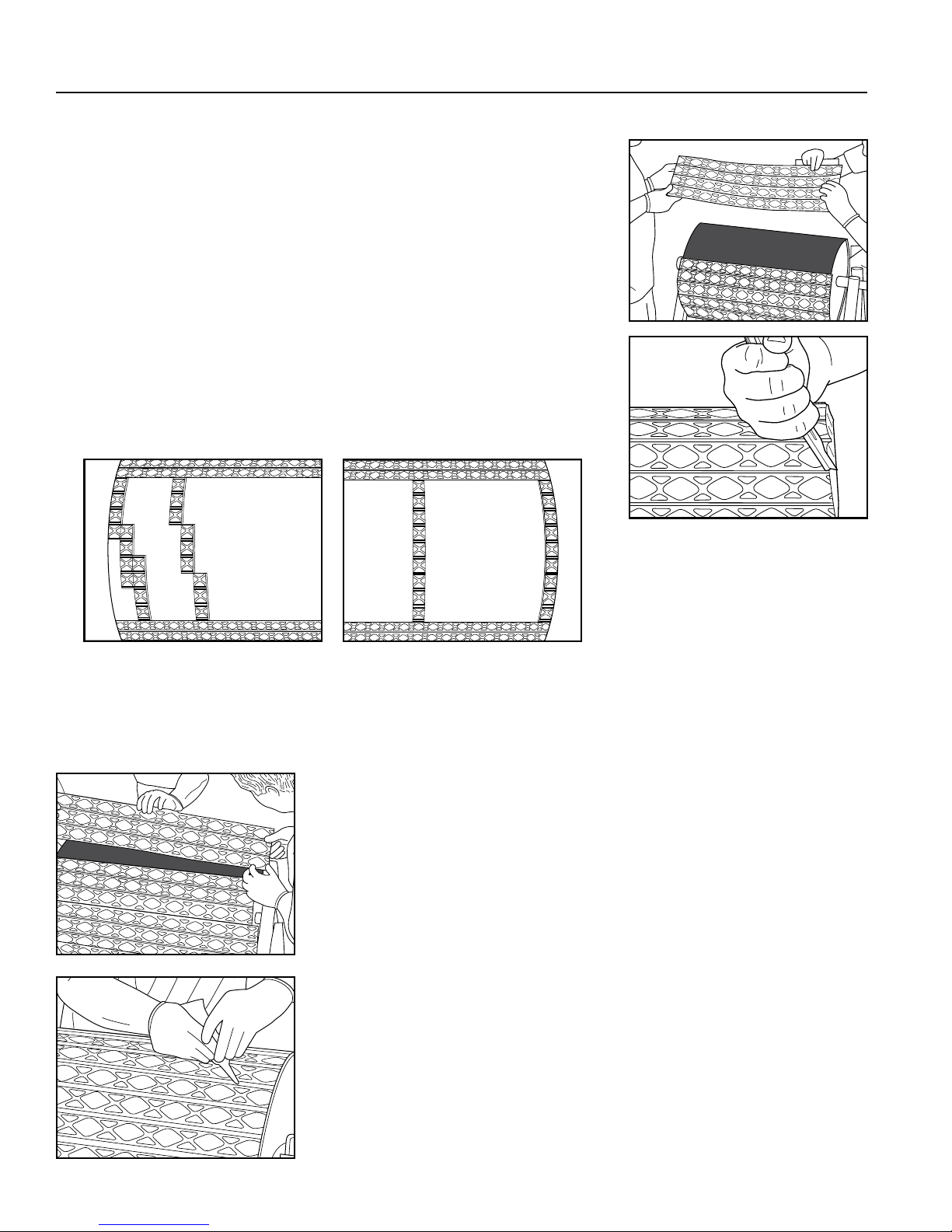

Section 4 – Installation Instructions (cont.)

9. Repeat Steps 6 and 7, then place the second strip of lagging against the first,

taking care to ensure there are no gaps between the lagging. Shift lagging sideto-side to align diamond/ceramic patterns. Additional stitching between strips

may be required to remove any gaps. Repeat the tamping and stitching process

in Step 8 to remove air gaps from the applied strip.

10. Trim the excess lagging from applied strips at the edge of the pulley using a

heavy duty knife or oscillating tool. Trim lagging at an angle up and away from

the pulley edge. This can be done every one or two strips.

Fig. 11a

Fig. 11b

Fig. 9

Fig. 10

11. To apply the last 3-4 strips, position cut-off pieces of lagging from Step 10 in the unlagged portion of the pulley.

Manipulate the pieces to determine trim requirements for the last few strips. Trim the pieces in the gutters to find the

proper fit. Use the pieces as templates to trim the last few strips of lagging. Note: Final strips should not consist of

less than three rows.

Fig. 12

Fig. 13

12. Follow Steps 6 through 10 to install the last 3-4 strips. The final piece of

lagging (largest of final pieces) should drop into position. Check the fit of the

last piece prior to applying the second coat of adhesive.

13. Fill any gaps between the lagging strips with rubber sealer. Also use the

buffing wheel on trimmed edge of lagging and apply final coat of adhesive

to seal the edge and joint area between lagging strips.

Note: Allow minimum of 24 hours of curing time before putting newly

lagged pulley into use.

8 Flex-Lag® Cold Bond Pulley Lagging

Page 11

Section 5 – Pre-Operation Checklist and Testing

5.1 Pre-Op Checklist

• Be sure that all installation materials and tools have been removed from the belt and the conveyor area.

5.2 Test Run the Conveyor

• Run the conveyor for at least 15 minutes and inspect the lagging performance.

NOTE: Observing the pulley lagging when it is running and performing properly will help to detect problems.

9

Page 12

Section 6 – Maintenance

Flexco lagging is designed to operate with minimum maintenance. However, to maintain superior performance some

service is required. This service will ensure that the lagging operates at optimal efficiency and problems can be identified

and fixed before the lagging stops working.

All safety procedures for inspection of equipment (stationary or operating) must be observed. Flex-Lag® Pulley Lagging

operates on all pulleys in the conveyor and is in direct contact with the moving belt. Only visual observations can be made

while the belt is running. Service tasks can be done only with the conveyor stopped and by observing the correct lockout/

tagout procedures.

6.1 New Installation Inspection

After the new lagging has run for a few days a visual inspection should be made to ensure the lagging is performing

prop erly.

6.2 Routine Visual Inspection (every 6-8 weeks)

A visual inspection of the lagging and belt can determine:

• If there is damage to the lagging.

• If fugitive material is built up on the lagging.

• If there is damage to the belt.

If any of the above conditions exist, a determination should be made on when the conveyor can be stopped for additional

maintenance.

6.3 Routine Physical Inspection (every 3-4 months)

When the conveyor is not in operation and properly locked and tagged out, conduct a physical inspection of the lagging

to perform the following tasks:

• Clean material buildup off of the lagging.

• Closely inspect the lagging for wear and any damage.

• Ensure full lagging to belt contact.

• Inspect the belt for damage.

• Replace any worn or damaged components.

• When maintenance tasks are completed, test run the conveyor to ensure the lagging is performing properly.

10 Flex-Lag® Cold Bond Pulley Lagging

Page 13

Section 6 – Maintenance (cont.)

6.4 Maintenance Log

Conveyor Name/No.

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

11

Page 14

Section 6 – Maintenance (cont.)

6.6 Lagging Maintenance Checklist

Site: ______________________________ Inspected by: ________________________________ Date: ______________________________

Lagging: _________________________________________________

Beltline Information:

Beltline Number: ____________________ Belt Condition: ___________________________________________________________________

Belt (18") (24") (30") (36") (42") (48") (54") (60") (72")

Width: ¨ 450mm ¨ 600mm ¨ 750mm ¨ 900mm ¨ 1050mm ¨ 1200mm ¨ 1350mm ¨ 1500mm ¨ 1800mm

Head Pulley Diameter (Belt & Lagging):__________ Belt Speed:________ fpm or m/s Belt Thickness: __________

Belt Splice:__________ Condition of Splice:_________ Number of Splices:________ ¨ Skived ¨ Unskived

Material conveyed: ____________________________________________________________________________________________________

Days per week run:_______________ Hours per day run:_______________

Lagging Life:

Date installed:___________ Date inspected:___________ Estimated life:____________

Lagging Thickness:___________

Lagging: ¨ Side Lag ¨ Ceramic ¨ Rubber ¨ Other ¨ None

Condition of lagging: ¨ Good ¨ Bad ¨ Other

Cleaner's Overall Performance: (Rate the following 1 - 5, 1= very poor - 5 = very good)

Appearance: ¨ Comments: ________________________________________________________________________________________

Location: ¨ Comments: ________________________________________________________________________________________

Maintenance: ¨ Comments: ________________________________________________________________________________________

Performance: ¨ Comments: ________________________________________________________________________________________

Other comments: ______________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

12 Flex-Lag® Cold Bond Pulley Lagging

Page 15

Section 7 – Troubleshooting

Problem Possible Cause Possible Solutions

Uneven wear in rubber

lagging

Belt Tension

Short Transition Increase distance to full trough idler

Change to ceramic lagging

Wrong Lagging for Application Increase thickness or change to ceramic lagging

Glue too wet or dry when applied

Refer to instructions on p. 5-8 for proper installation instructions

Delaminating

Pulley surface not prepped correctly Refer to instructions on p. 5-8 for proper installation instructions

For additional troubleshooting questions, please contact Customer Service or your territory manager.

Section 8 – Specifications and CAD Drawings

8.1 Specications

®

Rubber

Plain

3/8" – 1"

(10 – 25 mm)

Any Width

12" (300mm)

Excellent

Average

Very Good

Good

Yes

Yes

Flex-Lag

Diamond

3/8" – 1"

(10 – 25 mm)

Any Width Any Width

12" (300mm) 12" (300mm) 12" (300mm) 12" (300mm) 16" (400mm) 16" (400mm)

Excellent Excellent Excellent Excellent Excellent Excellent

Good Very Good Excellent Excellent Good Excellent

Very Good Excellent Excellent Excellent Very Good Excellent

Good Good Good Good Excellent Excellent

Yes Yes Yes Ye s Ye s Yes

Yes Yes Yes Ye s Ye s Yes

Diamond

Ceramic

1/2"

(12.7 mm)

Criteria

Total Thickness*

Belt Width*

Minimum Pulley Diameter

Dry Performance

Wet Performance

Wear Life

Ease of Installation

Drainage Grooves

FRAS (Fire Resistant Anti Static)

Light Duty

19/64"

(7.5 mm)

Any Width

12" (300mm)

Very Good

Average

Good

Good

No

No

Flex-Lag

Rubber Compound

Hardness (Shore A)

Ceramic Compound

Hardness (HRA Rockwell Scale A)

Ceramic Coverage

Operating Temperature

A1

2O3

83 83 83

13% 39% 80%

(-15° – 85° C)

*Additional thicknesses and widths available as special orders. For weld-on lagging, this includes the steel backing plate.

Medium

Ceramic

(450 – 2100 mm)

SBR

68 +/-3

5° – 185° F

®

Ceramic Flex-Lag® Weld-On

Full Ceramic

5/8"

(15 mm)

18" – 84"

A12O

3

1/2"

(12.7 mm)

18" – 84"

(450 – 2100 mm)

A12O

3

Rubber

Diamond

9/16"

(14 mm)

18" – 72"

(450 – 1800 mm)

Full Ceramic

5/8"

(15 mm)

18" – 72"

(450 – 1800 mm)

A1

2O3

83

74%

™

13

Page 16

Section 8 – Specifications and CAD Drawings (cont.)

DESCRIPTION

WHITE NITRILE

BLACK NATURAL

RUBBER

8.2 Lagging - Light Duty Rubber

0.75

0.25

+0.25

+

6 -

7.5 -0.75

200 - 0.5

+0.5

3300

71076

ITEM CODE

NUMBER

ORDERING

7.5WLD3.3/11

RUBBER

71077

7.5NLD3.3/11

14 Flex-Lag® Cold Bond Pulley Lagging

Page 17

6500

Section 8 – Specifications and CAD Drawings (cont.)

SECTION

A-A

SCALE

1 : 4

45°

11.0

7.0

DETAIL B

NATURAL RUBBER

THICKNESS

THICKNESS

32

ALL MACHINED SURFACES

9/19/2013

REMOVE BURRS & BREAK SHARP EDGES

UNSPECIFIED SHARP EDGES & FILLETS

WITHIN 1 mm (.04 in)

SURFACE ROUGHNESS

102

REV.

DRAWN BY: TLC

GR-25780

DOC. ID

LAGGING

1

of

1

SCALE: 1:1

DATE:09/26/2013

PLAIN LAGGIN

THIRD ANGLE PROJECTION

TOLERANCES - mm (INCH)

(UNLESS OTHERWISE SPECIFIED)

X.XX

.1 (0.004 in)

X.X

.5 (0.020 in)

X

1 (0.04 in)

Ang.

1

THIS DRAWING IN DESIGN AND DETAIL IS

THE PROPERTY OF FLEXIBLE STEEL LACING CO.

AND MAY NOT BE USED EXCEPT IN CONNECTION

WITH OUR WORK. ALL RIGHTS OF INVENTION OR

DESIGN ARE RESERVED. RETURN UPON REQUEST.

CONFIDENTIAL! NO COPYING OR REPRODUCING!

DRAWING NO.

SIZE: A

SHEET

TITLE:

1995 OAK INDUSTRIAL DRIVE, N.E.

GRAND RAPIDS, MI. 49505

PHONE: (616) 459-3196

FAX: (616) 459-4976

71010T

8.3 Lagging - Plain Rubber

16

18

23

WEIGHT

NUMBER

ORDERING

10NP6.5/21

12NP6.5/21

ITEM

CODE

71012

12

10 71010

15NP6.5/21

71017

15

THICKNESS -0.75

+0.25

200 - 0.5

+ 0.5

29

26

20NP6.5/21

25NP6.5/21

FRAS RUBBER

71021

71163

20

25

17

20

WEIGHT

NUMBER

ORDERING

10FRP6.5/21

12FRP6.5/21

ITEM

CODE

10 71020

12 71022

24

27

15FRP6.5/21

20FRP6.5/21

15 71015

20 72129

A

DETAIL A

SCALE 1 : 2

MANUFACTURE DATE

(MONTH YEAR)

MATERIAL

"NAT" - NATURAL RUBBER

"MSHA IC190" - FRAS

15

Page 18

Section 8 – Specifications and CAD Drawings (cont.)

THICKNESS

8.4 Lagging - Diamond-Pattern Rubber

THICKNESS -0.75

+0.25

200 - 0.5

+0.5

24

18

14.5

WEIGHT

NUMBER

ORDERING

15FRD6.5/21

10FRD6.5/21

12FRD6.5/21

FRAS RUBBER

ITEM CODE

27

20FRD6.5/21

6500

DETAIL A

A

MANUFACTURE DATE (MONTH/YEAR)

SCALE 1 : 2

MATERIAL -

"NAT" - NATURAL RUBBER

"MSHA IC 190" - FRAS

15 71018

12 71016

10 71014

THICKNESS

13

17

22

24

WEIGHT

NUMBER

ORDERING

10ND6.5/21

12ND6.5/21

15ND6.5/21

20ND6.5/21

NATURAL RUBBER

ITEM CODE

12 71004

15 71006

10 71002

20 71008

20 71019

2725 71152

25ND6.5/21

16 Flex-Lag® Cold Bond Pulley Lagging

Page 19

Section 8 – Specifications and CAD Drawings (cont.)

THICKNESS

MATERIAL

ITEM CODE

ORDERING

NUMBER

WEIGHT

QTY. TILES

12

NATURAL RUBBER

71155

12NDC6.5/21

25 328

12

FRAS

71159

12FRDC6.5/21

27 328

71155T

1995 OAK INDUSTRIAL DRIVE, N.E.

GRAND RAPIDS, MI. 49505

PHONE: (616) 459-3196

FAX: (616) 459-4976

TITLE:

DRAWN BY: KAC

SHEET

SCALE:

SIZE: B

DRAWING NO.

THIS DRAWING IN DESIGN AND DETAIL IS

THE PROPERTY OF FLEXIBLE STEEL LACING CO.

AND MAY NOT BE USED EXCEPT IN CONNECTION

WITH OUR WORK. ALL RIGHTS OF INVENTION OR

DESIGN ARE RESERVED. RETURN UPON REQUEST.

CONFIDENTIAL! NO COPYING OR REPRODUCING!

THIRD ANGLE PROJECTION

DIAMOND LAGGING NAT/FRAS

DATE:01/16/2014

1:5

1

of

1

X

XX-XXXXX

DOC. ID

TOLERANCES - INCH (mm)

(UNLESS OTHERWISE SPECIFIED)

.XXX

.005 (0.13mm)

.XX

.015 (0.38mm)

FRACT.

1/16 (1.59mm)

Ang.

1

REMOVE BURRS & BREAK SHARP EDGES

UNSPECIFIED SHARP EDGES & FILLETS

WITHIN 1/32 (.79mm)

REV.

100

6500

8.5 Lagging - Diamond Ceramic

+0.25

12 -0.75

200 - 0.5

+0.5

TILE ITEM CODE P3673

77 TYP.

17

Page 20

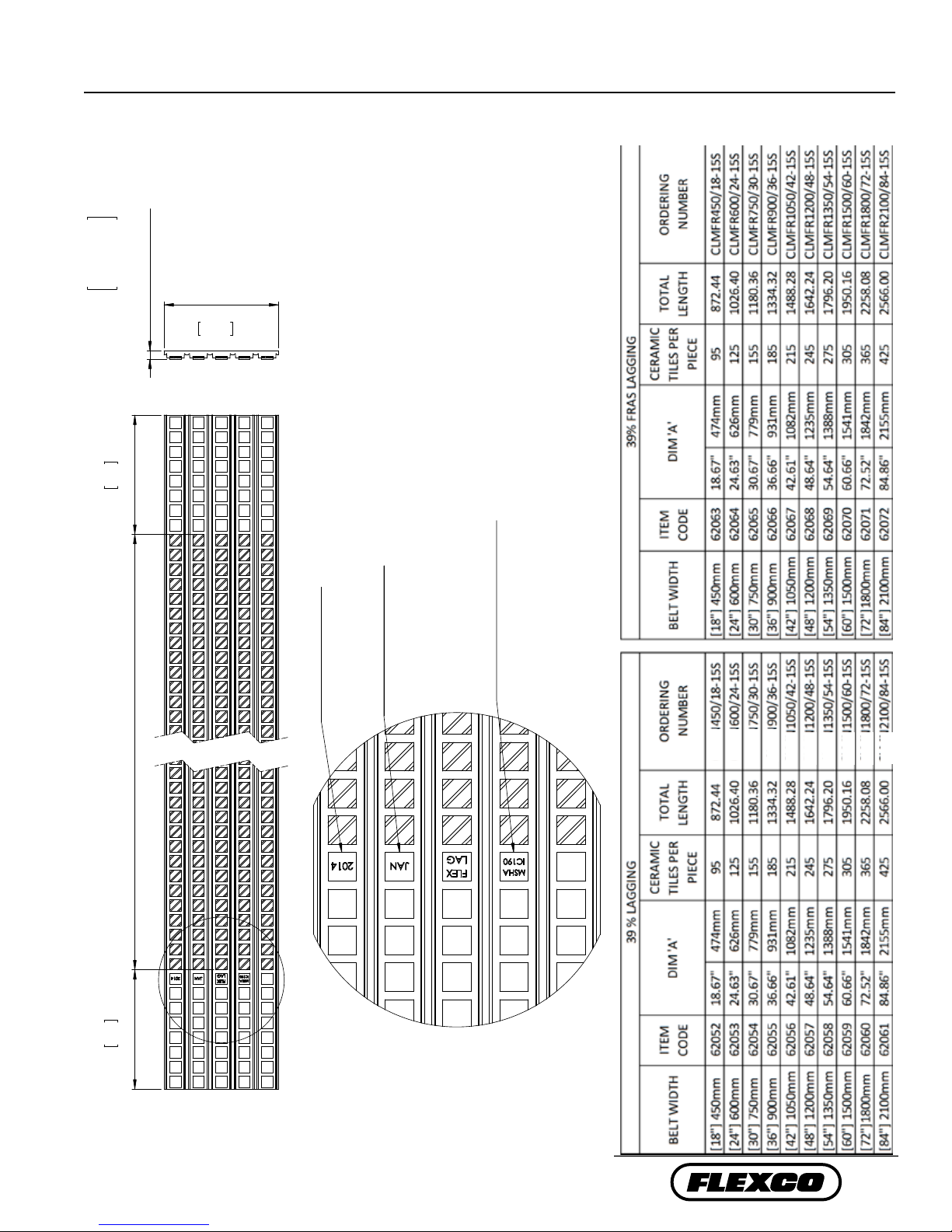

Section 8 – Specifications and CAD Drawings (cont.)

REMOVE BURRS & BREAK SHARP EDGES

UNSPECIFIED SHARP EDGES & FILLETS

WITHIN 1/32 (.79mm)

SURFACE ROUGHNESS

125

ALL MACHINED SURFACES

203

8.0

203

8.0

CERAMIC TILE LENGTH - DIM 'A'

196

7.72

15

0.59

NOTE: SAMPLE PART NUMBER L0493

THIS DRAWING IN DESIGN AND DETAIL IS

THE PROPERTY OF FLEXIBLE STEEL LACING CO.

AND MAY NOT BE USED EXCEPT IN CONNECTION

WITH OUR WORK. ALL RIGHTS OF INVENTION OR

DESIGN ARE RESERVED. RETURN UPON REQUEST.

CONFIDENTIAL! NO COPYING OR REPRODUCING!

61294T

1995 OAK INDUSTRIAL DRIVE, N.E.

GRAND RAPIDS, MI. 49505

PHONE: (616) 459-3196

FAX: (616) 459-4976

TITLE:

SHEET

SIZE: A

DRAWING NO.

TOLERANCES - INCH (mm)

(UNLESS OTHERWISE SPECIFIED)

.XXX

.005 (0.13mm)

.XX

.015 (0.38mm)

FRACT.

1/16 (1.59mm)

Ang.

1

THIRD ANGLE PROJECTION

39% STRIP LAGGING

DATE:11/9/2010

SCALE: 1:5

1

of

2

DOC. ID

GR-24308

DRAWN BY: TLC

REV.

103

10/11/2013

SCALE 1 : 2

8.6 Lagging - Medium Ceramic, Dimpled Tiles, Natural and FRAS

0.01

+

0.03

-

0.59

0.25

+

0.75

-

15

203.5

8.01

8.0

YEAR MANUFACTURED

MONTH MANUFACTURED

DIMENSIONS IN BRACKETS INCHES

NOTES:

MATERIAL

"NAT" - NATURAL RUBBER

"MSHA IC190" - FRAS RUBBER

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CERAMIC LENGTH - DIM 'A' 203

A

8.0

203

DETAIL A

18 Flex-Lag® Cold Bond Pulley Lagging

62216

Page 21

Section 8 – Specifications and CAD Drawings (cont.)

REMOVE BURRS & BREAK SHARP EDGES

UNSPECIFIED SHARP EDGES & FILLETS

WITHIN 1/32 (.79mm)

SURFACE ROUGHNESS

125

ALL MACHINED SURFACES

203

8.0

203

8.0

CERAMIC LENGTH - DIM 'A'

13

0.51

196

7.72

THIS DRAWING IN DESIGN AND DETAIL IS

THE PROPERTY OF FLEXIBLE STEEL LACING CO.

AND MAY NOT BE USED EXCEPT IN CONNECTION

WITH OUR WORK. ALL RIGHTS OF INVENTION OR

DESIGN ARE RESERVED. RETURN UPON REQUEST.

CONFIDENTIAL! NO COPYING OR REPRODUCING!

61294T

1995 OAK INDUSTRIAL DRIVE, N.E.

GRAND RAPIDS, MI. 49505

PHONE: (616) 459-3196

FAX: (616) 459-4976

TITLE:

SHEET

SIZE: A

DRAWING NO.

TOLERANCES - INCH (mm)

(UNLESS OTHERWISE SPECIFIED)

.XXX

.005 (0.13mm)

.XX

.015 (0.38mm)

FRACT.

1/16 (1.59mm)

Ang.

1

THIRD ANGLE PROJECTION

39% STRIP LAGGING

DATE:11/9/2010

SCALE: 1:5

2

of

2

DOC. ID

GR-24308

DRAWN BY: TLC

REV.

103

10/11/2013

SCALE 1 : 2

8.7 Lagging - Medium Ceramic, Smooth Tiles, Natural and FRAS

+0.01

0.59 - 0.03

+0.25

15 - 0.75

203.5

8.01

8.0

203

CERAMIC LENGTH - DIM 'A'

NOTES:

DIMENSIONS IN BRACKETS INCHES

MATERIAL

"NAT" - NATURAL RUBBER

YEAR MANUFACTURE

MONTH MANUFACTURE

"MSHA IC190" - FRAS RUBBER

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

CLMN

A

8.0

203

DETAIL A

19

Page 22

Section 8 – Specifications and CAD Drawings (cont.)

B

SECTION

A-A

SCALE 1 : 2

45°

11 7

DETAIL B

SCALE 1 : 1

REFERENCE TABLE FOR FULL CERAMIC NATURAL RUBBER

ITEM CODE

71111

1995 OAK INDUSTRIAL DRIVE, N.E.

GRAND RAPIDS, MI. 49505

PHONE: (616) 459-3196

FAX: (616) 459-4976

TITLE:

SHEET

SIZE: B

DRAWING NO.

THIS DRAWING IN DESIGN AND DETAIL IS

THE PROPERTY OF FLEXIBLE STEEL LACING CO.

AND MAY NOT BE USED EXCEPT IN CONNECTION

WITH OUR WORK. ALL RIGHTS OF INVENTION OR

DESIGN ARE RESERVED. RETURN UPON REQUEST.

CONFIDENTIAL! NO COPYING OR REPRODUCING!

TOLERANCES - mm (INCH)

(UNLESS OTHERWISE SPECIFIED)

X.XX

.1 (0.004 in)

X.X

.5 (0.020 in)

X

1 (0.04 in)

Ang.

1

THIRD ANGLE PROJECTION

FULL CERAMIC DIMPLE LAGGING

DATE:10/11/2008

SCALE: 1:33.3

1

of

2

LAGGING

DOC. ID

GR-22262

DRAWN BY: MJC

REV.

103

REMOVE BURRS & BREAK SHARP EDGES

UNSPECIFIED SHARP EDGES & FILLETS

WITHIN 1 mm (.04 in)

SURFACE ROUGHNESS

8/13/2013

125

ALL OVER

+0.25

MATERIAL

MANUFACTUR

(MONTH

8.8 Lagging - Full Ceramic, Dimpled Tiles, Natural and FRAS

OVERALL

LENGTH DIM 'B'

460 860

DIM 'A'

CERAMIC SPAN

NUMBER

ORDERING

CLFR460/18.4-12

71118

ITEM CODE

REFERENCE TABLE FOR FULL CERAMIC FRAS COMPOUND LAGGING

OVERALL

LENGTH DIM 'B'

12 -0.75

7.5

515151

±0.5203

B

SCALE 1 : 2

SECTION A-A

600 1000

760 1160

800 1200

900 1300

1060 1500

CLFR600/24-12

CLFR800/32-12

CLFR900/36-12

CLFR760/30.4-12

CLFR1060/42.4-12

71120

71121

71122

71123

71119

1200 1600

1360 1800

1400 1900

1520 2000

1600 2100

1700 2200

CLFR1200/48-12

CLFR1400/56-12

CLFR1600/64-12

CLFR1700/68-12

CLFR1360/54.4-12

CLFR1520/60.8-12

71005

71007

71009

71124

71078

A1636

1800 2300

1900 2400

2000 2500

2100 2600

2200 2700

2300 2800

CLFR1800/72-12

CLFR1900/76-12

CLFR2000/80-12

CLFR2100/84-12

CLFR2200/88-12

CLFR2300/92-12

71079

71080

71081

71082

71083

71084

2400 2900

2500 3000

2600 3000

2800 3300

3000 3300

CLFR2400/96-12

CLFR2500/100-12

CLFR2600/104-12

CLFR2800/112-12

CLFR3000/120-12

71085

71086

71087

71088

71089

10

DIM 'B'

600 1000

460 860

760 1160

800 1200

900 1300

1060 1500

1200 1600

1360 1800

1400 1900

1520 2000

1600 2100

1700 2200

1800 2300

1900 2400

2000 2500

2100 2600

2200 2700

2300 2800

2400 2900

2500 3000

2600 3000

2800 3300

+0.25

=

12 - 0.75

7.5

CERAMIC

SPAN DIM 'A'

3000 3300

LAGGING

A

A

11

SCALE 1 : 1

DETAIL B TYP.

NUMBER

ORDERING

CLN600/24-12

CLN460/18.4-12

71111

71112

CLN800/32-12

CLN900/36-12

CLN1200/48-12

CLN760/30.4-12

CLN1060/42.4-12

CLN1360/54.4-12

71113

71114

71115

71116

71039

71126

CLN1400/56-12

CLN1600/64-12

CLN1700/68-12

CLN1800/72-12

CLN1520/60.8-12

71040

71127

71117

71041

71042

CLN1900/76-12

CLN2000/80-12

CLN2100/84-12

CLN2200/88-12

CLN2300/92-12

71043

71037

71044

71045

71046

CLN2400/96-12

CLN2500/100-12

CLN2600/104-12

CLN2800/112-12

CLN3000/120-12

71047

71048

71049

71050

71000

+20

DIM 'A' 0

CERAMIC TILE

DETAIL C

SCALE 1 : 2

P2924

C

=

E DATE

-

YEAR)

20 Flex-Lag® Cold Bond Pulley Lagging

"NAT" - NATURAL RUBBER

"MSHA IC190" - FRAS

Page 23

REFERENCE TABLE FOR FULL CERAMIC NATURAL RUBBER

ITEM CODE

Section 8 – Specifications and CAD Drawings (cont.)

+0.25

MATERIAL

MANUFACTUR

(MONTH

8.9 Lagging - Full Ceramic, Smooth Tiles, Natural and FRAS

OVERALL

LENGTH DIM 'B'

460 860

600 1000

760 1160

800 1200

900 1300

1060 1500

1200 1600

1360 1800

CERAMIC

SPAN DIM 'A'

1400 1900

1520 2000

1600 2100

1700 2200

1800 2300

1900 2400

2000 2500

2100 2600

2200 2700

2300 2800

2400 2900

2500 3000

2600 3000

2800 3300

3000 3300

12 - 0.75

7.5

+0.25

12 -0.75

7.5

11

±0.5203

51 5151

SCALE 1 : 1

DETAIL B TYP.

LAGGING

NUMBER

ORDERING

CLFR600/24-12S

CLFR800/32-12S

CLFR900/36-12S

CLFR1200/48-12S

CLFR1400/56-12S

CLFR1600/64-12S

CLFR1700/68-12S

CLFR1800/72-12S

CLFR1900/76-12S

CLFR2000/80-12S

79418

79419

79420

CLFR2100/84-12S

79421

CLFR460/18.4-12S

CLFR760/30.4-12S

CLFR1060/42.4-12S

CLFR1360/54.4-12S

CLFR1520/60.8-12S

79407

79406

79408

79409

79410

79411

79412

79413

79414

79415

79416

REFERENCE TABLE FOR FULL CERAMIC FRAS COMPOUND

ITEM CODE

79417

CLFR2200/88-12S

CLFR2300/92-12S

CLFR2400/96-12S

CLFR2500/100-12S

CLFR2600/104-12S

CLFR2800/112-12S

79422

79423

79424

79425

79426

79427

CLFR3000/120-12S

79428

B

SCALE 1 : 2

SECTION A-A

OVERALL

LENGTH DIM 'B'

460 860

600 1000

760 1160

800 1200

900 1300

1060 1500

1200 1600

1360 1800

1400 1900

1520 2000

1600 2100

1700 2200

1800 2300

1900 2400

=

A

A

CERAMIC

SPAN DIM 'A'

LAGGING

NUMBER

ORDERING

CLN600/24-12S

CLN800/32-12S

CLN460/18.4-12S

CLN900/36-12S

CLN760/30.4-12S

CLN1060/42.4-12S

CLN1400/56-12S

CLN1200/48-12S

CLN1600/64-12S

CLN1360/54.4-12S

CLN1520/60.8-12S

2000 2500

CLN1700/68-12S

CLN1800/72-12S

CLN1900/76-12S

CLN2000/80-12S

2400 2900

2100 2600

CLN2100/84-12S

2500 3000

2200 2700

2300 2800

CLN2200/88-12S

CLN2300/92-12S

CLN2400/96-12S

CLN2500/100-12S

2600 3000

2800 3300

3000 3300

CLN2600/104-12S

CLN2800/112-12S

CLN3000/120-12S

10

+20

DIM 'B'

DIM 'A' 0

=

P2924

CERAMIC TILE

79384

79385

79383

DETAIL C

SCALE 1 : 2

79386

79387

79388

79389

79390

79391

79392

79393

79394

79395

79396

79397

79398

79399

79400

79401

79402

79403

79404

79405

C

E DATE

-

YEAR)

"MSHA IC190" - FRAS

"NAT" - NATURAL RUBBER

21

Page 24

Section 9 – Lagging Adhesives and Toolbox

Flex-Lag® Adhesive/Activator/Primer

ORDERING NUMBER DESCRIPTION ITEM CODE WEIGHT VOLUME

FL-ADH-0.8 Adhesive 75017

FL-ACT Activator 70186

FL-PR-0.75 Primer 70189

Each Flex-Lag® Adhesive is mixed with one Flex-Lag Activator.

Refer to the usage chart below to calculate the number of cans

required for your pulley. For sizes not included in the chart

please contact Flexco Customer Service for assistance.

FLEX-LAG® ADHESIVE 0.8L / ACTIVATOR 40g (1:1 mix ratio)

Face Width

In. 10 14 18 22 26 30 34 38 42 46 50 54 58 62 66 70 74 78 82 86 90

Pulley Diameter

FLEX-LAG

Face Width

Pulley Diameter

mm 254 356 457 559 660 762 864 965 1067 1168 1270 1372 1473 1575 1676 1778 1880 1981 2083 2184 2286

8 203 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 3 3 3

12 305 1 1 1 1 1 2 2 2 2 2 2 3 3 3 3 3 3 3 4 4 4

16 406 1 1 1 2 2 2 2 2 3 3 3 3 3 4 4 4 4 4 5 5 5

20 508 1 1 2 2 2 2 3 3 3 3 4 4 4 4 5 5 5 5 6 6 6

24 610 1 2 2 2 2 3 3 3 4 4 4 5 5 5 5 6 6 6 7 7 7

28 711 1 2 2 2 3 3 3 4 4 5 5 5 6 6 6 7 7 7 8 8 8

32 813 2 2 2 3 3 4 4 4 5 5 6 6 6 7 7 8 8 8 9 9 10

36 914 2 2 3 3 3 4 4 5 5 6 6 7 7 8 8 8 9 9 10 10 11

40 1016 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 10 10 11 11 12

44 1118 2 2 3 4 4 5 5 6 6 7 7 8 9 9 10 10 11 11 12 12 13

48 1219 2 3 3 4 4 5 6 6 7 7 8 9 9 10 10 11 12 12 13 13 14

52 1321 2 3 3 4 5 5 6 7 7 8 9 9 10 11 11 12 13 13 14 15 15

56 1422 2 3 4 4 5 6 6 7 8 9 9 10 11 11 12 13 14 14 15 16 16

60 1524 2 3 4 5 5 6 7 8 8 9 10 11 11 12 13 14 14 15 16 17 17

®

PRIMER .75L

In. 10 14 18 22 26 30 34 38 42 46 50 54 58 62 66 70 74 78 82 86 90

mm 254 356 457 559 660 762 864 965 1067 1168 1270 1372 1473 1575 1676 1778 1880 1981 2083 2184 2286

8 203 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

12 305 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

16 406 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

20 508 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

24 610 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

28 711 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

32 813 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

36 914 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2

40 1016 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2

44 1118 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2

48 1219 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2

52 1321 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2

56 1422 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2

60 1524 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2

1.6 lb. 0.7 Kg 27.1 oz 0.8L

0.1 lb. 40 g - -

1.6 lb. 0.7 Kg 25.4 oz 0.75L

Flex-Lag® Toolbox

ORDERING NUMBER DESCRIPTION ITEM CODE WT. (LBS)

LAGGING-TB with Power Tools 79080

LAGGING-TB2 without Power Tools 79099

Both Include:

• 25-ft measuring tape • Paint brushes (3) • HD knife and replacement blades

• BCP location tool • Lagging stitchers (3) • Bench brush

• Chalk line • White paint marker • Deadblow hammer

LAGGING-TB Also Includes:

• Air hammer kit • Grinder

• 24-grit flap disc • Metal grinding disc

• Rubber buffing disc • Oscillating tool and accessories

22 Flex-Lag® Cold Bond Pulley Lagging

32.0

20.0

Page 25

Page 26

Page 27

Section 10 – Other Flexco Conveyor Products

Flexco provides many conveyor products that help your conveyors to run more efficiently and safely.

These components solve typical conveyor problems and improve productivity.

Here is a quick overview on just a few of them:

MSP Precleaner

• Patented ConShear™ blade renews its cleaning edge as it

wears

• Visual Tension Check™ for optimal blade tensioning and

simple retensioning

• Quick and easy one-pin blade replacement

• Material Path Option™ for optimal cleaning and reduced

maintenance

EZS2 Secondary Cleaner

DRX™ Impact Beds

• Exclusive Velocity Reduction Technology™ to better protect

the belt

• Slide-Out Service™ gives direct access to all impact bars for

change-out

• Impact bar supports for longer bar life

• 4 models to custom fit to the application

PT Max™ Belt Trainer

• Long-wearing tungsten carbide blades for superior cleaning

efficiency

• Patented FormFlex™ cushions independently tension each

blade to the belt for consistent, constant cleaning power

• Easy to install, simple to service

• Works with Flexco mechanical belt splices

Flexco Specialty Belt Cleaners

• “Limited space” cleaners for tight conveyor applications

• High Temp cleaners for severe, high heat applications

• A rubber-fingered cleaner for chevron and raised-rib belts

• Multiple cleaner styles in stainless steel for corrosive

applications

• Patented “pivot & tilt” design for superior training action

• Dual sensor rollers on each side to minimize belt damage

• Pivot point guaranteed not to seize or freeze up

• Available for topside and return side belts

Belt Plows

• A belt cleaner for the tail pulley

• Exclusive blade design quickly spirals debris off the belt

• Economical and easy to service

• Available in vee or diagonal models

25

Page 28

The Flexco Vision

To become the leader in maximising

belt conveyor productivity for our customers worldwide

through superior service and innovation.

2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 • USA

Tel: (630) 971-0150 • Fax: (630) 971-1180 • E-mail: info@flexco.com

Visit www.flexco.com for other Flexco locations and products.

©2017 Flexible Steel Lacing Company. 12/05/17. For reorder: X2975

Loading...

Loading...