Flexco Corded series, Cordless series, EBC1, EBC1-220, CEBC1 Safety And Operating Manual

...Page 1

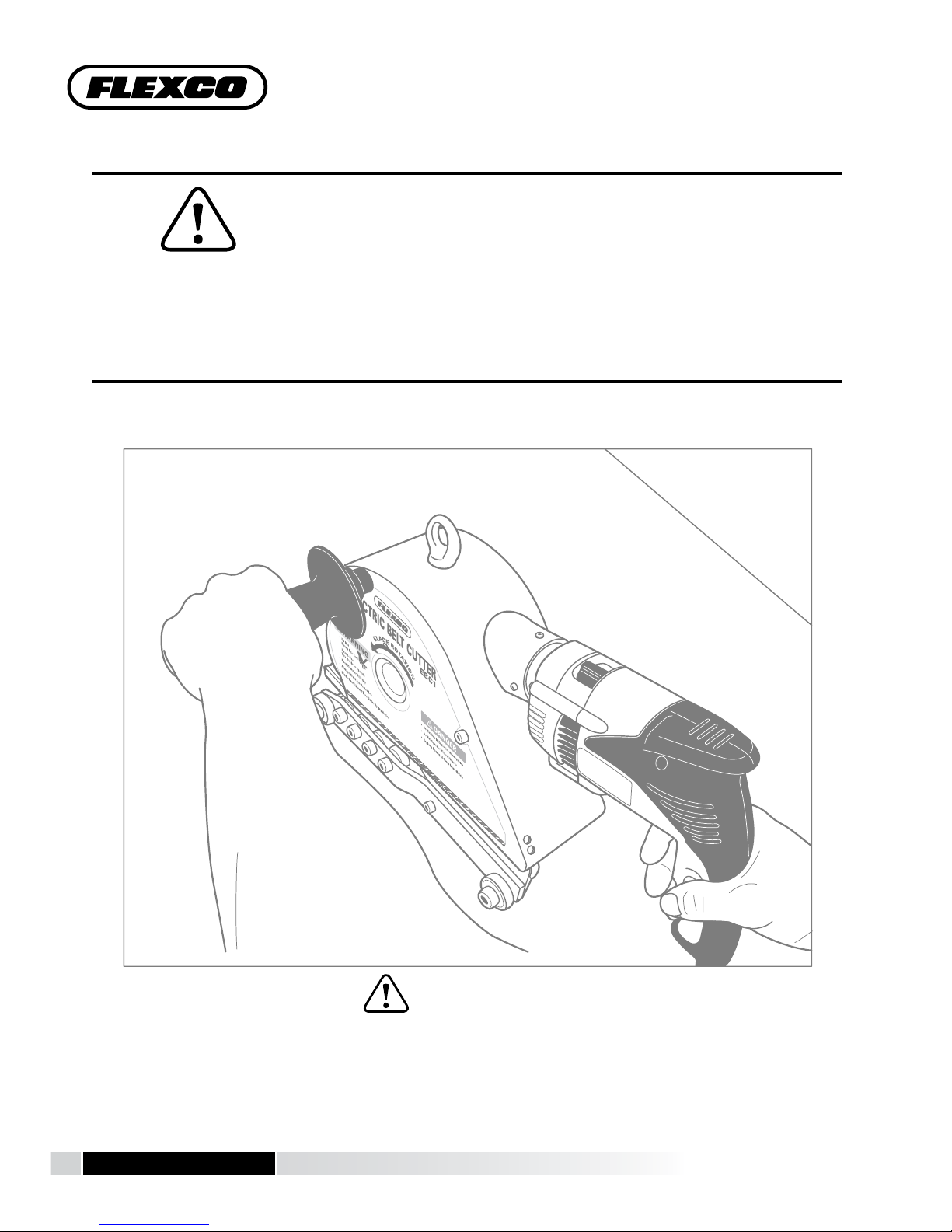

Electric Belt Cutter

Safety and Operating Manual

for Corded and Cordless Models

For cutting rubber and elastomeric materials only.

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily injury!

is manual contains important information about product function and safety. Please read and

understand this manual BEFORE operating the power tool. Please keep this manual available for

other users and owners before they use the power tool. is manual should be stored in a safe place.

www.flexco.com

www.flexco.com

WARNING

Page 2

Electric Belt Cutter

Table of Contents

Main Components ...................................................................................pg. 3

Tool Specications ...................................................................................pg. 3

General Safety Rules .......................................................................... pgs. 4-7

Tool Preparation ......................................................................................pg. 8

Operation of Electric Hammer Drill ....................................................pg. 8

Electric Cutter Operation .......................................................................pg. 9

Tool Maintenance–Bearings ..................................................................pg. 9

Tool Maintenance–Blade Replacement ..............................................pg. 10

Logbook ..................................................................................................pg. 11

Spare Parts ..............................................................................................pg. 12

ww w.flexco.com

—2—

Page 3

Electric Belt Cutter

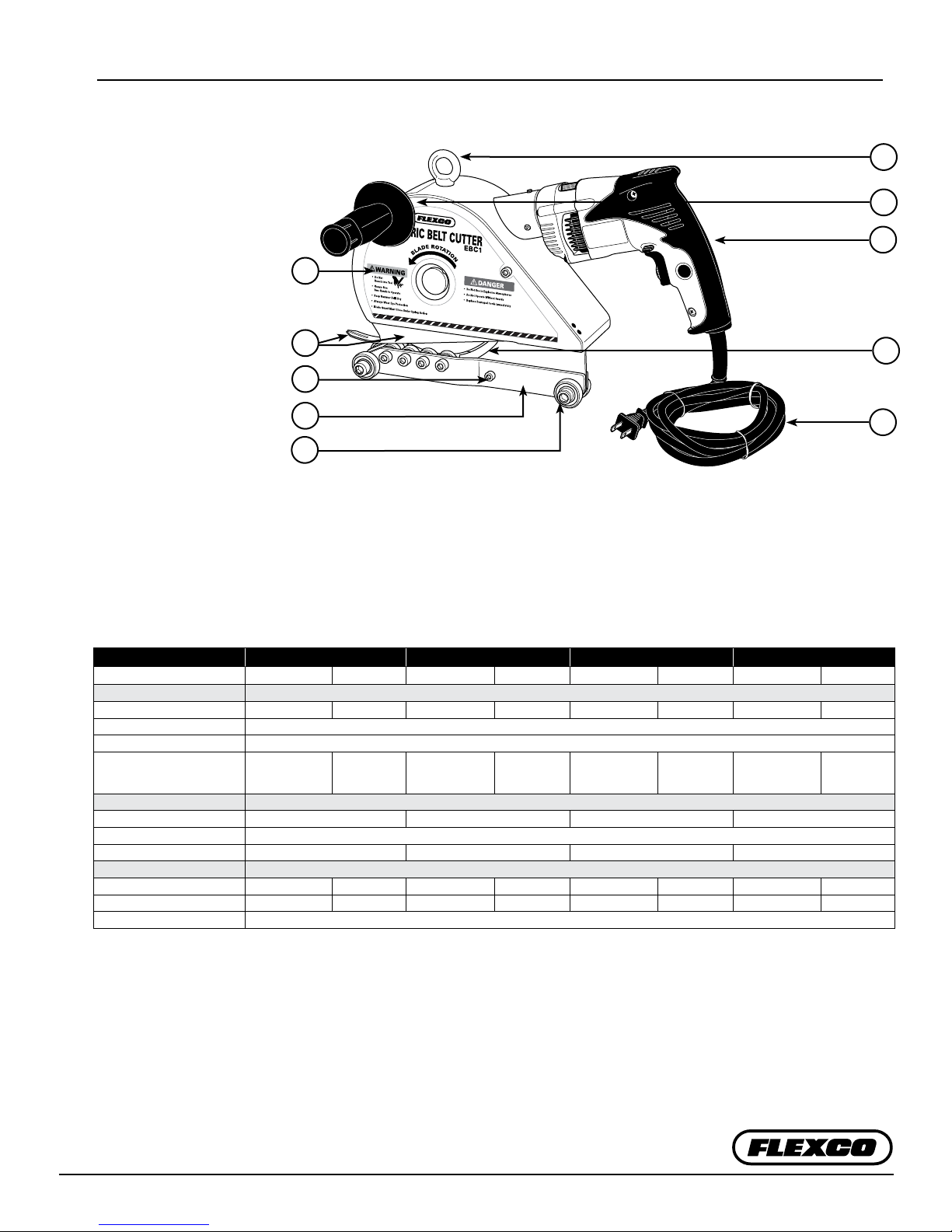

Main Components (corded model shown)

1. Housing

2. Blade Guard and

Cutting Guide

3. Carriage

4. Eye Bolt

5. Handle

6. Electric Hammer Drill

7. Circular Blade

8. Power Cord

9. Rear Carriage Bolt

10. Carriage Support Bolt

1

2

10

3

9

DO NOT carry tool by electric hammer drill handle. It is recommended that

you place tool in carrying case for traveling extended distances.

4

5

6

7

8

Tool Specications

EBC1

EBC1 / EBC1-220 CEBC1 / CEBC1-220 EBC2 / EBC2-220 CEBC2 / CEBC2-220

Specifications Imperial Metric Imperial Metric Imperial Metric Imperial Metric

Tool Description

Weight 30 lbs 13.6 kg 30 lbs 13.6 kg 40 lbs 18.1 kg 40 lbs 18.1 kg

Machine Housing Stainless Steel

Blade Material High Speed Steel

Blade Size

Drill Description

Drill – Make and Model Hitachi, DV16 V Makita BHP 454 Metabo, SBE750 Bosch 38636

Power Source / Charger Source EBC1, CEBC1, EBC2, and CEBC2 use 120V. EBC1-220, CEBC1-220, EBC2-220, AND CEBC2-220 USE 230V

Drill – Current 6.0A 2.2A 6.2A 2.3A

Cutting Capacity

Cutting Capacity – Rubber Belt Up to 1 inch Up to 25 mm Up to 1 inch Up to 25 mm Up to 2 inch Up to 50 mm Up to 2 inch Up to 50 mm

Cutting Capacity – PVC Belt Up to 360 PIW Up to 630 EP Up to 360 PIW Up to 630 EP Up to 1140 PIW Up to 2000 EP Up to 1140 PIW Up to 2000 EP

Material Hardness 25° - 90° Shore A

ø 6.70 x .157, hole

ø .787, key way

.236 (in)

ø 170 x 4, hole

ø 20, key way

6 (mm)

ø 6.70 x .157, hole

ø .787, key way

.236 (in)

ø 170 x 4, hole

ø 20, key way

6 (mm)

ø 8.66 x .236, hole

ø .984, key way

.315 (in)

ø 220 x 6, hole

ø 25, key way

8 (mm)

ø 8.66 x .236, hole

ø .984, key way

.315 (in)

ø 220 x 6, hole

ø 25, key way

8 (mm)

—3—

Page 4

Electric Belt Cutter

General Safety Rules

–Save ese Instructions–

Signal words:

“DANGER” indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury. e signal word is

limited to the most extreme situations.

“WARNING” indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used to

alert against unsafe practices.

Safety Symbol

!

is international safety symbol is used to

identify and call attention to specic safety

matters.

Safety Information

To Avoid Severe Personal Injury or Property

Damage, read carefully and understand the

following Safety Precautions.

1. WORK AREA

!

CAUTION

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

!

DANGER

Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust of fumes.

!

CAUTION

Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

!

WARNING

Never leave tool until it comes to a complete stop.

!

CAUTION

Operation of gear units is permitted at ambient

temperatures between -4°F and +104°F (-20°C

and +40°C). However, for temperatures between

-4°F and +14°F (-20°C and -10°C) unit may

only start up aer it has been progressively and

evenly pre-heated, or otherwise initially operated

unloaded. Load may then be connected to the

output sha when the gear unit has reached the

temperature of 14°F (-10°C) or higher.

ww w.flexco.com

—4—

2. ELECTRICAL SAFETY

!

DANGER

Double Insulated tools are equipped with a

polarized plug (one blade is wider than the

other). is plug will t in a polarized outlet

only one way. If the plug does not t fully in

the outlet, reverse the plug. If it still does not

t, contact a qualied electrician to install a

polarized outlet. Do not change the plug in any

way. Double Insulation eliminates the need

for the three wire grounded power cord and

grounded power supply system.

Page 5

Electric Belt Cutter

General Safety Rules

!

WARNING

Avoid body contact with grounded surfaces such

as pipes, radiators, ranges, and refrigerators.

ere is an increased risk of electric shock.

Under abusive conditions, liquid may be ejected

from the battery, avoid contact. If contact

accidentally occurs, ush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause

irritation or burns.

!

WARNING

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

!

DANGER

Do not abuse cords. Never use cords to carry

the tool or pull the plug from a receptacle.

Keep cord away from heat, oil, sharp edges,

or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of

electricshock.

!

WARNING

When operating a power tool outdoors, use an

outdoor extension cord marked “W-A” or “W”.

ese cords are rated for outdoor use and reduce

the risk of electric shock.

!

CAUTION

CEBC1/CEBC2 Battery Tool Use and Care

3. PERSONAL SAFETY

!

WARNING

Stay alert, watch what you are doing and

use common sense when operating a power

tool. Donot use tool while tired or under the

inuence of drugs, alcohol, or medication.

Amoment of inattention while operating power

tools may result in serious personal injury.

!

WARNING

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be

caught in moving parts.

!

WARNING

Avoid accidental starting. Be sure switch is o

before plugging in or before battery is inserted.

Carrying tools with your nger on the switch

or plugging in tools that have the switch on

invitesaccidents.

Ensure the switch is in the o position before

inserting battery pack. Inserting the battery pack

into power tools that have the switch on invites

accidents.

Recharge only with the charger specied by the

manufacturer. A charger that is suitable for one

type of battery pack may create a risk of re

when used with another battery pack.

Use power tools only with specically designated

battery packs. Use of any other battery packs

may create a risk of injury and re. When

battery pack is not in use, keep it away from

other metal objects like paper clips, coins, keys,

nails, screws, or other small metal objects that

can make a connection from one terminal to

another. Shorting the battery terminals together

may cause burns or a re.

—5—

!

WARNING

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

!

CAUTION

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

Page 6

Electric Belt Cutter

General Safety Rules

!

WARNING

Never alter or remove safety devices.

!

WARNING

Keep your hands and ngers away from all

moving parts, e.g. the blade, at all times.

4. TOOL USE AND CARE

!

WARNING

Always use belt cutter on a level, rm surface.

Cutting is only allowed when operating the

machine with one hand on the handle and the

other on the drill. Before starting the machine,

the handle must be installed on either the right

or le side.

!

CAUTION

Do not force tool.

!

CAUTION

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools, with

sharp cutting edges are less likely to bind and are

easier to control.

!

CAUTION

Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may aect the tool’s operation. If damaged,

have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

5. SERVICE AND MAINTENANCE

!

WARNING

Tool service must be performed only by

qualied repair personnel. Service or

maintenance performed by unqualied

personnel could result in a risk of injury.

!

WARNING

Do not use tool if switch does not turn it on or

o. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

!

WARNING

Disconnect the plug from the power source or

remove battery before making any adjustments,

changing accessories, or storing the tool. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

!

WARNING

Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

!

CAUTION

When servicing a tool, use only identical

replacement parts. Use of unauthorized parts or

failure to follow Maintenance Instruction may

create a risk of electric shock or injury.

!

DANGER

Do not use power tools if the plastic housing or

handle is cracked. Cracks in the tool’s housing

or handle can lead to electric shock. Such tools

should not be used until repaired.

!

CAUTION

Do not wipe plastic parts with solvent. Solvents

such as gasoline, thinner, benzene, carbon

tetrachloride, and alcohol may damage and

crack plastic parts. Do not wipe them with

such solvents. Wipe plastic parts with a so

cloth lightly dampened with soapy water and

drythoroughly.

ww w.flexco.com

—6—

Page 7

Electric Belt Cutter

General Safety Rules

!

WARNING

NEVER use a tool which is defective or

operating abnormally. If the tool appears to be

operating unusually, making strange noises,

or otherwise appears defective, stop using it

immediately and arrange for repairs.

!

WARNING

Before performing any belt cutter maintenance,

remove the plug from the socket or remove

battery from tool and follow all procedures

noted in manual.

6. CIRCULAR CUTTER SAFETY

!

WARNING

Make sure that any power cable is not located

between circular blade and lower carriage.

!

WARNING

Keep your body positioned to either side of the

cutter blade, but not in line with the cutter blade.

!

WARNING

Do not run the cutter while carrying it.

Lower guard may be opened by contact with

your clothing. Accidental contact with the

spinning cutter blade could result in serious

personalinjury.

!

CAUTION

Do not use dull or damaged blade.

7. REPLACING THE CIRCULAR BLADE

!

CAUTION

Do not attempt to resharpen blades. is will

aect cutting completely through belt.

!

WARNING

Always wear cut-proof safety gloves and safety

glasses when replacing blade. Blade is razor

sharp, treat it accordingly.

!

WARNING

Check blade guard for proper closing before

each use. Do not operate cutter if blade guard

does not move freely and close instantly. Never

clamp or tie blade guard into the open position.

!

WARNING

Never hold piece being cut in your hands or

across your leg. It is important to support the

work properly to minimize body exposure, blade

binding, or loss of control.

!

DANGER

Hold tool by the insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring. Contact

with a “live” wire will also make exposed metal

parts of the tool “live” and shock the operator.

!

WARNING

Before performing a blade replacement, remove

the plug from the socket or remove battery

from tool and follow all procedures noted

inmanual.

!

WARNING

Only authorized and trained technicians should

work on the cutter.

!

WARNING

Test the cutter aer blade replacement to make

sure that it can be used safely.

—7—

Page 8

Electric Belt Cutter

Tool Preparation

Fig. 1. Right-Handed Operation

Mounting of side handle:

e Flexco Electric Belt Cutter is supplied

with a handle that can be mounted on

either side of the tool: For right-handed

operation, thread the handle into the le

side of the tool housing, see Fig. 1. For lehanded operation, thread the handle into

the right side of the housing, see Fig. 2.

Fig. 2. Le-Handed Operation

Eye bolt use with optional balancer:

e Flexco Electric Belt Cutters are supplied

with an eye bolt for mounting the cutters to

tool balancers. NOTE: Tool balancer must be

purchased separately. Be sure to use a balancer

that is properly rated for the weight of the belt

cutter and has a cable long enough to permit safe

operation of the cutter. e EBC1 and CEBC1

weigh 30 lbs. (13.6 kg) and the EBC2 and CEBC2

weigh 40 lbs. (18.1 kg).

Operation of Electric Hammer Drill

EBC1

(corded model shown)

EBC2

For normal use, operate in Reverse Direction;

press drilling direction button for reverse

direction operation.

ww w.flexco.com

Operate in Drill Mode only; slide the action

mode selector switch to indicate drill mode.

—8—

Lorem ipsum dolor sit ng elit.ed

WARNIN G

amet, consectetuer adipiscing elit.ed

Lorem ipsum

AVERTISS EMENT

amet, consectetuer adipiscing elit.ed amet, consecte

ng elit.ed amet, consecteng elit.ed amet, consecte

Cutting Speed Adjustment; adjust Electric

Hammer Drill to low speed by turning switch to

low speed. For best results, always operate cutters

in low speed.

Page 9

Electric Belt Cutter

Electric Cutter Operation

For best results: Always elevate belt. • Always use appropriate lubricant. • Always cut in low speed.

Square belt using centerline method

Use of Cutting Guide

Make sure belt is clean. Spray area to be cut

with silicone lubricant (Flexco # 30932, not

included). Li Blade Guard and insert belt

between Carriage and Blade Guard. Position

Electric Belt Cutter so that slot in Cutting Guide

is directly centered above cut line on belt.

Producing Square Edge during cutting

In order to produce a square edge during

cutting, hold Electric Belt Cutter perpendicular

to belt throughout the entire cutting

operation. Use two hands for operation.

Tool Maintenance–Bearings

Unplug drill from power source prior to performing any maintenance.

EBC1 / CEBC1 EBC2 / CEBC2

Belt Cutting

Position Electric Belt Cutter on edge of

belt at square line. Align Cutting Guide

on the Blade Guard with square line on

belt. Squeeze drill trigger to start drill.

Clean Belt Support Bearings when dirty. Wipe

Bearings with a clean cloth and a solvent such as

mineral spirits.

Support Bearings may be taken apart for a more thorough cleaning. Replace Bearings in the order

shown above.

—9—

Page 10

Electric Belt Cutter

Tool Maintenance–Blade Replacement (corded model shown)

If the Belt Cutter is dicult to operate, the blade may be worn and need replacement. Unplug drill from power source.

Always wear cut-proof safety gloves and safety glasses when replacing blade.

1. Loosen Rear Carriage Bolt.

4. Remove Blade Mount Bolt.

2. Remove Carriage Support Bolt and Nut.

WARNING: DO NOT TOUCH BLADE.

5. Remove Blade Mount Sha.

WARNING: Blade edge is very sharp.

DO NOT TOUCH EDGE OF BLADE!

Push the Blade Guard into the Cutter Housing just

enough to clear the Blade. Remove the Blade and

Blade Spacer carefully.

3. Rotate Carriage away from Blade.

6. Carefully replace Blade Spacer and slide new

Blade into Housing. Align keyway in Blade, Spacer,

and Gearbox and insert Blade Mount Sha.

Secure Blade with Blade Mount Bolt.

7. Carefully pivot Carriage back into place. Be

careful to not damage Blade as it slides between

theBelt Support Bearings.

ww w.flexco.com

8. Replace Carriage Support Bolt. Tighten rear

Carriage Bolt.

—10—

Page 11

Electric Belt Cutter

Logbook

DATE NOTES DATE NOTES

—11—

Page 12

Electric Belt Cutter

Spare Parts (corded model shown)

1. Replacement Blade

3

2. Handle

3. Eye Bolt

2

4. Electric Hammer Drill

1

Spare Parts List

Description Ordering Number Item Code

Replacement blade for EBC1 EBC1-B 30003

Replacement blade for EBC2 EBC2-B 30004

Replacement electric hammer drill for EBC1 EBC1-DR 30005

Replacement electric hammer drill for EBC2 EBC2-DR 30006

Replacement electric hammer drill for EBC1-220 EBC1-220-DR 30013

Replacement electric hammer drill for EBC2-220 EBC2-220-DR 30014

Replacement eye bolt for EBC1 & EBC2 EBC-EB 30007

Replacement handle for EBC1 & EBC2 EBC-H 30008

4

2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 U.S.A.

Telephone: (630)-971-0150 • Fax: (630)-971-1180 • E-mail: info@exco.com

Visit www.flexco.com for other Flexco locations and products.

©2011 Flexible Steel Lacing Company. 12-13. For reorder: X2143 01/08-5. For Reorder: X0000

Loading...

Loading...